Abstract

Chickpeas and other high protein plants are becoming increasingly popular. Traditionally, attrition or hammer mills are used for milling chickpeas. However, the use of roller mills on chickpeas has not been extensively researched. This study compared pilot-scale milling trials involving whole Kabuli compared to split and de-hulled Desi chickpeas. A flow sheet was designed and optimized for meal production with minimal co-product flour produced. Milling yields, particle size, and proximate analysis data were recorded. The optimum flow sheet consisted of 4 break passages, 2 smooth roll passages, and 4 purifiers. Results showed whole Kabuli chickpeas had a higher meal yield, at 63.8%, than split Desi seeds, at 54.1%; with both percentages proportional to the weight of milled seed. The remaining 36.2% or 45.9% consisted of co-product flour, feed streams and process losses. Both meals had an average particle size between 600 and 850 microns and both flours had a bimodal particle size distribution with peaks at 53 and 90–150 microns. The use of purifiers facilitated better separation of hull and resulted in lower crude fiber levels in the Kabuli meal. Proximate analysis trends were similar for both chickpea meals with higher protein (~2% more), crude fiber (~1% more) and ash (0.1–0.3% more) in the meal compared to the co-product flour. The co-product flour had substantially higher total starch (~15% more) than the meal. The results of this research can be used to modify wheat mills to process chickpeas.

1. Introduction

Pulses have recently been gaining more consumer attention for being a good source of plant-based protein, without being an allergen such as soybeans. Sustainability is another reason for the growing popularity of pulses. Chickpeas are a pulse crop that contain high levels of proteins (23–26%), while also containing substantial levels of carbohydrates (37–39%) [1]. Many varieties are commercially available and can thrive in diverse regions and climates. The wide growing region has led chickpeas to become an important food crop worldwide [1]. Chickpeas require fewer resources, such as land and water, to grow than animal protein [2]. As global demand for protein increases the demand for more sustainable plant-based ingredients will increase, and chickpeas fit this criterion well. New processing methods and novel products are needed to fulfill the consumer demand for plant-based proteins. Proteins isolated from chickpeas and other pulses such as peas are important ingredients for such products, for example, plant-based meat alternatives [3].

Chickpeas are beneficial as they exhibit antioxidant properties [4]. Unfortunately, polyphenols in chickpeas also reduce digestibility due to their anti-nutritional properties, the mitigation of which is a bigger priority. Previous research found that 75% of these polyphenolic compounds are found in the hull (seed coat or testa) [5]. Some of the anti-nutritional properties can be reduced by cooking [6]. Some traditional processing methods include roasting, boiling or slurry cooking. Milling and removing the hull can also be very effective in lowering the anti-nutritional factors, reducing the need for intense cooking.

Chickpeas are often sold as whole seeds, but milling is also used to break down chickpeas into smaller particles, such as split chickpeas or flour, that require lower cooking times. This allows for a wide variety of food applications. Chickpea milling has primarily been carried out using dahl mills, which use attrition forces to de-hull the seeds and split the cotyledons apart [7]. Hammer milling is another method used, which grinds the chickpeas into flour [7]. These milling and dehulling methods typically require soaking, dehulling, drying, and then milling. The overall process can be very energy-, water- and time-intensive and limits capacity by using batch hydration methods.

The use of roller milling for chickpeas can lead to substantial process efficiency, although research and industry usage has not focused much on this technique. Previous milling research with chickpeas has been focused on attrition mills for de-branning and splitting [8]. Roller milling has a long history and is used extensively for grains such as wheat to produce many products, such as de-hulled or whole flours, coarser meals, etc. Improvements have been made but the same principle remains of passing the grain, between two rotating rollers to break it open, remove the hull and reduce the particle size. The removal of bran from wheat using roller mills requires minimal water for tempering, and the technique could be used with adaptations to de-hull chickpeas. Roller mills also provide a more controlled particle size range than hammer mills. In a recent study, Pulivarthi et al. [9] adopted roller milling for processing lentils and yellow pea flours. The usage of roller mills for processing chickpeas will not only facilitate efficiencies in energy and water consumption but also gives products with a uniform particle size distribution compared to the hammer and attrition mills. Energy efficiency in processing operations including milling is increasingly coming into focus for a sustainable food supply in both emerging and developed regions of the world [10,11,12,13]. Milling is a very energy-intensive process, depending on several factors, including the technology used, type of grain, throughput and fineness of desired particle size. Limited research exists on the milling of pulses, but energy usage has been studied for cereal grain milling in various food and feed applications and different size reduction technologies, with roller milling reported to be more energy-efficient than hammer milling and attrition milling [12,14,15,16].

