Catalytic Pyrolysis of Waste Plastics over Industrial Organic Solid-Waste-Derived Activated Carbon: Impacts of Activation Agents

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Sample Preparation

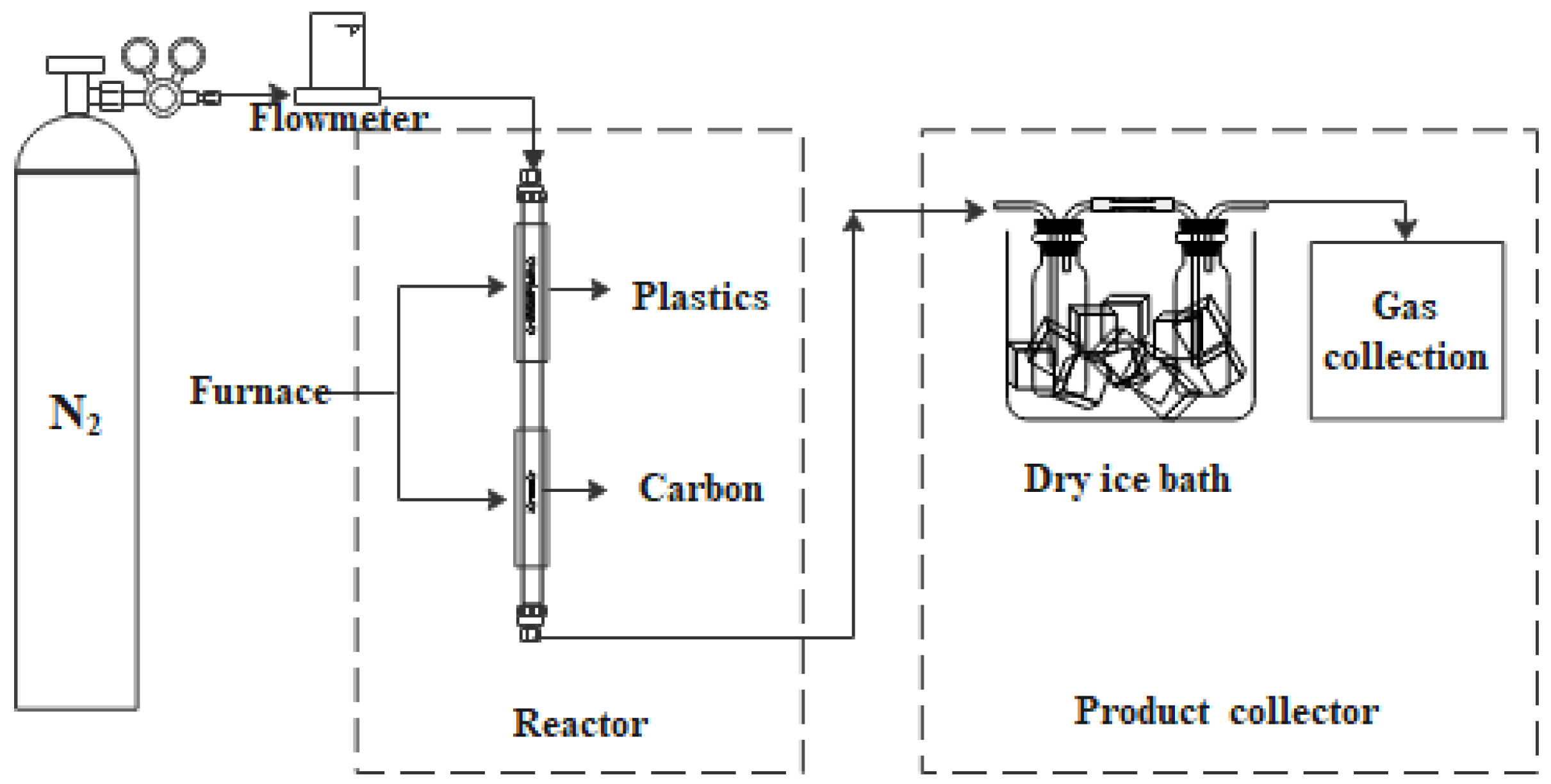

2.3. Performance Test and Product Analysis

