Application of Ba0.5Sr0.5TiO3 (Bst) Film Doped with 0%, 2%, 4% and 6% Concentrations of RuO2 as an Arduino Nano-Based Bad Breath Sensor

Abstract

1. Introduction

2. Research Method

2.1. Preparation of the Type-p Silicon (100) Substrate

2.2. Preparation of the Ba0.5Sr0.5TiO3 Film Doped with RuO2 Solution

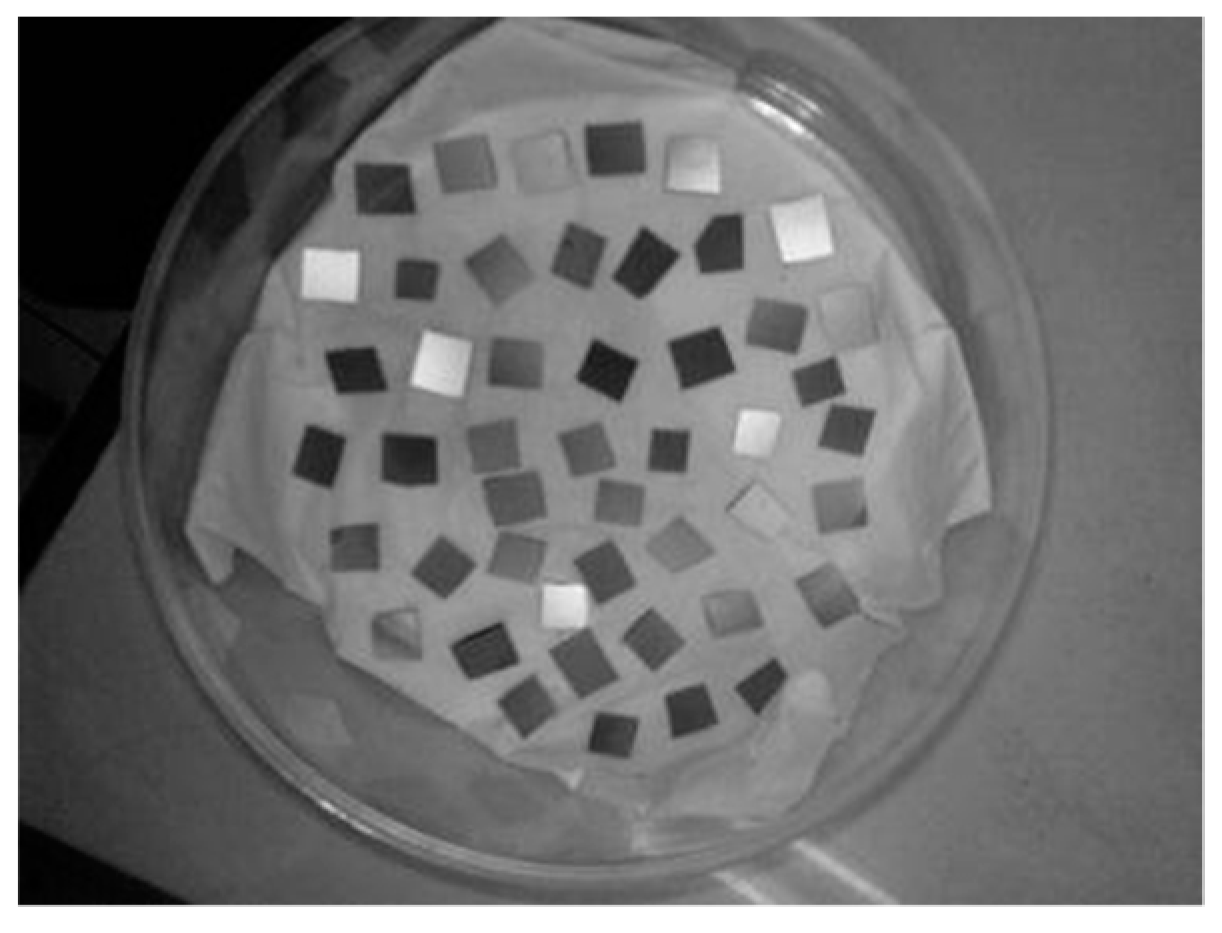

2.3. Growing the Ba0.5Sr0.5TiO3 Film Doped with RuO2

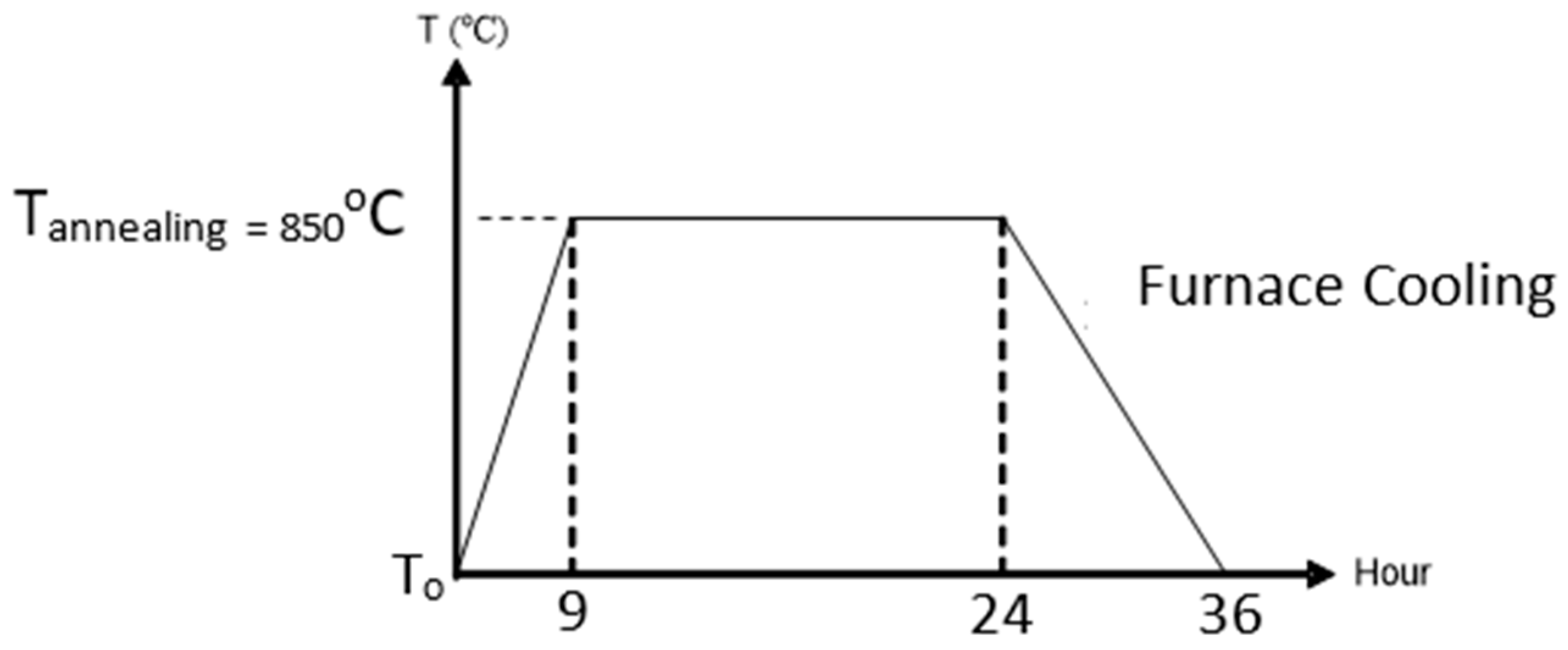

2.4. The Annealing Process

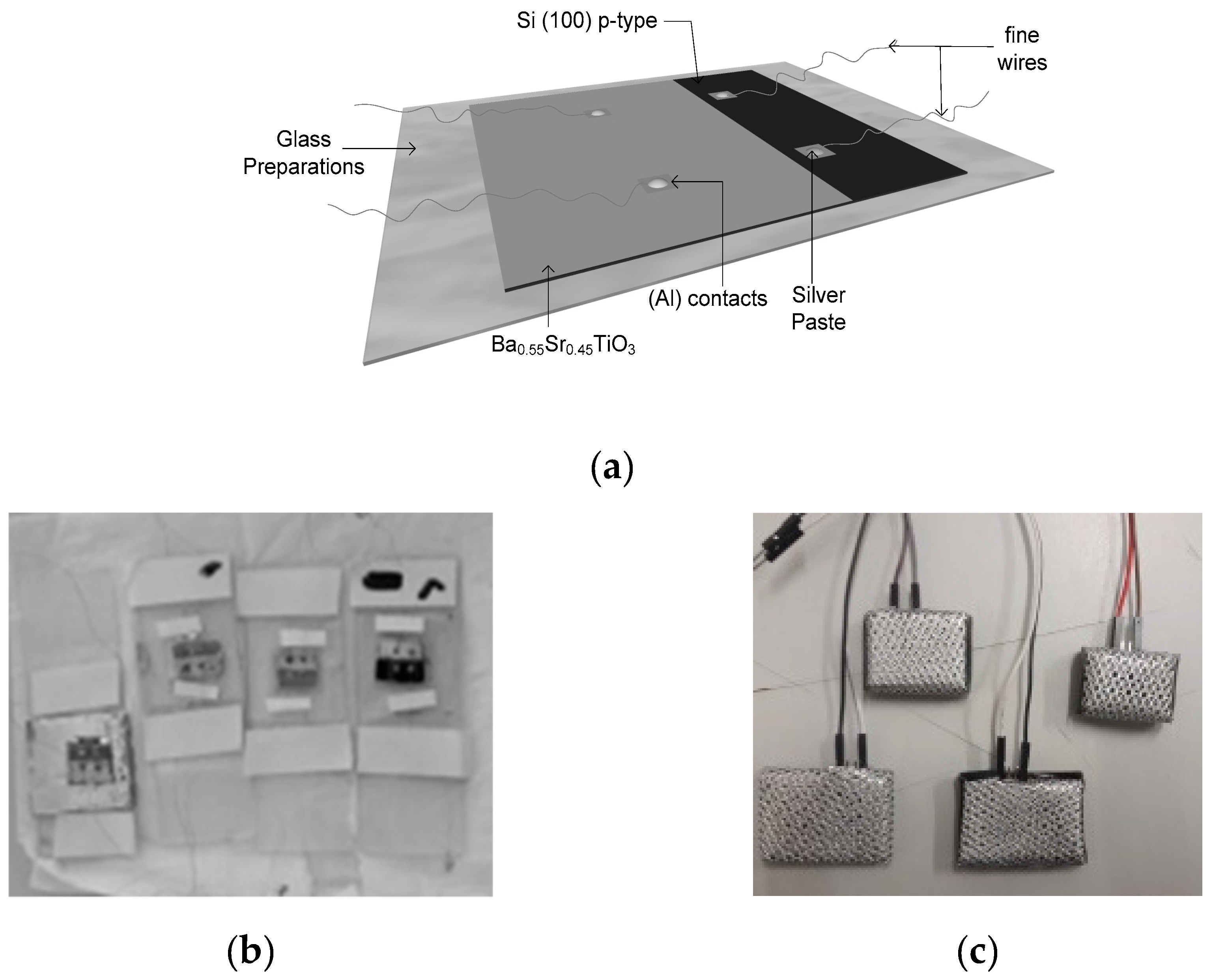

