Material Removal Optimization Strategy of 3D Block Cutting Based on Geometric Computation Method

Abstract

1. Introduction

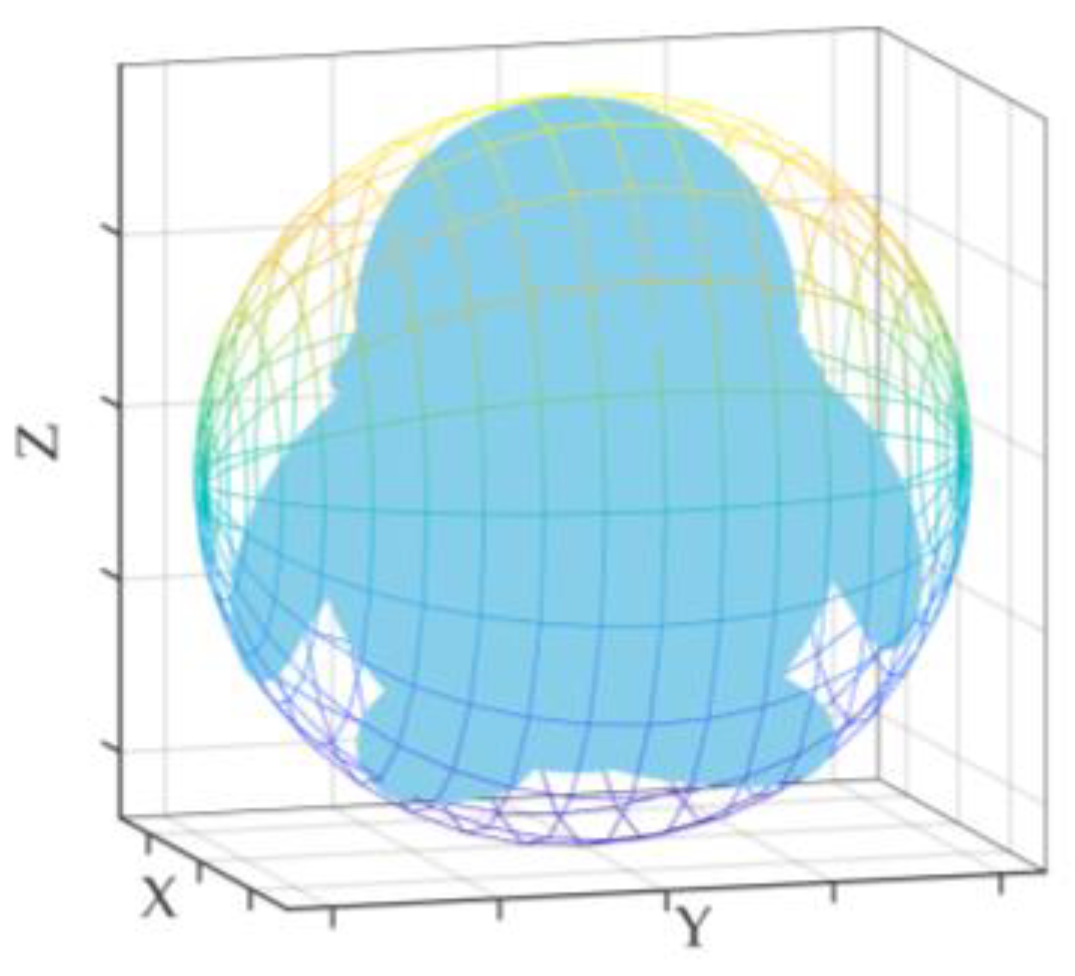

2. Preliminaries: Block Cutting Mechanism

- Reconstruction description of the CPH: During a continuous block cutting process, it is inevitable to be confronted with the problem of the CPH reconstruction and intersection calculation between a plane and the CPH combining with computational geometry. Therefore, it is important but challenging to update the CPH information including removal vertices, intersection vertices, intersection faces and updated faces using an appropriate, available data structure. We hope these can be efficiently implemented to carry out dynamic data storage so that any queries about the workpiece during the cutting process can be answered with the need for less data and calculation. Meanwhile, the visual image of the live cutting can be displayed to demonstrate the reconstruction of the CPH after each cutting.

- Design cuttable big blocks: For block cutting, aiming for the highest efficiency for the removal of materials, it is better when removal blocks are designed larger, and as far as possible, with the minimum number of cutting times. The difficult question is how to construct the CP so as to determine the angle of the circular saw, which is related to the vertices of the blank CPH and the BS surface.

