Scheduling by NSGA-II: Review and Bibliometric Analysis

Abstract

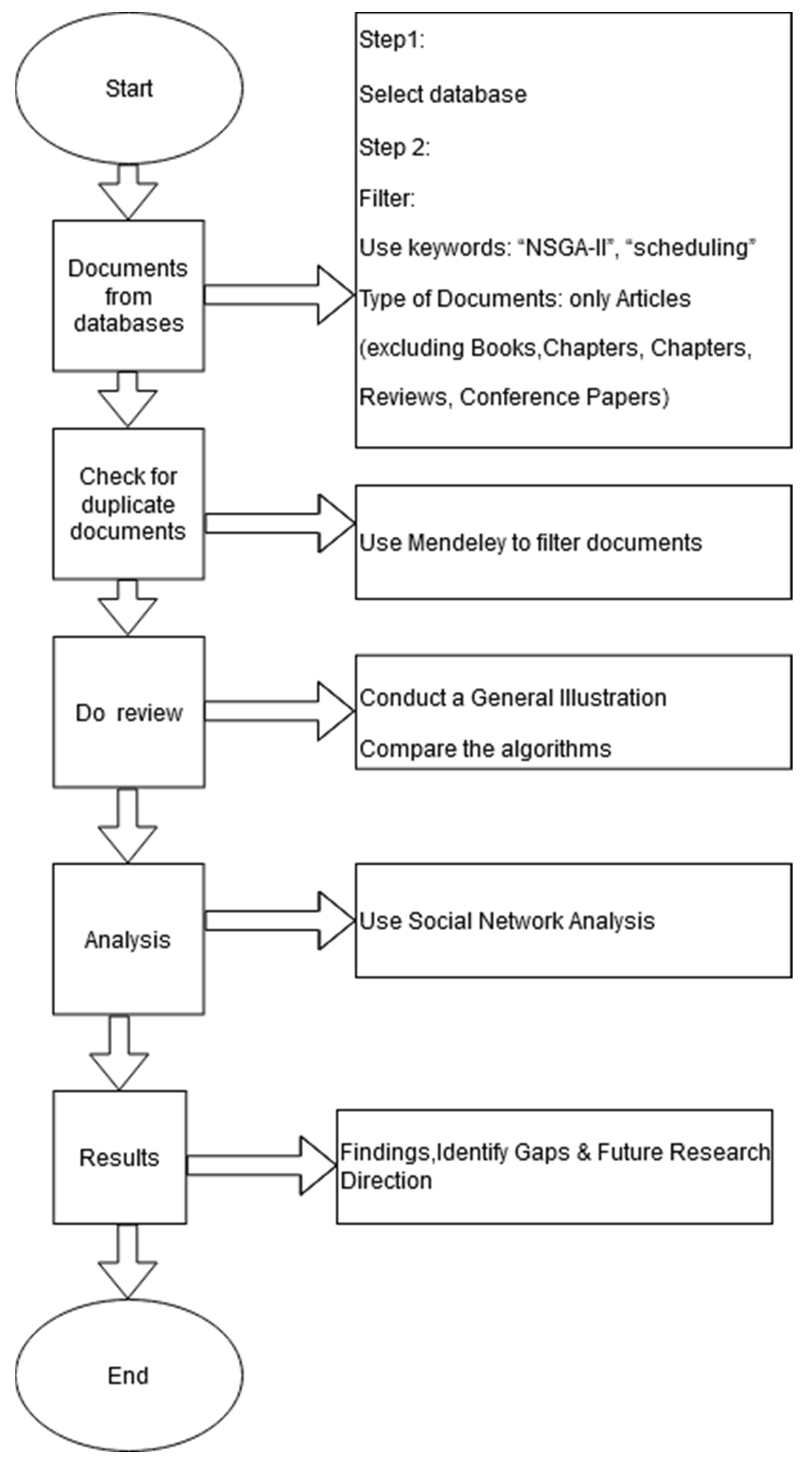

1. Introduction

- What is the basic concept of scheduling, and why is NSGA-II important (Section 2)?

- What is the contribution of NSGA-II in scheduling (Section 3.2)?

- What are the different types of scheduling? Which fields of scheduling are the most important (Section 2)?

- What are the most important problems in scheduling, how do researchers tackle them, and what do researchers find from their experiments (Section 2 and Section 3.2)?

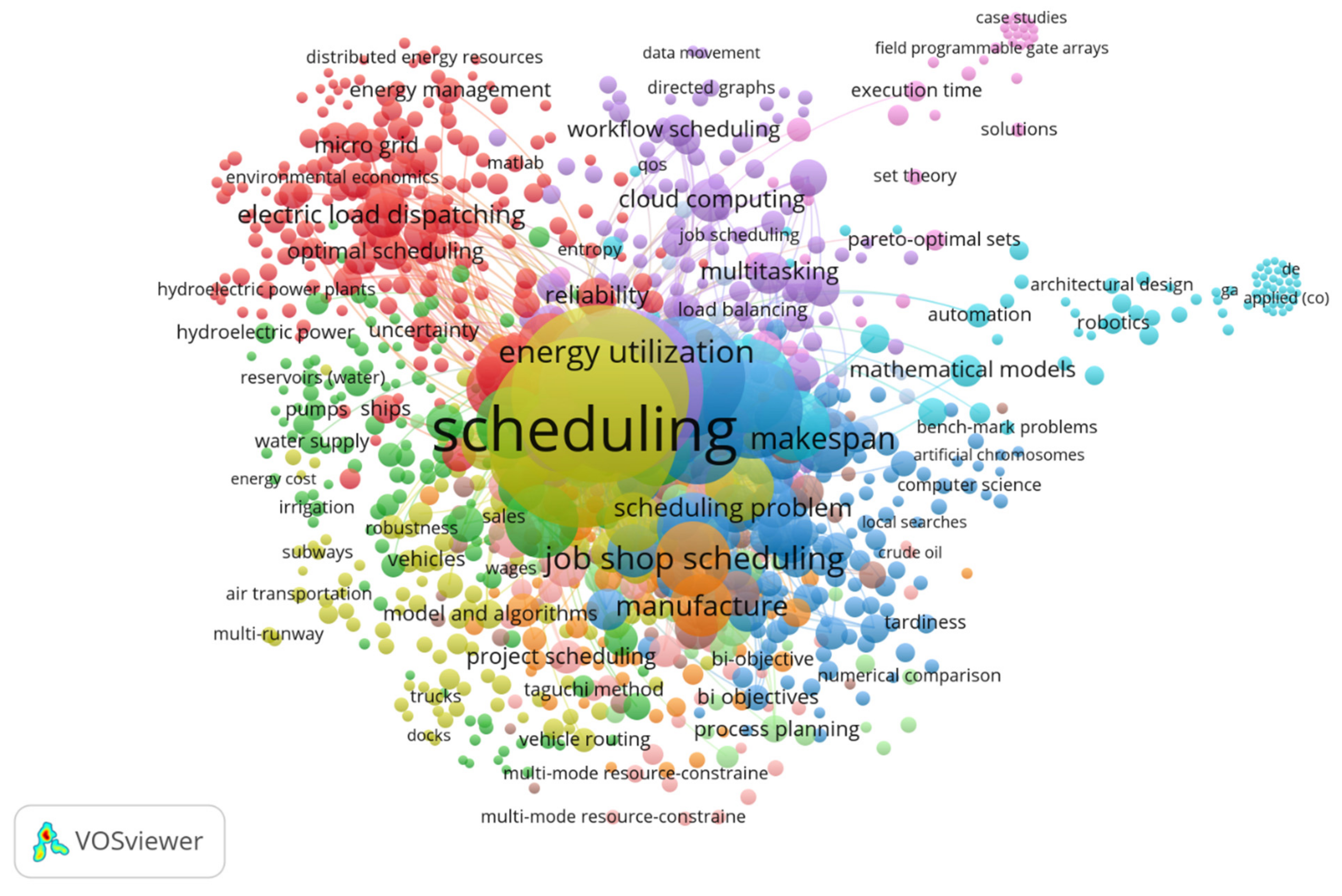

- What are the main topics and keywords regarding NSGA-II and scheduling problems (Section 4)?

