Abstract

Effective monitoring of perishable food products has become increasingly important for ensuring quality, enabling smart packaging to be a key consideration for food companies. Among the promising technologies available for transforming packaging into intelligent packaging, chipless radio frequency identification (RFID) sensors stand out. Despite the high initial implementation costs associated with chipless RFID technology, the potential benefits could outweigh the costs if electrical challenges can be overcome. We examine various economic methods to analyze the economic benefits of chipless RFID technology, evaluating the benefits of using this technology for the quality monitoring of seafood products of an Australian seafood producer, Tassal. The analysis considers three primary business drivers, viz. quality monitoring, operational efficiency, and tracking and tracing, using net present value and return on investment as the key indicators to assess the feasibility of implementing the technology. Based on sensitivity analysis, we suggest chipless RFID technology is currently best suited for large firms facing significant quality monitoring and operational efficiency challenges. However, as the cost of chipless RFID sensors decreases with further development, this technology may become a more viable option for small businesses in the future.

1. Introduction

The primary purpose of food packaging is to protect food from damage and spoilage. Over time, packaging has evolved to incorporate additional functionalities such as active packaging, which responds to internal changes, and intelligent packaging, which communicates with the external environment. These developments aim to reduce food waste and improve food safety. As a result, there has been a significant increase in demand for the smart packaging of food products worldwide [1,2].

The demand for smart packaging of food products in the United States is expected to reach USD 3.6 billion within this decade. Japan ranks second with a market capacity of USD 2.36 billion, while Australia comes in third with a market capacity of USD 1.69 billion. The United Kingdom has a market capacity of USD 1.27 billion, while Germany has a market capacity of USD 1.4 billion. These figures demonstrate the global growth and importance of smart packaging in the food industry [3].

Highly perishable products such as dairy, meat, and seafood are susceptible to changes in their properties after processing and packaging due to biological and chemical processes, which can result in spoilage. Before dispatch, the quality of these products is regularly monitored using chemical and microbiological tests. However, there is no consistent monitoring system in place after the product has been delivered to retailers. Intelligent packaging, which includes tracking, tracing, sensing, and communicating functions, can fill this quality-monitoring gap after delivery. This technology not only helps to ensure product quality but also provides consumers with additional information about the product and pre-warning of any internal or external issues [4,5,6].

The three types of technologies proposed for smart packaging systems are indicators [7], sensors [8], and data carriers such as barcodes and RFID [9]. Indicators are used to detect the presence of specific substances due to changes to the packed food, which are typically visualized by color changes associated with the type of indicators used in the package. Sensors are devices that can measure chemical, thermal, and other physical changes and convert them into electrical, optical, or thermal signals using transducers. Data carriers are devices that enable the efficient flow of information in the supply chain, ensuring automation, theft protection, traceability, and counterfeit protection [4].

Barcodes are the most commonly used and cost-effective data carriers. They were initially introduced for automatic checkouts and inventory controls. However, conventional RFID tags were later introduced as more advanced technology, with non-contact and non-line-of-sight abilities in real-time data collection and a higher data storage capacity of up to 1 MB for supply chain management purposes [10,11].

There has been a significant increase in the use of RFID technology in the food industry for tracing, monitoring, and packaging purposes [12,13]. This technology has the potential to improve supply chain management efficiency and enhance food safety and quality. RFID systems can be used for various operations, including food manufacturing and supply chain management. By providing real-time data, RFID systems can increase the speed and efficiency of product tracking and improve retailers’ on-shelf availability while saving time and costs for wholesalers and retailers. Moreover, RFID technology can enable the integration of sensors into food packages to evaluate food quality and safety, further enhancing the benefits of this technology in the food industry [14].

In 2003, Walmart, the largest retailer in the United States, drew attention to RFID technology by mandating its top 100 suppliers to attach RFID tags to their packages, cases, and pallets. The implementation was a long-term project, and suppliers were required to comply with the new technology by 2005 [15]. Other companies such as the U.S. Department of Defense, Albertsons, Target, Tesco, and Marks Spencer also endorsed the use of RFID technology [16].

To make the RFID technology more user-friendly and smarter, RFID tags are also designed to provide information on the environmental conditions and integrity of food packages during storage and transport [17]. This would be possible by measuring one or two environmental parameters such as temperature, relative humidity, pressure, light exposure, and gas concentrations. One or two sensors must be integrated with the RFID tags for this kind of measurement. Intelligent packaging with RFID technology with sensing functionalities can only be useful when it suits the requirements of food products. The RFID technology currently has higher development and integration costs than a barcode, thus limiting the applications of the technology in food packaging. However, this technology has potential applications for expensive and extremely perishable food products such as meat and seafood. Such products can benefit from remote and non-invasive food monitoring systems to optimize their distribution and transport system and reduce food waste [18].

The cost of conventional chipped RFID tags is the main hurdle to the widespread use of technology in food packaging [9]. Another unresolved issue in making RFID meet the requirements of the food industry is the development of flexible RFID tags that can be appropriately integrated with food packaging. Many projects have been launched during the last decade to develop RFID-based intelligent packaging in the food industry. The prototype of RFID sensors integrated with RFID tags was presented by the Good Food project in 2003 in the Netherlands. For this project, the low-power sensor was integrated with a semi-passive RFID tag to monitor relative humidity, temperature, and light intensity. The SmartPack project started in Germany in 2005 to integrate passive RFID tags with packaging materials. The low cost and higher flexibility are the two main factors that play an important role in adopting RFID in the current food packaging field. FlexSmell is a project that started in 2010 to design and investigate printed RFID sensors on flexible materials such as plastic substrates. The objective of the project was to reduce the cost of the RFID tag and obtain low-cost, low-power RFID sensors for food safety and the quality monitoring of packaging [15].

