Performance Analysis of MAU-9 Electronic-Nose MOS Sensor Array Components and ANN Classification Methods for Discrimination of Herb and Fruit Essential Oils

Abstract

:1. Introduction

2. Materials and Methods

2.1. Essential Oil Samples

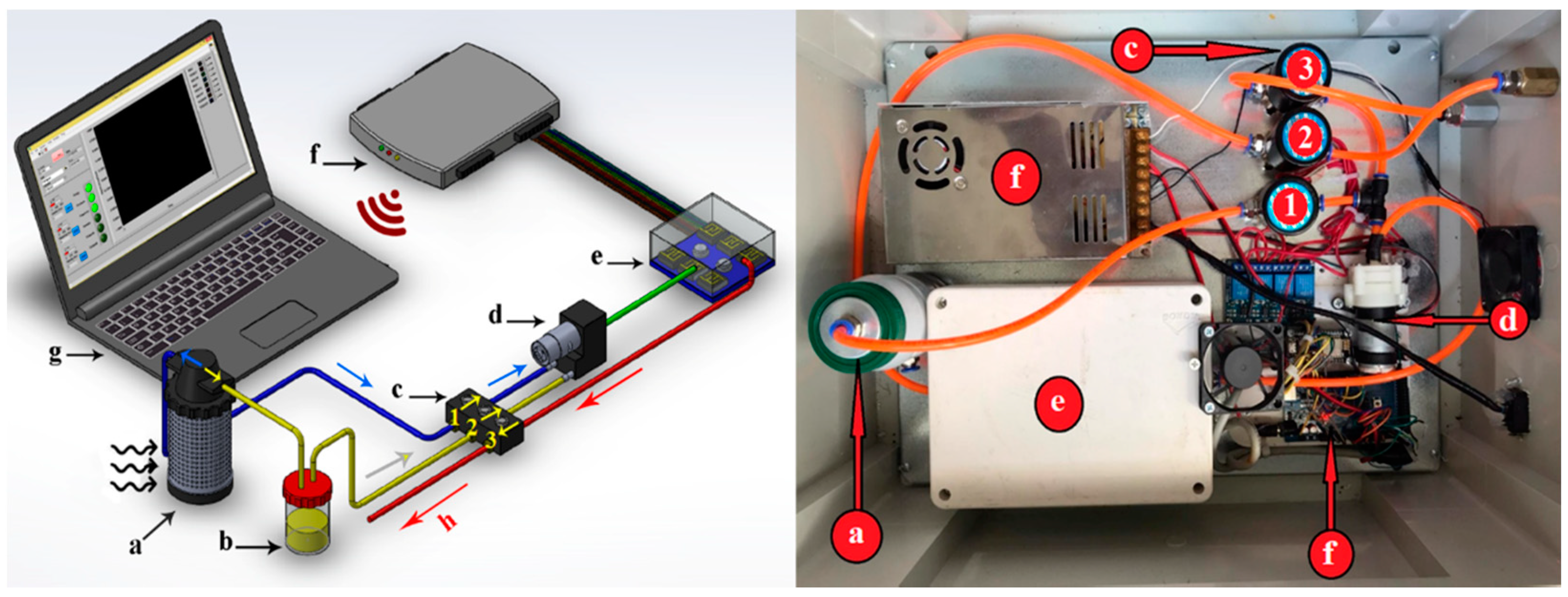

2.2. Electronic Nose Instrument

2.3. Data Analysis

2.3.1. Statistical Methods

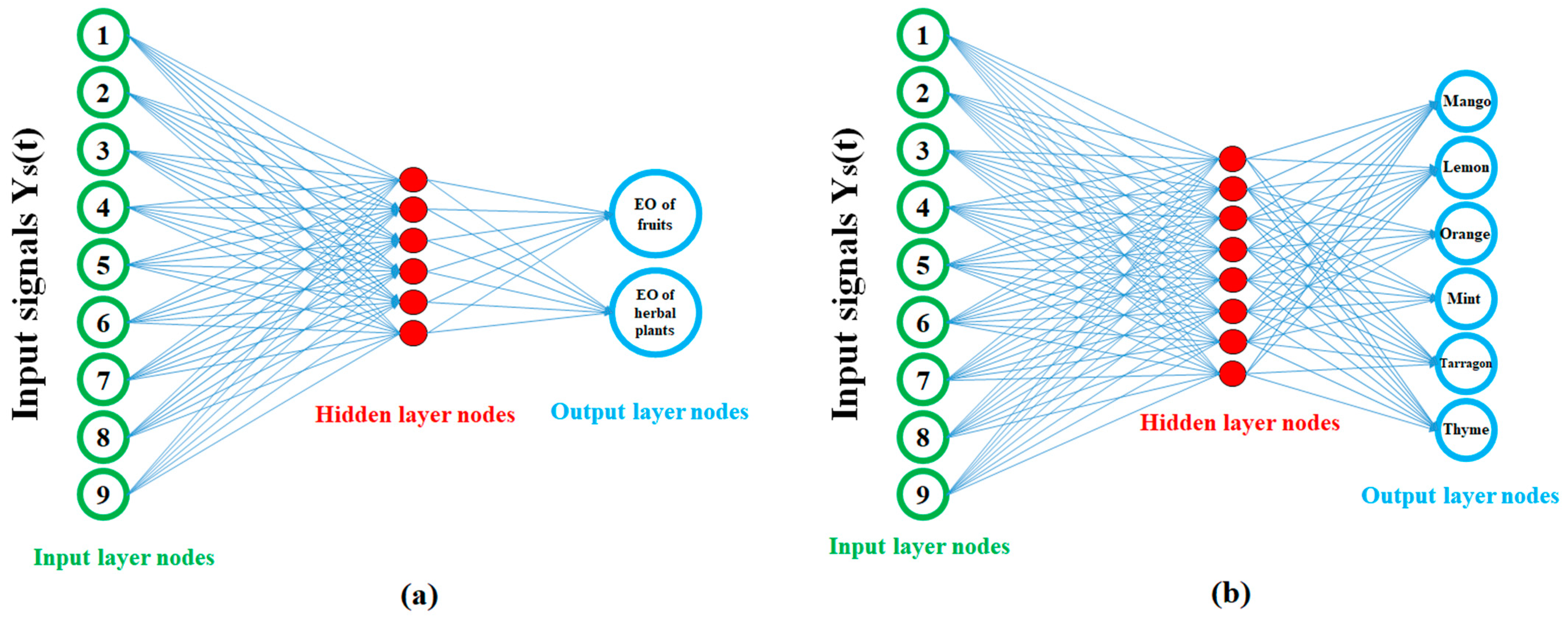

