Chemical Sensing Applications of Carbon Nanotube-Deposited Optical Fibre Sensors

Abstract

1. Introduction

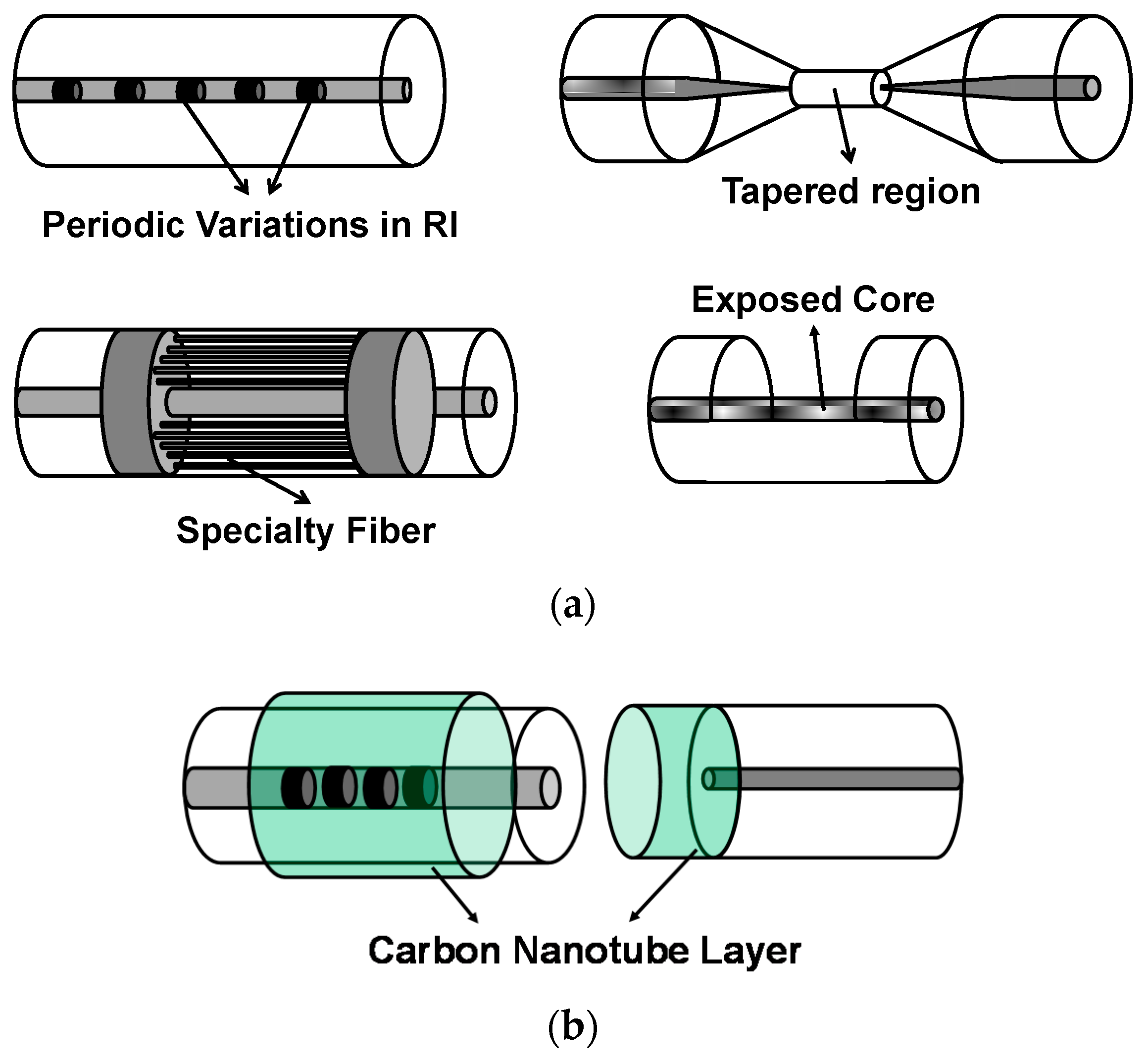

2. Operating Principle

3. Methods of Deposition

