The Development of an Information Technology Architecture for Automated, Agile and Versatile Companies with Ecological and Ethical Guidelines

Abstract

:1. Introduction

2. Setting the Scene

2.1. Historical Example

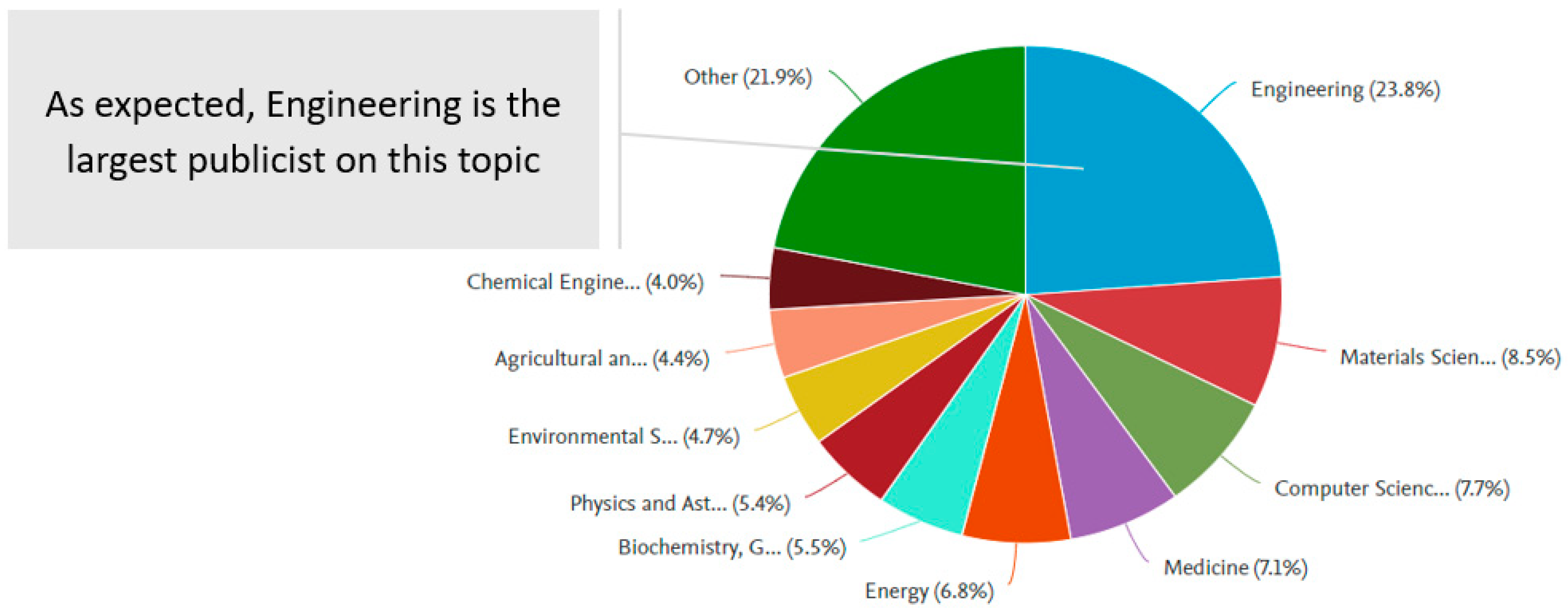

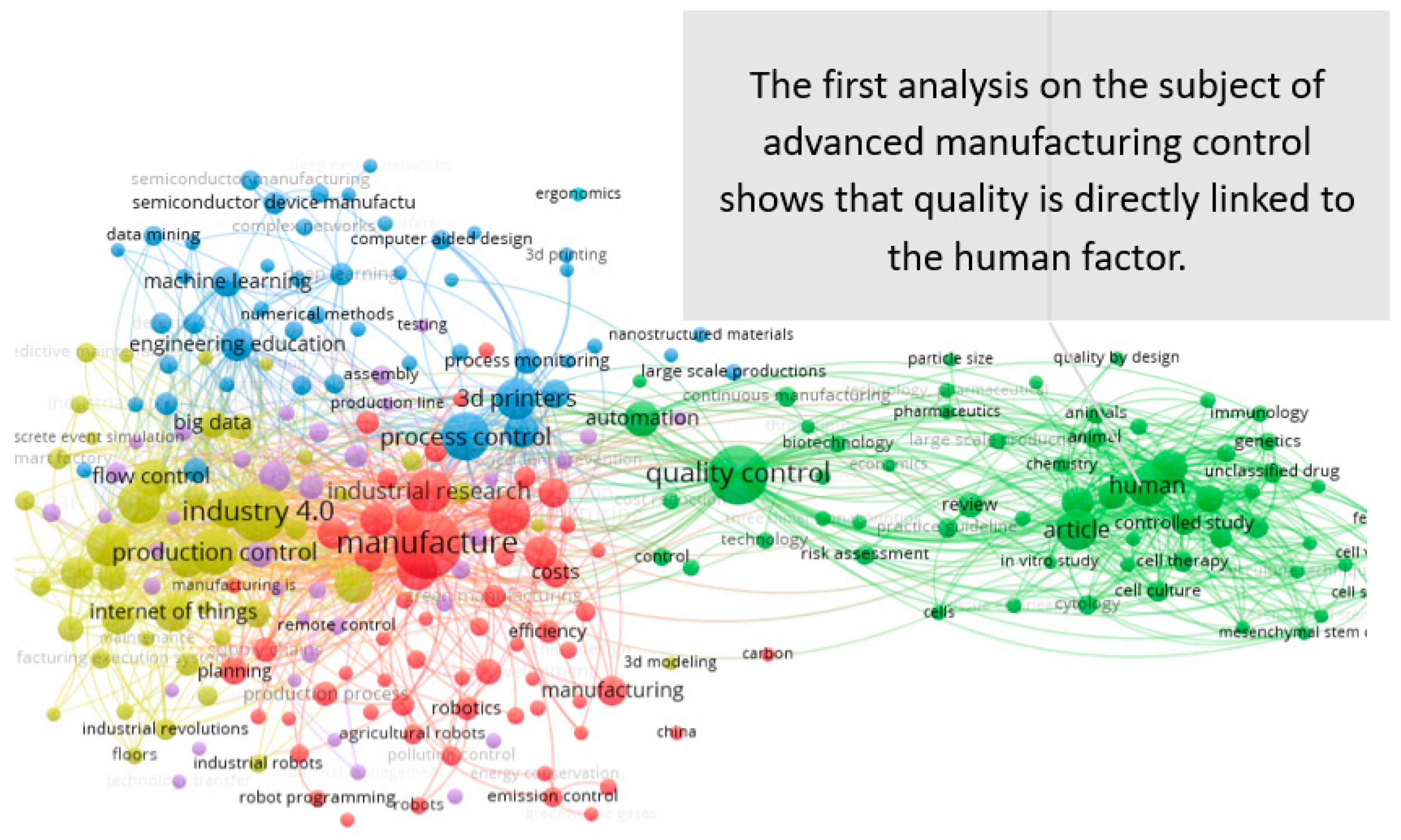

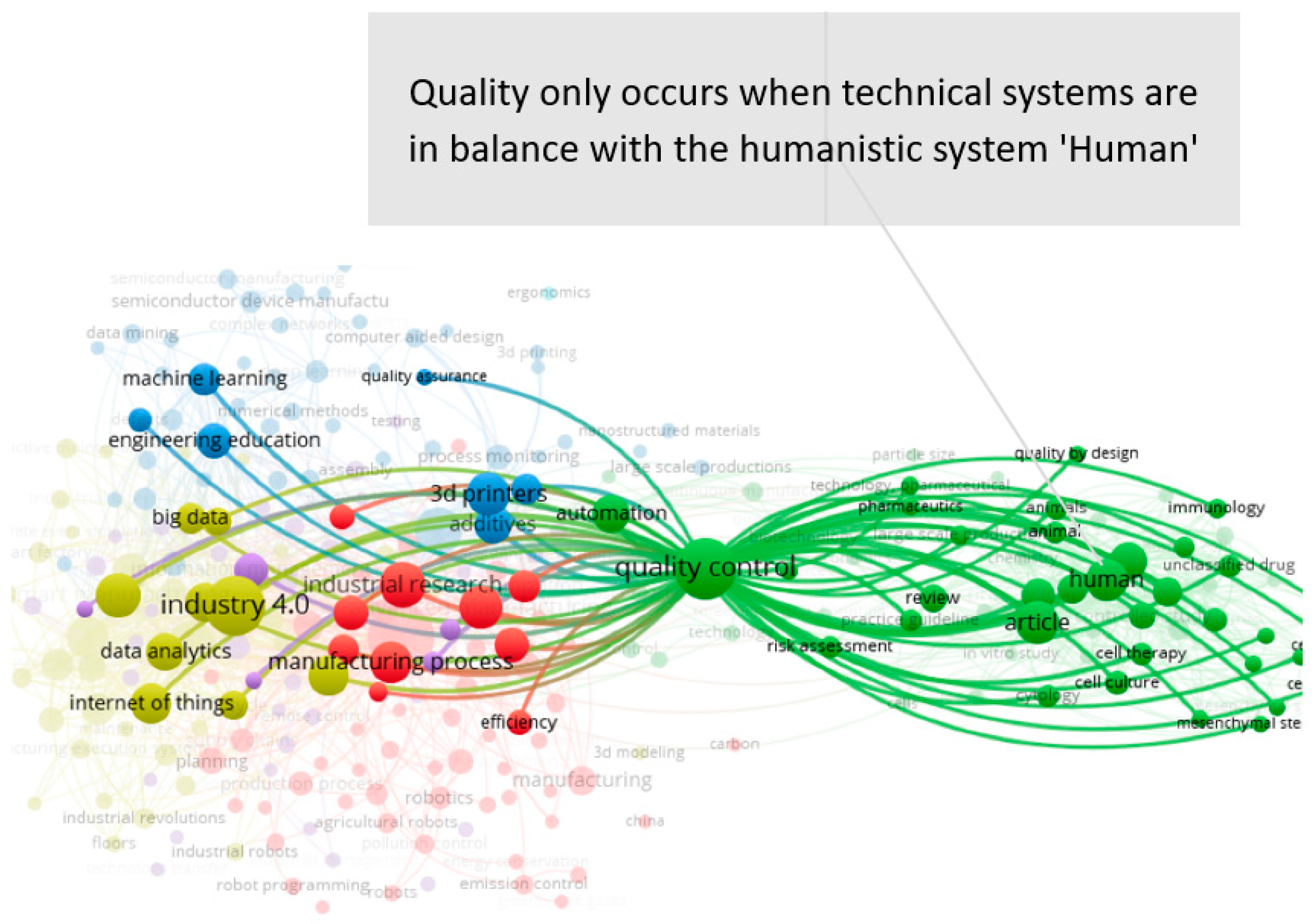

2.2. Derivation of the Knowledge for the Research Work

