Numerical Simulation Study on the Effect of Port Water Injector Position on the Gasoline Direct Injection Engine

Abstract

:1. Introduction

2. Numerical Simulation Model, Verification and Knock Condition

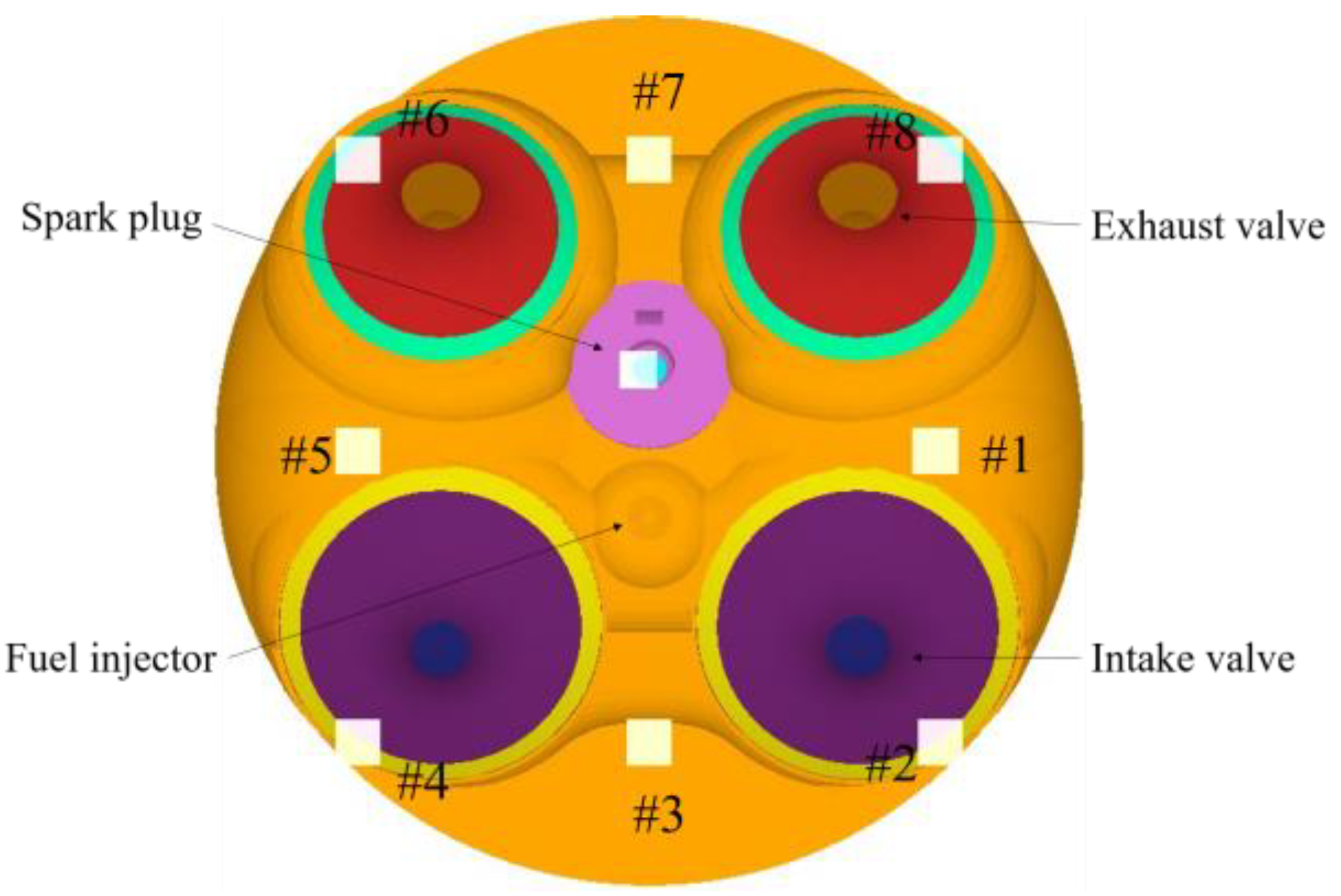

2.1. Numerical Simulation Model

2.2. Initial Parameter and Calculation Conditions

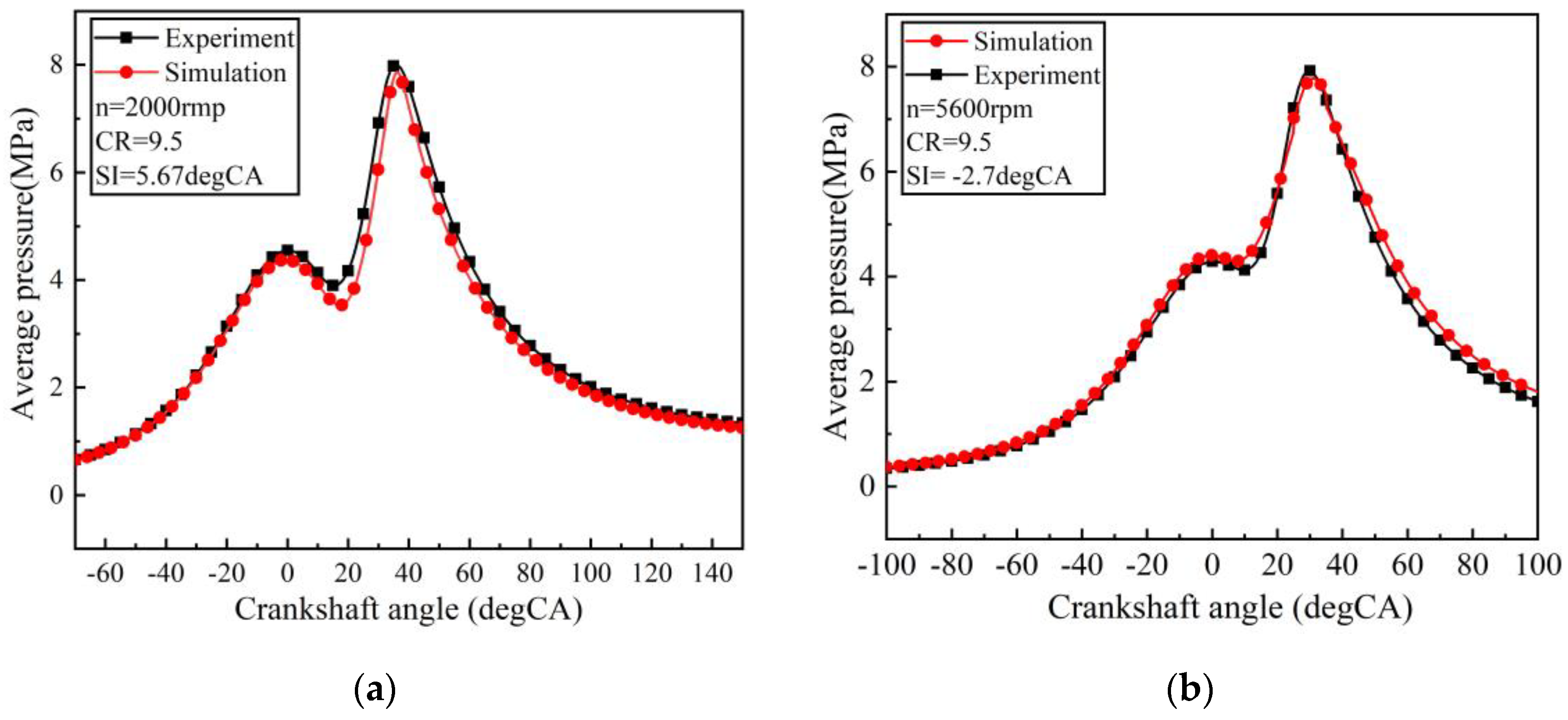

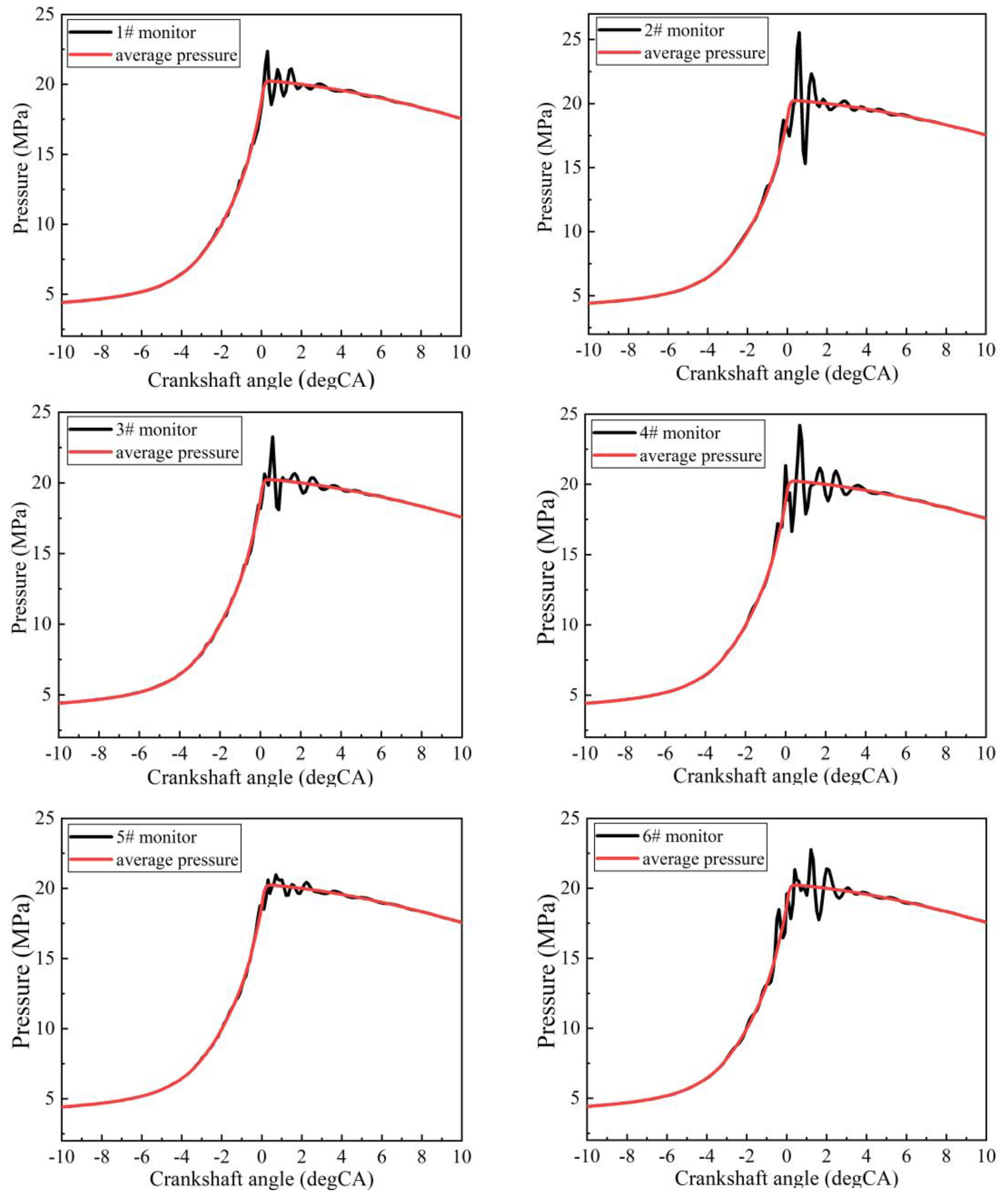

2.3. Verification of the Numerical Simulation Model of GDI Engine

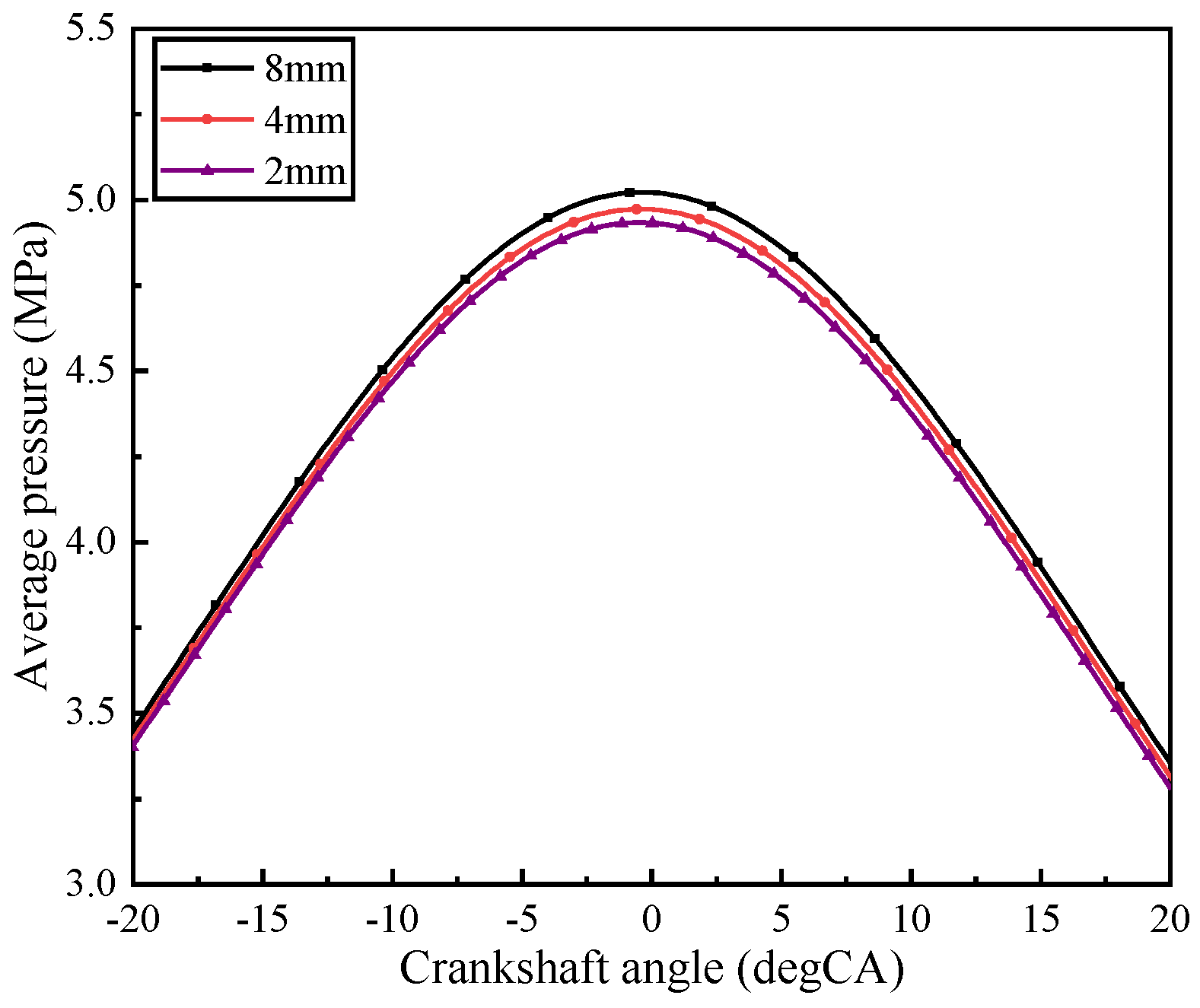

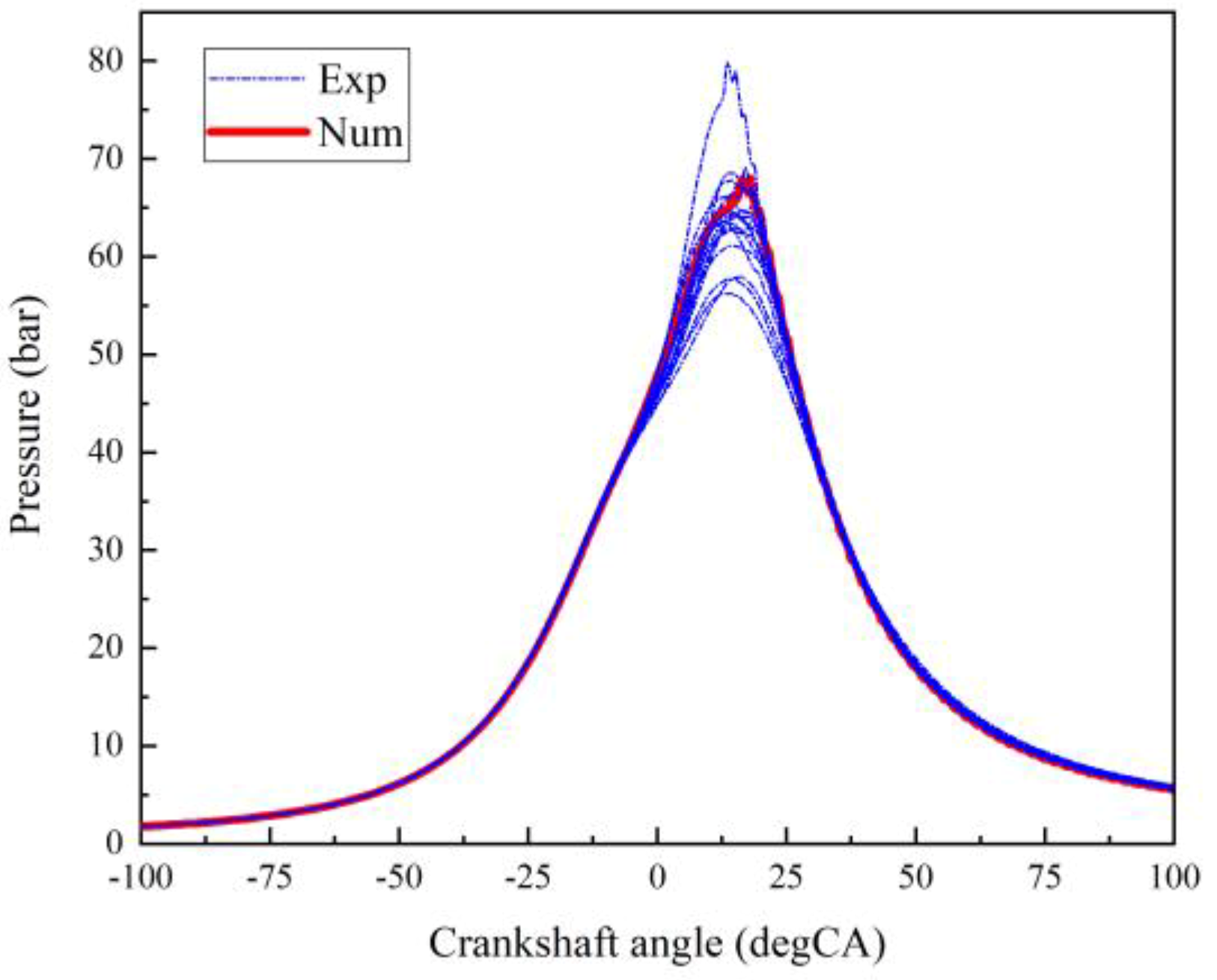

2.4. Determination of the Knock Conditions

2.5. Knock Detection

3. Results and Discussion

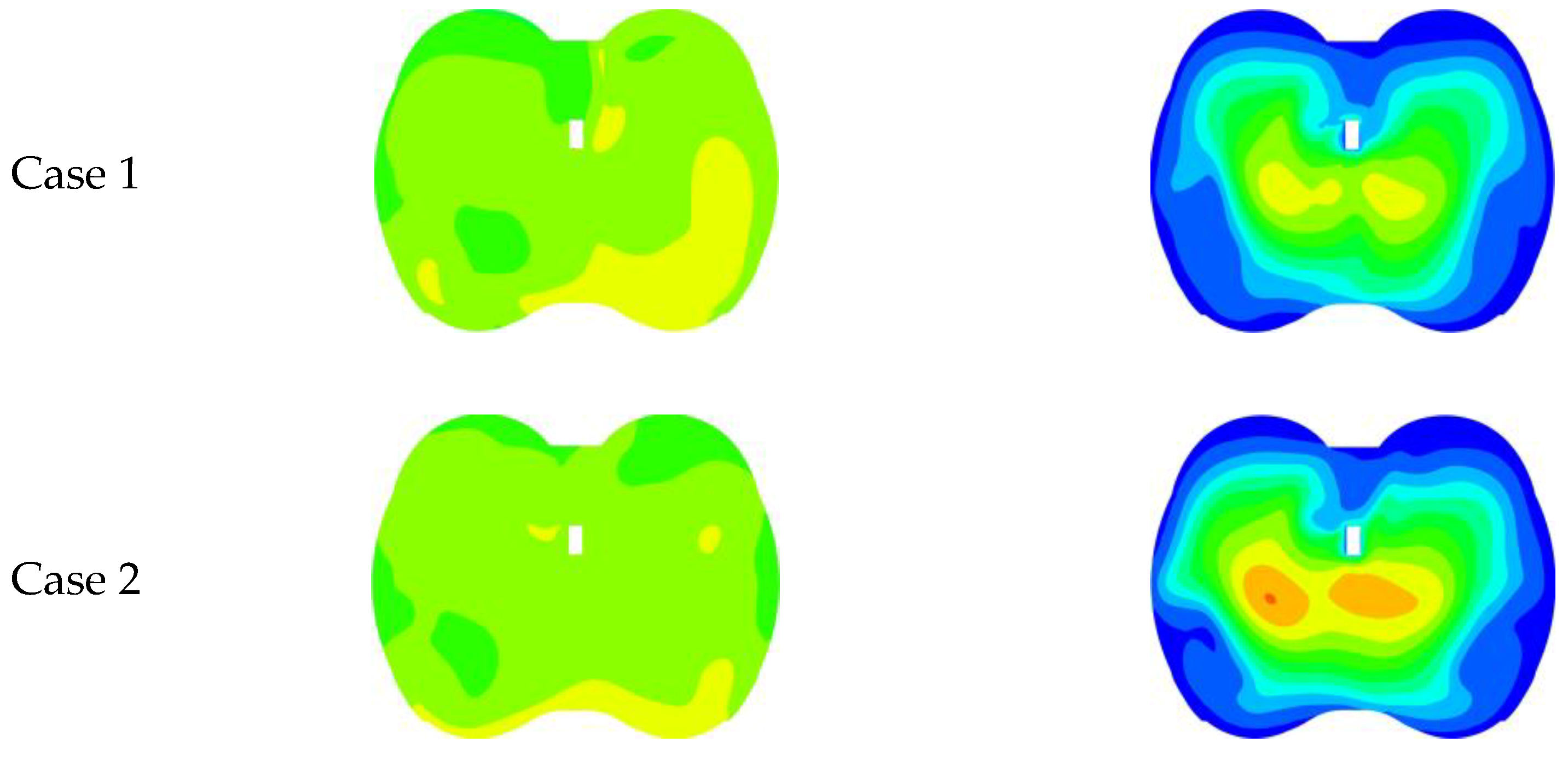

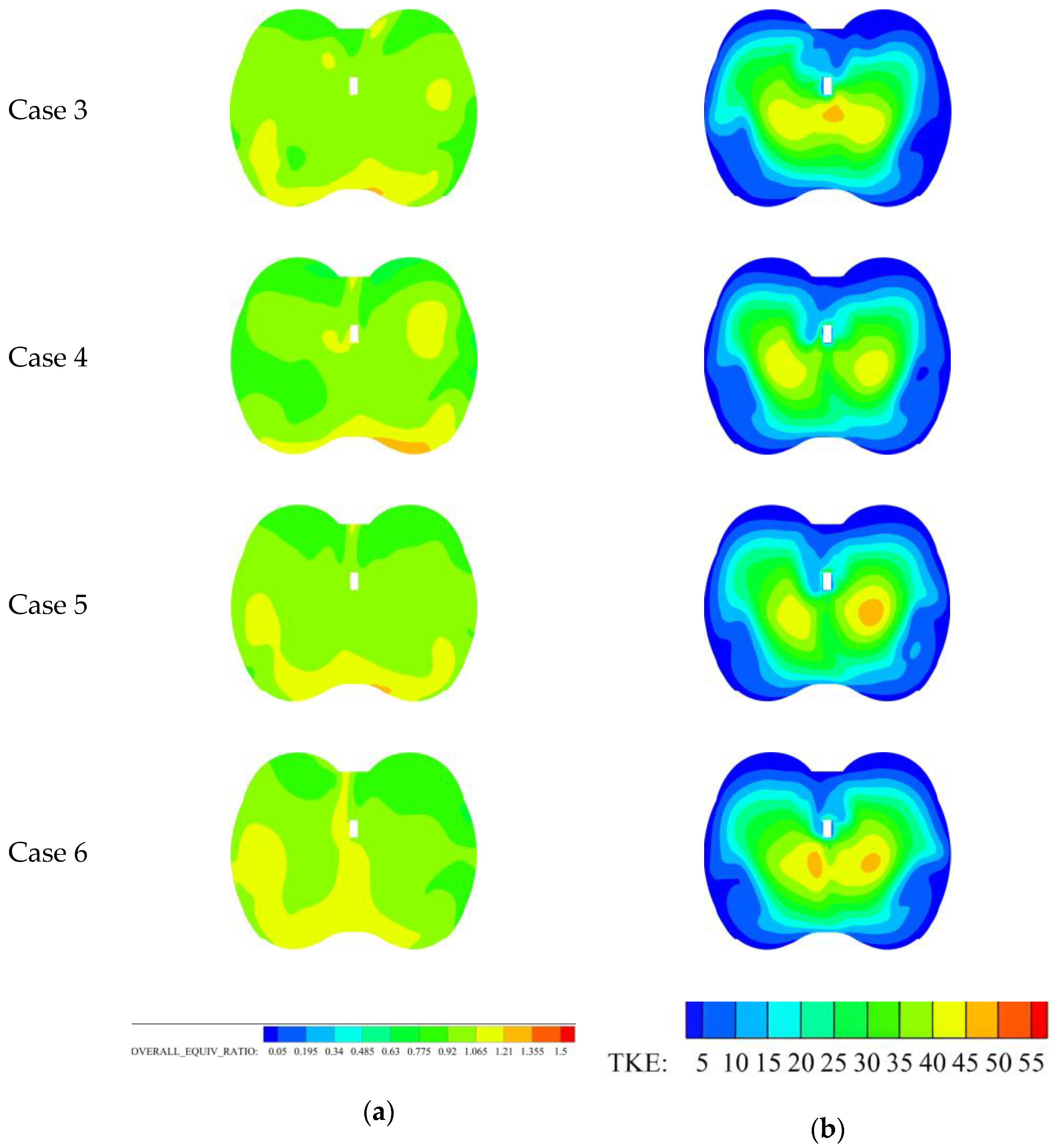

3.1. Different Water Injection Cases: The Atomization of Water and Mixture Formation

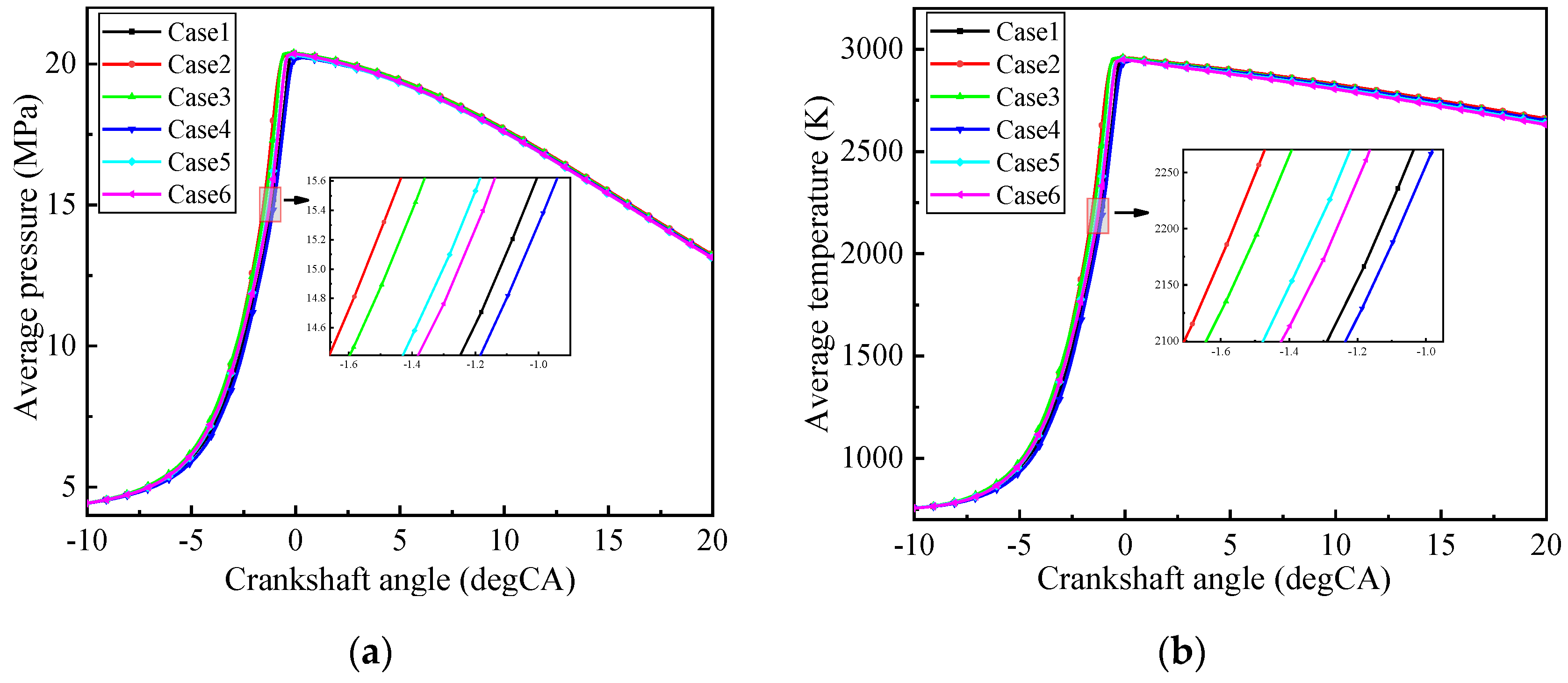

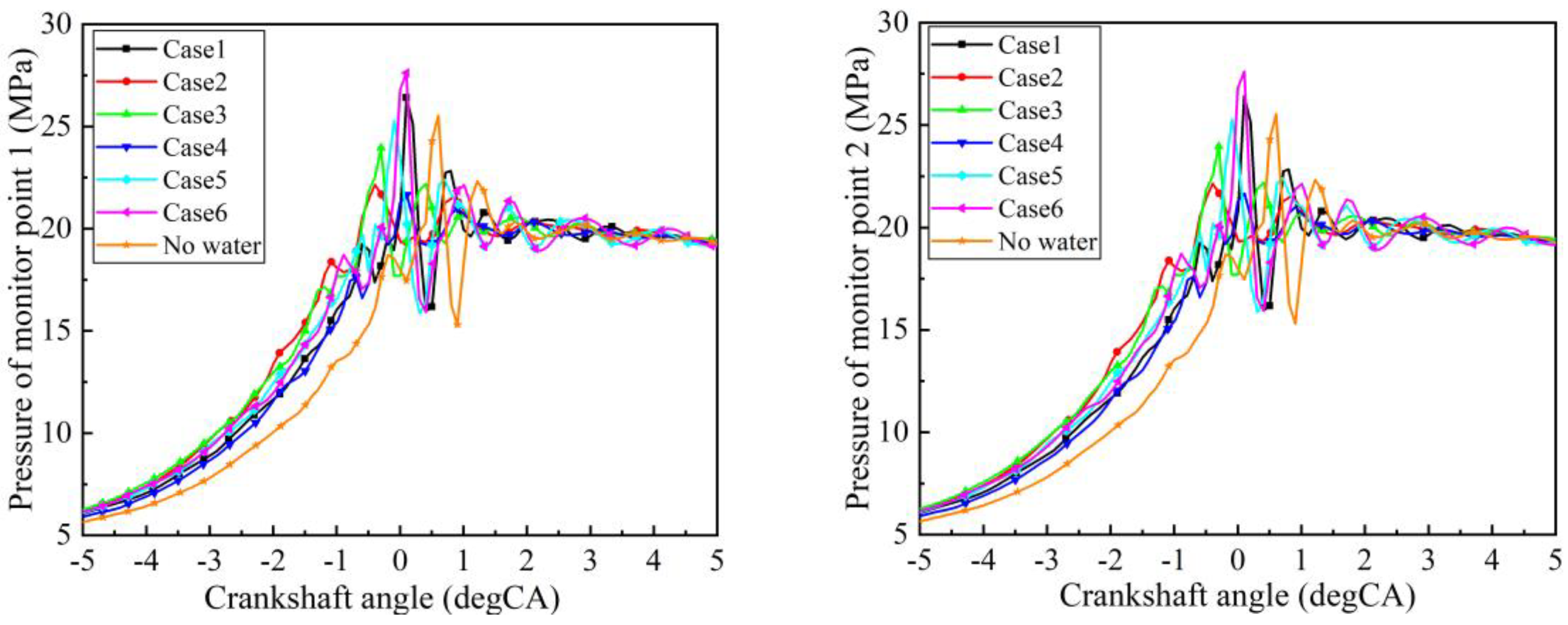

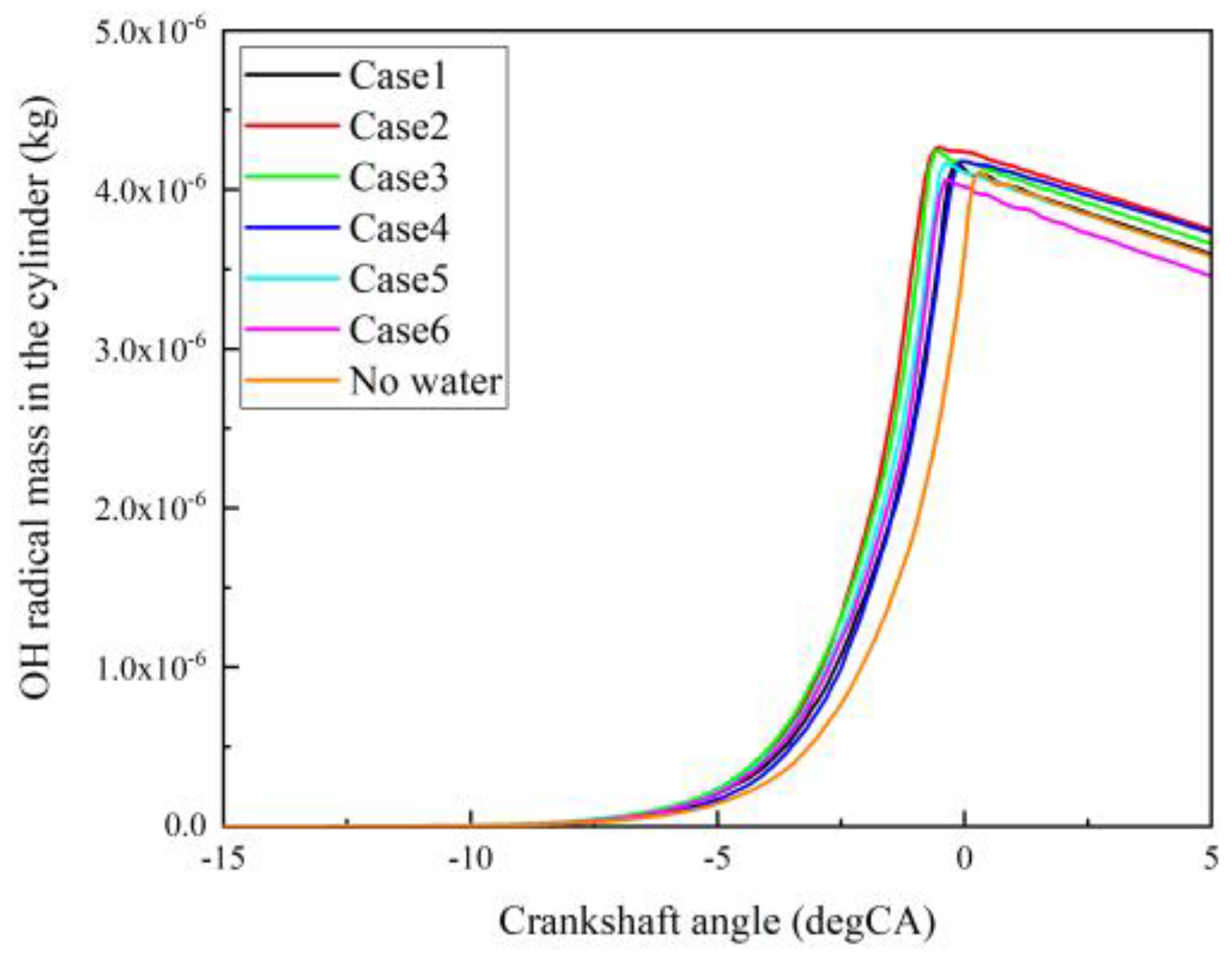

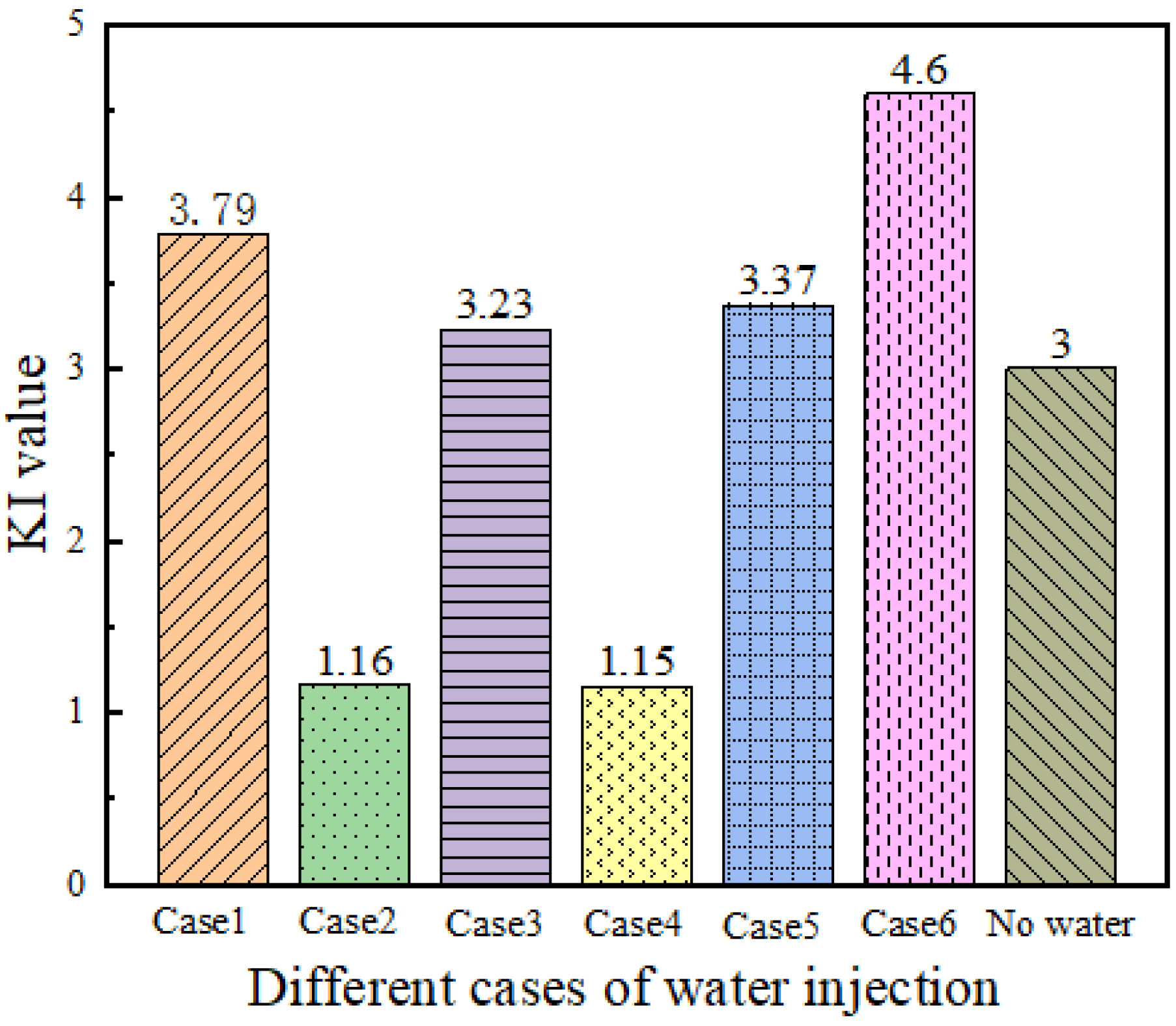

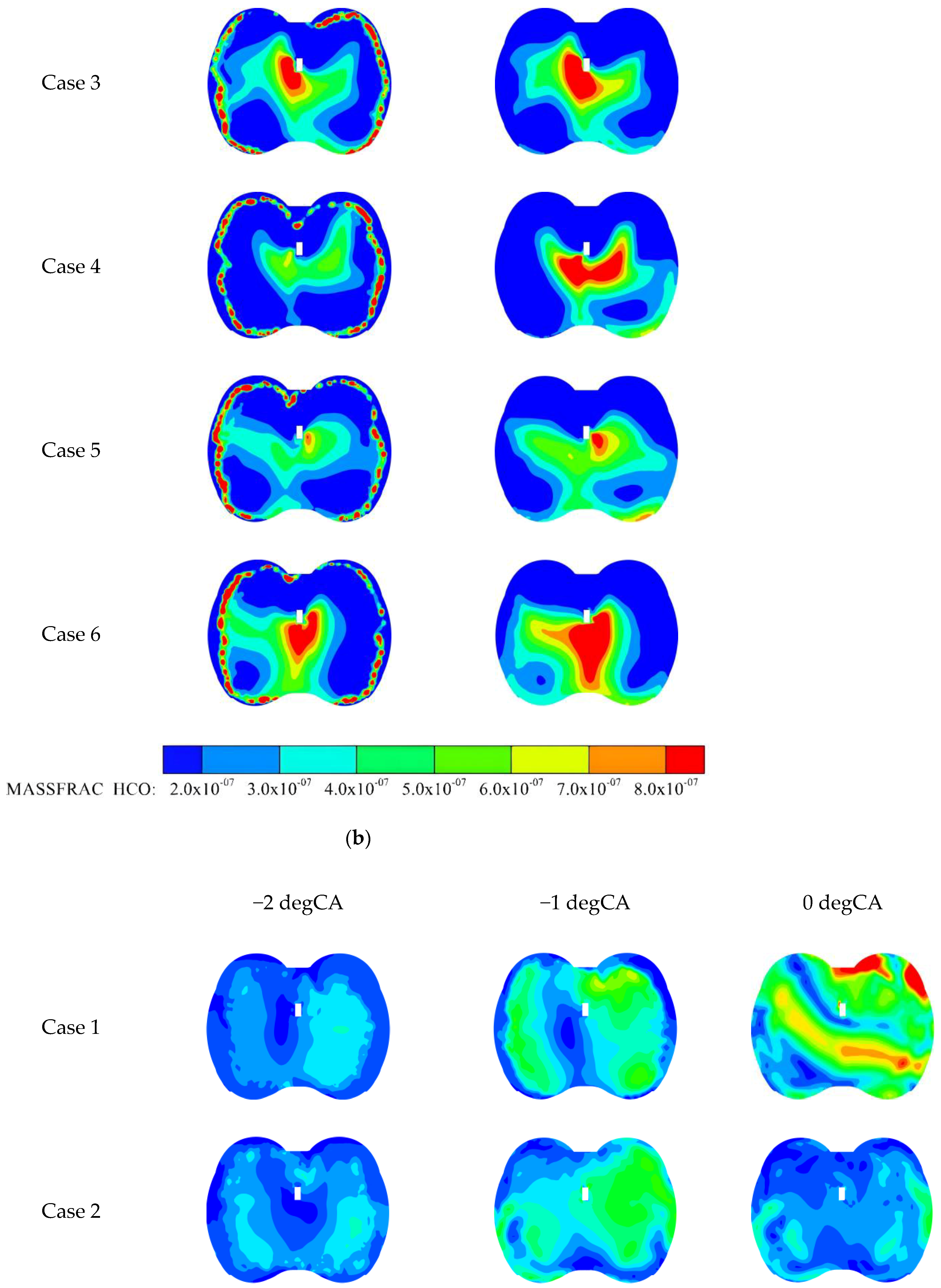

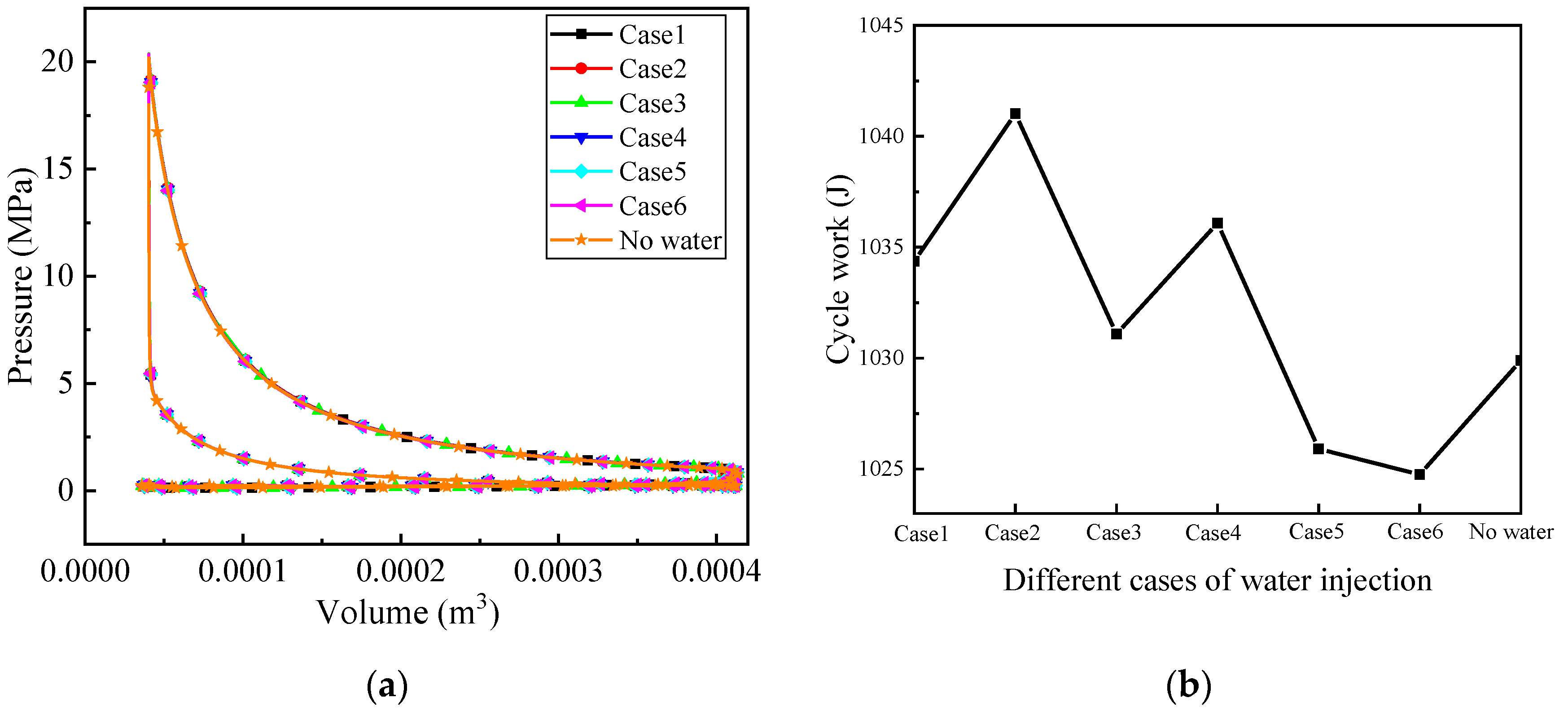

3.2. Different Water Injection Cases: Combustion Characteristics and Knock Suppression