3. Results and Discussion

3.1. BET, FTIR, and Raman Spectroscopy

3.2. Pyrolysis Behaviors of Plastics and Carbon Mixture

3.3. Catalytic Performance of Carbon on Pyrolysis of Plastic

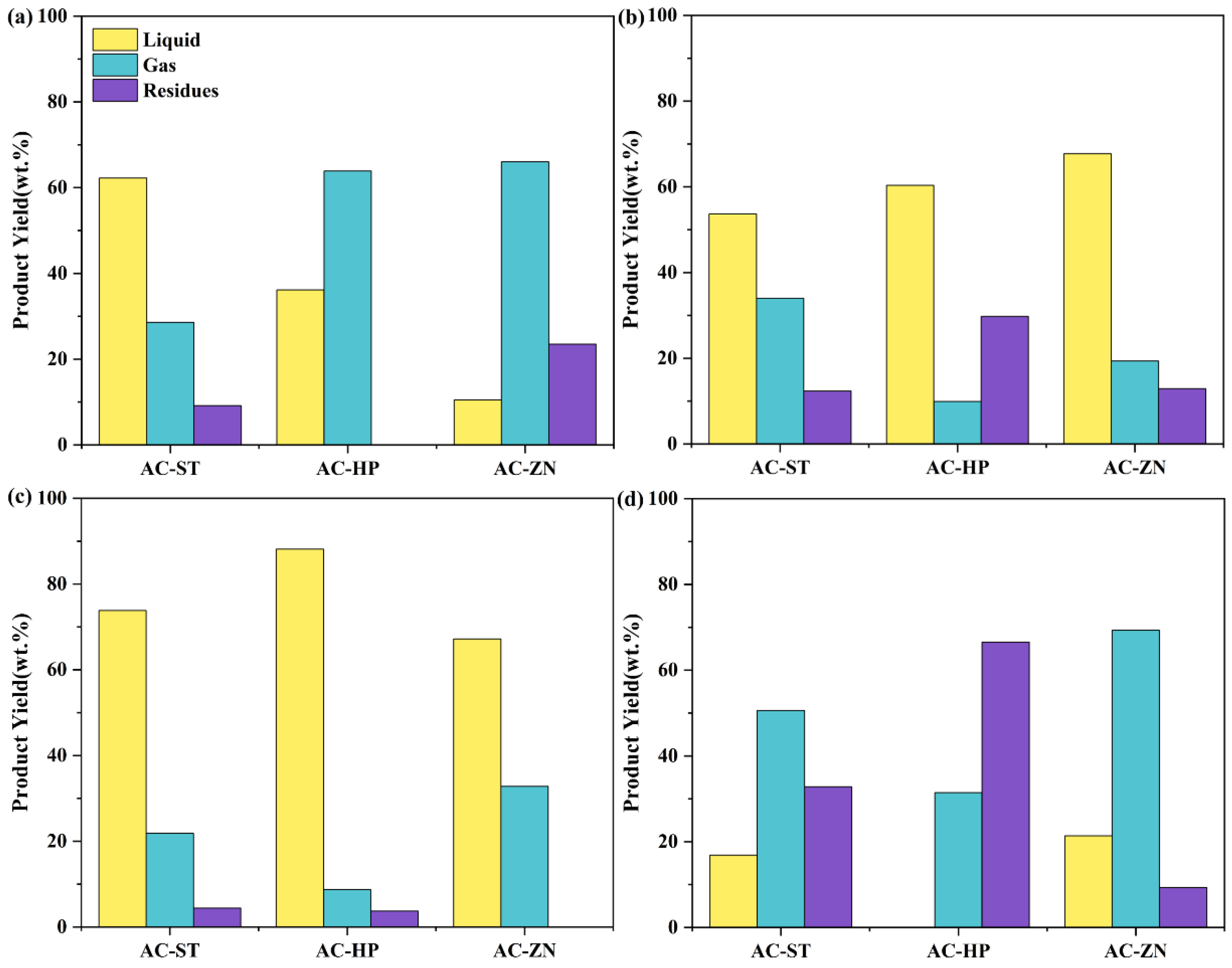

3.3.1. Product Yields

