Abstract

Municipal solid waste treatment and disposal have become one of the major concerns in waste management due to the excessive production of waste and higher levels of pollution. To address these challenges and protect the environment in sustainable ways, the hydrothermal pretreatment (HTP) technique coupled with anaerobic digestion (AD) becomes a preferred alternative technology that can be used for municipal solid waste stabilization and the production of renewable energy. However, the impact of HTP parameters such as temperature, retention time, pH, and solid content on the fermentation of TWAS is yet to be well studied and analyzed. Hence this study was conducted to review the effect of hydrothermal pretreatment of thickened waste-activated sludge (TWAS) on fermentation and anaerobic digestion processes. Many studies reported that fermentation of TWAS at pretreatment temperature ranges from 160 °C to 180 °C resulted in a 50% increase in volatile fatty acid (VFA) yields compared to no pretreatment. However, for the AD process, HTP in the range of 175 °C to 200 °C with a 30–60 min retention time was considered the optimal condition for higher biogas production, with 30% increase in biodegradability and greater than 55% increase in biogas production. Even though there is a direct relationship between increased HTP temperature and the hydrolysis of TWAS, a pretreatment temperature range beyond 200 °C alters the biogas production. The solid content (SC) of sludge plays a crucial role in HTP, where in practice up to 16% SC has been utilized for HTP. Further, a combined alkaline-HTP enhances the process performance.

1. Introduction

Population and economic growth coupled with climate change and food security have resulted in significantly increased usage of natural resources and energy consumption. The inevitable exploitation of natural resources has created increasing concerns worldwide. One of the major concerns is the excessive generation of waste [1], which becomes a basis for the current and future challenges of solid waste management [2]. These days, to address these challenges and protect the environment in sustainable ways, reduction, reuse, recycling, and recovery of natural resources have gained more attention [3]. Disposing of organic wastes as part of industrial or municipal wastes with improper treatment methods or no treatment at all results in detrimental effects on the environment. Landfills of organic wastes, as an example, exhibit emissions of greenhouse gases because of the anaerobic decomposition of the waste [4]. These conventional habits of putting organic wastes in landfills have created potential pollution of soil and groundwater resources resulting from the landfill leachate [1,5].

It was estimated that the volume of worldwide municipal wastewater produced in 2020 was 360–380 km3/year and it is predicted to increase by 24% by 2030 and by 51% by 2050 [6,7]. In 2017, the annual global municipal sewage sludge production rate was estimated to be 45 million tons as dry solid (DS) [8]. The USA and Canada produced 14 and 1.2 million tons of municipal sewage sludge, respectively [9,10]. According to Shanmugam et al. [11], global sewage sludge production is predicted to reach 127.5 million tons as DS by 2030. The most-used thickening processes for municipal sewage include gravity thickening, dissolved air flotation, rotary drum thickening, and centrifuge. The type of thickening selected is usually determined by the size of the WWTP, its physical constraints, and the planned operations further downstream. Stabilization is usually achieved using chemical, biological, and thermochemical treatments [12]. The typical form of chemical stabilization is alkaline stabilization by adding lime (or lime and waste solid materials) to the thickened liquid sludge to raise the pH to greater than 12 for several days [13]. Recently, ozonation and other advanced oxidation processes such as peroxone have been used for chemical stabilization prior to biological stabilization [14]. Biological stabilization can be either aerobic [15] or anaerobic [16]. According to the WEF Manual of Practice [17], AD is generally applied for WWTPs treating wastewater inbound flows greater than about twenty million liters per day, whereas AS is typically applied in smaller WWTPs. On the other hand, there are a range of thermal stabilization technologies such as drying, torrefaction, hydrothermal carbonization, hydrothermal liquefaction, pyrolysis, gasification, and incineration. Drying is an evaporation process achieved by boiling the sludge. Torrefaction is a thermochemical process performed at atmospheric pressure at 200–300 °C, for a relatively low residence time [18]. Hydrothermal carbonization is performed at 180–250 °C, and the residence time ranges from 0.25 to 2 h [19]. Hydrothermal treatment is performed at 300–360 °C under pressurized water, and the residence time ranges from 0.25 to 1 h [20]. Pyrolysis involves applying heat in a gaseous or liquid environment without oxygen [19]. Gasification is a process that converts carbonaceous organic or fossil-based materials at high temperatures (>700 °C) without combustion, while incineration must be performed above 850 °C [21].

Anaerobic digestion (AD) has been used worldwide, as it can be employed with various types of organic waste streams. In modern wastewater treatment plants, the anaerobic digestion process becomes a practical solution to sustainable waste management practices and is considered an environmentally friendly technology for municipal solid waste treatment and disposal [22,23,24]. According to Elbeshbishy et al. [24], applying the anaerobic digestion process to produce renewable energy or bioenergy has been recognized as an energy-efficient process with a smaller environmental imprint. Compared with other technologies like landfilling and incineration, the anaerobic digestion process has also significantly reduced the volume of sludge [23,25,26]. In addition, the stabilized sludge produced during the AD process can be used as organic fertilizer for agricultural purposes [23].

The anaerobic digestion process is an environmentally friendly method of bioenergy production, as it reduces numerous problems originating from inadequate disposal. Even though the AD process consists of different stages to achieve its goal, including hydrolysis, acidogenesis, acetogenesis, and methanogenesis, hydrolysis is known to be the rate-limiting step [27,28]. Thus, suitable pretreatment is required to enhance digestibility by improving the hydrolysis stage [27,28,29].

Several pretreatment methods are used to increase the anaerobic digestibility of organic wastes for processing. These include chemical, biological, mechanical, and thermal pretreatments [29,30]. These pretreatment technologies change the complex organic structures by breaking chemical bonds and increasing the process of hydrolysis and biogas production [31]. Between the two, physical pretreatment methods are mainly used because of their low investment and operating suitability [30]. It also has a relatively greater advantage when it comes to environmental conditions. For example, chemical pretreatment yields secondary pollution [25], and biological pretreatment conditions have difficulty controlling the process [30]. Combined treatment has the difficulties of both the chemical and biological treatments [25,30].

Thermal pretreatment is a type of pretreatment whereby organic waste is exposed to heating at different temperatures and pressures. The temperature could range between 50–295 °C [29,30] depending on the intended use. Thermal pretreatment can be hydrothermal, steam injection, or microwave heating, based on the method used [26,32].

