Author Contributions

Conceptualization, H.-J.K. and C.-S.K.; validation, K.-S.K. and J.-H.S.; writing—original draft preparation, H.-J.K., J.-H.S. and C.-S.K.; writing—review and editing, K.-S.K. and C.-S.K.; visualization, J.-H.S. and C.-S.K.; project administration, C.-S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Korea National University of Transportation Industry–Academy Cooperation Foundation in 2025.

Institutional Review Board Statement

All study procedures were approved by the Korea National University of Transportation Institutional Review Board (KNUT IRB-HR-09-12), approval date 2 August 2024.

Informed Consent Statement

Informed written consent was obtained from the participants.

Conflicts of Interest

Author Hwi-Jin Kwon was employed by Seoul Metro. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Park, K.J. A Study for the Development of the Reliability/Availability Management System of the Urban Transit Vehicles (I). J. Korean Soc. Railw 2023, 16, 163–168. [Google Scholar] [CrossRef]

- Kwon, H.J.; Lee, S.I.; Park, J.H.; Kim, C.S. Design of Augmented Reality Training Content for Railway Vehicle Maintenance Focusing on the Axle-Mounted Disc Brake System. Appl. Sci. 2021, 11, 9090. [Google Scholar] [CrossRef]

- Kwon, H.J.; Cha, J.H.; Park, Y.K.; Kim, C.S. A Study on the Realistic Content for Air Compressor Maintenance of the Ur-ban Railway Vehicle. J. Korean Soc. Urban Railw 2022, 10, 1231–1238. [Google Scholar] [CrossRef]

- Kang, G.H.; Cha, H.J.; Chung, I.S.; Kim, C.S. A Study on the Development of Augmented Reality Contents for Air Compressor of Railway Vehicles. In Proceedings of the 2023 Prognostics and Health Management Conference (PHM), Paris, France, 31 May–2 June 2023; pp. 59–63. [Google Scholar] [CrossRef]

- Amo, I.D.; Erkoyunci, J.A.; Roy, R.; Palmarini, R.; Onoufriou, D. A systematic review of Augmented Reality content-related techniques for knowledge transfer in maintenance applications. Comput. Ind. 2018, 103, 47–71. [Google Scholar] [CrossRef]

- Simon, J.; Gogolak, L.; Sarosi, J.; Fürstner, I. Augmented Reality Based Distant Maintenance Approach. Actuators 2023, 12, 302. [Google Scholar] [CrossRef]

- Malta, A.; Farinha, T.; Mendes, M. Augmented reality in maintenance—History and perspectives. J. Imaging 2023, 9, 142. [Google Scholar] [CrossRef]

- Zhu, J.; Ong, S.K.; Nee, A.Y.C. An authorable context-aware augmented reality system to assist the maintenance technicians. Int. J. Adv. Manuf. Technol. 2013, 66, 1699–1714. [Google Scholar] [CrossRef]

- Mourtzis, D.; Siatras, V.; Angelopoulos, J. Real-Time Remote Maintenance Support Based on Augmented Reality (AR). Appl. Sci. 2020, 10, 1855. [Google Scholar] [CrossRef]

- Bodhwani, K.; Sharma, A. The Future of Augmented Reality: Emerging Trends and Challenges. Landscape 2023, 4, 63. [Google Scholar] [CrossRef]

- Peng, C.C.; Chang, A.C.; Chu, Y.L. Application of augmented reality for aviation equipment inspection and maintenance training. In Proceedings of the 2022 8th International Conference on Applied System Innovation (ICASI), Nantou, Taiwan, 22–23 April 2022; pp. 58–63. [Google Scholar] [CrossRef]

- Song, J.W. Augmented Reality (AR) and Virtual Reality (VR) Based Plant Work Support Technology for Smart Work Environment. Masters’s Thesis, University of Sungkyunkwan, Seoul, Republic of Korea, 2021. Available online: https://dcollection.skku.edu/srch/srchDetail/000000162059 (accessed on 13 September 2025).

- Borro, D.; Suescun, A.; Brazalez, A.; González, J.M.; Ortega, E.; González, E. WARM: Wearable AR and tablet-based assistant systems for bus maintenance. Appl. Sci. 2021, 11, 1443. [Google Scholar] [CrossRef]

- Lee, W.H.; Lee, K.H.; Lee, J.J.; Nam, B.W. A Study on Pipe Model Registration for Augmented Reality Based O&M Environment Improving. J. Comput. Struct. Eng. Inst. Korea 2019, 32, 191–197. [Google Scholar] [CrossRef]

- Lim, H.Y.; Ro, K.H. A Study on a CMS Platform for AR-based Remote Collaboration in a Smart Factory. J. Digit. Converg. 2018, 16, 327–334. [Google Scholar] [CrossRef]

- Jung, W. Application of Location-Based Augmented Reality to Support Operation and Maintenance in Indoor Environment of Power Plant. Bachelor’s Thesis, University of Inha, Incheon, Republic of Korea, 2020. Available online: http://inha.dcollection.net/common/orgView/200000288305 (accessed on 13 September 2025).