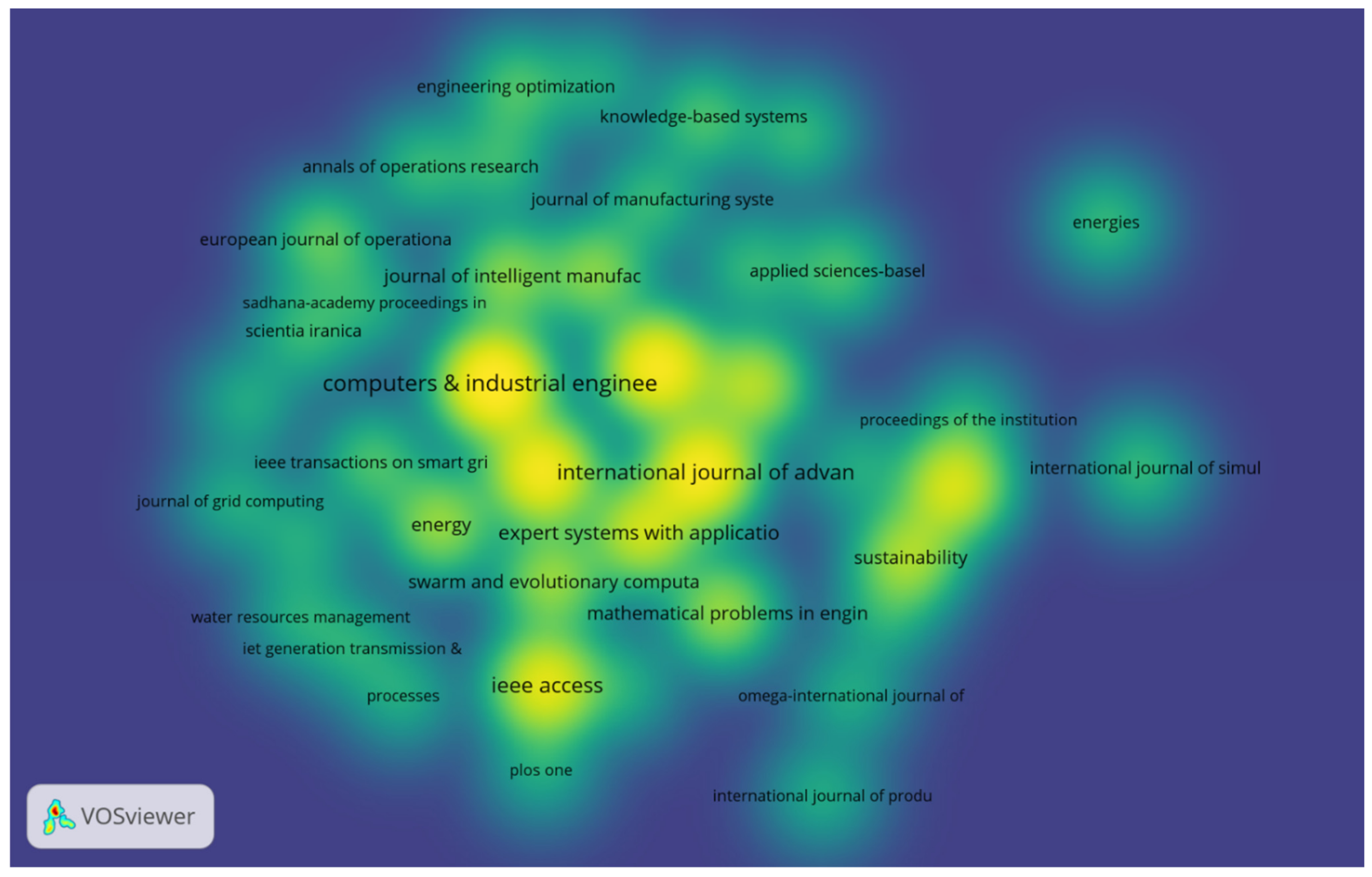

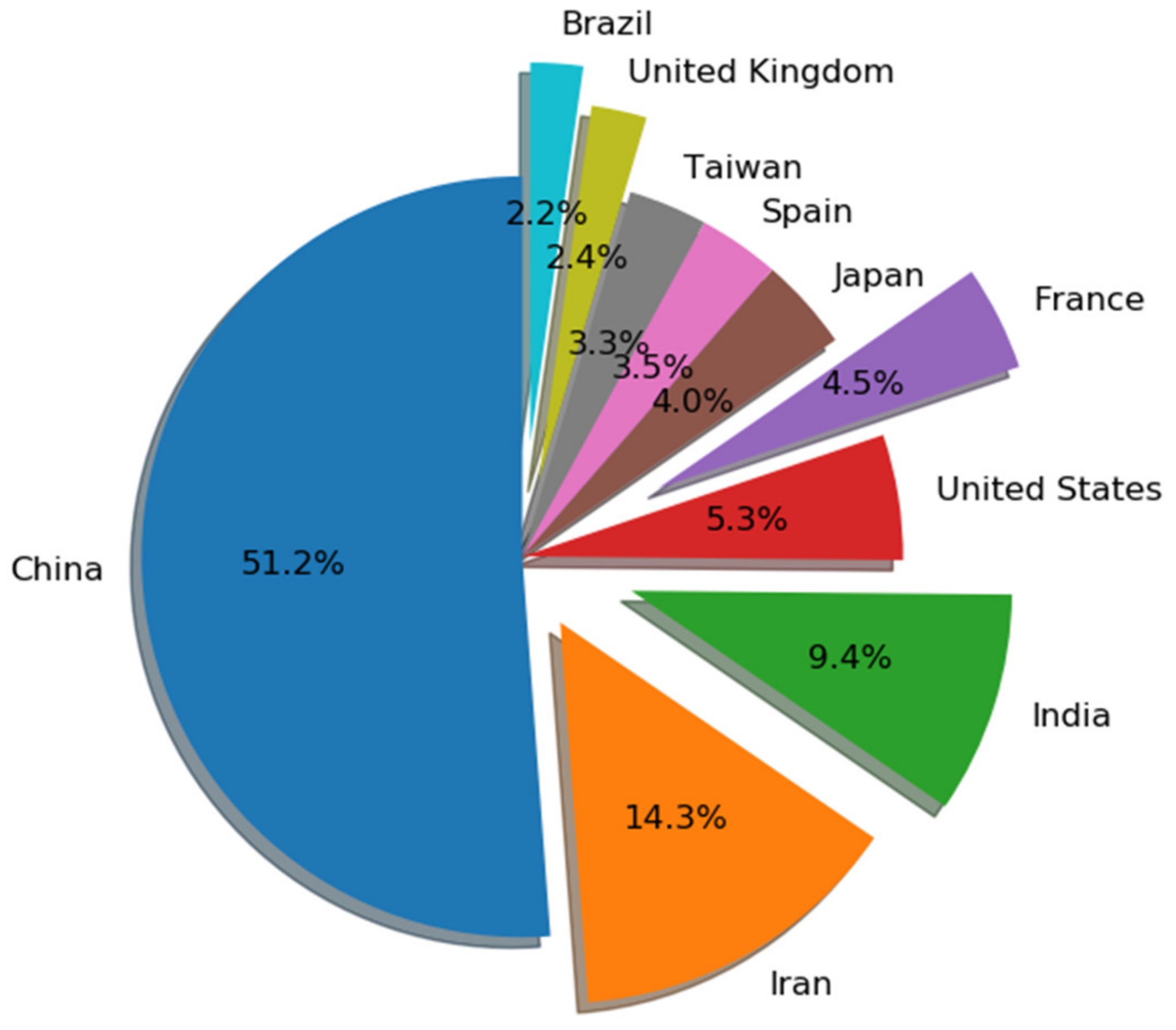

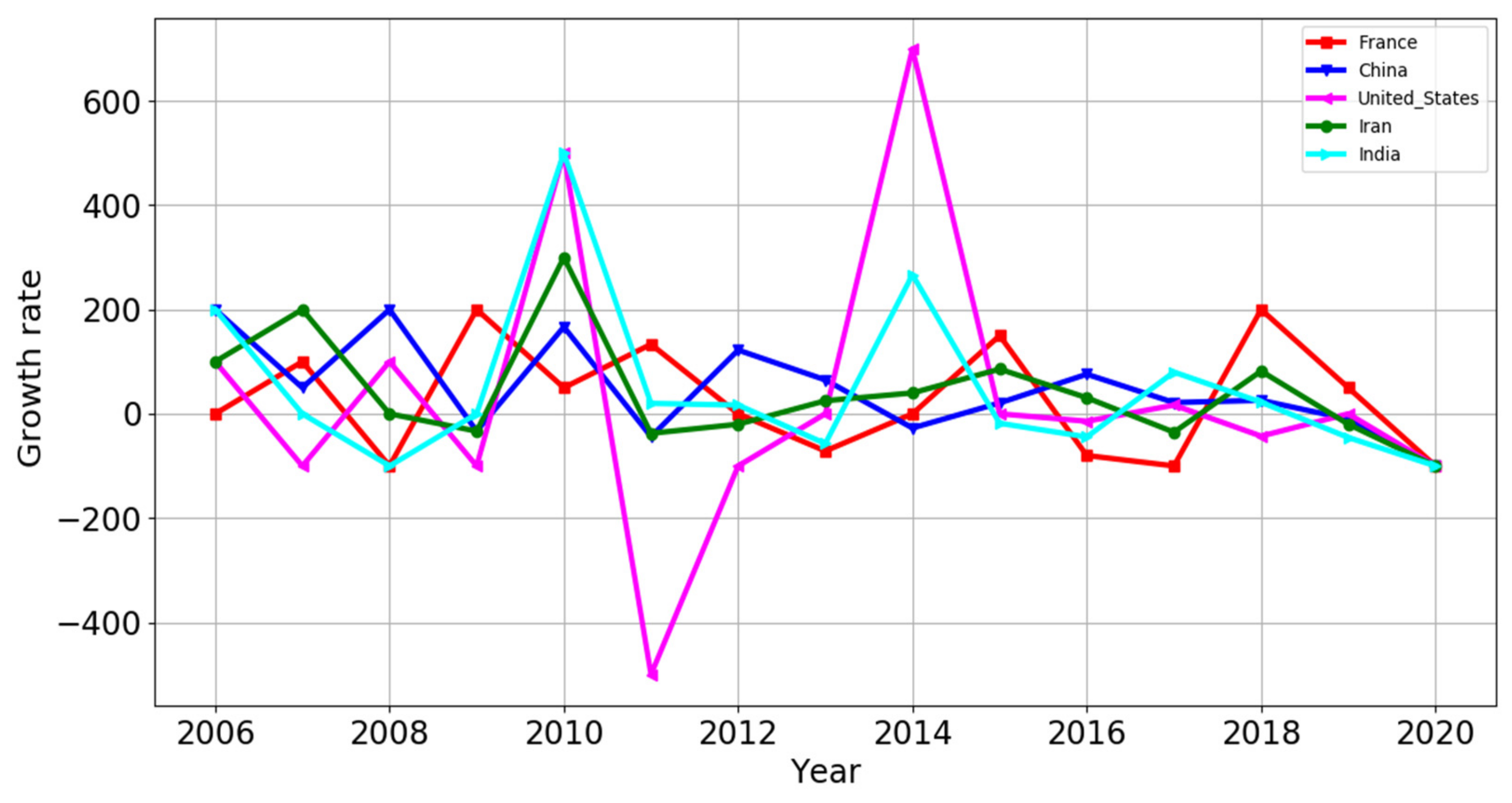

- Which journals have the most contributions in the field? Who are the best researchers in the area, and what are their respective countries of origin (Section 4)?

2. Overview of Scheduling

2.1. Scheduling

2.1.1. Scheduling in Manufacturing

Machine Scheduling

Flexible Manufacturing

Lot Scheduling System

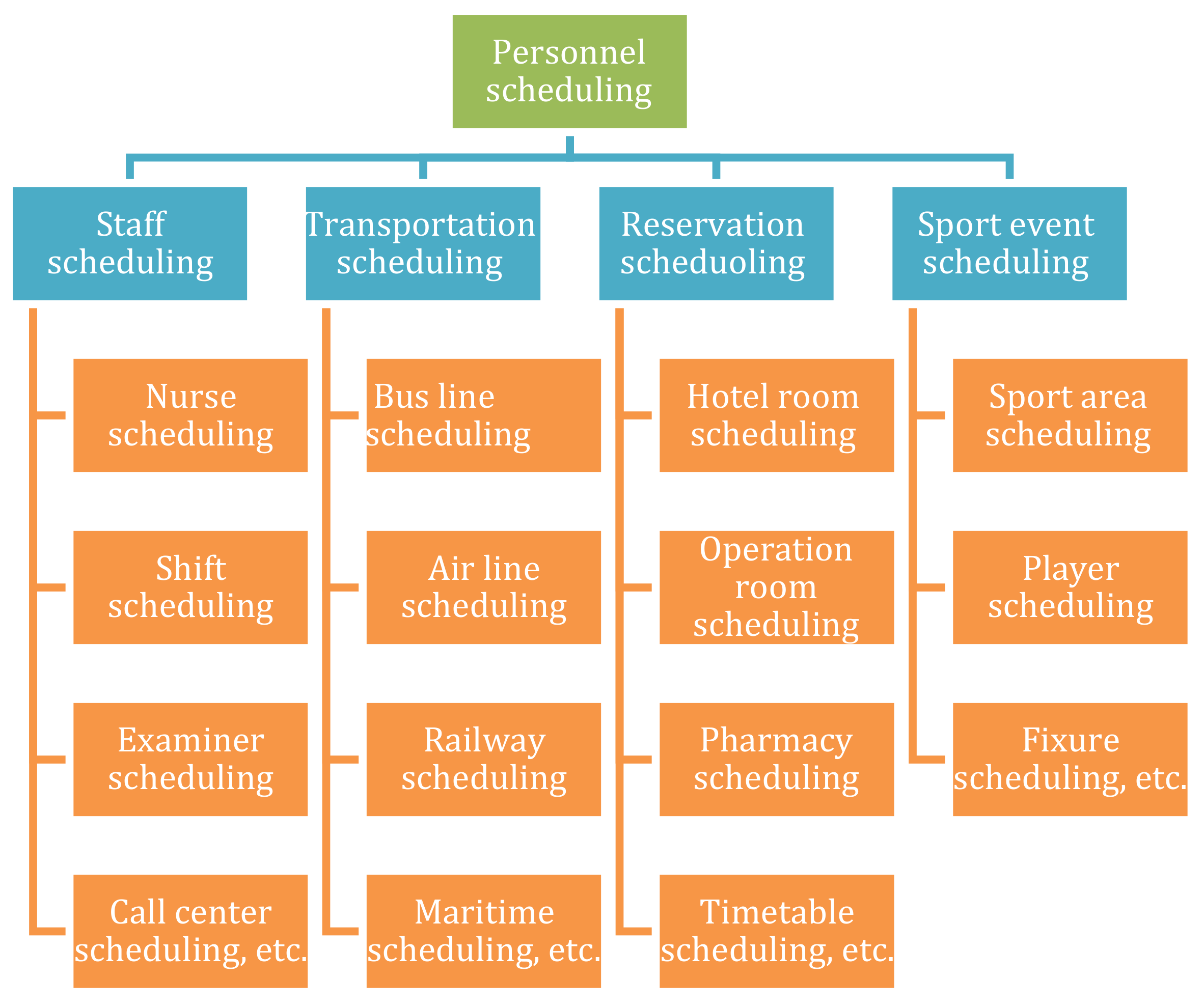

2.1.2. Personnel Scheduling

3. Scheduling Algorithms

3.1. Genetic Algorithm (GA)-Based Solution Methods

- VEGA (Vector-Evaluated Genetic Algorithm) [124]

- MOGA (Multi-Objective Genetic Algorithm) [125]

- WBGA (Weighted Based Genetic Algorithm) [126]

- RWGA (Random Weighted Genetic Algorithm) [127]

- NSGA (Non-Dominated Sorted Genetic Algorithm) [128]

- NSGA-II (Fast Non-Dominated Sorted Genetic Algorithm) [20]

- RDGA (Rank Density-Based Genetic Algorithm) [129]

- DMOEA (Dynamic Multi-Objective Evolutionary Algorithm) [132]

3.2. NSGA-II

- Computational cost in non-dominated sorting increases significantly when the population increases;

- Lack of elitism reduces the algorithm’s performance and inhibits individuals with good fitness values in different generations;

- Difficulty in the parameter settings largely affects the performance of the majority of evolutionary algorithms.