2.3.2. ANN Methods

3. Results

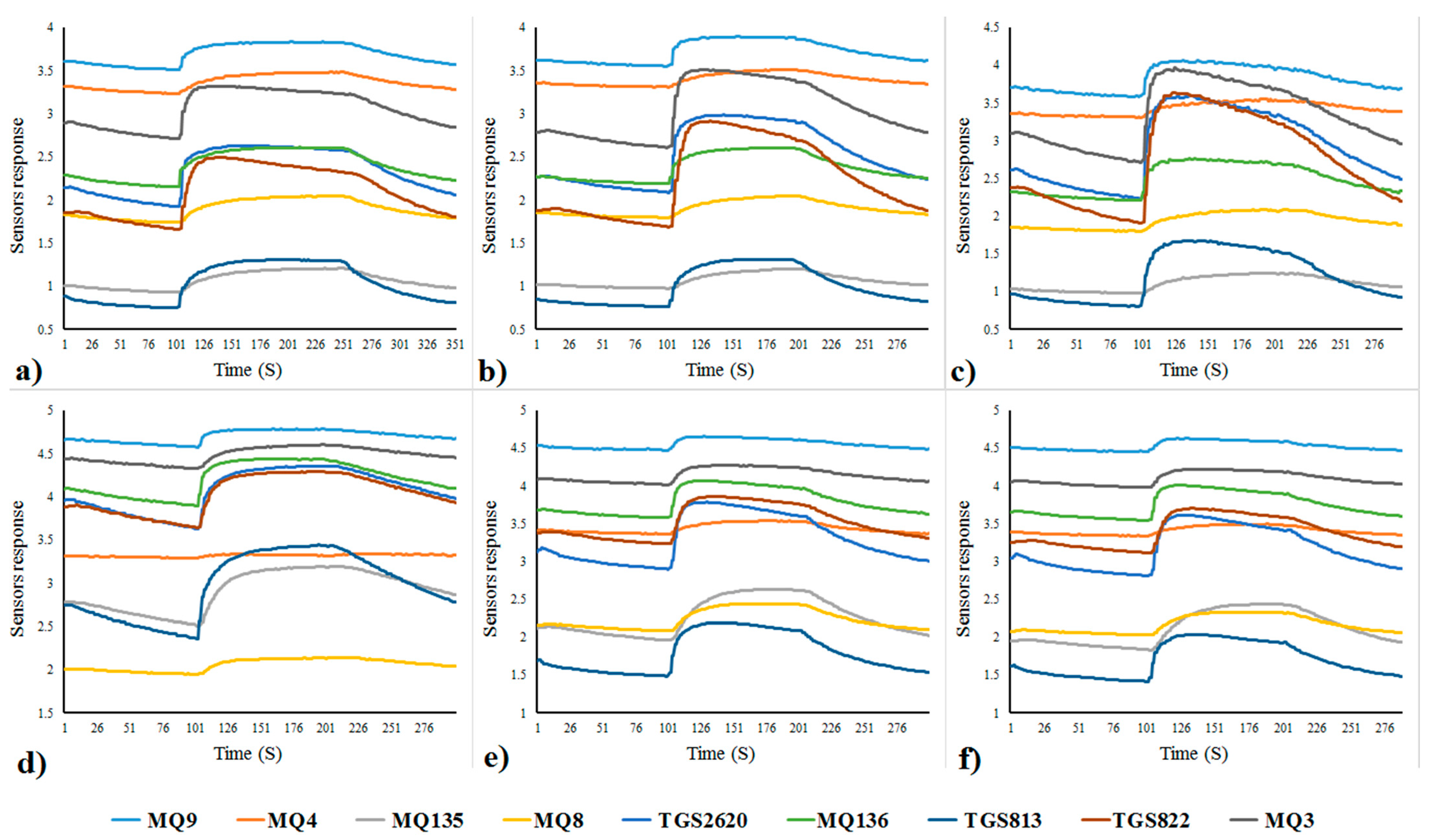

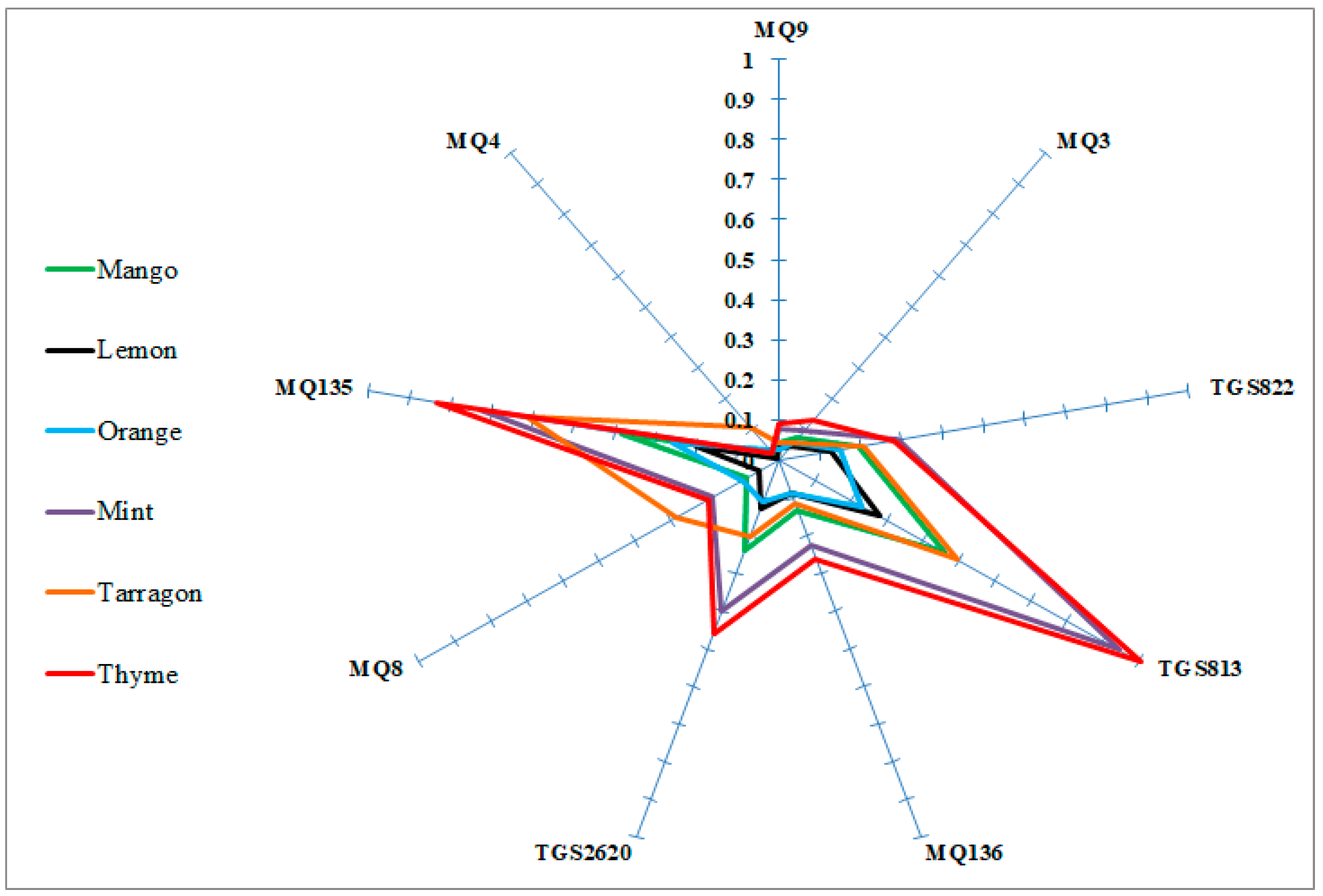

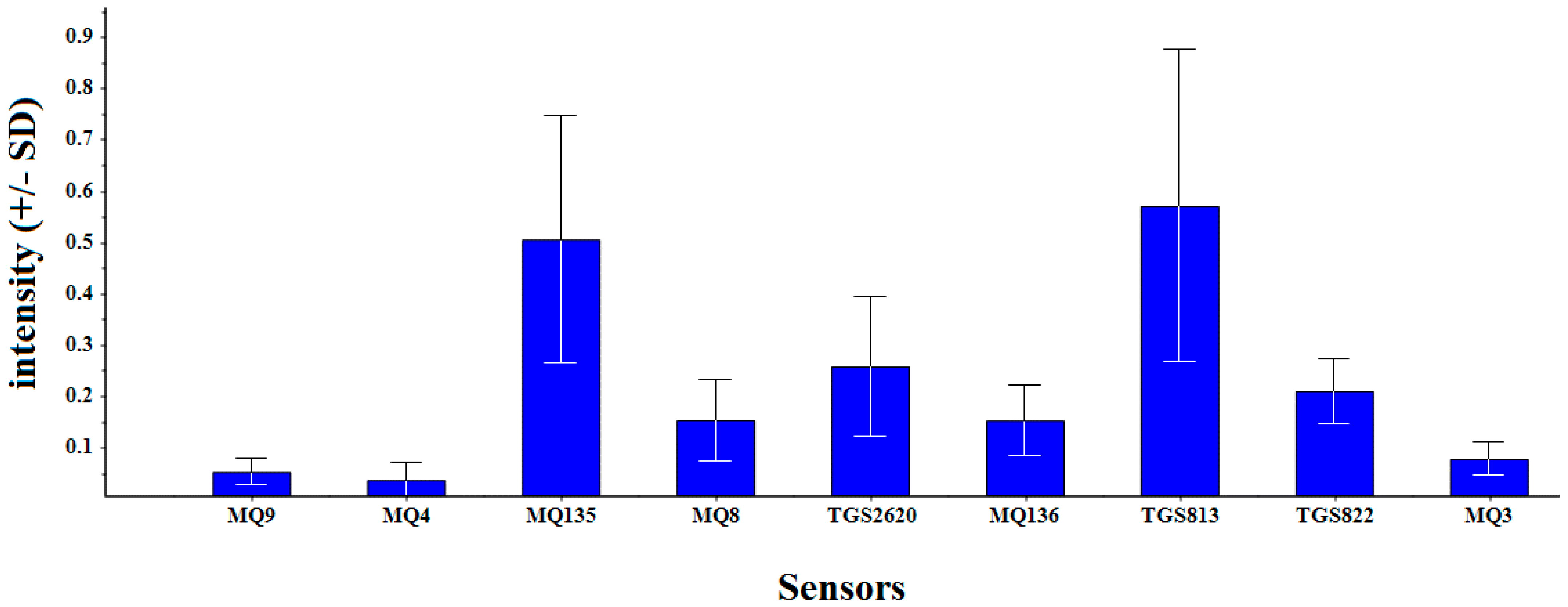

3.1. Electronic-Nose Sensor-Component Analysis

