Concept of an Enzymatic Reactive Extraction Centrifuge

Abstract

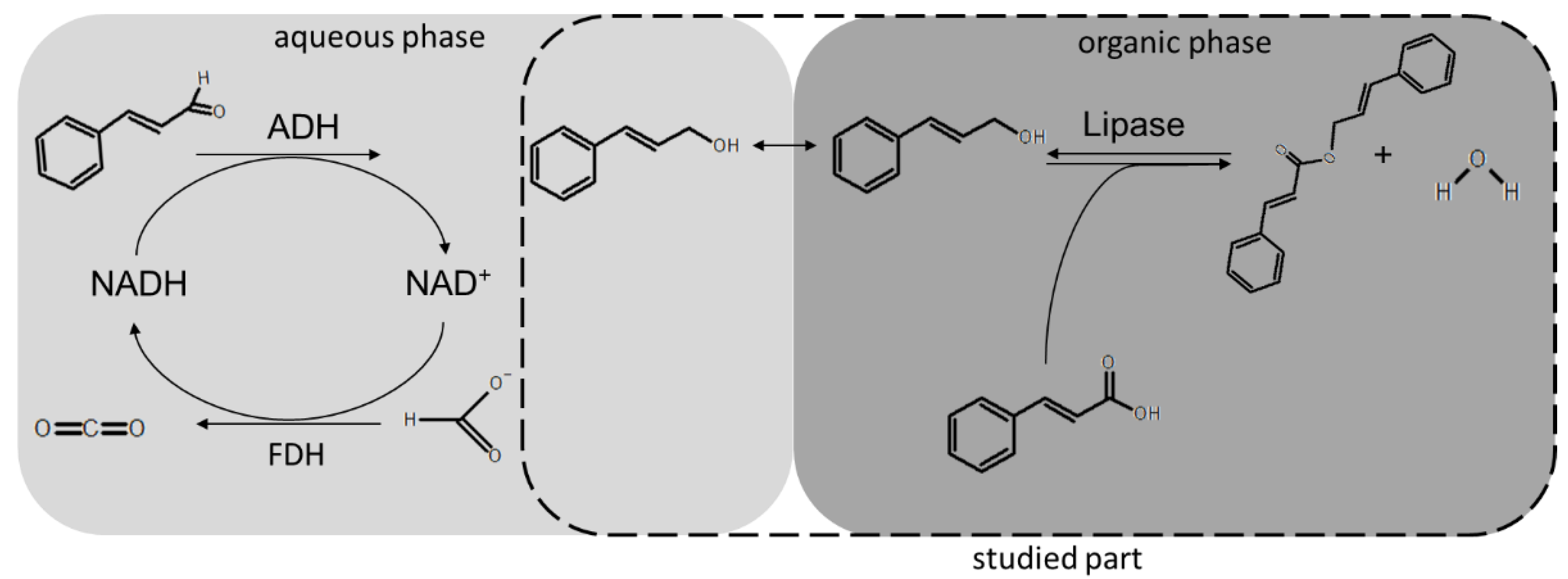

:1. Introduction

2. Materials and Methods

3. Results and Discussion

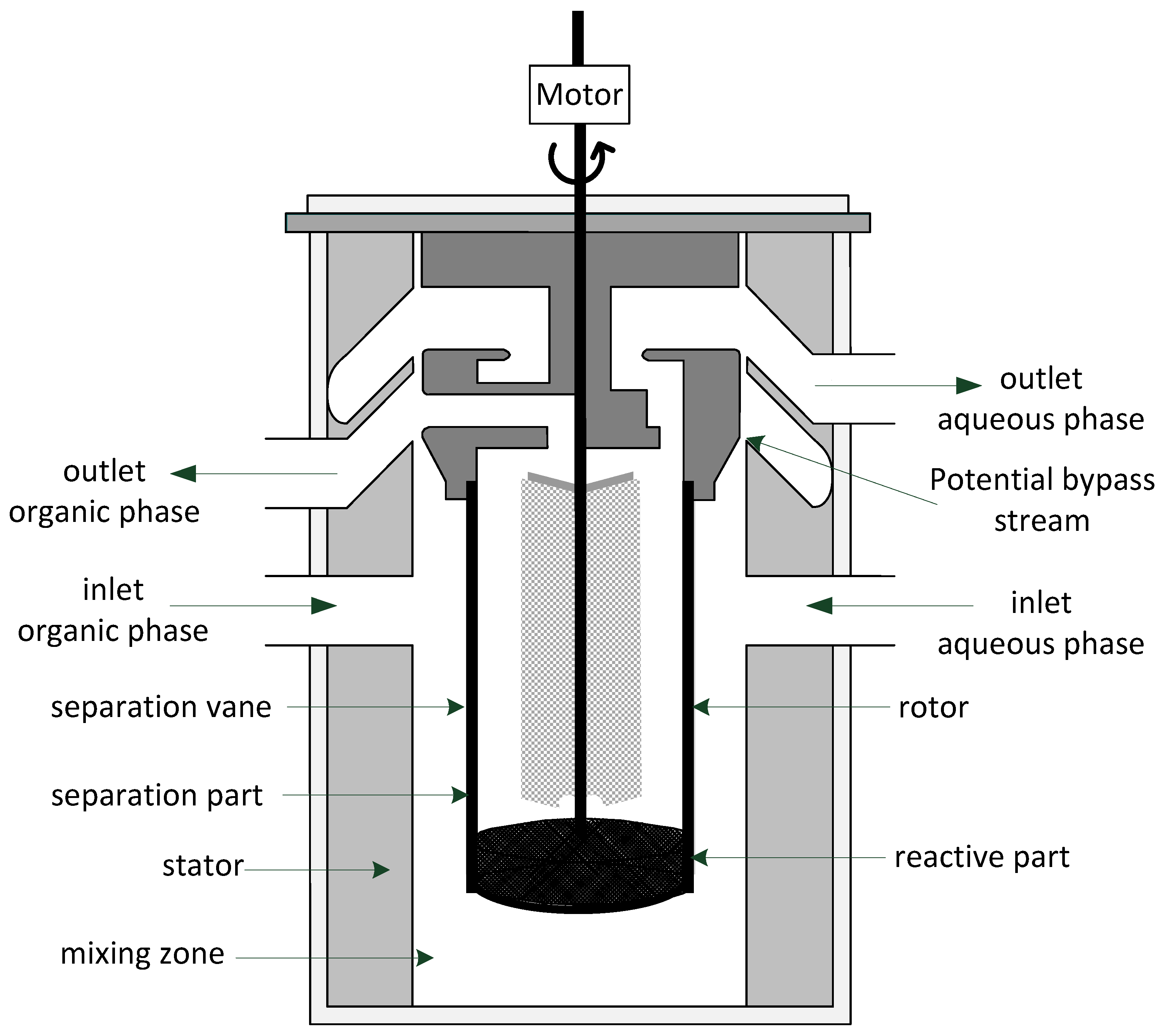

3.1. Construction

3.2. Operation

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schmidt, A.; Köster, D.; Strube, J. Climate Neutrality Concepts for the German Chemical–Pharmaceutical Industry. Processes 2022, 10, 467. [Google Scholar] [CrossRef]

- Fernandes, P.; de Carvalho, C.C.C.R. Multi-Enzyme Systems in Flow Chemistry. Processes 2021, 9, 225. [Google Scholar] [CrossRef]

- Bié, J.; Sepodes, B.; Fernandes, P.C.B.; Ribeiro, M.H.L. Enzyme Immobilization and Co-Immobilization: Main Framework, Advances and Some Applications. Processes 2022, 10, 494. [Google Scholar] [CrossRef]

- Foley, A.M.; Maguire, A.R. The Impact of Recent Developments in Technologies which Enable the Increased Use of Biocatalysts. Eur. J. Org. Chem. 2019, 2019, 3713–3734. [Google Scholar] [CrossRef]

- Sarak, S.; Sung, S.; Jeon, H.; Patil, M.D.; Khobragade, T.P.; Pagar, A.D.; Dawson, P.E.; Yun, H. An Integrated Cofactor/Co-Product Recycling Cascade for the Biosynthesis of Nylon Monomers from Cycloalkylamines. Angew. Chem. 2021, 133, 3523–3528. [Google Scholar] [CrossRef]

- Lucato, W.; Santos, J.; Pacchini, A. Measuring the Sustainability of a Manufacturing Process: A Conceptual Framework. Sustainability 2018, 10, 81. [Google Scholar] [CrossRef] [Green Version]