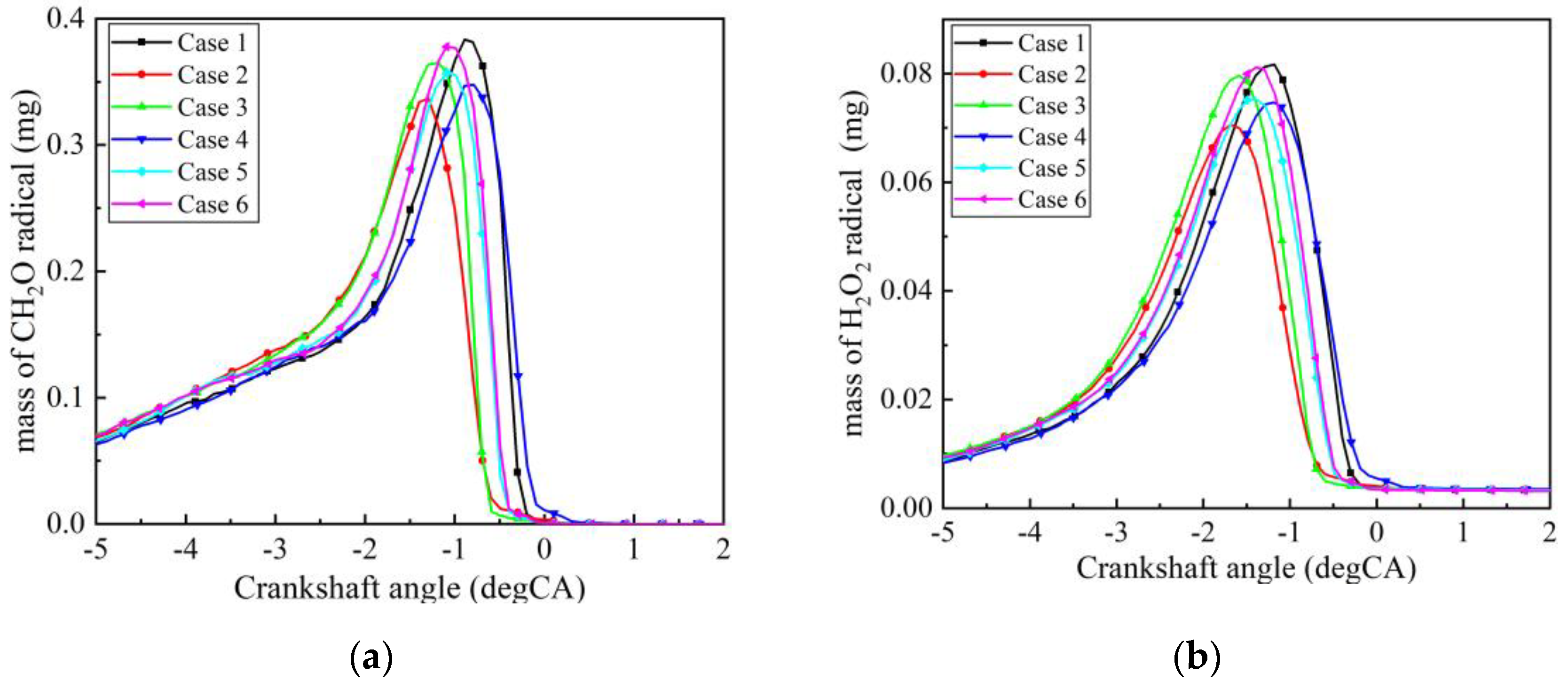

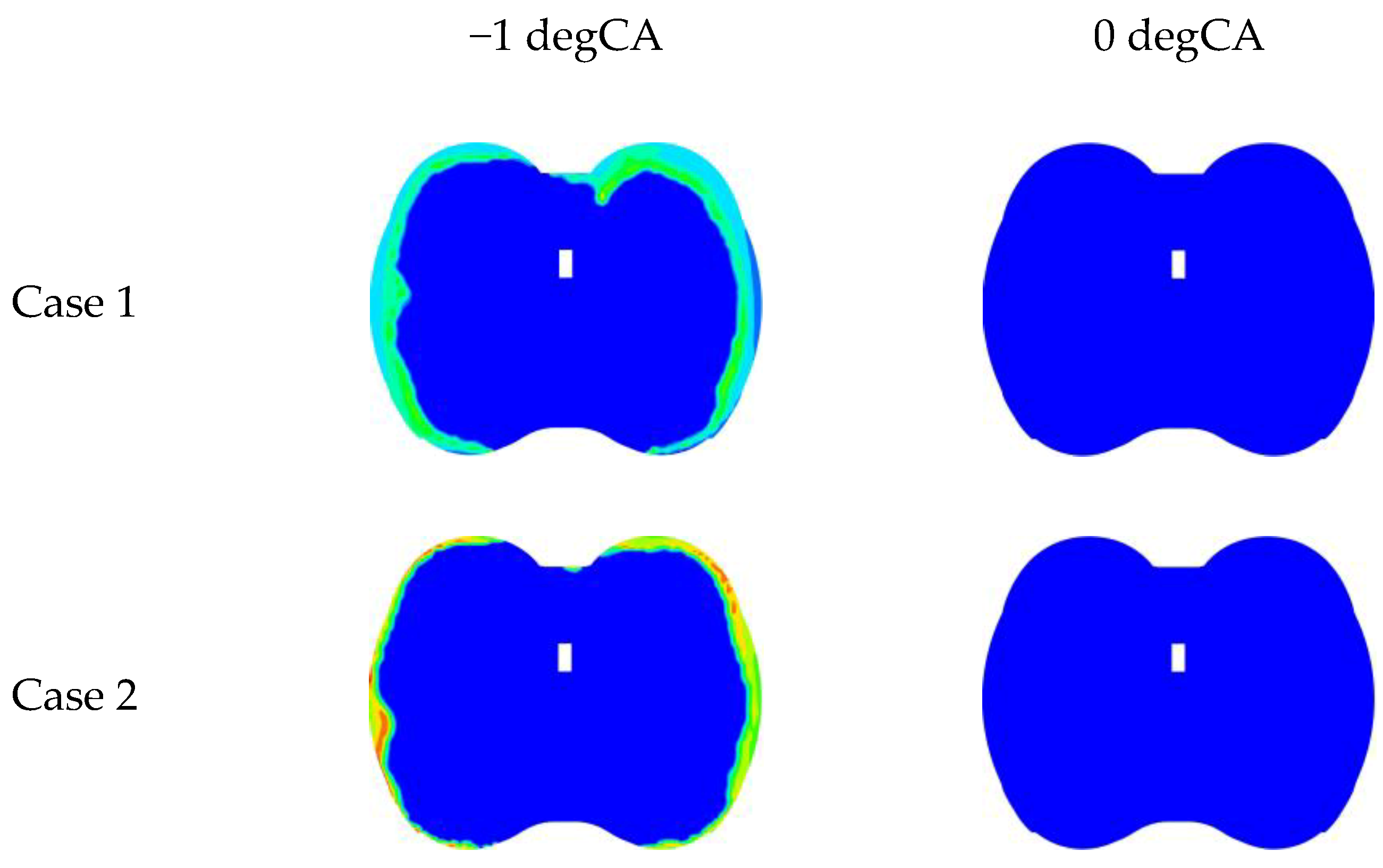

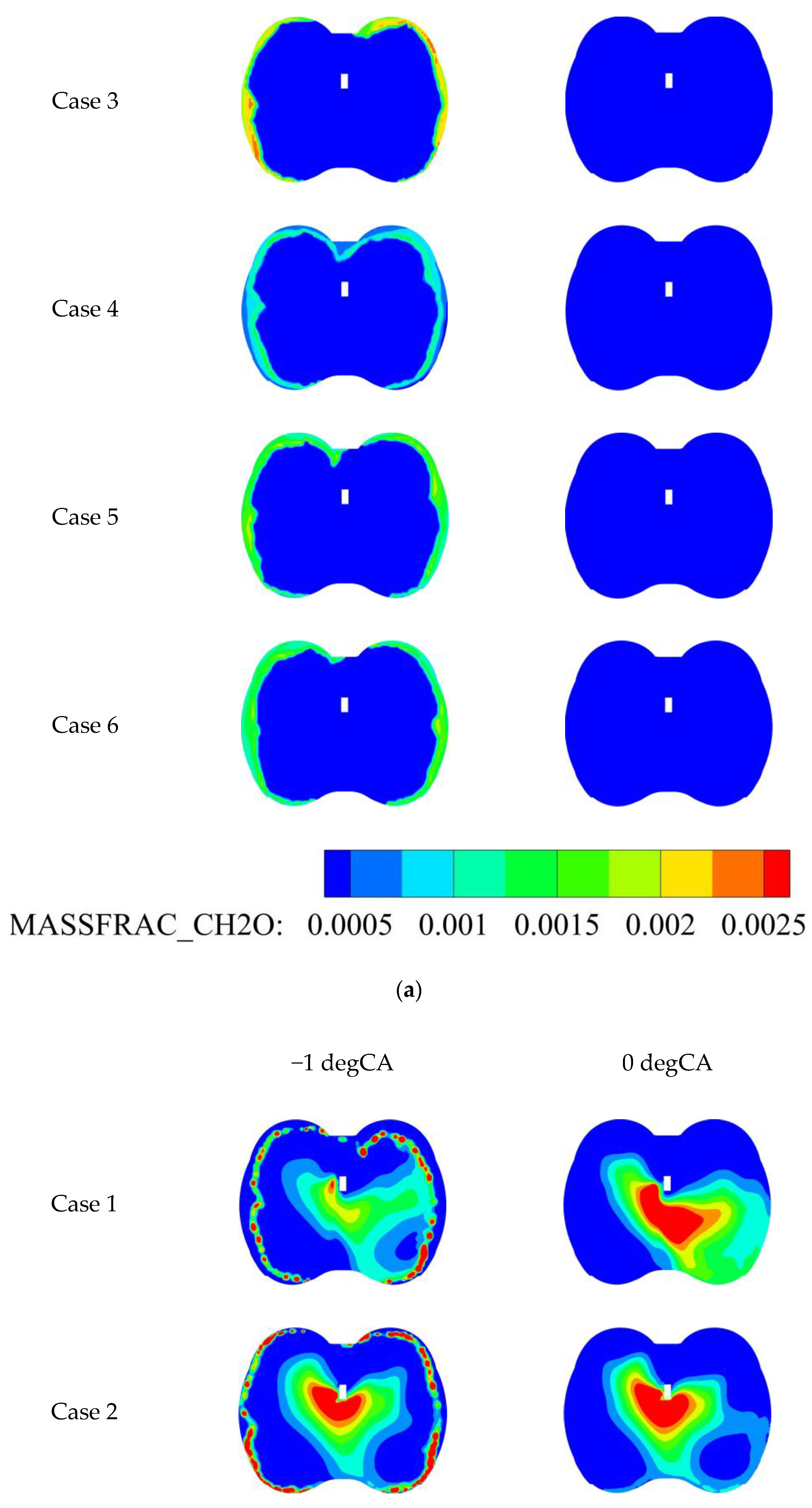

3.3. Different Water Injection Cases: Intermediate Combustion Products

3.4. Different Water Injection Cases: The Emissions Characteristics

4. Conclusions

- Different vertical distances and injection directions affect the distribution of water in the intake port and in the cylinder. The 90° injection direction is more reasonable than the 60°, because the water in the 90° injection direction case has less impact on the intake port wall. Cases 2 and 4 had ideal injection positions, as these two cases allowed as much water as possible to enter the cylinder for evaporation, which is favorable to knock inhibition.

- The PWI technology allowed for increased air density at the intake port and therefore a lower in-cylinder equivalence ratio compared to the no water cases. In addition, in the six cases, the equivalence ratio under the intake valve was greater than that under the exhaust valve, and the TKE in the center of the cylinder was greater than that around the cylinder wall. The center of the cylinder of case 2 showed the largest TKE due to differences in the flow of the mixture caused by differences in injector installation, which facilitates the propagation of the flame to the cylinder wall and reduces the tendency to knock.