The primary hypotheses of this study were that roller milling can be used for dehulling of chickpeas and will allow for the production of coarse chickpea meal and fine flour from the same equipment. A pilot-scale facility designed to mill wheat was used after necessary modification in unit operations and flows for the evaluation of efficiency of dehulling and particle size reduction in chickpeas. Two varieties of chickpeas with different pre-processing levels were evaluated: whole Kabuli and split and de-hulled Desi. These varieties are common and commercially available. Whole Kabuli seeds are typically larger and have twice the 100-seed weight of whole Desi seeds [7]. The use of split and de-hulled versus whole chickpeas provided insight into whether starting with whole or pre-processed seeds was more efficient. The milled chickpea samples were evaluated for yields, proximate analysis, particle size and flowability. The results of this research can be used and adapted to process chickpeas on equipment typically used in commercial wheat mills and allow for the diversification of their milling portfolio.

2. Materials and Methods

2.1. Materials

Two varieties of chickpeas were studied: Kabuli and Desi. Kabuli chickpeas were received as whole seeds and Desi chickpeas received spilt and de-hulled seeds. These were chosen to compare differences in chickpea varieties and preprocessing levels. The main hardware parameters or unit operations used in the pilot-scale milling are mentioned in Table 1.

Table 1.

Summary of pilot-scale roller milling parameters or unit operations.

2.2. Pilot Scale Milling

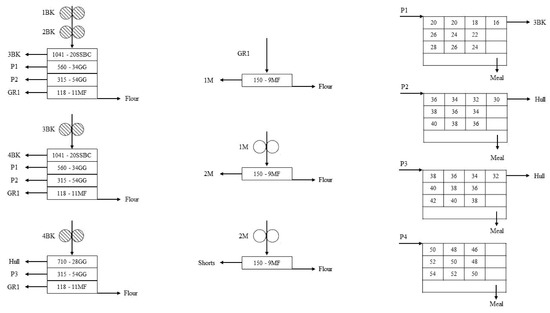

Chickpeas were milled on a pilot-scale research wheat flour mill (Hal Ross Flour Mill, Kansas State University, Manhattan, KS, USA). The mill was modified to produce the maximum amount of chickpea meal and minimal co-product flour. This decision was made to create a novel ingredient, chickpea meal, and because designing the flow for meal would be a more difficult task than for flour. The milling flow shown in Figure 1 could easily be modified to produce only flour by regrinding the meal to flour, if desired.

Figure 1.

Roller milling flow sheet to obtain Chickpea Meal.

2.2.1. Cleaning House

Chickpeas were processed through the “cleaning house” system of the flour mill, which consisted of a combi-cleaner, scourer and infestation destroyer. The combi-cleaner used aspiration and gyratory vibration to separate based on density. The combi-cleaner removed light materials, such as loose hull or discolored seeds, and denser materials, such as stones. The scourer used abrasion to remove dust and debris from the outside of the seeds. The scourer was originally tested to remove the hull of the chickpea, by increasing intensity, but was found to be not effective. The infestation destroyer used impact force to remove hollowed-out grain from insect pests. The chickpea seeds did not show any evidence of insects, but this equipment was used to split some seeds and break off loose hull. All cleaning equipment had a capacity of 6000 lbs/h (2751.6 kg/h).

2.2.2. Storage and Tempering

After cleaning, the chickpeas were stored in tempering bins. Benchtop laboratory milling trials (unpublished data), showed that tempering to 11% moisture content (MC) on wet basis (w.b.) for 12 h was ideal for hull separation. The chickpeas arrived at the flour mill at 10.9% MC, so tempering was not needed.