Hydrothermal pretreatment (HTP) is considered one of the most effective and popular methods of thermal pretreatment of municipal solid wastes [31]. The application of HTP is well-documented for its improvement of dewaterability and enhancement of anaerobic digestion performance, as it alters the structure of the insoluble portion of organic matter into more biodegradable matter [26,31,33]. Hydrothermal pretreatment enhances the soluble chemical oxygen demand (SCOD) because of its degradation of macromolecular matter. HTP can significantly increase the hydrolysis of insoluble organic compounds in municipal solid wastes, resulting in a shorter hydraulic retention time for solubilization and a reduction in the total volume of the reactor [2].

Several studies have been conducted to evaluate the effect of hydrothermal pretreatment on municipal sludge [1,2,3,26,29,31,32,33,34,35,36,37]. Accordingly, most of the results confirmed a positive effect on the fermentation/acidification process and biogas production. These studies also reveal that different results were obtained based on the composition and characteristics of the substrates used for the hydrothermal pretreatment process. Although hydrothermal pretreatment is used to degrade municipal solid wastes, there is no defined agreement on the range of heating temperature and retention time for solubilization and biogas production. Currently, the most successfully operated industrial-scale plants, such as Cambi, have used an HTP temperature range of 160–180 °C [31]. Therefore, the objective of this study is updating the standards for the effect of hydrothermal pretreatment of thickened waste-activated sludge for fermentation and the anaerobic digestion process. In this review, new correlations between the different operating parameters and the performance of the hydrothermal pretreatment were generated.

2. Hydrothermal Pretreatment and Sludge Disintegration

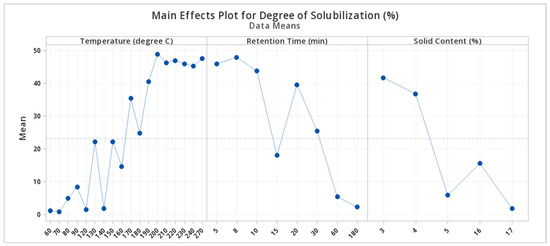

The degree of solubilization, which is often considered a performance indicator of the pretreatment process, states the ratio of the SCOD produced through the process by the particle COD of the influent substrate [35]. Figure 1 indicates the main effect plots for COD solubilization vs. HTP parameters, incorporating data from the literature. The impact of temperature, retention time, and solid content are illustrated as the main variables.

Figure 1.

Main effect plot for the degree of solubilization after HTP vs. temperature, retention time, and solid content.

As seen in the figure, temperature directly correlates with COD solubilization, while retention time and SC have an indirect relationship. As the temperature of the HTP process increases to 200 °C, the COD solubilization increases, stabilizing afterward. The stabilization and slight decline in sludge solubilization should be due to the formation of toxic compounds such as melanoidin [33]. Furthermore, reducing retention time from 180 min to 5 min causes a decrease in COD solubilization, although it should be noted that the temperature plays a crucial role in COD solubilization, and retention time is dependent on the temperature it is combined with. However, it has been proven that retaining the sludge for a longer time does not significantly enhance COD solubilization. Moreover, as with retention time, solid content proved to adversely impact the sludge disintegration rate.

As seen in Figure 1, the highest COD solubilization of 50% is observed at a temperature of 200 °C, a retention time of 8 min, and sludge SC of 3%. Although these data indicate the better performance of the HTP in lower RT, SC, and higher HTP, the actual operation of the process depends on the impact of COD solubilization on the target by-product (VFAs or methane) as well as the feasibility of the operation. For example, HTP plants currently operate with higher SC sludge (16%), as a higher sludge volume can be treated. Further details on the impact of COD solubilization and its impact on VFAs and methane production are discussed in the following sections.

On the other hand, as shown in Table 1, there were some inconsistent and contradictory results for the degree of solubilization, and the variation is significant. For example, Xue et al. [38] reported a degree of solubilization of 85%, which is very high compared to most reports in the literature (20–50%), this was due to the high particulate SOD (pCOD) of about 158 g/L and the extended time for the pretreatment of 72 h, which are not common for HTP. Furthermore, Zang et al. [39] reported a low degree of solubilization of only 9.2%, which was due to the low temperature applied of 55 °C. Therefore, the contradictions in the results in the literature are mainly due to different in pretreatment conditions and/or the nature of the feedstock (source, solids content, pCOD content, sludge age, etc.).

Table 1.

Studies on hydrothermal pretreatment of TWAS for VFAs recovery.

3. Hydrothermal Pretreatment and Fermentation

Various studies have been conducted to examine the effect of hydrothermal pretreatment on the fermentation of waste-activated sludge. Table 1 summarizes batch fermentation tests carried out to assess pretreated sludge potential for VFA recovery. All the studies reviewed were carried out at 35 °C in a thermostatic room, with anaerobic sludge from a mesophilic anaerobic digester fed with raw secondary sewage sludge for the hydrolysis experiments. A wide range of pretreatment temperatures ranging from 60 to 270 °C, retention times from 30–180 min, and pressures within 5–8 bar were used for the fermentation processes under a mesophilic environment.

Most of the studies [33,36,37,38,39,40] reported a relatively increased VFA production under high temperature ranges from 160 °C to 180 °C. For the fermentation process to be efficient, other studies reported that an optimum temperature of 100 °C to 180 °C is required to disrupt the cell walls and make them readily available for biological disintegration [33,41]. A fermentation process operated below the standard temperature is likely to achieve low quantities of VFAs [39,41].

Most authors reported that 55–60% of volatile solids were destroyed, and sludge dewaterability was improved [37,40]. Furthermore, waste-activated sludge treated with the hydrothermal pretreatment technique resulted in a 35 to 50% increase in VFA yields compared with the raw sample, and a significant increase in SCOD has also been observed as compared to the raw samples [33,37,40,42].

Abe et al. [33] studied the effect of thermal pretreatment on thickened waste-activated sludge at different temperatures ranging from 120 °C to 200 °C and a 60-min retention time to reduce sewage sludge volume. This study revealed the highest gas production and VSS destruction efficiency of 77% at a VSS loading rate of 8 g/L/d. The digestion efficiency was about 30% higher than anaerobic digestion without sludge pretreatment. This study achieved the highest VFA production of 2.94 g/L at a pretreatment temperature of 200 °C.

Kim et al. [33] assessed the effect of hydrothermal pretreatment of waste-activated sludge to enhance biogas production by anaerobic digestion at a temperature range of 150 to 270 °C. According to this study, the solubilization of particles significantly increased from 3 to 31% after HTP. VFA production of 3.31 g/L was achieved, which is a five-times increase compared to the raw sample at a pretreatment temperature of 210 °C. Xue et al. [38] also studied the effect of thermal hydrolysis on organic matter solubilization and anaerobic digestion of high-solid sludge. The study also concluded that the best pretreatment temperature for VFAs and biomethane production from high-solid sludge is 160 °C.