2.5. Contact Installation in the Ba0.5Sr0.5TiO3 Film Doped with RuO2

2.6. Characterization of the Ba0.5Sr0.5TiO3 Film Doped with RuO2 as a Bad Breath-Gas Sensor

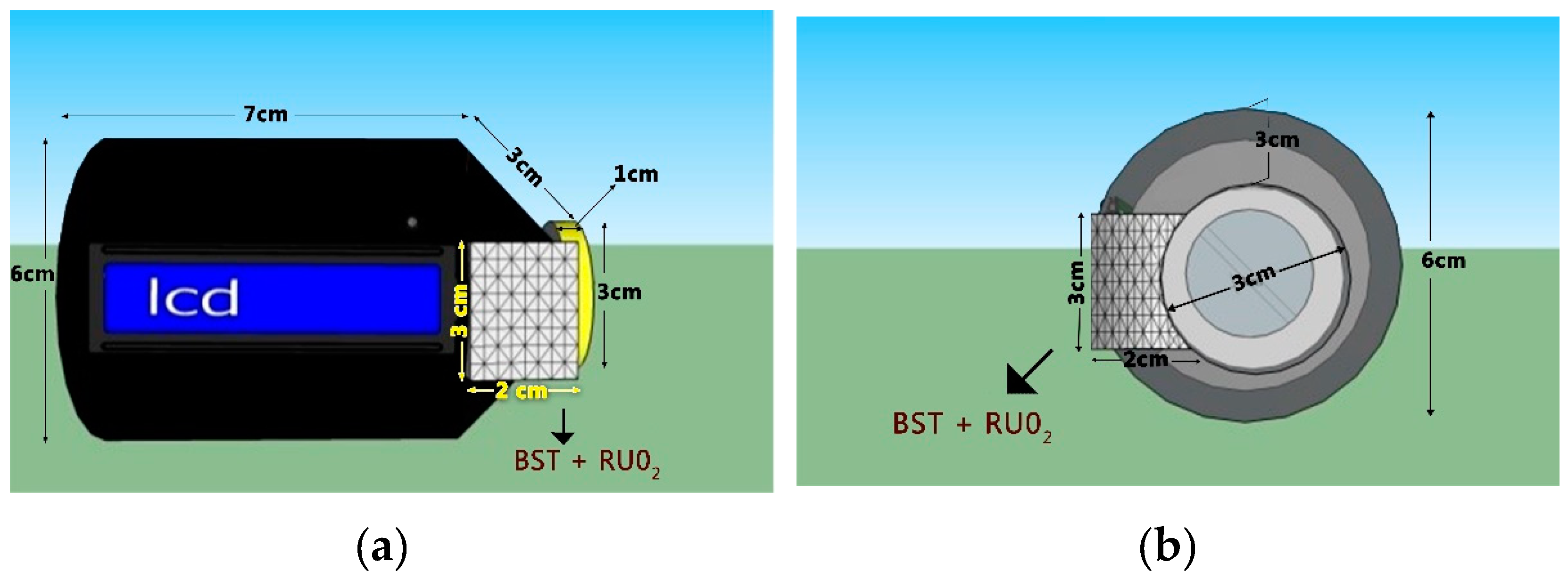

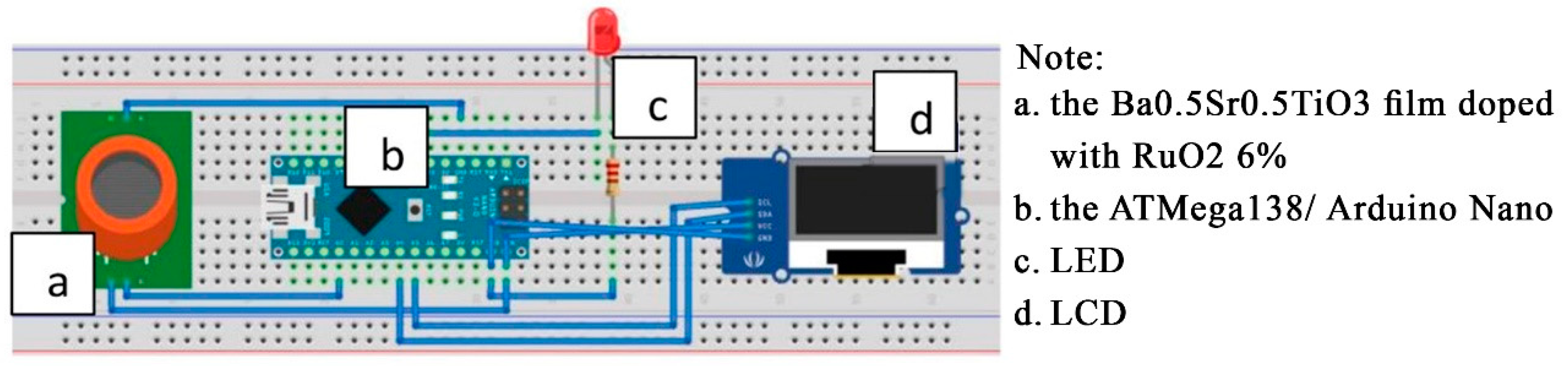

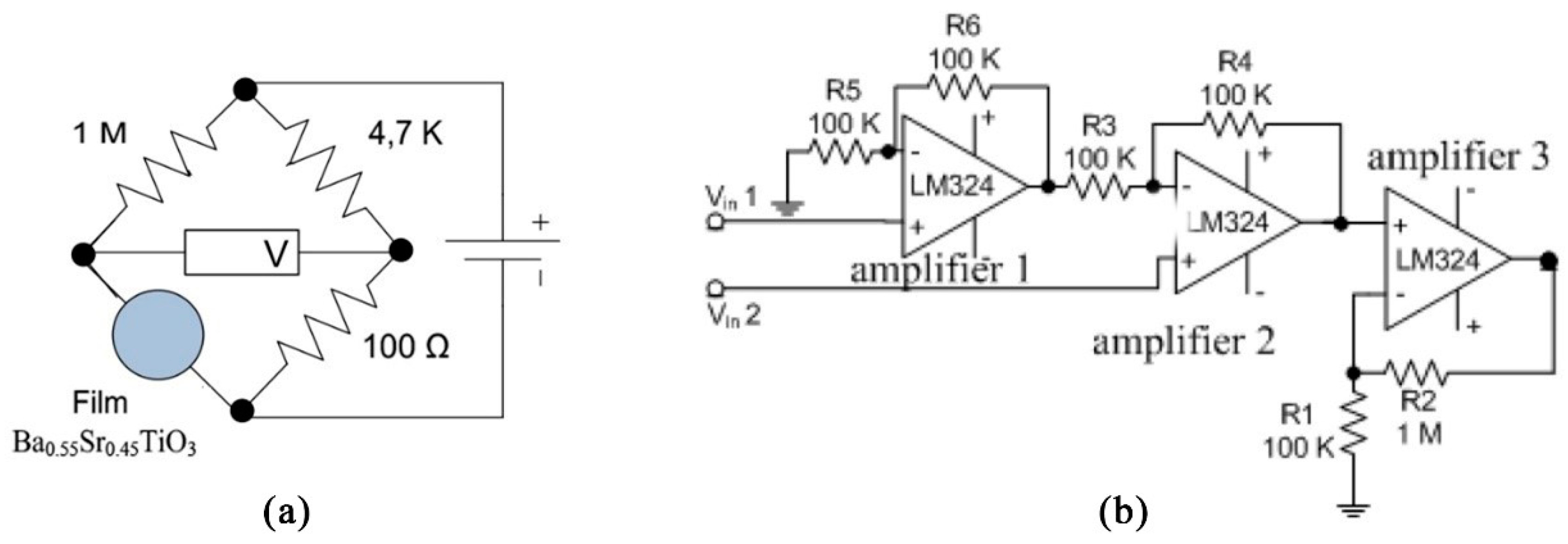

2.7. Equipment Design