2.2.3. Roller Milling

Chickpeas were milled using roller mills to create a coarse meal between 300 and 600 microns. Particles that were produced finer than 300 microns were milled to flour less than 150 microns. The roller mills and sifters had a capacity of 2.5 MT/h but were operated at 1 MT/h Milling equipment included a double high-break roll stand (MDDO, Bühler Group, Uzwil, Switzerland) and a single high-break roll (MDDM, Bühler Group, Uzwil, Switzerland). Samples were sifted with sifter boxes (MPAJ, Bühler Group, Uzwil, Switzerland) to remove larger particles of hull (>1041 microns), finer particles too small for meal (<315 microns) and flour (<150 microns). Air separation was used to separate light hull from the meal through the use of four purifiers (MQRF, Bühler Group, Uzwil, Switzerland). The final flow sheet used for both Kabuli and Desi chickpeas is shown in Figure 1.

The roll gaps were adjusted, but not recorded between samples to ensure similar milling intensity between chickpea samples. The break system was similar to the benchtop trial flow sheet for process 2. The major difference between benchtop and pilot scale was that there was no sieve separation between the 1st and 2nd break because a double high-roll stand was used. The pilot-scale reduction rolls (2M and 3M) were gear-driven and could grind with more force than the belt driven benchtop mills, so fewer roll stands were needed.

Chickpeas were first pneumatically transported from the tempering tanks to the 1st and 2nd break (BK) double high-roll stand. At this double high-roll stand, the chickpeas were ground twice without sifting in-between to break open the seeds and remove the hull in large pieces. After grinding, particles were pneumatically transferred sifters where particles were separated according to size. Particles larger than 1041 microns were sent to the third break (3BK), particles larger than 560 microns were sent to the 1st Purifier (P1), particles larger than 315 microns were sent to the 2nd Purifier (P2), particles larger than 118 microns were sent to the grader sifter (GR-1), and particles smaller than 118 microns was collected as flour (F1-2).

The next break roll stand, 3BK, the material from the 1/2 BK roll stands and P1was processed. After grinding on 3BK particles were sent to be sifted. Particles were sifted with the same separation as before; the only difference was that particles larger than 1041 were sent to the fourth break roll (4BK) stand.

The 4BK roll stand processed material from 3BK and P1. After grinding on 4BK separation differed from the other break roll stands. Particles larger than 710 microns were separated as hull or feed. Particles larger than 315 microns were sent to the third purifier (P3). Particles larger than 118 microns were sent to GR-1 and those smaller than 118 microns were separated as flour.

The grader sifter separated material from 1/2BK, 3BK, 4BK and the 4th purifier (P4). Particles less than 150 and 118 microns were separated as flour. Particles larger than 150 microns were sent to the 4th purifier (P4).

Smooth roll stands were used to grind particles too small for meal (<315 microns) but larger than flour (>150 microns). These stands were labeled as they would be in a commercial flour mill as 1M and 2M for processing “middlings”. After grinding on the first smooth roll, 1M, particles less than 150 microns were separated as flour and particles larger than flour were sent to 2M. The same separation was used after 2M but with larger particles removed as feed and labeled as overs of 2M or shorts.

The purifiers had 3 decks and used screens with the openings recorded in grit gauze (GG). The particles pass along each screen, aided with air agitation, from left to right, with larger GG numbers corresponding to smaller openings. As particles fall through one deck, they pass onto the lower deck. Empty squares in the purifier figure show where screens were removed. These screens were removed to reduce the amount of purified chickpea meal being sent to be reground. Screen size could be manipulated in future research or milling facilities to achieve the desired particle ranges.

For P1, particles that did not fall though the first deck were sent to 3BK to be reground. For P2 and P3, particles that did not fall through to the second deck were collected as hull. Particles that fell through the first deck but remained on the second deck and fell through the open screen at the end were collected as meal. Particles that fell through the first two decks and remained on the 3rd deck until falling through the open screen were also collected as meal. P4 differed from the other purifiers by having all right end sieves removed, as no hull contamination was found in any of the outlets. The last purifier, P4, was not needed for sifting but was necessary to ensure the product flowed through the correct pneumatic lines for separation.