Donoso-Bravo et al. [36] carried out laboratory and pilot-scale experiments to evaluate the influence of thermal pretreatment time on waste-activated sludge properties and anaerobic biodegradability. This study analyzed six experimental conditions from 0 to 30 min of hydrolysis time for a 170 °C pretreatment temperature. The degree of solubilization increased from 31% to 45% for laboratory-scale experiments and 47% to 70% for pilot-scale experiments. The highest VFA production of 0.52 g/L was achieved at a pretreatment temperature of 170 °C for a pilot-scale experiment. According to this study, HTP conditions had a positive effect on anaerobic biodegradability, and the maximum biogas production rate was more affected by pretreatment time than total biogas production.

Our previous study investigated hydrothermal pretreatment’s impact on organic solubilization and anaerobic acidification of thickened waste-activated sludge [40]. For this study, 15 different hydrothermal pretreatment scenarios were developed, with pretreatment temperatures ranging from 150 to 240 °C, retention times 5 to 30 min, and pressures from 5 to 33.64 bar. Accordingly, the highest solubilization of 48% was achieved at the HTP condition of 200 °C. The highest VFA production yield of 5.38 g/L was obtained at the HTP condition of 190 °C.

On the other hand, Appels et al. [41] and Ennouri et al. [42] studied the effect of low-temperature thermal pretreatment on sludge solubilization. According to Appels et al. [41], the efficiency of the anaerobic digestion slightly decreased for sludge pretreated at 70 °C than 90 °C. At 90 °C pretreatment temperatures, VFA and biogas production slightly increased with the 60 min retention time. Ennouri et al. [42] also conducted research to address the effect of thermal pretreatment on the microbial populations’ balance and biogas production during anaerobic digestion of WAS coming from urban sludge and industrial sludge. This study used a pretreatment temperature ranging from 60 to 120 °C. The highest VFA yields of 0.23 g/L and 0.28 g/L were obtained with urban and industrial sludge, respectively, pretreated at 120 °C.

Table 1 also summarizes HTP operation in a semi-continuous configuration reactor. Though very few studies were carried out using this technology, Zhang et al. [42,43] conducted research on waste-activated sludge hydrolysis and short-chain fatty acid accumulation under mesophilic and thermophilic conditions.

According to Zhang et al. [42,44], the VFA yield increased from 0.07 gCOD/gVSS to 0.31 gCOD/gVSS under mesophilic conditions, indicating a 45% increase in VFA yield. Regarding the thermophilic condition, the highest VFA yield was 0.39 gCOD/gVSS, a 55% increase. These studies revealed slightly higher results when thermally pretreated samples were managed in a thermophilic environment than in a mesophilic condition, but most of the research reviewed was conducted in mesophilic conditions because the cost of heating is lower than thermophilic [44,45,46].

Morgan-Sagastume et al. [43] also conducted research using a semi-continuous reactor. This study focused on the production of volatile fatty acids by fermenting waste-activated sludge, pretreated in full-scale thermal hydrolysis ranging from 130 to 180 °C. Accordingly, a two- to five-times increase in VFA yield and a four- to six-times increase in VFA production rate was obtained compared to the fermentation of raw WAS.

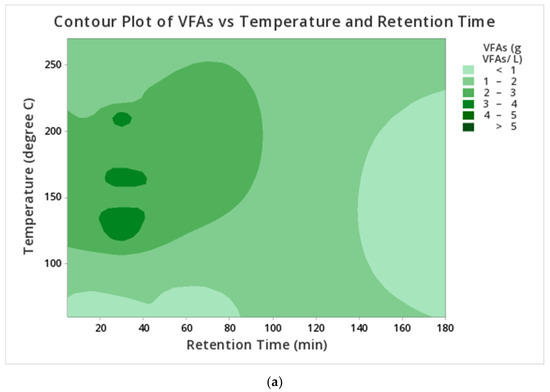

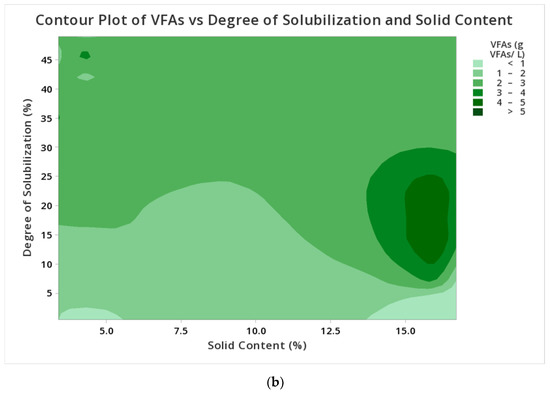

Generally, HTP parameters impact VFA production differently, and Figure 2 explains these correlations. Figure 2a illustrates the relationship between COD solubilization and two main HTP factors, temperature and RT, while higher VFAs are produced as the temperature increases up to 200 °C and retention time goes below 60 min. Figure 2b shows the impact of COD solubilization on VFA production during anaerobic fermentation based on the data from the literature. As the sludge disintegration rate increases, the VFA-producing bacteria function better by converting the readily biodegradable compounds to VFAs. The high COD solubilization during HTP overcomes the hydrolysis challenge and impacts the fractionation of the VFAs. It has been reported that different HTP conditions are associated with an enhancement in the production of certain types of VFAs [44,45], while in general, acetic acid has been reported to be the most abundant VFA, followed by propionic acid.

Figure 2.

Contour plots for VFA production vs. solubilization and hydrothermal pretreatment parameters, (a) Contour plot of VFA vs. temperature and retention time, (b) Contour plot of VFA vs. COD solubilization due to HTP and solid content of sludge.

In conclusion, most of the reviewed studies on the fermentation of TWAS revealed that the HTP condition operated both in batch and in semi-continuous reactors increased dissolution of organic matter and suspended-solid removal efficiency. Moreover, higher VFA yield was observed at pretreatment temperature ranges from 160 °C to 180 °C, RT ranges between 8–30 min, and SC of 3–18%.