- Kampers, L.F.C.; Asin-Garcia, E.; Schaap, P.J.; Wagemakers, A.; Martins Dos Santos, V.A.P. From Innovation to Application: Bridging the Valley of Death in Industrial Biotechnology. Trends Biotechnol. 2021, 39, 1240–1242. [Google Scholar] [CrossRef]

- Lv, L.; Dai, L.; Du, W.; Liu, D. Progress in Enzymatic Biodiesel Production and Commercialization. Processes 2021, 9, 355. [Google Scholar] [CrossRef]

- Žnidaršič-Plazl, P. Biocatalytic process intensification via efficient biocatalyst immobilization, miniaturization, and process integration. Curr. Opin. Green Sustain. Chem. 2021, 32, 100546. [Google Scholar] [CrossRef]

- Boodhoo, K.; Flickinger, M.C.; Woodley, J.M.; Emanuelsson, E. Bioprocess intensification: A route to efficient and sustainable biocatalytic transformations for the future. Chem. Eng. Process. Process Intensif. 2022, 172, 108793. [Google Scholar] [CrossRef]

- Foo, D.; El-Halwagi, M. Special Issue on “Process Design, Integration, and Intensification”. Processes 2019, 7, 194. [Google Scholar] [CrossRef] [Green Version]

- Stankiewicz, A.I.; Yan, P. 110th Anniversary: The Missing Link Unearthed: Materials and Process Intensification. Ind. Eng. Chem. Res. 2019, 58, 9212–9222. [Google Scholar] [CrossRef] [Green Version]

- Rong, B.-G. Process Synthesis and Process Intensification: Methodological Approaches; De Gruyter: Berlin, Germany; Boston, MA, USA, 2017; ISBN 311046506X. [Google Scholar]

- Dias, L.S.; Ierapetritou, M.G. Optimal operation and control of intensified processes—Challenges and opportunities. Curr. Opin. Chem. Eng. 2019, 25, 82–86. [Google Scholar] [CrossRef]

- Rüffer, N.; Heidersdorf, U.; Kretzers, I.; Sprenger, G.A.; Raeven, L.; Takors, R. Fully integrated L-phenylalanine separation and concentration using reactive-extraction with liquid-liquid centrifuges in a fed-batch process with E. coli. Bioprocess Biosyst. Eng. 2004, 26, 239–248. [Google Scholar] [CrossRef]

- Kuzmin, A.; Pravdina, M.; Yavorsky, A.; Yavorsky, N.; Parmon, V. Vortex centrifugal bubbling reactor. Chem. Eng. J. 2005, 107, 55–62. [Google Scholar] [CrossRef]

- Abduh, M.Y.; van Ulden, W.; van de Bovenkamp, H.H.; Buntara, T.; Picchioni, F.; Manurung, R.; Heeres, H.J. Synthesis and refining of sunflower biodiesel in a cascade of continuous centrifugal contactor separators. Eur. J. Lipid Sci. Technol. 2015, 117, 242–254. [Google Scholar] [CrossRef]

- Fayyazi, E.; Ghobadian, B.; Mousavi, S.M.; Najafi, G. Intensification of continues biodiesel production process using a simultaneous mixer- separator reactor. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1125–1136. [Google Scholar] [CrossRef]

- Ilmi, M.; Abduh, M.Y.; Hommes, A.; Winkelman, J.G.M.; Hidayat, C.; Heeres, H.J. Process Intensification of Enzymatic Fatty Acid Butyl Ester Synthesis Using a Continuous Centrifugal Contactor Separator. Ind. Eng. Chem. Res. 2018, 57, 470–482. [Google Scholar] [CrossRef] [Green Version]

- Hamamah, Z.A.; Grützner, T. Liquid-Liquid Centrifugal Extractors: Types and Recent Applications—A Review. ChemBioEng Rev. 2022, 9, 286–318. [Google Scholar] [CrossRef]

- Tang, K.; Wang, Y.; Zhang, P.; Huang, Y.; Dai, G. Process optimization of continuous liquid–liquid extraction in centrifugal contactor separators for separation of oxybutynin enantiomers. Sep. Purif. Technol. 2015, 150, 170–178. [Google Scholar] [CrossRef]

- Lei, W.; Li, Z. Improved extraction of penicillin G using hydrocarbon sulfoxides. J. Chem. Technol. Biotechnol. 2004, 79, 281–285. [Google Scholar] [CrossRef]