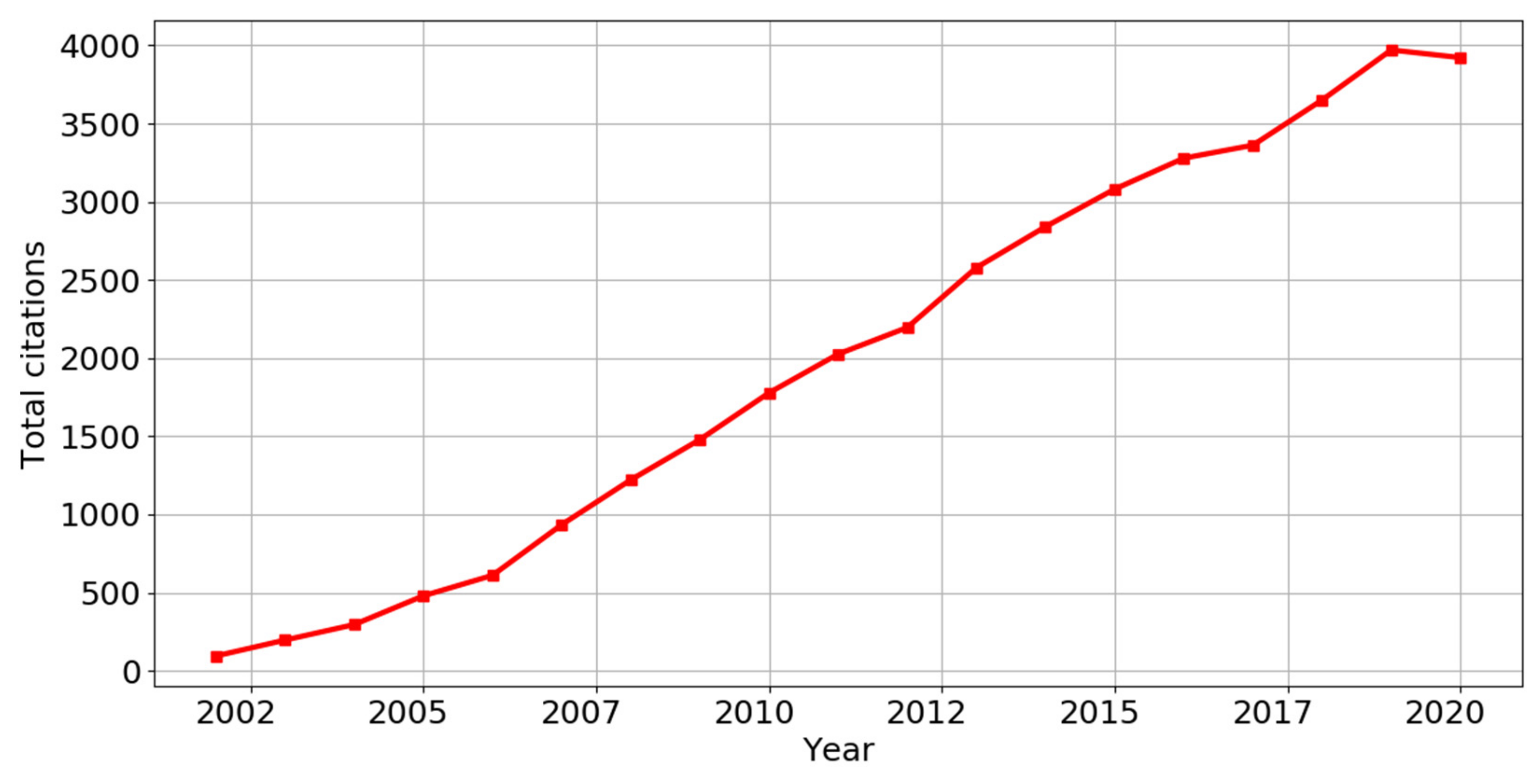

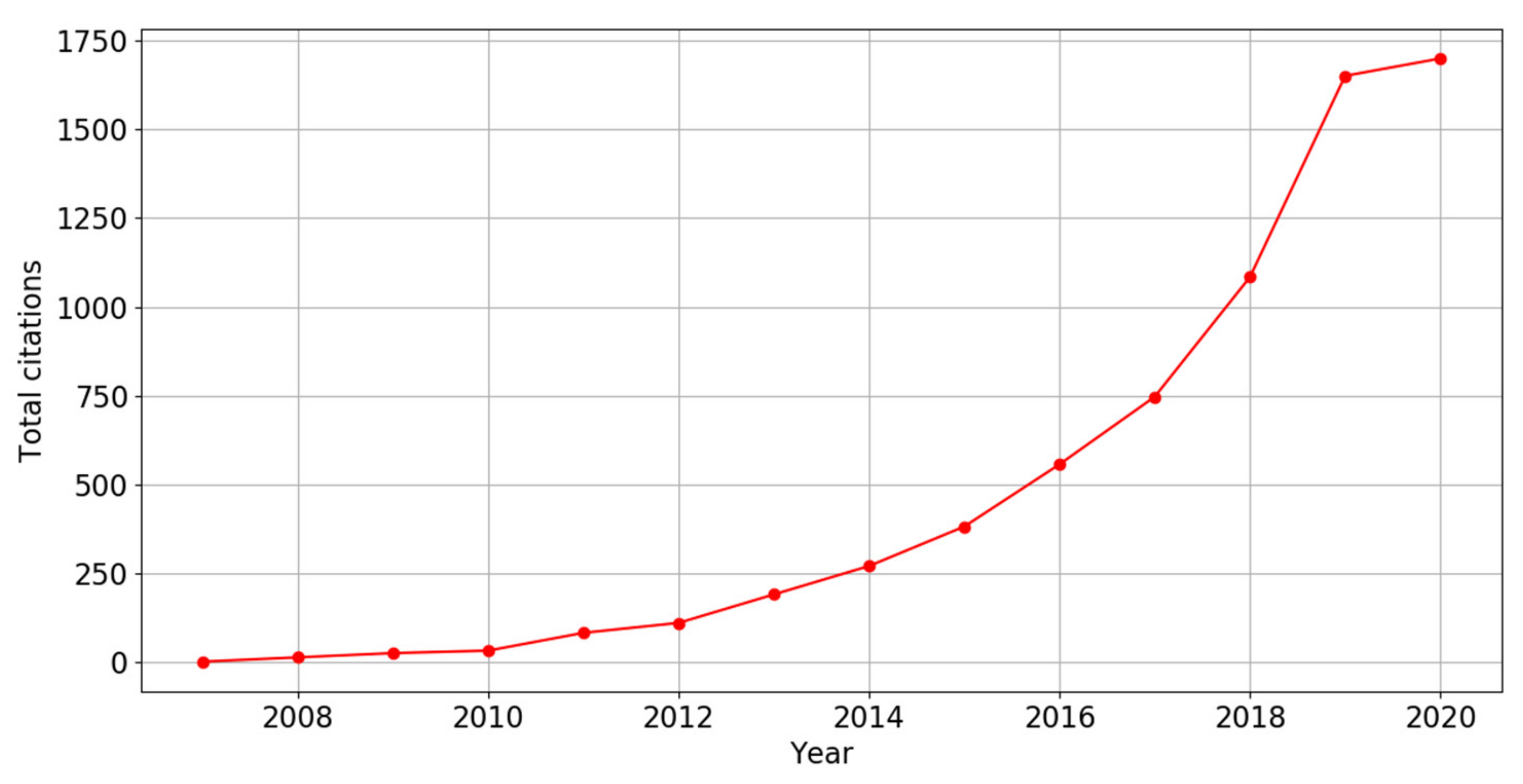

4. Scientometric Analysis

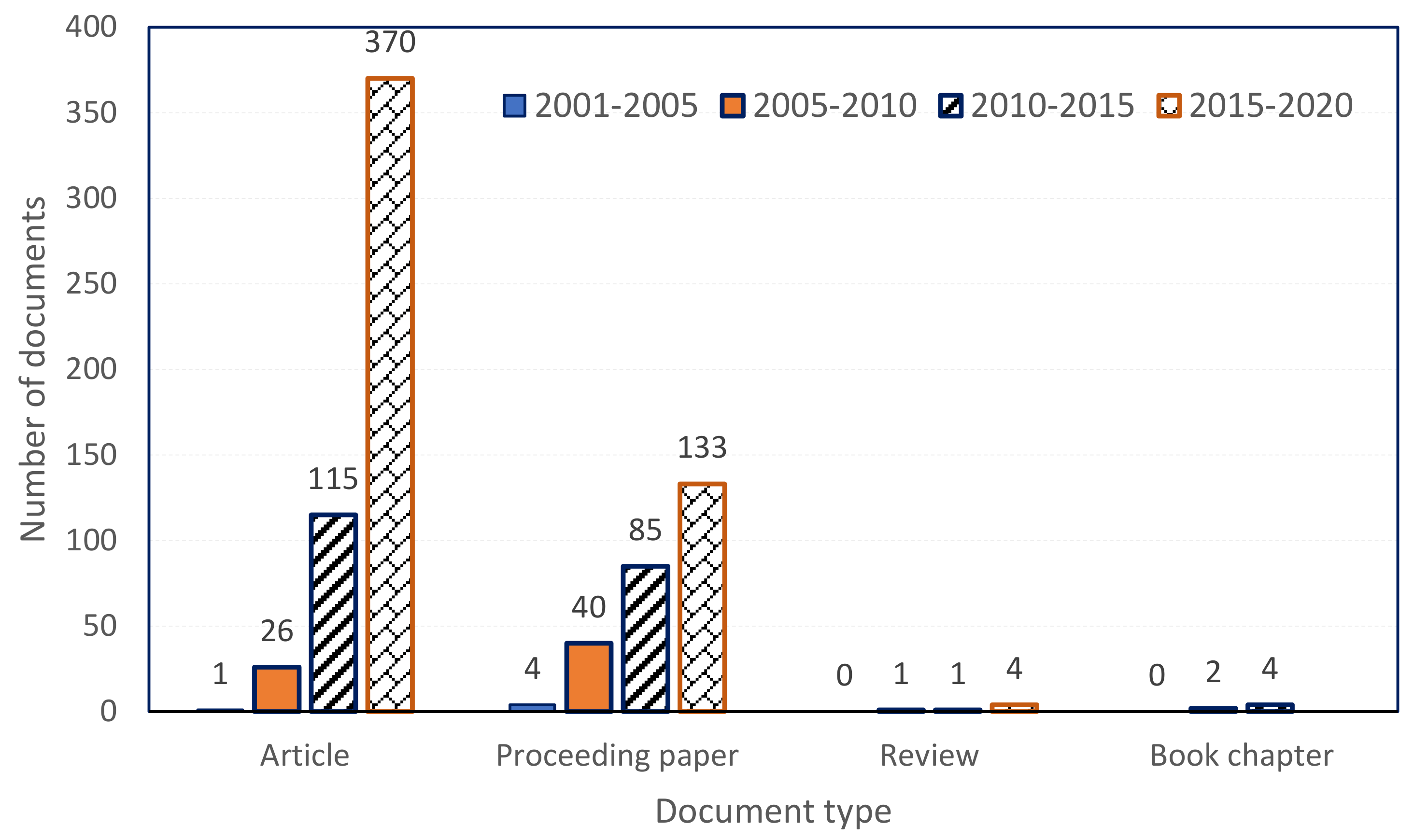

4.1. Statistics Based on Document Types

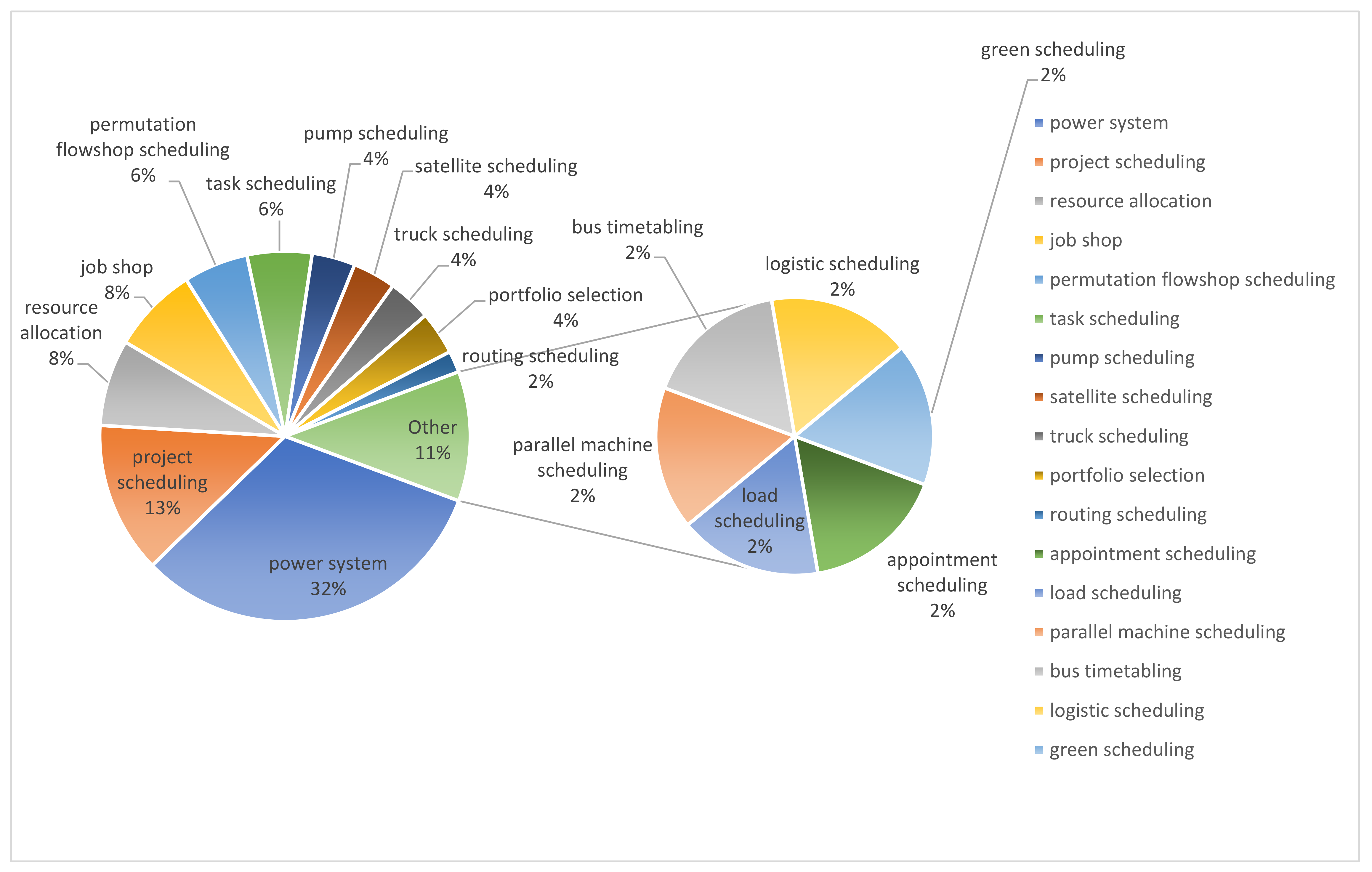

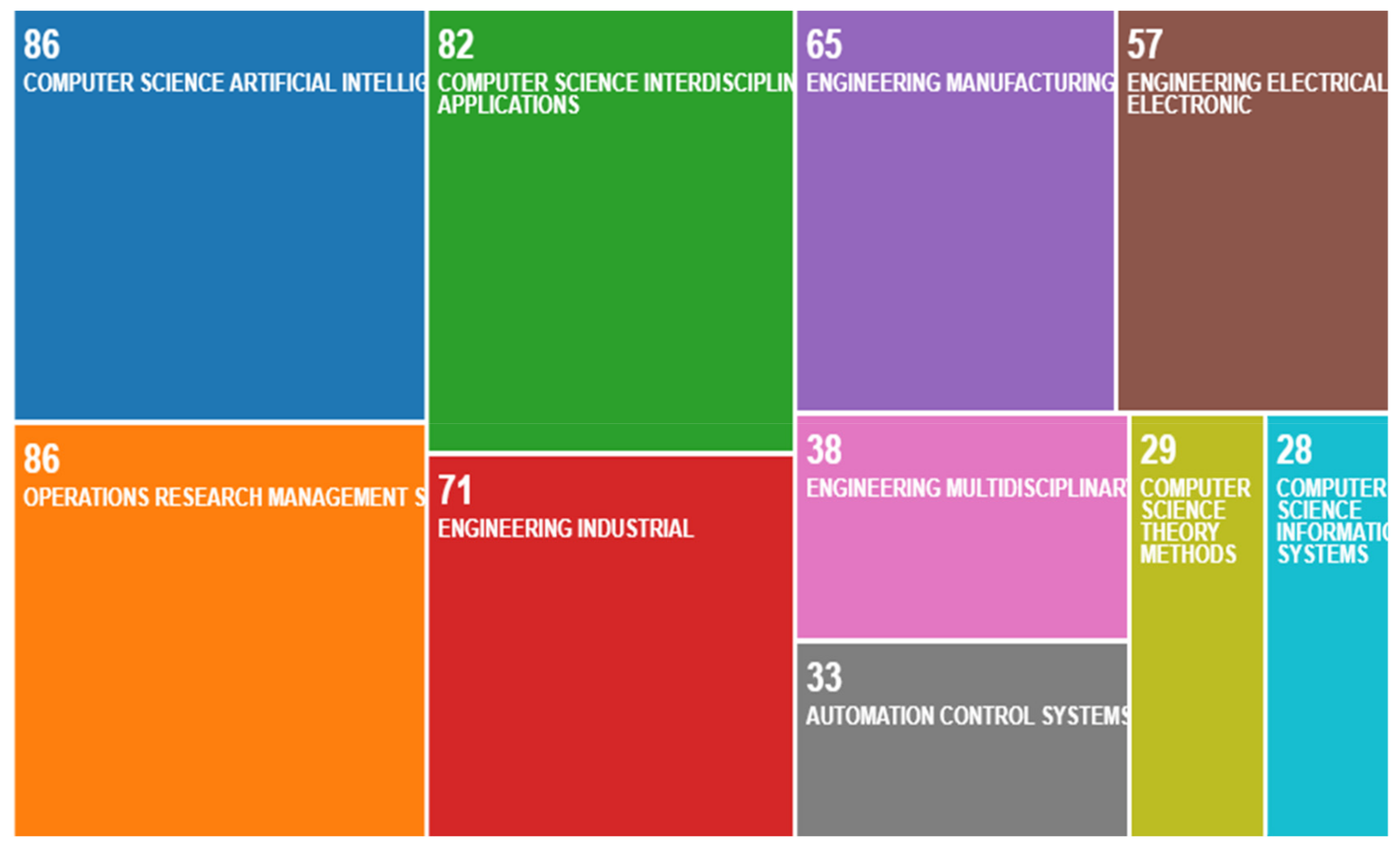

4.2. Keyword Analysis

4.3. Network Visualization

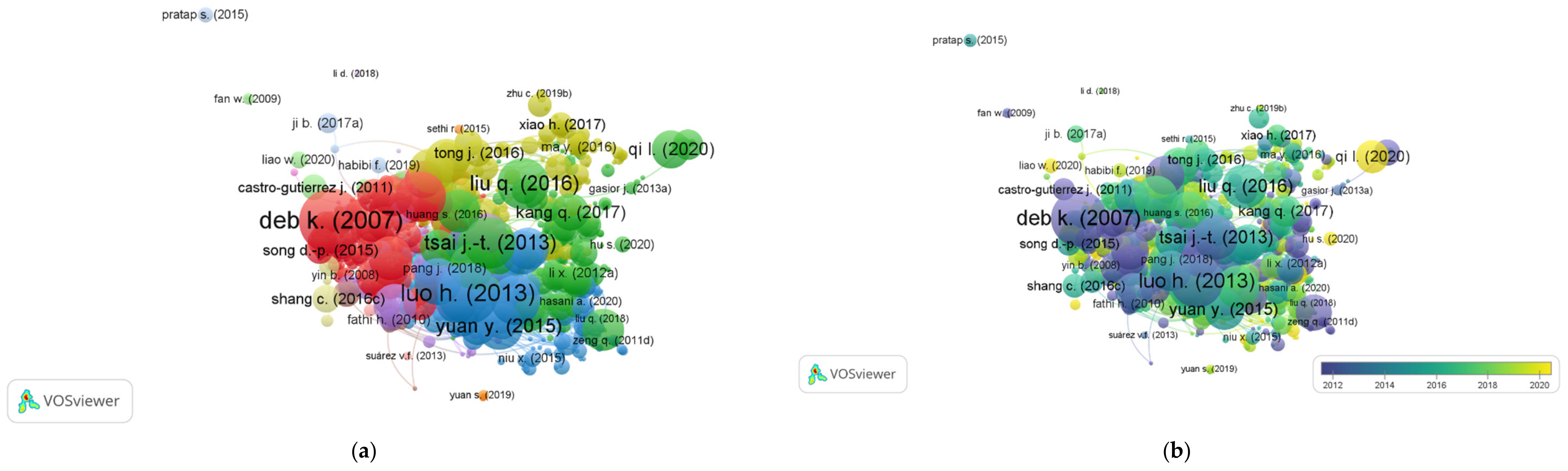

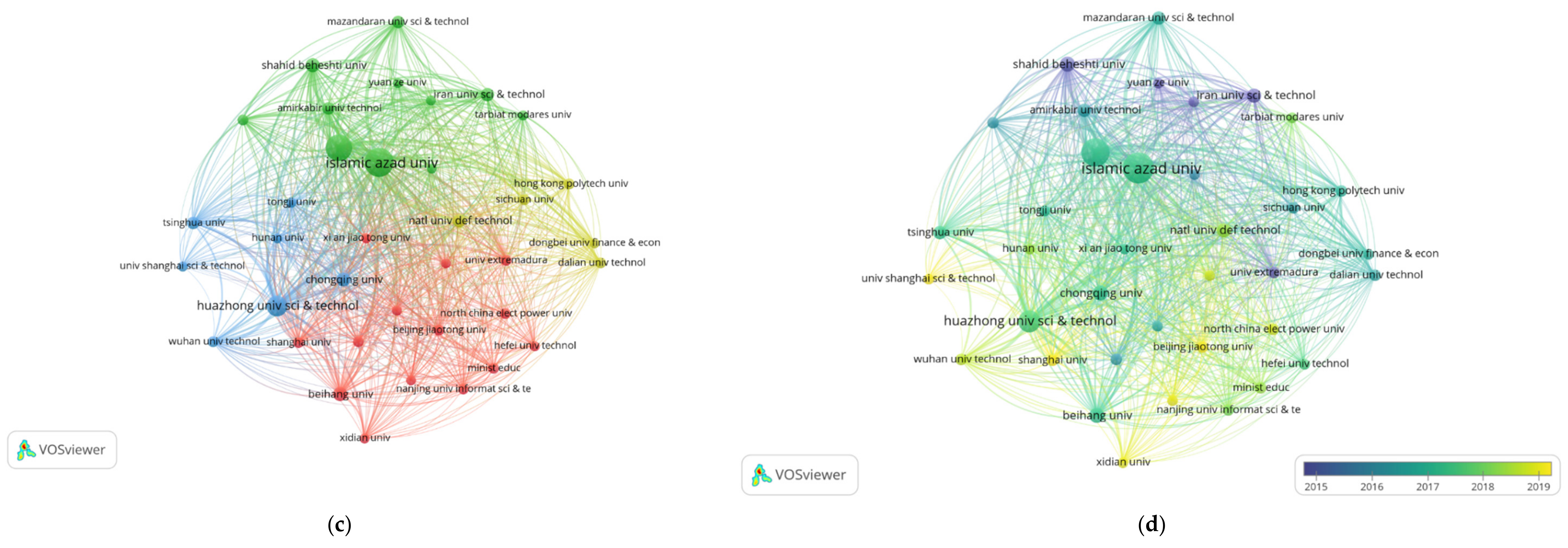

4.4. Bibliographic Coupling

4.5. Publication Statistics Based on the Journal

4.6. Statistics Based on Authors

4.7. Publication Statistics by Country

5. Summary

Future Studies

6. Conclusions and Discussions

- In terms of keyword analysis, scheduling, optimization, NSGA-II, makespan, design, cost, genetic algorithm, and decision making are the most prevalent keywords for scholars;

- Among the current scheduling problems, machine scheduling (specifically job-shop scheduling), routing, satellite scheduling, project scheduling, weapon selection, and forest planning are most predominant in the reviewed articles;

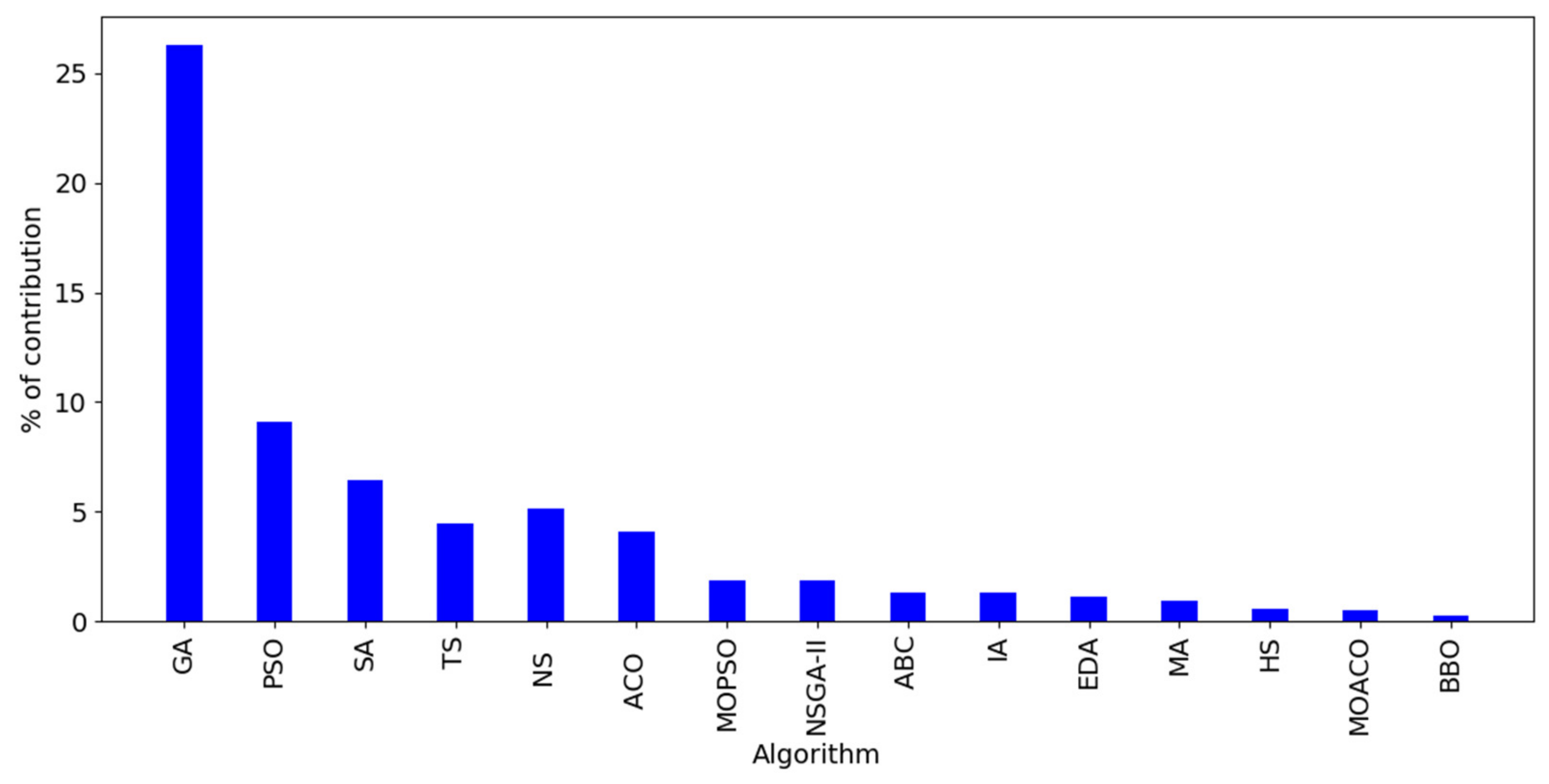

- Among the proposed solution methods for solving scheduling problems, the genetic algorithm possessed the greatest contribution of (26%), followed by PSO (9%), SA (6.4%), ACO (4.09%), and then tabu search (4.47%);

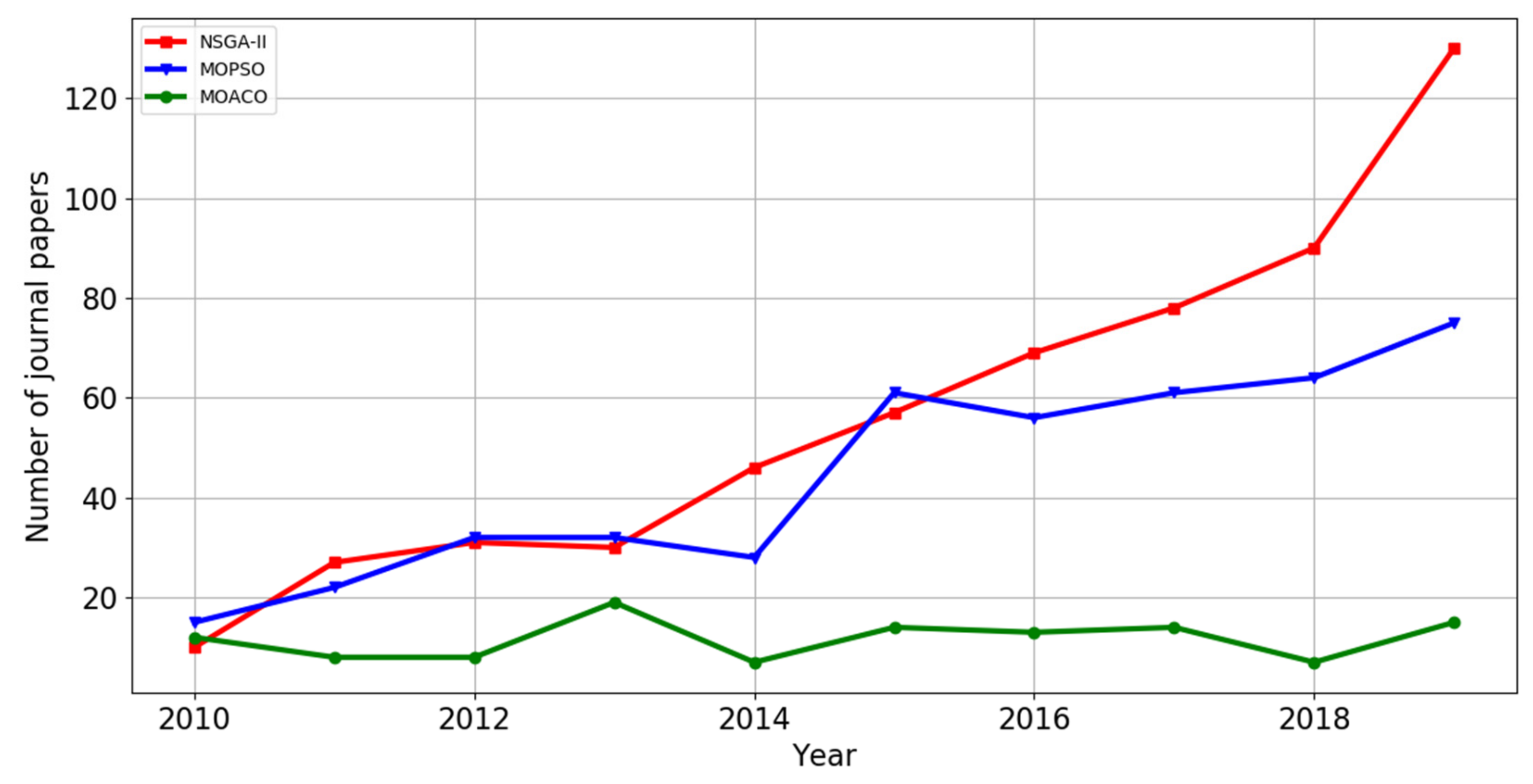

- Since 2014, NSGA-II has been the most studied algorithm, followed by MOPSO and then MOACO;

- Despite the increasing complexity of scheduling problems, metaheuristic algorithms (specifically NSGA-II) are more suitable for finding efficient solutions or near-optimal solutions.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deb, K.; Agrawal, S.; Pratap, A.; Meyarivan, T. A fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. In International Conference on Parallel Problem Solving from Nature; Springer: Berlin/Heidelberg, Germany, 2000; pp. 849–858. [Google Scholar]

- Salvendy, G. Handbook of Industrial Engineering: Technology and Operations Management; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Lenstra, J.K.; Kan, A.H.G.R. Complexity of vehicle routing and scheduling problems. Networks 1981, 11, 221–227. [Google Scholar] [CrossRef]