4. Hydrothermal Pretreatment and Anaerobic Digestion

Several studies have been conducted to assess the effect of HTP on the anaerobic digestion of thickened waste-activated sludge. These studies were conducted at pretreatment temperature conditions ranging from 70 °C to 275 °C, matching with different retention times of 30 to 180 min. According to the findings of these studies, a pretreatment temperature in the range of 175 °C to 200 °C with a 60 min retention time was the optimal condition for increased biogas production [1,5]. Even though higher pretreatment temperatures resulted in increased biogas production, the temperature range beyond 200 °C showed a significant reduction in biogas production. Reported temperature increases above 200 °C may result in the formation of melanoidins or the Maillard reaction [47], which results when sugars and amino acids combine at high temperatures. The Maillard reaction could significantly retard biomethane production during hydrothermal pretreatment.

Table 2 summarizes various studies conducted using the HTP technique in batch reactors. Most of the studies reviewed showed a direct linear relationship between temperature increase and biomethane production up to 200 °C. Generally, up to a 35% increase was observed in the biodegradability of waste-activated sludge, resulting in higher biogas production, although severe temperatures beyond 200 °C can negatively impact the AD process. Recent studies have shown that hydrothermal pretreatment of WAS subjected to a pretreatment temperature range of 100 °C to 300 °C resulted in improved SCOD concentration by around 35% compared to the raw sample [33,48,49,50]. The optimum thermal temperature was also reported to be between 180 °C and 210 °C for increased biogas production, which is 55% higher compared to untreated samples [33].

Table 2.

Studies on hydrothermal pretreatment of TWAS for biomethane recovery.

Temperature and retention time are considered the two most important parameters that affect the hydrothermal pretreatment of WAS. Almost all the reviewed articles have addressed the effect of pretreatment temperature on biogas production. Most of the studies reported that HTP increases the hydrolysis of WAS up to a specific temperature range. Some of the articles reported that temperatures higher than 180 °C result in a decrease in the biodegradability of sludge [33,34,51,52]. Others reported that pretreatment temperatures higher than 200 °C caused an adverse effect on the AD process [1,34]. Therefore, depending on the nature of the waste, the temperature point where inhibitory compounds are formed is different.

On the other hand, retention time significantly affects the solubilization and degradability of organic matter when the waste is processed at a low pretreatment temperature [39,41,48,53]. However, compared to temperature, retention time shows little effect on the hydrolysis of WAS when treated with a temperature greater than 100 °C [1]. These findings are proven by Figure 2a, illustrating different combinations of temperature and RT and their impact on methane production.

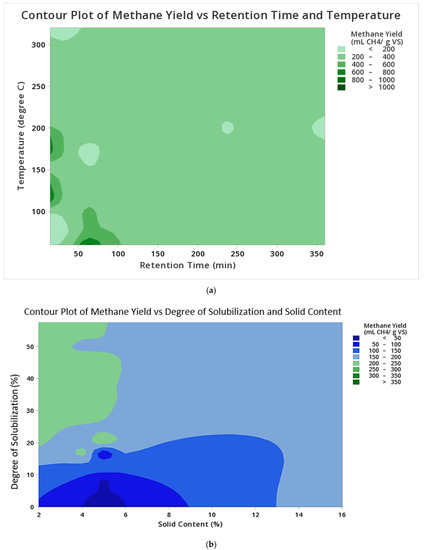

Further, the SC of the sludge significantly impacts methane production (p < 0.005). As the sludge SC increases to 12% there is higher methane production potential. Figure 3b shows the relationship between SC and methane production yield based on the literature findings studied in this article. As seen in the Figure 3, increasing the SC results in an increase in methane yield but the highest methane production was observed for the 3–6% SC, while keeping in mind that this was due to COD solubilization. As mentioned earlier, COD solubilization directly impacts methane production, and the higher the COD solubilization, the better the AD performance.

Figure 3.

Contour plots for methane production, (a) methane yield vs. temperature and retention time, (b) methane yield vs. degree of solubilization and solid content.

Ferrentino et al. [52] studied the effects of thermal hydrolysis (TH) pretreatment on anaerobic digestion (AD) under mesophilic conditions (35 °C). In this study, thickened sludge from a wastewater treatment plant (WWTP) was thermally treated under two different temperatures (150 °C and 170 °C) and reaction times (30 and 60 min). The study revealed a significant increase in soluble COD compared with the untreated or raw sludge when processed at a pretreatment temperature of 170 °C for 60 min. The thermal hydrolysis pretreatment of the sludge also accelerated the AD process and resulted in increased biogas yield ranging between 17 and 24%. On the other hand, Chen et al. [50] researched the hydrothermal conversion of sewage sludge, focusing on the characterization of liquid products and their methane yields under different temperatures (170–320 °C) and residence times (0.5–6.0 h) through AD. Results showed that the methane yield achieved 286 mL CH4/g COD when the pretreatment temperature was 170 °C. In comparison, methane yield was decreased to 136 mL CH4/g COD at 320 °C. The methane yield also decreased with the increase in residence time beyond 0.5 hrs.

Xue et al. [38] studied the effects of thermal hydrolysis on organic matter solubilization and anaerobic digestion of high-solid sludge under mesophilic conditions. This study showed that pretreatments at high temperatures (120–160 °C) accelerated the digestion rate and increased the biogas yield following biomethane production tests (BMP). Meanwhile, Liu et al. [54] investigated the effect of thermal pretreatment on municipal biomass wastes’ physical and chemical properties. Their results showed a 34.8% methane yield increase and a doubled methane production rate after thermal pretreatment at 175 °C/60 min. Qiao et al. [34] also studied the evaluation of biogas production from different biomass wastes with or without hydrothermal pretreatment. After hydrothermal pretreatment at typical conditions (170 °C at 60 min), the biogas production of municipal sewage sludge increased 67.8% compared with the untreated sample. This high number might be due to the nature of the sludge source, as the sludge in this study was collected from a WWTP that uses a biological A/O process and membrane bioreactor, which results in different sludge than that collected from a typical activated-sludge process in terms of solid content and characteristics. Furthermore, the authors diluted the sludge by adding tap water before applying the thermal pretreatment.

Nazari et al. [48] examined the relationship between the degree of solubilization and biodegradability of wastewater sludge in anaerobic digestion by low-temperature thermal pretreatment. According to this study, the optimum temperature, reaction time, and pH of the process were 80 °C, 5 h, and pH 10, respectively. This research showed that thermal pretreatments, carried out on seven different municipal wastewater sludges under the optimum operating conditions, produced an increased COD solubilization of 20.3% compared to the untreated sludge. The research also reported that the treatment did not significantly affect methane yields. Ennouri et al. [42] reported an increase in biogas production was obtained with urban (420 mL CH4/g VS) and industrial sludge (370 mL CH4/g VS) pretreated at 120 °C.