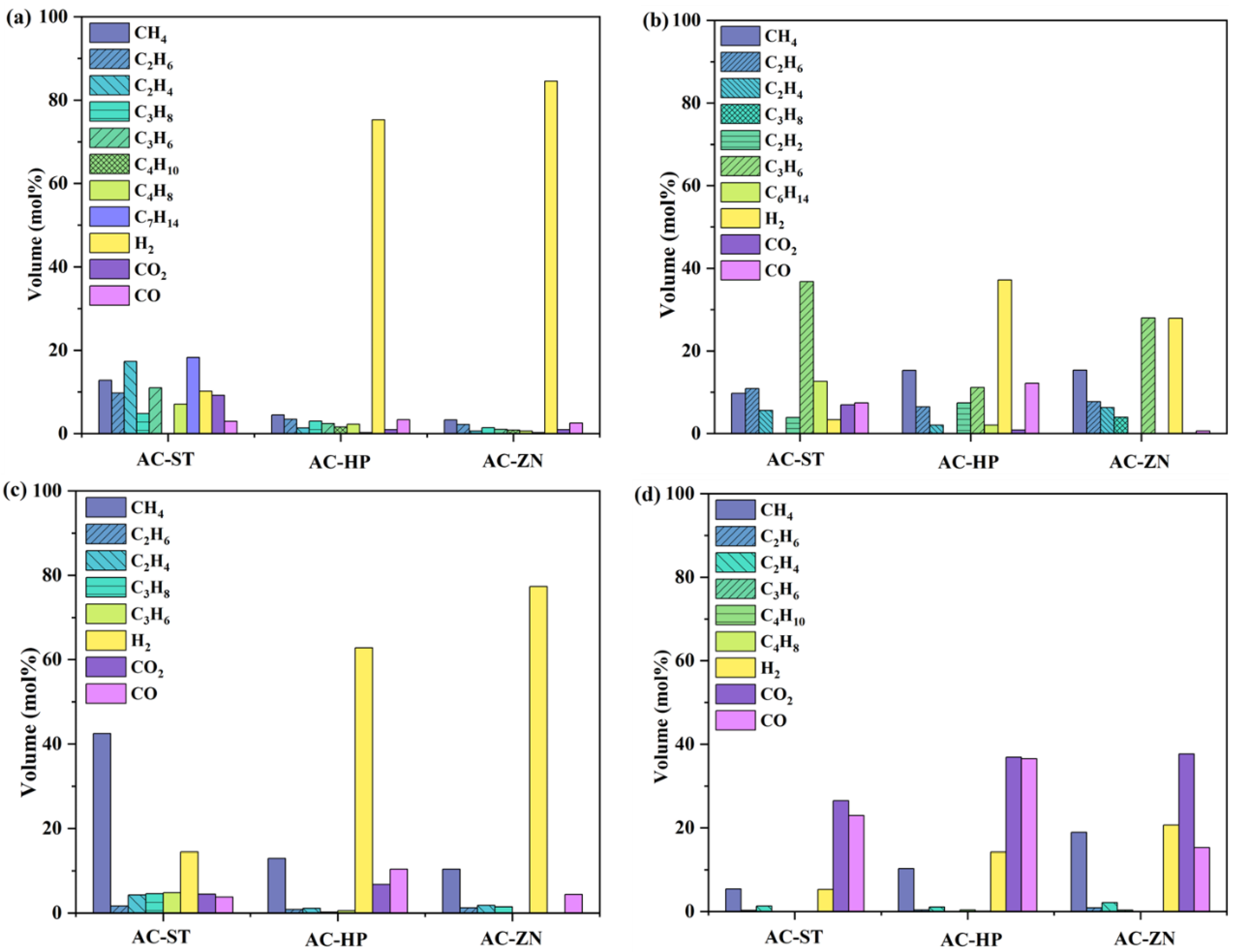

3.3.2. Product Compositions

3.4. Effects of Mass Ratio of Activator on Carbons’ Performance

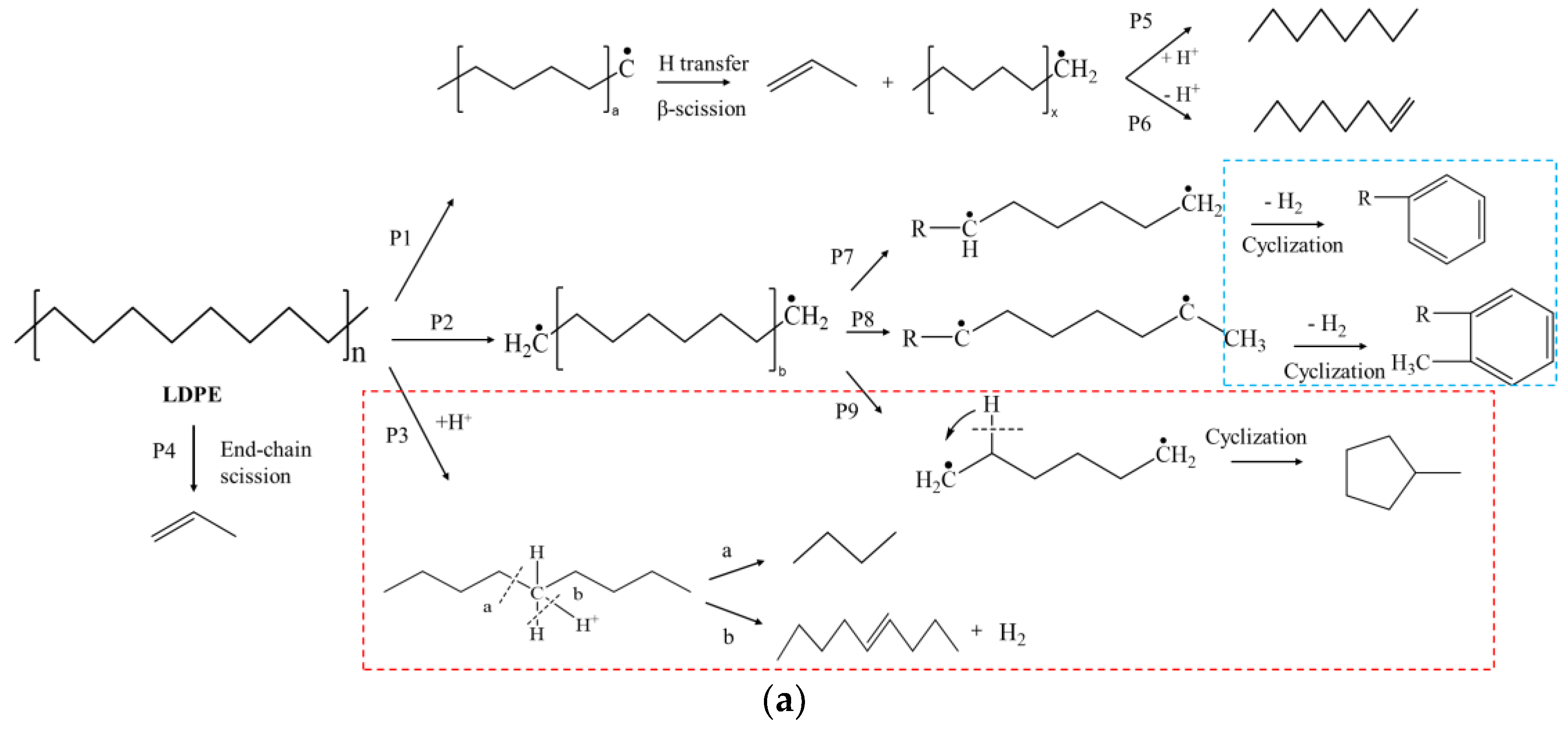

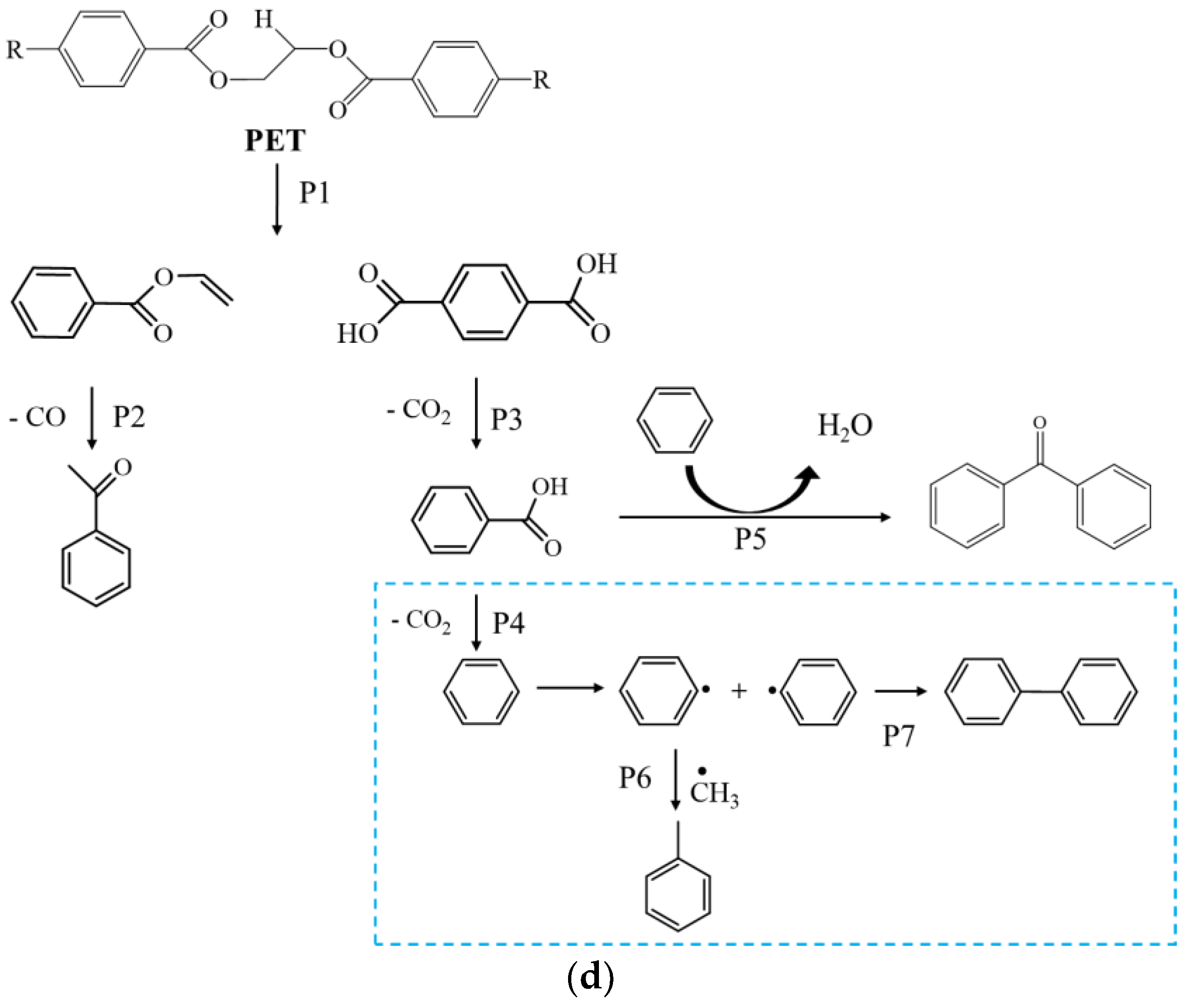

3.5. Discussion of Possible Reaction Mechanism over Carbons

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jehanno, C.; Alty, J.W.; Roosen, M.; De Meester, S.; Dove, A.P.; Chen, E.Y.-X.; Leibfarth, F.A.; Sardon, H. Critical Advances and Future Opportunities in Upcycling Commodity Polymers. Nature 2022, 603, 803–814. [Google Scholar] [CrossRef]