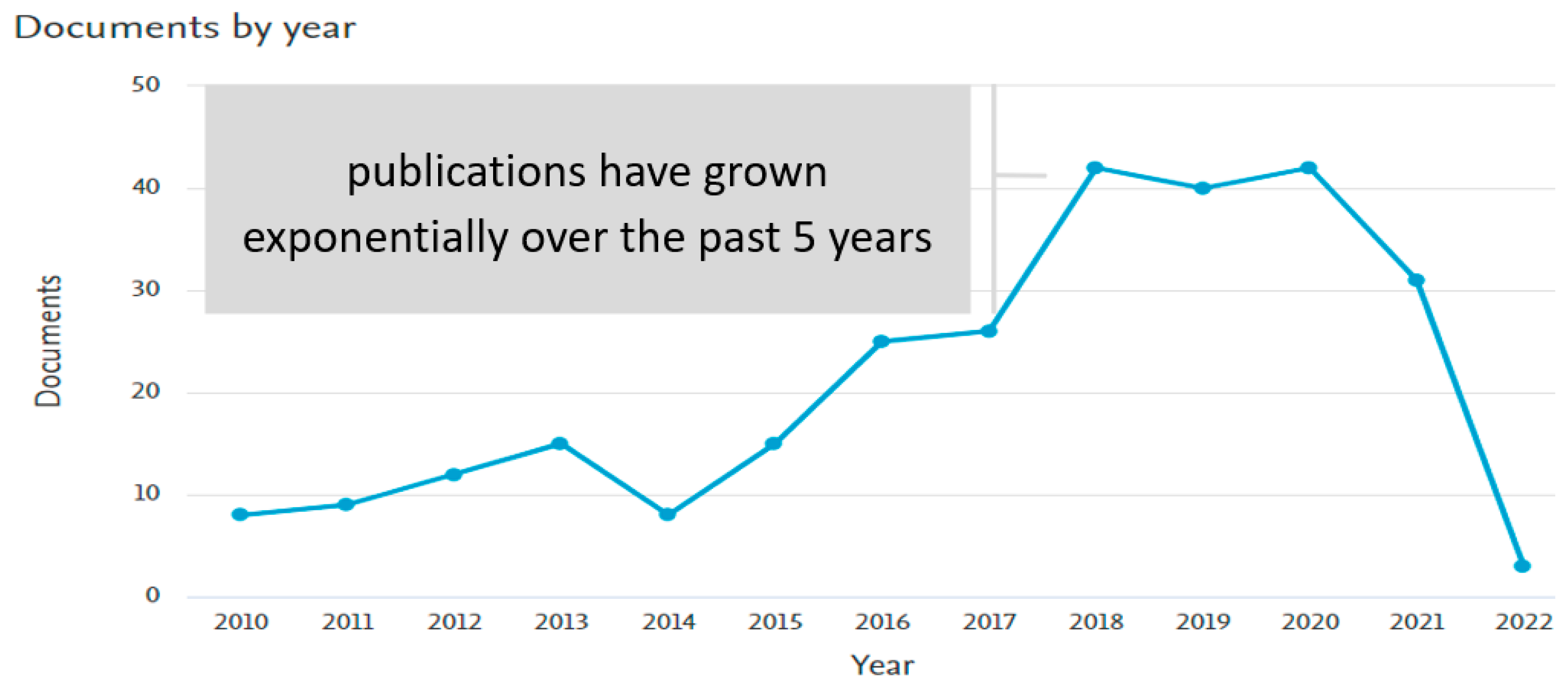

3. Methodology

- (1)

- Increase productivity;

- (2)

- Reduce costs with personnel, hence saving precious financial resources;

- (3)

- Enlarge the capacity of this production area (to around double the current capacity, based on the current situation of the semiconductor industry, where there is high demand);

- (4)

- Respond to customer requirements more efficiently;

- (5)

- Have fewer “headaches” due to continuous change in the plant;

- (6)

- Improve our quality to reduce waste and re-work (a great effort to further reduce costs).

- Get an initial general overview with the help of the central keywords;

- Analyze the statistics in SCOPUS and use them for further filtering;