- The difference in water injector position has little effect on the peak in-cylinder temperature and pressure, but affects the combustion rate. Cases 2 and 4 successfully suppressed the knock, so that the pressure oscillations were not significant in both cases. Interestingly, the water injection promoted the generation of OH radicals in the cylinder, so the PWI cases had a shorter combustion delay period compared to the no water cases.

- Strong low temperature reactions tend to cause a knock in the high-temperature reaction stage. When the knock occurs, the local burned gas velocity in the cylinder will exceed 100 m/s. The cycle work of case 2 was the largest. Because the knock was suppressed, the turbulence intensity in the cylinder and the heat transfer loss were low.

- PWI (except for in case 6) can reduce in-cylinder soot emissions and increase NOX emissions. PWI (except for in case 6) also reduced in-cylinder UHC and CO emissions. Case 6 caused combustion deterioration due to too high in-cylinder oil film quality.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Golzari, R.; Zhao, H.; Hall, J.; Bassett, M.; Williams, J.; Pearson, R. Impact of intake port injection of water on boosted downsized gasoline direct injection engine combustion, efficiency and emissions. Int. J. Engine Res. 2019, 22, 295–315. [Google Scholar] [CrossRef]

- Amann, M.; Alger, T.; Mehta, D. The effect of EGR on low-speed pre-ignition in boosted SI engines. In Proceedings of the SAE 2011 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2011. [Google Scholar]

- Haenel, P.; Seyfried, P.; Kleeberg, H.; Tomazic, D. Systematic approach to analyze and characterize pre-ignition events in turbocharged direct-injected gasoline engines. In Proceedings of the SAE 2011 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2011. [Google Scholar]

- Hudson, C.; Gao, X.; Stone, R. Knock measurement for fuel evaluation in spark ignition engines. Fuel 2001, 80, 395–407. [Google Scholar] [CrossRef]

- Zahdeh, A.; Rothenberger, P.; Nguyen, W.; Anbarasu, M.; Schmuck-Soldan, S.; Schaefer, J.; Goebel, T. Fundamental Approach to Investigate Pre-Ignition in Boosted SI Engines. SAE Int. J. Engines 2011, 4, 246–273. [Google Scholar] [CrossRef]