2.2.4. Packaging and Sealing

Final products, meal and flour, were bagged in plastic lined kraft paper bags and sealed with thread. Each bag weighed approximately 50 lbs (22.7 kg) and was palleted with 5 bags per row and was no more than 10 rows high.

2.3. Proximate Analysis

Proximate analysis of samples was carried out by SDK laboratories (Hutchinson, KS, USA) in duplicate. The crude protein (AOAC 976.06) [17] was measured by combusting samples and analyzing the amount of nitrogen in the sample. Crude protein for chickpeas was calculated using N × 6.25. Crude fiber (AOAC 962.09) [17] was determined after digestion of sample with sulfuric acid and sodium hydroxide and then combusted. Crude fat by acid hydrolysis (AOCS Ba 3-38) [17] was measured by extracting oil with petroleum ether and given as a percentage of original sample weight. Total starch (AOAC 979.10) was measured by digesting starch with enzymes and the glucose level was measured through spectrophotometry. Whole-chickpea moisture contents were determined using a laboratory oven at 105 °C for 72 h (ASABE S352.2) [18]. Moisture contents of ground samples were determined using a laboratory oven at 135 °C for 2 h (AACC44-19.01) [17].

2.4. Particle Size

Particle size analysis on final flour and meal streams was carried out using an Alpine jet sieve analyzer (e200LS, Hosokawa Alpine, Germany) or a Ro-Tap sieve (RX-29, W.S. Tyler, Mentor, OH, USA). Samples were measured in triplicate.

2.5. Flow Properties

Bulk density of the meal and flour was determined using a Winchester cup arrangement that ensured consistent filling into a cup of known volume, and the mass was recoded. Bulk density was calculated using the equation below.

where Sm is sample mass (g) and Sv is sample volume (4.732 × 10−4 m3).

Tapped density was calculated using an Autotap density analyzer (Quanta Chrome Instruments, Boynton Beach, FL, USA). A graduated cylinder was filled with a known mass of sample and then the cylinder was then tapped 720 times (260 taps/min) and the volume was recorded after tapping. The tap density was calculated using the sample mass and tapped volume and recoded in g/mL.

Angle of repose was measured using a Winchester cup arrangement. The funnel was filled with 100 g of sample and allowed to pour from a height of 10 cm to a flat aluminum tray. The diameter of the pile was recorded three times from varying angles and averaged. The height was measured once. Angle of repose was calculated using the following equation

where Ɵ is the angle of repose, H is the height of the pile formed, and D is the average diameter of the pile.

The flowability of the flour and meal was measured by comparing the Hausner ratio (HR) shown in Equation (3) and the Compressibility Index (CI), as shown in Equation (4). These values, along with the angle of repose, will be able to categorize the flow properties of the product as excellent to very, very poor, as shown in Table 2.

where TD is the tapped density and BD is the bulk density.

where TD is the tapped density and BD is the bulk density.

Table 2.

Physicochemical properties of chickpea.

2.6. Statistical Analyses

One-way ANOVA was performed on data to ascertain statistical significance of treatment effects (chickpea variety, milling process, flour stream, etc.). ANOVA was followed by Tukey’s test for comparison of means and determine statistical significance of differences. Analyses was conducted using the SAS analysis software (Version 9.4, SAS, Cary, NC, USA) and statistical significance of p < 0.05.

3. Results and Discussion

3.1. Milling Yields

An overview of the milling yields can be found in Table 3. Almost twice the amount of Kabuli chickpeas was milled compared to Desi chickpeas. This was important to note because process loss was higher for the Desi chickpeas and this loss was most likely attributed to the shorter runtime. The process loss for both chickpeas would be expected to be lower if the mill was running for a longer production time.

Table 3.

Milling yields (% as-is) of kabuli and desi chickpeas from roller mill.