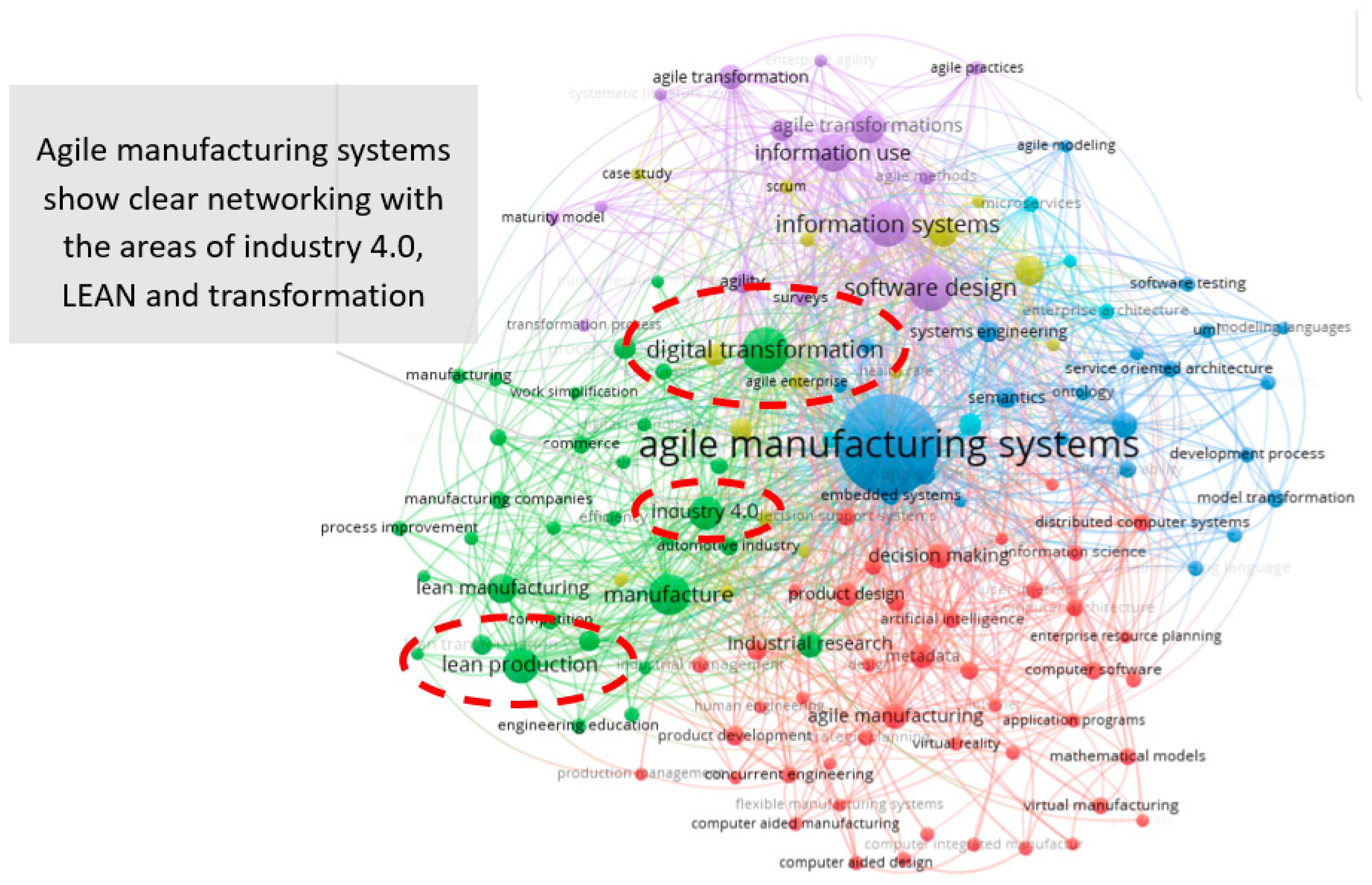

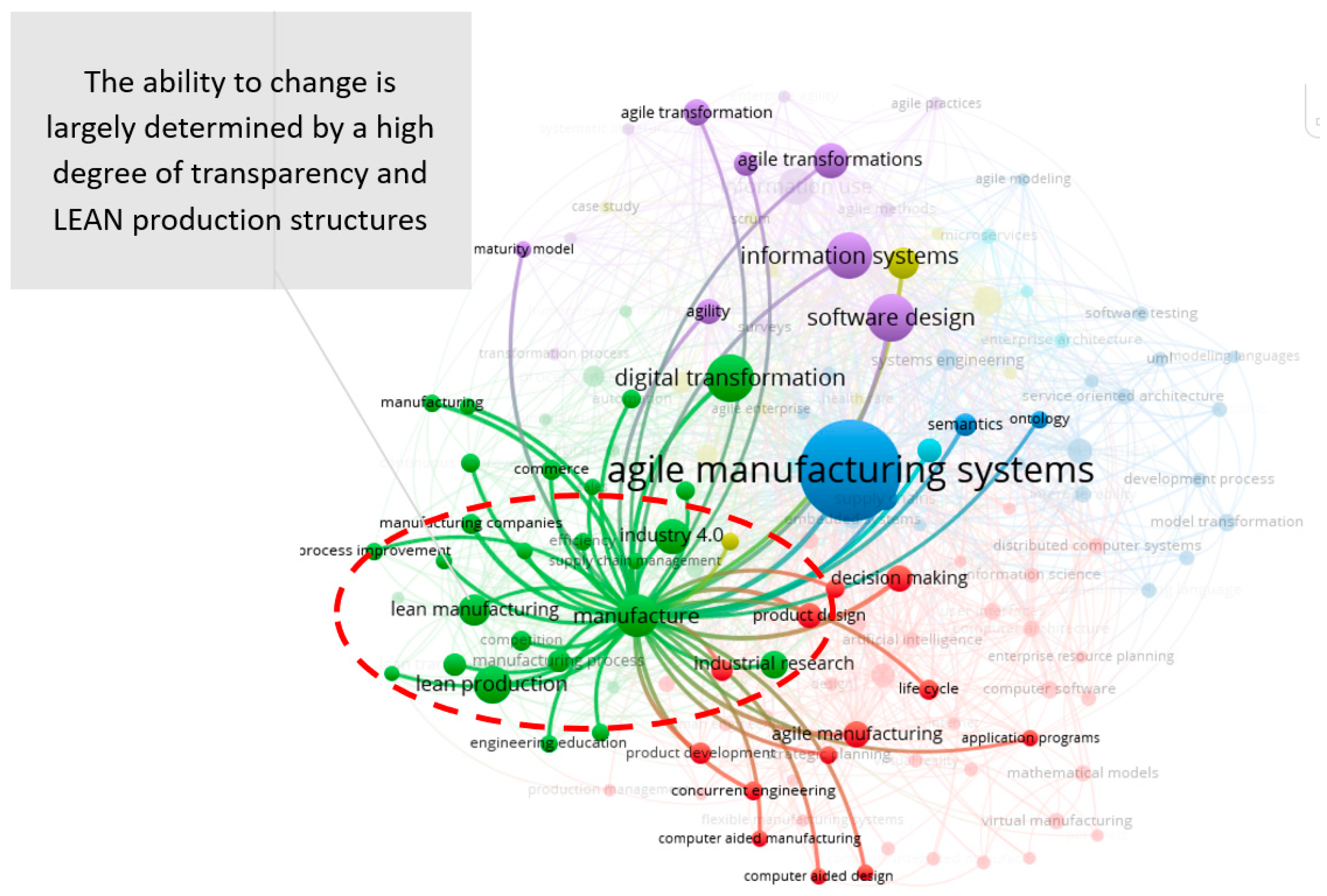

- After the second step, use the VOSviewer to sound out the direction for further areas through the significant nodes [20];

- This results in very good hits when selecting interesting and target-oriented articles;

- Read and categorize the article content for further references and continuations to confirm the research study purpose.