- Pinedo, M.; Hadavi, K. Scheduling: Theory, Algorithms and Systems Development. In Operations Research Proceedings 1991; Springer: Berlin/Heidelberg, Germany, 1992; pp. 35–42. [Google Scholar]

- Gandomi, A.H.; Emrouznejad, A.; Rahimi, I. Evolutionary Computation in Scheduling: A Scientometric Analysis. In Evolutionary Computation in Scheduling; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 1–10. [Google Scholar]

- Wang, Y.; Dang, C. An Evolutionary Algorithm for Global Optimization Based on Level-Set Evolution and Latin Squares. IEEE Trans. Evol. Comput. 2007, 11, 579–595. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Q.; Tsang, E.P.K. DE/EDA: A new evolutionary algorithm for global optimization. Inf. Sci. 2005, 169, 249–262. [Google Scholar] [CrossRef]

- Wang, Y.-J.; Zhang, J.-S. Global optimization by an improved differential evolutionary algorithm. Appl. Math. Comput. 2007, 188, 669–680. [Google Scholar] [CrossRef]

- Guo, D.; Wang, J.; Huang, J.; Han, R.; Song, M. Chaotic-NSGA-II: An effective algorithm to solve multi-objective optimization problems. In Proceedings of the 2010 International Conference on Intelligent Computing and Integrated Systems, Guilin, China, 22–24 October 2010; pp. 20–23. [Google Scholar]

- Liu, J.; Abbass, H.A.; Tan, K.C. Evolutionary Computation and Complex Networks. In Evolutionary Computation and Complex Networks; Springer: Singapore, 2019; pp. 3–22. [Google Scholar]

- Simon, D. Evolutionary Optimization Algorithms; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Coello, C.A.C.; Lamont, G.B.; Van Veldhuizen, D.A. Evolutionary Algorithms for Solving Multi-Objective Problems; Springer: Berlin/Heidelberg, Germany, 2007; Volume 5. [Google Scholar]

- Behmanesh, R.; Rahimi, I.; Gandomi, A.H. Evolutionary Many-Objective Algorithms for Combinatorial Optimization Problems: A Comparative Study. Arch. Comput. Methods Eng. 2021, 28, 673–688. [Google Scholar] [CrossRef]