Kabuli chickpeas milled more efficiently into meal than Desi chickpeas, with almost 10% more meal. Desi chickpeas produced less meal and less flour but produced more “overs of 4th BK”; this was coarser material that would be hull if it were Kabuli chickpeas. Upon visual inspection, this stream was coarse cotyledon. This larger section showed that the break system should have had smaller roll gaps to increase grinding action to produce smaller particles. Another solution could have been to send this section back into the break system. However, due to the capabilities of the Hal Ross Flour mill, it was not possible to re-route this stream back into the process.

Comparing only the products of each process, (meal/(meal + flour) or flour/meal + flour), Desi chickpeas actually produced more meal than flour. Kabuli chickpeas, using the previous formulas produced 72.7% meal and 27.3% flour compared to Desi Chickpeas yields of 77.1% meal and 22.9% flour. If the “Overs of 4th BK” from process 2 (Desi) could have been re-entered into the break system; this could have increased the meal and flour production. This could have made split Desi chickpeas more efficient to mill. Both meal yields were still low (<80%) and, therefore, could not be considered an efficient process when designed for meal. Selling the co-product flour would increase the cost-effectiveness of the process.

The hull stream, “Overs of 4th BK”, yielded 6% hull removal from the Kabuli chickpeas. This is similar to reported previously levels, where chickpeas contained 5% hull [7]. The 1% difference could have been from cotyledon still in the hull stream or due to varietal differences. The remaining 1% could be separated by density or air separation, but since the amount is so small, it would likely not be cost-effective. The “overs of 2M” represent any material that was not ground to flour through the reduction system. This material was harder than the rest of the flour and, therefore, stayed intact longer. This increased strength was a result of increased protein level. It had previously been reported that the outer layer of the chickpea cotyledon had higher protein levels, while the center of the cotyledon consisted of more starch [19].

3.2. Proximate Analysis

The proximate analysis data for both processes were recorded in Table 4. The raw material section showed the similarities and differences between the two chickpea types. They both had similar protein levels of around 24%. Crude fiber was lower in the Desi seeds because they had previously been dehulled. The dehulling partially explained the increased fat and starch in the Desi seeds as chickpea hull is known to contain low levels of fat and protein while having high levels of fiber [20]. Direct correlations cannot be made solely between the raw materials as they can have varietal differences. When all proximate contents were combined, it was clear that a portion of the composition was missing. The large difference (~25%) was believed to be oligosaccharides that would have not shown up in any of the other analysis [21].

Table 4.

Proximate Analysis of kabuli and desi chickpeas.

The proximate analysis of process 1 showed the effect of de-hulling process as well as differences in meal and flour. The hull stream contained the largest amount of crude fiber and ash of all the process 1 streams. The meal stream had higher crude fiber and ash than the flour stream showing signs of higher hull contamination in the meal. The ash content of the hull contradicted the benchtop work (unpublished data) with Kabuli chickpeas that found that ash content was not significantly lowered by hull removal. One possibility was that the use of the purifiers increased hull separation and reduced cotyledon in the hull stream that allowed for proximate analysis differences to be observed. Further studies would need to be carried out to correlate the ash content and hull contamination in chickpeas before ash could be used as an indicator, similar to wheat milling.

The significantly higher protein and lower starch in the meal stream from both processes further enforced the theory that protein content increases strength. The outside of the cotyledon that contained higher protein remained in larger granules than the inner cotyledon that contained more starch [19]. Similar trends are seen with corn, horny vs. floury cotyledon, and wheat, hard vs. soft wheat [22]. The “Overs of 2M”/shorts had significantly higher protein than the flour stream, again reinforcing the strength theory.

Process 2 results followed similar patterns as process 1. The meal stream again contained significantly more protein and lower levels of starch. The flour stream from process 2 had the highest starch content of any tested sample. The “Overs of 4th BK” proximate results were practically similar to the meal stream. This similarity further emphasizes that the “Overs of 4th BK” stream should be re-milled to create meal and not discarded as feed.

The differences in starch and protein showed additional benefits to focusing on meal. The separation based on particle size resulted in different proximate results. These differences, such as in the flour, could lead to different functionalities in the raw flour, making it more beneficial in products or processes where increased protein is not desired. The decreased protein was also found without the use of water or chemicals, further increasing the sustainability of the ingredient.