- Bulkova, Z. Possibilities of Implementing Augmented Reality in Railway Freight Transport. Transp. Tech. Technol. 2023, 19, 1–7. [Google Scholar] [CrossRef]

- Scheffer, S.; Martinetti, A.; Damgrave, R.; Thiede, S.; van Dongen, L. How to make augmented reality a tool for railway maintenance operations: Operator 4.0 perspective. Appl. Sci. 2021, 11, 2656. [Google Scholar] [CrossRef]

- Jeon, H.I.; Yu, Y.S.; Ko, B.J.; Kim, S.; Koo, B. Augmented Reality-based safety inspection framework for safety management in railway bridge and tunnel projects. J. Korean Soc. Railw 2021, 24, 590–607. [Google Scholar] [CrossRef]

- Kostolani, M.; Murin, J.; Kozak, S. Intelligent predictive maintenance control using augmented reality. In Proceedings of the 2019 22nd International Conference on Process Control (PC19), Strbske Pleso, Slovakia, 11–14 June 2019; pp. 58–63. [Google Scholar] [CrossRef]

- Garcia, C.; Ortega, M.; Ivorra, E.; Contero, M.; Mora, P.; Alcañiz, M.L. Holorailway: An augmented reality system to support assembly operations in the railway industry. Adv. Manuf. 2024, 12, 764–783. [Google Scholar] [CrossRef]

- Kim, K.S.; Kim, C.S. Development and Usability Evaluation of Augmented Reality Content for Light Maintenance Training of Air Spring for Electric Multiple Unit. Appl. Sci. 2024, 14, 7702. [Google Scholar] [CrossRef]

- Syed, T.A.; Siddiqui, M.S.; Abdullah, H.B.; Jan, S.; Namoun, A.; Alzahrani, A.; Nadeem, A.; Alkhodre, A.B. In-Depth Re-view of Augmented Reality: Tracking Technologies, Development Tools, AR Displays, Collaborative AR, and Security Concerns. Robot. Appl. Sci. 2022, 23, 146. [Google Scholar] [CrossRef]

- Chatzopoulos, D.; Bermejo, C.; Huang, Z.; Hui, P. Mobile Augmented Reality Survey: From Where We Are to Where We Go. IEEE Access 2017, 23, 6917–6950. [Google Scholar] [CrossRef]

- Kwon, H.J.; Kim, K.S.; Kim, C.S. Development and Evaluation of Augmented Reality Learning Content for Pneumatic Flow: Case Study on Brake Operating Unit. IEEE Access 2023, 11, 46173–46184. [Google Scholar] [CrossRef]

- Cao, J.; Lam, K.Y.; Lee, L.H.; Liu, X.; Hui, P.; Su, X. Mobile Augmented Reality: User Interfaces, Frameworks, and Intelligence. Acm. Comput. Surv. 2023, 55, 1–36. [Google Scholar] [CrossRef]

- Su, X.; Cao, J. 5G edge enhanced mobile augmented reality. In Proceedings of the 26th Annual International Conference on Mobile Computing and Networking, London, UK, 21–25 September 2020; pp. 1–3. [Google Scholar] [CrossRef]

- Kim, J.Y.; Sung, J.H. Structuralization of User Flow System in the Mobile Augmented Reality-Focused on Mobile and Spatial characteristics. J. Korean Basic Art 2011, 12, 139–147. Available online: http://scholarworks.bwise.kr/ssu/handle/2018.sw.ssu/13807 (accessed on 13 September 2025).

- Song, J.H.; Han, K.Y. Development of Digital Content for Electric Multiple Unit Maintenance: A Case Study on the Semi-Permanent Coupler. J. Digi Conten. Soc. 2024, 25, 3431–3440. [Google Scholar] [CrossRef]

- Baek, J.H.; Yoon, S.H.; Um, B.K.; Han, S.B.; Um, D.J. Study on the Institutionalization for Rolling Stock Maintenance Engineer and Maintenance Organization Certification. In Proceedings of the 2018 Spring Conference of the Korean Society for Railway, Jeju, Republic of Korea, 16–18 May 2018; pp. 421–422. Available online: https://www.dbpia.co.kr/journal/articleDetail?nodeId=NODE07455000&language=ko_KR&hasTopBanner=true&language=ko_KR&hasTopBanner=true (accessed on 13 September 2025).

- You, J.W.; Park, K.H. A case study on user experience evaluation of a virtual reality training content for advanced metering infrastructure. J. Educ. Inf. Media 2018, 24, 779–803. [Google Scholar] [CrossRef]

- Palmarini, R.; Erkoyuncu, J.A.; Roy, R.; Torabmostaedi, H. A systematic review of augmented reality applications in maintenance. Robot. Comput. Integr. Manuf. 2018, 49, 215–228. [Google Scholar] [CrossRef]

- Dirin, A.; Laine, T.H. User Experience in Mobile Augmented Reality: Emotions, Challenges, Opportunities and Best Practices. Computers 2018, 7, 33. [Google Scholar] [CrossRef]

- Valentini, L.; Grandi, F.; Peruzzini, M.; Pellicciari, M. UX-Driven Methodology to Design Usable Augmented Reality Applications for Maintenance. In Leveraging Transdisciplinary Engineering in a Changing and Connected World; IOS Press: Amsterdam, The Netherlands, 2023; pp. 42–51. [Google Scholar] [CrossRef]

- Shin, J.M.; Lee, S.H.; Yoo, J.E.; Roh, C.; Oh, J.A.; Kim, S.Y. Development and Evaluation of a Virtual Maintenance Training System for Thermal Power Plant Boiler. J. Digi Conten. Soc. 2021, 22, 791–800. [Google Scholar] [CrossRef]

- Jebb, A.T.; Ng, V.; Tay, L. A review of key Likert scale development advances: 1995–2019. Front. Psychol. 2021, 12, 637547. [Google Scholar] [CrossRef]