3. Results and Discussion

3.1. Characterization of the Ba0.5Sr0.5TiO3 Film Doped with RuO2 as a Bad Breath-Gas Sensor

3.2. The Atmega168/Arduino Nano Microcontroller Circuit

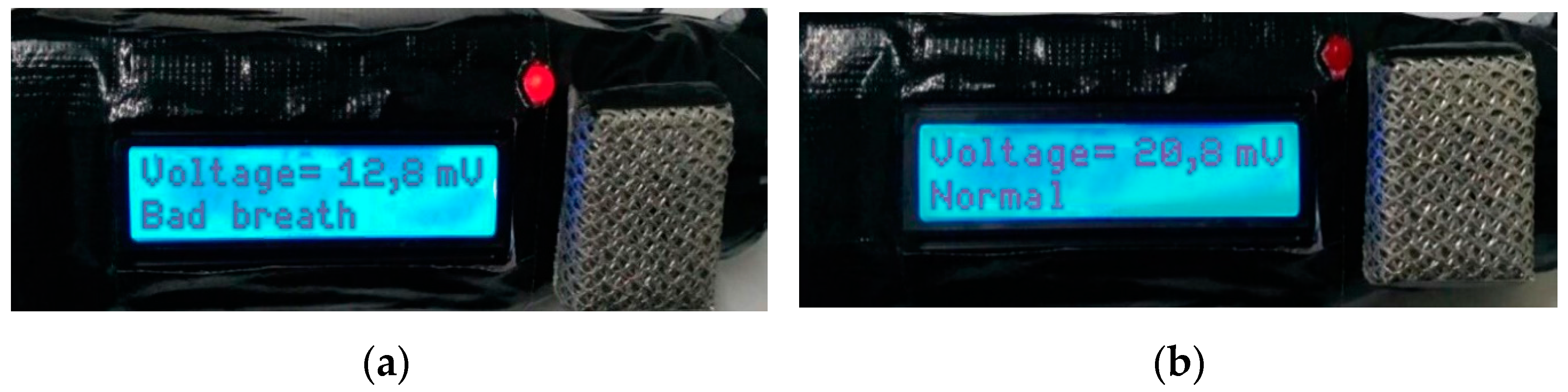

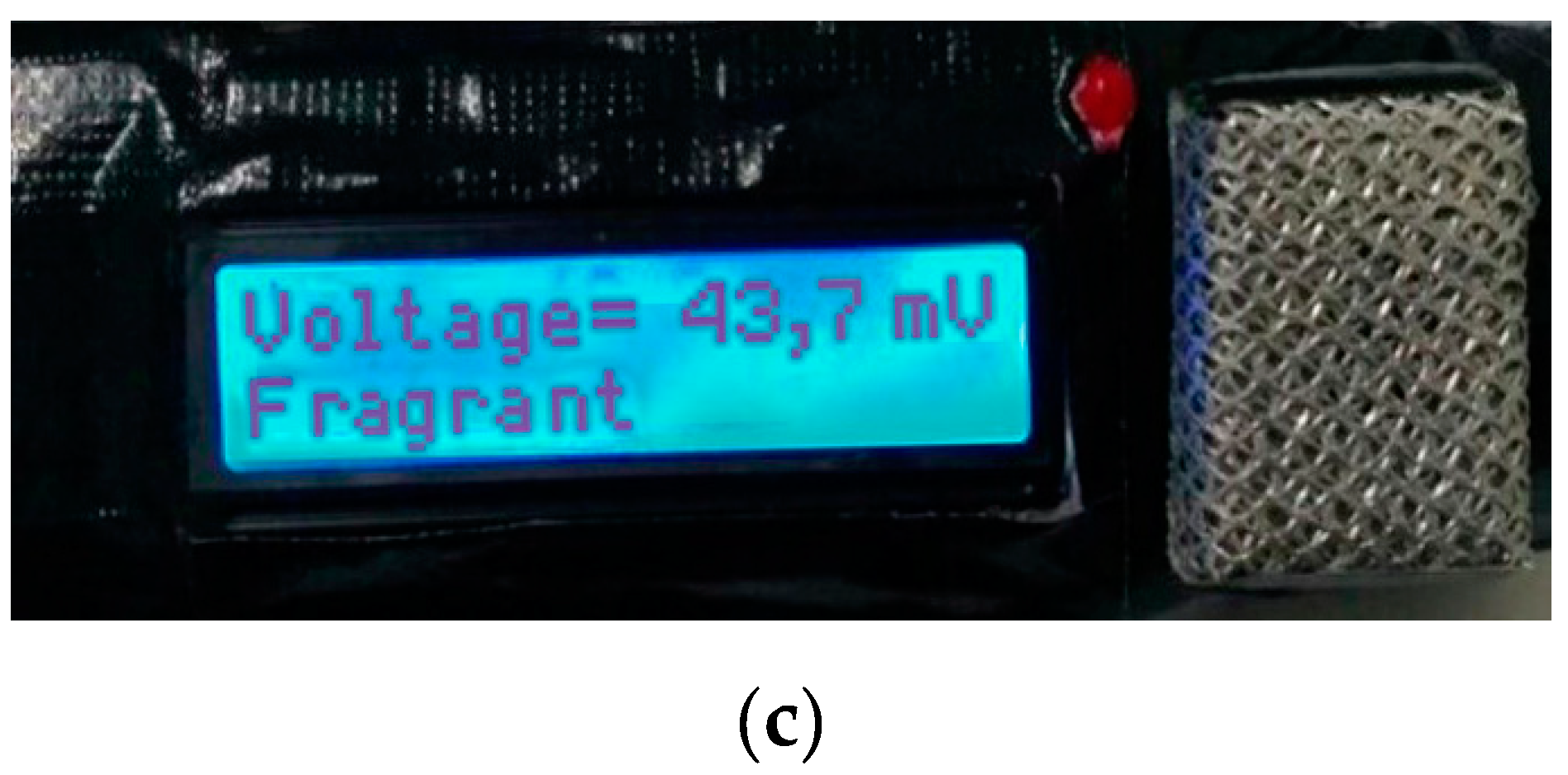

3.3. Testing the Entire System

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Herawati, D. Mengenali halitosis patologis berdasarkan lokasi asal untuk keberhasilan perawatan Mal-odor Oral. Majalah Ceramah Ilmiah FKG UGM Yogyakarta 2003, 3, 118–121. [Google Scholar]