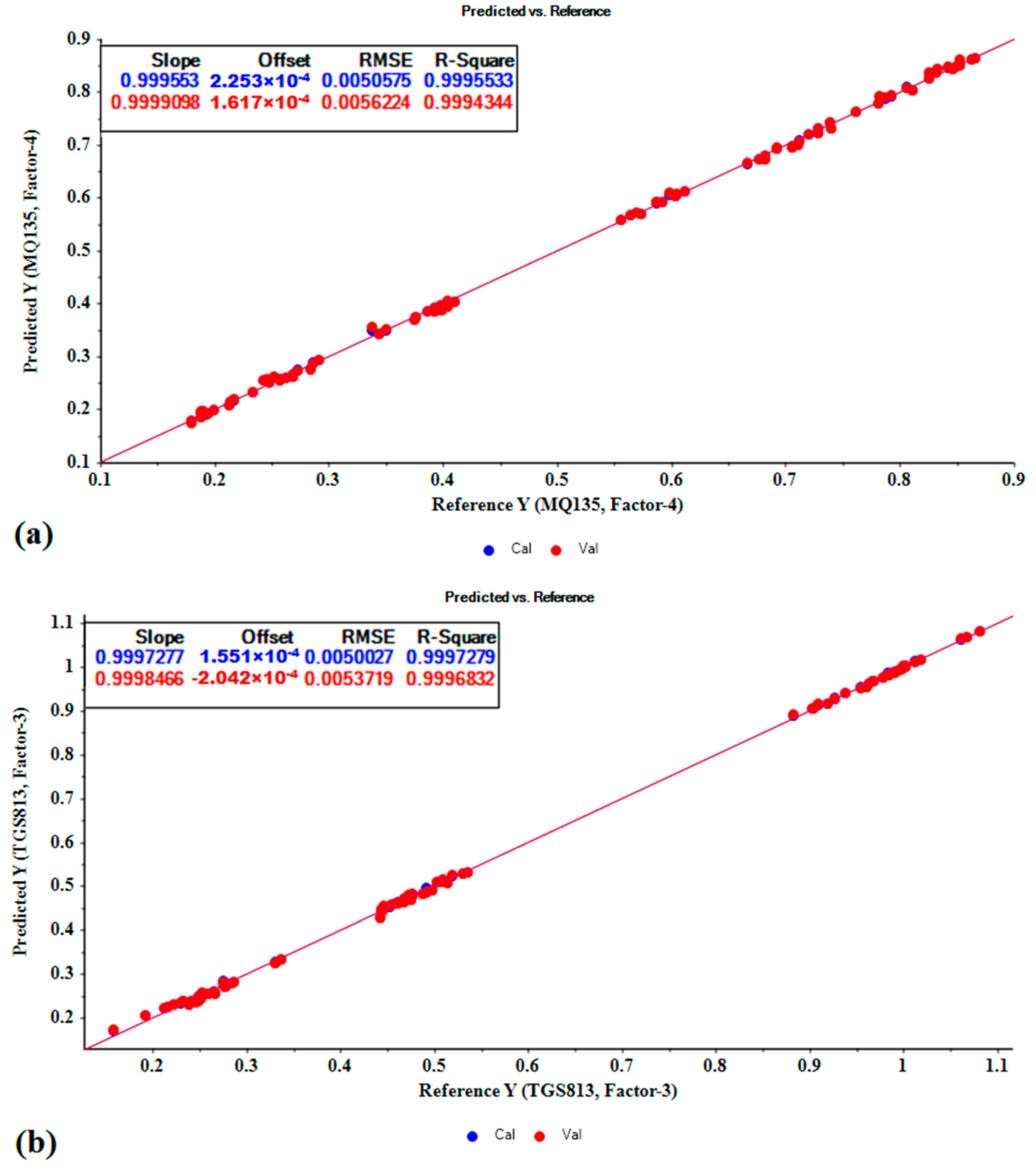

3.2. Partial Least Squares and Principal Regression Analyses

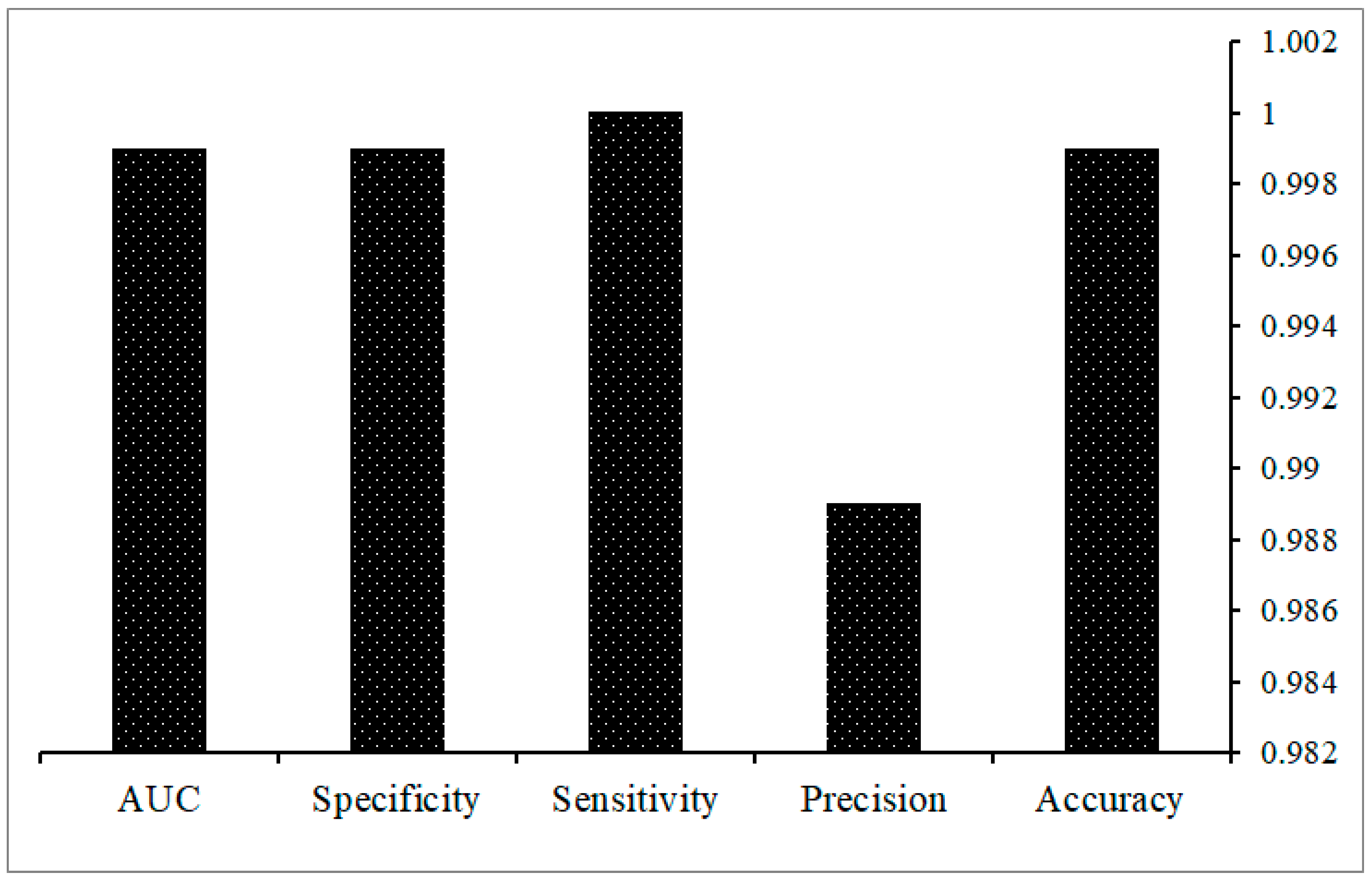

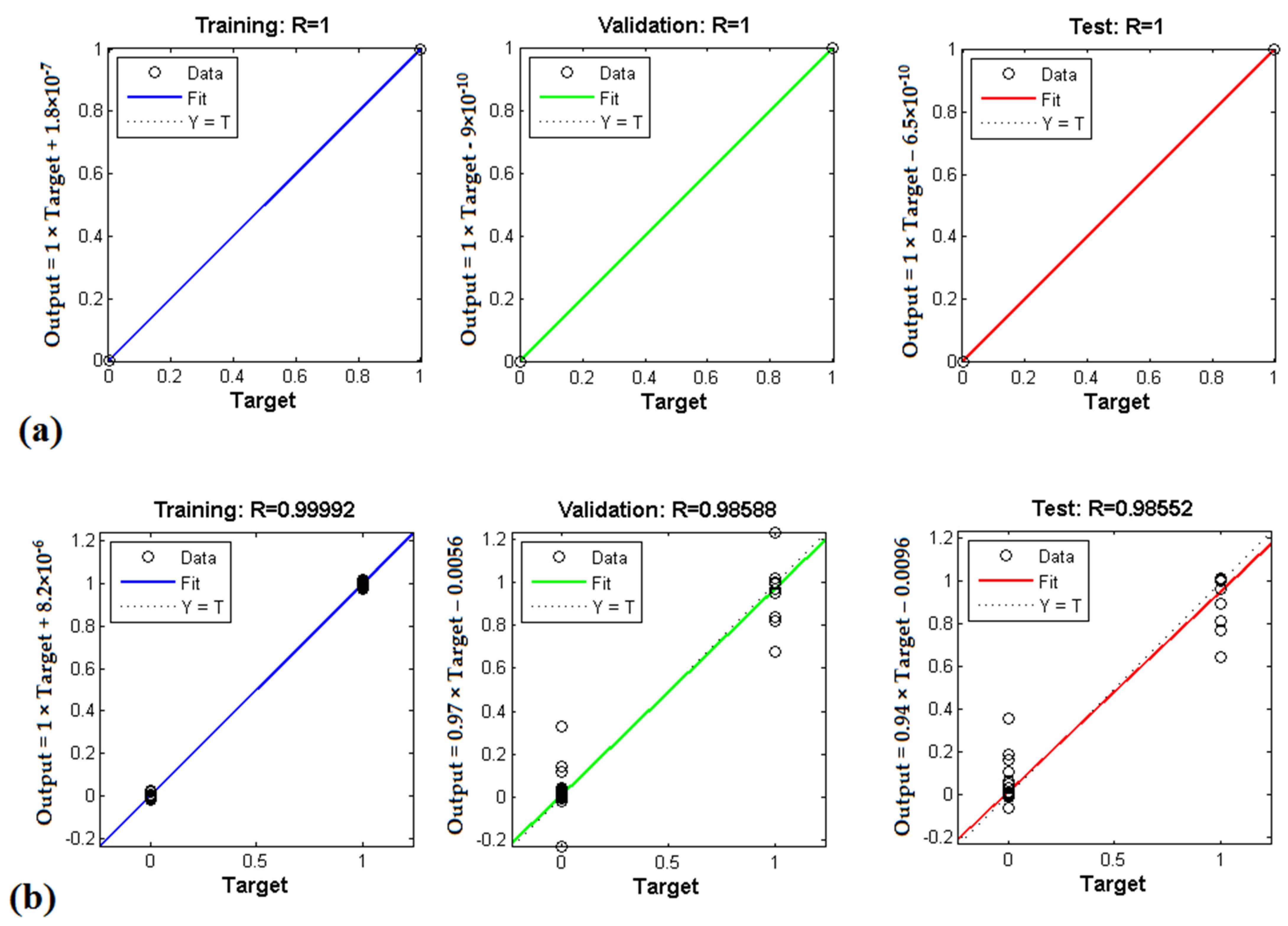

3.3. ANN Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Supplementary Sensor Raw Output, Essential Oils Data from the MAU-9 MOS E-Nose System

Appendix B. Definitions of Statistical Methods and Algorithms (with Associated Acronyms)