- Norman, G. Likert scales, levels of measurement and the “laws” of statistics. Adv. Health Sci. Educ. 2010, 15, 625–632. [Google Scholar] [CrossRef]

- Finstad, K. Response interpolation and scale sensitivity: Evidence against 5-point scales. J. Usability Stud. 2010, 5, 104–110. [Google Scholar]

- Ahn, S.H.; Yoo, E.Y.; Lee, S.H. A Validation Study of the Gross Motor Scale of Korean Version of Bayley Scales of Infant and Toddler Development. J. Korean Soc. Occup. Therap. 2018, 26, 81–97. [Google Scholar] [CrossRef]

- Kang, S.H. The Effects of Empowerment on Accountability. Bachelor’s Thesis, University of Seoul, Seoul, Republic of Korea, 2014. Available online: https://hdl.handle.net/10371/130416 (accessed on 13 September 2025).

- Oh, J.H.; Lee, J.I.; Karadeniz, F.; Kim, H.R.; Park, S.Y.; Jung, K.I.; Jeon, B.-J.; Kim, D.; Park, J.H.; Kong, C.-S. Quality characteristics of grilled fish paste formulation added with hot water extract powder from Lentinus edodes using one-way ANOVA. J. Korean Soc. Food Sci. Nutr. 2015, 50, 307–314. [Google Scholar] [CrossRef]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53–55. [Google Scholar] [CrossRef] [PubMed]

- Boenett, D.G.; Wright, T.A. Cronbach’s alpha reliability: Interval estimation, hypothesis testing, and sample size planning. J. Organ. Behav. 2015, 36, 3–15. [Google Scholar] [CrossRef]

- Bressler, D.M.; Bodzin, A.M. A mixed methods assessment of students’ flow experiences during a mobile augmented reality science game. J. Comput. Assist. Learn. 2013, 29, 505–517. [Google Scholar] [CrossRef]

- Oleksy, T.; Wunk, A. Augmented places: An impact of embodied historical experience on attitudes towards places. Comput. Hum. Behav. 2016, 57, 11–16. [Google Scholar] [CrossRef]

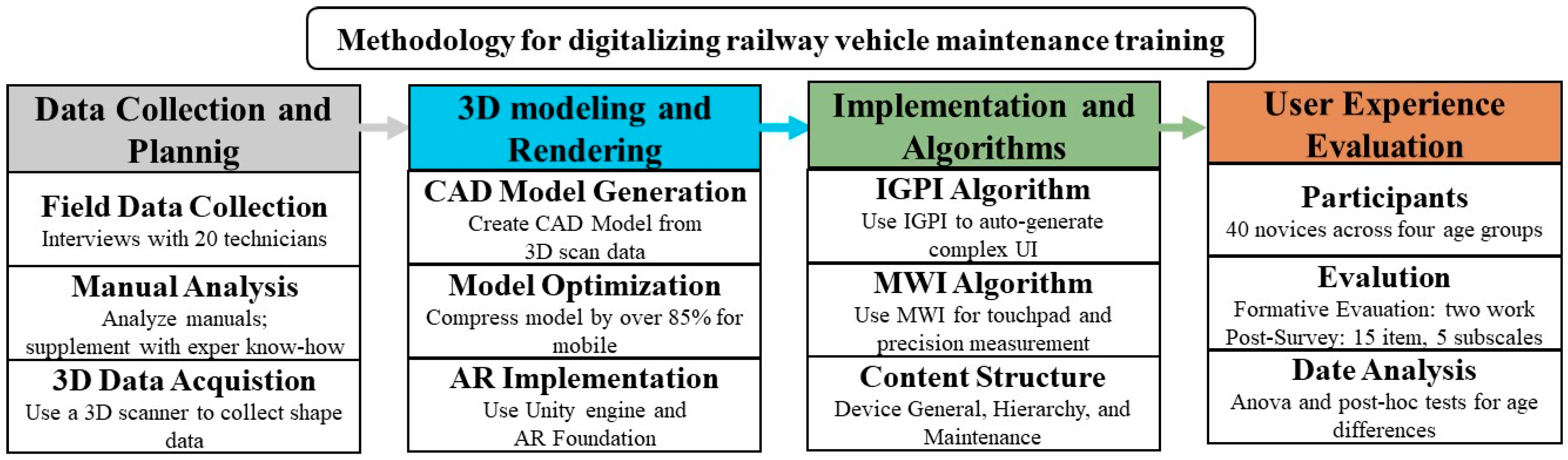

Figure 1.

Methodology for digitalizing railway vehicle maintenance training.

Figure 3.

Three-dimensional modeling process of axle box.