- Grandin, B.; Denbratt, I.; Bood, J.; Brackmann, C.; Bengtsson, P.-E.; Gogan, A.; Mauss, F.; Sunden, B. Heat release in the end-gas prior to knock in lean, rich and stoichiometric mixtures with and without EGR. In Proceedings of the SAE 2002 World Congress, Detroit, MI, USA, 4–7 March 2002. [Google Scholar]

- Abu-Qudais, M. Exhaust gas temperature for knock detection and control in spark ignition engine. Energy Convers. Manag. 1996, 37, 1383–1392. [Google Scholar] [CrossRef]

- Lim, G.; Lee, S.; Park, C.; Choi, Y.; Kim, C. Effect of ignition timing retard strategy on NOx reduction in hydrogen-compressed natural gas blend engine with increased compression ratio. Int. J. Hydrogen Energy 2014, 39, 2399–2408. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, H.; Reitz, R.D. Knocking combustion in spark-ignition engines. Prog. Energy Combust. Sci. 2017, 61, 78–112. [Google Scholar] [CrossRef]

- Su, J.; Xu, M.; Li, T.; Gao, Y.; Wang, J. Combined effects of cooled EGR and a higher geometric compression ratio on thermal efficiency improvement of a downsized boosted spark-ignition direct-injection engine. Energy Convers. Manag. 2014, 78, 65–73. [Google Scholar] [CrossRef]