- Optimize cutting time: The cutting time under the condition with a constant feed speed can be confirmed by investigating the cutting path. Therefore, in order to obtain the shortest cutting time, it is necessary to analyze the geometrical characteristics of the CPG generated by the intersection of the CP with the CPH, so as to calculate the cutting feed direction and cutting point of the shortest path under constraints.

3. Reconstruction Description of the CPH

3.1. Data Structure of CPH

3.2. CPH Model Reconstruction

| Algorithm 1 CPH List Updating. |

| Input: Vertex-Face List of Qi−1, πi Output: Vertex-Face List of Qi 1: function ConstructCPHList(Vertex-Face List of Qi−1 ,πi ) 2: // Construct the Vertex-Face List of the first type face of Qi 3: for all F in Face List of Qi−1 do 4: for all vertexi−1,j in Fm do 5: vertexi−1,j ←Vertex of Qi−1[Fm [j]] //Index the corresponding vertex 6: vertexi−1,j+1 ←Vertex of Qi−1[Fm [j + 1]] 7: if πi (vertexi−1,j ) ≤ 0 ∧ πi (vertexi−1,j+1) ≤ 0 then//Two vertices are in negative half-space 8: Vertex List of Qi ←vertexi−1,j , vertexi−1,j+1 9: Face List of Qi ←indexes of vertexi−1,j and vertexi−1,j+1 10: else if πi (vertexi−1,j ) ≤ 0 ∧ πi (vertexi−1,j+1 ) > 0 then//Two vertices lie on either side of πi 11: Ei−1,j ←line(vertexi−1,j, vertexi−1,j+1 ) 12: Pcsij ←Ei−1,j ∩ πi //Find the intersection of Ei−1,j and πi 13: if Pcsij ∉ T empList then 14: T empList←Pcsij //T empList is used to store the Pcsij 15: Vertex List of Qi ←Pcsij 16: end if 17: Face List of Qi ←index of Pcsij 18: end if 19: end for 20: end for 21: // Construct the Vertex-Face List of the second type face of Qi 22: [Ni ]←ComputeNormalVector(Pcsi) 23: [Pcsi ]←3DCoordinateTransformation(Ni, Pcsi) //3D Coordinate transformation for vertex sorting 24: Face List of Qi ←index of Pcsi 25: return Vertex-Face List of Qi 26: end function |