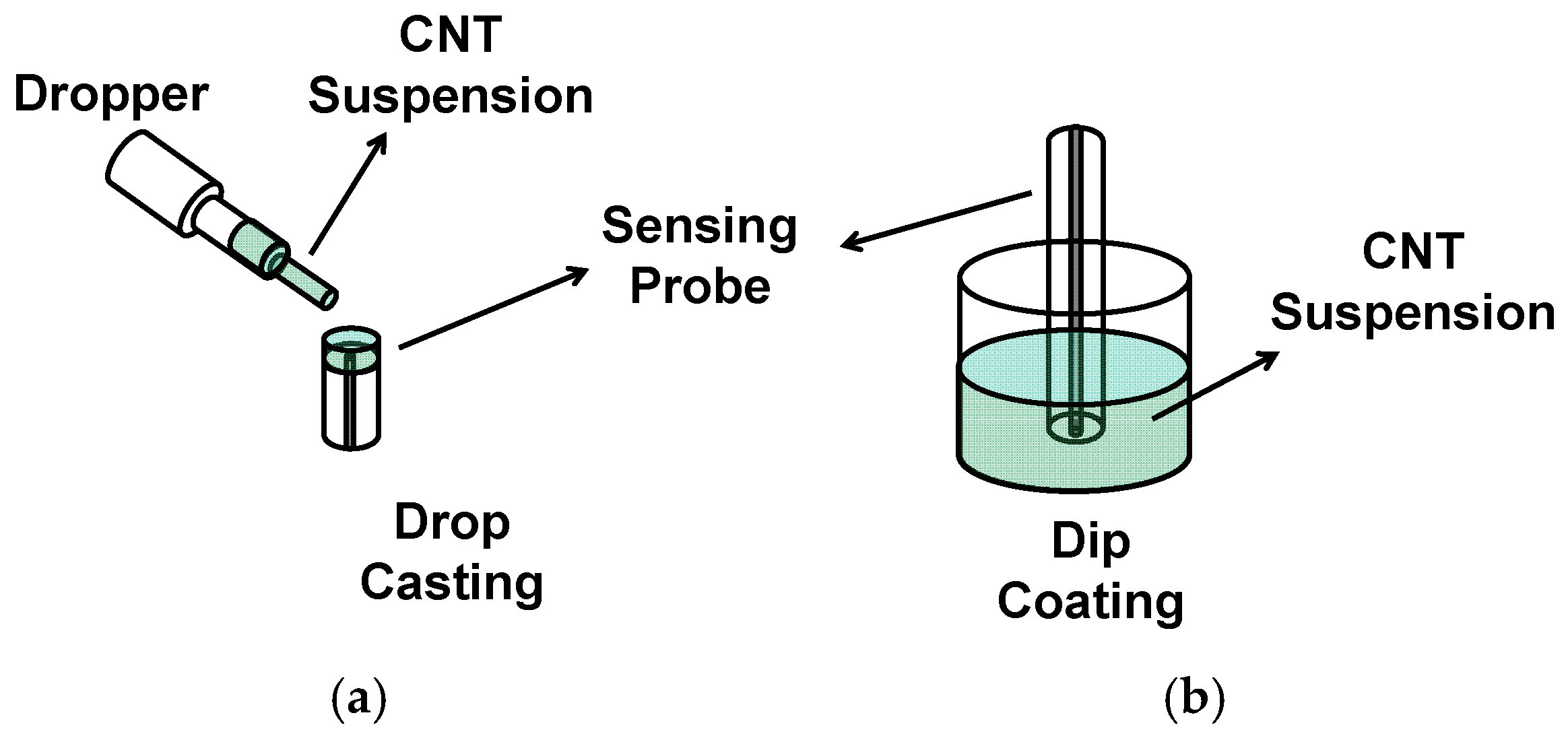

3.1. Drop Casting and Dip Coating