Appels et al. [41] also assessed the influence of low-temperature (70–90 °C) thermal pretreatment on sludge solubilization, heavy metal release, and anaerobic digestion. At a higher pretreatment temperature of 90 °C, the biogas production increased significantly, up to 378 mL CH4/g VS for 60 min, whereas the anaerobic digestion efficiency slightly decreased for sludge pretreated at 70 °C.

Observation of HTP impact on AD in batch experiences was also validated through more reliable experiments in semi-continuous mode. Table 2 also reports the hydrothermal pretreatment of waste-activated sludge followed by semi-continuous BMP experiments. Results from semi-continuous experiments also confirmed the findings of the batch BMPs reporting the optimum pretreatment temperature of 170–190 °C with retention time ranging between 15–90 min.

Bougrier et al. [51] conducted research to investigate and compare the impact of thermal sludge pretreatments on the semi-continuous anaerobic digestion of two waste-activated sludge samples collected from different urban wastewater plants. The studies were conducted at thermal pretreatments of 130–170 °C and a pH of 10 for a 30 min retention time to enhance anaerobic digestion performance compared with untreated raw samples. This research revealed that an organic sludge processed at a pretreatment temperature of 170 °C resulted in a significant increase in anaerobic digestion performance, with an 80% improvement in biogas yield and removal of matter. Choi et al. [49] also assessed the enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment using a temperature range of 75–200 °C and 15–90 min retention time. This study found the optimal conditions at 180 °C of reaction temperature and 76 min of reaction time. On the other hand, Wei et al. [56] studied the effects of HTP on the performance of two-stage anaerobic digestion of food waste. They reported that the highest biomethane yield, 591 mL/g VS, was obtained at an HTP temperature of 140 °C, which was about 12% higher than that obtained from the untreated sample. In another study, the biomethane yield of 878 mL/g VS was achieved from pretreated food waste with an HTP at 220 °C, compared to 637 for the untreated sample [57].

Furthermore, aside from the main HTP parameters (temperature, RT and SC), combining the HTP with other pretreatment methods significantly influenced the sludge disintegration properties. Table 3 summarizes studies on HTP combined with either chemical, mechanical, or biological pretreatments. It was found that the combination of HTP with another pretreatment has a high potential of enhancing the COD solubilization by up to 50%. Among all the pretreatments, the HTP and alkaline combination is one of the most promising technologies utilized in the industry.

Table 3.

Studies on Combined hydrothermal pretreatments prior to AD.

In conclusion, thermal hydrolysis pretreatment has a reasonably positive effect on the AD process [1,2,3,10,13,15,17]. For instance, pretreatment by thermal hydrolysis under high temperatures between 160–200 °C and retention time of 0–60 min has an important effect on process enhancement. This pretreatment temperature and retention time are considered optimum conditions for relatively higher VFA and biogas production. On the other hand, operating the thermal hydrolysis process below or above the standard condition might affect the desired output.

5. Full-Scale Hydrothermal Pretreatment Technologies

Thermal hydrolysis becomes a vital part of the AD process to decompose and disintegrate substantial parts of the solid portions of the sludge into simpler and soluble molecules [23]. Different literature has reported that the anaerobic digestion process could achieve up to 60% reduction of solids after the thermal hydrolysis process [1,2,26,29,31,33,34]. Thermal hydrolysis also improves sludge dewaterability [26,31,33].

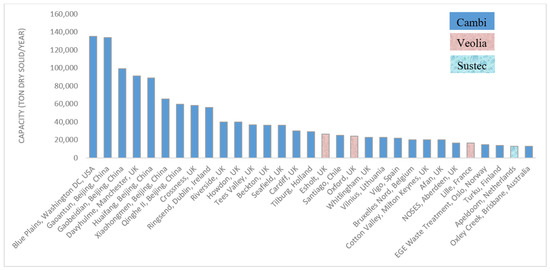

Table 4 summarizes some of the commercial methods that have been developed for the thermal hydrolysis of primary and secondary sludge, biosolids, and biomass before and after the AD process. The methods were developed based on the type and characteristics of the sludge being processed. Each technology defined its own specific thermal temperature condition and retention time for improved biogas production and solubilization of solids. Every year thousands of dry ton waste is treated using these large scale facilities (Figure 4).

Table 4.

Comparison of commercially available full-scale hydrothermal pretreatment/post-treatment technologies.

Figure 4.

Largest full-scale thermal hydrolysis plants as of 2021 (Source: Adapted from companies’ websites).

Cambi, Inc. (Asker, Norway) has developed a thermal hydrolysis process based on the type of sludge being processed. This company reported setting the HTP condition at 165 °C for a 30 min treatment depending on the characteristics of the processed sludge. A significant improvement in biogas production by about 150% is reported. The solubilization of solids is about 30%, as per the company’s website. The patented thermal hydrolysis process (THP) is a pretreatment of sludge combined with anaerobic digestion. Here, THP works by dissolving and disintegrating sludge using pressure and temperature. To increase the efficiency of THP, the sludge needs to be dewatered at around 16% solid concentration before passing to the equalization tank. The equalization tank is responsible for accommodating large flow-rate variations, which is essential for thermal pretreatment to function at a constant flow rate. The pre-heated sludge is then introduced to the reactor and heated again, with the higher temperature reaching 165 °C and 8 to 9 bar pressure. After 30 min of retention time, the treated sludge is pumped into the flash tank with a solid concentration of approximately 12% to 15%.

Exelys, a subsidiary of Veolia group, has reported solubilization of solids by 30% at 165 °C for 30 min, increasing biogas production by 150%. When HTP is associated with conventional digestion, it also delivers around a 40% reduction of sludge, which could be readily available for disposal, and 30% more biogas production. The process works in batch mode, combining thermal hydrolysis and anaerobic digestion. The dehydrated sludge goes through a batch thermal hydrolysis phase during which steam is injected into reactors operating under specific pressure (9 bar) and temperature (165 °C) conditions for approximately 30 min. The process handles all kinds of organic, industrial, or municipal sludge and can also handle grease. The advantages of using such thermal hydrolysis pretreatment processes are reduced sludge volume, improved sludge quality, and increased biogas production.

6. Conclusions

The article review conducted by this research reviewed the parameters affecting the hydrothermal pretreatment prior to fermentation and AD. The impact of individual parameters such as temperature, RT, pH, SC, and combined HTP and other pretreatments were analysed. According to this study, HTP improves the solubilization and biodegradability of the TWAS and enhances VFA and biomethane production.