- Deb, K. Multi-objective optimization. In Search Methodologies; Springer: New York, NY, USA, 2014. [Google Scholar]

- Marler, R.; Arora, J. Survey of multi-objective optimization methods for engineering. Struct. Multidiscip. Optim. 2004, 26, 369–395. [Google Scholar] [CrossRef]

- Deb, K. Multi-objective Optimisation Using Evolutionary Algorithms: An Introduction. In Multi-objective Evolutionary Optimisation for Product Design and Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–34. [Google Scholar]

- Liu, L.; Gu, S.; Fu, D.; Zhang, M.; Buyya, R. A New Multi-objective Evolutionary Algorithm for Inter-Cloud Service Composition. KSII Trans. Internet Inf. Syst. 2018, 12, 1–20. [Google Scholar]

- Yuan, S.; Deng, G.; Feng, Q.; Zheng, P.; Song, T. Multi-Objective Evolutionary Algorithm Based on Decomposition for Energy-aware Scheduling in Heterogeneous Computing Systems. J. Univers. Comput. Sci. 2017, 23, 636–651. [Google Scholar]

- Long, Q.; Wu, X.; Wu, C. Non-dominated sorting methods for multi-objective optimization: Review and numerical comparison. J. Ind. Manag. Optim. 2021, 17, 1001–1023. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Yusoff, Y.; Ngadiman, M.S.; Zain, A.M. Overview of NSGA-II for Optimizing Machining Process Parameters. Procedia Eng. 2011, 15, 3978–3983. [Google Scholar] [CrossRef]

- Deb, K.; Rao, U.B.N.; Karthik, S. Dynamic multi-objective optimization and decision-making using modified NSGA-II: A case study on hydro-thermal power scheduling. In Proceedings of the International Conference on Evolutionary Multi-Criterion Optimization, Matsushima, Japan, 5–8 March 2007; pp. 803–817. [Google Scholar]

- Bekele, E.G.; Nicklow, J.W. Multi-objective automatic calibration of SWAT using NSGA-II. J. Hydrol. 2007, 341, 165–176. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual; Univeristeit Leiden: Leiden, The Netherlands, 2013; Volume 1, pp. 1–53. [Google Scholar]

- Van Eck, N.J.; Waltman, L. CitNetExplorer: A new software tool for analyzing and visualizing citation networks. J. Inf. 2014, 8, 802–823. [Google Scholar] [CrossRef]

- Pinedo, M. Planning and Scheduling in Manufacturing and Services; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Özdamar, L.; Ulusoy, G. A note on an iterative forward/backward scheduling technique with reference to a procedure by Li and Willis. Eur. J. Oper. Res. 1996, 89, 400–407. [Google Scholar] [CrossRef]

- Li, K.; Willis, R. An iterative scheduling technique for resource-constrained project scheduling. Eur. J. Oper. Res. 1992, 56, 370–379. [Google Scholar] [CrossRef]

- Gonçalves, J.F.; Resende, M.G.C.; Mendes, J.J.M. A biased random-key genetic algorithm with forward-backward improvement for the resource constrained project scheduling problem. J. Heuristics 2010, 17, 467–486. [Google Scholar] [CrossRef]

- Qi, X. A logistics scheduling model: Inventory cost reduction by batching. Nav. Res. Logist. 2005, 52, 312–320. [Google Scholar] [CrossRef]

- Tiemessen, H.; van Houtum, G. Reducing costs of repairable inventory supply systems via dynamic scheduling. Int. J. Prod. Econ. 2013, 143, 478–488. [Google Scholar] [CrossRef]

- Liu, W.; Ke, G.Y.; Chen, J.; Zhang, L. Scheduling the distribution of blood products: A vendor-managed inventory routing approach. Transp. Res. Part E Logist. Transp. Rev. 2020, 140, 101964. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; Chu, F.; Yu, J. An energy-efficient two-stage hybrid flow shop scheduling problem in a glass production. Int. J. Prod. Res. 2020, 58, 2283–2314. [Google Scholar] [CrossRef]

- Xu, Z.; Zheng, Z.; Gao, X. Energy-efficient steelmaking-continuous casting scheduling problem with temperature constraints and its solution using a multi-objective hybrid genetic algorithm with local search. Appl. Soft Comput. 2020, 95, 106554. [Google Scholar] [CrossRef]

- Li, X.; Jin, X.; Lu, S.; Li, Z.; Wang, Y.; Cao, J. Carbon-Efficient Production Scheduling of a Bioethanol Plant Considering Diversified Feedstock Pelletization Density: A Case Study. Processes 2020, 8, 1189. [Google Scholar] [CrossRef]

- Wang, S.; Che, Y.; Zhao, H.; Lim, A. Accurate Tracking, Collision Detection, and Optimal Scheduling of Airport Ground Support Equipment. IEEE Internet Things J. 2020, 8, 572–584. [Google Scholar] [CrossRef]

- Zhou, B.; Zhu, Z. Optimally scheduling and loading tow trains of in-plant milk-run delivery for mixed-model assembly lines. Assem. Autom. 2020, 40, 511–530. [Google Scholar] [CrossRef]

- Torabbeigi, M.; Lim, G.J.; Kim, S.J. Drone delivery scheduling optimization considering payload-induced battery consumption rates. J. Intell. Robot. Syst. 2020, 97, 471–487. [Google Scholar] [CrossRef]

- Sheikh, S.Z.; Pasha, M.A. Energy-efficient real-time scheduling on multicores: A novel approach to model cache contention. ACM Trans. Embed. Comput. Syst. 2020, 19, 1–25. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Zhang, Y.; Ren, S.; Liu, Y. Infinitely repeated game based real-time scheduling for low-carbon flexible job shop considering multi-time periods. J. Clean. Prod. 2020, 247, 119093. [Google Scholar] [CrossRef]

- Kim, E.; Lee, Y.; He, L.; Shin, K.G.; Lee, J. Power Guarantee for Electric Systems Using Real-Time Scheduling. IEEE Trans. Parallel Distrib. Syst. 2020, 31, 1783–1798. [Google Scholar] [CrossRef]

- Fathollahi-Fard, A.M.; Ranjbar-Bourani, M.; Cheikhrouhou, N.; Hajiaghaei-Keshteli, M. Novel modifications of social engineering optimizer to solve a truck scheduling problem in a cross-docking system. Comput. Ind. Eng. 2019, 137, 106103. [Google Scholar] [CrossRef]

- Bossche, T.V.D.; Çalık, H.; Jacobs, E.-J.; Toffolo, T.A.; Berghe, G.V. Truck scheduling in tank terminals. EURO J. Transp. Logist. 2020, 9, 100001. [Google Scholar] [CrossRef]

- Demeulemeester, E.L.; Herroelen, W.S. Project Scheduling: A Research Handbook; Springer Science & Business Media: Berlin, Germany, 2006; Volume 49. [Google Scholar]

- Brucker, P.; Drexl, A.; Möhring, R.; Neumann, K.; Pesch, E. Resource-constrained project scheduling: Notation, classification, models, and methods. Eur. J. Oper. Res. 1999, 112, 3–41. [Google Scholar] [CrossRef]

- Biskup, D. Single-machine scheduling with learning considerations. Eur. J. Oper. Res. 1999, 115, 173–178. [Google Scholar] [CrossRef]

- Mosheiov, G. Parallel machine scheduling with a learning effect. J. Oper. Res. Soc. 2001, 52, 1165–1169. [Google Scholar] [CrossRef]

- Cheng, T.C.E.; Sin, C.C.S. A state-of-the-art review of parallel-machine scheduling research. Eur. J. Oper. Res. 1990, 47, 271–292. [Google Scholar] [CrossRef]

- Garey, M.R.; Johnson, D.S.; Sethi, R. The Complexity of Flowshop and Jobshop Scheduling. Math. Oper. Res. 1976, 1, 117–129. [Google Scholar] [CrossRef]

- Fu, Y.; Tian, G.; Fathollahi-Fard, A.M.; Ahmadi, A.; Zhang, C. Stochastic multi-objective modelling and optimization of an energy-conscious distributed permutation flow shop scheduling problem with the total tardiness constraint. J. Clean. Prod. 2019, 226, 515–525. [Google Scholar] [CrossRef]

- Denzler, D.R.; Boe, W.J. Experimental investigation of flexible manufacturing system scheduling decision rules. Int. J. Prod. Res. 1987, 25, 979–994. [Google Scholar] [CrossRef]

- Zhang, W.; Freiheit, T.; Yang, H. Dynamic scheduling in flexible assembly system based on timed Petri nets model. Robot. Comput. Manuf. 2005, 21, 550–558. [Google Scholar] [CrossRef]

- Sawik, T. Loading and scheduling of a flexible assembly system by mixed integer programming. Eur. J. Oper. Res. 2004, 154, 1–19. [Google Scholar] [CrossRef]

- Valckenaers, P.; Van Brussel, H.; Bongaerts, L.; Bonneville, F. Programming, scheduling, and control of flexible assembly systems. Comput. Ind. 1995, 26, 209–218. [Google Scholar] [CrossRef]

- Elmaghraby, S.E. The Economic Lot Scheduling Problem (ELSP): Review and Extensions. Manag. Sci. 1978, 24, 587–598. [Google Scholar] [CrossRef]

- Dobson, G. The Economic Lot-Scheduling Problem: Achieving Feasibility Using Time-Varying Lot Sizes. Oper. Res. 1987, 35, 764–771. [Google Scholar] [CrossRef]

- Rogers, J. A Computational Approach to the Economic Lot Scheduling Problem. Manag. Sci. 1958, 4, 264–291. [Google Scholar] [CrossRef]

- Schoenfelder, J.; Bretthauer, K.M.; Wright, P.D.; Coe, E. Nurse scheduling with quick-response methods: Improving hospital performance, nurse workload, and patient experience. Eur. J. Oper. Res. 2020, 283, 390–403. [Google Scholar] [CrossRef]

- Hamid, M.; Tavakkoli-Moghaddam, R.; Golpaygani, F.; Vahedi-Nouri, B. A multi-objective model for a nurse scheduling problem by emphasizing human factors. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2019, 234, 179–199. [Google Scholar] [CrossRef]

- Simić, S.; Milutinović, D.; Sekulić, S.; Simić, D.; Simić, S.D.; Đorđević, J. A hybrid case-based reasoning approach to detecting the optimal solution in nurse scheduling problem. Log. J. IGPL 2020, 28, 226–238. [Google Scholar] [CrossRef]

- Legrain, A.; Omer, J.; Rosat, S. An online stochastic algorithm for a dynamic nurse scheduling problem. Eur. J. Oper. Res. 2020, 285, 196–210. [Google Scholar] [CrossRef]

- Jiang, J.; Xiong, X.; Ou, Y.; Wang, H. An Improved Bacterial Foraging Optimization with Differential and Poisson Distribution Strategy and its Application to Nurse Scheduling Problem. In International Conference on Swarm Intelligence; Springer: Berlin/Heidelberg, Germany, 2020; pp. 312–324. [Google Scholar]

- Rerkjirattikal, P.; Huynh, V.-N.; Olapiriyakul, S.; Supnithi, T. A Framework for a Practical Nurse Scheduling Approach: A Case of Operating Room of a Hospital in Thailand. In International Conference on Applied Human Factors and Ergonomics; Springer: Singapore, 2020; pp. 259–264. [Google Scholar]

- İnanç, Ş.; Şenaras, A.E. Solving Nurse Scheduling Problem via Genetic Algorithm in Home Healthcare. In Transportation, Logistics, and Supply Chain Management in Home Healthcare: Emerging Research and Opportunities; IGI Global: Hershey, PA, USA, 2020; pp. 20–28. [Google Scholar]

- Aydas, O.T.; Ross, A.D.; Scanlon, M.C.; Aydas, B. New results on integrated nurse staffing and scheduling: The medium-term context for intensive care units. J. Oper. Res. Soc. 2021, 72, 2631–2648. [Google Scholar] [CrossRef]

- Batun, S.; Karpuz, E. Nurse Scheduling and Rescheduling Under Uncertainty. Hacettepe Univ. J. Econ. Adm. Sci. Üniversitesi Iktis. ve Idari Bilim. Fakültesi Derg. 2020, 38, 75–95. [Google Scholar] [CrossRef][Green Version]

- Roshanaei, V.; Luong, C.; Aleman, D.M.; Urbach, D.R. Reformulation, linearization, and decomposition techniques for balanced distributed operating room scheduling. Omega 2020, 93, 102043. [Google Scholar] [CrossRef]

- Schiele, J.; Koperna, T.; Brunner, J.O. Predicting intensive care unit bed occupancy for integrated operating room scheduling via neural networks. Nav. Res. Logist. 2020, 68, 65–88. [Google Scholar] [CrossRef]

- Zhu, S.; Fan, W.; Liu, T.; Yang, S.; Pardalos, P.M. Dynamic three-stage operating room scheduling considering patient waiting time and surgical overtime costs. J. Comb. Optim. 2019, 39, 185–215. [Google Scholar] [CrossRef]

- Ahmed, A.; Ali, H. Modeling patient preference in an operating room scheduling problem. Oper. Res. Health Care 2020, 25, 100257. [Google Scholar] [CrossRef]

- Najjarbashi, A.; Lim, G.J. A Decomposition Algorithm for the Two-Stage Chance-Constrained Operating Room Scheduling Problem. IEEE Access 2020, 8, 80160–80172. [Google Scholar] [CrossRef]

- Varmazyar, M.; Akhavan-Tabatabaei, R.; Salmasi, N.; Modarres, M. Operating room scheduling problem under uncertainty: Application of continuous phase-type distributions. IISE Trans. 2020, 52, 216–235. [Google Scholar] [CrossRef]

- Barrera, J.; Carrasco, R.A.; Mondschein, S.; Canessa, G.; Rojas-Zalazar, D. Operating room scheduling under waiting time constraints: The Chilean GES plan. Ann. Oper. Res. 2020, 286, 501–527. [Google Scholar] [CrossRef]

- Abdeljaouad, M.A.; Bahroun, Z.; Saadani, N.E.H.; Zouari, B. A simulated annealing for a daily operating room scheduling problem under constraints of uncertainty and setup. INFOR Inf. Syst. Oper. Res. 2020, 58, 456–477. [Google Scholar] [CrossRef]

- Divsalar, A.; Jokar, A.; Emami, S. Operating Room Scheduling considering Patient Priority: Case of Shomal Hospital in Amol. Int. J. Ind. Eng. Manag. Sci. 2020, 7, 57–68. [Google Scholar]

- Roshanaei, V.; Booth, K.E.; Aleman, D.M.; Urbach, D.R.; Beck, J.C. Branch-and-check methods for multi-level operating room planning and scheduling. Int. J. Prod. Econ. 2020, 220, 107433. [Google Scholar] [CrossRef]

- Akbarzadeh, B.; Moslehi, G.; Reisi-Nafchi, M.; Maenhout, B. A diving heuristic for planning and scheduling surgical cases in the operating room department with nurse re-rostering. J. Sched. 2020, 23, 265–288. [Google Scholar] [CrossRef]