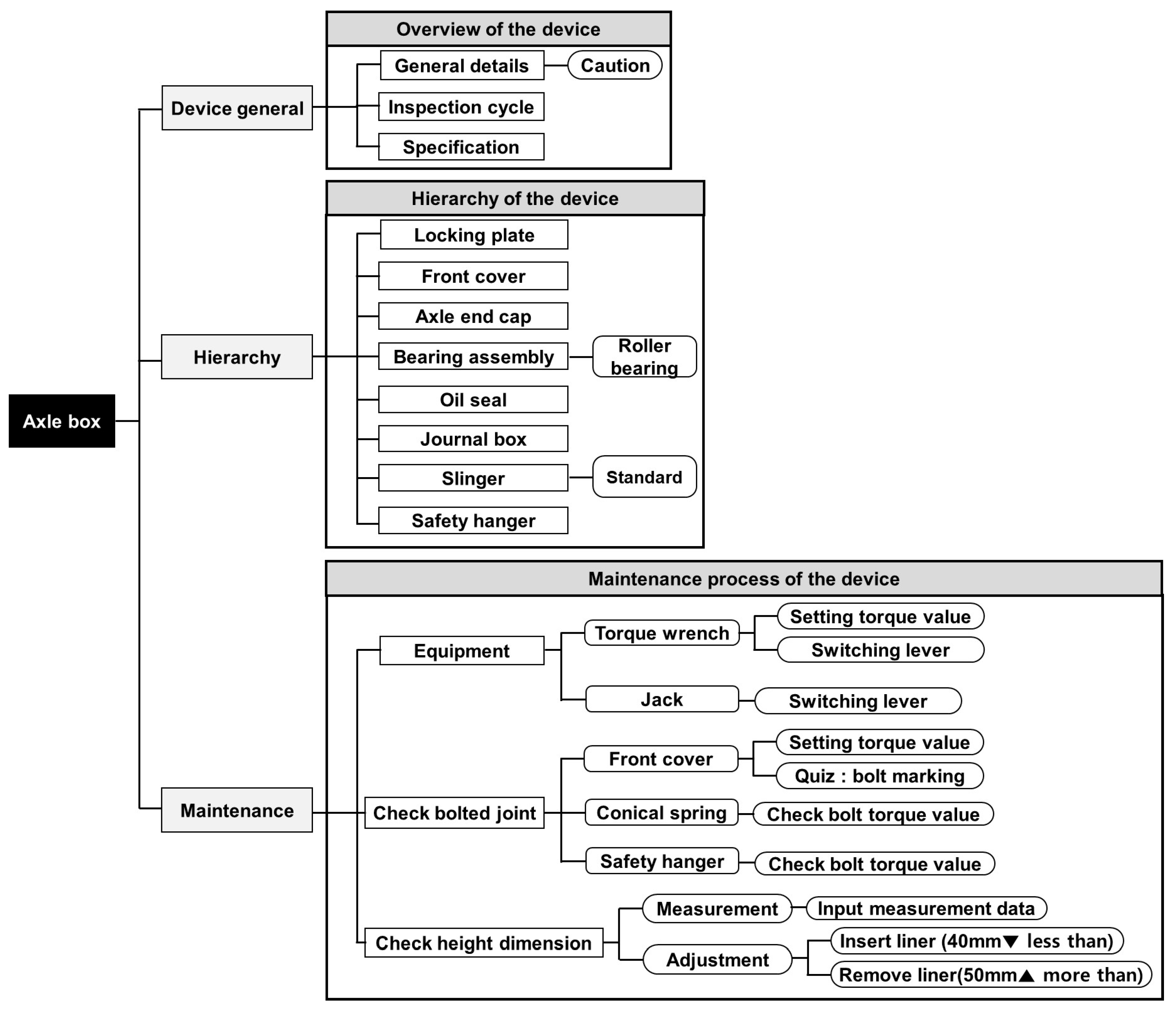

Figure 4.

Top-down mapping of essential information on axle box maintenance.

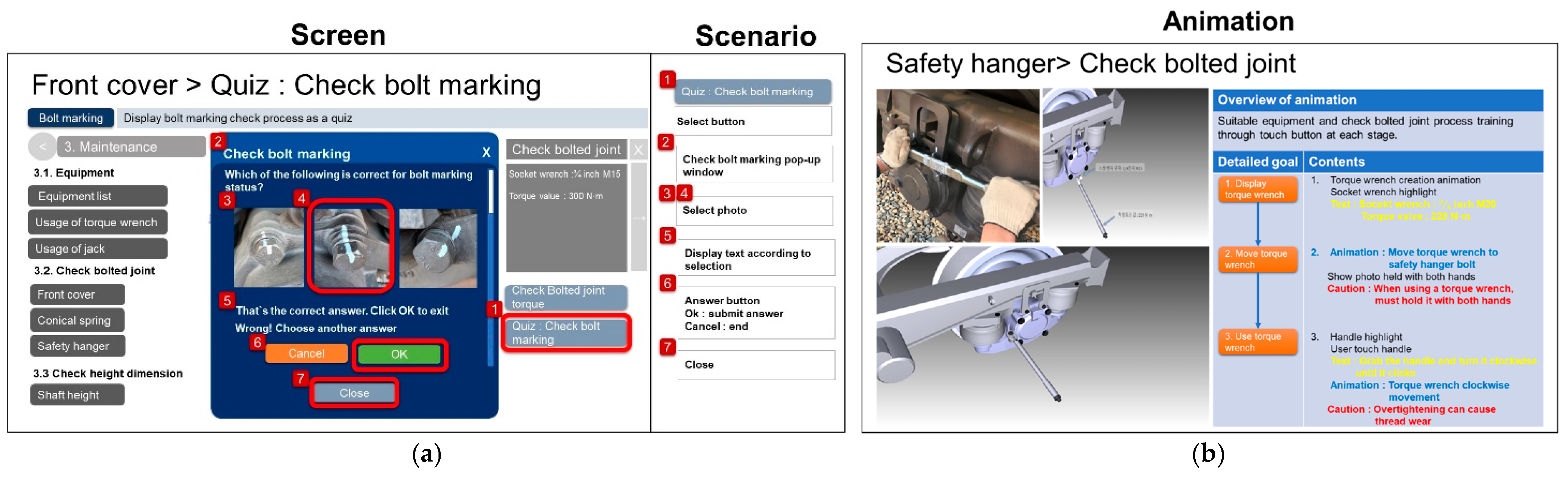

Figure 5.