- Djaya, A. Halitosis: Nafas Tak Sedap, 1st ed.; Dental Lintas Mediatama: Jakarta, Indonesia, 2000; pp. 2–35. [Google Scholar]

- McDowell, K.; Denise, K. Halitosis holistik. Maj. Kedokt. Gigi Dent. Horis. 2002, 3, 30–37. [Google Scholar]

- Darwis, E.W. Jangan biarkan nafas bau menghambat pergaulan. J. PDGI 1997, 25, 12–14. [Google Scholar]

- Preti, G.; Lawley, H.J.; Hormann, C.A.; Cowart, B.J.; Feldman, R.S.; Lowry, L.D.; Young, I.M. Non-Oral and oral aspect of oral malodor. In Bad Breath Research Perspectives, 2nd ed.; Rosenberg, M., Ed.; Ramot Publishing-Tel Aviv University: Tel Aviv, Israel, 1997; pp. 149–150. [Google Scholar]

- Richie, E.; Nani, D.; Pasole, D.; Muhammad, D.; Ade, K.; Johan, I.; Hendradi, H. ‘The optical band gap of LiTaO3 and Nb2O5—Doped LiTaO3 thin films based on Tauc Plot method to be applied on satellite’. IOP Conf. Ser. Earth Environ. Sci. 2017, 54, 012092–012099. [Google Scholar]

- Irzaman, Y.; Darvina, A.; Fuad, P.; Arifin, M.; Budiman, M.; Barmawi, M. Physical and pyroelectric properties of tantalum oxide doped lead zirconium titanate [Pb0.9950(Zr0.525Ti0.465Ta0.010)O3] thin films and its application for IR sensor. Phys. Status Solidi (a) Ger. 2003, 199, 416–424. [Google Scholar] [CrossRef]

- Syafutra, H.; Irzaman, H.; Subrata, I.D.M. Integrated visible light sensor based on thin film ferroelectric material BST to microcontroller ATMega8535. Mater. Sci. Technol. 2010, 1, 291–296. [Google Scholar]

- Irzaman; Pebriyanto, Y.; Apipah, E.R.; Noor, I.; Alkadri, A. Characterization of Optical and Structural of Lanthanum Doped LiTaO3 Thin Films. Integr. Ferroelectr. 2015, 167, 137–145. [Google Scholar] [CrossRef]

- Mulyadi, R.; Wahyuni, H. Barium strontium titanate thin film growth with variation of lanthanum dopant compatibility as sensor prototype in the satellite technology. IOP Conf. Ser. Earth Environ. Sci. 2018, 149, 012069–012076. [Google Scholar] [CrossRef]

- Irzaman Syafutra, H.; Rancasa, E.; Nuayi, A.W.; Rahman, T.G.N.; Nuzulia, N.A.; Supu, I.; Sugianto Tumimomor, F.; Surianty Muzikarno, O. The effect of Ba/Sr ratio on electrical and optical properties of BaxSr(1-x)TiO3(x = 0.25; 0.35; 0.45; 0.55) thin film semiconductor. J. Ferroelectr. 2013, 445, 4–17. [Google Scholar] [CrossRef]

- Choi, E.S.; Lee, J.C.; Hwang, J.S.; Yoon, S.G. Electrical characteristics of the contour vibration mode piezoelectric transformer with ring/dot electrode area ratio. J. Appl. Phys. 1993, 38, 5317. [Google Scholar] [CrossRef]

- Momose, S.; Nakamura, T.; Tachibana, K. Effects of gas phase thermal decompositions of chemical vapor deposition source molecules on the deposition of BST films. J. Appl. Phys. 2000, 39, 5384. [Google Scholar] [CrossRef]

- Gao, Y.; He, S.; Alluri, P.; Engelhard, M.; Lea, A.; Finder, S.; Melnick, J.; Hance, B. Effect of precursors and substrate materials on microstructure, dielectric properties and step coverage of (Ba, Sr)TiO3 films grown by metalorganic chemical vapor deposition. J. Appl. Phys. 2000, 87, 124–132. [Google Scholar] [CrossRef]

- Auciello, O.; Scott, J.F.; Ramesh, R. The physics of ferroelectric memories. Phys. Today 1998, 51, 22–27. [Google Scholar] [CrossRef]

- Verma, K.; Sharma, S.; Sharma, D.K.; Kumar, R.; Rai, R. Sol-gel processing and characterization of nanometer-sized (Ba,Sr)TiO3 ceramics. Adv. Mater. Lett. 2012, 3, 44–49. [Google Scholar] [CrossRef]