Even though there are several semi-passive or NFC commercially available RFID-enabled sensors that can monitor relative humidity, temperature, pH, and light exposure, none of them is flexible and integrable with food packages [19,20]. A new paradigm shift has recently occurred in RFID technology with the introduction of passive and chipless RFID tags that can operate completely passively without batteries. Passive RFID tags may include an integrated circuit (I.C.). However, chipless RFID tags do not possess any I.C. Hence, the deployment of chipless RFID tags for identification, tracing, and sensing applications can result in additional cost reductions. Also, the absence of I.C. in this type of tag makes the structure of the tag flexible and easy to integrate with packaging materials [21,22].

The chipped RFID technology has been adopted by many industries, including health care, retailers, airlines, and the military. In the literature, different approaches are used to investigate investment analysis in these sectors. Currently, the use of RFID technology, especially the low-cost chipless one, in developing intelligent packages is gaining a lot of attention [23]. Its communication standardizations, sensing, and detection challenges are also being investigated. However, a limited number of studies incorporate the economic investigation of the large-scale implementation of this technology in the food packaging industry. With its current implementation costs, RFID technology can be adopted by expensive and highly perishable food product companies such as meat, fish, and prawn producers to avoid exceeding the suggested maximum packaging cost of 10% of the product value [24].

A packaging cost of 10% of the product value is being regulated by many companies. In this paper, an economic evaluation of the chipless RFID sensor technology, in the case of large Australian seafood company Tassal, has been made. An economic analysis has been conducted, evaluating cost and benefit, where the benefits are determined by assessing the reduced cost using the added-profits approach. Most of the data were collected from the annual and sustainability reports published by Tassal.

2. Literature Review

In addition to smart packaging, RFID technology has been introduced in other applications, including inventory management, healthcare, distribution process, and library [25]. Hence, the investment analysis of RFID technology and its adoption hurdles and factors have become the subject of many studies in the literature. The research area of assessing RFID technology adoption can be categorized under three approaches: qualitative [26,27], quantitative [28,29], and hybrid [30,31].

The qualitative approaches for the investment analysis of RFID are proposed in different research studies. In [32], RFID adoption is evaluated from the perspective of an organization. Technological issues are assumed as information attributes, and the authors mapped the benefits and information attributes to the retailing process using an RFID benefits–information value chain. A strategic investment analysis of RFID technology is presented in [33] by demonstrating the assessment of its value to obtain substantial competitiveness. A conceptual framework of RFID benefits such as supply chain visibility and item tracking is proposed, while the learning organization theory is employed to assess the benefits of RFID adoption. The strategic investment analysis of RFID adoption is investigated in [34,35,36] with a particular focus on retailing and healthcare sectors, respectively. Several analytical and experimental methods such as the diffusion of innovation (DOI) model, technology-organization environment (TOE) model, and technology acceptance model (TAM) are introduced in the literature and used in the empirical research on organizational-level information technology (IT) adoption. For example, a modified technology acceptance model is introduced in [37] to predict public attitudes toward using RFID-based subcutaneous microchips (RFID-MS). A summary of the different qualitative economic analysis methods can be found in Table 1.

Table 1.

Economic analysis methods used in the study.

On the other hand, the quantitative approaches predominantly focus on the profitability assessment of RFID technology in different applications. Ref. [38] is an empirical study to evaluate the performance of RFID technology in the supply chain of the printing industry and figure out the implementation requirements, RFID adaptation, and acceptance using a cost–benefit analysis. An investment analysis was conducted in [39] based on the Return on Investment (ROI) model for the distribution sector. Different operational scenarios are compared according to RFID tag prices and specific activities. A cost–benefit analysis is implemented in [40] to evaluate the potential gains of using RFID technology in inventory management and shrinkage prevention. An effective model, based on the well-known activity-based costing (ABC) technique was proposed in [41] to evaluate the economic feasibility of using RFID technology in pallet management. Different pallet management scenarios are investigated to incorporate the implementation of RFID technology in pallet management to reduce overall costs [42].

In addition to the above-mentioned methods, other economic techniques such as cost/effectiveness analysis [43], system dynamics [44], simulative approaches [45], and Markov chains [46] can also be found in the literature. A summary of the different quantitative economic analysis methods can be found in Table 2.

The last approach in the investment evaluation is the hybrid approach, shown in Table 3. A hybrid model integrates different types of models that enhance the global effectiveness of investment evaluation. Traditional methods for investment evaluation are integrated by a survey analysis in [47,48] to enhance the effectiveness of the proposed model. In [47], the proposed hybrid method uses conventional indexes such as the net present value (NPV) and the internal rate of return (IRR) to evaluate the economic feasibility of RFID in inventory management for the U.S. Army. A survey-based qualitative method is integrated with the quantitative analysis to determine the potential benefits of the RFID applications. Lastly, implementation barriers and cost savings are detailed by a sensitivity analysis. A similar method was proposed in [48] to evaluate the feasibility of RFID technology adoption in the Fast-Moving Consumer Goods (FMCG) supply chain. First, a questionnaire survey was prepared to analyse the supply chain management in FMCGs. Quantitative indices such as NPV, IIR, the payback period, and ROI were calculated to evaluate the different scenarios of RFID applications.

Reference [38] proposes a hybrid method based on the cost–benefit analysis of RFID application in the printing supply chain. First, a survey is conducted in the Taiwanese printing industry to determine the potential applications of RFID in the supply chain. Then, a cost–benefit analysis is implemented to figure out the potential benefits of RFID application for manual and barcode-based information systems. Another hybrid model is proposed in [49] to compare the RFID against barcode performance in postal carrier firms. Time-driven activity-based costing is integrated with the simulation model to evaluate the quantitative performance of both RFID and barcode technologies.

In [50], RFID technology adoption is evaluated in the retailer sector by considering the customer’s perspectives. An analysis based on the technology acceptance model (TAM) is implemented. The TAM model is a strategic approach used to evaluate new technology by customers. It is also used to assess the benefits and usefulness of RFID technology in the industrial context. A specific survey analysis was conducted to validate the general proposed framework developed by the model.