References

- Ali, M.M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Principles and recent advances in electronic nose for quality inspection of agricultural and food products. Trends Food Sci. Technol. 2020, 99, 1–10. [Google Scholar] [CrossRef]

- Tan, J.; Xu, J. Applications of electronic nose (e-nose) and electronic tongue (e-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 2020, 4, 104–115. [Google Scholar] [CrossRef]

- Wilson, A.D. Diverse applications of electronic nose technologies in agriculture and forestry. Sensors 2013, 13, 2295–2348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ottoboni, M.; Pinotti, L.; Tretola, M.; Giromini, C.; Fusi, E.; Rebucci, R.; Grillo, M.; Tassoni, L.; Foresta, S.; Gastaldello, S.; et al. Combining e-nose and lateral flow immunoassays (LFIAs) for rapid occurrence/co-occurrence aflatoxin and fumonisin detection in maize. Toxins 2018, 10, 416. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Timsorn, K.; Lorjaroenphon, Y.; Wongchoosuk, C. Identification of adulteration in uncooked jasmine rice by a portable low-cost artificial olfactory system. Measurement 2017, 108, 67–76. [Google Scholar] [CrossRef]

- Karami, H.; Rasekh, M.; Mirzaee-Ghaleh, E. Comparison of chemometrics and AOCS official methods for predicting the shelf life of edible oil. Chemom. Intell. Lab. Syst. 2020, 206, 104165. [Google Scholar] [CrossRef]

- Peris, M.; Escuder-Gilabert, L.A. 21st century technique for food control: Electronic noses. Anal. Chim. Acta 2009, 638, 1–15. [Google Scholar] [CrossRef]

- Wilson, A.D.; Baietto, M. Applications and advances in electronic nose technologies. Sensors 2009, 9, 5099–5148. [Google Scholar] [CrossRef]

- Hernández-Mesa, M.; Escourrou, A.; Monteau, F.; Le Bizec, B.; Dervilly-Pinel, G. Current applications and perspectives of ion mobility spectrometry to answer chemical food safety issues. TrAC 2017, 94, 39–53. [Google Scholar] [CrossRef]

- Wilson, A.D. Review of electronic-nose technologies and algorithms to detect hazardous chemicals in the environment. Proc. Technol. 2012, 1, 453–463. [Google Scholar] [CrossRef] [Green Version]

- Kafle, G.K.; Khot, L.R.; Sankaran, S.; Bahlol, H.Y.; Tufariello, J.A.; Hill, H.H. State of ion mobility spectrometry and applications in agriculture: A review. Eng. Agric. Environ. Food 2016, 9, 346–357. [Google Scholar] [CrossRef]

- Gancarz, M.; Malaga-Toboła, U.; Oniszczuk, A.; Tabor, S.; Oniszczuk, T.; Gawrysiak-Witulska, M.; Rusinek, R. Detection and measurement of aroma compounds with the electronic nose and a novel method for MOS sensor signal analysis during the wheat bread making process. Food Bioprod. Process. 2021, 127, 90–98. [Google Scholar] [CrossRef]

- Wilson, A.D. Applications of electronic-nose technologies for noninvasive early detection of plant, animal and human diseases. Chemosensors 2018, 9, 45. [Google Scholar] [CrossRef] [Green Version]

- Rusinek, R.; Gawrysiak-Witulska, M.; Siger, A.; Oniszczuk, A.; Ptaszyńska, A.A.; Knaga, J.; Malaga-Toboła, U.; Gancarz, M. Effect of supplementation of flour with fruit fiber on the volatile compound profile in bread. Sensors 2021, 21, 2812. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D. Noninvasive early disease diagnosis by electronic-nose and related VOC-detection devices. Biosensors 2020, 10, 73. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D.; Baietto, M. Advances in electronic-nose technologies developed for biomedical applications. Sensors 2011, 11, 1105–1176. [Google Scholar] [CrossRef]

- Camardo Leggieri, M.; Mazzoni, M.; Fodil, S.; Moschini, M.; Bertuzzi, T.; Prandini, A.; Battilani, P. An electronic nose supported by an artificial neural network for the rapid detection of aflatoxin B1 and fumonisins in maize. Food Control 2021, 123, 107722. [Google Scholar] [CrossRef]

- Zhang, L.; Tian, F.; Zhang, D. Book Review and Future Work. In Electronic Nose: Algorithmic Challenges; Springer: Singapore, 2018; pp. 335–339. [Google Scholar]

- Goodner, K.L.; Dreher, J.G.; Rouseff, R.L. The dangers of creating false classifications due to noise in electronic nose and similar multivariate analyses. Sens. Actuators B Chem. 2001, 80, 261–266. [Google Scholar] [CrossRef]

- Borowik, P.; Adamowicz, L.; Tarakowski, R.; Siwek, K.; Grzywacz, T. Odor detection using an e-nose with a reduced sensor array. Sensors 2020, 20, 3542. [Google Scholar] [CrossRef] [PubMed]

- Phaisangittisagul, E.; Nagle, H.T. Sensor selection for machine olfaction based on transient feature extraction. IEEE Trans. Instrum. Meas. 2008, 57, 369–378. [Google Scholar] [CrossRef]

- Phaisangittisagul, E.; Nagle, H.T.; Areekul, V. Intelligent method for sensor subset selection for machine olfaction. Sens. Actuators B Chem. 2010, 145, 507–515. [Google Scholar] [CrossRef]

- Guo, D.; Zhang, D.; Zhang, L. An LDA based sensor selection approach used in breath analysis system. Sens. Actuators B Chem. 2011, 157, 265–274. [Google Scholar] [CrossRef]

- Geng, Z.; Yang, F.; Wu, N. Optimum design of sensor arrays via simulation-based multivariate calibration. Sens. Actuators B Chem. 2011, 156, 854–862. [Google Scholar] [CrossRef]

- Zhang, L.; Tian, F.; Pei, G. A novel sensor selection using pattern recognition in electronic nose. Measurement 2014, 54, 31–39. [Google Scholar] [CrossRef]