- Giridharan, N.V.; Jayavel, R.; Ramasamy, P. Structural, morphological and electrical studies on barium strontium titanate thin films prepared by sol-gel technique. Crystal Res. Technol. 2001, 36, 65–72. [Google Scholar] [CrossRef]

- Chen, X.; Cai, W.; Fu, C.; Chen, H.; Zhang, Q. Synthesis and morphology of Ba(Zr0,20Ti0,80)O3 powder obtained by sol-gel methode. J. Sol-Gel Sci. Technol. 2011, 57, 149–156. [Google Scholar] [CrossRef]

- Wang, F.; Uusimaki, A.; Leppavuori, S.; Karmanenko, S.F.; Dedyk, A.I.; Sakharov, V.I.; Serenkov, I.T. BST ferroelectric film prepared with sol-gel process and its dielectric performance in planar capacitor structure. J. Mater. 1998, 13, 1243. [Google Scholar]

- Tyunina, M. Dielectric properties of atomic layer deposited thin film barium strontium titanate. Integr. Ferroelectr. 2008, 102, 29–36. [Google Scholar] [CrossRef]

- Kim, S.; Kang, T.S.; Je, J.H. Structural characterization of laser ablation epitaxial BST thin films on MgO (001) by synchrotron x-ray scattering. J. Mater. 1999, 14, 2905–2911. [Google Scholar]

- Zhu, X.H.; Zheng, D.N.; Peng, J.L.; Chen, Y.F. Enhanced dielectric properties of Mn-doped Ba0,6Sr0,4TiO3 thin films fabricated by pulsed laser deposition. Mater. Lett. 2005, 60, 1224–1228. [Google Scholar] [CrossRef]

- Izuha, M.; Ade, K.; Koike, M.; Takeno, S.; Fukushima, N. Electrical properties and microstructure of Pt/BST/SrRuO3 capacitors. J. Appl. Phys. 1997, 70, 1405. [Google Scholar]

- Lee, J.S.; Park, J.S.; Kim, J.S.; Lee, J.H.; Lee, Y.H.; Hahn, S.R. Preparation of BST thin films with high pyroelectric coefficients in ambient temperatures. J. Appl. Phys. 1999, 38, L574. [Google Scholar] [CrossRef]

- Irzaman, H.; Darmasetiawan, H.; Hardhienata, H.; Erviansyah, R.; Maddu, A.; Hikam, M.; Arifin, P. Electrical properties of photodiode BST thin film doped with ferrium oxide using chemical deposition solution method. J. Atom Indones. 2010, 6, 57–62. [Google Scholar]

- Irzaman, H.; Syafutra, H.; Darmasetiawan, H.; Hardhienata, H.; Erviansyah, R.; Huriawati, F.; Maddu, A.; Arifin, P. Electrical properties of photodiode Ba0.25Sr0.75TiO3 (BST) thin film doped with ferric oxide on p-type Si (100) substrate using chemical solution deposition method. J. Atom Indones. 2011, 37, 133–138. [Google Scholar] [CrossRef][Green Version]

- Baumert, B.A.; Chang, L.H.; Matsuda, A.T.; Tracy, C.J. A study of BST thin films for use in bypass capacitors. J. Mater. 1998, 13, 197. [Google Scholar]

- Itskovsky, M.A. Kinetics of ferroelectric phase transition: Nonlinear pyroelectric effect and ferroelectric solar cell. J. Appl. Phys. 1999, 38, 4812. [Google Scholar] [CrossRef]

- Darmasetiawan, H.; Irzaman, H.; Indro, M.N.; Sukaryo, S.G.; Hikam, M.; Bo, N.P. Optical properties of crystalline Ta2O5 thin films. Phys. Status Solidi (a) 2002, 193, 53–60. [Google Scholar] [CrossRef]

- Irzaman, A.; Nuraisah, A.; Aminullah; Hamam, K.A.; Alatas, H. Optical properties and crystal structure of lithium doped Ba0.55Sr0.45TiO3 (BLST) thin films. Ferroelectr. Lett. Sect. 2018, 45, 14–21. [Google Scholar] [CrossRef]

- Dahrul, M.; Syafutra, H.; Arif, A.; Irzaman, H.; Indro, M.N.; Siswadi. Synthesis and characterizations photodiode thin film barium strontium titanate (BST) doped niobium and iron as light sensor. In Proceedings of the The 4th Asian Physics Symposium, American Institute of Physics (AIP) Conference, West Java, Indonesia, 12–13 October 2010; Volume 1325, pp. 43–46. [Google Scholar]

- Irzaman Dahrul, M.; Yuliarto, B.; Hammam, K.A.; Alatas, H. Effects of Li and Cu dopants on the crystal structure of Ba0.65Sr0.35TiO3 thin films. Ferroelectr. Lett. Sect. 2018, 45, 49–57. [Google Scholar] [CrossRef]

- Irzaman; Sitompul, H.; Masitoh; Misbakhusshudur, M. Optical and structural properties of lanthanum doped lithium niobate thin films. Ferroelectrics 2016, 502, 9–18. [Google Scholar] [CrossRef]