4. Results

Iteration Level of the Systematic Research Process

- As flexible as possible in highly technological and turbulent times and able to adapt to rigorous and unpredictable market demands;

- Improve the use of overall opportunities regarding system data;

5. Discussion

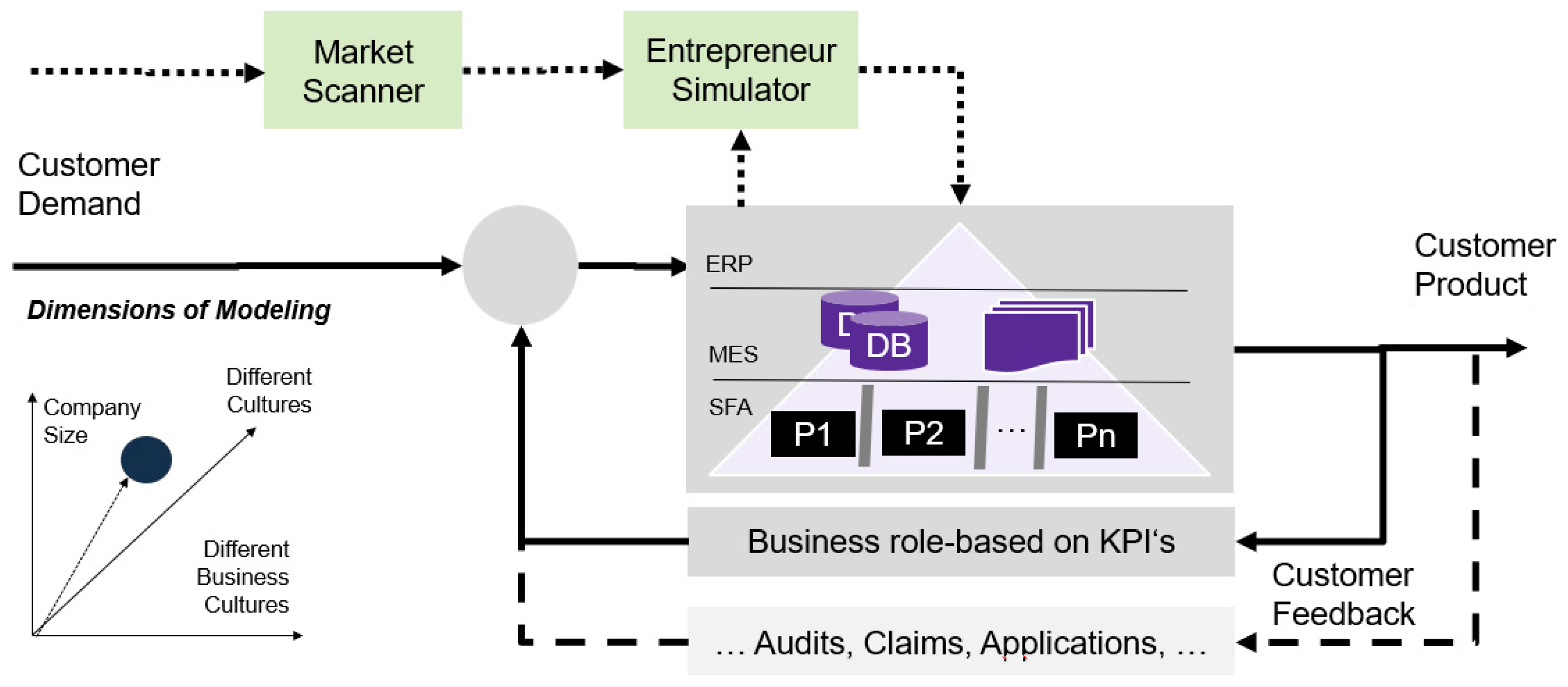

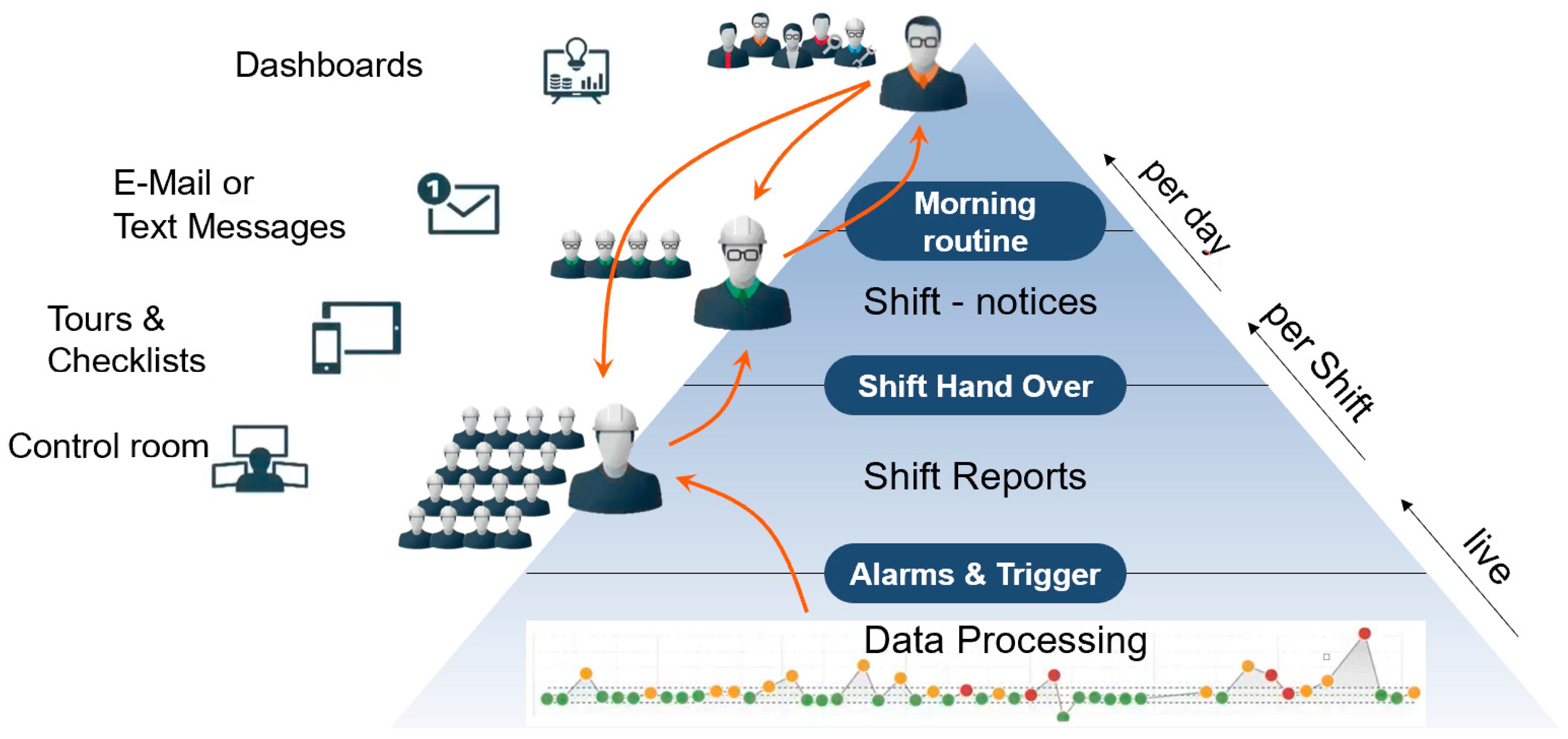

5.1. Event-Driven Manufacturing Information System

5.2. Agile Architectures and Point-to-Point Integration

5.3. Service-Oriented Architectures (SOAs)

5.4. Architecture of the Agile Information System

5.5. AISA Events

5.6. AISA Message Bus System

5.7. Business Control Systems

- A.

- Strengthen government’s policy support and the introduction of external digital technology.

- B.

- Enterprise’s digital planning and implementation:

- (a)

- Evaluation of the foundation of enterprise digitalizationStrengthen exchanges with high-quality companies in digital-related technologies; learn about new market dynamics/new management concepts and management models by overall planning and step-by-step implementation—specific requirements of lean production—analyze the value stream.

- (b)

- Informatization, digital planning and integration:The construction of the information architecture is the core content—value chain as the penetration line, in order to complete the enterprise informatization and digital planning including:Implementation enterprise digitalization route.

- C.

- Intelligent manufacturing strategies through…

- Interoperation, integration, and the merging of the physical world and the cyber world of manufacturing. IoT: Acquisition of data from the physical world;

- Cloud computing, big data, mobile Internet: Processing and transferring to the Internet;