4. Design Cuttable Big Blocks

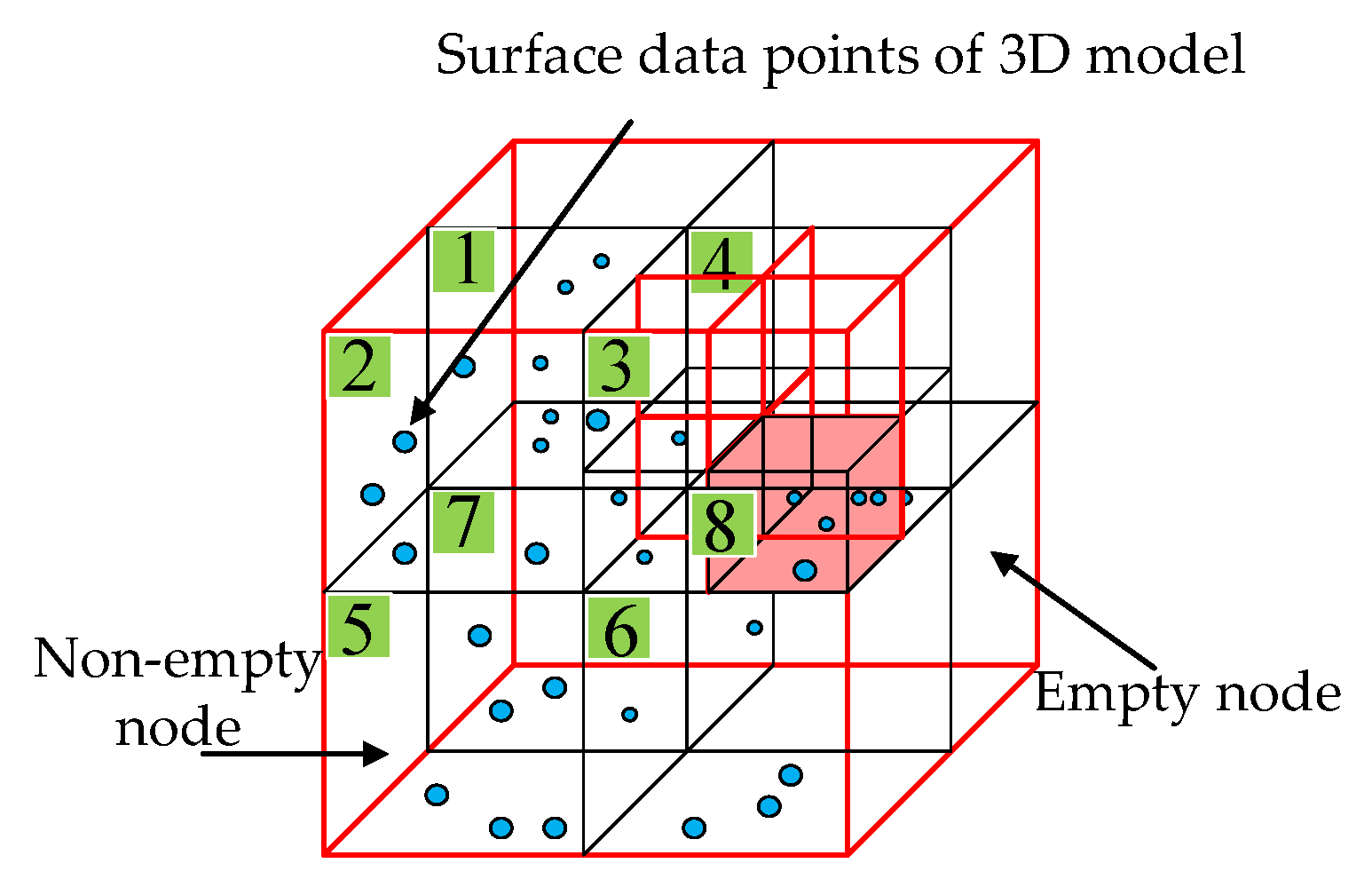

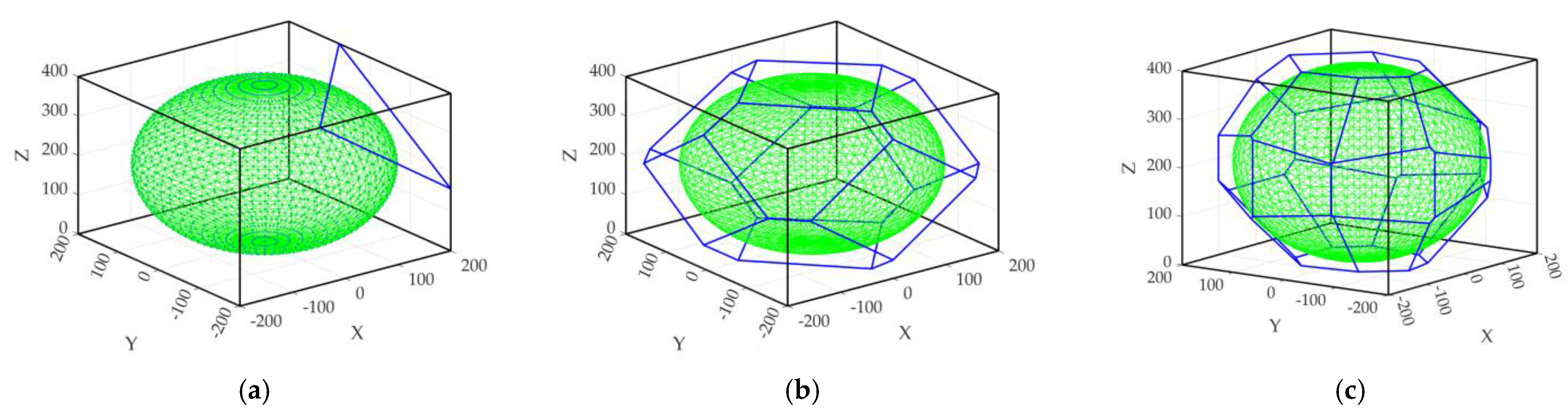

4.1. Octree Space Partition

4.2. Construct Cutting Plane

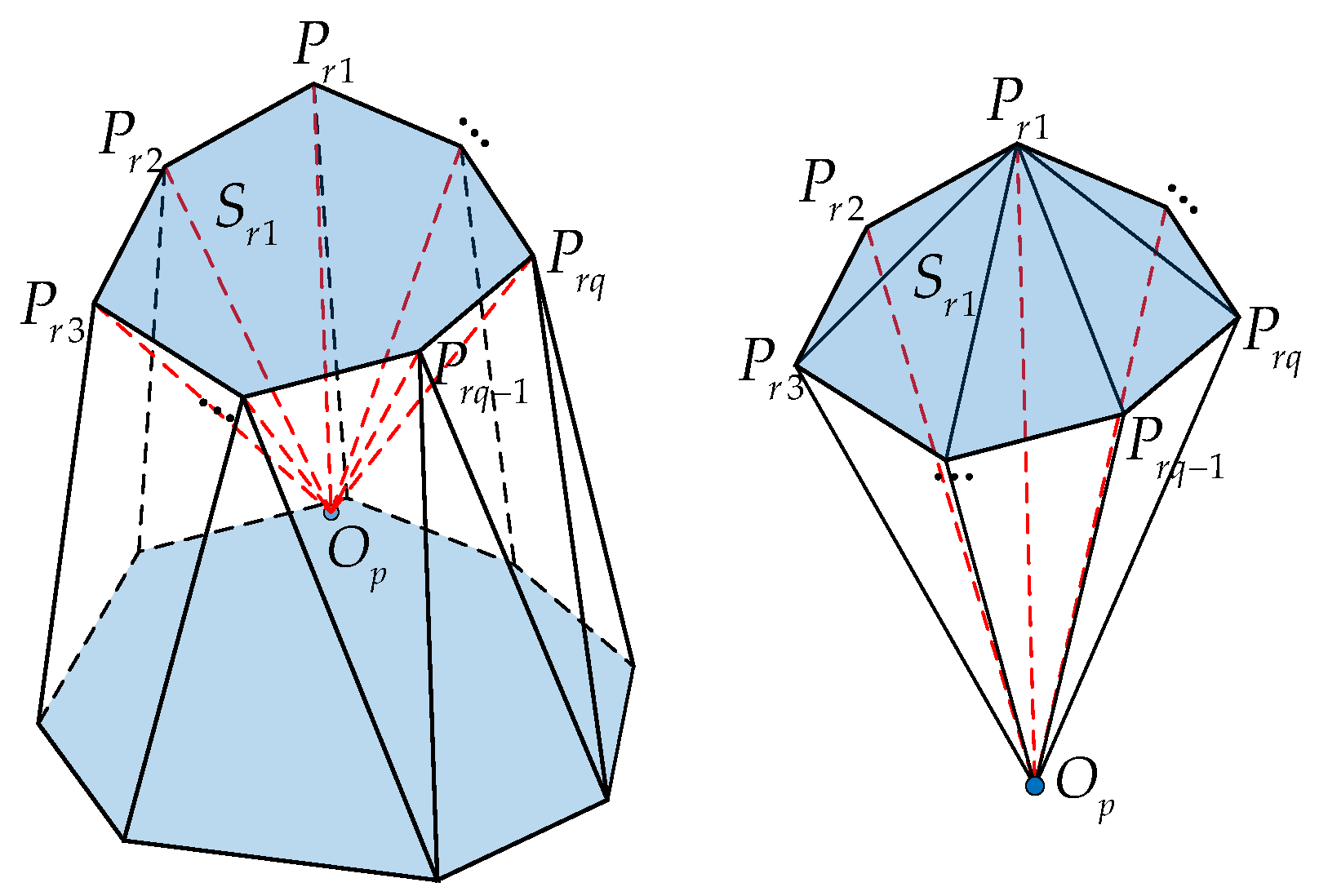

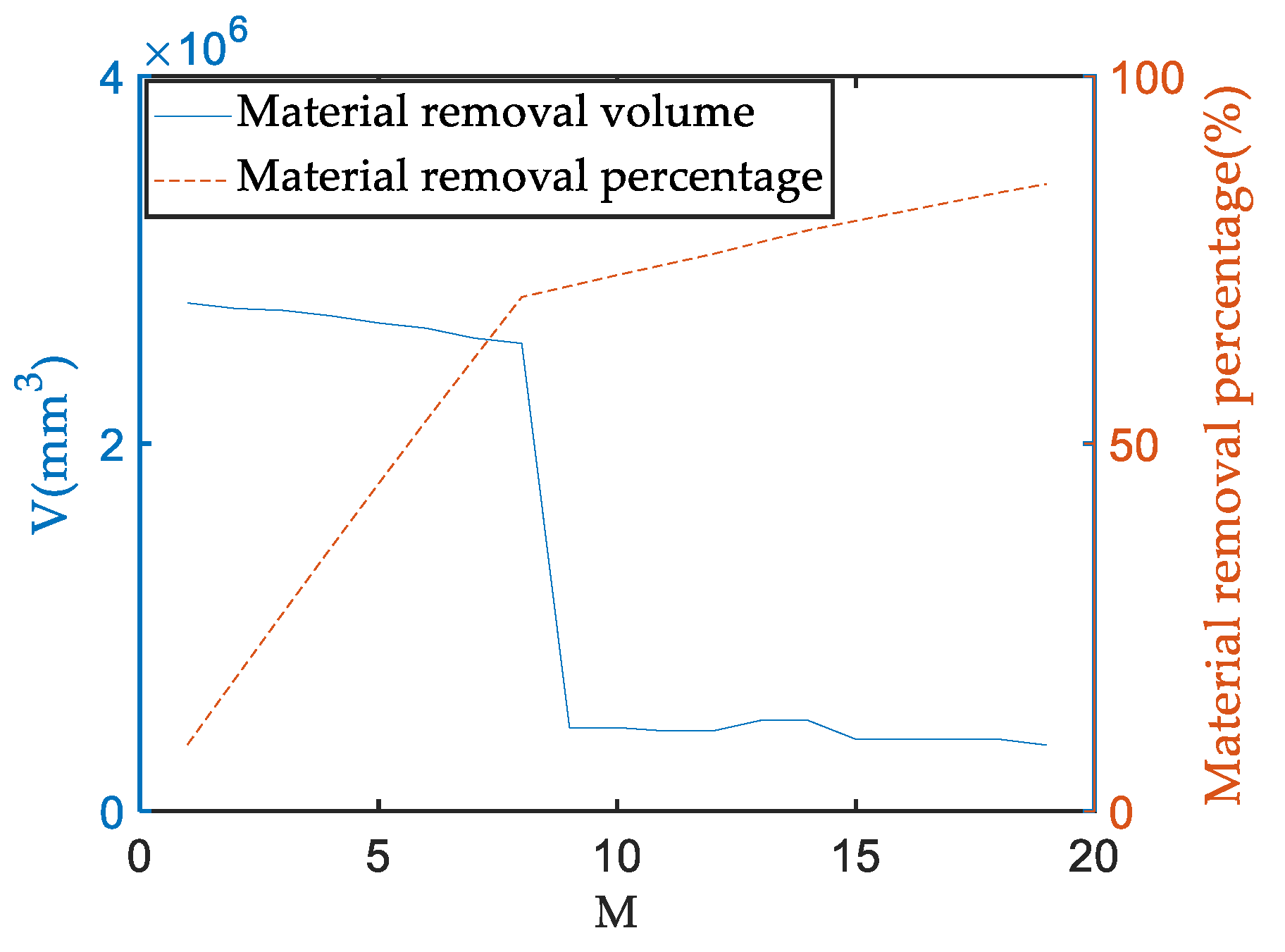

4.3. Calculate Material Removal Volume (MRV)

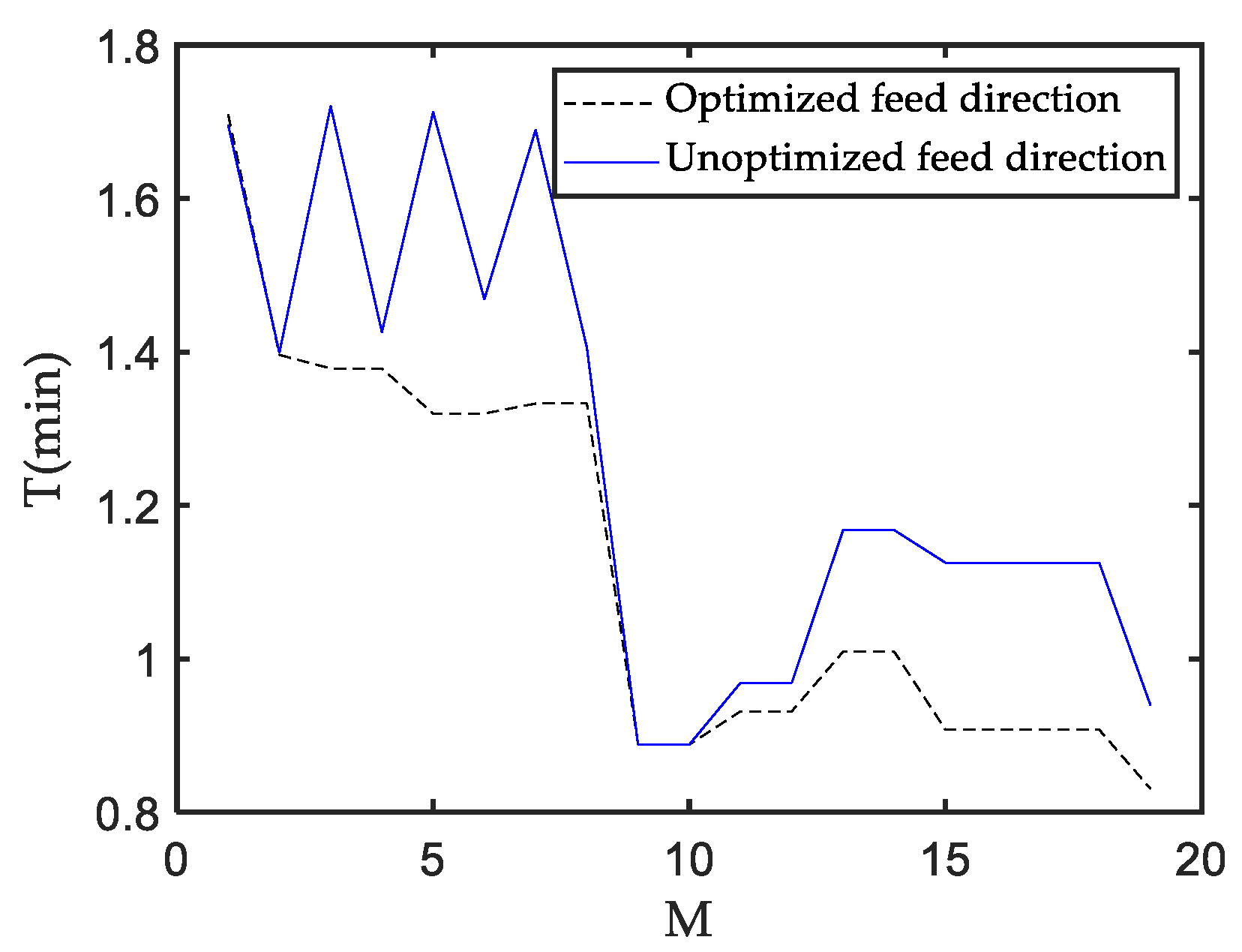

5. Optimize Cutting Time

5.1. Time Optimization Model

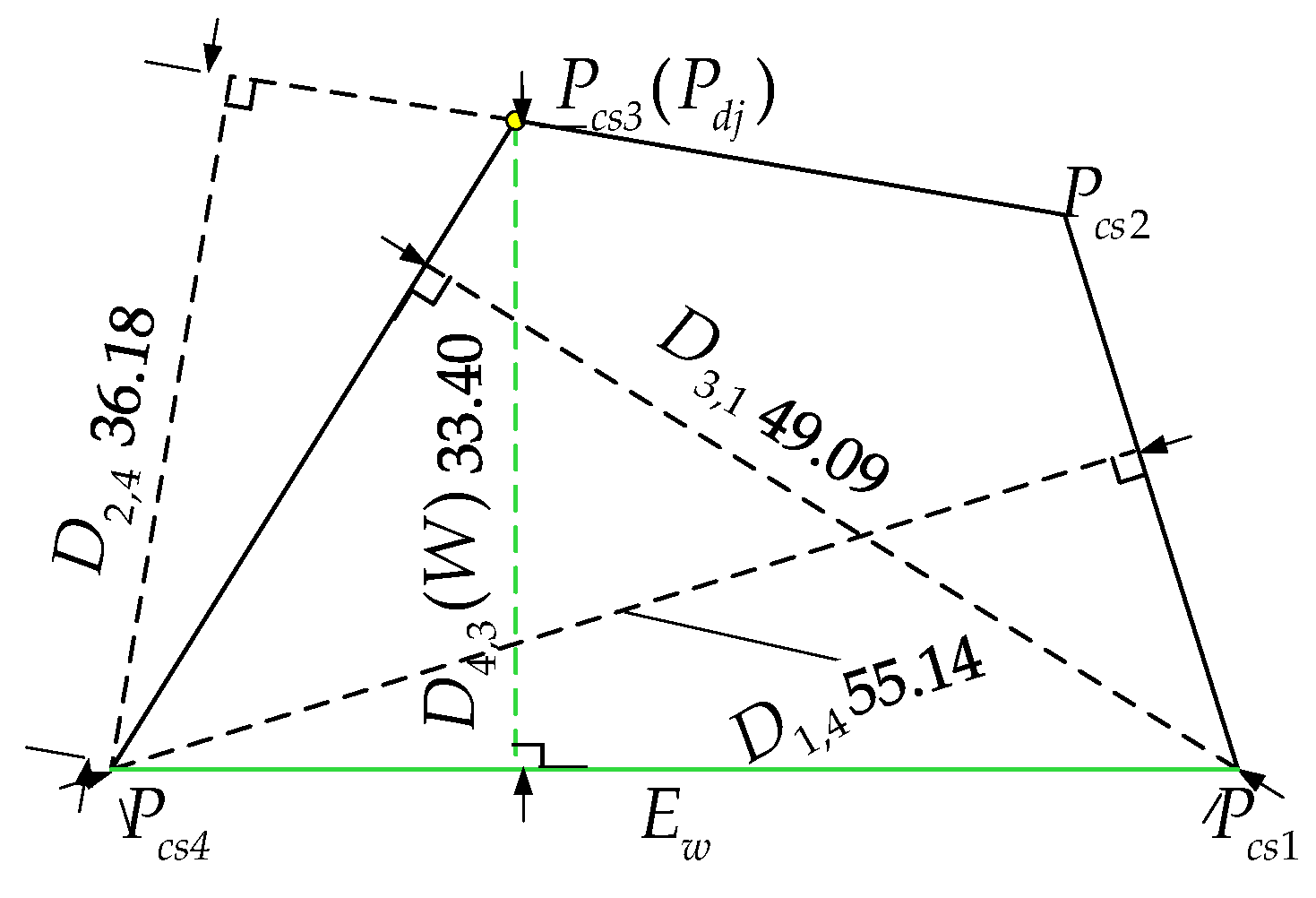

5.2. Intersection CPG Analysis

5.3. Cutting Path Optimization

6. Simulation Results and Analysis

6.1. Simulation Verification

6.2. Comparison of Sawing and Milling

7. Conclusions and Future Scope