3.3. Particle Size

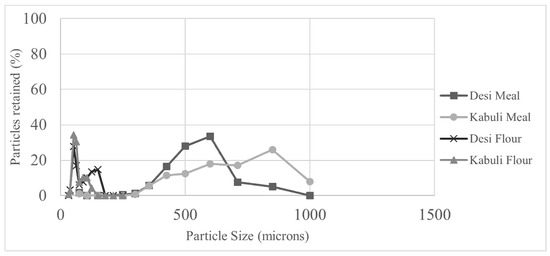

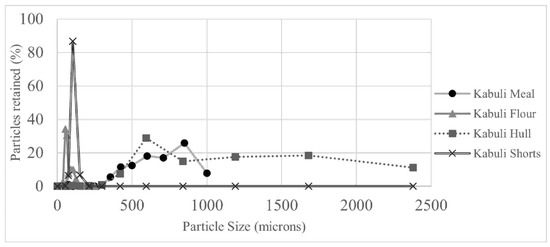

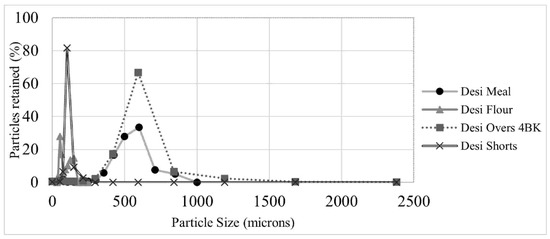

Particle size data are recorded in Figure 2, Figure 3 and Figure 4. The particles retained on each sieve were represented as a percent of each sample and the magnitude of the distributions was not related to yield.

Figure 2.

Particle Size of Chickpea Meal and Co-Product Flour Streams.

Figure 3.

Particle Size of Process 1, (Kabuli) Milling Streams.

Figure 4.

Particle Size of Process 2, (Desi) Milling Streams.

The particle sizes of the final products from both processes were recorded in Figure 2. The flour for both chickpeas follows similar particle size ranges, with a bimodal distribution of around 53 and 90–150 microns. These bimodal peaks were also seen in benchtop milling trials [23]. The previously mentioned strength theory that compared meal and flour could explain the bimodal peaks. The larger micron peak could contain more protein than the smaller micron peak. Further testing could be carried out to confirm this.

The wider range of Kabuli meal was previously observed in benchtop trials and was due to the grinding intensity of the break system. However, at pilot scale, the larger range was more likely attributed to the removed purifier screens. The range of meal could be further adjusted by a change of purifier screens. The majority (~92%) of Kabuli meal was less than 850 microns, which ensured it was still an acceptable range of meal.

All products from process 1 are shown in Figure 3. The extremely large range of the hull showed that the break system was efficient at removing the hull in as large pieces as possible. The parts of the meal and hull distribution that overlap showed the importance of the purifiers in the milling flow. The purifier separated the bran with air separation that could not be separated by only particle size differences. The smaller particle range of the shorts stream showed that this could have been collected as flour. It was not clear if blinding of the screens led to these smaller particles not being included in the flour stream. However, because this stream was so small, at 1.9%, it was not a major concern that warranted further research.

Figure 4 shows that the “Overs of 4th BK” for Desi chickpeas needs only minimal grinding to convert it into meal. As mentioned previously, there was not a way to transport this stream back into the break system. In a commercial mill, this would not be wasted and would increase meal and flour yields. Again, the shorts stream should have been collected as flour, but this stream only contributed to 0.7% of the total products and was not considered practically significant.

3.4. Flow Properties

The flow properties of the chickpea products were recorded in Table 5. As expected, both flour streams flowed less easily compared to the meal streams. Kabuli flour from process 1 had better flow properties than Desi Flour. Kabuli flour was labeled as “excellent” by the Hausner Ratio and Compressibility Index, but only “passable” by the Angle of Repose test. Desi Flour was labeled “good” by the Hausner Ratio and Compressibility Index, but on the upper end of “passable” by the Angle of Repose” test. These tests show the importance of using more than one flowability measurement when testing a sample, as they can often times result in different classifications. Fortunately, by this scale, neither of the flour streams showed any major flowability or transportation issues.