- Cyber-Physical Systems (CPS): Integration of the physical world and the cyber world of manufacturing. The “Manufacturing-as-a-Service” concept provides manufacturing as a service for users on the basis of interoperability and platform independence;

- The “Service-oriented smart manufacturing (SoSM)” combines new IT and services and proposes a framework for manufacturing through the full use of new IT and services.

6. Conclusions

6.1. Limitations of the Research

6.2. Suggestions for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moore, G.C.; Benbasat, I. Development of an instrument to measure the perceptions of adopting an information technology innovation. Inf. Syst. Res. 1991, 2, 192–222. [Google Scholar] [CrossRef] [Green Version]

- El-Gayar, O.F.; Ambati, L.S.; Nawar, N. Wearables, artificial intelligence, and the future of healthcare. In AI and Big Data’s Potential for Disruptive Innovation; IGI Global: Hershey, PA, USA, 2019; pp. 104–129. [Google Scholar]

- Lindvall, M.; Muthig, D.; Dagnino, A.; Wallin, C.; Stupperich, M.; Kiefer, D.; May, J.; Kahkonen, T. Agile software development in large organizations. Computer 2004, 37, 26–34. [Google Scholar] [CrossRef] [Green Version]

- Klebanov, B.B.; Madnani, N. Synthesis Lectures on Human Language Technologies. In Synthesis Lectures on Human Language Technologies; Morgan and Claypool Publishers: San Rafael, CA, USA, 2022; pp. 1–314. [Google Scholar]

- Aurégan, P.; Tellier, A. Nintendo in the pursuit of the blue ocean. In Innovation in the Cultural and Creative Industries; Wiley: Hoboken, NJ, USA, 2019; pp. 1–28. [Google Scholar]

- Lantano, F.; Petruzzelli, A.M.; Panniello, U. Business model innovation in video-game consoles to face the threats of mobile gaming: Evidence from the case of Sony PlayStation. Technol. Forecast. Soc. Chang. 2022, 174, 121210. [Google Scholar] [CrossRef]

