Linear Golden Section Speed Adaptive Control of Permanent Magnet Synchronous Motor Based on Model Design

Abstract

:1. Introduction

- Based on the characteristic model theory, the rotational speed control characteristic model of PMSM is built.

- Based on the characteristic model theory, a linear golden section and integral compensation PMSM rotational speed adaptive model is built.

- Based on the model design method, the specific modeling method and the verification process of the controller proposed in this paper are proposed.

- The simulation and experiment results show that the proposed method has good performance and is suitable for practical applications.

2. Modeling of PMSM

2.1. Mathematical Model of PMSM

- Ignore magnetic saturation and hysteresis loss, etc.;

- Assuming the rotor adopts no damping winding, the external conditions change, and the physical properties of the stator do not change;

- The conductivity of the rotor permanent magnets and the internal rotor permeability are assumed to be 0;

- It is assumed that the induced potential in the three-phase winding is a standard sine wave during steady-state operation;

- Ignore all spatial harmonics in the magnetic field;

- The windings are distributed symmetrically, the windings turn’s number is the same, and the displacement electrical angles between the axes are the same.

2.2. Characteristic Model of PMSM

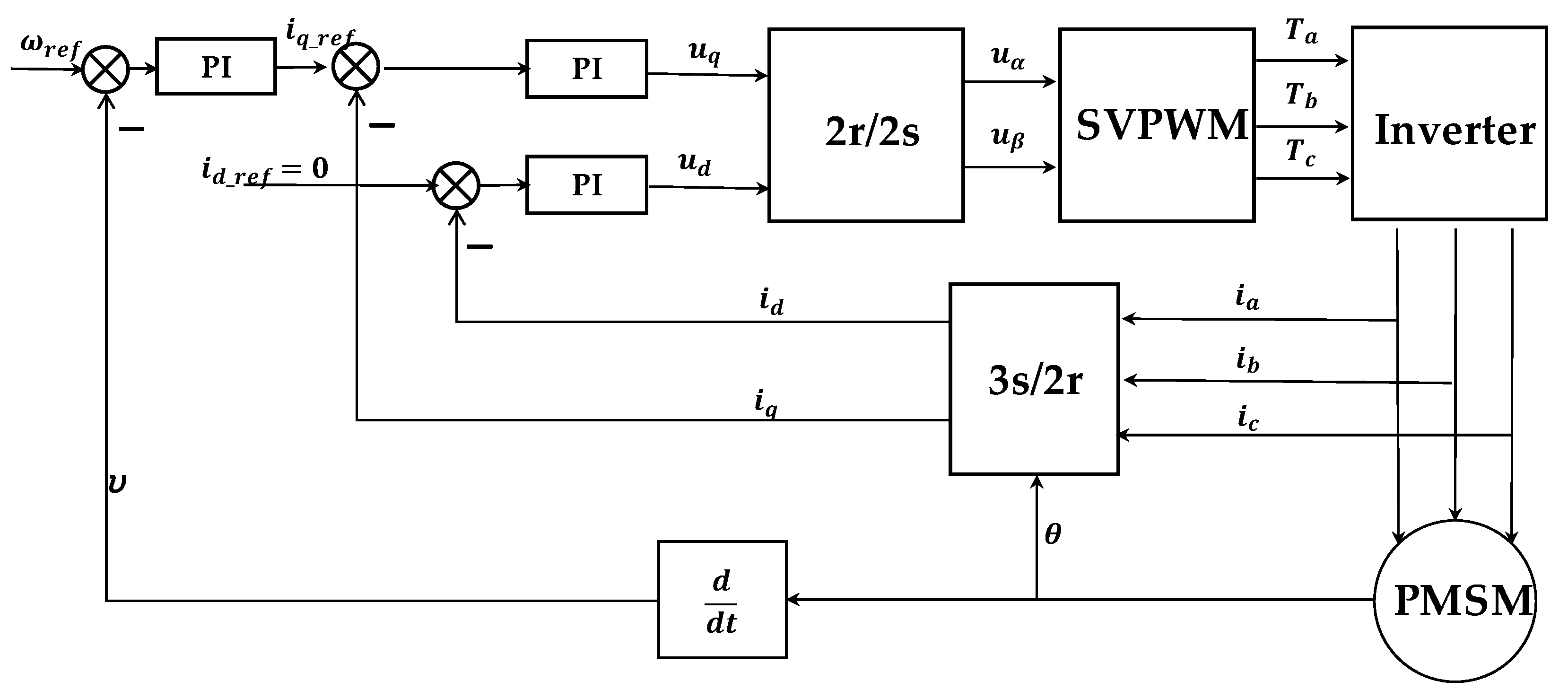

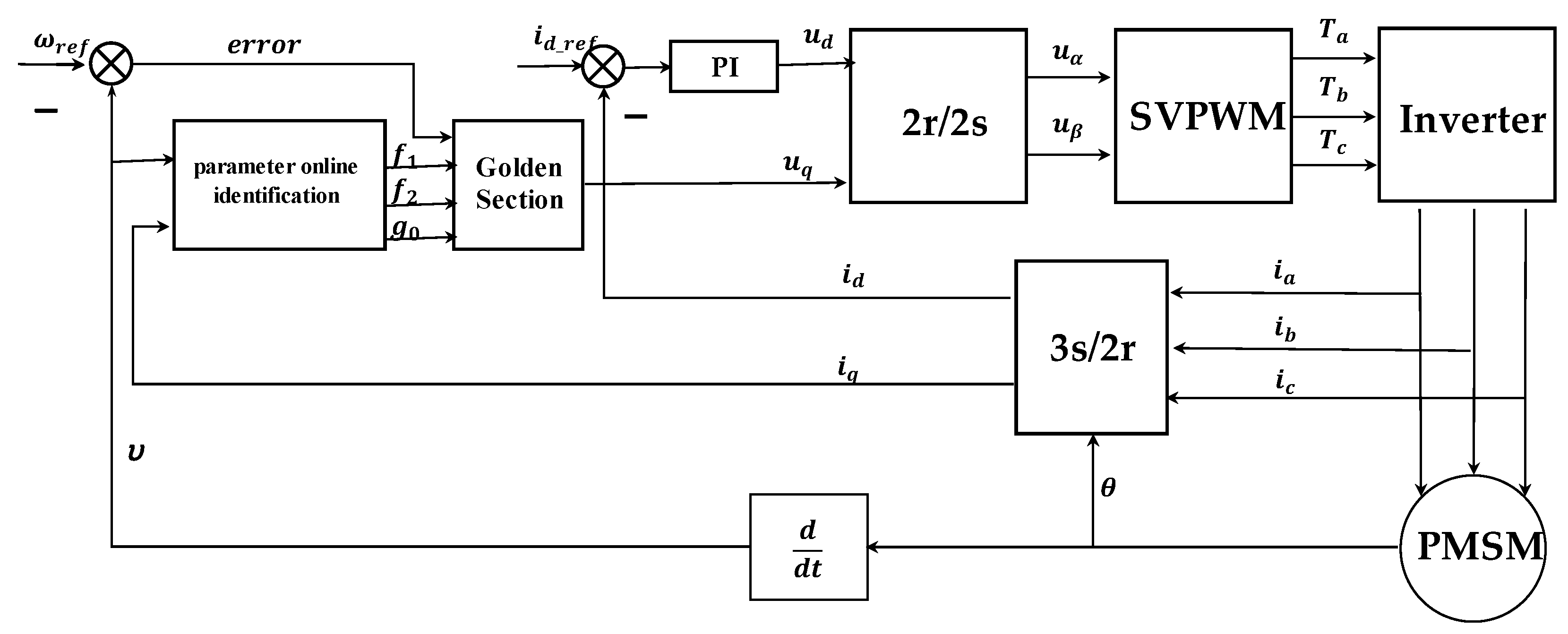

3. Speed Adaptive Control Scheme

3.1. Input Signal Processing

3.2. Linear Golden-Section Speed Adaptive Controller

3.3. Integral Compensator