AR content storyboard: (a) example of scenario; (b) example of animation.

Figure 6.

Logical flow of the implementation process.

Figure 7.

Visual implementation of digital content on a mobile device.

Figure 8.

Flowchart of the IGPI algorithm.

Figure 9.

The user interface implemented using IGPI algorithm.

Figure 10.

Flowchart of the MWI algorithm.

Figure 11.

Actual photos and descriptions of bearing damage and grease leakage.

Figure 12.

Exploded view of the axle box and a cross-section of the ball bearing.

Figure 13.

Equipment usage and detailed inspection: (a) ‘Next’ button click; (b) quiz pop-up window.

Figure 14.

Maintenance parts: (a) bolt fastening inspection process; (b) shaft height dimension checking process.

Figure 15.

Examples implemented through the MWI algorithm: (a) touchpad; (b) animation when the tolerance is exceeded or falls below the tolerance.

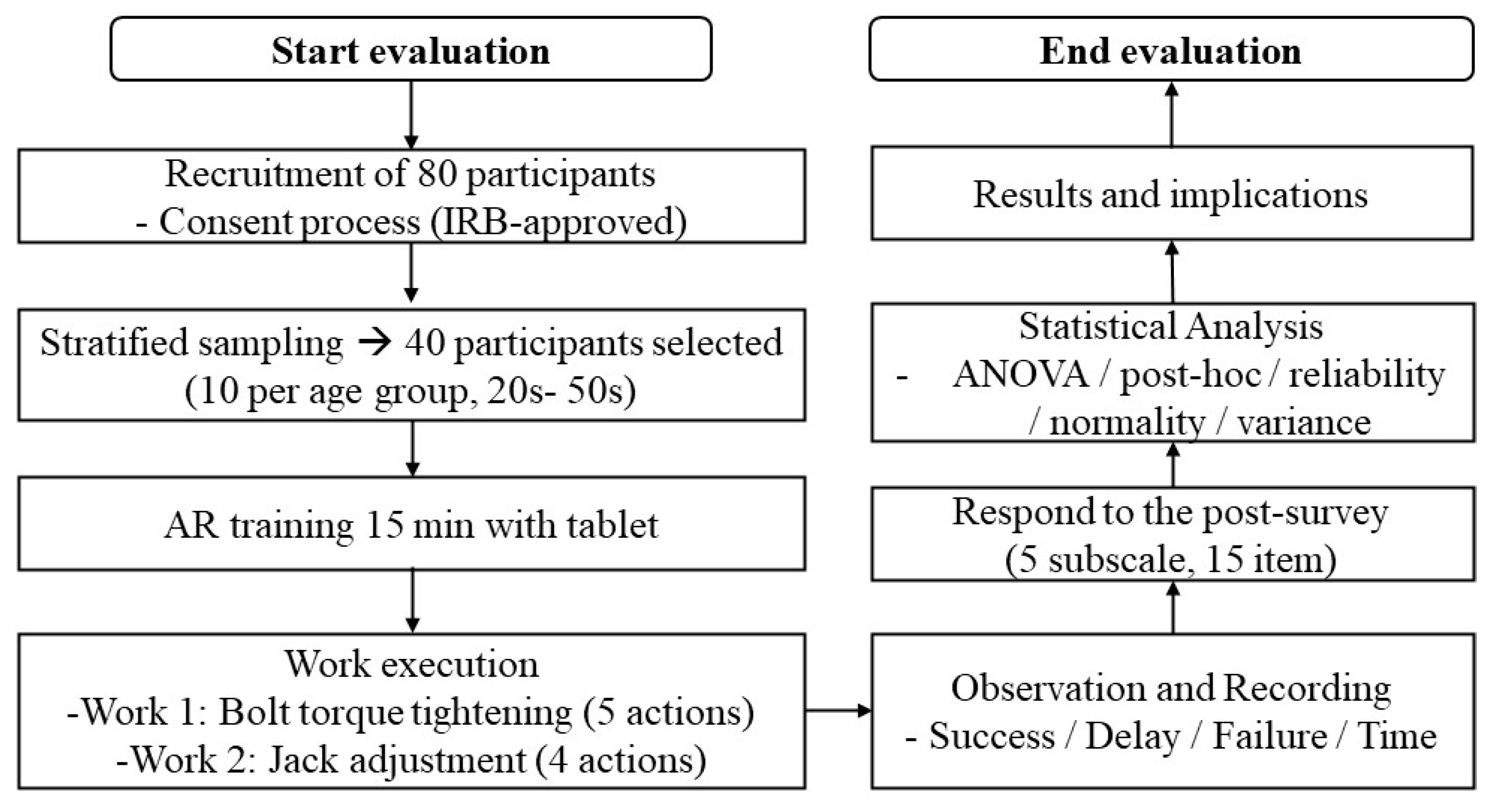

Figure 16.

The overall evaluation schema.

