Improving the Mechanical Properties of Orthodontic Occlusal Splints Using Nanoparticles: Silver and Zinc Oxide

Abstract

1. Introduction

2. Materials and Methods

2.1. Manufacturing of Experimental Samples

2.1.1. Commercial PMMA Samples

2.1.2. Synthesis of Graphene Oxide PMMA

2.2. Evaluation of Mechanical Properties

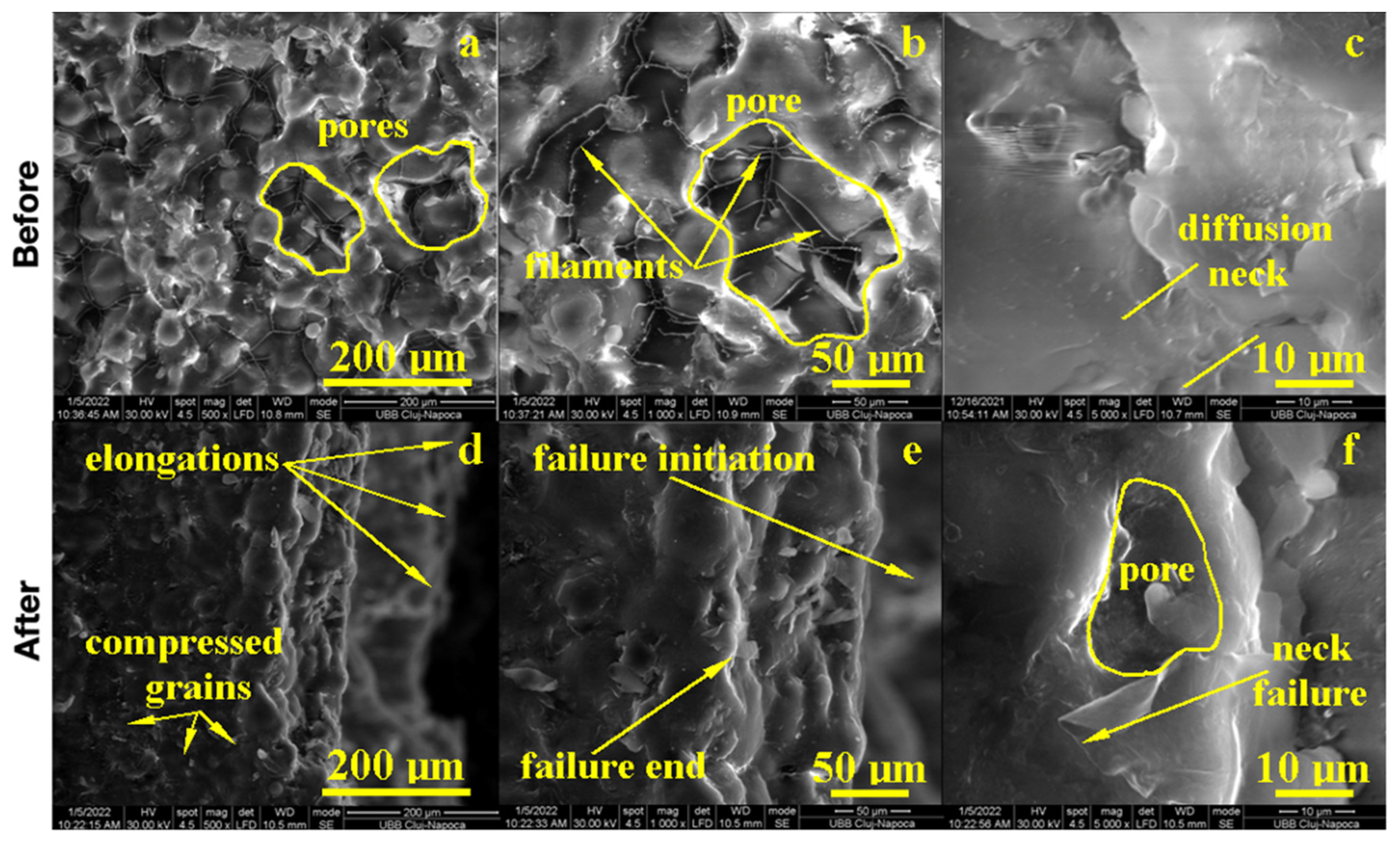

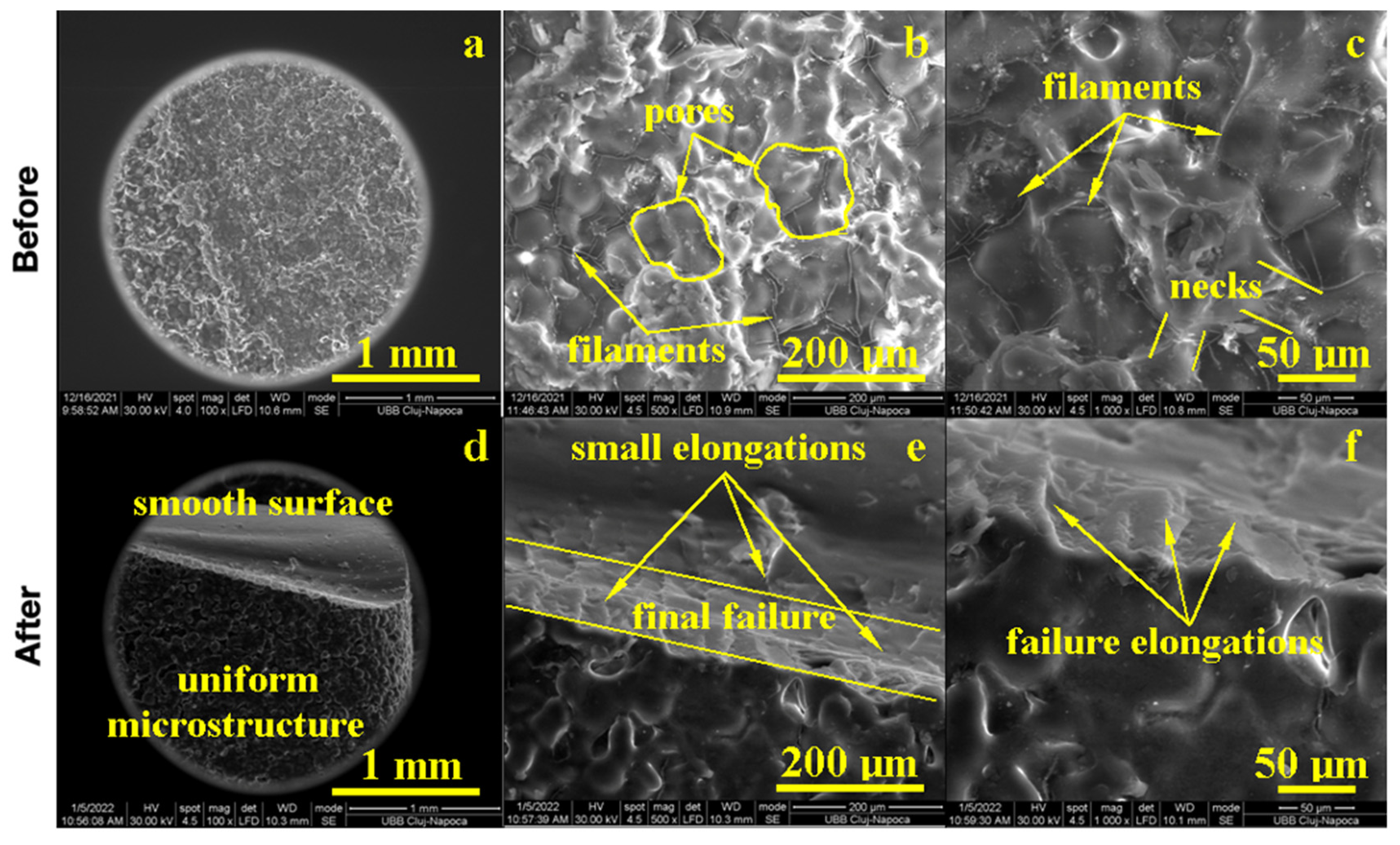

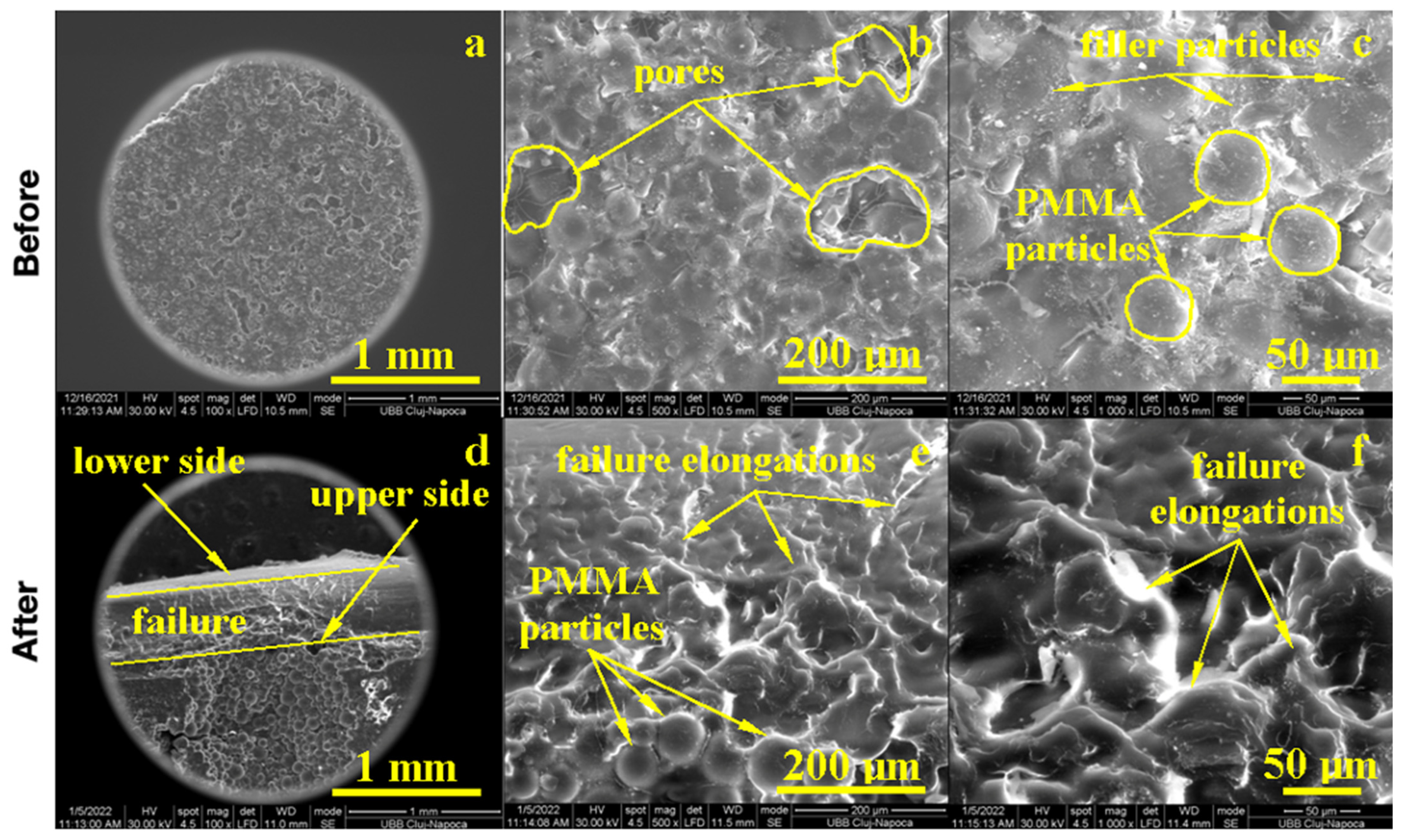

2.3. Scanning Electron Microscopy

2.4. Statistical Analysis

3. Results

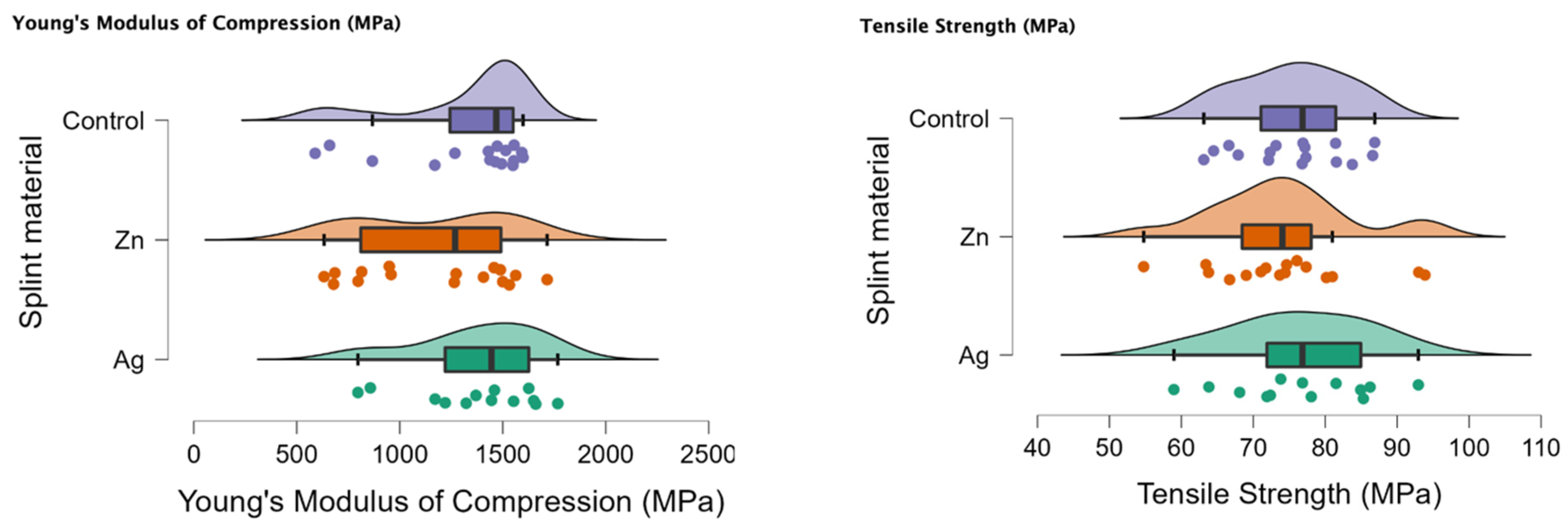

3.1. Compression

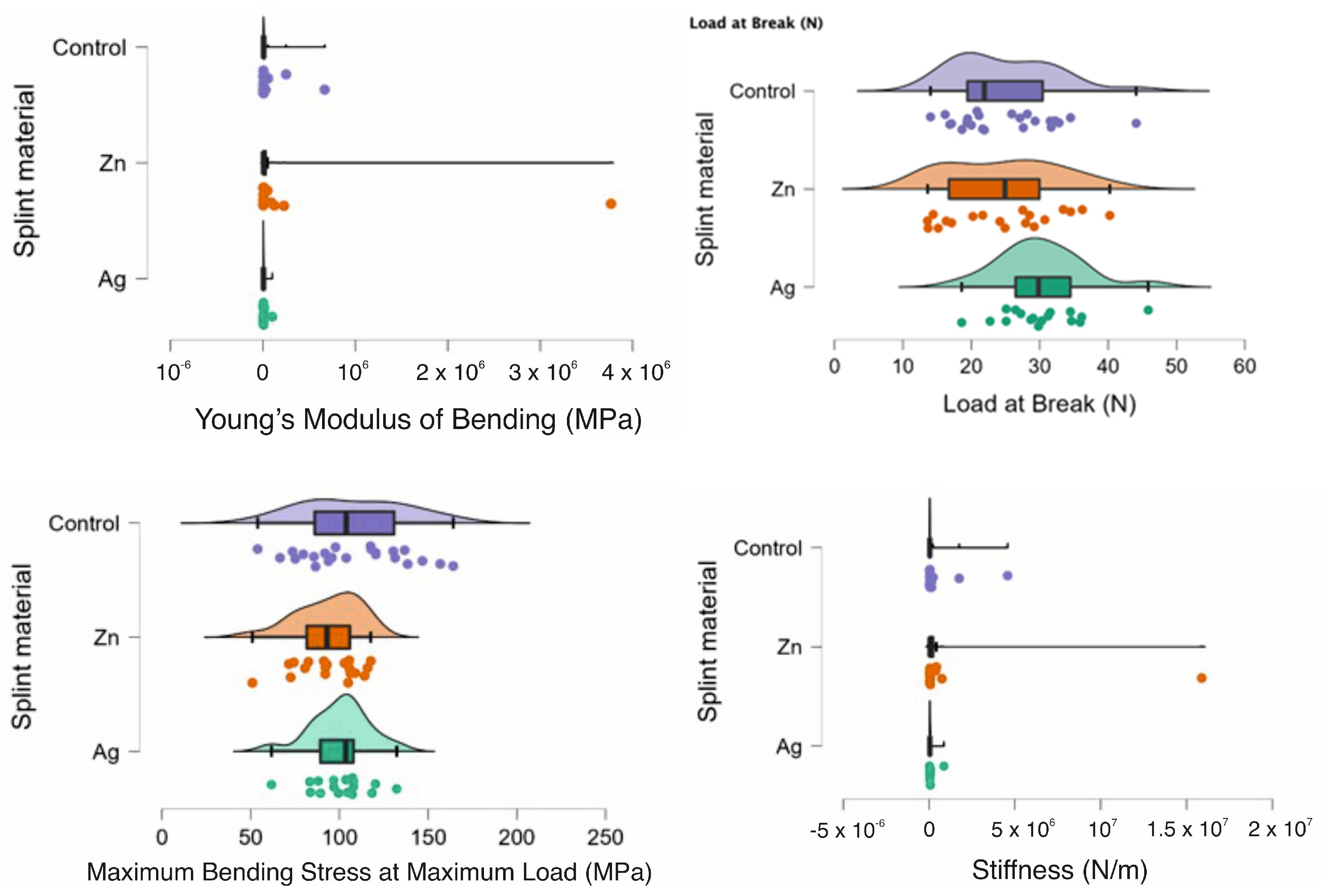

3.2. Bending/Flexural

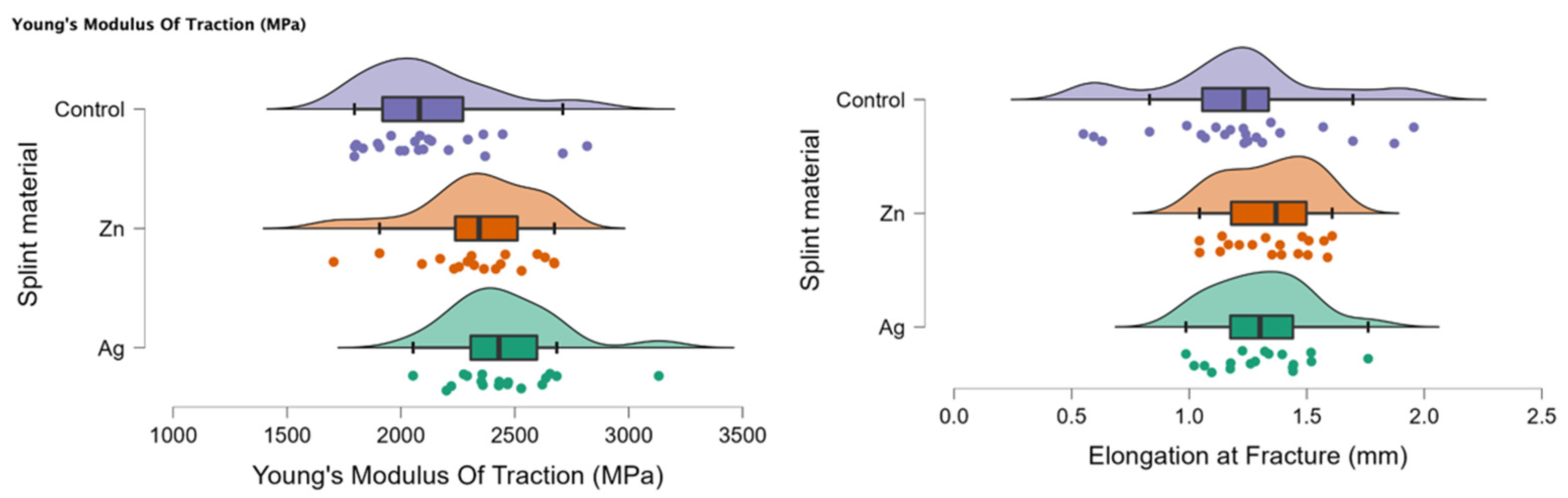

3.3. Traction