The following major conclusions are drawn:

- HTP condition operated both in batch and semi-continuous reactors increased dissolution of organic matter and suspended-solid removal efficiency.

- Most of the reviewed articles on fermentation of TWAS revealed that higher VFA yields were observed at pretreatment temperature ranges from 160 °C to 180 °C. Waste-activated sludge treated with the hydrothermal pretreatment technique resulted in a 35 to 50% increase in VFA yields compared with the raw sample.

- Temperature, retention time, and solid content are considered the most important parameters affecting the hydrothermal pretreatment of TWAS, while the temperature is the dominant factor.

- HTP in the range of 175 °C to 200 °C with a 60 min retention time was the optimal condition for increased biogas production. At the optimum condition, a 30% increase in biodegradability of waste-activated sludge was generally observed, which resulted in higher biogas production.

- Most of the studies reported that HTP increases the hydrolysis of WAS up to a specific temperature range. The temperature range beyond 200 °C showed a significant reduction in VFA and biogas production. In addition, a lower temperature cannot efficiently decompose the complex organics in the AD process unless combined with other pretreatment techniques.

To further understand the impact of thermal hydrolysis on fermentation and AD, further research is required to intensify these processes. There is a great potential for reducing the HRT of the AD with HTP integration, therefore studying HRTs from 8 to 20 days would be valuable. Another gap in the literature to be filled is the different configurations of the HTP, fermentation, and AD, varying the HTP parameters and HRT of the fermentation and AD.

Author Contributions

Conceptualization, F.L.K. and E.E.; Methodology, F.L.K., F.T. and E.E.; Formal Analysis, F.L.K. and F.T; Data Curation, F.L.K. and F.T.; Writing—Original Draft Preparation, F.L.K. and F.T.; Writing—Review & Editing, F.L.K. and E.E.; Supervision, E.E.; Funding Acquisition, E.E. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Natural Sciences and Engineering Research Council of Canada (NSERC), grant number [RGPIN-2022-03825].

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to acknowledge the research funding awarded to E.E. by the Natural Sciences and Engineering Research Council of Canada (NSERC), and for the award of the Vanier Canada Graduate Scholarship by the Government of Canada to F.L.K.

Conflicts of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Razavi, A.S.; Hosseini Koupaie, E.; Azizi, A.; Hafez, H.; Elbeshbishy, E. Hydrothermal pretreatment of source separated organics for enhanced solubilization and biomethane recovery. Bioresour. Technol. 2019, 274, 502–511. [Google Scholar] [CrossRef] [PubMed]

- Azizi, A.; Hosseini Koupaie, E.; Hafez, H.; Elbeshbishy, E. Improving single-and two-stage anaerobic digestion of source separated organics by hydrothermal pretreatment. Biochem. Eng. J. 2019, 148, 77–86. [Google Scholar] [CrossRef]

- Ding, L.; Cheng, J.; Qiao, D.; Yue, L.; Li, Y.Y.; Zhou, J.; Cen, K. Investigating hydrothermal pretreatment of food waste for two-stage fermentative hydrogen and methane co-production. Bioresour. Technol. 2017, 241, 491–499. [Google Scholar] [CrossRef]

- Mancini, G. Different Approaches to Enhance the Biogas Production from the Anaerobic Digestion of Lignocellulosic Materials. Ph.D. Thesis, Universite Paris-EST, Champs-sur-Marne, France, 2019. [Google Scholar]

- Zlatko, S. Investigation of Co-Digestion of Food Waste and Primary Sludge at SNJ-Wastewater Treatment Plant. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2020. [Google Scholar]

- Ehalt MacEdo, H.; Lehner, B.; Nicell, J.; Grill, G.; Li, J.; Limtong, A.; Shakya, R. Distribution and characteristics of wastewater treatment plants within the global river network. Earth Syst. Sci. Data 2022, 14, 559–577. [Google Scholar] [CrossRef]

- Qadir, M.; Drechsel, P.; Jiménez Cisneros, B.; Kim, Y.; Pramanik, A.; Mehta, P.; Olaniyan, O. Global and regional potential of wastewater as a water, nutrient and energy source. Nat. Resour. Forum 2020, 44, 40–51. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, J.; Lee, D.J.; Chang, Y.; Lee, Y.J. Sludge treatment: Current research trends. Bioresour. Technol. 2017, 243, 1159–1172. [Google Scholar] [CrossRef]

- Environment and Climate Change Canada. Canadian Environmental Sustainability Indicators: Greenhouse Gas Emissions; Environment and Climate Change Canada: Winnipeg, MB, Canada, 2020.

- EPA Basic Information about Biosolids. Available online: https://www.epa.gov/biosolids/basic-information-about-biosolids (accessed on 13 November 2022).

- Shanmugam, K.; Gadhamshetty, V.; Tysklind, M.; Bhattacharyya, D.; Upadhyayula, V.K.K. A sustainable performance assessment framework for circular management of municipal wastewater treatment plants. J. Clean. Prod. 2022, 339, 130657. [Google Scholar] [CrossRef]

- Norouzi, O.; Dutta, A. The Current Status and Future Potential of Biogas Production from Canada’s Organic Fraction Municipal Solid Waste. Energies 2022, 15, 475. [Google Scholar] [CrossRef]

- Papastergiadis, E.; Sklari, S.; Zouboulis, A.; Chasiotis, A.; Samaras, P. The use of steelmaking slag for sewage sludge stabilization. Desalin. Water Treat. 2015, 55, 1697–1702. [Google Scholar] [CrossRef]

- Kosowski, P.; Szostek, M.; Pieniazek, R.; Antos, P.; Skrobacz, K.; Piechowiak, T.; Zaczek, A.; Józefczyk, R.; Balawejder, M. New approach for sewage sludge stabilization with ozone. Sustainability 2020, 12, 886. [Google Scholar] [CrossRef]

- Kozak, J.; Wlodarczyk-Makula, M.; Popenda, A. Impact of Aerobic Stabilization of Sewage Sludge on PAHs Concentration in Reject Waters. J. Ecol. Eng. 2021, 22, 27–35. [Google Scholar]

- Hanum, F.; Yuan, L.C.; Kamahara, H.; Aziz, H.A.; Atsuta, Y.; Yamada, T.; Daimon, H. Treatment of sewage sludge using anaerobic digestion in Malaysia: Current state and challenges. Front. Energy Res. 2019, 7, 19. [Google Scholar] [CrossRef]

- Water Environment Federation. Design of Municipal Wastewater Treatment Plants; Water Environment Federation: Alexandria, VA, USA, 2009; Volume 30. [Google Scholar]