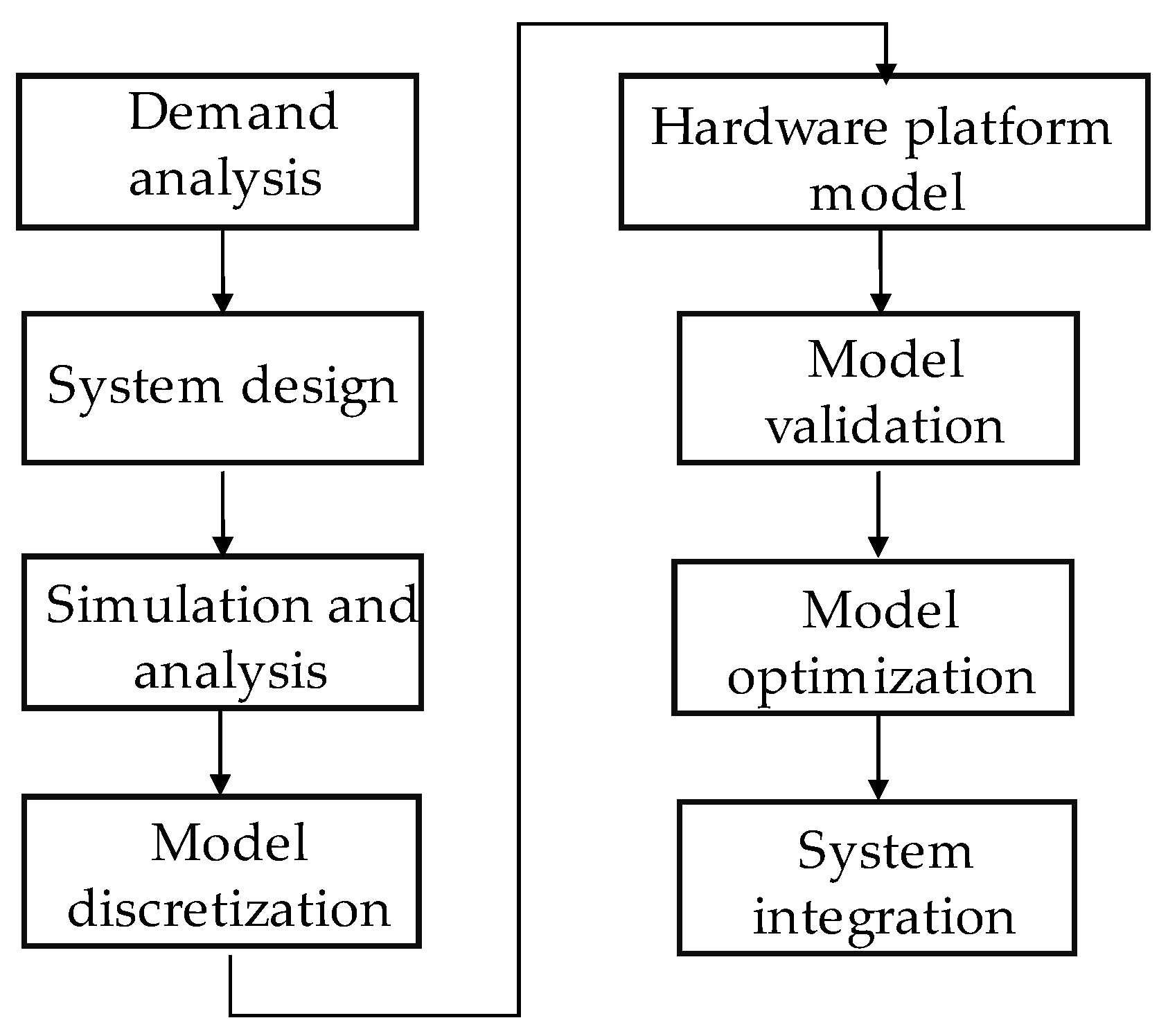

4. PMSM Control System Based on Model Design

4.1. General Process of Model-Based Design

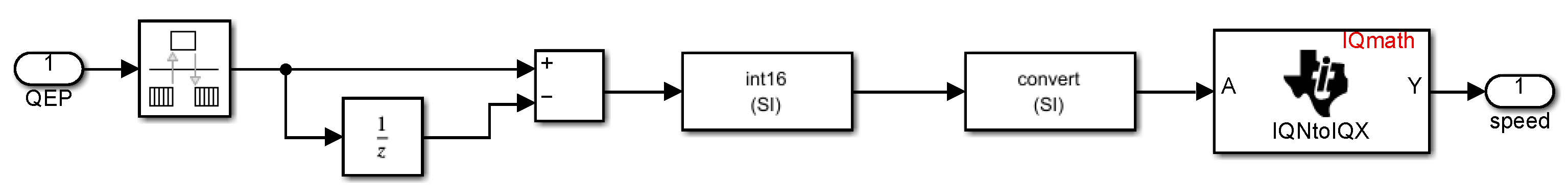

4.2. DSP Peripheral Configuration Based on Model Design

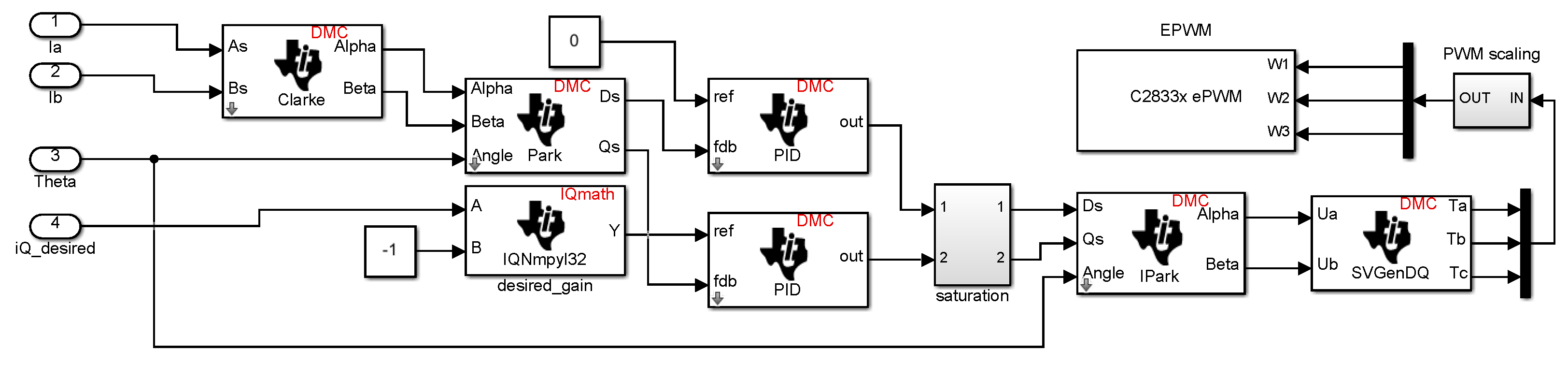

4.3. Build PMSM Golden-Section Adaptive Code Generation Model

5. Simulation and Experimental Research

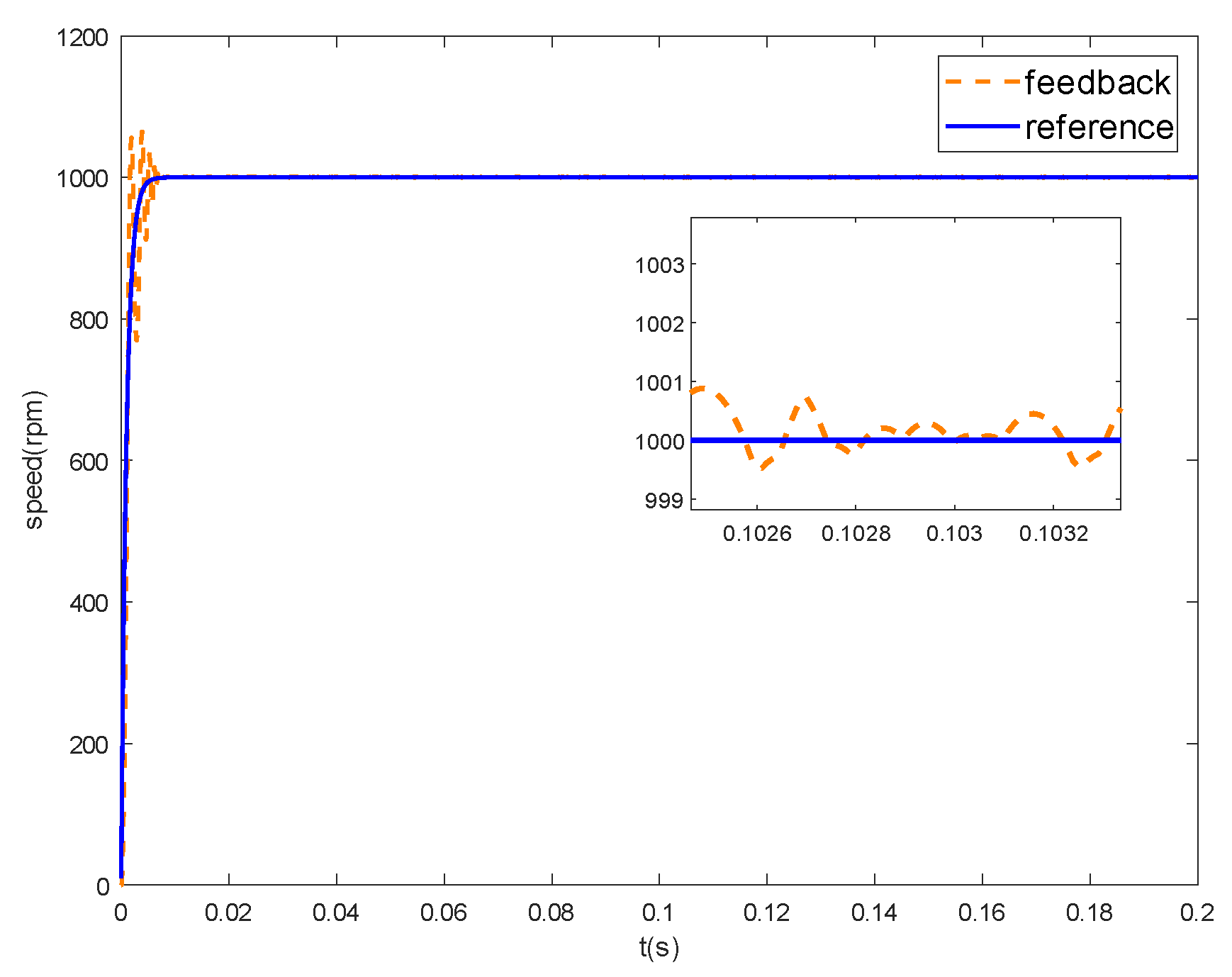

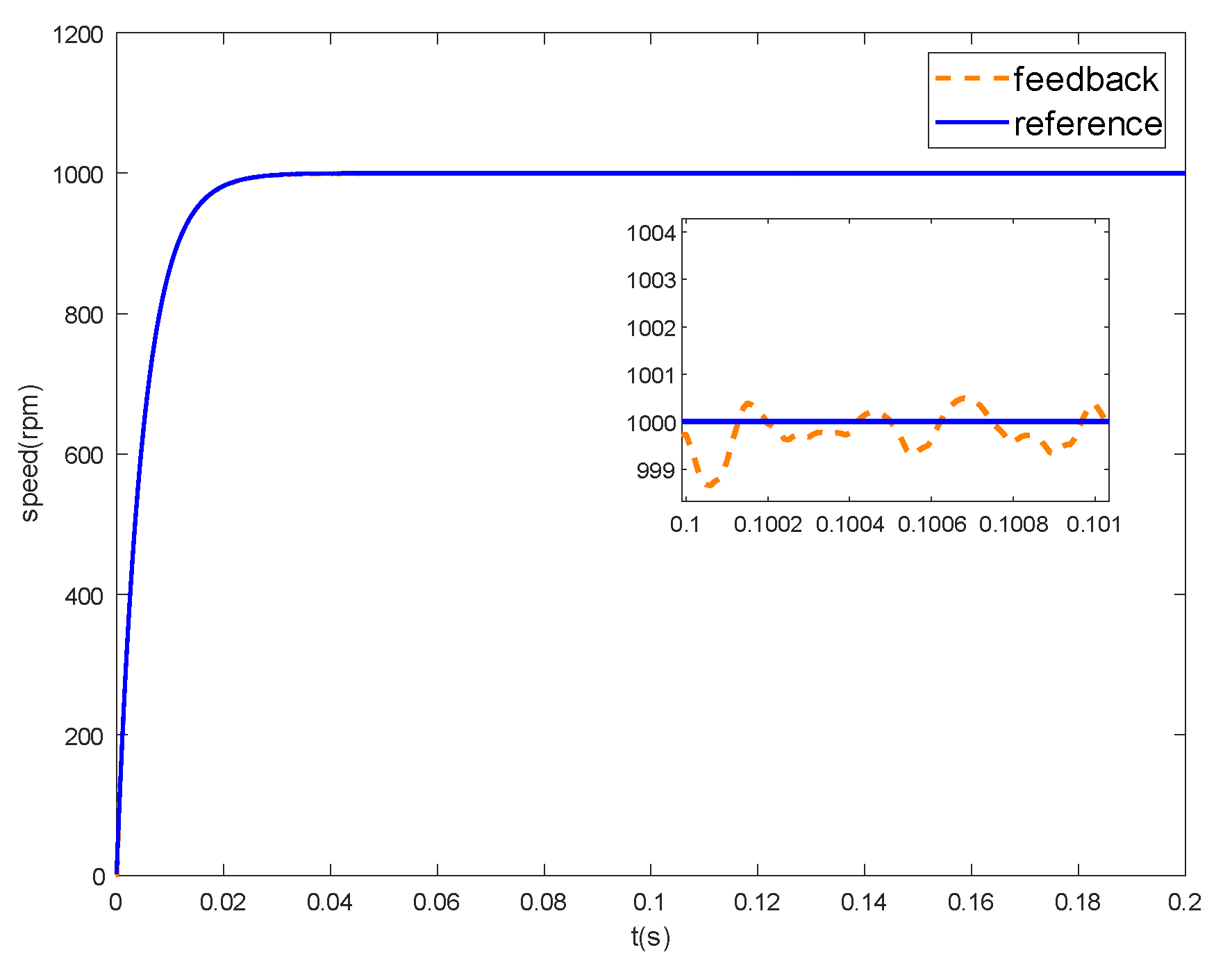

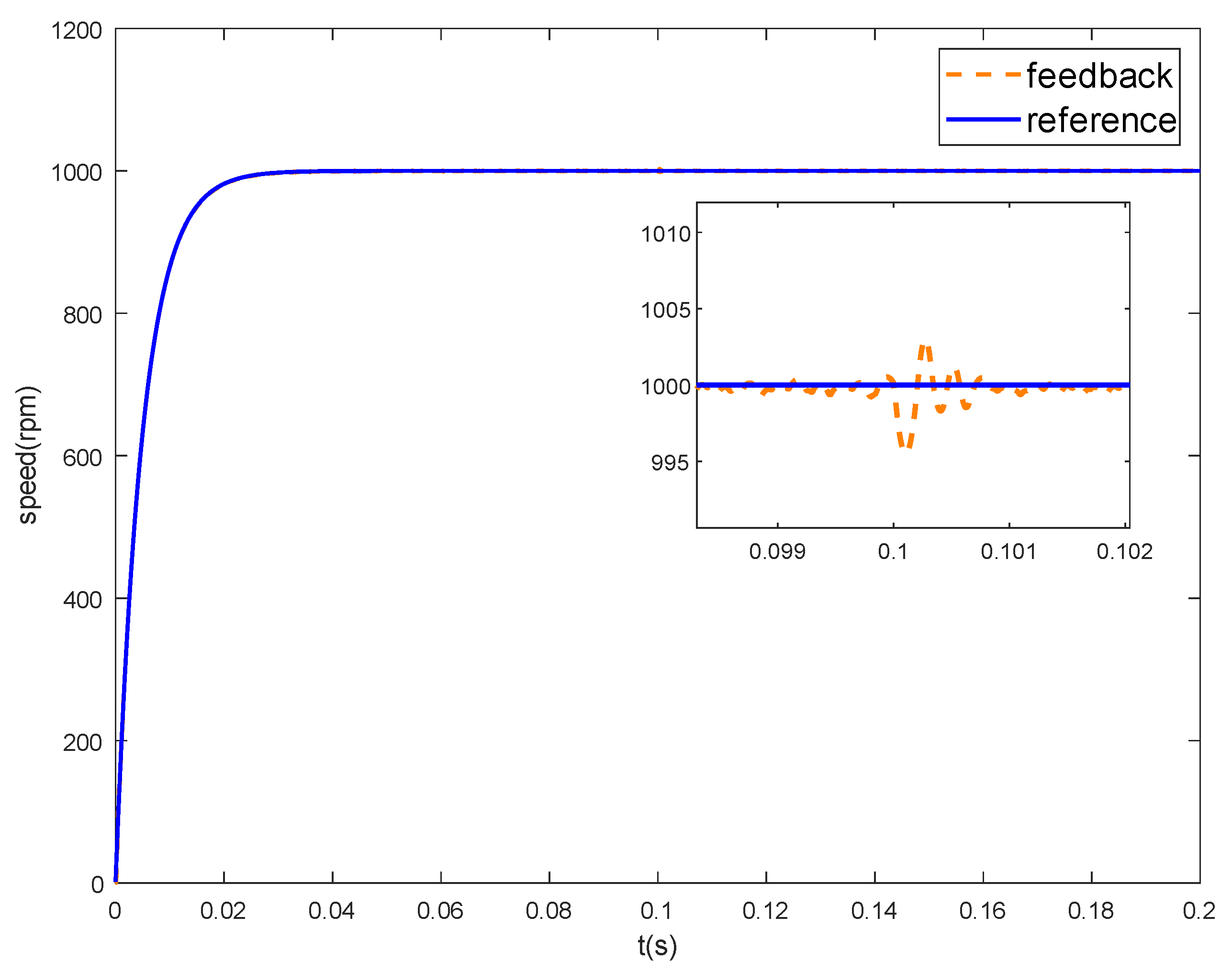

5.1. Simulation Analysis