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, S.W.; Qiu, H.; Rabe, L.; Jia, S.; Elwert, T.; Wang, Q.Y.; Wang, Q.; Sun, Y. A study on energy-saving optimization strategy for the stone processing industry—An improved method for modeling cutting power and energy consumption: A case study of block sawing process. J. Clean. Prod. 2021, 300, 126922. [Google Scholar] [CrossRef]

- Şirin, E.; Bonduà, S.; Elkarmoty, M. Environmental and economic optimization for block cutting of dimension stones in a limestone quarry. Resour. Policy 2021, 74, 102396. [Google Scholar] [CrossRef]

- Kim, D.; Kim, H.; Lee, S. Characterization of diamond wire-cutting performance for lifetime estimation and process optimization. J. Mech. Sci. Technol. 2016, 30, 847–852. [Google Scholar] [CrossRef]

- Kumar, V.; Saraswat, P.; Kumar, A. Experimental investigation of rotary ultrasonic face milling on red granite: A comparison with conventional grinding. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Yin, F.C.; Ji, Q.Z.; Wang, C.Z. Research on machining error prediction and compensation technology for a stone-carving robotic manipulator. Int. J. Adv. Manuf. Technol. 2021, 115, 1683–1700. [Google Scholar] [CrossRef]

- Buyuksagis, I.S.; Rostami, J.; Yagiz, S. Development of models for estimating specific energy and specific wear rate of circular diamond saw blades based on properties of carbonate rocks. Int. J. Rock Mech. Min. Sci. 2020, 135, 104497. [Google Scholar] [CrossRef]

- Gao, Z.; Chen, M.Z.Q.; Zhang, D. Special Issue on “Advances in Condition Monitoring, Optimization and Control for Complex Industrial Processes”. Processes 2021, 9, 664. [Google Scholar] [CrossRef]

- Yamada, Y.; Sasahara, H. Free-form curves cutting using flexible circular saw. Precis. Eng. 2014, 38, 611–616. [Google Scholar] [CrossRef]

- Demaine, E.D.; Demaine, M.L.; Kaplan, C.S. Polygons cuttable by a circular saw. Comput. Geom. 2001, 20, 69–84. [Google Scholar] [CrossRef][Green Version]

- Jaromczyk, J.W.; Kowaluk, M. Sets of lines and cutting out polyhedral objects. Comput. Geom. 2003, 25, 67–95. [Google Scholar] [CrossRef][Green Version]

- Van Sosin, B.; Bartoň, M.; Elber, G. Accessibility for line-cutting in freeform surfaces. Comput.-Aided Des. 2019, 114, 202–214. Available online: https://www.researchgate.net/publication/332670481 (accessed on 13 January 2022). [CrossRef]

- Dumitrescu, A. An approximation algorithm for cutting out convex polygons. Comput. Geom. 2004, 29, 223–231. [Google Scholar] [CrossRef][Green Version]