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a Circular Economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, D.; Dong, L.; Xu, Y.; Liu, J. Pollution Status and Environmental Sound Management (ESM) Trends on Typical General Industrial Solid Waste. Procedia Environ. Sci. 2016, 31, 615–620. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, H.; Du, L.; Lu, W.; Qi, K. Exploring the Industrial Solid Wastes Management System: Empirical Analysis of Forecasting and Safeguard Mechanisms. J. Environ. Manag. 2021, 279, 111627. [Google Scholar] [CrossRef] [PubMed]

- Zhou, B.; Sun, C.; Yi, H. Solid Waste Disposal in Chinese Cities: An Evaluation of Local Performance. Sustainability 2017, 9, 2234. [Google Scholar] [CrossRef]

- Wu, L.; Jiang, X.; Lv, G.; Li, X.; Yan, J. Interactive Effect of the Sorted Components of Solid Recovered Fuel Manufactured from Municipal Solid Waste by Thermogravimetric and Kinetic Analysis. Waste Manag. 2020, 102, 270–280. [Google Scholar] [CrossRef]

- Parthasarathy, P.; Sheeba, K.N. Generation of Fuel Char through Biomass Slow Pyrolysis. Energy Sources Part Recovery Util. Environ. Eff. 2017, 39, 599–605. [Google Scholar] [CrossRef]

- Arribas, L.; Arconada, N.; González-Fernández, C.; Löhrl, C.; González-Aguilar, J.; Kaltschmitt, M.; Romero, M. Solar-Driven Pyrolysis and Gasification of Low-Grade Carbonaceous Materials. Int. J. Hydrogen Energy 2017, 42, 13598–13606. [Google Scholar] [CrossRef]

- Parthasarathy, P.; Al-Ansari, T.; Mackey, H.R.; Sheeba Narayanan, K.; McKay, G. A Review on Prominent Animal and Municipal Wastes as Potential Feedstocks for Solar Pyrolysis for Biochar Production. Fuel 2022, 316, 123378. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, D.; Lei, H.; Villota, E.; Ruan, R. Jet Fuel Production from Waste Plastics via Catalytic Pyrolysis with Activated Carbons. Appl. Energy 2019, 251, 113337. [Google Scholar] [CrossRef]

- Sun, K.; Huang, Q.; Ali, M.; Chi, Y.; Yan, J. Producing Aromatic-Enriched Oil from Mixed Plastics Using Activated Biochar as Catalyst. Energy Fuels 2018, 32, 5471–5479. [Google Scholar] [CrossRef]

- Mei, Z.; He, X.; Chen, D.; Wang, N.; Yin, L.; Qian, K.; Feng, Y. Comparison of Chars from Municipal Solid Waste and Wheat Straw for Understanding the Role of Inorganics in Char-Based Catalysts during Volatile Reforming Process. Energy 2021, 229, 120619. [Google Scholar] [CrossRef]

- Mei, Z.; Chen, D.; Qian, K.; Zhang, R.; Yu, W. Producing Eco-Methane with Raw Syngas Containing Miscellaneous Gases and Tar by Using a Municipal Solid Waste Char-Based Catalyst. Energy 2022, 254, 124244. [Google Scholar] [CrossRef]

- Tsyntsarski, B.; Stoycheva, I.; Tsoncheva, T.; Genova, I.; Dimitrov, M.; Petrova, B.; Paneva, D.; Cherkezova-Zheleva, Z.; Budinova, T.; Kolev, H.; et al. Activated Carbons from Waste Biomass and Low Rank Coals as Catalyst Supports for Hydrogen Production by Methanol Decomposition. Fuel Process. Technol. 2015, 137, 139–147. [Google Scholar] [CrossRef]

- Fu, G.; Wang, Z.; Zhang, Y.; Huang, Z.; Liu, J.; Zhou, J.; Cen, K. Effect of Raw Material Sources on Activated Carbon Catalytic Activity for HI Decomposition in the Sulfur-Iodine Thermochemical Cycle for Hydrogen Production. Int. J. Hydrogen Energy 2016, 41, 7854–7860. [Google Scholar] [CrossRef]

- Yeganeh, M.M.; Kaghazchi, T.; Soleimani, M. Effect of Raw Materials on Properties of Activated Carbons. Chem. Eng. Technol. 2006, 29, 1247–1251. [Google Scholar] [CrossRef]

- Wani Likun, P.K.; Zhang, H. Insights into Pyrolysis of Torrefied-Biomass, Plastics/Tire and Blends: Thermochemical Behaviors, Kinetics and Evolved Gas Analyses. Biomass Bioenergy 2020, 143, 105852. [Google Scholar] [CrossRef]

- Sun, K.; Huang, Q.; Meng, X.; Chi, Y.; Yan, J. Catalytic Pyrolysis of Waste Polyethylene into Aromatics by H3PO4-Activated Carbon. Energy Fuels 2018, 32, 9772–9781. [Google Scholar] [CrossRef]