Table 5.

Flow properties’ data of kabuli and desi chickpea meal and flour.

The meal streams flowed better than the flour samples. This was expected due the larger particle size [24]. Kabuli and Desi meal were labeled as “excellent” or better. The Hausner ratio and Compressibility Index values were better than shown in the table due to the tapped density levels. Both meals flowed so well that it caused negative values for the Compressibility index.

4. Conclusions

The results of this research showed that chickpeas can be de-hulled and can be ground into meal and flour using roller (wheat) mills. Whole Kabuli chickpeas milled more efficiently (63.8% meal yield and only 4.4% losses) than split and de-hulled Desi chickpeas (only 54.1% meal yield and 11.8% losses). Differences in the protein and starch levels reinforced that protein is not distributed evenly across then cotyledon and led to higher protein (24.6% versus 22.4–22.8%) and lower starch (33.2–37.2% versus 49.7–52.0%) levels in the meal streams as compared to flour streams. Flowability tests confirmed that the produced chickpea products would not lead to any major flow concerns (good to excellent flow properties based on Hausner ratio of 0.927–1.161). Usage of the wheat (roller) mills for processing chickpeas will not only facilitate efficiencies in energy and water consumption but also gives products (meal and flour) with a uniform particle size distribution compared to the reported hammer and attrition mills. More research will be needed to increase the meal yields of both processes; however, selling the flour as a desirable product would increase profitability.

Author Contributions

Conceptualization, S.A.; methodology, R.M., K.S., J.W., P.B. and S.A.; formal analysis, R.M. and K.S.; investigation, R.M., S.A. and K.S.; resources, J.W., P.B. and S.A.; data curation, R.M., S.A. and K.S.; writing—original draft preparation, R.M.; writing—review and editing, K.S. and S.A.; supervision, S.A.; project administration, S.A.; funding acquisition, S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gil, J.; Nadal, S.; Luna, D.; Moreno, M.T.; Haro, A.D. Variability of Some Physicochemical Characters in Desi and Kabuli Chickpea Types. J. Sci. Food Agric. 1996, 71, 179–184. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. Value of Water Research Report. Series No. 48. In Value of Water; UNESCO-IHE Institute for Water Education: Delft, The Netherlands, 2010. [Google Scholar]

- Van der Weele, C.; Feindt, P.; van der Goot, A.J.; van Mierlo, B.; van Boekel, M. Meat alternatives: An integrative comparison. Trends Food Sci. Technol. 2019, 88, 505–512. [Google Scholar] [CrossRef]

- Heiras-Palazuelos, M.J.; Ochoa-Lugo, M.I.; Gutiérrez-Dorado, R.; López-Valenzuela, J.A.; Mora-Rochín, S.; Milán-Carrillo, J.; Garzón-Tiznado, J.A.; Reyes-Moreno, C. Technological properties, antioxidant activity and total phenolic and flavonoid content of pigmented chickpea (Cicer arietinum L.) cultivars. Int. J. Food Sci. Nutr. 2013, 64, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Singh, U. Antinutritional factors of chickpea and pigeonpea and their removal by processing. Plant Foods Hum. Nutr. 1988, 38, 251–261. [Google Scholar] [CrossRef] [PubMed]

- Adamidou, S.; Nengas, I.; Grigorakis, K.; Nikolopoulou, D.; Jauncey, K. Chemical Composition and Antinutritional Factors of Field Peas (Pisum sativum), Chickpeas (Cicer arietinum), and Faba Beans (Vicia faba) as Affected by Extrusion Preconditioning and Drying Temperatures. Cereal Chem. J. 2011, 88, 80–86. [Google Scholar] [CrossRef]

- Ravi, R.; Harte, J.B. Milling and physicochemical properties of chickpea (Cicer arietinum L.) varieties. J. Sci. Food Agric. 2009, 89, 258–266. [Google Scholar] [CrossRef]