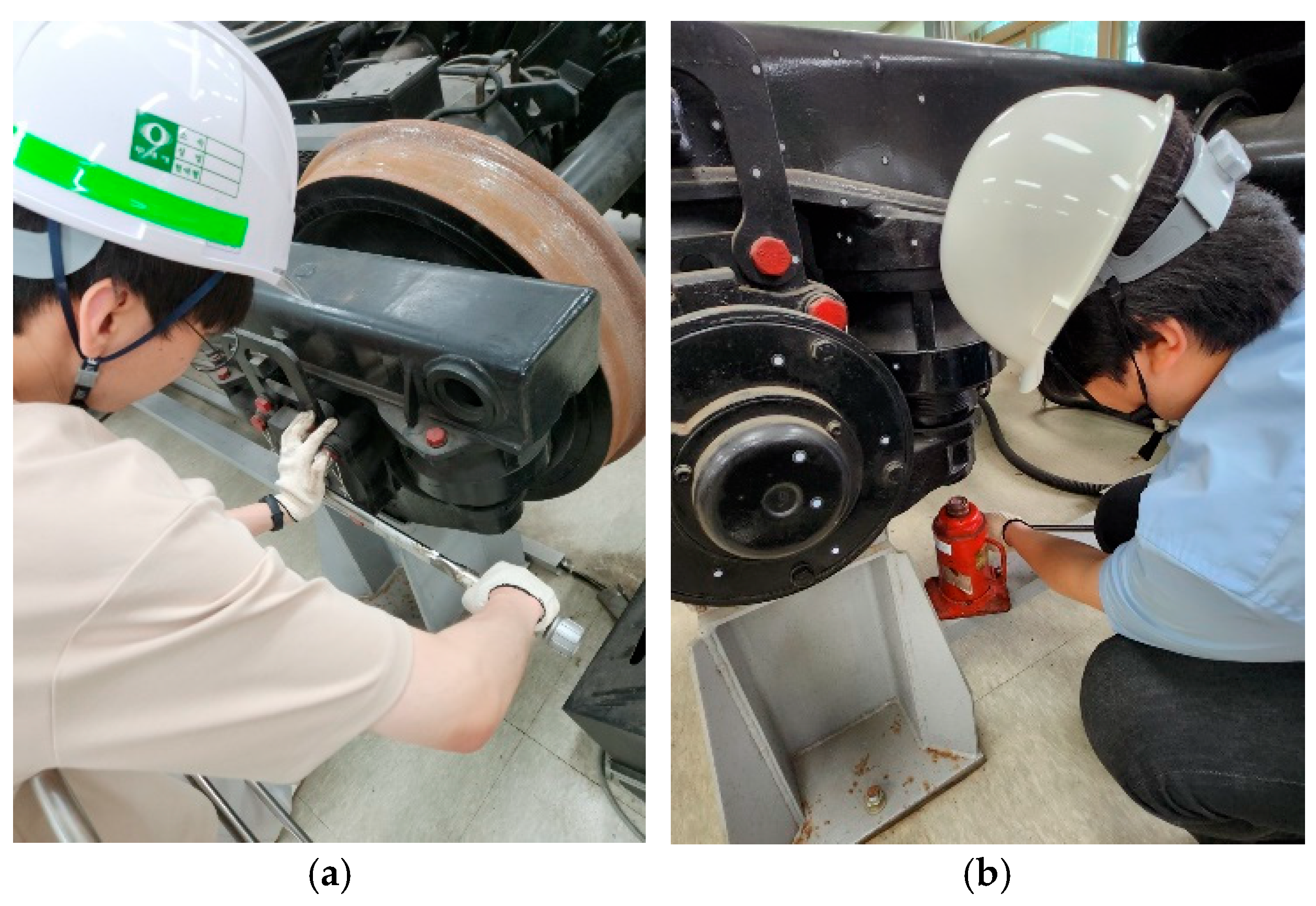

Figure 17.

Participants performing the work: (a) tightening the bolt with a torque wrench; (b) switching the lever of jack.