3.4. SEM Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Frazer, R.Q.; Byron, R.T.; Osborne, P.B.; West, K.P. PMMA: An Essential Material in Medicine and Dentistry. J. Long-Term Eff. Med. Implant. 2005, 15, 629–639. [Google Scholar] [CrossRef] [PubMed]

- Zafar, M.S. Prosthodontic Applications of Polymethyl Methacrylate (PMMA): An Update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef] [PubMed]

- Hardy, R.S.; Bonsor, S.J. The Efficacy of Occlusal Splints in the Treatment of Bruxism: A Systematic Review. J. Dent. 2021, 108, 103621. [Google Scholar] [CrossRef] [PubMed]

- Askinas, S.W. Fabrication of an Occlusal Splint. J. Prosthet. Dent. 1972, 28, 549–551. [Google Scholar] [CrossRef] [PubMed]

- Carlier, J.-F. Usefulness of Occlusal Splints. J. Dentofac. Anomalies Orthod. 2012, 15, 204. [Google Scholar] [CrossRef]

- Crout, D.K. Anatomy of an Occlusal Splint. Gen. Dent. 2017, 65, 52–59. [Google Scholar]

- Chintalacheruvu, V.K.; Balraj, R.U.; Putchala, L.S.; Pachalla, S. Evaluation of Three Different Processing Techniques in the Fabrication of Complete Dentures. J. Int. Soc. Prev. Community Dent. 2017, 7 (Suppl. S1), S18–S23. [Google Scholar] [CrossRef]

- Elshereksi, N.W.; Kundie, F.A.; Muchtar, A.; Azhari, C.H. Protocols of Improvements for PMMA Denture Base Resin: An Overview. J. Met. Mater. Miner. 2022, 32, 1–11. [Google Scholar] [CrossRef]

- Muhammad Firdaus, S.; Sheng, T.J.; Ariffin, Z.; Mariatti, M. Properties Improvement of Acrylic Resin for Denture Application: Effect of Single and Hybrid Types of Fillers with Different Weight Loadings. Plast. Rubber Compos. 2021, 50, 329–339. [Google Scholar] [CrossRef]