In [51], the authors proposed an integrated and comprehensive framework based on the Analytic Hierarchic Process (AHP) to identify dynamic RFID adoption and diffusion. AHP combines both qualitative and quantitative aspects in a single framework and generates a set of priorities for alternatives, which helps in analyzing and solving complex decision problems.

Lastly, in [52], a systematic model is developed for the investment analysis of RFID in the construction industry. Firstly, the cost and benefit elements for RFID investment values are determined. Then, the expected customer orders are evaluated in terms of delivery time and accuracy using a fuzzy rule-based system. Finally, the Monte Carlo simulation method is used to determine the input values for testing the developed model. In summary, the proposed models in different research highlight various approaches for analyzing RFID technology investments in different applications. This is summarized in Table 1, Table 2 and Table 3, presenting an overview of potential methods that can be used to evaluate chipless RFID sensor technology investments in the food industry.

Table 2.

Quantitative approach.

Table 2.

Quantitative approach.

| Ref. | Country of Study | Approach | Methodology | Application | Major Conclusion | The Variables of Interest |

|---|---|---|---|---|---|---|

| [38] | China | Quantitative | Cost–benefit analysis based on survey results | Distribution process | Item tagging is the ideal approach in the printing industry’s supply chain | Tag cost, reader cost, IT infrastructure costs, required number of readers, price of controller and antennas, required number of controllers, number of publications, the average time saved via RFID, working hours of labour, and average salary of labour. |

| [40] | The Netherlands | Quantitative | Break-even analysis | Inventory management | RFID technology facilitates more information about inventory that comes with a price. The break-even prices of the implementation of the technology should be considered and compared with potential gains | Tag costs, observation cycle length, audit costs, theft fraction, the value of an item, annual interest rate, expected demand, coefficient of variation demand, lead time, target fill rate, and fraction of theft that cannot be solved by using RFID. |

| [41] | Italy | Quantitative | Activity-Based Costing (ABC) analysis | Pallet management | Results show that the proposed model clearly allocates the cost of the technology by introducing benefits in terms of cost savings | Direct costs (pallet park purchase, RFID equipment and infrastructure), indirect costs (replenishment, maintenance, tag replacement, cleaning, storage, reverse logistics, tracking and tracing, RFID system maintenance, and accounting). |

| [42] | Europe | Quantitative | Cost/effetive-ness analysis | Onboard emergency response system for passenger ships | Using RFID technology in passenger-monitoring systems is not a cost-effective approach at this point. So, the technology should not be implemented for safety considerations alone. | Data acquisition and installation, support, maintenance and renewal, tags cost, training costs, distribution of accidents on year and accident type, and distribution of number of fatalities. |

| [46] | United States | Quantitative | Markov chain model | Equipment Tracking in U.S hospitals | The proposed model can be used to estimate the benefits and choose appropriate RFID-based investment plans. | Patient demand and service (daily patient demand, average duration of patient service), searching efficiency (average duration of search, probability of search upon demand, average time until inquired equipment is declared lost, average time until lost equipment is found), preparation and maintenance policies (average time equipment spent in preparation, time until lost equipment needs maintenance) |

| [44] | Italy | Quantitative | System Dynamics | Italian apparel retailer | It has been revealed that RFID implementation increases sales in addition to reducing the operational costs. | Order rate, incoming items rate, sales, returnable items, inventory level check, staff-assisted sales time, time index, weekly sales, a binary RFID input variable (1 for store with RFID, 0 for store without RFID). |

| [53] | Italy | Quantitative | ROI based cost benefit analysis model | Fashion supply chain | A proposed model that considers most cost variables in implementing and managing RFID systems, which provides managers with a useful tool to benchmark RFID implementation in their firms. | Hourly labour cost for error correction, tag insertion, reworks cost, tag cost, purchase cost, holding item costs, receiving errors, shipping errors, picking errors. |

| [54] | China | Quantitative | Classic economic Order quantity (EOQ) model | Supply chain | This study reveals the impact of imperfect RFID technology on inventory management and provides a quantitative model to suggest optimal investment decisions for RFID adoption in inventory management. | Annual demand rate, an order quantity of the manufacturer, inventory level, setup cost, shortage in inventory, the unit cost of item, holding cost per unit, shortage cost. |

| [55] | South Africa | Quantitative | Cost–benefit analysis | Sheep feed lot | RFID can provide supplier data and consequently helps in selecting lambs from top suppliers | RFID ear tag lifespan, daily feed intake, feed-conversion ratio, slaughter percentage, feeding cost, meat price, selling price, buying price, veterinary costs, transport cost, feedlot numbers, water consumption, inflation, and minimum wage. |

| [56] | Portugal | Quantitative | IRR and NPV analysis | Home appliance retail business | This study reveals that RFID can reduce checking, control, reception, picking, and delivery-processing time, resulting in avoided costs of labour. | Tag, reader, software, printer, and RFID tunnel costs, elimination of checking and handling of disputes, time reduction in item search, delivery, and item reception. |

Table 3.

Hybrid approach.

Table 3.

Hybrid approach.

| Ref. | Country of Study | Approach | Methodology | Application | Major Conclusion | The Variables of Interest |

|---|---|---|---|---|---|---|

| [47] | United States | Hybrid | Factorial structure for non-cost related benefits and traditional ROI analysis | U.S army in inventory management | Cost analysis shows that RFID technology implementations result in substantial cost reductions. Sensitivity analysis shows that the cost reduction is robust against inaccurate estimation of parameters. | Unit cost of fixed readers, unit cost of portable readers, unit cost of handheld readers, unit cost of frequency extenders, cost of hardware installation, cost of software installation, number of personnel to be trained, number of hours required per person, annual scheduled tag re-placement, annual frequency extender failure, annual tag failure, annual reader failure, reported labour savings, causative research labour saving, transportation redistribution savings, demilitarisation, maintenance and surveillance (DMS) out of pocket holding cost savings, DMS surveillance maintenance labour savings. |