- Negrini, S.; Bissolotti, L.; Ferraris, A.; Noro, F.; Bishop, M.D.; Villafañe, J.H. Nintendo Wii Fit for balance rehabilitation in patients with Parkinson’s disease: A comparative study. J. Bodyw. Mov. Ther. 2017, 21, 117–123. [Google Scholar] [CrossRef]

- Schön, S.; Schön, R.; Kröger, K.; Creutzburg, R. Overview and forensic investigation approaches of the gaming console sony playstation portable. In Multimedia Content and Mobile Devices; SPIE: Burlingame, CA, USA, 2013. [Google Scholar]

- Madhavan, S.; Pradhan, S. Relationship between Nintendo’s Wii balance board derived variables and clinical balance scores in individuals with stroke. Gait Posture 2020, 79, 170–174. [Google Scholar] [CrossRef]

- Gašpar, T.; Deniša, M.; Radanovič, P.; Ridge, B.; Savarimuthu, T.R.; Kramberger, A.; Priggemeyer, M.; Roßmann, J.; Wörgötter, F.; Ivanovska, T.; et al. Smart hardware integration with advanced robot programming technologies for efficient reconfiguration of robot workcells. Robot. Comput.-Integr. Manuf. 2020, 66, 101979. [Google Scholar] [CrossRef]

- Gallo-Molina, J.P.; Cogoni, G.; Peeters, E.; Ambati, S.R.; Nopens, I. A hybrid model for multipoint real time potency observation in continuous direct compression manufacturing operations. Int. J. Pharm. 2022, 613, 121385. [Google Scholar] [CrossRef]

- Cerquitelli, T.; Pagliari, D.J.; Calimera, A.; Bottaccioli, L.; Patti, E.; Acquaviva, A.; Poncino, M. Manufacturing as a Data-Driven Practice: Methodologies, Technologies, and Tools. Proc. IEEE 2021, 109, 399–422. [Google Scholar] [CrossRef]

- De Modesti, P.H.; Carvalhar Fernandes, E.; Borsato, M. Production Planning and Scheduling Using Machine Learning and Data Science Processes. In Proceedings of the 9th Swedish Production Symposium, SPS 2020, Jönköping, Sweden, 21–24 April 2020; IOS Press BV: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Remenyi, D. Dictionary of Research Concepts and Issues, 2nd ed.; ACPI: Reading, UK, 2017. [Google Scholar]

- Saunders, M.N.K.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 8th ed.; Pearson Education: Harlow, UK, 2009. [Google Scholar]

- Kotter, J.P. Leading Change; Harvard Business Review Press: Boston, MA, USA, 2012. [Google Scholar]

- Wu, K.J.; Tse, E.C.M.; Shang, C.; Guo, Z. Nucleation and growth in solution synthesis of nanostructures—From fundamentals to advanced applications. Prog. Mater. Sci. 2022, 123, 100821. [Google Scholar] [CrossRef]

- Mason, J. Qualitative Researching, 2nd ed.; Sage: London, UK, 2002. [Google Scholar]

- Yan, J.; Li, B. Research hotspots and tendency of intelligent manufacturing. Kexue Tongbao/Chin. Sci. Bull. 2020, 65, 684–694. [Google Scholar] [CrossRef]

- Svobodová, L.; Bednarska-Olejniczak, D. SMART City and Economy: Bibliographic Coupling and Co-occurrence. In Proceedings of the 19th IFIP WG 6.11 Conference on e-Business, e-Services, and e-Society, I3E 2020, Skukuza, South Africa, 6–8 April 2020; Hattingh, M., Matthee, M., Smuts, H., Pappas, I., Dwivedi, Y.K., Mäntymäki, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 102–113. [Google Scholar]

- Frazzon, E.M.; Agostino, Í.R.S.; Broda, E.; Freitag, M. Manufacturing networks in the era of digital production and operations: A socio-cyber-physical perspective. Annu. Rev. Control 2020, 49, 288–294. [Google Scholar] [CrossRef]

- Brandi, S.; Gallo, A.; Capozzoli, A. A predictive and adaptive control strategy to optimize the management of integrated energy systems in buildings. Energy Rep. 2022, 8, 1550–1567. [Google Scholar] [CrossRef]

- Theorin, A.; Bengtsson, K.; Provost, J.; Lieder, M.; Johnsson, C.; Lundholm, T.; Lennartson, B. An Event-Driven Manufacturing Information System Architecture for Industry 4.0. Int. J. Prod. Res. 2017, 55, 1297–1311. [Google Scholar] [CrossRef]

- Cao, J.; Brinksmeier, E.; Fu, M.; Gao, R.X.; Liang, B.; Merklein, M.; Schmidt, M.; Yanagimoto, J. Manufacturing of advanced smart tooling for metal forming. CIRP Ann. 2019, 68, 605–628. [Google Scholar] [CrossRef]

- Biuki, M.; Kazemi, A.; Alinezhad, A. An integrated location-routing-inventory model for sustainable design of a perishable products supply chain network. J. Clean. Prod. 2020, 260, 120842. [Google Scholar] [CrossRef]

- Fouz-González, J. Using apps for pronunciation training: An empirical evaluation of the English File Pronunciation app. Lang. Learn. Technol. 2020, 24, 62–85. [Google Scholar]

- Cappuccio, P.; Burrafato, S.; Maliardi, A.; Ricci Maccarini, G.; Taccori, D.; Dalla Costa, R.; Raunholt, L.; Larsen, Ø. Full robotic drill floor as advanced rig automation. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference 2019, ADIP 2019, Abu Dhabi, United Arab Emirates, 11–14 November 2019; Society of Petroleum Engineers: Richardson, TX, USA, 2019. [Google Scholar]