- Rahimi, I.; Gandomi, A.H. A Comprehensive Review and Analysis of Operating Room and Surgery Scheduling. Arch. Comput. Methods Eng. 2021, 28, 1667–1688. [Google Scholar] [CrossRef]

- Bandi, C.; Gupta, D. Operating Room Staffing and Scheduling. Manuf. Serv. Oper. Manag. 2020, 22, 958–974. [Google Scholar] [CrossRef]

- Oliveira, M.; Bélanger, V.; Marques, I.; Ruiz, A. Assessing the impact of patient prioritization on operating room schedules. Oper. Res. Health Care 2020, 24, 100232. [Google Scholar] [CrossRef]

- Moosavi, A.; Ebrahimnejad, S. Robust operating room planning considering upstream and downstream units: A new two-stage heuristic algorithm. Comput. Ind. Eng. 2020, 143, 106387. [Google Scholar] [CrossRef]

- Bovim, T.R.; Christiansen, M.; Gullhav, A.N.; Range, T.M.; Hellemo, L. Stochastic master surgery scheduling. Eur. J. Oper. Res. 2020, 285, 695–711. [Google Scholar] [CrossRef]

- Gegg, D.L. The Impact of Middle School Scheduling Practices on Adolescent Math Achievement in Louisiana Public Schools. Ph.D. Thesis, 2020. [Google Scholar]

- Khan, K.; Sahai, A. Tabu Ant Colony Optimisation for School Timetable Scheduling Problem. Int. J. Eng. Res. Appl. 2020, 10, 1–9. [Google Scholar]

- Hao, X.; Liu, J.; Zhang, Y.; Sanga, G. Mathematical model and simulated annealing algorithm for Chinese high school timetabling problems under the new curriculum innovation. Front. Comput. Sci. 2020, 15, 1–11. [Google Scholar] [CrossRef]

- Tan, J.S.; Goh, S.L.; Sura, S.; Kendall, G.; Sabar, N.R. Hybrid particle swarm optimization with particle elimination for the high school timetabling problem. Evol. Intell. 2020, 14, 1915–1930. [Google Scholar] [CrossRef]

- Hoshino, R.; Fabris, I. Optimizing Student Course Preferences in School Timetabling. In Proceedings of the International Conference on Integration of Constraint Programming, Artificial Intelligence, and Operations Research, Vienna, Austria, 5–8 July 2020; pp. 283–299. [Google Scholar]

- Tassopoulos, I.X.; Iliopoulou, C.A.; Beligiannis, G.N. Solving the Greek school timetabling problem by a mixed integer programming model. J. Oper. Res. Soc. 2019, 71, 117–132. [Google Scholar] [CrossRef]

- Chen, P.S.; Huang, W.T.; Peng, N.C.; Chen, G.Y.H. Modularising school timetabling problems in different types of classes for Taiwanese elementary and junior high schools. Int. J. Math. Oper. Res. 2020, 17, 110. [Google Scholar] [CrossRef]

- Saviniec, L.; Santos, M.O.; Costa, A.M.; Santos, L.M.R.d. Pattern-based models and a cooperative parallel metaheuristic for high school timetabling problems. Eur. J. Oper. Res. 2020, 280, 1064–1081. [Google Scholar] [CrossRef]

- Cacchiani, V.; Salazar-González, J.-J. Heuristic approaches for flight retiming in an integrated airline scheduling problem of a regional carrier. Omega 2020, 91, 102028. [Google Scholar] [CrossRef]

- Zhou, L.; Liang, Z.; Chou, C.-A.; Chaovalitwongse, W.A. Airline planning and scheduling: Models and solution methodologies. Front. Eng. Manag. 2020, 7, 1–26. [Google Scholar] [CrossRef]

- Khanmirza, E.; Nazarahari, M.; Haghbeigi, M. A heuristic approach for optimal integrated airline schedule design and fleet assignment with demand recapture. Appl. Soft Comput. 2020, 96, 106681. [Google Scholar] [CrossRef]

- Bayliss, C.; De Maere, G.; Atkin, J.A.D.; Paelinck, M. Scheduling airline reserve crew using a probabilistic crew absence and recovery model. J. Oper. Res. Soc. 2019, 71, 543–565. [Google Scholar] [CrossRef]

- Sanchez, D.T. Optimising Airline Maintenance Scheduling Decisions; Lancaster University: Lancaster, UK, 2020. [Google Scholar]

- Fairbrother, J.; Zografos, K.G.; Glazebrook, K.D. A Slot-Scheduling Mechanism at Congested Airports That Incorporates Efficiency, Fairness, and Airline Preferences. Transp. Sci. 2019, 54, 115–138. [Google Scholar] [CrossRef]

- Kerkemezos, Y.; Karreman, B. On the Benefits of Being Alone: Scheduling Changes, Intensity of Competition and Dynamic Airline Pricing; Tinbergen Institute Discussion Paper 2020-042/VII; Tinbergen Institute: MS Amsterdam, The Netherlands, 2020. [Google Scholar]

- Shiau, J.-Y.; Huang, M.-K.; Huang, C.-Y. A Hybrid Personnel Scheduling Model for Staff Rostering Problems. Mathematics 2020, 8, 1702. [Google Scholar] [CrossRef]

- Chutima, P.; Arayikanon, K. Many-objective low-cost airline cockpit crew rostering optimisation. Comput. Ind. Eng. 2020, 150, 106844. [Google Scholar] [CrossRef]

- Sun, J.Y. Airport curfew and scheduling differentiation: Domestic versus international competition. J. Air Transp. Manag. 2020, 87, 101839. [Google Scholar] [CrossRef]

- Nenem, S.; Graham, A.; Dennis, N. Airline schedule and network competitiveness: A consumer-centric approach for business travel. Ann. Tour. Res. 2020, 80, 102822. [Google Scholar] [CrossRef]

- Wagner, H.M. An integer linear-programming model for machine scheduling. Nav. Res. Logist. Q. 1959, 6, 131–140. [Google Scholar] [CrossRef]

- Brooks, G.H. An algorithm for finding optimal or near optimal solutions to the production scheduling problem. J. Ind. Eng. 1969, 16, 34–40. [Google Scholar]

- Lomnicki, Z.A. A “Branch-and-Bound” Algorithm for the Exact Solution of the Three-Machine Scheduling Problem. J. Oper. Res. Soc. 1965, 16, 89–100. [Google Scholar] [CrossRef]

- Barker, J.R.; McMahon, G.B. Scheduling the General Job-Shop. Manag. Sci. 1985, 31, 594–598. [Google Scholar] [CrossRef]

- French, S. Sequencing and scheduling. In An Introduction to the Mathematics of the Job-Shop; Wiley: Hoboken, NJ, USA, 1982. [Google Scholar]

- Morton, T.; Pentico, D.W. Heuristic Scheduling Systems: With Applications to Production Systems and Project Management; John Wiley & Sons: Hoboken, NJ, USA, 1993; Volume 3. [Google Scholar]

- Fonseca, D.J.; Navaresse, D. Artificial neural networks for job shop simulation. Adv. Eng. Inform. 2002, 16, 241–246. [Google Scholar] [CrossRef]

- Aarts, E.; Aarts, E.H.L.; Lenstra, J.K. Local Search in Combinatorial Optimization; Princeton University Press: Princeton, NJ, USA, 2003. [Google Scholar]

- Reeves, C.R. Modern Heuristic Techniques for Combinatorial Problems; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1993. [Google Scholar]

- Jones, D.F.; Mirrazavi, S.; Tamiz, M. Multi-objective meta-heuristics: An overview of the current state-of-the-art. Eur. J. Oper. Res. 2002, 137, 1–9. [Google Scholar] [CrossRef]

- Sarker, R.; Ray, T. An improved evolutionary algorithm for solving multi-objective crop planning models. Comput. Electron. Agric. 2009, 68, 191–199. [Google Scholar] [CrossRef]

- Poojari, C.; Beasley, J. Improving benders decomposition using a genetic algorithm. Eur. J. Oper. Res. 2009, 199, 89–97. [Google Scholar] [CrossRef]

- Herrmann, J.W.; Lee, C.-Y.; Hinchman, J. Global job shop scheduling with a genetic algorithm. Prod. Oper. Manag. 1995, 4, 30–45. [Google Scholar] [CrossRef]

- Tung, L.-F.; Lin, L.; Nagi, R. Multiple-objective scheduling for the hierarchical control of flexible manufacturing systems. Int. J. Flex. Manuf. Syst. 1999, 11, 379–409. [Google Scholar] [CrossRef]

- Jensen, M.T. Generating robust and flexible job shop schedules using genetic algorithms. IEEE Trans. Evol. Comput. 2003, 7, 275–288. [Google Scholar] [CrossRef]

- Mati, Y.; Xie, X. The complexity of two-job shop problems with multi-purpose unrelated machines. Eur. J. Oper. Res. 2004, 152, 159–169. [Google Scholar] [CrossRef]

- Xia, W.; Wu, Z. An effective hybrid optimization approach for multi-objective flexible job-shop scheduling problems. Comput. Ind. Eng. 2005, 48, 409–425. [Google Scholar] [CrossRef]

- Torabi, S.A.; Karimi, B.; Ghomi, S.F. The common cycle economic lot scheduling in flexible job shops: The finite horizon case. Int. J. Prod. Econ. 2005, 97, 52–65. [Google Scholar] [CrossRef]

- Gomes, M.C.; Barbosa-Povoa, A.P.; Novais, A.Q. Optimal scheduling for flexible job-shop operation. Int. J. Prod. Res. 2005, 43, 2323–2353. [Google Scholar] [CrossRef]

- Chan, F.T.; Wong, T.C.; Chan, L.Y. Flexible job-shop scheduling problem under resource constraints. Int. J. Prod. Res. 2006, 44, 2071–2089. [Google Scholar] [CrossRef]

- Fattahi, P.; Mehrabad, M.S.; Jolai, F. Mathematical modeling and heuristic approaches to flexible job shop scheduling problems. J. Intell. Manuf. 2007, 18, 331–342. [Google Scholar] [CrossRef]

- Tay, J.C.; Ho, N.B. Evolving dispatching rules using genetic programming for solving multi-objective flexible job-shop problems. Comput. Ind. Eng. 2008, 54, 453–473. [Google Scholar] [CrossRef]

- Schaffer, J.D. Multiple objective optimization with vector evaluated genetic algorithms. In Proceedings of the 1st International Conference on Genetic Algorithms, Pittsburgh, PA, USA, 24–26 July 1985. [Google Scholar]

- Konak, A.; Coit, D.W.; Smith, A.E. Multi-objective optimization using genetic algorithms: A tutorial. Reliab. Eng. Syst. Saf. 2006, 91, 992–1007. [Google Scholar] [CrossRef]

- Fang, Z. A Weight-Based Multiobjective Genetic Algorithm for Flowshop Scheduling. In Proceedings of the 2009 International Conference on Artificial Intelligence and Computational Intelligence, Shanghai, China, 7–8 November 2009; Volume 1, pp. 373–377. [Google Scholar]

- Zhou, H.; Cheung, W.; Leung, L.C. Minimizing weighted tardiness of job-shop scheduling using a hybrid genetic algorithm. Eur. J. Oper. Res. 2009, 194, 637–649. [Google Scholar] [CrossRef]

- Srinivas, N.; Deb, K. Muiltiobjective Optimization Using Nondominated Sorting in Genetic Algorithms. Evol. Comput. 1994, 2, 221–248. [Google Scholar] [CrossRef]

- Lu, H.; Yen, G. Rank-density-based multiobjective genetic algorithm and benchmark test function study. IEEE Trans. Evol. Comput. 2003, 7, 325–343. [Google Scholar]

- Horn, J.; Nafpliotis, N.; Goldberg, D.E. Multiobjective Optimization using the Niched Pareto Genetic Algorithm; IlliGAL Report, No. 93005; Illinois Genetic Algorithms Laboratory, University of Illinois at Urbana-Champaign: Urbana-Champaign, IL, USA, 1993; pp. 1–32. [Google Scholar]

- Horn, J.; Nafpliotis, N.; Goldberg, D.E. A niched Pareto genetic algorithm for multiobjective optimization. In Proceedings of the first IEEE conference on evolutionary computation. IEEE world congress on computational intelligence, Orlando, FL, USA, 27–29 June 1994; pp. 82–87. [Google Scholar]

- Wang, Y.; Dang, C. An evolutionary algorithm for dynamic multi-objective optimization. Appl. Math. Comput. 2008, 205, 6–18. [Google Scholar] [CrossRef]

- Mao, T.; Xu, Z.; Hou, R.; Peng, M. Efficient Satellite Scheduling Based on Improved Vector Evaluated Genetic Algorithm. J. Netw. 2012, 7, 517. [Google Scholar] [CrossRef]

- Zhang, W.; Fujimura, S. Multiobjective process planning and scheduling using improved vector evaluated genetic algorithm with archive. IEEJ Trans. Electr. Electron. Eng. 2012, 7, 258–267. [Google Scholar] [CrossRef]

- Zhang, W.; Fujimura, S. Improved vector evaluated genetic algorithm with archive for solving multiobjective pps problem. In Proceedings of the 2010 International Conference on E-Product E-Service and E-Entertainment, Henan, China, 7–9 November 2010; pp. 1–4. [Google Scholar]

- Zhang, W.; Gen, M.; Jo, J. Hybrid sampling strategy-based multiobjective evolutionary algorithm for process planning and scheduling problem. J. Intell. Manuf. 2014, 25, 881–897. [Google Scholar] [CrossRef]

- Wang, X.; Gao, L.; Zhang, C.; Shao, X. A multi-objective genetic algorithm based on immune and entropy principle for flexible job-shop scheduling problem. Int. J. Adv. Manuf. Technol. 2010, 51, 757–767. [Google Scholar] [CrossRef]

- Lee, L.H.; Lee, C.U.; Tan, Y.P. A multi-objective genetic algorithm for robust flight scheduling using simulation. Eur. J. Oper. Res. 2007, 177, 1948–1968. [Google Scholar] [CrossRef]

- Chang, F.-S.; Wu, J.-S.; Lee, C.-N.; Shen, H.-C. Greedy-search-based multi-objective genetic algorithm for emergency logistics scheduling. Expert Syst. Appl. 2014, 41, 2947–2956. [Google Scholar] [CrossRef]

- Balasubramanian, H.; Mönch, L.; Fowler, J.; Pfund, M. Genetic algorithm based scheduling of parallel batch machines with incompatible job families to minimize total weighted tardiness. Int. J. Prod. Res. 2004, 42, 1621–1638. [Google Scholar] [CrossRef]

- Kar, C.; Rakesh, V.K.; Samanta, T.; Banerjee, S. A New Approach to Grid Scheduling using Random Weighted Genetic Algorithm with Fault Tolerance Strategy. Int. J. Comput. Appl. 2012, 48, 42–47. [Google Scholar] [CrossRef]

- Qian, B.; Wang, L.; Huang, D.-X.; Wang, X. Multi-objective flow shop scheduling using differential evolution. In Intelligent Computing in Signal Processing and Pattern Recognition; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1125–1136. [Google Scholar]