- Potteau, S.; Lutz, P.; Leroux, S.; Moroz, S.; Tomas, E. Cooled EGR for a turbo SI engine to reduce knocking and fuel consumption. In Proceedings of the Powertrain and Fluid Systems Conference and Exhibition, Rosemont, IL, USA, 29 October–1 November 2007. [Google Scholar]

- Zheng, M.; Reader, G.T.; Hawley, J.G. Diesel engine exhaust gas recirculation––a review on advanced and novel concepts. Energy Convers. Manag. 2004, 45, 883–900. [Google Scholar] [CrossRef]

- Morikawa, K.; Moriyoshi, Y.; Kuboyama, T.; Imai, Y.; Yamada, T.; Hatamura, K. Investigation and Improvement of LSPI Phenomena and Study of Combustion Strategy in Highly Boosted SI Combustion in Low Speed Range. In Proceedings of the SAE 2015 World Congress and Exhibition, Detroit, MI, USA, 21–23 April 2015. [Google Scholar]

- Teodosio, L.; De Bellis, V.; Bozza, F. Combined Effects of Valve Strategies, Compression Ratio, Water Injection, and Cooled EGR on the Fuel Consumption of a Small Turbocharged VVA Spark-Ignition Engine. SAE Int. J. Engines 2018, 11, 643–656. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Boles, M.A. Thermodynamics: An engineering approach, second edition. Appl. Mech. Rev. 1995, 48, B66. [Google Scholar]