- Ţucureanu, V.; Matei, A.; Avram, A.M. FTIR Spectroscopy for Carbon Family Study. Crit. Rev. Anal. Chem. 2016, 46, 502–520. [Google Scholar] [CrossRef]

- Yudianti, R.; Onggo, H.; Sudirman; Saito, Y.; Azuma, J.I. Analysis of Functional Group Sited on Multi-Wall Carbon Nanotube Surface. Open Mater. Sci. J. 2011, 5, 242–247. [Google Scholar] [CrossRef]

- Obreja, A.C.; Cristea, D.; Gavrila, R.; Schiopu, V.; Dinescu, A.; Danila, M.; Comanescu, F. Isocyanate Functionalized Graphene/P3HT Based Nanocomposites. Appl. Surf. Sci. 2013, 276, 458–467. [Google Scholar] [CrossRef]

- Hussain, Z.; Kumar, R. Synthesis and Characterization of Novel Corncob-Based Solid Acid Catalyst for Biodiesel Production. Ind. Eng. Chem. Res. 2018, 57, 11645–11657. [Google Scholar] [CrossRef]

- Hita, I.; Cordero-Lanzac, T.; Gallardo, A.; Arandes, J.M.; Rodríguez-Mirasol, J.; Bilbao, J.; Cordero, T.; Castaño, P. Phosphorus-Containing Activated Carbon as Acid Support in a Bifunctional Pt–Pd Catalyst for Tire Oil Hydrocracking. Catal. Commun. 2016, 78, 48–51. [Google Scholar] [CrossRef]

- Qiu, T.; Yang, J.-G.; Bai, X.-J.; Wang, Y.-L. The Preparation of Synthetic Graphite Materials with Hierarchical Pores from Lignite by One-Step Impregnation and Their Characterization as Dye Absorbents. RSC Adv. 2019, 9, 12737–12746. [Google Scholar] [CrossRef]

- Westerhout, R.W.J.; Waanders, J.; Kuipers, J.A.M.; van Swaaij, W.P.M. Kinetics of the Low-Temperature Pyrolysis of Polyethene, Polypropene, and Polystyrene Modeling, Experimental Determination, and Comparison with Literature Models and Data. Ind. Eng. Chem. Res. 1997, 36, 1955–1964. [Google Scholar] [CrossRef]

- Williams, P.T.; Williams, E.A. Interaction of Plastics in Mixed-Plastics Pyrolysis. Energy Fuels 1999, 13, 188–196. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A Review on Thermal and Catalytic Pyrolysis of Plastic Solid Waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, X.; Miller, J.B.; Huber, G.W. The Chemistry and Kinetics of Polyethylene Pyrolysis: A Process to Produce Fuels and Chemicals. ChemSusChem 2020, 13, 1764–1774. [Google Scholar] [CrossRef] [PubMed]

- Escande, V.; Olszewski, T.K.; Grison, C. Preparation of Ecological Catalysts Derived from Zn Hyperaccumulating Plants and Their Catalytic Activity in Diels–Alder Reaction. C. R. Chim. 2014, 17, 731–737. [Google Scholar] [CrossRef]

- Fanchiang, W.-L.; Lin, Y.-C. Catalytic Fast Pyrolysis of Furfural over H-ZSM-5 and Zn/H-ZSM-5 Catalysts. Appl. Catal. Gen. 2012, 419–420, 102–110. [Google Scholar] [CrossRef]

- Li, L.; Zhu, W.; Liu, Y.; Shi, L.; Liu, H.; Ni, Y.; Liu, S.; Zhou, H.; Liu, Z. Phosphorous-Modified Ordered Mesoporous Carbon for Catalytic Dehydrogenation of Propane to Propylene. RSC Adv. 2015, 5, 56304–56310. [Google Scholar] [CrossRef]

- Kruse, T.M.; Wong, H.-W.; Broadbelt, L.J. Mechanistic Modeling of Polymer Pyrolysis: Polypropylene. Macromolecules 2003, 36, 9594–9607. [Google Scholar] [CrossRef]

- Lashchinskaya, Z.N.; Gabrienko, A.A.; Arzumanov, S.S.; Kolganov, A.A.; Toktarev, A.V.; Freude, D.; Haase, J.; Stepanov, A.G. Which Species, Zn2+ Cations or ZnO Clusters, Are More Efficient for Olefin Aromatization? 13C Solid-State NMR Investigation of n-But-1-Ene Transformation on Zn-Modified Zeolite. ACS Catal. 2020, 10, 14224–14233. [Google Scholar] [CrossRef]

- Huang, J.; Li, X.; Meng, H.; Tong, H.; Cai, X.; Liu, J. Studies on Pyrolysis Mechanisms of Syndiotactic Polystyrene Using DFT Method. Chem. Phys. Lett. 2020, 747, 137334. [Google Scholar] [CrossRef]

- Verma, A.; Sharma, S.; Pramanik, H. Pyrolysis of Waste Expanded Polystyrene and Reduction of Styrene via In-Situ Multiphase Pyrolysis of Product Oil for the Production of Fuel Range Hydrocarbons. Waste Manag. 2021, 120, 330–339. [Google Scholar] [CrossRef] [PubMed]