- Elloumi, S.; Fortemps, P. A hybrid rank-based evolutionary algorithm applied to multi-mode resource-constrained project scheduling problem. Eur. J. Oper. Res. 2010, 205, 31–41. [Google Scholar] [CrossRef]

- Kim, K.; Walewski, J.; Cho, Y.K. Multiobjective Construction Schedule Optimization Using Modified Niched Pareto Genetic Algorithm. J. Manag. Eng. 2016, 32, 04015038. [Google Scholar] [CrossRef]

- Benedict, S.; Vasudevan, V. Scheduling of scientific workflows using Niched Pareto GA for Grids. In Proceedings of the 2006 IEEE International Conference on Service Operations and Logistics, and Informatics, Shanghai, China, 21–23 June 2006; pp. 908–912. [Google Scholar]

- Benedict, S.; Vasudevan, V. A Niched Pareto GA Approach for Scheduling Scientific Workflows in Wireless Grids. J. Comput. Inf. Technol. 2008, 16, 101–108. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Santos, M.; Antón, J.R. Supply chain of renewable energy: A bibliometric review approach. Biomass Bioenergy 2019, 126, 70–83. [Google Scholar] [CrossRef]

- Sankar, S.S.; Ponnambalam, S.G.; Rathinavel, V.; Gurumarimuthu, M. A pareto based multi-objective genetic algorithm for scheduling of FMS. IEEE Conf. Cybern. Intell. Syst. 2004, 2, 700–705. [Google Scholar]

- Lu, H.; Xu, X.; Zhang, M.; Yin, L. Dynamic multi-objective evolutionary algorithm based on decomposition for test task scheduling problem. In Proceedings of the 2015 Sixth International Conference on Intelligent Control and Information Processing (ICICIP), Wuhan, China, 26–28 November 2015; pp. 11–18. [Google Scholar]

- Bagchi, T.P.; Jayaram, K.; Srinivas, T.D. Pareto optimal production scheduling by meta-heuristic methods. In Proceedings of the PICMET’99: Portland International Conference on Management of Engineering and Technology, Proceedings Vol-1: Book of Summaries (IEEE Cat. No. 99CH36310), Portland, OR, USA, 29 July 1999; Volume 1, p. 448. [Google Scholar]

- Bagchi, T.P. A Comparison of Multiobjective Flowshop Sequencing by NSGA and ENGA. In Multiobjective Scheduling by Genetic Algorithms; Springer: Singapore, 1999; pp. 245–255. [Google Scholar]

- Bagchi, T.P. Multiobjective Job Shop Scheduling. In Multiobjective Scheduling by Genetic Algorithms; Springer: Singapore, 1999; pp. 256–266. [Google Scholar]

- Bagchi, T.P. Multiobjective Open Shop Scheduling. In Multiobjective Scheduling by Genetic Algorithms; Springer: Singapore, 1999; pp. 267–276. [Google Scholar]

- Bagchi, T.P. Multiobjective Flowshop Scheduling. In Multiobjective Scheduling by Genetic Algorithms; Springer: Singapore, 1999; pp. 203–215. [Google Scholar]

- Bandyopadhyay, S.; Bhattacharya, R. Solving multi-objective parallel machine scheduling problem by a modified NSGA-II. Appl. Math. Model. 2013, 37, 6718–6729. [Google Scholar] [CrossRef]

- Ciro, G.C.; Dugardin, F.; Yalaoui, F.; Kelly, R. A NSGA-II and NSGA-III comparison for solving an open shop scheduling problem with resource constraints. IFAC PapersOnLine 2016, 49, 1272–1277. [Google Scholar] [CrossRef]

- Rabiee, M.; Zandieh, M.; Ramezani, P. Bi-objective partial flexible job shop scheduling problem: NSGA-II, NRGA, MOGA and PAES approaches. Int. J. Prod. Res. 2012, 50, 7327–7342. [Google Scholar] [CrossRef]

- Han, Y.-Y.; Gong, D.-W.; Sun, X.-Y.; Pan, Q.-K. An improved NSGA-II algorithm for multi-objective lot-streaming flow shop scheduling problem. Int. J. Prod. Res. 2013, 52, 2211–2231. [Google Scholar] [CrossRef]

- Makaremi, Y.; Haghighi, A.; Ghafouri, H.R. Optimization of Pump Scheduling Program in Water Supply Systems Using a Self-Adaptive NSGA-II; a Review of Theory to Real Application. Water Resour. Manag. 2017, 31, 1283–1304. [Google Scholar] [CrossRef]

- Huang, B.; Buckley, B.; Kechadi, M.T. Multi-objective feature selection by using NSGA-II for customer churn prediction in telecommunications. Expert Syst. Appl. 2010, 37, 3638–3646. [Google Scholar] [CrossRef]

- Xu, W.; Xu, J.; He, D.; Tan, K.C. A combined differential evolution and NSGA-II approach for parametric optimization of a cancer immunotherapy model. In Proceedings of the 2017 IEEE Symposium Series on Computational Intelligence (SSCI), Honolulu, HI, USA, 27 November–1 December 2017; pp. 1–8. [Google Scholar]

- Atiquzzaman, M.; Liong, S.-Y.; Yu, X. Alternative Decision Making in Water Distribution Network with NSGA-II. J. Water Resour. Plan. Manag. 2006, 132, 122–126. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, D.; Yuan, J.; Li, H.; Gao, Y. Application of NSGA-II Algorithm for fault diagnosis in power system. Electr. Power Syst. Res. 2019, 175, 105893. [Google Scholar] [CrossRef]

- Sadeghi, J.; Sadeghi, S.; Niaki, S.T.A. A hybrid vendor managed inventory and redundancy allocation optimization problem in supply chain management: An NSGA-II with tuned parameters. Comput. Oper. Res. 2014, 41, 53–64. [Google Scholar] [CrossRef]

- Xiong, J.; Zhou, Z.; Tian, K.; Liao, T.; Shi, J. A multi-objective approach for weapon selection and planning problems in dynamic environments. J. Ind. Manag. Optim. 2017, 13, 1189–1211. [Google Scholar] [CrossRef]

- Guo, Z.; Wong, W.K.; Leung, S. A hybrid intelligent model for order allocation planning in make-to-order manufacturing. Appl. Soft Comput. 2013, 13, 1376–1390. [Google Scholar] [CrossRef]

- Niu, X.; Tang, H.; Wu, L. Satellite scheduling of large areal tasks for rapid response to natural disaster using a multi-objective genetic algorithm. Int. J. Disaster Risk Reduct. 2018, 28, 813–825. [Google Scholar] [CrossRef]

- Luong, N.H.; Alderliesten, T.; Bel, A.; Niatsetski, Y.; Bosman, P.A. Application and benchmarking of multi-objective evolutionary algorithms on high-dose-rate brachytherapy planning for prostate cancer treatment. Swarm Evol. Comput. 2018, 40, 37–52. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, M.; Shen, L.; Song, H. Sequential Scheduling Method for FJSP with Multi-Objective under Mixed Work Calendars. Processes 2019, 7, 888. [Google Scholar] [CrossRef]

- Balasubramaniyan, S.; Srinivasan, S.; Buonopane, F.; Subathra, B.; Vain, J.; Ramaswamy, S. Design and verification of Cyber-Physical Systems using TrueTime, evolutionary optimization and UPPAAL. Microprocess. Microsyst. 2016, 42, 37–48. [Google Scholar] [CrossRef]

- Tavakkoli-Moghaddam, R.; Azarkish, M.; Sadeghnejad-Barkousaraie, A. Solving a multi-objective job shop scheduling problem with sequence-dependent setup times by a Pareto archive PSO combined with genetic operators and VNS. Int. J. Adv. Manuf. Technol. 2011, 53, 733–750. [Google Scholar] [CrossRef]

- Motlagh, M.M.; Azimi, P.; Amiri, M.; Madraki, G. An efficient simulation optimization methodology to solve a multi-objective problem in unreliable unbalanced production lines. Expert Syst. Appl. 2019, 138, 112836. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Y.; Li, X.; Wang, Z.; Wanga, S.; Gao, C. A New Evolutionary Multiobjective Model for Traveling Salesman Problem. IEEE Access 2019, 7, 66964–66979. [Google Scholar] [CrossRef]

- Ghoddousi, P.; Ansari, R.; Makui, A. An improved robust buffer allocation method for the project scheduling problem. Eng. Optim. 2016, 49, 718–731. [Google Scholar] [CrossRef]

- Shokouhi, E. Integrated multi-objective process planning and flexible job shop scheduling considering precedence constraints. Prod. Manuf. Res. 2017, 6, 61–89. [Google Scholar] [CrossRef]

- Li, D.; Das, S.; Pahwa, A.; Deb, K. A multi-objective evolutionary approach for generator scheduling. Expert Syst. Appl. 2013, 40, 7647–7655. [Google Scholar] [CrossRef]

- Fotakis, D.G.; Sidiropoulos, E.; Myronidis, D.; Ioannou, K. Spatial genetic algorithm for multi-objective forest planning. For. Policy Econ. 2012, 21, 12–19. [Google Scholar] [CrossRef]

- Jerić, S.V.; Figueira, J.R. Multi-objective scheduling and a resource allocation problem in hospitals. J. Sched. 2012, 15, 513–535. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, C.; Shao, X.; Yang, X.; Tian, G. A multi-objective memetic algorithm for integrated process planning and scheduling. Int. J. Adv. Manuf. Technol. 2016, 85, 1513–1528. [Google Scholar] [CrossRef]

- Ji, B.; Sun, H.; Yuan, X.; Yuan, Y.; Wang, X. Coordinated optimized scheduling of locks and transshipment in inland waterway transportation using binary NSGA-II. Int. Trans. Oper. Res. 2019, 27, 1501–1525. [Google Scholar] [CrossRef]

- Mohapatra, P.; Nayak, A.; Kumar, S.; Tiwari, M. Multi-objective process planning and scheduling using controlled elitist non-dominated sorting genetic algorithm. Int. J. Prod. Res. 2014, 53, 1712–1735. [Google Scholar] [CrossRef]

- Hu, C.; Yan, X.; Gong, W.; Liu, X.; Wang, L.; Gao, L. Multi-objective based scheduling algorithm for sudden drinking water contamination incident. Swarm Evol. Comput. 2020, 55, 100674. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Li, X.; Wang, Q.; Liao, W.; Zhao, Q. An Efficient Multiobjective Backtracking Search Algorithm for Single Machine Scheduling with Controllable Processing Times. Math. Probl. Eng. 2017, 2017, 1–24. [Google Scholar] [CrossRef]

- Cho, H.-M.; Bae, S.-J.; Kim, J.; Jeong, I.-J. Bi-objective scheduling for reentrant hybrid flow shop using Pareto genetic algorithm. Comput. Ind. Eng. 2011, 61, 529–541. [Google Scholar] [CrossRef]

- De, A.; Choudhary, A.; Tiwari, M.K. Multiobjective Approach for Sustainable Ship Routing and Scheduling with Draft Restrictions. IEEE Trans. Eng. Manag. 2019, 66, 35–51. [Google Scholar] [CrossRef]

- Leydesdorff, L.; Milojević, S. Scientometrics. arXiv 2012, arXiv:1208.4566. [Google Scholar]

- Childress, D. Citation tools in academic libraries: Best practices for reference and instruction. Ref. User Serv. Q. 2011, 51, 143. [Google Scholar] [CrossRef][Green Version]

- Estabrooks, C.A.; Derksen, L.; Winther, C.; Lavis, J.N.; Scott, S.D.; Wallin, L.; Profetto-McGrath, J. The intellectual structure and substance of the knowledge utilization field: A longitudinal author co-citation analysis, 1945 to 2004. Implement. Sci. 2008, 3, 49. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Marra, M. Big Data: Who, What and Where? Social, Cognitive and Journals Map of Big Data Publications with Focus on Optimization. In Big Data Optimization: Recent Developments and Challenges; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–16. [Google Scholar]

- Rahimi, I.; Ahmadi, A.; Zobaa, A.F.; Emrouznejad, A.; Aleem, S.H.E.A. Big Data Optimization in Electric Power Systems: A Review; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Musigmann, B.; Von Der Gracht, H.; Hartmann, E. Blockchain Technology in Logistics and Supply Chain Management—A Bibliometric Literature Review from 2016 to January 2020. IEEE Trans. Eng. Manag. 2020, 67, 988–1007. [Google Scholar] [CrossRef]

- Neelam, S.; Sood, S.K. A Scientometric Review of Global Research on Smart Disaster Management. IEEE Trans. Eng. Manag. 2021, 68, 317–329. [Google Scholar] [CrossRef]

- Weinberg, B.H. Bibliographic coupling: A review. Inf. Storage Retr. 1974, 10, 189–196. [Google Scholar] [CrossRef]

- Luo, H.; Du, B.; Huang, G.Q.; Chen, H.; Li, X. Hybrid flow shop scheduling considering machine electricity consumption cost. Int. J. Prod. Econ. 2013, 146, 423–439. [Google Scholar] [CrossRef]

- Liu, P.; Guo, S.; Xu, X.; Chen, J. Derivation of Aggregation-Based Joint Operating Rule Curves for Cascade Hydropower Reservoirs. Water Resour. Manag. 2011, 25, 3177–3200. [Google Scholar] [CrossRef]

- Sengupta, S.; Das, S.; Nasir, M.; Vasilakos, A.V.; Pedrycz, W. An Evolutionary Multiobjective Sleep-Scheduling Scheme for Differentiated Coverage in Wireless Sensor Networks. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2012, 42, 1093–1102. [Google Scholar] [CrossRef]

- Langdon, W.B.; Harman, M.; Jia, Y. Efficient multi-objective higher order mutation testing with genetic programming. J. Syst. Softw. 2010, 83, 2416–2430. [Google Scholar] [CrossRef]

- Wang, W.; Tian, G.; Chen, M.; Tao, F.; Zhang, C.; Ai-Ahmari, A.; Li, Z.; Jiang, Z. Dual-objective program and improved artificial bee colony for the optimization of energy-conscious milling parameters subject to multiple constraints. J. Clean. Prod. 2020, 245, 118714. [Google Scholar] [CrossRef]

- Wu, X.; Cao, Y.; Xiao, Y.; Guo, J. Finding of urban rainstorm and waterlogging disasters based on microblogging data and the location-routing problem model of urban emergency logistics. Ann. Oper. Res. 2020, 290, 865–896. [Google Scholar] [CrossRef]

- Xu, X.; Mo, R.; Dai, F.; Lin, W.; Wan, S.; Dou, W. Dynamic Resource Provisioning with Fault Tolerance for Data-Intensive Meteorological Workflows in Cloud. IEEE Trans. Ind. Inform. 2020, 16, 6172–6181. [Google Scholar] [CrossRef]

- Salkuti, S.R. Day-ahead thermal and renewable power generation scheduling considering uncertainty. Renew. Energy 2019, 131, 956–965. [Google Scholar] [CrossRef]