- Chen, B.; Zhang, L.; Han, J.; Chen, X. Investigating the effect of increasing specific heat and the influence of charge cooling of water injection in a TGDI engine. Appl. Therm. Eng. 2019, 149, 1105–1113. [Google Scholar] [CrossRef]

- Wei, X.; Qian, Y.; Meng, S.; Hua, Y.; Qiu, L.; Sun, Y.; Wan, J.; Zhang, X. Effects of Coupling Port Water Injection and Egr on the Spray Water Evolution, Combustion and Emission of a Premixed Stoichiometric Natural Gas Engine: A Numerical Study. Fuel 2022, 324, 124315. [Google Scholar] [CrossRef]

- Segawa, D.; Yamasaki, H.; Kadota, T.; Tanaka, H.; Enomoto, H.; Tsue, M. Water-coalescence in an oil-in-water emulsion droplet burning under microgravity. Proc. Combust. Inst. 2000, 28, 985–990. [Google Scholar] [CrossRef]

- Samec, N.; Kegl, B.; Dibble, R.W. Numerical and experimental study of water/oil emulsified fuel combustion in a diesel engine. Fuel 2002, 81, 2035–2044. [Google Scholar] [CrossRef]

- Abu-Zaid, M. Performance of single cylinder, direct injection Diesel engine using water fuel emulsions. Energy Convers. Manag. 2004, 45, 697–705. [Google Scholar] [CrossRef]