- Aydogan Ayaz, E.; Durkan, R. Influence of Acrylamide Monomer Addition to the Acrylic Denture-Base Resins on Mechanical and Physical Properties. Int. J. Oral Sci. 2013, 5, 229–235. [Google Scholar] [CrossRef]

- Hussein, M.A. Role of Cross-Linking Process on the Performance of PMMA. Int. J. Biosens. Bioelectron. 2017, 3, 279–284. [Google Scholar] [CrossRef]

- Attia, N.F.; Elashery, S.E.A.; Zakria, A.M.; Eltaweil, A.S.; Oh, H. Recent Advances in Graphene Sheets as New Generation of Flame Retardant Materials. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2021, 274, 115460. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly(methyl methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Kelly, K.L.; Coronado, E.; Zhao, L.L.; Schatz, G.C. The Optical Properties of Metal Nanoparticles: The Influence of Size, Shape, and Dielectric Environment. J. Phys. Chem. B 2003, 107, 668–677. [Google Scholar] [CrossRef]

- Weickmann, H.; Tiller, J.C.; Thomann, R.; Mülhaupt, R. Metallized Organoclays as New Intermediates for Aqueous Nanohybrid Dispersions, Nanohybrid Catalysts and Antimicrobial Polymer Hybrid Nanocomposites. Macromol. Mater. Eng. 2005, 290, 875–883. [Google Scholar] [CrossRef]

- Demir, M.M.; Memesa, M.; Castignolles, P.; Wegner, G. PMMA/Zinc Oxide Nanocomposites Prepared by In-Situ Bulk Polymerization. Macromol. Rapid Commun. 2006, 27, 763–770. [Google Scholar] [CrossRef]

- ISO 4049:2019; Dentistry—Polymer-Based Restorative Materials, 2019th ed. International Standardisation Organisation: Geneva, Switzerland, 2019.