| [48] | Germany | Hybrid | Survey integrated with technology acceptance model (TAM) | Electronic retail corporation | This study reveals that the acceptance of RFID technology depends mostly on perceived usefulness and transparency in data privacy. | Perceived ease of use, security concerns, perceived use fulness, general attitude toward new technology, general attitude toward data security, male customer, younger costumer, school degree, income, political attitude, reduction of waiting time of checkout, cost reduction. |

| [49] | Italy | Hybrid | Analytic hierarchic Process | - | Important factors affecting RFID technology adoption are identified and classified into three categories: development phase, trial phase, and implementation phase. | Cost (system integration costs, system maintenance costs, reusability of tags), environmental sustainability (energy consumption, electromagnetic compatibility, WEEE disposal), technology (sensitivity, transmit power, communication, tag), international standards (system compatibility in the supply chain, consistency of data format, standard isolation of frequency), security and privacy (relevant legal regulations, exposure and outflow of product information, prevention of stealing and loss), and product (material, placement in the market, geometry). |

| [50] | Thailand | Hybrid | Adaptive neurofuzzy inference system (ANFIS) integrated by Monte Carlo simulation | Construction industries | This study reveals that the cost–benefit analysis of RFID investments can be improved using the ANFIS model | Hardware costs, software costs, service costs, improvements of management materials, men, and machines. |

3. Methodology

We consider NPV and ROI analysis [57,58] to evaluate RFID sensor technology implementation at the Tassal Group facilities using the annual reports and cost information obtained for RFID fabrication and development costs at Monash University laboratory (MMARS).

The Tassal Group is the premium market share holder of Tasmanian Salmon in Australia and has 25.1% of the Australian market share within the seafood industry. The group started commercial fish harvesting in 1987 and has since expanded to become the leading company in the aquaculture market. Its main salmon farm and processing location is in Tasmania, and the prawn farm is in New South Wales. The company’s products are traded mainly in domestic retailing and wholesale markets. These products have 56% and 28% shares of the domestic retailing and wholesale markets, respectively, while they hold only 16% of the international export market.

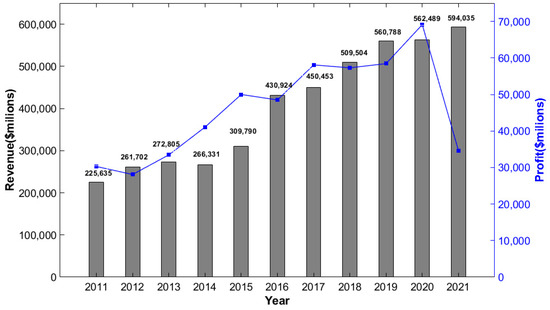

The current annual revenues of the company continue to improve every year, as shown in Figure 1. The maximum annual growth of 39.1% was recorded in 2016 due to contracted supply obligations and the introduction of De Costi Seafoods’ platform that boosted operational efficiencies.

Figure 1.

Annual revenues for the Tassal Group (annual reports, https://tassalgroup.com.au/information/reports/annual-reports/, Accessed on 14 July 2024).

The current annual revenues of the company continue to improve every year, as shown in Figure 1. The maximum annual growth of 39.1% was recorded in 2016 due to contracted supply obligations and the introduction of De Costi Seafoods’ platform that boosted operational efficiencies. The annual revenue reduction recorded in 2020, the first since 2014 when the company experienced a tough supply period due to the negative impacts of the 2012 and 2013 hot summers, as a result of the COVID-19 pandemic.

The decline in annual revenue in 2020 resulted in a reduction of the 2021 net profit by nearly 50%, as shown in Figure 1 (right axis). Five years of roll-out time is assumed for RFID sensor technology implementation in all Tassal Group facilities to minimise employee requirements and improve quality-monitoring techniques. Hence, the revenue is extrapolated in Year 5 using the 10-year average annual growth rate from 2011 to 2021, as shown in Table 4. The annual growth rate for each year i is denoted by AGRi and can be calculated as follows:

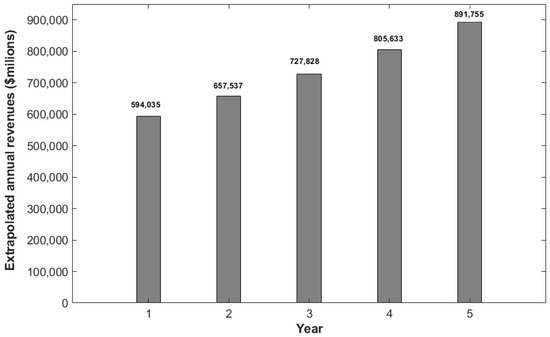

where CRi is the current revenue in Year i. The extrapolated 5-year revenue period beginning from 2021 is shown in Figure 2.

Table 4.

Summary of revenue and profit of the Tassal Group (2011–2021).

Figure 2.

Extrapolated annual revenues for the next 5 years (calculated using the average annual revenue growth).

The net profit margin in Table 4 is calculated using:

where is current net profit in Year i. The average net profit margin is calculated using the average profit margins for 10 years.

3.1. Costs

Among cost items, we include both variable and fixed costs in producing RFID sensors. The fixed costs are hardware costs (readers), software costs, integration and consulting costs, and training costs. The variable costs may vary each year, depending on the number of required sensors and hardware faulty. These are the total annual cost of tags used for production tracking and sensing and total annual maintenance costs.

The tag and reader prices for the current year are estimated as in Table 5, with the assumption that the unit price of the tags and readers will be lower in 5 years. The reason behind this assumption is that RFID technology is still under improvement and new low-cost solutions are being proposed both in designing and developing tag/sensor for the reader, RFID tag, and sensor [21].

Table 5.

The number of tag/sensor labels obtained from salmon and prawn volume.

Software costs, including license costs, are estimated to be fixed and assumed to be USD 5000 per annum [59]. For the overall implementation of the project, an RFID engineer is required for system integration and consulting, and the average base salary of RFID engineers is assumed for system integration and consulting costs, plus a 2.8% average salary rise per annum. The total annual maintenance and training costs are estimated in Table 6.

Table 6.