- Acharya, B.; Sule, I.; Dutta, A. A review on advances of torrefaction technologies for biomass processing. Biomass Convers. Biorefinery 2012, 2, 349–369. [Google Scholar] [CrossRef]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.-M.; Fuhner, C.; Bens, O.; Kern, J.; et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Hu, M.; Ye, Z.; Zhang, H.; Chen, B.; Pan, Z.; Wang, J. Thermochemical conversion of sewage sludge for energy and resource recovery: Technical challenges and prospects. Environ. Pollut. Bioavailab. 2021, 33, 145–163. [Google Scholar] [CrossRef]

- Chen, Y.; Yi, L.; Li, S.; Yin, J.; Jin, H. Catalytic gasification of sewage sludge in near and supercritical water with different catalysts. Chem. Eng. J. 2020, 388, 124292. [Google Scholar] [CrossRef]

- Aragón-Briceño, C.; Ross, A.B.; Camargo-Valero, M.A. Evaluation and comparison of product yields and bio-methane potential in sewage digestate following hydrothermal treatment. Appl. Energy 2017, 208, 1357–1369. [Google Scholar] [CrossRef]

- Abdulazeez, M. Scholarship @ Western Co-Digestion of Food Waste and Thickened Waste Activated Sludge: Microbial Communities and Inhibition Control Using Biochar. Available online: http://ezproxy.lib.ryerson.ca/login?url=https://www.proquest.com/dissertations-theses/co-digestion-food-waste-thickened-activated/docview/2714864402/se-2 (accessed on 12 November 2022).

- Elbeshbishy, E.; Dhar, B.R.; Nakhla, G.; Lee, H.S. A critical review on inhibition of dark biohydrogen fermentation. Renew. Sustain. Energy Rev. 2017, 79, 656–668. [Google Scholar] [CrossRef]

- Yu, L.; Jiang, W.; Yu, Y.; Sun, C. Effects of dilution ratio and Fe° dosing on biohydrogen production from dewatered sludge by hydrothermal pretreatment. Environ. Technol. 2014, 35, 3092–3104. [Google Scholar] [CrossRef]

- Yuan, T.; Cheng, Y.; Zhang, Z.; Lei, Z.; Shimizu, K. Comparative study on hydrothermal treatment as pre- and post-treatment of anaerobic digestion of primary sludge: Focus on energy balance, resources transformation and sludge dewaterability. Appl. Energy 2019, 239, 171–180. [Google Scholar] [CrossRef]

- Carrère, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenès, J.P.; Steyer, J.P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Elbeshbishy, E.E. Enhancement of Biohydrogen and Biomethane Production from Wastes Using Ultrasonication. Ph.D. Thesis, University of Western Ontario, London, ON, Canada, 2011. [Google Scholar]

- Kakar, F.; Koupaie, E.; Hafez, H.; Elbeshbishy, E. Effect of Hydrothermal Pretreatment on Volatile Fatty Acids Production from Source-Separated Organics. Processes 2019, 7, 576. [Google Scholar] [CrossRef]

- Rajput, A.A.; Zeshan, S.; Visvanathan, C. Effect of thermal pretreatment on chemical composition, physical structure and biogas production kinetics of wheat straw. J. Environ. Manag. 2018, 221, 45–52. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Guo, J.; Cheng, H.; Wang, W.; Dong, R. Two-phase anaerobic digestion of municipal solid wastes enhanced by hydrothermal pretreatment: Viability, performance and microbial community evaluation. Appl. Energy 2017, 189, 613–622. [Google Scholar] [CrossRef]

- Yin, J.; Wang, K.; Yang, Y.; Shen, D.; Wang, M.; Mo, H. Improving production of volatile fatty acids from food waste fermentation by hydrothermal pretreatment. Bioresour. Technol. 2014, 171, 323–329. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Park, K. Enhancement of biogas production from anaerobic digestion of waste activated sludge by hydrothermal pre-treatment. Int. Biodeterior. Biodegrad. 2015, 101, 42–46. [Google Scholar] [CrossRef]

- Qiao, W.; Yan, X.; Ye, J.; Sun, Y.; Wang, W.; Zhang, Z. Evaluation of biogas production from different biomass wastes with/without hydrothermal pretreatment. Renew. Energy 2011, 36, 3313–3318. [Google Scholar] [CrossRef]

- Higgins, M.; Beightol, S.; Mandahar, U.; Suzuki, R.; Xiao, S.; Lu, H.; Le, T.; Mah, J.; Pathak, B.; DeClippeleir, H.; et al. Pretreatment of a primary and secondary sludge blend at different thermal hydrolysis temperatures: Impacts on anaerobic digestion, dewatering and filtrate characteristics. Water Res. 2017, 122, 557–569. [Google Scholar] [CrossRef]

- Donoso-Bravo, A.; Pérez-Elvira, S.; Aymerich, E.; Fdz-Polanco, F. Assessment of the influence of thermal pre-treatment time on the macromolecular composition and anaerobic biodegradability of sewage sludge. Bioresour. Technol. 2011, 102, 660–666. [Google Scholar] [CrossRef]

- Abe, N.; Tang, Y.; Iwamura, M.; Morimura, S.; Kida, K. Pretreatment followed by anaerobic digestion of secondary sludge for reduction of sewage sludge volume. Water Sci. Technol. 2013, 67, 2527–2533. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, H.; Chen, S.; Dichtl, N.; Dai, X.; Li, N. Effects of thermal hydrolysis on organic matter solubilization and anaerobic digestion of high solid sludge. Chem. Eng. J. 2015, 264, 174–180. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Zhou, Q. Waste activated sludge hydrolysis and short-chain fatty acids accumulation under mesophilic and thermophilic conditions: Effect of pH. Water Res. 2009, 43, 3735–3742. [Google Scholar] [CrossRef] [PubMed]

- Kakar, F.I.; Koupaie, E.H.; Razavi, A.S.; Hafez, H.; Elbeshbishy, E. Effect of Hydrothermal Pretreatment on Volatile Fatty Acids Production from Thickened Waste Activated Sludge. Bioenergy Res. 2020, 13, 591–604. [Google Scholar] [CrossRef]

- Appels, L.; Degrève, J.; Van der Bruggen, B.; Van Impe, J.; Dewil, R. Influence of low temperature thermal pre-treatment on sludge solubilisation, heavy metal release and anaerobic digestion. Bioresour. Technol. 2010, 101, 5743–5748. [Google Scholar] [CrossRef] [PubMed]