- Version 4—The Nexygen-Eration in Testing Software. Aircr. Eng. Aerosp. Technol. 2000, 72, 763–770. [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2015.

- JASP Team. JASP (Version 0.17.2) [Computer Software]; JASP Team: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Di Carlo, S.; De Angelis, F.; Brauner, E.; Pranno, N.; Tassi, G.; Senatore, M.; Bossù, M. Flexural Strength and Elastic Modulus Evaluation of Structures Made by Conventional PMMA and PMMA Reinforced with Graphene. Eur. Rev. Med Pharmacol. Sci. 2020, 24, 5201–5208. [Google Scholar] [CrossRef]

- Al-Dwairi, Z.N.; Tahboub, K.Y.; Baba, N.Z.; Goodacre, C.J. A Comparison of the Flexural and Impact Strengths and Flexural Modulus of CAD/CAM and Conventional Heat-Cured Polymethyl Methacrylate (PMMA). J. Prosthodont. 2020, 29, 341–349. [Google Scholar] [CrossRef]

- de Oliveira Limírio, J.P.J.; de Luna Gomes, J.M.; Alves Rezende, M.C.R.; Lemos, C.A.A.; Rosa, C.D.D.R.D.; Pellizzer, E.P. Mechanical Properties of Polymethyl Methacrylate as a Denture Base: Conventional versus CAD-CAM Resin—A Systematic Review and Meta-Analysis of In Vitro Studies. J. Prosthet. Dent. 2022, 128, 1221–1229. [Google Scholar] [CrossRef]

- Al-Harbi, F.A.; Abdel-Halim, M.S.; Gad, M.M.; Fouda, S.M.; Baba, N.Z.; AlRumaih, H.S.; Akhtar, S. Effect of Nanodiamond Addition on Flexural Strength, Impact Strength, and Surface Roughness of PMMA Denture Base. J. Prosthodont. 2019, 28, e417–e425. [Google Scholar] [CrossRef]

- Li, M.; Wang, S.; Li, R.; Wang, Y.; Fan, X.; Gong, W.; Ma, Y. The Mechanical and Antibacterial Properties of Boron Nitride/Silver Nanocomposite Enhanced Polymethyl Methacrylate Resin for Application in Oral Denture Bases. Biomimetics 2022, 7, 138. [Google Scholar] [CrossRef] [PubMed]

- Bacali, C.; Buduru, S.; Nastase, V.; Craciun, A.; Prodan, D.; Constantiniuc, M.; Badea, M.; Moldovan, M.; Sarosi, C. Solubility, Ductility and Resilience of a PMMA Denture Resin with Graphene and Silver Nanoparticles Addition. Stud. UBB Chem. 2019, 64, 471–481. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.; Wang, J.; Li, Y.; Zhou, X.; Guo, X.; Zhang, T.; Guo, H. Characterization and Evaluation of a Novel Silver Nanoparticles-Loaded Polymethyl Methacrylate Denture Base: In Vitro and In Vivo Animal Study. Dent. Mater. J. 2021, 40, 1100–1108. [Google Scholar] [CrossRef]

- Wacharawichanant, S.; Thongbunyoung, N.; Churdchoo, P.; Sookjai, T.; Thongyai, S. Morphology and Properties of Poly(styrene-co-acrylonitrile)/Poly(methyl methacrylate)/Zinc Oxide Composites. J. Reinf. Plast. Compos. 2013, 32, 1112–1121. [Google Scholar] [CrossRef]

- Rudolf, R.; Popović, D.; Tomić, S.; Bobovnik, R.; Lazić, V.; Majerič, P.; Anžel, I.; Čolić, M. Microstructure Characterisation and Identification of the Mechanical and Functional Properties of a New PMMA-ZnO Composite. Materials 2020, 13, 2717. [Google Scholar] [CrossRef] [PubMed]

- Salahuddin, N.; El-Kemary, M.; Ibrahim, E. Reinforcement of Polymethyl Methacrylate Denture Base Resin with ZnO Nanostructures. Int. J. Appl. Ceram. Technol. 2018, 15, 448–459. [Google Scholar] [CrossRef]

- An, J.; Ding, N.; Zhang, Z. Mechanical and Antibacterial Properties of Polymethyl Methacrylate Modified with Zinc Dimethacrylate. J. Prosthet. Dent. 2022, 128, e1–e100. [Google Scholar] [CrossRef]