The total annual implementation cost of RFID sensor.

To estimate the number of RFID sensor labels for packages, the annual production of salmon and prawn is obtained from annual reports. We assume that the salmon and prawn are packed in 100 kg boxes with three sensor labels per package for a wholesale market.

N(salmon/prawn,packages) = (salmon/prawn Volume × 1000)/100

The annual growth in the number of sensors is calculated by considering the average growth in the number of salmon and prawn packages in the past 4 years, as shown in Table 5. The annual growth in the number of packages is calculated by (GN(salmon/prawn,packages)).

The variable cost of tags/sensors is obtained for 5 years (as shown in Table 5) by estimating the required number of sensors. To find the installation costs (rendered as one min of labour work per 12 tags/sensors), an hourly salary of USD 28.79 is considered [60].

3.2. Benefits

The RFID sensor implementation in salmon and prawn packaging for the wholesale market has the potential benefits listed below. Each business driver listed as a benefit of RFID sensor implementation is further elaborated on in this section.

3.3. Operational Efficiency

RFID tag implementation contributes significantly to operational efficiency by reducing redundant operations, the time required for package counting and scanning, and, consequently, the labour costs for employees working in the delivery and transport sections. The benefits of automated scanning using RFID technology are calculated in by considering the time spent picking and scanning salmon and prawn packages. It is assumed that all packages are 100 kg, and 90 s of labour time is dedicated to this job. The number of packages is obtained from the total estimated number of sensors in Table 7, and a 90% reduction in control time is assumed after RFID implementations [56] in Table 8.

Table 7.

Price and number of per tag/sensor and RFID reader.

Table 8.

Cost reduction due to improved RFID.

3.3.1. Automated Tracking and Tracing

One of the most significant benefits of RFID technology in the food industry is the real-time visibility in the inventory and production that enhances the tracking and tracing efficiency. The reduced cost due to automated tracking and tracing is calculated in Table 9, considering that tracking and tracing costs take up 0.01% of the overall revenue. We assume a maximum cost reduction of 60% after RFID implementation.

Table 9.

Reduced costs due to automated tracking and tracing.

3.3.2. Quality Improvement

Adding sensing functionality to the RFID tags enables live monitoring of perishable seafood packages during production, storage, and transfer. This type of sensor notifies of any temperature control violation and eliminates quality loss. Following Table 10 it is assumed that losses due to quality issues take up 0.1% of overall revenue. These losses can be reduced by 80% after RFID implementation. Sensitivity analysis is implemented in the next section to estimate the effects of these parameters on overall ROI and NPV.

Table 10.

Cost reduction due to quality monitoring.

4. Investment Analysis

The selected financial indicators for calculation are NPV and ROI. These indicators were calculated considering the total fixed and variable costs, benefits, and average annual growth rate of 10.69% (calculated in Table 4) as a discount rate. The calculations are presented in Table 11, assuming a 5-year lifetime for the project.

Table 11.

Investment analysis of RFID sensor implementation.

The positive value of NPV and the 14% ROI value demonstrate that the introduction of RFID sensors reduces overall costs and introduces additional annual benefits, thus indicating the profitability of investments under the assumed conditions. To figure out the effect of assumptions in this calculation, a sensitivity analysis is conducted for the parameters listed below, and NPV and ROI are recalculated.

- Package sizes

- Tag/sensor per unit cost

- Total traceability issues as a percentage of 1-year revenue

- Total quality issues as a percentage of 1-year revenue.

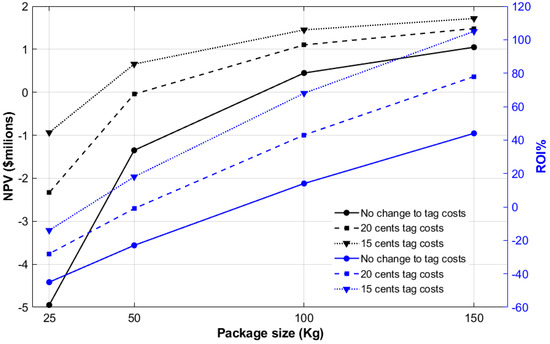

As shown in Figure 3, NPV and ROI calculations for variable package sizes and tag costs indicate that increasing the package sizes by 50% increases NPV by almost USD 0.6 million and ROI by 40%. On the other hand, decreasing package sizes by 50% decreases NPV by almost USD 0.9 million and ROI by 37%. The unit cost of the tag/sensor also affects these parameters significantly. Figure 3 shows that a 50% reduction in tag/sensor costs enhances NPV and ROI values by USD 0.6 million and 29%, respectively. Note that the effect of highly reflective large packaging boxes can be eliminated post-processing; package size increase will not affect RFID system performance [61].

Figure 3.

NPV and ROI calculations for package sizes varying from 25 kg to 150 kg, with tag costs varying from 40 cents to 15 cents.

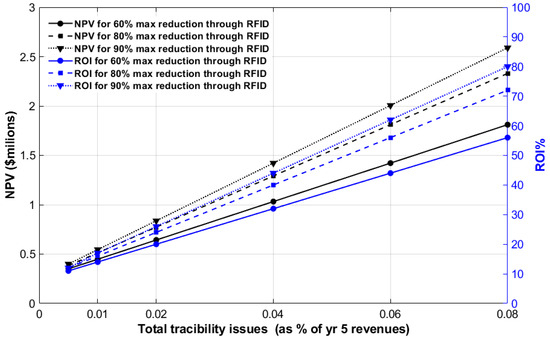

As mentioned before, the investment analysis is conducted in Table 11, with the assumption that 0.01% of total revenue is dedicated to tracing and tracking costs, in the absence of RFID. It has been assumed that RFID implementation contributes to a 60% reduction in costs. However, we have varied these assumptions, as shown in Figure 4. The recalculated NPV and ROI values indicate that a 50% increase/decrease in the tracking and traceability issues varies NPV by almost USD 0.05 million and ROI by 3%. The expected cost reduction through RFID implementation also has varied from 60% to 90% in this analysis. Following Figure 4, the expected cost reduction through RFID variations for 0.01% and 0.02% of total traceability issues increase NPV by USD 0.1 million and USD 0.2 million and ROI by 3% and 6%, respectively.