- Nuayi, A.W.; Alatas, H.; Irzaman, H.; Rahmat, M. Enhancement of Photon Absorption on BaxSr(1-x)TiO3 Thin-Film Semiconductor Using Photonic Crystal. Int. J. Opt. 2014, 2014, 534145. [Google Scholar] [CrossRef]

- Hamdani, A.; Komaro, M. A Synthesis of BaxSr1-XTiO3 Film and Characterization Of Ferroelectric Properties and Its Extension as Random Access Memory. Mater. Phys. Mech. 2019, 42, 131–140. [Google Scholar]

- Schwartz, R.W. Chemical solution deposition of perovskite thin film. J. Chem. Mater. 1997, 9, 2325–2340. [Google Scholar] [CrossRef]

- Endah, K.P.; Rofiqul, U.; Bibin, B.A.; Hidetoshi, S.; Brian, Y.; Husin, A. Micro-Raman analysis of Ba0.2Sr0.8TiO3 (barium strontium titanate) doped of chlorophyll of cassava leaf. Ferroelectrics 2019, 540, 227–237. [Google Scholar]

- Irzaman; Siskandar, R.; Aminullah; Irmansyah; Alatas, H. Characterization of Ba0.55Sr0.45TiO3 films as light and temperature sensors and its implementation on automatic drying system model. J. Integr. Ferroelectr. 2016, 168, 130–150. [Google Scholar] [CrossRef]

- Peverall, R.; Hancock, G. GAD Ritchie. Portable Breath Volatile Organic Compounds Analyser and Corresponding Unit. U.S. Patent 2016/0150995 A1.

| Ba0.5Sr0.5TiO3 Film with Variations in RuO2 Dope (%) | Output Voltage at 2 cm Exposure (mV) | Output Voltage at 4 cm Exposure (mV) | Output Voltage at 6 cm Exposure (mV) | Output Voltage at 8 cm Exposure (mV) |

|---|---|---|---|---|

| 0 | 12.5 | 12.4 | 12.4 | 12.4 |

| 2 | 12.5 | 12.5 | 12.1 | - |

| 4 | 16.9 | 14.4 | - | - |

| 6 | 29.0 | 27.7 | 26.4 | 20.3 |

| Ba0.5Sr0.5TiO3 Film with Variations in RuO2 Dope (%) | Film Output Voltage | ∆V before and after Cleaning (mV) | ||

|---|---|---|---|---|

| before Cleansing (Straight out of Bed) (mV) | after Cleansing (after Brushing Teeth) (mV) | after 15 min after (after Brushing Teeth+Eat) (mV) | ||

| 0 | 12.4 | 12.7 | 12.7 | 0.3 |

| 2 | 11.3 | 12.5 | 12.4 | 1.2 |

| 4 | 13.6 | 17.9 | 17.8 | 4.3 |

| 6 | 12.9 | 42.1 | 41.9 | 29.2 |

| Output Voltage | |||

|---|---|---|---|

| before Cleansing (Straight out of Bed) (mV) | after Cleansing (after Brushing Teeth) (mV) | after 15 min after (after Brushing Teeth + Eat) (mV) | |

| Ba0.5Sr0.5TiO3 film with 6% doping variations | 12.9 | 42.1 | 41.9 |

| Gas sensor, manufacturer’s product (MQ 136) | 12.7 | 42.4 | 42.2 |

| ∆V (mV) | 0.2 | 0.3 | 0.3 |

| Accuracy (%) | 98.4 | 99.3 | 99.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irzaman; Siskandar, R.; Yuliarto, B.; Zakki Fahmi, M.; Ferdiansjah. Application of Ba0.5Sr0.5TiO3 (Bst) Film Doped with 0%, 2%, 4% and 6% Concentrations of RuO2 as an Arduino Nano-Based Bad Breath Sensor. Chemosensors 2020, 8, 3. https://doi.org/10.3390/chemosensors8010003

Irzaman, Siskandar R, Yuliarto B, Zakki Fahmi M, Ferdiansjah. Application of Ba0.5Sr0.5TiO3 (Bst) Film Doped with 0%, 2%, 4% and 6% Concentrations of RuO2 as an Arduino Nano-Based Bad Breath Sensor. Chemosensors. 2020; 8(1):3. https://doi.org/10.3390/chemosensors8010003

Chicago/Turabian StyleIrzaman, Ridwan Siskandar, Brian Yuliarto, Mochammad Zakki Fahmi, and Ferdiansjah. 2020. "Application of Ba0.5Sr0.5TiO3 (Bst) Film Doped with 0%, 2%, 4% and 6% Concentrations of RuO2 as an Arduino Nano-Based Bad Breath Sensor" Chemosensors 8, no. 1: 3. https://doi.org/10.3390/chemosensors8010003

APA StyleIrzaman, Siskandar, R., Yuliarto, B., Zakki Fahmi, M., & Ferdiansjah. (2020). Application of Ba0.5Sr0.5TiO3 (Bst) Film Doped with 0%, 2%, 4% and 6% Concentrations of RuO2 as an Arduino Nano-Based Bad Breath Sensor. Chemosensors, 8(1), 3. https://doi.org/10.3390/chemosensors8010003