- Chen, W.; Liu, H.; Qi, E. Discrete event-driven model predictive control for real-time work-in-process optimization in serial production systems. J. Manuf. Syst. 2020, 55, 132–142. [Google Scholar] [CrossRef]

- Oluyisola, O.E.; Bhalla, S.; Sgarbossa, F.; Strandhagen, J.O. Designing and developing smart production planning and control systems in the industry 4.0 era: A methodology and case study. J. Intell. Manuf. 2022, 33, 311–332. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Lau, W.C. Accordia: Adaptive Cloud Configuration Optimization for Recurring Data-Intensive Applications. In Proceedings of the 10th ACM Symposium on Cloud Computing, SoCC 2019, Santa Cruz, CA, USA, 20–23 November 2019; Association for Computing Machinery: New York, NY, USA, 2019. [Google Scholar]

- Aileni, R.M.; George, S.; Pasca, S.; Alberto, V.S.C. Data fusion-based AI algorithms in the context of IIoTS. In EAI/Springer Innovations in Communication and Computing; Springer Science and Business Media Deutschland GmbH: Berlin, Germany, 2020; pp. 17–38. [Google Scholar]

- Christou, I.T.; Kefalakis, N.; Soldatos, J.K.; Despotopoulou, A.-M. End-to-end industrial IoT platform for Quality 4.0 applications. Comput. Ind. 2022, 137, 103591. [Google Scholar] [CrossRef]

- Bentabet, D.; Cloud-Io, T. Platform for Smart Irrigation Solution Based on NodeMCU. In Proceedings of the International Conference in Artificial Intelligence in Renewable Energetic Systems, ICAIRES 2020, Tipaza, Algeria, 22 November–24 November 2020; Hatti, M., Ed.; Springer Science and Business Media Deutschland GmbH: Berlin, Germany, 2021; pp. 689–696. [Google Scholar]

- Crawford, B.; Sourki, R.; Khayyam, H.; Milani, A.S. A machine learning framework with dataset-knowledgeability pre-assessment and a local decision-boundary crispness score: An industry 4.0-based case study on composite autoclave manufacturing. Comput. Ind. 2021, 132, 103510. [Google Scholar] [CrossRef]

- Castro-Martin, A.P.; Ahuett-Garza, H.; Guamán-Lozada, D.; Márquez-Alderete, M.F.; Urbina Coronado, P.D.; Orta Castañon, P.A.; Kurfess, T.R.; González de Castilla, E. Connectivity as a design feature for industry 4.0 production equipment: Application for the development of an in-line metrology system. Appl. Sci. 2021, 11, 1312. [Google Scholar] [CrossRef]

- Keserica, H.; Sučić, S.; Capuder, T. Standards-compliant chat-based middleware platform for smart grid management. Energies 2019, 12, 694. [Google Scholar] [CrossRef] [Green Version]

- Maia, R.F.; Bálsamo, Â.J.; Lopes, G.A.W.; Massote, A.A. Evaluation of OPC-UA communication in an autonomous advanced manufacturing cell implementation. Gest. E Prod. 2021, 27, e5414. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Tan, D.; Zhang, Y. Key Technologies and Development Trends in Advanced Intelligent Sawing Equipments. Chin. J. Mech. Eng. 2021, 34, 30. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. Impact of Industry 4.0 on supply chain performance. Prod. Plan. Control 2021, 32, 63–81. [Google Scholar] [CrossRef]

- Fallahpour, A.; Yazdani, M.; Mohammed, A.; Wong, K.Y. Green sourcing in the era of industry 4.0: Towards green and digitalized competitive advantages. Ind. Manag. Data Syst. 2021, 121, 1997–2025. [Google Scholar] [CrossRef]

- Grznár, P.; Gregor, M.; Krajčovič, M.; Mozol, Š.; Schickerle, M.; Vavrík, V.; Ďurica, L.; Marschall, M.; Bielik, T. Modeling and simulation of processes in a factory of the future. Appl. Sci. 2020, 10, 4503. [Google Scholar] [CrossRef]

- Gallo, T.; Santolamazza, A. Industry 4.0 and human factor: How is technology changing the role of the maintenance operator? In Proceedings of the 2nd International Conference on Industry 4.0 and Smart Manufacturing, ISM 2020, Virtual Event, Austria, 23–25 November 2020; Elsevier B.V.: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Francisco, A.; Taylor, J.E. Understanding citizen perspectives on open urban energy data through the development and testing of a community energy feedback system. Appl. Energy 2019, 256, 113804. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuehnel, K.; Au-Yong-Oliveira, M. The Development of an Information Technology Architecture for Automated, Agile and Versatile Companies with Ecological and Ethical Guidelines. Informatics 2022, 9, 37. https://doi.org/10.3390/informatics9020037

Kuehnel K, Au-Yong-Oliveira M. The Development of an Information Technology Architecture for Automated, Agile and Versatile Companies with Ecological and Ethical Guidelines. Informatics. 2022; 9(2):37. https://doi.org/10.3390/informatics9020037

Chicago/Turabian StyleKuehnel, Klaus, and Manuel Au-Yong-Oliveira. 2022. "The Development of an Information Technology Architecture for Automated, Agile and Versatile Companies with Ecological and Ethical Guidelines" Informatics 9, no. 2: 37. https://doi.org/10.3390/informatics9020037

APA StyleKuehnel, K., & Au-Yong-Oliveira, M. (2022). The Development of an Information Technology Architecture for Automated, Agile and Versatile Companies with Ecological and Ethical Guidelines. Informatics, 9(2), 37. https://doi.org/10.3390/informatics9020037