- Miao, J.; Zhang, T.; Wang, Y.; Li, G. Optimal sensor selection for classifying a set of ginsengs using metal-oxide sensors. Sensors 2015, 15, 16027–16039. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, H.; Tian, F.; Liang, Z.; Sun, T.; Yu, B.; Yang, S.X.; He, Q.; Zhang, L.; Liu, X. Sensor array optimization of electronic nose for detection of bacteria in wound infection. IEEE Trans. Ind. Electron. 2017, 64, 7350–7358. [Google Scholar] [CrossRef]

- Llobet, E.; Ionescu, R.; Al-Khalifa, S.; Brezmes, J.; Vilanova, X.; Correig, X.; Barsan, N.; Gardner, J.W. Multicomponent gas mixture analysis using a single tin oxide sensor and dynamic pattern recognition. IEEE Sens. J. 2001, 1, 207–213. [Google Scholar] [CrossRef]

- Szczurek, A.; Krawczyk, B.; Maciejewska, M. VOCs classification based on the committee of classifiers coupled with single sensor signals. Chemom. Intell. Lab. Syst. 2013, 125, 1–10. [Google Scholar] [CrossRef]

- Szczurek, A.; Maciejewska, M. “Artificial sniffing” based on induced temporary disturbance of gas sensor response. Sens. Actuators B Chem. 2013, 186, 109–116. [Google Scholar] [CrossRef]

- Hossein-Babaei, F.; Amini, A. Recognition of complex odors with a single generic tin oxide gas sensor. Sens. Actuators B Chem. 2014, 194, 156–163. [Google Scholar] [CrossRef]

- Herrero-Carrón, F.; Yáñez, D.J.; de Borja Rodríguez, F.; Varona, P. An active, inverse temperature modulation strategy for single sensor odorant classification. Sens. Actuators B Chem. 2015, 206, 555–563. [Google Scholar] [CrossRef]

- Rasekh, M.; Karami, H.; Wilson, A.D.; Gancarz, M. Classification and identification of essential oils from herbs and fruits based on a MOS electronic-nose technology. Chemosensors 2021, 9, 142. [Google Scholar] [CrossRef]

- Karami, H.; Rasekh, M.; Mirzaee-Ghaleh, E. Application of the e-nose machine system to detect adulterations in mixed edible oils using chemometrics methods. J. Food Process. Preserv. 2020, 44, e14696. [Google Scholar] [CrossRef]

- Sanaeifar, A.; Mohtasebi, S.S.; Ghasemi-Varnamkhasti, M.; Ahmadi, H. Application of MOS based electronic nose for the prediction of banana quality properties. Measurement 2016, 82, 105–114. [Google Scholar] [CrossRef]

- Abu-Khalaf, N. Identification and quantification of olive oil quality parameters using an electronic nose. Agriculture 2021, 11, 674. [Google Scholar] [CrossRef]

- Karami, H.; Rasekh, M.; Mirzaee-Ghaleh, E. Qualitative analysis of edible oil oxidation using an olfactory machine. J. Food Meas. Charact. 2020, 14, 2600–2610. [Google Scholar] [CrossRef]

- Rasekh, M.; Karami, H. E-nose coupled with an artificial neural network to detection of fraud in pure and industrial fruit juices. Int. J. Food Prop. 2021, 24, 592–602. [Google Scholar] [CrossRef]

- Ozyildirim, B.M.; Mariam, K. Levenberg-Marquardt multi-classification using hinge loss function. Neural. Netw. 2021, 143, 564–571. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, J.; Liao, W. Technique potential for classification of honey by electronic tongue. J. Food Eng. 2009, 94, 260–266. [Google Scholar] [CrossRef]

- Kiani, S.; Minaee, S.; Ghasemi-Varnamkhasti, M. Integration of computer vision and electronic nose as non-destructive systems for saffron adulteration detection. Comput. Electron. Agric. 2017, 141, 46–53. [Google Scholar] [CrossRef]

- Lerma-García, M.J.; Simó-Alfonso, E.F.; Bendini, A.; Cerretani, L. Metal oxide semiconductor sensors for monitoring of oxidative status evolution and sensory analysis of virgin olive oils with different phenolic content. Food Chem. 2009, 117, 608–614. [Google Scholar] [CrossRef]

- Rasekh, M.; Karami, H. Application of electronic nose with chemometrics methods to the detection of juices fraud. J. Food Process. Preserv. 2021, 45, e15432. [Google Scholar] [CrossRef]

- Karami, H.; Rasekh, M.; Mirzaee–Ghaleh, E. Identification of olfactory characteristics of edible oil during storage period using metal oxide semiconductor sensor signals and ANN methods. J. Food Process. Preserv. 2021, 45, e15749. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, F.; He, Y.; Li, X. Application of hyperspectral imaging and chemometric calibrations for variety discrimination of maize seeds. Sensors 2012, 12, 17234–17246. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi-Varnamkhasti, M.; Tohidi, M.; Mishra, P.; Izadi, Z. Temperature modulation of electronic nose combined with multi-class support vector machine classification for identifying export caraway cultivars. Postharvest Biol. Technol. 2018, 138, 134–139. [Google Scholar] [CrossRef]

- Mabood, F.; Hussain, J.; Jabeen, F.; Abbas, G.; Allaham, B.; Albroumi, M.; Alghawi, S.; Alameri, S.; Gilani, S.A.; Al-Harrasi, A.; et al. Applications of FT-NIRS combined with PLS multivariate methods for the detection & quantification of saccharin adulteration in commercial fruit juices. Food Addit. Contam. Part A 2018, 35, 1052–1060. [Google Scholar] [CrossRef]

- Lias, S.; Mohamad Ali, N.A.; Jamil, M.; Tolmanan, M.S.Y.; Misman, M.A. A study on the application of electronic nose coupled with DFA and statistical analysis for evaluating the relationship between sample volumes versus sensor intensity of agarwood essential oils blending ratio. MATEC Web Conf. 2018, 201, 2008. [Google Scholar] [CrossRef]