- Ennouri, H.; Miladi, B.; Diaz, S.; Güelfo, L.; Solera, R.; Hamdi, M.; Bouallagui, H. Effect of thermal pretreatment on the biogas production and microbial communities balance during anaerobic digestion of urban and industrial waste activated sludge. Bioresour. Technol. 2016, 214, 184–191. [Google Scholar] [CrossRef] [PubMed]

- Morgan-Sagastume, F.; Pratt, S.; Karlsson, A.; Cirne, D.; Lant, P.; Werker, A. Production of volatile fatty acids by fermentation of waste activated sludge pre-treated in full-scale thermal hydrolysis plants. Bioresour. Technol. 2011, 102, 3089–3097. [Google Scholar] [CrossRef]

- Zhang, D.; Jiang, H.; Chang, J.; Sun, J.; Tu, W.; Wang, H. Effect of thermal hydrolysis pretreatment on volatile fatty acids production in sludge acidification and subsequent polyhydroxyalkanoates production. Bioresour. Technol. 2019, 279, 92–100. [Google Scholar] [CrossRef]

- Gavala, H.N.; Yenal, U.; Skiadas, I.V.; Westermann, P.; Ahring, B.K. Mesophilic and thermophilic anaerobic digestion of primary and secondary sludge. Effect of pre-treatment at elevated temperature. Water Res. 2003, 37, 4561–4572. [Google Scholar] [CrossRef]

- Abelleira-Pereira, J.M.; Pérez-Elvira, S.I.; Sánchez-Oneto, J.; de la Cruz, R.; Portela, J.R.; Nebot, E. Enhancement of methane production in mesophilic anaerobic digestion of secondary sewage sludge by advanced thermal hydrolysis pretreatment. Water Res. 2015, 71, 330–340. [Google Scholar] [CrossRef]

- Tran, K.C. Anaerobic digestion of microalgal biomass: Effects of solid concentration and pre-treatment. Ph.D. Thesis, University of Southampton, Southhampton, UK, 2017; p. 182. Available online: https://eprints.soton.ac.uk/415791/1/Final_e_thesis_for_e_prints_Khanh_Tran_24542342.pdf (accessed on 20 October 2022).

- Nazari, L.; Yuan, Z.; Santoro, D.; Sarathy, S.; Ho, D.; Batstone, D.; Xu, C.; Ray, M. Low-temperature thermal pre-treatment of municipal wastewater sludge: Process optimization and effects on solubilization and anaerobic degradation. Water Res. 2017, 113, 111–123. [Google Scholar] [CrossRef]

- Choi, J.; Han, S.; Lee, C. Enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment. Bioresour. Technol. 2018, 25, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Rao, Y.; Cao, L.; Shi, Y.; Hao, S.; Luo, G.; Zhang, S. Hydrothermal conversion of sewage sludge: Focusing on the characterization of liquid products and their methane yields Huihui. Chem. Eng. J. 2019, 357, 367–375. [Google Scholar] [CrossRef]

- Bougrier, C.; Delgenès, J.; Carrère, H. Impacts of thermal pre-treatments on the semi-continuous anaerobic digestion of waste activated sludge. Biochem. Eng. J. 2007, 34, 20–27. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Biochemical Methane Potential Tests to Evaluate Anaerobic Digestion Enhancement by Thermal Hydrolysis Pretreatment. Bioenergy Res. 2019, 12, 722–732. [Google Scholar] [CrossRef]

- Kim, J.; Park, C.; Kim, T.H.; Lee, M.; Kim, S.; Kim, S.W.; Lee, J. Effects of various pretreatments for enhanced anaerobic digestion with waste activated sludge. J. Biosci. Bioeng. 2003, 95, 271–275. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, W.; Gao, X.; Zhou, Y.; Shen, R. Effect of thermal pretreatment on the physical and chemical properties of municipal biomass waste. Waste Manag. 2012, 32, 249–255. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.J.; Li, X.X.; Liu, Y.X.; Yang, F.; Zhou, Q.; Ren, R.P. Optimization of hydrothermal pretreatment conditions for mesophilic and thermophilic anaerobic digestion of high-solid sludge. Bioresour. Technol. 2021, 321, 124454. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Gao, J.; Shi, Z.; Li, X.; Ma, W.; Yuan, H. Effect of hydrothermal pretreatment on two-stage anaerobic digestion of food waste and Enteromorpha: Digestion performance, bioenergy efficiency, and microbial community dynamics. Fuel 2022, 318, 123639. [Google Scholar] [CrossRef]

- Cheng, J.; Yue, L.; Hua, J.; Dong, H.; Zhou, J.; Li, Y.-Y. Hydrothermal alkali pretreatment contributes to fermentative methane production of a typical lipid from food waste through co-production of hydrogen with methane. Bioresour. Technol. 2020, 306, 123164. [Google Scholar] [CrossRef]

- Perendeci, N.A.; Ciggin, A.S.; Kökdemir Ünşar, E.; Orhon, D. Optimization of alkaline hydrothermal pretreatment of biological sludge for enhanced methane generation under anaerobic conditions. Waste Manag. 2020, 107, 9–19. [Google Scholar] [CrossRef]

- Bayr, S.; Kaparaju, P.; Rintala, J. Screening pretreatment methods to enhance thermophilic anaerobic. Chem. Eng. J. 2013, 223, 479–486. [Google Scholar] [CrossRef]

- Mustafa, A.H.; Radwan, A.; Sheng, K.; Chen, X. Effect of hydrothermal and Ca(OH)2 pretreatments on anaerobic digestion of sugarcane bagasse for biogas production. Bioresour. Technol. 2018, 259, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Yue, L.; Ding, L.; Li, Y.; Ye, Q.; Zhou, J.; Cen, K.; Lin, R. Improving fermentative hydrogen and methane production from an algal bloom through hydrothermal/steam acid pretreatment. Int. J. Hydrog. Energy 2019, 44, 5812–5820. [Google Scholar] [CrossRef]

- Wang, J.; Yin, Y. Principle and application of different pretreatment methods for enriching hydrogen-producing bacteria from mixed cultures. Int. J. Hydrog. Energy 2017, 42, 4804–4823. [Google Scholar] [CrossRef]

- Kakar, F.I.; Purohit, N.; Okoye, F.; Liss, S.N.; Elbeshbishy, E. Combined hydrothermal and free nitrous acid, alkali and acid pretreatment for biomethane recovery from municipal sludge. Waste Manag. 2021, 131, 376–385. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).