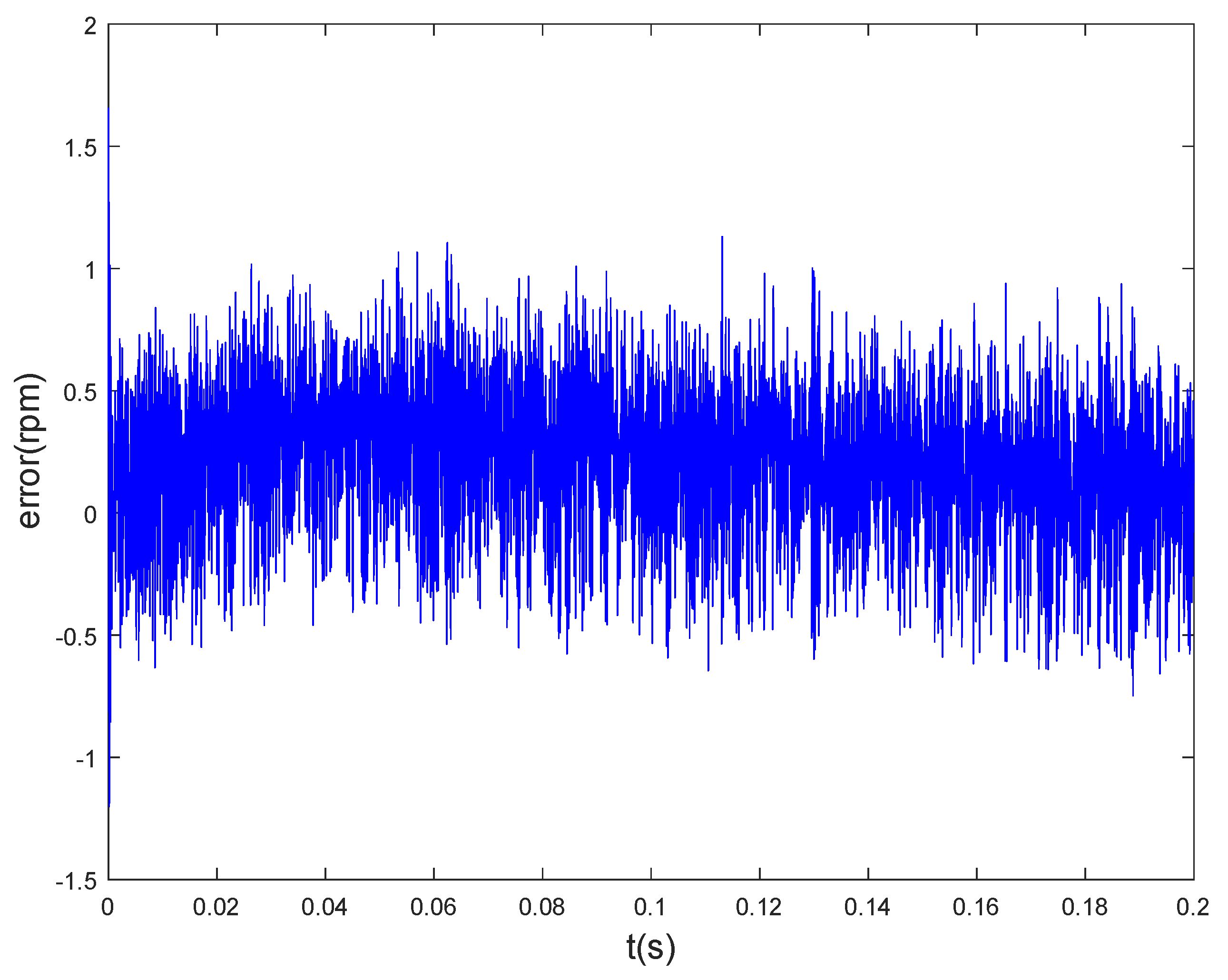

5.1.1. Influence of Filter Coefficient on the System

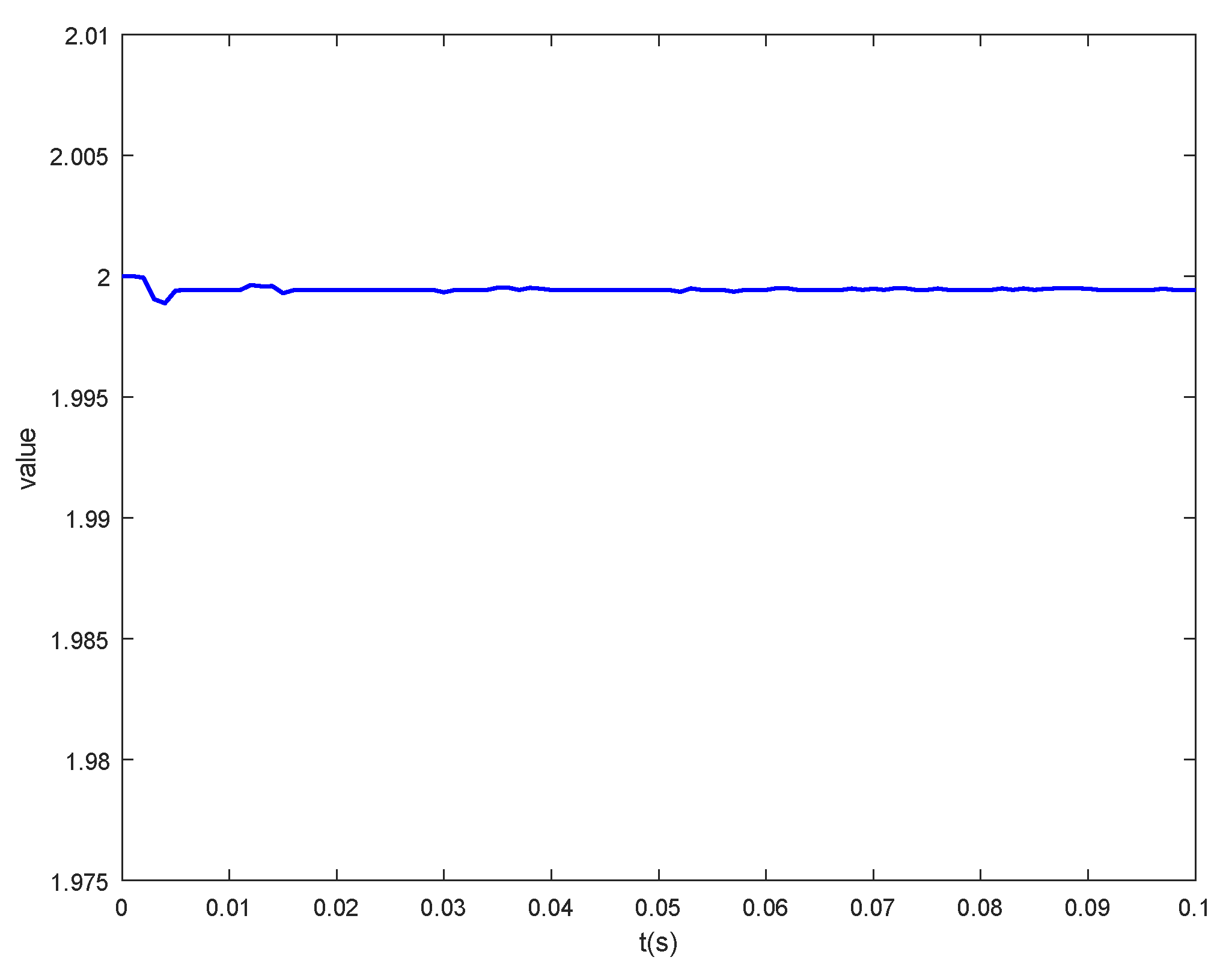

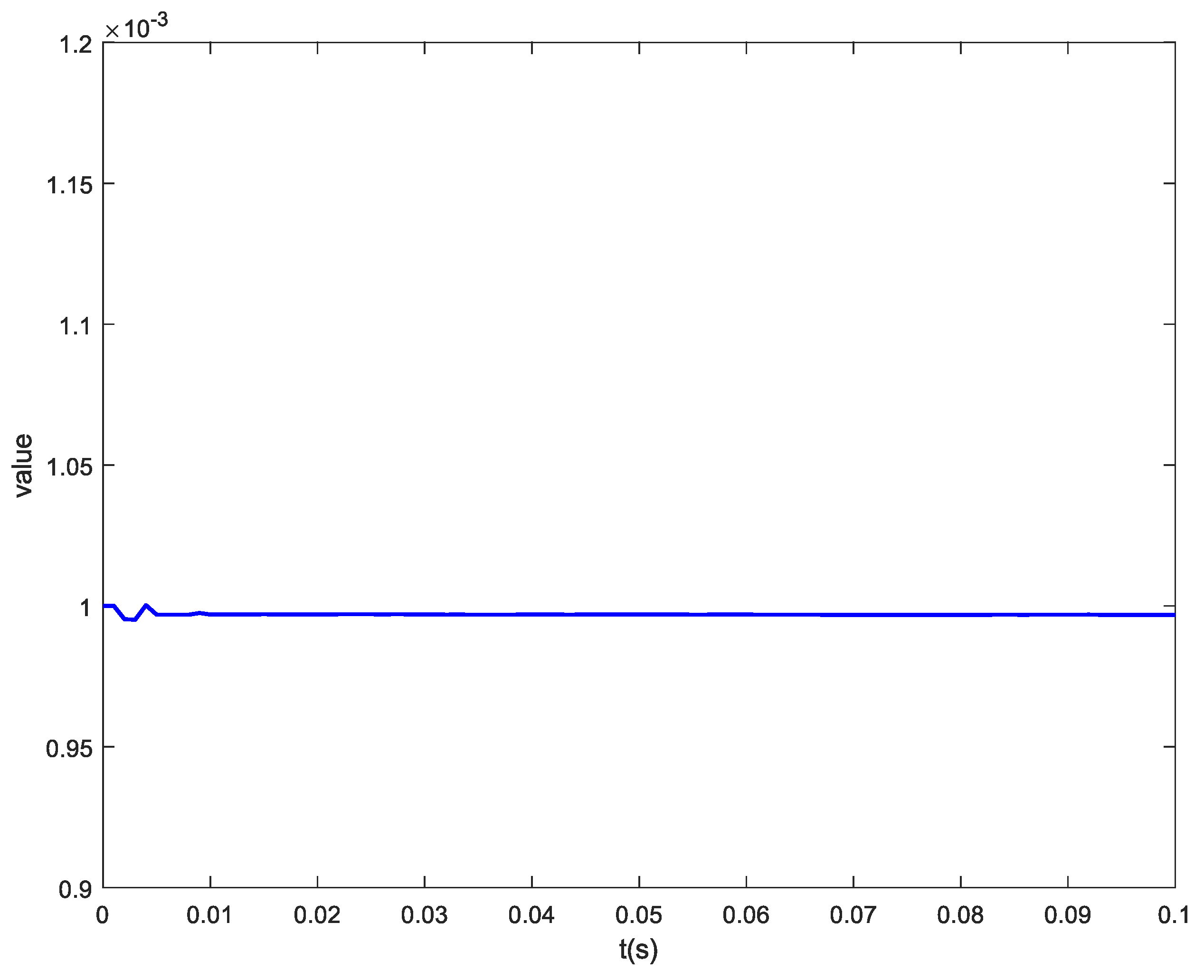

5.1.2. Parameter Identification Results and Analysis

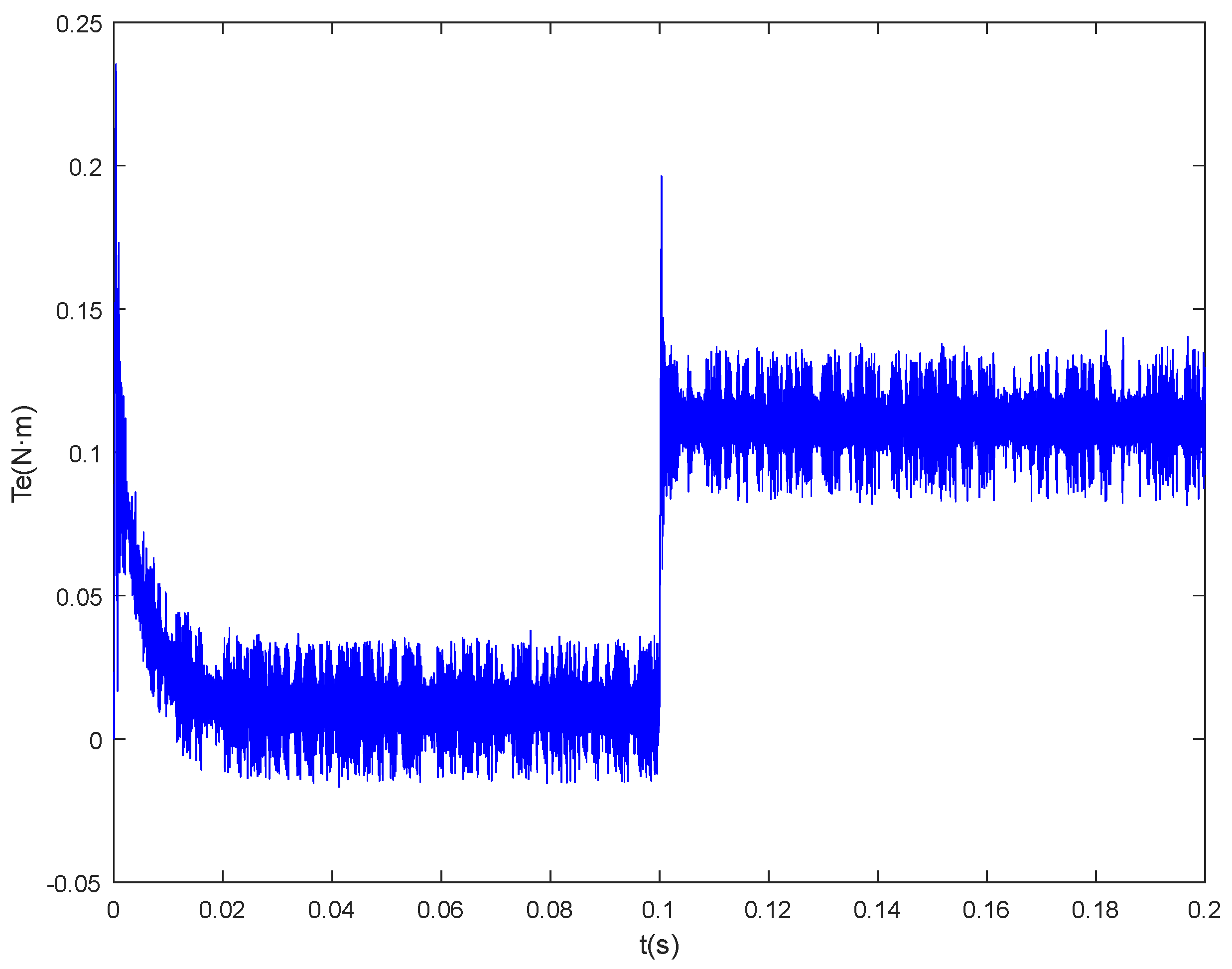

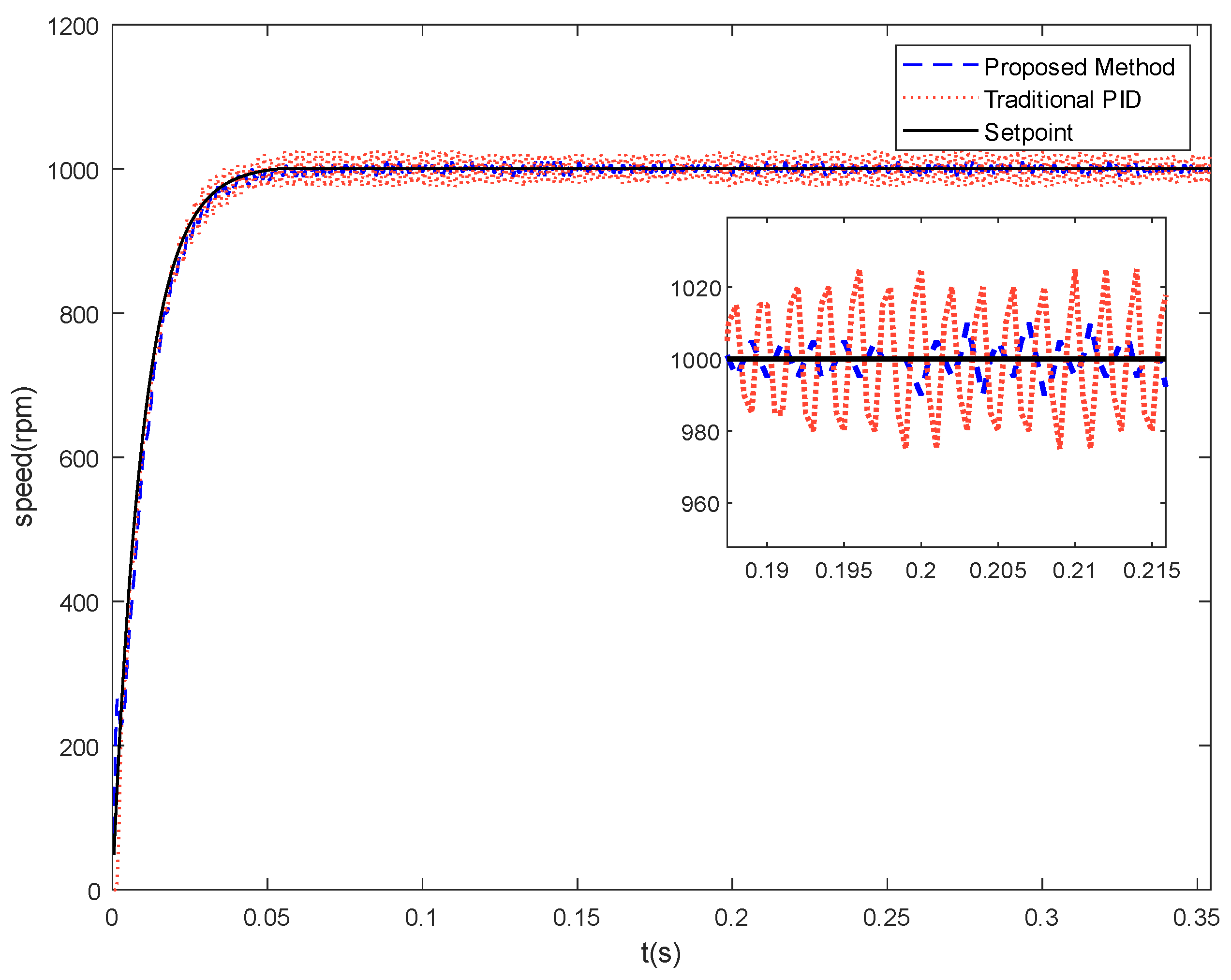

5.1.3. Load Performance Analysis

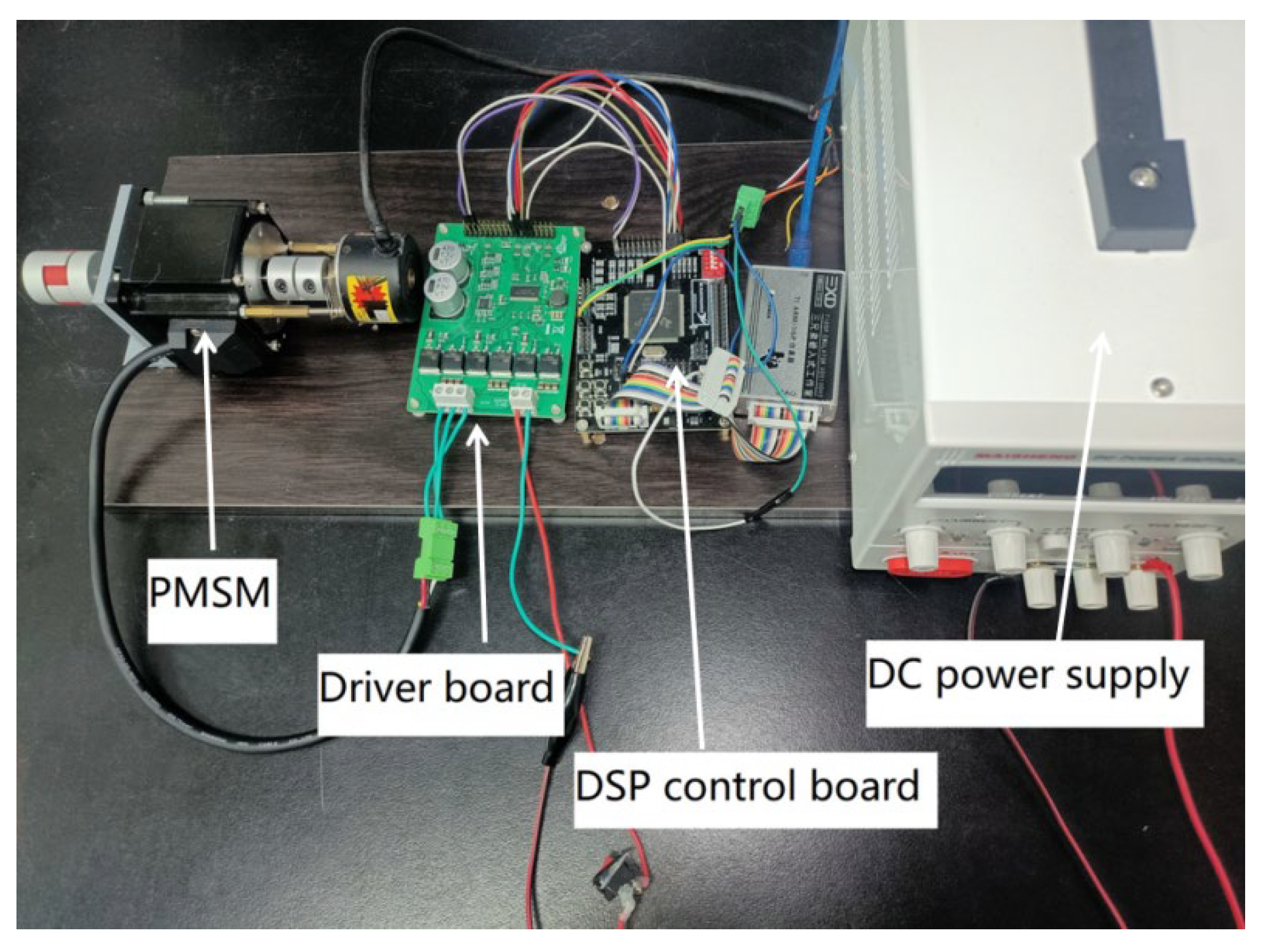

5.2. Actual Product to Verify

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Valla, M.; Solsona, J. Position Sensorless Permanent Magnet Synchronous Machine Drives—A Review. IEEE Trans. Ind. Electron. 2019, 67, 5830–5842. [Google Scholar] [CrossRef]

- Lin, R.; Chen, S.; Ding, X. Modeling and Simulation of Neuron Integral-separated PID Control for Permanent Magnet Synchronous Motor. J. Fuzhou Univ. 2009, 37, 849–852. [Google Scholar]

- Ding, W.; Gao, L. Modeling and Simulation of Permanent Magnet Synchronous Motor Vector Control System. Micromotors 2010, 43, 66–71. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wang, J.Z. Design of Neural Network Adaptive Sliding Mode Controller for Permanent Magnet Synchronous Motor. Electr. Mach. Control. 2009, 13, 290–295. [Google Scholar] [CrossRef]

- Ma, H.C. Design of a New Sliding Mode Speed Controller for Permanent Magnet Low Speed Synchronous. Motor. Control. Eng. China 2016, 23, 1757–1762. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Z.H. Current Decoupling and Harmonic Suppression Strategy of Permanent Magnet Synchronous Motor Based on Proportional Resonant Active Disturbance Rejection Control. Proc. CSEE 2021, 58, 1–10. [Google Scholar] [CrossRef]