Figure 4.

NPV and ROI calculations for total traceability issues, varying from 0.005–0.08% of Year 5 revenue, with maximum cost reduction varying from 60% to 90%.

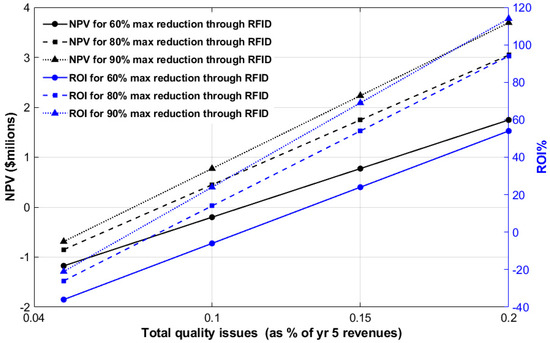

The investment analysis in Table 11 is conducted considering that the loss due to quality issues claims 0.01% of total revenue, and with the assumption that introducing the RFID sensor system reduces these costs by 80%. Similarly, we have varied these assumptions, as shown in Figure 5. The recalculated NPV and ROI values indicate that a 50% increase/decrease in the losses due to quality issues varies NPV by USD 1.3 million and ROI by 40%. As shown in Figure 5, for 60–90% variations in expected cost reduction through RFID, NPV increases by USD 0.97 million and USD 3 million and ROI by 30% and 45%, respectively, for quality issues equal to 0.1% and 0.15% of 1-year revenue.

Figure 5.

NPV and ROI calculations for total quality issues, varying from 0.05–0.2% of Year 5 revenue, with maximum cost reduction, varying from 60% to 90%.

5. Concluding Remarks

We explore and analyze the applications of RFID sensors in the case of an Australian fresh seafood industry. The Tasmanian salmon producer, Tassal Group, was selected for this purpose. Using publicly available annual data for a decade, we estimate production volume, and the required number of RFID sensors is obtained in addition to costs. The fixed costs are obtained based on the required number of readers in the system. Additional costs such as maintenance, software updates, and training costs are also included in the total investment cost calculations.

The benefits of the technology are estimated considering three major business drivers: quality monitoring, operational efficiency, and tracking and tracing. The gains due to RFID implementation are calculated by estimating the reduction in labour time and current issues as a percentage of annual revenues. The investment analysis models in this study were the NPV and ROI calculations, and these have indicated the economic viability of the project under specific conditions for business drivers.

The high investment cost makes the technology suitable for large businesses with considerable quality, tracing, and operation efficiency issues, while the technology requires cost reduction to make it adaptable to low-income/small businesses. It should also be noted that only conservative benefits are included in our analysis. However, RFID technology has other intangible benefits, such as an enhanced reputation for quality service, improved customer trust, and improved delivery time. This is our agenda for future research.

Author Contributions

P.F.—investigation, formal analysis, original draft preparation; M.B.—conceptualization, methodology, review and editing, supervision; S.B.—conceptualization, methodology, review and editing; N.K.—project administration. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by Monash University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data has been referenced and publicly available.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yousefi, H.; Su, H.-M.; Imani, S.M.; Alkhaldi, K.; Filipe, C.D.M.; Didar, T.F. Intelligent food packaging: A review of smart sensing technologies for monitoring food quality. ACS Sens. 2019, 4, 808–821. [Google Scholar] [CrossRef] [PubMed]

- Abraham, J. Future of food packaging: Intelligent packaging. In Nanotechnology in Intelligent Food Packaging; Wiley: Hoboken, NJ, USA, 2022; pp. 383–417. [Google Scholar]

- Alizadeh, A.M.; Masoomian, M.; Shakooie, M.; Khajavi, M.Z.; Farhoodi, M. Trends and applications of intelligent packaging in dairy products: A review. Crit. Rev. Food Sci. Nutr. 2021, 62, 383–397. [Google Scholar] [CrossRef] [PubMed]

- Mu, P.; Schmid, M. Intelligent packaging in the food sector: A brief overview. Foods 2019, 8, 16. [Google Scholar] [CrossRef]

- Yang, G.; Xie, L.; Ma, M.; Zhou, X.; Pang, Z.; Da Xu, L.; Walter, S.K.; Chen, Q.; Zheng, L.-R. A health-iot platform based on the integration of intelligent packaging, unobtrusive bio-sensor, and intelligent medicine box. IEEE Trans. Ind. Inform. 2014, 10, 2180–2191. [Google Scholar] [CrossRef]

- Pang, Z.; Tian, J.; Chen, Q. Intelligent packaging and intelligent medicine box for medication management towards the internet-of-things. In Proceedings of the 16th International Conference on Advanced Communication Technology, Pyeong Chang, Republic of Korea, 16–19 February 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 352–360. [Google Scholar]

- Endoza, T.M.; Welt, B.; Otwell, S.; Teixeira, A.; Kristonsson, H.; Balaban, M. Kinetic parameter estimation of time-temperature integrators intended for use with packaged fresh seafood. J. Food Sci. 2004, 69, FMS90–FMS96. [Google Scholar] [CrossRef]

- Pandey, S.K.; Kim, K.-H. The relative performance of RFID-based sensors in the near real-time analysis of CO2 in air. Sensors 2007, 7, 1683–1696. [Google Scholar] [CrossRef] [PubMed]

- Bibi, F.; Guillaume, C.; Gontard, N.; Sorli, B. A review: RFID technology having sensing aptitudes for food industry and their contribution to tracking and monitoring of food products. Trends Food Sci. Technol. 2017, 62, 91–103. [Google Scholar] [CrossRef]

- Preradovic, S.; Karmakar, N.C. Multiresonator-Based Chipless RFID: Barcode of the Future; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Bi, H.H.; Lin, D.K. RFID-enabled discovery of supply networks. IEEE Trans. Eng. Manag. 2008, 56, 129–141. [Google Scholar] [CrossRef]