- Baietto, M.; Wilson, A.D. Electronic-nose applications for fruit identification, ripeness, and quality grading. Sensors 2015, 15, 899–931. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Lv, J. Using recurrent neural network to optimize electronic nose system with dimensionality reduction. Electronics 2020, 9, 2205. [Google Scholar] [CrossRef]

- Wei, P.; Ning, Z.; Ye, S.; Sun, L.; Yang, F.; Wong, K.C.; Westerdahl, D.; Louie, P.K.K. Impact analysis of temperature and humidity conditions on electrochemical sensor response in ambient air quality monitoring. Sensors 2018, 18, 59. [Google Scholar] [CrossRef] [Green Version]

- Wilson, A.D. Recent progress in the design and clinical development of electronic-nose technologies. Nanobiosens. Dis. Diagn. 2016, 5, 15–27. [Google Scholar] [CrossRef] [Green Version]

- Wilson, A.D.; Lester, D.G.; Oberle, C.S. Development of conductive polymer analysis for the rapid detection and identification of phytopathogenic microbes. Phytopathology 2004, 94, 419–431. [Google Scholar] [CrossRef] [PubMed]

| Sample Classification | Model 1 | R 2 | RMSE | Offset | |||

|---|---|---|---|---|---|---|---|

| Calibration | Validation | Calibration | Validation | Calibration | Validation | ||

| 2-group | PR | 0.977 | 0.965 | 1.085 | 1.122 | 1.975 | 2.252 |

| PLS | 0.956 | 0.945 | 1.005 | 1.215 | 1.617 | 2.325 | |

| 6-group | PR | 0.967 | 0.953 | 1.968 | 2.138 | 2.083 | 2.694 |

| PLS | 0.945 | 0.938 | 2.036 | 2.562 | 1.995 | 2.564 | |

| Coefficients of Predictor Variables 3 (for Individual MOS Sensors in MAU-9 Sensor Array) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample Classification | Model 1 | B0 2 | MQ9 c1 | MQ4 c2 | MQ135 c3 | MQ8 c4 | TGS2620 c5 | MQ136 c6 | TGS813 c7 | TGS822 c8 | MQ3 c9 |

| 2-group | PR | 0.022 | −10.3 | −4.8 | 3.24 | −11.7 | −14.7 | −14.9 | −3.5 | −12.1 | −13.6 |

| PLS | 0.092 | 9.67 | 4.3 | −2.78 | 12.3 | 14.3 | 9.3 | 3.3 | −4.7 | 1.24 | |

| 6-group | PR | 0.019 | 1.68 | 10 | 10.9 | −21.6 | −8.7 | 4.1 | 1.87 | −20.9 | 16.7 |

| PLS | 0.045 | 1.57 | 17.6 | 11.7 | −12.7 | 10.2 | 5.80 | 1.88 | −11.8 | −7.50 | |

| Sensor No. | Sensor Name | R2val | R2cal | RMSEval | RMSEcal | Sample Discrimination 1 (SD) Contribution |

|---|---|---|---|---|---|---|

| 1 | MQ-9 | 0.891 | 0.893 | 0.1122 | 0.1257 | High |

| 2 | MQ4 | 0.525 | 0.527 | 0.5425 | 0.5469 | Low |

| 3 | MQ135 | 0.999 | 0.999 | 0.0050 | 0.0056 | Very high |

| 4 | MQ8 | 0.744 | 0.746 | 0.1235 | 0.1239 | Moderate |

| 5 | TGS2620 | 0.854 | 0.855 | 0.1853 | 0.1893 | High |

| 6 | MQ-136 | 0.855 | 0.856 | 0.1201 | 0.1205 | High |

| 7 | TGS813 | 0.999 | 0.999 | 0.0050 | 0.0053 | Very high |

| 8 | TGS822 | 0.855 | 0.856 | 0.1349 | 0.1359 | High |

| 9 | MQ3 | 0.701 | 0.700 | 0.1920 | 0.1934 | Moderate |

| Sample Classification | All Sensors (R1-R9) 1 | High-Performing Sensors (MQ135, TGS813) 1 | ||

|---|---|---|---|---|

| Calibration Set | Prediction Set | Calibration Set | Prediction Set | |

| R2 | RMSE | R2 | RMSE | |

| 2-group | 0.945 | 0.215 | 0.999 | 0.0050 |

| 6-group | 0.938 | 0.162 | 0.999 | 0.0056 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasekh, M.; Karami, H.; Wilson, A.D.; Gancarz, M. Performance Analysis of MAU-9 Electronic-Nose MOS Sensor Array Components and ANN Classification Methods for Discrimination of Herb and Fruit Essential Oils. Chemosensors 2021, 9, 243. https://doi.org/10.3390/chemosensors9090243

Rasekh M, Karami H, Wilson AD, Gancarz M. Performance Analysis of MAU-9 Electronic-Nose MOS Sensor Array Components and ANN Classification Methods for Discrimination of Herb and Fruit Essential Oils. Chemosensors. 2021; 9(9):243. https://doi.org/10.3390/chemosensors9090243

Chicago/Turabian StyleRasekh, Mansour, Hamed Karami, Alphus Dan Wilson, and Marek Gancarz. 2021. "Performance Analysis of MAU-9 Electronic-Nose MOS Sensor Array Components and ANN Classification Methods for Discrimination of Herb and Fruit Essential Oils" Chemosensors 9, no. 9: 243. https://doi.org/10.3390/chemosensors9090243

APA StyleRasekh, M., Karami, H., Wilson, A. D., & Gancarz, M. (2021). Performance Analysis of MAU-9 Electronic-Nose MOS Sensor Array Components and ANN Classification Methods for Discrimination of Herb and Fruit Essential Oils. Chemosensors, 9(9), 243. https://doi.org/10.3390/chemosensors9090243