- Zebarjad, S.M.; Sajjadi, S.A.; Sdrabadi, T.E.; Yaghmaei, A.; Naderi, B. A Study on Mechanical Properties of PMMA/Hydroxyapatite Nanocomposite. Engineering 2011, 03, 795–801. [Google Scholar] [CrossRef]

- Hoang, V.T.; Luu, D.B.; Tao, Q.B.; Chen, C.C.A. Mechanical Properties of PMMA/PC Blend by Injection Molding Process. Key Eng. Mater. 2020, 863, 67–71. [Google Scholar] [CrossRef]

- Kanie, T.; Arikawa, H.; Fujii, K.; Inoue, K. Physical and Mechanical Properties of PMMA Resins Containing γ-Methacryloxypropyltrimethoxysilane. J. Oral Rehabil. 2004, 31, 166–171. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Nelson, G.L. PMMA/Silica Nanocomposite Studies: Synthesis and Properties. J. Appl. Polym. Sci. 2004, 91, 3844–3850. [Google Scholar] [CrossRef]

- Chęcińska, K.; Chęciński, M.; Sikora, M.; Nowak, Z.; Karwan, S.; Chlubek, D. The Effect of Zirconium Dioxide (ZrO2) Nanoparticles Addition on the Mechanical Parameters of Polymethyl Methacrylate (PMMA): A Systematic Review and Meta-Analysis of Experimental Studies. Polymers 2022, 14, 1047. [Google Scholar] [CrossRef] [PubMed]

- Jain, S.; Sayed, M.E.; Shetty, M.; Alqahtani, S.M.; Al Wadei, M.H.D.; Gupta, S.G.; Othman, A.A.A.; Alshehri, A.H.; Alqarni, H.; Mobarki, A.H.; et al. Physical and Mechanical Properties of 3D-Printed Provisional Crowns and Fixed Dental Prosthesis Resins Compared to CAD/CAM Milled and Conventional Provisional Resins: A Systematic Review and Meta-Analysis. Polymers 2022, 14, 2691. [Google Scholar] [CrossRef] [PubMed]

- Al-Dwairi, Z.N.; Al Haj Ebrahim, A.A.; Baba, N.Z. A Comparison of the Surface and Mechanical Properties of 3D Printable Denture-Base Resin Material and Conventional Polymethylmethacrylate (PMMA). J. Prosthodont. 2023, 32, 40–48. [Google Scholar] [CrossRef] [PubMed]

| Young’s Modulus of Compression (MPa) | Tensile Strength (MPa) | |||||

|---|---|---|---|---|---|---|

| Ag | Zn | Control | Ag | Zn | Control | |

| Valid N | 13 | 16 | 16 | 13 | 16 | 16 |

| Shapiro–Wilk p-value | 0.271 | 0.069 | <0.001 | 0.992 | 0.606 | 0.586 |

| Median | 1445.47 | 1269.19 | 1468.61 | 76.84 | 74.05 | 76.85 |

| Mean | 1377.07 | 1169.98 | 1326.18 | 76.53 | 74.05 | 75.51 |

| SD | 301.12 | 371.98 | 331.97 | 9.69 | 10.12 | 7.49 |

| IQR | 405.81 | 680.58 | 307.19 | 13.04 | 9.61 | 10.40 |

| Minimum | 797.06 | 632.75 | 589.36 | 58.97 | 54.77 | 63.12 |

| Maximum | 1767.32 | 1715.57 | 1598.58 | 92.95 | 93.87 | 86.89 |

| Young’s Modulus of Compression (MPa) | Tensile Strength (MPa) | |

|---|---|---|

| ANOVA p-values | ||

| Ag-Zn-Control | 0.259 | 0.799 |

| Dunn Post Hoc p-values | ||

| Ag-Zn | 0.075 | 0.190 |

| Ag-Control | 0.374 | 0.394 |

| Zn-Control | 0.118 | 0.259 |

| Young’s Modulus of Bending (MPa) | Load at Break (N) | Maximum Bending Stress at Maximum Load (MPa) | Stiffness (N/m) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ag | Zn | Control | Ag | Zn | Control | Ag | Zn | Control | Ag | Zn | Control | |

| Valid N | 17 | 19 | 23 | 17 | 19 | 23 | 17 | 19 | 23 | 17 | 19 | 23 |

| Shapiro–Wilk p-value | <0.001 | <0.001 | <0.001 | 0.699 | 0.321 | 0.174 | 0.800 | 0.220 | 0.833 | <0.001 | <0.001 | <0.001 |

| Median | 5570.76 | 6842.74 | 7092.49 | 29.82 | 24.92 | 21.91 | 103.63 | 92.96 | 103.81 | 45,978.47 | 60,589.80 | 41,222.01 |

| Mean | 11,908.41 | 228,844.87 | 50,237.74 | 30.169 | 24.72 | 24.88 | 100.53 | 93.82 | 108.04 | 101,873.52 | 977,346.56 | 330,098.91 |