- Li, A.; Zheng, Z.; Peng, T. Effect of water injection on the knock, combustion, and emissions of a direct injection gasoline engine. Fuel 2020, 268, 117376. [Google Scholar] [CrossRef]

- Sun, X.; Ning, J.; Liang, X.; Jing, G.; Chen, Y.; Chen, G. Effect of direct water injection on combustion and emissions characteristics of marine diesel engines. Fuel 2022, 309, 122213. [Google Scholar] [CrossRef]

- Zhang, Z.; Kang, Z.; Jiang, L.; Chao, Y.; Deng, J.; Hu, Z.; Li, L.; Wu, Z. Effect of direct water injection during compression stroke on thermal efficiency optimization of common rail diesel engine. In Proceedings of the 9th International Conference on Applied Energy, ICAE 2017, Cardiff, UK, 21–24 August 2017; pp. 1251–1258. [Google Scholar]

- Liu, Z.; Zheng, Z.; Zhang, Z.; Li, M. The effect of direct water injection on the combustion stability of a downsized boost engine under high compression ratios and load conditions. Fuel 2022, 308, 121945. [Google Scholar] [CrossRef]

- Arabaci, E.; Icingur, Y.; Solmaz, H.; Uyumaz, A.; Yilmaz, E. Experimental investigation of the effects of direct water injection parameters on engine performance in a six-stroke engine. Energy Convers. Manag. 2015, 98, 89–97. [Google Scholar] [CrossRef]

- Wang, J.; Duan, X.; Liu, Y.; Wang, W.; Liu, J.; Lai, M.-C.; Li, Y.; Guo, G. Numerical investigation of water injection quantity and water injection timing on the thermodynamics, combustion and emissions in a hydrogen enriched lean-burn natural gas SI engine. Int. J. Hydrogen Energy 2020, 45, 17935–17952. [Google Scholar] [CrossRef]

- Ishida, M.; Ueki, H.; Sakaguchi, D. Prediction of NOx reduction rate due to port water injection in a di diesel engine. In Proceedings of the International Fall Fuels and Lubricants Meeting and Exposition, Tulsa, OK, USA, 13–16 October 1997. [Google Scholar]

- Nicholls, J.E.; Ei-Messiri, I.A.; Newhali, H.K. Inlet manifold water injection for control of nitrogen oxides—Theory and experiment. Sae Trans. 1969, 78, 167–176. [Google Scholar]

- Cavina, N.; Rojo, N.; Businaro, A.; Brusa, A.; Corti, E.; De Cesare, M. Investigation of Water Injection Effects on Combustion Characteristics of a GDI TC Engine. In Proceedings of the SAE 13th International Conference on Engines and Vehicles, ICE 2017, Capri, Napoli, Italy, 10–14 September 2017. [Google Scholar]

- Berni, F.; Breda, S.; Lugli, M.; Cantore, G. A numerical investigation on the potentials of water injection to increase knock resistance and reduce fuel consumption in highly downsized GDI engines. In Proceedings of the 69th Conference of the Italian Thermal Engineering Association, ATI 2014, Milan, Italy, 10–13 September 2015; pp. 826–835. [Google Scholar]

- Worm, J.; Naber, J.; Duncan, J.; Barros, S.; Atkinson, W. Water Injection as an Enabler for Increased Efficiency at High-Load in a Direct Injected, Boosted, SI Engine. SAE Int. J. Engines 2017, 10, 951–958. [Google Scholar] [CrossRef]

- Tornatore, C.; Siano, D.; Marchitto, L.; Iacobacci, A.; Valentino, G.; Bozza, F. Water Injection: A Technology to Improve Performance and Emissions of Downsized Turbocharged Spark Ignited Engines. SAE Int. J. Engines 2017, 10, 2319–2329. [Google Scholar] [CrossRef]

- Jones, W.P.; Launder, B.E. Prediction of laminarization with a two- equation model of turbulence. Int. J. Heat Mass Transf. 1972, 15, 301–314. [Google Scholar] [CrossRef]

- Senecal, P.K.; Pomraning, E.; Richards, K.J.; Briggs, T.E.; Choi, C.Y.; McDavid, R.M.; Patterson, M.A. Multi-dimensional modeling of direct-injection diesel spray liquid length and flame lift-off length using cfd and parallel detailed chemistry. In Proceedings of the 2003 SAE World Congress, Detroit, MI, USA, 3–6 March 2003. [Google Scholar]

- Song, Y.; Zheng, Z.; Xiao, J. Development and validation of a reduced chemical kinetic mechanism for supercritical gasoline of GDI engine. Fuel 2019, 241, 676–685. [Google Scholar] [CrossRef]

- Liang, L.; Reitz, R.D.; Iyer, C.O.; Yi, J. Modeling knock in spark-ignition engines using a G-equation combustion model incorporating detailed chemical kinetics. In Proceedings of the 2007 World Congress, Detroit, MI, USA, 16–19 April 2007. [Google Scholar]

- Zhen, X.; Wang, Y.; Xu, S.; Zhu, Y. Study of knock in a high compression ratio spark-ignition methanol engine by multi-dimensional simulation. Energy 2013, 50, 150–159. [Google Scholar] [CrossRef]

- Zhen, X.; Wang, Y.; Zhu, Y. Study of knock in a high compression ratio SI methanol engine using LES with detailed chemical kinetics. Energy Convers. Manag. 2013, 75, 523–531. [Google Scholar] [CrossRef]

- Singh, D.; Nishiie, T.; Tanvir, S.; Qiao, L. An experimental and kinetic study of syngas/air combustion at elevated temperatures and the effect of water addition. Fuel 2012, 94, 448–456. [Google Scholar] [CrossRef]

- Merola, S.S.; Vaglieco, B.M. Knock investigation by flame and radical species detection in spark ignition engine for different fuels. Energy Convers. Manag. 2007, 48, 2897–2910. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Reitz, R.D. Pressure Oscillation and Chemical Kinetics Coupling during Knock Processes in Gasoline Engine Combustion. Energy Fuels 2012, 26, 7107–7119. [Google Scholar] [CrossRef]

| Parameter | Numerical Value |

|---|---|

| Number of cylinders | 1 |

| Bore diameter (mm) | 76 |

| Stroke (mm) | 82.6 |

| Connecting rod length (mm) | 139.3 |

| Displacement (L) | 0.375 |

| CR | 9.5 |

| Parameter | Numerical Value |

|---|---|

| Rotational speed (rpm) | 2000 |

| Ignition time (degCA) | 5.67 |

| Start of fuel injection time (degCA) | −280 |

| Fuel injection duration (degCA) | 52.0 |

| Mass of fuel injection (mg) | 65 |

| Intake valves opening/closing timing (degCA) | −409/−128 |

| Exhaust valves opening/closing timing (degCA) | 150/395 |

| Model | Setting |

|---|---|

| Turbulence model | k-ε double equation |

| Combustion model | SAGE |

| Fuel fracture model | KH-RT |

| Fuel wall model | Wall film |

| Collision model | NTC collision |

| Fuel evaporation model | Frossling |

| Wall heat transfer model | O’Rourke and Amsden |

| NOx model | Extended Zeldovich |

| Soot model | Hiroyasu |

| Boundary | Temperature (K) |

|---|---|

| Piston head | 565.9 |

| Spark plug | 1100.0 |

| Cylinder wall | 500.0 |

| Cylinder inside | 565 |

| Intake port wall | 350 |

| Exhaust port wall | 1064.65 |

| Encrypted Location | Encrypted Levels |

|---|---|

| Cylinder | 2 |

| Intake valve angle | 4 |

| Exhaust valve angle | 4 |

| Source | 4 |

| Fuel injector | 4 |

| Water injector | 4 |

| Parameter | Low-Speed | High-Speed |

|---|---|---|

| Start of fuel injection time (degCA) | −280 | −330 |

| Fuel injection duration (degCA) | 52.02 | 140.13 |

| Mass of fuel injection (mg) | 65 | 62 |

| Ignition time (degCA) | 5.67 | −2.7 |

| Rotational speed (r/min) | 2000 | 5600 |

| Parameter | Numerical Value |

|---|---|

| Number of cylinders | 1 |

| Bore diameter (mm) | 75 |

| Stroke (mm) | 127.5 |

| Connecting rod length (mm) | 245 |

| Displacement (L) | 0.563 |

| CR | 17 |

| Parameter | Numerical Value |

|---|---|

| CR | 10.3 |

| Ignition time (degCA) | −14 |

| Rotational speed (r/min) | 2000 |

| Parameter | Numerical Value |

|---|---|

| Water temperature (K) | 298 |

| Water injection time (degCA) | −370 |

| Water injection pressure (bar) | 5 |

| Water injection mass (mg) | 19.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Dai, X.; Zheng, Z. Numerical Simulation Study on the Effect of Port Water Injector Position on the Gasoline Direct Injection Engine. Processes 2022, 10, 1909. https://doi.org/10.3390/pr10101909

Zhang Z, Dai X, Zheng Z. Numerical Simulation Study on the Effect of Port Water Injector Position on the Gasoline Direct Injection Engine. Processes. 2022; 10(10):1909. https://doi.org/10.3390/pr10101909

Chicago/Turabian StyleZhang, Zhongjie, Xuejiao Dai, and Zhaolei Zheng. 2022. "Numerical Simulation Study on the Effect of Port Water Injector Position on the Gasoline Direct Injection Engine" Processes 10, no. 10: 1909. https://doi.org/10.3390/pr10101909

APA StyleZhang, Z., Dai, X., & Zheng, Z. (2022). Numerical Simulation Study on the Effect of Port Water Injector Position on the Gasoline Direct Injection Engine. Processes, 10(10), 1909. https://doi.org/10.3390/pr10101909