- Sha, L.; Song, Y.; Li, Z. Permanent Magnet Synchronous Motor Control Method Based on Fuzzy PI and Sliding Mode Observer. J. Phys. Conf. Ser. IOP Publ. 2022, 2218, 012053. [Google Scholar] [CrossRef]

- Ding, X.; Li, R.; Cheng, Y.; Liu, Q.; Liu, J. Design of and Research into a Multiple-Fuzzy PID Suspension Control System Based on Road Recognition. Processes 2021, 9, 2190. [Google Scholar] [CrossRef]

- Wang, A.P.; Huang, X.Z. Variable Weight Coefficient Multi-step Model Predictive Current Control Method for Permanent Magnet Linear Synchronous Motor. Proc. CSEE 2022, 59, 1–11. [Google Scholar] [CrossRef]

- Yang, P.M.; Liu, Y.C. Voltage Stability Control Strategy Based on Model Predictive Current Compensation. Micromotors 2022, 55, 56–64. [Google Scholar] [CrossRef]

- Bai, C.G.; Wei, X.J. Research on Nonlinear Active Disturbance Rejection Compound Control Strategy of Permanent Magnet Synchronous Motor. Small Spec. Electr. Mach. 2021, 49, 46–50. [Google Scholar] [CrossRef]

- Liu, C.; Hu, J.H. Torque Ripple Suppression Strategy of Open-winding Permanent Magnet Synchronous Motor with Common DC Bus Based on Improved Active Disturbance Rejection Control. Proc. CSEE 2022, 59, 1–12. [Google Scholar] [CrossRef]

- Tavoosi, J. PMSM Speed Control Based on Intelligent Sliding Mode Technique. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2020, 39, 1315–1328. [Google Scholar] [CrossRef]

- Tavoosi, J.; Shirkhani, M.; Abdali, A.; Mohammadzadeh, A.; Nazari, M.; Mobayen, S.; Asad, J.H.; Bartoszewicz, A. A New General Type-2 Fuzzy Predictive Scheme for PID Tuning. Appl. Sci. 2021, 11, 10392. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Yan, B. Simulation Research on Deadbeat Direct Torque and Flux Control of Permanent Magnet Synchronous Motor. Energies 2022, 15, 3009. [Google Scholar] [CrossRef]

- Zhong, Z.; You, J.; Zhou, S. Torque Ripple Reduction of DTC Based on An Analytical Model of PMSM. World Electr. Veh. J. 2020, 11, 28. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.-H.; Wu, T.-X.; Zhai, D.-W.; Zhao, C.-H.; Zhou, Y.-F.; Qin, Y.-G.; Su, J.-S.; Qin, H. Hybrid Decision Based on DNN and DTC for Model Predictive Torque Control of PMSM. Symmetry 2022, 14, 693. [Google Scholar] [CrossRef]

- Mahfoud, S.; Derouich, A.; El Ouanjli, N.; Quynh, N.V.; Mossa, M.A. A New Hybrid Ant Colony Optimization Based PID of the Direct Torque Control for a Doubly Fed Induction Motor. World Electr. Veh. J. 2022, 13, 78. [Google Scholar] [CrossRef]

- Dou, X.H.; Wang, Y. Golden Section Adaptive Control of Permanent Magnet Synchronous Motor. Electron. Technol. 2015, 44, 18–22. [Google Scholar] [CrossRef]

- Dou, X.H.; Wang, Y. Nonlinear Golden-section Adaptive Control of Permanent Magnet Synchronous Motor. J. Syst. Sci. Math. Sci. 2015, 35, 860. [Google Scholar] [CrossRef]

- Wu, H.; HU, J. Intelligent Adaptive Control Based on Characteristic Model; China Science and Technology Press: Beijing, China, 2009; pp. 55–67. [Google Scholar]

- Han, Z.G. A New Method of Dynamic System Forecasting. Acta Autom. Sin. 1983, 21, 161–168. [Google Scholar] [CrossRef]

- Cao, Y.; Guo, J. Adaptive Anti-saturation Control of High Speed Motor Based on Characteristic Model. Electr. Mach. Control. 2021, 25, 86–93. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, H.; Che, Z.; Wang, Y.; Liu, Y. The Direct Speed Control of Pmsm Based on Terminal Sliding Mode and Finite Time Observer. Processes 2019, 7, 624. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.Z.; You, D.M. Golden Section Adaptive Speed Control of Ultrasonic Motors. Trans. China Electrotech. Soc. 2013, 28, 59–65. [Google Scholar] [CrossRef]

- Wu, J.R.; Guo, Y. Adaptive Control of Dual Motor Servo System Based on Characteristic Model. J. Huazhong Univ. Sci. Technol. 2013, 41, 436–439. [Google Scholar] [CrossRef]

- Wang, S.W.; Wang, S.D. Research on Automatic Code Generation Technology of SVPWM Algorithm Based on Model Design. Electr. Eng. 2018, 24, 134–136. [Google Scholar] [CrossRef]

- Wu, Z.J.; Li, J.G. Research on Automatic Code Generation for Permanent Magnet Synchronous Motor Control. Mach. Des. Manuf. 2021, 10, 182–185. [Google Scholar] [CrossRef]

- Yan, F.C.; Zhao, Y.X. Vector Control of Permanent Magnet Synchronous Motor Based on Matlab and CCS. Micromotors 2017, 50, 60–64. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Rated voltage (V) | 36 |

| Rated current (A) | 4.6 |

| Pole pairs | 4 |

| Phase resistance (Ω) | 0.38 |

| Phase inductance (mH) | 1 |

| Coefficient of viscous friction () | 0.0001 |

| Moment of inertia () | 0.0588 |

| Magnetic flux amplitude (Wb) | 0.11867 |

| Rated torque (N) | 0.318 |

| Method | Settling Time/ms | Average Volatility/% |

|---|---|---|

| LGSC | 14 | 0.23 |

| NGSC | 35 | 0.43 |

| PID | 260 | 1.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, W.; Han, W.; Wang, L.; Liu, Z.; Du, W. Linear Golden Section Speed Adaptive Control of Permanent Magnet Synchronous Motor Based on Model Design. Processes 2022, 10, 1010. https://doi.org/10.3390/pr10051010

Jiang W, Han W, Wang L, Liu Z, Du W. Linear Golden Section Speed Adaptive Control of Permanent Magnet Synchronous Motor Based on Model Design. Processes. 2022; 10(5):1010. https://doi.org/10.3390/pr10051010

Chicago/Turabian StyleJiang, Wenping, Wenchao Han, Lingyang Wang, Zhouyang Liu, and Weidong Du. 2022. "Linear Golden Section Speed Adaptive Control of Permanent Magnet Synchronous Motor Based on Model Design" Processes 10, no. 5: 1010. https://doi.org/10.3390/pr10051010

APA StyleJiang, W., Han, W., Wang, L., Liu, Z., & Du, W. (2022). Linear Golden Section Speed Adaptive Control of Permanent Magnet Synchronous Motor Based on Model Design. Processes, 10(5), 1010. https://doi.org/10.3390/pr10051010