| SD | 23,088.49 | 858,455.75 | 144,037.90 | 6.24 | 8.28 | 7.40 | 16.47 | 17.96 | 29.96 | 197,193.30 | 3,616,000 | 991,464.40 |

| IQR | 3572.37 | 23,655.77 | 7143.04 | 8.02 | 13.24 | 11.01 | 18.63 | 24.29 | 44.77 | 32,255.68 | 192,847.16 | 25,595.48 |

| Minimum | 3599.78 | 4573.92 | 4115.90 | 18.60 | 13.60 | 14.04 | 61.71 | 50.97 | 53.94 | 30,268.68 | 34,481.91 | 25,276.75 |

| Maximum | 100,798.61 | 3,766,000.00 | 668,077.42 | 45.86 | 40.24 | 44.10 | 132.29 | 117.67 | 164.11 | 864,222.07 | 15,890,000 | 4,575,000 |

| Young’s Modulus of Bending (MPa) | Load at Break (N) | Maximum Bending Stress at Maximum Load (MPa) | Stiffness (N/m) | |

|---|---|---|---|---|

| Applied Test | Kruskal–Wallis | ANOVA | ANOVA | Kruskal–Wallis |

| p-values | ||||

| Ag-Zn-Control | 0.071 | 0.032 | 0.167 | 0.300 |

| Dunn Post Hoc p-values | ||||

| Ag-Zn | 0.029 | 0.019 | 0.165 | 0.287 |

| Ag-Control | 0.017 | 0.014 | 0.286 | 0.185 |

| Zn-Control | 0.443 | 0.496 | 0.051 | 0.063 |

| Young’s Modulus of Traction (MPa) | Elongation at Fracture (mm) | |||||

|---|---|---|---|---|---|---|

| Ag | Zn | Control | Ag | Zn | Control | |

| Valid N | 18 | 18 | 22 | 18 | 18 | 22 |

| Shapiro–Wilk p-value | 0.169 | 0.285 | 0.046 | 0.831 | 0.268 | 0.397 |

| Median | 2430.55 | 2343.13 | 2081.06 | 1.30 | 1.37 | 1.23 |

| Mean | 2453.66 | 2337.33 | 2126.85 | 1.30 | 1.34 | 1.21 |

| SD | 240.97 | 259.39 | 279.89 | 0.202 | 0.19 | 0.37 |

| IQR | 291.41 | 273.43 | 353.65 | 0.27 | 0.32 | 0.28 |

| Minimum | 2053.22 | 1704.73 | 1795.76 | 0.99 | 1.04 | 0.55 |

| Maximum | 3131.94 | 2673.89 | 2817.36 | 1.76 | 1.61 | 1.96 |

| Young’s Modulus of Traction (MPa) | Elongation at Fracture (mm) | |

|---|---|---|

| ANOVA p-values | ||

| Ag-Zn-Control | 0.001 | 0.324 |

| Dunn Post Hoc p-values | ||

| Ag-Zn | 0.174 | 0.274 |

| Ag-Control | <0.001 | 0.150 |

| Zn-Control | 0.007 | 0.048 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbur, I.; Opris, H.; Colosi, H.A.; Baciut, M.; Opris, D.; Cuc, S.; Petean, I.; Moldovan, M.; Dinu, C.M.; Baciut, G. Improving the Mechanical Properties of Orthodontic Occlusal Splints Using Nanoparticles: Silver and Zinc Oxide. Biomedicines 2023, 11, 1965. https://doi.org/10.3390/biomedicines11071965

Barbur I, Opris H, Colosi HA, Baciut M, Opris D, Cuc S, Petean I, Moldovan M, Dinu CM, Baciut G. Improving the Mechanical Properties of Orthodontic Occlusal Splints Using Nanoparticles: Silver and Zinc Oxide. Biomedicines. 2023; 11(7):1965. https://doi.org/10.3390/biomedicines11071965

Chicago/Turabian StyleBarbur, Ioan, Horia Opris, Horatiu Alexandru Colosi, Mihaela Baciut, Daiana Opris, Stanca Cuc, Ioan Petean, Marioara Moldovan, Cristian Mihail Dinu, and Grigore Baciut. 2023. "Improving the Mechanical Properties of Orthodontic Occlusal Splints Using Nanoparticles: Silver and Zinc Oxide" Biomedicines 11, no. 7: 1965. https://doi.org/10.3390/biomedicines11071965

APA StyleBarbur, I., Opris, H., Colosi, H. A., Baciut, M., Opris, D., Cuc, S., Petean, I., Moldovan, M., Dinu, C. M., & Baciut, G. (2023). Improving the Mechanical Properties of Orthodontic Occlusal Splints Using Nanoparticles: Silver and Zinc Oxide. Biomedicines, 11(7), 1965. https://doi.org/10.3390/biomedicines11071965