- Michailidis, D.; Angelis, A.; Aligiannis, N.; Mitakou, S.; Skaltsounis, L. Recovery of Sesamin, Sesamolin, and Minor Lignans From Sesame Oil Using Solid Support-Free Liquid-Liquid Extraction and Chromatography Techniques and Evaluation of Their Enzymatic Inhibition Properties. Front. Pharmacol. 2019, 10, 723. [Google Scholar] [CrossRef] [PubMed]

- Johannsen, J.; Meyer, F.; Engelmann, C.; Liese, A.; Fieg, G.; Bubenheim, P.; Waluga, T. Multi-enzyme cascade reaction in a miniplant two-phase-system: Model validation and mathematical optimization. AIChE J. 2021, 67, e17158. [Google Scholar] [CrossRef]

- Johannsen, J.; Engelmann, C.; Liese, A.; Fieg, G.; Bubenheim, P.; Waluga, T. Pilot-scale Operation of a Multi-enzymatic Cascade Reaction in a Multiphase System. Chem. Eng. Trans. 2020, 79, 25–30. [Google Scholar] [CrossRef]

- Meyer, F.; Johannsen, J.; Liese, A.; Fieg, G.; Bubenheim, P.; Waluga, T. Evaluation of process integration for the intensification of a biotechnological process. Chem. Eng. Process. Process Intensif. 2021, 167, 108506. [Google Scholar] [CrossRef]

- Engelmann, C.; Johannsen, J.; Waluga, T.; Fieg, G.; Liese, A.; Bubenheim, P. A Multi-Enzyme Cascade for the Production of High-Value Aromatic Compounds. Catalysts 2020, 10, 1216. [Google Scholar] [CrossRef]

- Buschulte, T.K.; Heimann, F. Verfahrensentwicklung durch Kombination von Prozeßsimulation und Miniplant-Technik. Chem. Ing. Tech. 1995, 67, 718–723. [Google Scholar] [CrossRef]

- Ilmi, M.; Kloekhorst, A.; Winkelman, J.; Euverink, G.; Hidayat, C.; Heeres, H.J. Process intensification of catalytic liquid-liquid solid processes: Continuous biodiesel production using an immobilized lipase in a centrifugal contactor separator. Chem. Eng. J. 2017, 321, 76–85. [Google Scholar] [CrossRef]

- Ajmal, M.; Fieg, G. Intensification of Lipase-Catalyzed Esterification using Ultrasound: Process Engineering Perspectives. Chem. Ing. Tech. 2017, 89, 1367–1373. [Google Scholar] [CrossRef]

- Wierschem, M.; Walz, O.; Mitsos, A.; Termuehlen, M.; Specht, A.L.; Kissing, K.; Skiborowski, M. Enzyme kinetics for the transesterification of ethyl butyrate with enzyme beads, coated packing and ultrasound assistance. Chem. Eng. Process. Process Intensif. 2017, 111, 25–34. [Google Scholar] [CrossRef]

- Enfors, S.-O.; Häggström, L. Bioprocess Technology: Fundamentals and Applications; Royal Institute of Technology: Stockholm, Sweden, 2000; ISBN 9171705112. [Google Scholar]

- Appl, C.; Baganz, F.; Hass, V.C. Development of a Digital Twin for Enzymatic Hydrolysis Processes. Processes 2021, 9, 1734. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meyer, F.; Gasimov, N.; Bubenheim, P.; Waluga, T. Concept of an Enzymatic Reactive Extraction Centrifuge. Processes 2022, 10, 2137. https://doi.org/10.3390/pr10102137

Meyer F, Gasimov N, Bubenheim P, Waluga T. Concept of an Enzymatic Reactive Extraction Centrifuge. Processes. 2022; 10(10):2137. https://doi.org/10.3390/pr10102137

Chicago/Turabian StyleMeyer, Francesca, Nijat Gasimov, Paul Bubenheim, and Thomas Waluga. 2022. "Concept of an Enzymatic Reactive Extraction Centrifuge" Processes 10, no. 10: 2137. https://doi.org/10.3390/pr10102137

APA StyleMeyer, F., Gasimov, N., Bubenheim, P., & Waluga, T. (2022). Concept of an Enzymatic Reactive Extraction Centrifuge. Processes, 10(10), 2137. https://doi.org/10.3390/pr10102137