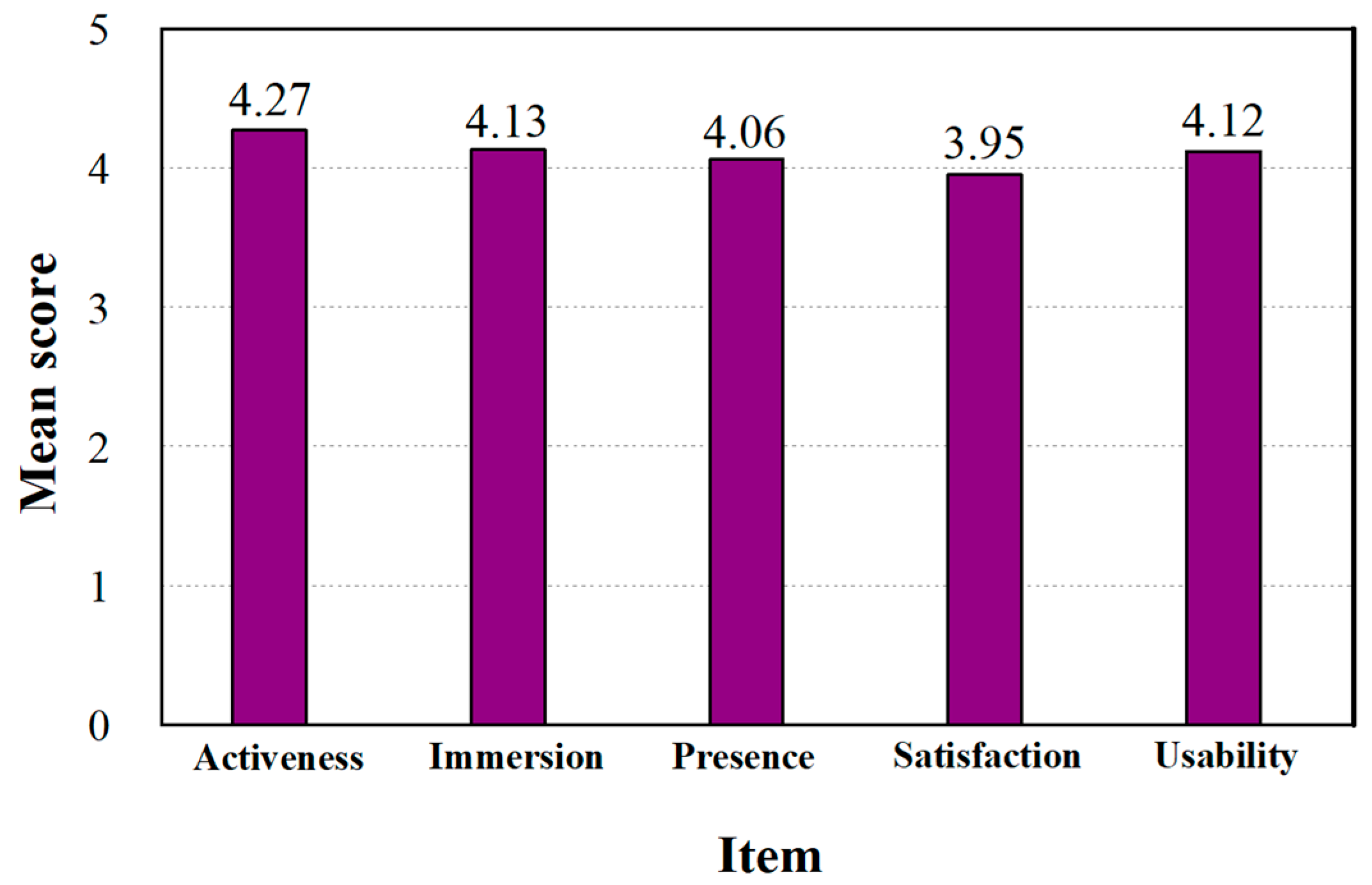

Figure 18.

The result graph of the five evaluation subscales.

Table 1.

Analysis results of AR research cases in the maintenance field.

| Field | Features | Usability Verification | Conclusions |

|---|

| Aerospace industry [11] | Visualizes standard maintenance process and provides them through simulations | - | Reduce maintenance process search time and human error rates |

| Plant industry [12] | Provides plant operation performance instructions and related videos based on AR | Compare maintenance execution times between two groups | Improve work efficiency and information accessibility |

| Automotive industry [13] | Detects vehicles and automatically provides necessary maintenance information | Performance comparison with existing booklet-type manuals based on the execution of four maintenance work | Improve work efficiency and performance speed |

| Shipbuilding industry [14] | Provides accurate AR-based model alignment for seamless object detection | Evaluate accuracy and execution time divided into three stages | Provides seamless augmented information and demonstrates validity |

| Smart factory industry [15] | Providing AR-based information through remote collaboration in real time with smart factory systems | - | Reduce maintenance time and costs for machinery and equipment |

| Thermal power plant industry [16] | Recognize power plant components, visualize and provide related information | Field experiments conducted in four stages | Reduce misoperations and human errors while increasing work efficiency |

| Railway industry | Proposes a systematic methodology for digitalizing maintenance training and a modular algorithm for precision measurement work, which was previously unaddressed | Formative evaluation and a post-survey with 40 participants | Enhances the accuracy of precision measurement work and reduces error rates |

Table 2.

Analysis results of AR research cases in the railway field.

| Field | Features | Usability Verification | Conclusions |

|---|

| Railway operation industry [17] | Provides AR-based automatic train recognition, transportation inspection, and technical inspection processes | Comparison of inspection times divided into two processes | Reduces inspection time and decreases error occurrences rates |

| Railway maintenance industry [18] | Provides maintenance instructions and related information through voice and visual interaction functions | Analyzes cases through interviews with experts | Provides real-time feedback and enhances technical capabilities |

| Railway safety inspection industry [19] | Provides remote inspection and indoor precision inspection processes using AR technology | - | Increases inspection continuity and enables management of inspection history |

| Railway manufacturing industry [20] | Visualize sensor status monitoring values and provides the maintenance process in real time | - | Improves maintenance quality and fault prediction accuracy |

| Railway assembly industry [21] | Provides real-time assembly information using SLAM technology and marker-based algorithms | Evaluate user experience by dividing into two groups | Reduces assembly time, decreases error rates, and improves usability |

| Railway maintenance industry | Focuses on complex procedures and supplements existing manuals with maintenance know-how from railway technicians. | A user experience evaluation was conducted with 40 railway vehicle maintenance staff, divided into four age-based groups. | Addresses research gaps by providing a methodology for complex maintenance procedures and conducting comprehensive usability verification. |

Table 3.

The IGPI algorithm UI frame types.

| Type | Primary Use Case | Constituent Elements | Example Content |

|---|

| 1 | Simple Information Display | Title Text, Detail Text | General Details, Precautions

|

| 2 | Visual Information | Title Text, Detail Text, Image |

Component Details

|

| 3 | User Action/Feedback | Title Text, Detail Text, Image, Button |

Button for Step Progression

|

| 4 | Complex Interaction | Title Text, Detail Text, Image, Button, Selections |

Quizzes, Scenario-Based Choices

|

Table 4.