- Adnan; Shah, J.; Jan, M.R. Polystyrene Degradation Studies Using Cu Supported Catalysts. J. Anal. Appl. Pyrolysis 2014, 109, 196–204. [Google Scholar] [CrossRef]

- Karmore, V.; Madras, G. Thermal Degradation of Polystyrene by Lewis Acids in Solution. Ind. Eng. Chem. Res. 2002, 41, 657–660. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Yoon, J.-H.; Kim, J.-R.; Park, D.-W. Degradation of Polystyrene Using Clinoptilolite Catalysts. J. Anal. Appl. Pyrolysis 2002, 64, 71–83. [Google Scholar] [CrossRef]

- Marczewski, M.; Kamińska, E.; Marczewska, H.; Godek, M.; Rokicki, G.; Sokołowski, J. Catalytic Decomposition of Polystyrene. The Role of Acid and Basic Active Centers. Appl. Catal. B Environ. 2013, 129, 236–246. [Google Scholar] [CrossRef]

- Du, S.; Valla, J.A.; Parnas, R.S.; Bollas, G.M. Conversion of Polyethylene Terephthalate Based Waste Carpet to Benzene-Rich Oils through Thermal, Catalytic, and Catalytic Steam Pyrolysis. ACS Sustain. Chem. Eng. 2016, 4, 2852–2860. [Google Scholar] [CrossRef]

- Dhahak, A.; Hild, G.; Rouaud, M.; Mauviel, G.; Burkle-Vitzthum, V. Slow Pyrolysis of Polyethylene Terephthalate: Online Monitoring of Gas Production and Quantitative Analysis of Waxy Products. J. Anal. Appl. Pyrolysis 2019, 142, 104664. [Google Scholar] [CrossRef]

- Kumagai, S.; Yamasaki, R.; Kameda, T.; Saito, Y.; Watanabe, A.; Watanabe, C.; Teramae, N.; Yoshioka, T. Tandem μ-Reactor-GC/MS for Online Monitoring of Aromatic Hydrocarbon Production via CaO-Catalysed PET Pyrolysis. React. Chem. Eng. 2017, 2, 776–784. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Elordi, G.; Olazar, M.; Bilbao, J. Operating Conditions for the Pyrolysis of Poly-(Ethylene Terephthalate) in a Conical Spouted-Bed Reactor. Ind. Eng. Chem. Res. 2010, 49, 2064–2069. [Google Scholar] [CrossRef]

- Veksha, A.; Ahamed, A.; Wu, X.Y.; Liang, L.; Chan, W.P.; Giannis, A.; Lisak, G. Technical and Environmental Assessment of Laboratory Scale Approach for Sustainable Management of Marine Plastic Litter. J. Hazard. Mater. 2022, 421, 126717. [Google Scholar] [CrossRef]

- Savage, P.E. Mechanisms and Kinetics Models for Hydrocarbon Pyrolysis. J. Anal. Appl. Pyrolysis 2000, 54, 109–126. [Google Scholar] [CrossRef]

- Vollmer, I.; Jenks, M.J.F.; Roelands, M.C.P.; White, R.J.; van Harmelen, T.; de Wild, P.; van der Laan, G.P.; Meirer, F.; Keurentjes, J.T.F.; Weckhuysen, B.M. Beyond Mechanical Recycling: Giving New Life to Plastic Waste. Angew. Chem. Int. Ed. 2020, 59, 15402–15423. [Google Scholar] [CrossRef]

- Kazansky, V.B.; Serykh, A.I.; Pidko, E.A. DRIFT Study of Molecular and Dissociative Adsorption of Light Paraffins by HZSM-5 Zeolite Modified with Zinc Ions: Methane Adsorption. J. Catal. 2004, 225, 369–373. [Google Scholar] [CrossRef]

- Park, K.-B.; Jeong, Y.-S.; Guzelciftci, B.; Kim, J.-S. Two-Stage Pyrolysis of Polystyrene: Pyrolysis Oil as a Source of Fuels or Benzene, Toluene, Ethylbenzene, and Xylenes. Appl. Energy 2020, 259, 114240. [Google Scholar] [CrossRef]

- Buxbaum, L.H. The Degradation of Poly(Ethylene Terephthalate). Angew. Chem. Int. Ed. 1968, 7, 182–190. [Google Scholar] [CrossRef]

- McNeill, I.C.; Bounekhel, M. Thermal Degradation Studies of Terephthalate Polyesters: 1. Poly(Alkylene Terephthalates). Polym. Stabilisation Mech. Appl. 1991, 34, 187–204. [Google Scholar] [CrossRef]

| Property | Component | Concentration (wt.%) |

|---|---|---|

| Proximate analysis (wt.%, ad a) | Moisture | 1.26 |

| Ash | 25.23 | |

| Volatile | 49.95 | |

| Fixed-carbon | 23.56 | |

| Ultimate analysis (wt.%, db b) | C | 42.51 |

| H | 6.58 | |

| N | 0.55 | |

| O c | 50.36 | |

| Physical composition(wt %, ad a) | ||

| Plastics | 15 | |

| Fabrics | 20 | |

| Paper | 25 | |

| Wood | 40 |

| Sample | Yield (wt.%) | SBET (m2/g) a | SMicro(m2/g) b | SExt(m2/g) c | VTotal(cm3/g) d | VMeso(cm3/g) b | DAverage (nm) e |