- Gandino, F.; Montrucchio, B.; Rebaudengo, M.; Sanchez, E.R. On improving automation by integrating RFID in the traceability management of the agri-food sector. IEEE Trans. Ind. Electron. 2009, 56, 2357–2365. [Google Scholar] [CrossRef]

- Osmo, E.; Stoma, M.; Starek-Wo, A. Application of biosensors, sensors, and tags in intelligent packaging used for food products—A review. Sensors 2022, 22, 9956. [Google Scholar] [CrossRef]

- Yam, K.L.; Takhistov, P.T.; Miltz, J. Intelligent packaging: Concepts and applications. J. Food Sci. 2005, 70, R1–R10. [Google Scholar] [CrossRef]

- Vanderroost, M.; Ragaert, P.; Devlieghere, F.; De Meulenaer, B. Intelligent food packaging: The next generation. Trends Food Sci. Technol. 2014, 39, 47–62. [Google Scholar] [CrossRef]

- Brody, A.L.; Bugusu, B.; Han, J.H.; Sand, C.K.; McHugh, T.H. Innovative food packaging solutions. J. Food Sci. 2008, 73, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Costa, F.; Genovesi, S.; Borgese, M.; Michel, A.; Dicandia, F.A.; Manara, G. A review of RFID sensors, the new frontier of internet of things. Sensors 2021, 21, 3138. [Google Scholar] [CrossRef] [PubMed]

- Athauda, T.; Karmakar, N.C. Review of RFID-based sensing in monitoring physical stimuli in smart packaging for food-freshness applications. Wirel. Power Transf. 2019, 6, 161–174. [Google Scholar] [CrossRef]

- Mezzanotte, P.; Palazzi, V.; Alimenti, F.; Roselli, L. Innovative RFID sensors for internet of things applications. IEEE J. Microw. 2021, 1, 55–65. [Google Scholar] [CrossRef]

- Lazaro, A.; Villarino, R.; Girbau, D. A survey of nfc sensors based on energy harvesting for iot applications. Sensors 2018, 18, 3746. [Google Scholar] [CrossRef] [PubMed]

- Fathi, P.; Karmakar, N.C.; Bhattacharya, M.; Bhattacharya, S. Potential chipless RFID sensors for food packaging applications: A review. IEEE Sens. J. 2020, 20, 9618–9636. [Google Scholar] [CrossRef]

- Dey, S.; Saha, J.K.; Karmakar, N.C. Smart sensing: Chipless RFID solutions for the internet of everything. IEEE Microw. Mag. 2015, 16, 26–39. [Google Scholar] [CrossRef]

- Zuo, J.; Feng, J.; Gameiro, M.G.; Tian, Y.; Liang, J.; Wang, Y.; Ding, J.; He, Q. RFID-based sensing in smart packaging for food applications: A review. Future Foods 2022, 6, 100198. [Google Scholar] [CrossRef]

- Dainelli, D.; Gontard, N.; Spyropoulos, D.; den Beuken, E.Z.-V.; Tobback, P. Active and intelligent food packaging: Legal aspects and safety concerns. Trends Food Sci. Technol. 2008, 19, S103–S112. [Google Scholar] [CrossRef]

- Casella, G.; Bigliardi, B.; Bottani, E. The evolution of RFID technology in the logistics field: A review. Procedia Comput. Sci. 2022, 200, 1582–1592. [Google Scholar] [CrossRef]

- Flanagan, J.; McGovern, C. A qualitative study of improving the operations strategy of logistics using radio frequency identification. J. Glob. Oper. Strateg. Sourc. 2022, 16, 47–68. [Google Scholar] [CrossRef]

- Hossain, M.A. Development of an integrated model for RFID extension. Bus. Process Manag. J. 2014, 20, 752–772. [Google Scholar] [CrossRef]

- Shahrabi, M.S. A quantitative analysis of inaccuracy inventory reducing in multi-period mode: Comparison between RFID and inventory counting. Comput. Ind. Eng. 2023, 177, 109089. [Google Scholar] [CrossRef]

- Ustundag, A.; Satoglu, S.I. Cost-Benefit Analysis for RFID Based Pallet Pooling Systems. 2010. Available online: https://www.researchgate.net/publication/299484863_Cost-Benefit_Analysis_for_RFID_Based_Pallet_Pooling_Systems (accessed on 14 July 2024).

- Bevilacqua, M.; Ciarapica, F.E.; Mazzuto, G.; Paciarotti, C. The impact of RFID technology in hospital drug management: An economic and qualitative assessment. Int. J. RF Technol. 2013, 4, 181–208. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Kapoor, K.K.; Williams, M.D.; Williams, J. RFID systems in libraries: An empirical examination of factors affecting system use and user satisfaction. Int. J. Inf. Manag. 2013, 33, 367–377. [Google Scholar] [CrossRef]

- Sellitto, C.; Burgess, S.; Hawking, P. Information quality attributes associated with RFID-derived benefits in the retail supply chain. Int. J. Retail Distrib. Manag. 2007, 35, 69–87. [Google Scholar] [CrossRef]

- Tajima, M. Strategic value of RFID in supply chain management. J. Purch. Supply Manag. 2007, 13, 261–273. [Google Scholar] [CrossRef]

- Kim, E.Y.; Ko, E.; Kim, H.; Koh, C.E. Comparison of benefits of radio frequency identification: Implications for business strategic performance in the US and Korean retailers. Ind. Mark. Manag. 2008, 37, 797–806. [Google Scholar] [CrossRef]

- Katz, J.E.; Rice, R.E. Public views of mobile medical devices and services: A us national survey of consumer sentiments towards RFID healthcare technology. Int. J. Med. Inform. 2009, 78, 104–114. [Google Scholar] [CrossRef] [PubMed]

- Kasemsap, K. The role of radio frequency identification in modern libraries. In Identity Theft: Breakthroughs in Research and Practice; IGI Global: Hershey, PA, USA, 2017; pp. 174–200. [Google Scholar]