The composition of the post-survey.

| Subscale | Item |

|---|

| Activeness | While using the educational content, I was able to learn how to use it and proceed with the training smoothly without the help of others. |

| While using the educational content, I was able to actively learn by selecting each desired item. |

| It was possible to learn all the items without missing any parts by identifying the entire progression scenario and evaluating the items of the educational content. |

| Immersion | While using the educational content, I found that irrelevant thoughts and distractions unrelated to learning were blocked, allowing me to fully engage in the educational process. |

| While using the educational content, I was able to focus on the change in perspective based on the model’s movement, and I found it enjoyable and interesting. |

| While using the educational content, it was possible to achieve an optimal learning experience through natural interaction, without any sense of heterogeneity or external interference. |

| Presence | While using the educational content, I was able to experience the actual maintenance work. |

| While using the educational content, I desired to follow the maintenance process directly using my body. |

| While using the educational content, I wanted to learn by using real objects in the field workplace. |

| Satisfaction | The learning items of the educational content were not difficult, and the necessary information and skills were properly and harmoniously organized. |

| While using the educational content, it was possible to freely manipulate the model and UI, and switch screens through touch gestures. |

| The entire composition of the educational content is designed to be easily comprehensible, and the work processes are implemented as animations for easy understanding. |

| Usability | The movements of the models in AR were natural and uninterrupted. |

| The graphics in the educational content were designed to maintain a consistent visual style throughout. |

| When using the educational content, the content system responded quickly to the learner’s intentions and actions. |

Table 5.

Demographic characteristics of the participants.

| Characteristics | 20 s | 30 s | 40 s | Total |

|---|

| Participants (N) | 10 | 10 | 10 | 10 |

| Gender | Male (7) | Female (3) | Male (8) | Female (2) | Male (9) | Female (1) | Male (9) | Female (1) |

| Prior Experience | None |

Table 6.

The evaluation of the first work.

| Work 1 | Action 1 | Action 2 | Action 3 | Action 4 | Action 5 |

|---|

| Success | 25 | 33 | 36 | 23 | 34 |

| Delay | 9 | 4 | 3 | 12 | 3 |

| Failure | 6 | 3 | 1 | 5 | 3 |

| Mean time | 2 min 38 s | 1 min 8 s | 51 s | 3 min 12 s | 49 s |

Table 7.

The evaluation of the second work.

| Work 2 | Action 1 | Action 2 | Action 3 | Action 4 |

|---|

| Success | 31 | 27 | 36 | 35 |

| Delay | 4 | 8 | 2 | 4 |

| Failure | 5 | 5 | 2 | 1 |

| Mean time | 1 min 21 s | 2 min 43 s | 57 s | 1 min 2 s |

Table 8.

Evaluation results of work 1 and work 2 with success, delay, failure, and main causes.

|

Work

|

Action

|

Delay/Failure Frequency

|

Main Cause of Delay/Failure

|

|---|

| Work 1 | 1 | 9 delays | 6 failures | Animation duration too short |

| 2 | 4 delays | 3 failures | Step-by-step animation (minor delay) |

| 3 | 3 delays | 1 failure | Step-by-step animation (minor delay) |

| 4 | 12 delays | 5 failures | Click sound provided only in text |

| 5 | 3 delays | 3 failures | Quiz pop-up supported learning (minor delay) |

| Work 2 | 1 | 4 delays | 5 failures | Position indicators generally clear (minor delay) |

| 2 | 8 delays | 5 failures | Rotation direction unclear and short animation |

| 3 | 2 delays | 2 failures | 3D animation supported repetitive learning (minor delay) |

| 4 | 4 delays | 1 failure | Lever guidance clear and well understood (minor delay) |

Table 9.

The results of the one-way ANOVA.

| Classification | Sum of Squares | Degrees of Freedom | Mean Square | F

(Variance Ratio) | Significance Probability |

|---|

| Between group | 0.659 | 3 | 0.220 | 3.839 | 0.018 |

| Within group | 2.060 | 36 | 0.057 | - | - |

| Total | 2.719 | 39 | - | - | - |

Table 10.

The results of the post hoc test.

| Classification | Mean

Difference | Mean

Error | Significance

Probability | 95% Confidence |

|---|

| Lower | Upper |

|---|

| 10 s | 20 s | 0.08 | 0.10698 | 0.877 | −0.2081 | 0.3681 |

| 30 s | 0.2 | 0.259 | −0.0881 | 0.4881 |

| 40 s | 0.34 | 0.015 | 0.0519 | 0.6281 |

| 20 s | 10 s | −0.08 | −0.877 | −0.3681 | 0.2081 |

| 30 s | 0.12 | 0.679 | −0.1681 | 0.4081 |

| 40 s | 0.26 | 0.089 | −0.0281 | 0.5481 |

| 30 s | 10 s | −0.2 | 0.259 | −0.4881 | 0.0881 |

| 20 s | −0.12 | 0.679 | −0.4081 | 0.1681 |

| 40 s | 0.14 | 0.564 | −0.1481 | 0.4281 |

| 40 s | 10 s | −0.34 | −0.015 | −0.6281 | −0.0519 |

| 20 s | −0.26 | 0.089 | −0.5481 | 0.0281 |

| 30 s | −0.14 | 0.564 | −0.4281 | 0.1481 |

Table 11.

Problems derived from user experience evaluation results.

| Problem | Details |

|---|

| Animation duration | Difficult to understand due to the short animation duration |

| Explanation of terms | Difficult to understand because there is no additional explanation of technical terminology in the railway vehicle field |

| Text | Lack of realism due to 2D-based text and lack of detailed explanation |

| Touch gesture | Interaction is not smooth when simultaneously controlling the position, size, and rotation of the model |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).