- Wood, J.A.; Knights, E.J.; Harden, S. Milling performance in desi-type chickpea (Cicer arietinum L.): Effects of genotype, environment and seed size. J. Sci. Food Agric. 2008, 88, 108–115. [Google Scholar] [CrossRef]

- Pulivarthi, M.K.; Nkurikiye, E.; Watt, J.; Li, Y.; Siliveru, K. Comprehensive understanding of roller milling on the physico chemical properties of red lentil and yellow pea flours. Processes 2021, 9, 1836. [Google Scholar] [CrossRef]

- Akinoso, R.; Lawal, I.A.; Aremu, A.K. Energy requirements of size reduction of some selected cereals using attrition mill. Int. Food Res. J. 2013, 20, 1205–1209. [Google Scholar]

- Sanchez, G.C.; Monteagudo Yanes, J.P.; Perez, M.M.; Cabrera Sanchez, J.L.; Padron, A.P.; Haeseldonckx, D. Efficiency in electromechanical drive motors and energy performance indicators for implementing a management system in balanced animal feed manufacturing. Energy 2020, 194, 116818. [Google Scholar] [CrossRef]

- Eras, J.J.C.; Gutierrez, A.S.; Ulloa, M.J.C. The temperature gradient of cereals as an optimization parameter of the milling process in hammermills. J. Clean. Prod. 2021, 297, 126685. [Google Scholar] [CrossRef]

- Sannik, U.; Pappel, T.K. Complete milling technologies of different valuable materials. In Proceedings of the 4th International DAAAM Conference “Industrial Engineering–Innovation as Competitive Edge for SME”, Tallinn, Estonia, 29–30 April 2004; pp. 146–148. [Google Scholar]

- Koch, K.B. Feed Mill Efficiency. Engormix. 2012. Available online: https://en.engormix.com/feed-machinery/articles/feed-mill-efficiency-t35290.htm (accessed on 11 September 2022).

- Smejtkova, A.; Vaculik, P. Comparison of power consumption of a two-roll mill and a disc mill. Agron. Res. 2018, 16 (Suppl. S2), 1486–1492. [Google Scholar]

- Ziggers, B.D. Hammering or rolling the grain. Feed. Technol. 2001, 5, 9–17. [Google Scholar]

- Official Methods of Analysis, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2006.

- S3194.4; Method of Determining and Expressing Fineness of Feed Materials by Sieving. ASABE Standards: St. Joseph, MI, USA, 2008.

- Wood, J.A.; Knights, E.J.; Chocty, M. Morphology of chickpea seeds (Cicer arietinum L.): Comparison of desi and kabuli types. Int. J. Plant Sci. 2011, 172, 632–643. [Google Scholar] [CrossRef]

- Soni, B.; Sarita, S. Comparative evaluation of milling bi-products: Finger millet seed coat (FMSC), chick pea husk (CPH) and wheat bran (WB) for their nutritional, nutraceutical potential. Int. J. Basic Appl. Agric. Res. 2014, 12, 104–110. [Google Scholar]

- Xu, Y.; Thomas, M.; Bhardwaj, H.L. Chemical composition, functional properties and microstructural characteristics of three kabuli chickpea (Cicer arietinum L.) as affected by different cooking methods. Int. J. Food Sci. Technol. 2014, 49, 1215–1223. [Google Scholar] [CrossRef]

- Hoseney, R.C. Principles of cereal science and technology. A general reference on cereal foods. In Principles of Cereal Science and Technology. A General Reference on Cereal Foods; American Association of Cereal Chemists, Inc.: St. Paul, MN, USA, 1986. [Google Scholar]

- Martin, R.C. Physico-Chemical Properties of Chickpea Flour Obtained Using Roller Milling and Extrusion Pre-Cooking. Master’s Thesis, Kansas State University, Manhattan, KS, USA, 2000. [Google Scholar]

- Riley, R.E.; Hausner, H.H. Effect of particle size distribution on the friction in a powder mass. Int. J. Powder Met. 1970, 6, 17–22. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).