|---|---|---|---|---|---|---|---|

| AC-ST | 18.72 | 6.68 | 1.77 | 4.91 | 0.02 | 0.01 | 11.70 |

| AC-HP | 45.74 | 606.08 | 286.28 | 319.80 | 0.34 | 0.18 | 2.34 |

| AC-ZN | 48.04 | 752.95 | 458.41 | 294.54 | 0.46 | 0.15 | 2.67 |

| Product | LDPE (area%) | PP (area%) | ||||

|---|---|---|---|---|---|---|

| AC-ST | AC-HP | AC-ZN | AC-ST | AC-HP | AC-ZN | |

| Alkanes | 57.34 | 60.21 | 48.56 | 17.88 | 24.65 | 14.11 |

| Straight Alkanes | 57.34 | 60.21 | 48.56 | |||

| Branched Alkanes | 4.93 | 2.08 | 11.9 | |||

| Cycloalkanes | 12.95 | 22.57 | 2.21 | |||

| Alkenes | 36.82 | 13.68 | 67.44 | 29.56 | 43.84 | |

| Straight Alkenes | 36.82 | 0.42 | 4.44 | 2.1 | ||

| Branched Alkenes | 13.26 | 61.71 | 1.24 | 41.75 | ||

| Cycloalkenes | 1.29 | 26.22 | 2.09 | |||

| Aromatics | 22.02 | 49.77 | 0.71 | 37.06 | 41.47 | |

| Benzene | 0.57 | |||||

| Toluene | 0.36 | 0.66 | 5.16 | |||

| Ethylbenzene | 0.34 | 1.12 | 0.58 | |||

| Xylene | 0.61 | 2.11 | 2.04 | 11.71 | ||

| Mesitylene | 0.16 | 0.5 | 0.71 | 19.01 | 15.76 | |

| Chain alkyl Aromatics | 10.61 | 25.62 | 14.11 | 6.6 | ||

| Naphthalenes | 7.73 | 11.09 | 1.9 | 1.09 | ||

| Other PAHs | 2.21 | 8.67 | ||||

| Others | 3.62 | 3.7 | 1.67 | 13.97 | 8.73 | |

| Product | PS (area%) | PET (area%) | |||

|---|---|---|---|---|---|

| AC-ST | AC-HP | AC-ZN | AC-ST | AC-ZN | |

| Alkanes | 0.08 | 0.65 | |||

| Benzene | 0.83 | 0.49 | 49.05 | ||

| Toluene | 5.58 | 4.9 | 8.23 | 0.52 | 10.62 |

| Ethylbenzene | 3.73 | 25.59 | 28.59 | 0.4 | 4.01 |

| Styrene | 65.51 | 43.51 | 39.11 | 0.36 | 4.87 |

| .alpha.-Methyl Styrene | 7.71 | 5.87 | 7.16 | ||

| Other Monocyclic Aromatics | 0.35 | 2.16 | |||

| Naphthalene | 0.57 | 9.29 | 5.36 | 0.46 | 2.83 |

| Biphenyls | 7.74 | 4.85 | 5.8 | 16.08 | 21.86 |

| Other PAHs | 0.19 | 4.16 | 2.86 | 2.41 | 2.5 |

| Benzoic Acid | 22.5 | 0.78 | |||

| Acetophenone | 15.17 | 1.51 | |||

| Benzophenone | 17.39 | 0.22 | |||

| Others | 0.5 | 0.24 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, K.; Tian, W.; Li, W.; Wu, S.; Chen, D.; Feng, Y. Catalytic Pyrolysis of Waste Plastics over Industrial Organic Solid-Waste-Derived Activated Carbon: Impacts of Activation Agents. Processes 2022, 10, 2668. https://doi.org/10.3390/pr10122668

Qian K, Tian W, Li W, Wu S, Chen D, Feng Y. Catalytic Pyrolysis of Waste Plastics over Industrial Organic Solid-Waste-Derived Activated Carbon: Impacts of Activation Agents. Processes. 2022; 10(12):2668. https://doi.org/10.3390/pr10122668

Chicago/Turabian StyleQian, Kezhen, Wenmin Tian, Wentao Li, Shutong Wu, Dezhen Chen, and Yuheng Feng. 2022. "Catalytic Pyrolysis of Waste Plastics over Industrial Organic Solid-Waste-Derived Activated Carbon: Impacts of Activation Agents" Processes 10, no. 12: 2668. https://doi.org/10.3390/pr10122668

APA StyleQian, K., Tian, W., Li, W., Wu, S., Chen, D., & Feng, Y. (2022). Catalytic Pyrolysis of Waste Plastics over Industrial Organic Solid-Waste-Derived Activated Carbon: Impacts of Activation Agents. Processes, 10(12), 2668. https://doi.org/10.3390/pr10122668