- Verma, S.; Pant, M.; Snassel, V. A Comprehensive Review on NSGA-II for Multi-Objective Combinatorial Optimization Problems. IEEE Access 2021, 9, 57757–57791. [Google Scholar] [CrossRef]

- Deb, K.; Jain, H. An Evolutionary Many-Objective Optimization Algorithm Using Reference-Point-Based Nondominated Sorting Approach, Part I: Solving Problems with Box Constraints. IEEE Trans. Evol. Comput. 2013, 18, 577–601. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, G.-G.; Dong, J.; Gandomi, A. Improved NSGA-III with Second-Order Difference Random Strategy for Dynamic Multi-Objective Optimization. Processes 2021, 9, 911. [Google Scholar] [CrossRef]

| Manufacturing Model | Model Type |

|---|---|

| Single | Linear Programing |

| Parallel Machines | Mixed-Integer Programming |

| Job-Shop | Mixed-Integer Quadratic Programming |

| Flow- or Open-Shop | Mixed-Integer Non-Linear Programming |

| Flexible Manufacturing | Queuing Techniques and Simulation |

| Lot Scheduling System | |

| Project Scheduling | |

| Objective Function | Constraints |

| Economic-Related Objective | Economic-Related Constraints |

| Minimize Makespan | Makespan Equation |

| Minimize or Maximize Tardiness | Makespan Value Limitation |

| Minimize Electricity Cost | Tardiness Equation |

| Minimize Labor Cost | Tardiness Value Limitation |

| Minimize Inventory Cost, etc. | Amount of Demand |

| Environment-Related Objective | Total Energy Cost |

| Minimize Total Energy Consumption | Energy Cost in Specific Mode |

| Minimize Peak Power | Electricity Price |

| Minimize Carbon Emissions | Revenue from Power Sold |

| Minimize Squatted Deviation | Labor Cost Equation, etc. |

| Maximize Utilization | Environment-Related Constraints |

| Minimize Water Consumption | Power’s Peak Constraint |

| Maximize Total Availability System, etc. | Total Energy Consumption |

| Social-Related Objective | Energy Consumption in Specific Mode |

| Minimize Noise Level | Total Power Supply |

| Capacity Limitation | |

| Duration of Initiatives | |

| Carbon Emissions Value Limitation | |

| Carbon Emissions Equation | |

| Amount of Water | |

| Water Quality Class Function | |

| Cleaning Cost | |

| Amount of Water Discharge | |

| Amount of Contaminant | |

| Waste Water and Effluent Limitation, etc. | |

| Social-Related Constraints | |

| Recovery Time Ergonomic Time Value Limitation, etc. |

| Algorithm | Fitness Function | Diversity | Elitism | Strengths | Weakness |

|---|---|---|---|---|---|

| VEGA [133,134,135,136] | Select subpopulation using an objective function | No | No | Easy to code | Fast convergence to an objective function |

| MOGA [137,138,139] | Pareto ranking | Using fitness function | No | Extension of single objective | Slow convergence and dependency on niche size parameter |

| WBGA [140] | Average normalized weighted objective function | Identifying weights | No | Extension of single objective | Difficulty in nonconvex space |

| RWGA [141,142] | Average normalized weighted objective function | Assign weight randomly | Yes | Easy to code | Difficulty in nonconvex space |

| RDGA [143] | Ranking based and reducing problem | Non-concentration based on cells | Yes | Updated cells | Difficulty in run |

| NPGA [144,145,146,147,148] | No | Niche count | No | Easy tournament selection | Dependency on niche size parameter |

| DMOEA [149] | Ranking based on cells | Adjusting density of cells | Yes | Updated cells | Difficulty in run |

| NSGA [150,151,152,153,154] | Ranking based on non-dominated solutions | Using fitness function | No | Fast convergence | Dependency on niche size parameter |

| NSGA-II [22,155,156,157,158,159] | Ranking based on non-dominated solutions | Crowding distance | Yes | Uses non-dominated sorting, crowding distance, and elitist techniques | Crowding distance performs only in objective functions |

| Source | Problem | Objective | Methodology | Results and Findings |

|---|---|---|---|---|

| [165] | Weapon selection and planning problem | Optimizing net present value (NPV) and effectiveness | An MOEA based on NSGA-II is employed | The proposed measures are able to adapt to dynamic changes. |

| [166] | Allocation problem | Integrating MOMO process and Monte Carlo simulation technique. | Integrating MOMO, NSGA-II, and Tabu search | The MOMO technique possesses a better performance of seeking global optimum than other proposed methods. |

| [167] | Satellite scheduling problem | Proposing a multi-objective optimization method to solve the mentioned problem | Designing a decomposition method. Expressing a multi-objective integer-programming model. Designing multi-objective genetic algorithm NSGA-II. | The applicability of the proposed method under different situations has been proven. |

| [168] | High-dose rate brachytherapy planning | Determining an appropriate schedule of a radiation source | Four different MOEAs have been employed | Results present that MO-RV-GOMEA is the best performing MOEA. |

| [169] | FJS problem under mixed work calendars | Proposing two key technologies, namely time reckoning and sequential scheduling | Designing NSGA-II with an elite strategy | The suggested technique can gain an effective Pareto set within an acceptable time. |

| Source | Problem | Objective | Methodology | Results and Findings |

|---|---|---|---|---|

| [170] | Reliability in Cyber-Physical Systems (CPS) components | Designing and verifying CPS using multi-objective evolutionary optimization. | Using three scheduling methods: fixed priority, earliest deadline first, and deadline monotonic. | The results show that the proposed approach can be used to design and validate CPS for performance and verify timing guarantees. |

| [171] | Job-shop scheduling problem | Minimizing the mean weighted completion time and the sum of the weighted tardiness costs. | Proposing a new integer linear programming. Modifying PSO and comparing with NSGA-II. | The results depict that the proposed PSO outperforms NSGA-II. |

| [172] | Multi-objective unreliable unbalanced production lines | Maximizes the throughput rate and minimizes the total buffer capacities and cost. | Proposing DOE and RSM along with NRGA and NSGA-II. | The proposed system could be applied to a large-scale production line. |

| Source | Problem | Objective | Methodology | Results and Findings |

|---|---|---|---|---|

| [173] | Multi-objective traveling salesman problem | Improving a GA-based algorithm, namely Physarum-inspired computational model (PCM). | Using the hill-climbing algorithm to improve the proposed method. | Findings show that the proposed method has a better performance compared with the other MOTSP. |

| [174] | Project scheduling problem | Proposing a robust project scheduling. | Two-stage multi-objective buffer allocation approach. | The results indicate that the obtained buffered schedule reduces the cost of disruptions. |

| [175] | Process planning and FJS scheduling. | Makespan, critical machine workload, and machine total workload. | Integration of WGA and NSGA-II. | The proposed algorithm outperforms the exact solutions. |

| Source | Problem | Objective | Methodology | Results and Findings |

|---|---|---|---|---|

| [176] | Generator scheduling considering environmental and economic issues. | Optimal generation scheduling. | Two-phase approach (hourly and 24-h scheduling) | Effectiveness of the proposed approach has been approved. |

| [177] | Multi-objective spatial forest planning. | Maximizing timber volume and minimizing sediment level. | Spatial NSGA-II approach | The results show that the proposed method has better performance for both constrained and unconstrained problems. |

| [178] | Resource allocation problem in a hospital. | Daily scheduling for residents or patients in a hospital. | Using variable neighborhood search, scatter search, and NSGA-II | Able to find efficient solutions. |

| [59] | Nurse scheduling problem considering human factors. | Minimizing the total cost of staffing as well as the sum of incompatibility and maximizing the satisfaction. | Keshtel algorithm, NSGA-II, and Tabu search. | Effectiveness of the proposed methods is approved. |

| Source | Problem | Objective | Methodology | Results and Findings |

|---|---|---|---|---|

| [179] | Process planning and scheduling | Optimizing the makespan, machine workload, and the total workload of machines. | Multi-objective memetic algorithm. | The results compared with NSGA-II show that the proposed algorithm has better performance. |

| [180] | Scheduling of locks and transshipment problem | Optimizing water–land transshipment co-scheduling. | Hybrid heuristic method using binary NSGA-II. | The feasibility and the superiority of the model have been verified. |

| [181] | Integration of process planning and scheduling | Minimizing of makespan, machining cost, and idle time. | Improved version of NSGA-II. | Results provide optimal and robust solutions. |

| [182] | Sudden drinking water contamination incident | Minimizing the volume of contaminated water and the operational costs. | Integration of NSGA-II and EPANET simulation model. | The validity of the model has been approved by two water distribution networks. |

| Source | Problem | Objective | Methodology | Results and Findings |

|---|---|---|---|---|

| [183] | Single machine scheduling with controllable processing times. | Developing a new multi-objective discrete backtracking search algorithm. | Through adaptive selection scheme and total cost reduction strategy. | The performance of the proposed method compared with other algorithms was validated. |

| [184] | Reentrant hybrid flow-shop scheduling. | Optimizing of makespan and total tardiness. | Genetic algorithms with Minkowski distance-based crossover operator. | The results show that NSGA-II outperformed in terms of convergence, diversity, and the dominance of solution. |

| [185] | Sustainable ship routing and scheduling. | Estimating the total fuel consumed and carbon emission from each vessel as well as improving the service level of the port. | Mixed-integer nonlinear programming using NSGA-II and MOPSO. | The robustness of the model has been approved by experimental results and comparative, and sensitive analysis. |

| Document type | TP | % | AU | APP | TC2020 | CPP2020 |

|---|---|---|---|---|---|---|

| Article | 462 | 67.64 | 1282 | 2.77 | 8766 | 18.97 |

| Proceedings paper | 231 | 33.82 | 652 | 2.82 | 1126 | 4.87 |

| Review | 5 | 0.73 | 15 | 3.0 | 155 | 31 |

| Other items | 15 | 2.19 | 154 | 10.26 | 269 | 17.93 |

| 1-Word | 2-Word | 3-Word | |||

|---|---|---|---|---|---|

| Keyword | Frequency | Keyword | Frequency | Keyword | Frequency |

| NSGA-II | 76 | Multi-objective optimization | 86 | Multi-objective genetic algorithm | 9 |

| Scheduling | 38 | Multi-objective | 19 | Particle swarm optimization | 6 |

| Makespan | 22 | Genetic algorithms | 17 | Unrelated parallel machine | 3 |

| Optimization | 10 | Energy consumption | 13 | Differential evolution algorithm | 3 |

| Reliability | 9 | Production scheduling | 10 | Single machine scheduling | 3 |

| Uncertainty | 8 | Cloud computing | 9 | Flexible job-shop | 3 |

| Microgrid | 6 | Project scheduling | 8 | Grey wolf optimizer | 3 |

| Metaheuristics | 5 | Preventive maintenance | 8 | Job-shop scheduling | 3 |

| Tardiness | 4 | Memetic algorithm | 7 | Just-in-time | 3 |

| Heuristic | 3 | Dynamic scheduling | 6 | Charge-discharge scheduling | 1 |

| 1-Word | 2-Word | 3-Word | |||

|---|---|---|---|---|---|

| Keyword | Frequency | Keyword | Frequency | Keyword | Frequency |

| NSGA-II | 100 | Preventive maintenance | 10 | Multi-objective evolutionary algorithm | 13 |

| Scheduling | 54 | NSGA-II algorithm | 10 | Particle swarm optimization | 7 |

| Multi-objective | 32 | Project scheduling | 10 | Non-dominated sorting | 7 |

| Makespan | 28 | Evolutionary algorithm | 9 | Ant colony optimization | 6 |

| Reliability | 9 | Multi-objective scheduling | 8 | Variable neighborhood search | 6 |

| Optimization | 9 | Optimal scheduling | 7 | Energy efficient scheduling | 6 |

| Microgrid | 9 | Task scheduling | 7 | Hybrid flow-shop | 4 |

| Metaheuristics | 7 | Memetic algorithm | 6 | Controllable processing times | 4 |

| Rescheduling | 7 | Generation scheduling | 5 | Demand side management | 3 |

| Uncertainty | 6 | Demand response | 5 | Single-machine scheduling | 3 |

| Scopus | ISSN | Number of Documents | |

|---|---|---|---|

| 1 | Lecture Notes in Computer Science | 1611-3349 | 30 |

| 2 | Computers and Industrial Engineering | 0360-8352 | 20 |

| 3 | Robotics and Computer-Integrated Manufacturing | 0736-5845 | 20 |

| 4 | International Journal of Advanced Manufacturing Technology | 1433-3015 | 19 |

| 5 | Applied Soft Computing Journal | 1568-4946 | 18 |

| 6 | International Journal of Production Research | 0020-7543 | 15 |

| 7 | Advances in Intelligent Systems and Computing | 2194-5365 | 13 |

| 8 | IEEE Access | 2169-3536 | 13 |

| 9 | China Mechanical Engineering | 2192-8258 | 13 |

| 10 | Computers and Operations Research | 0305-0548 | 11 |

| Web of Science Category | TP | AU | APP | TC 2020 | CPP 2020 | |

|---|---|---|---|---|---|---|

| 1 | Computer Science Artificial Intelligence | 175 | 523 | 2.98 | 2023 | 11.56 |

| 2 | Computer Science Theory Methods | 49 | 159 | 3.24 | 290 | 5.91 |

| 3 | Engineering Electrical Electronic | 40 | 125 | 3.12 | 541 | 13.52 |

| 4 | Computer Science Interdisciplinary Applications | 37 | 118 | 3.18 | 664 | 17.94 |

| 5 | Operations Research Management Science | 24 | 82 | 3.41 | 418 | 17.41 |

| 6 | Automation Control Systems | 16 | 44 | 2.75 | 201 | 12.56 |

| 7 | Computer Science Information Systems | 15 | 55 | 3.66 | 46 | 3.60 |

| 8 | Engineering Manufacturing | 9 | 31 | 3.44 | 167 | 18.55 |

| 9 | Robotics | 8 | 25 | 3.12 | 14 | 1.75 |

| 10 | Computer Science Cybernetics | 7 | 19 | 2.71 | 197 | 28.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahimi, I.; Gandomi, A.H.; Deb, K.; Chen, F.; Nikoo, M.R. Scheduling by NSGA-II: Review and Bibliometric Analysis. Processes 2022, 10, 98. https://doi.org/10.3390/pr10010098

Rahimi I, Gandomi AH, Deb K, Chen F, Nikoo MR. Scheduling by NSGA-II: Review and Bibliometric Analysis. Processes. 2022; 10(1):98. https://doi.org/10.3390/pr10010098

Chicago/Turabian StyleRahimi, Iman, Amir H. Gandomi, Kalyanmoy Deb, Fang Chen, and Mohammad Reza Nikoo. 2022. "Scheduling by NSGA-II: Review and Bibliometric Analysis" Processes 10, no. 1: 98. https://doi.org/10.3390/pr10010098

APA StyleRahimi, I., Gandomi, A. H., Deb, K., Chen, F., & Nikoo, M. R. (2022). Scheduling by NSGA-II: Review and Bibliometric Analysis. Processes, 10(1), 98. https://doi.org/10.3390/pr10010098