- Shafeie, S.; Chaudhry, B.M.; Mohamed, M. Modeling subcutaneous microchip implant acceptance in the general population: A cross-sectional survey about concerns and expectations. Informatics 2022, 9, 24. [Google Scholar] [CrossRef]

- Hou, J.-L.; Huang, C.-H. Quantitative performance evaluation of RFID applications in the supply chain of the printing industry. Ind. Manag. Data Syst. 2006, 106, 96–120. [Google Scholar] [CrossRef]

- Duran-Sindreu, M.; Bonache, J.; Martin, F.; Itoh, T. Single-layer fully-planar extended-composite right-/left-handed transmission lines based on substrate integrated waveguides for dual-band and quad- band applications. Int. J. Microw. Wirel. Technol. 2013, 5, 213–220. [Google Scholar] [CrossRef]

- Alfiana, G.; Syafrudinb, M.; Farooqc, U.; Ma, M.R.; Syaekhonib, M.A.; Fitriyanib, N.L.; Leea, J.; Rhee, J. Improving efficiency of RFID-based traceability system for perishable food by utilizing IoT sensors and machine learning model. Food Control 2020, 110, 107016. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Rollo, A. A scenario analysis for evaluating RFID investments in pallet management. Int. J. RF Technol. 2010, 2, 1–21. [Google Scholar] [CrossRef]

- Visich, J.K.; Li, S.; Khumawala, B.M.; Reyes, P.M. Empirical evidence of RFID impacts on supply chain performance. Int. J. Oper. Prod. Manag. 2009, 29, 1290–1315. [Google Scholar] [CrossRef]

- Vanem, E.; Ellis, J. Evaluating the cost-effectiveness of a monitoring system for improved evacuation from passenger ships. Saf. Sci. 2010, 48, 788–802. [Google Scholar] [CrossRef]

- Yue, C.; Wang, J.; Wang, Z.; Kong, B.; Wang, G. Flexible printed electronics and their applications in food quality monitoring and intelligent food packaging: Recent advances. Food Control 2023, 154, 109983. [Google Scholar] [CrossRef]

- Feng, J.; Fu, Z.; Wang, Z.; Xu, M.; Zhang, X. Development and evaluation on a RFID-based traceability system for cattle/beef quality safety in China. Food Control 2013, 31, 314–325. [Google Scholar] [CrossRef]

- Qu, X.; Simpson, L.T.; Stanfield, P. A model for quantifying the value of RFID-enabled equipment tracking in hospitals. Adv. Eng. Inform. 2011, 25, 23–31. [Google Scholar] [CrossRef]

- Mehannaoui, R.; Mouss, K.N.; Aksa, K. IoT-based food traceability system: Architecture, technologies, applications, and future trends. Food Control 2023, 145, 109409. [Google Scholar] [CrossRef]

- Bottani, E.; Rizzi, A. Economical assessment of the impact of RFID technology and epc system on the fast-moving consumer goods supply chain. Int. J. Prod. Econ. 2008, 112, 548–569. [Google Scholar] [CrossRef]

- Oztaysi, B.; Baysan, S.; Dursun, P. A novel approach for economic-justification of RFID technology in courier sector: A real-life case study. In Proceedings of the 2007 1st Annual RFID Eurasia, Istanbul, Turkey, 5–6 September 2007; IEEE: New York, NY, USA, 2007; pp. 1–5. [Google Scholar]

- Mu, G.; Dautzenberg, K.; Creusen, U.; Stromereder, C. Customer acceptance of RFID technology: Evidence from the german electronic retail sector. J. Retail. Consum. Serv. 2009, 16, 31–39. [Google Scholar]

- De Felice, F.; Petrillo, A. RFID in green supply chain: Proposal of a multicriteria decision model based on ahp. In Proceedings of the 2013 IEEE 10th International Conference on e-Business Engineering, Coventry, UK, 11–13 September 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 364–369. [Google Scholar]

- Thipparate, T. Economic analysis of RFID investments for construction project management using anfis. Int. J. Inf. Technol. Manag. 2013, 12, 129–142. [Google Scholar] [CrossRef]

- Rinaldi, R.; Bandinelli, R. A model to evaluate logistics RFID-based investments economic effectiveness in the apparel field. Int. J. RF Technol. 2015, 6, 121–150. [Google Scholar] [CrossRef]

- Li, D.; Li, J.; Zhang, Y. RFID investment evaluation model for eoq inventory system with planned shortage. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 8340–8345. [Google Scholar]

- De Wet, P.-S. A Financial Evaluation of RFID Technology in Sheep Feedlots. Ph.D. Dissertation, University of the Free State, Bloemfontein, South Africa, 2018. [Google Scholar]

- Ferreira, P.; Rodrigues, J.; Carvalho, M.S. Economic evaluation of a radio frequency identification system for a home appliance retail business. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 13–16 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 37–40. [Google Scholar]

- Baysan, S.; Ustundag, A. The cost–benefit models for RFID investments. In The Value of RFID: Benefits vs. Costs; Springer: Berlin/Heidelberg, Germany, 2012; pp. 13–22. [Google Scholar]

- Lee, I. Valuation methods for RFID investments. In Encyclopedia of e-Commerce Development, Implementation, and Management; IGI Global: Hershey, PA, USA, 2016; pp. 522–534. [Google Scholar]

- Tagmatiks Products Pricing. Available online: https://RFID4u.com/tagmatiks-RFID-software-pricing/ (accessed on 20 May 2022).

- Employee Earnings. August 2021, Australian Bureau of Statistics. Available online: https://www.abs.gov.au/statistics/labour/earnings-and-working-conditions/employee-earnings/latest-release#occupation (accessed on 18 July 2022).

- Aliasgari, J.; Karmakar, N.C. Mathematical model of chipless RFID tags for detection improvement. IEEE Trans. Microw. Theory Tech. 2020, 68, 4103–4115. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).