- Tan, X.; Wu, G. Approximation algorithms for cutting a convex polyhedron out of a sphere. Theor. Comput. Sci. 2013, 508, 66–73. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Su, H.D.; Lin, S.Z.; Shi, G.H. Algorithm for three-dimensional curved block cutting analysis in solid modeling. Comput. Methods Appl. Mech. Eng. 2020, 360, 112721. Available online: https://www.researchgate.net/publication/337304188 (accessed on 13 January 2022). [CrossRef]

- Boon, C.W.; Houlsby, G.T.; Utili, S. A new rock slicing method based on linear programming. Comput. Geotech. 2015, 65, 12–29. [Google Scholar] [CrossRef]

- Chiodi, R.; Desjardins, O. General, robust, and efficient polyhedron intersection in the Interface Reconstruction Library. J. Comput. Phys. 2022, 449, 110787. [Google Scholar] [CrossRef]

- Chen, Z.; Tagliasacchi, A.; Zhang, H. Learning mesh representations via binary space partitioning tree networks. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 1, 1. [Google Scholar] [CrossRef]

- Kim, Y.H.; Ko, S.L. Improvement of cutting simulation using the octree method. Int. J. Adv. Manuf. Technol. 2006, 28, 1152–1160. [Google Scholar] [CrossRef]

- Zhou, K.; Gong, M.; Huang, X. Data-parallel octrees for surface reconstruction. IEEE Trans. Vis. Comput. Graph. 2010, 17, 669–681. [Google Scholar] [CrossRef]

- Xu, J.; Liu, Z.; Yang, C. A pseudo-distance algorithm for collision detection of manipulators using convex-plane-polygons-based representation. Robot. Comput. -Integr. Manuf. 2020, 66, 101993. [Google Scholar] [CrossRef]

- Trinidad, M.C.; Vinacua, A.; Carruesco, A. Sweep Encoding: Serializing Space Subdivision Schemes for Optimal Slicing. Comput.-Aided Des. 2022, 146, 103189. [Google Scholar] [CrossRef]

- Goldman, R. IV.1 Area of Planar Polygons and Volume of Polyhedra. In Graphics GEMS II, 2nd ed.; Arvo, J., Ed.; Academic Press/Morgan Kaufmann: San Francisco, CA, USA, 1991; pp. 169–171. [Google Scholar] [CrossRef]

- Berg, M.; Cheong, O. Computational Geometry: Algorithms and Applications, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–17. [Google Scholar]

- Lassak, M. Spherical Geometry—A Survey on Width and Thickness of Convex Bodies. In Surveys in Geometry; Papadopoulos, A., Ed.; Springer: Cham, Germany, 2022; pp. 7–47. [Google Scholar] [CrossRef]

- Sánchez Egea, A.; Martynenko, V.; Martínez Krahmer, D.; López de Lacalle, L.; Benítez, A.; Genovese, G. On the Cutting Performance of Segmented Diamond Blades When Dry-Cutting Concrete. Materials 2018, 11, 264. [Google Scholar] [CrossRef] [PubMed]

| Symbols | Quantity | Unit | Symbols | Quantity | Unit |

|---|---|---|---|---|---|

| Blank box (Blank workpiece) | / | Vertex set of intersetion CPG | / | ||

| Parent CPH | / | The ith intersection CPG | / | ||

| Child CPH | / | T | Homogeneous transformation matrix | / | |

| Final CPH | / | R | Radius of sawblade | mm | |

| Removal block by the ith cutting | / | Feeding speed | mm/min | ||

| Cutting plane | / | The ith material removal volume | mm3 | ||

| The ith CP | / | The ith cutting time | min | ||

| / | W | Width of CPG | mm | ||

| Removal vertex set of the ith cutting | / | Cutting path | mm/min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, H.; Liu, Q.; Gao, Z. Material Removal Optimization Strategy of 3D Block Cutting Based on Geometric Computation Method. Processes 2022, 10, 695. https://doi.org/10.3390/pr10040695

Shao H, Liu Q, Gao Z. Material Removal Optimization Strategy of 3D Block Cutting Based on Geometric Computation Method. Processes. 2022; 10(4):695. https://doi.org/10.3390/pr10040695

Chicago/Turabian StyleShao, Hui, Qimeng Liu, and Zhiwei Gao. 2022. "Material Removal Optimization Strategy of 3D Block Cutting Based on Geometric Computation Method" Processes 10, no. 4: 695. https://doi.org/10.3390/pr10040695

APA StyleShao, H., Liu, Q., & Gao, Z. (2022). Material Removal Optimization Strategy of 3D Block Cutting Based on Geometric Computation Method. Processes, 10(4), 695. https://doi.org/10.3390/pr10040695