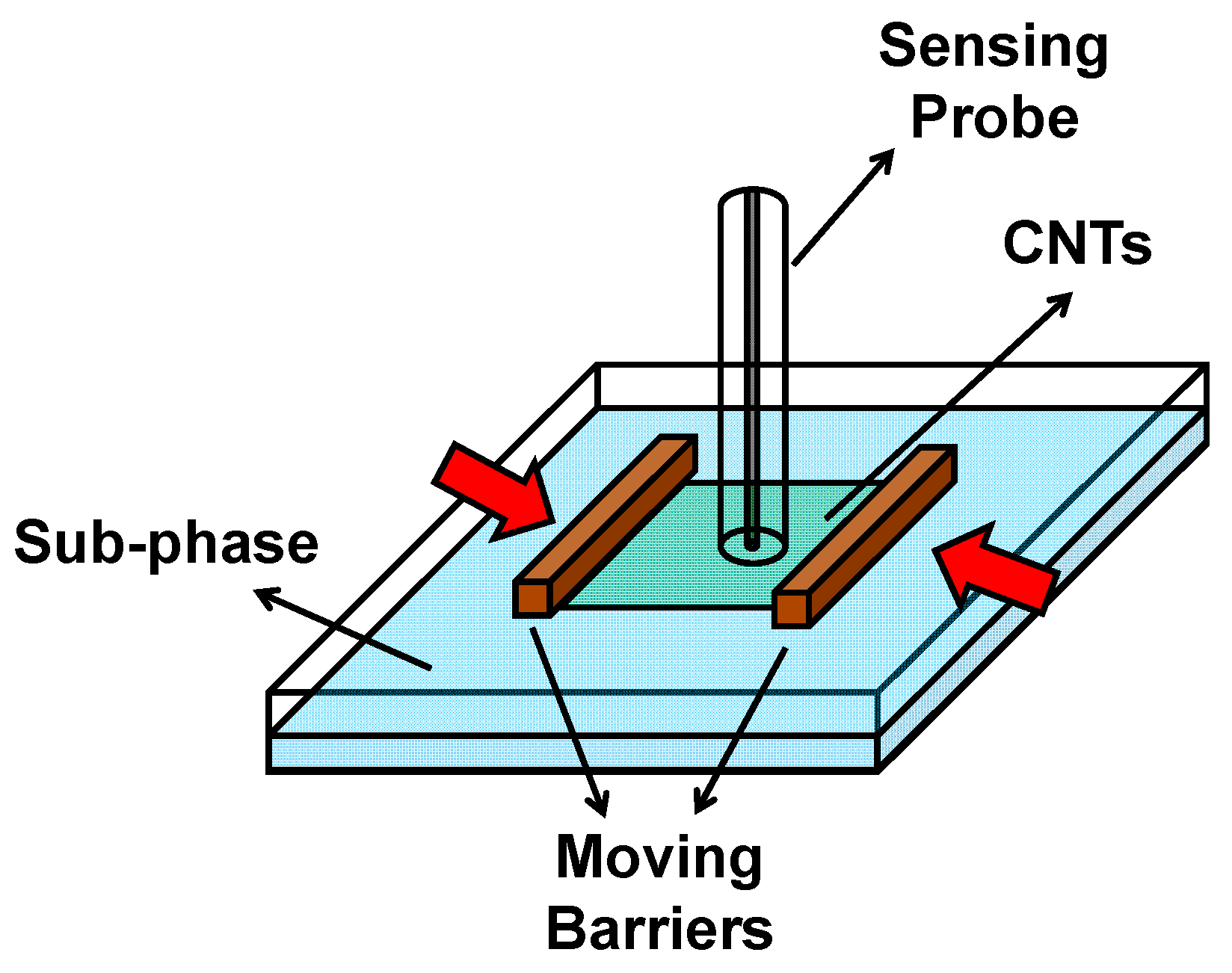

3.2. Langmuir-Blodgett (LB)

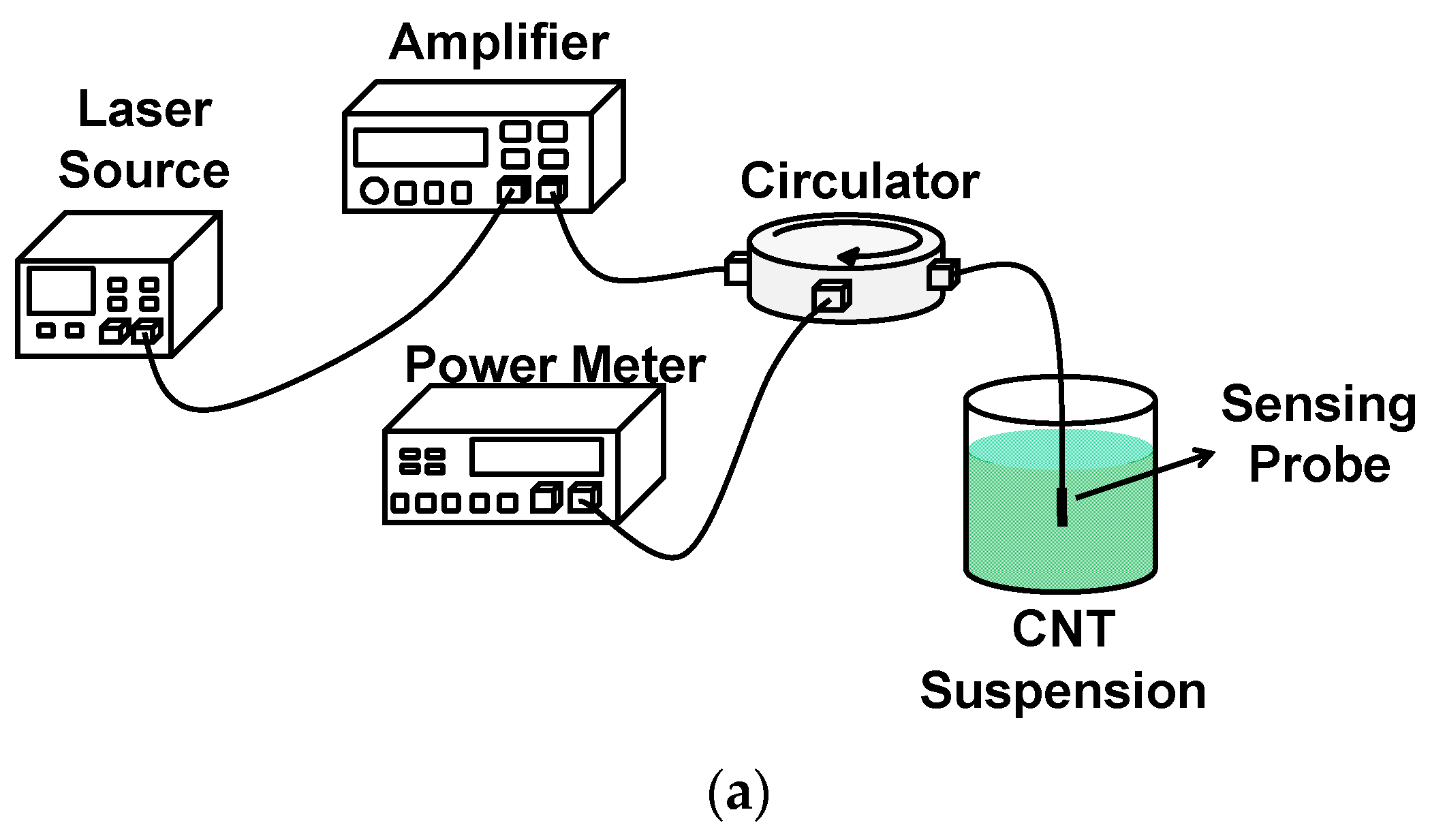

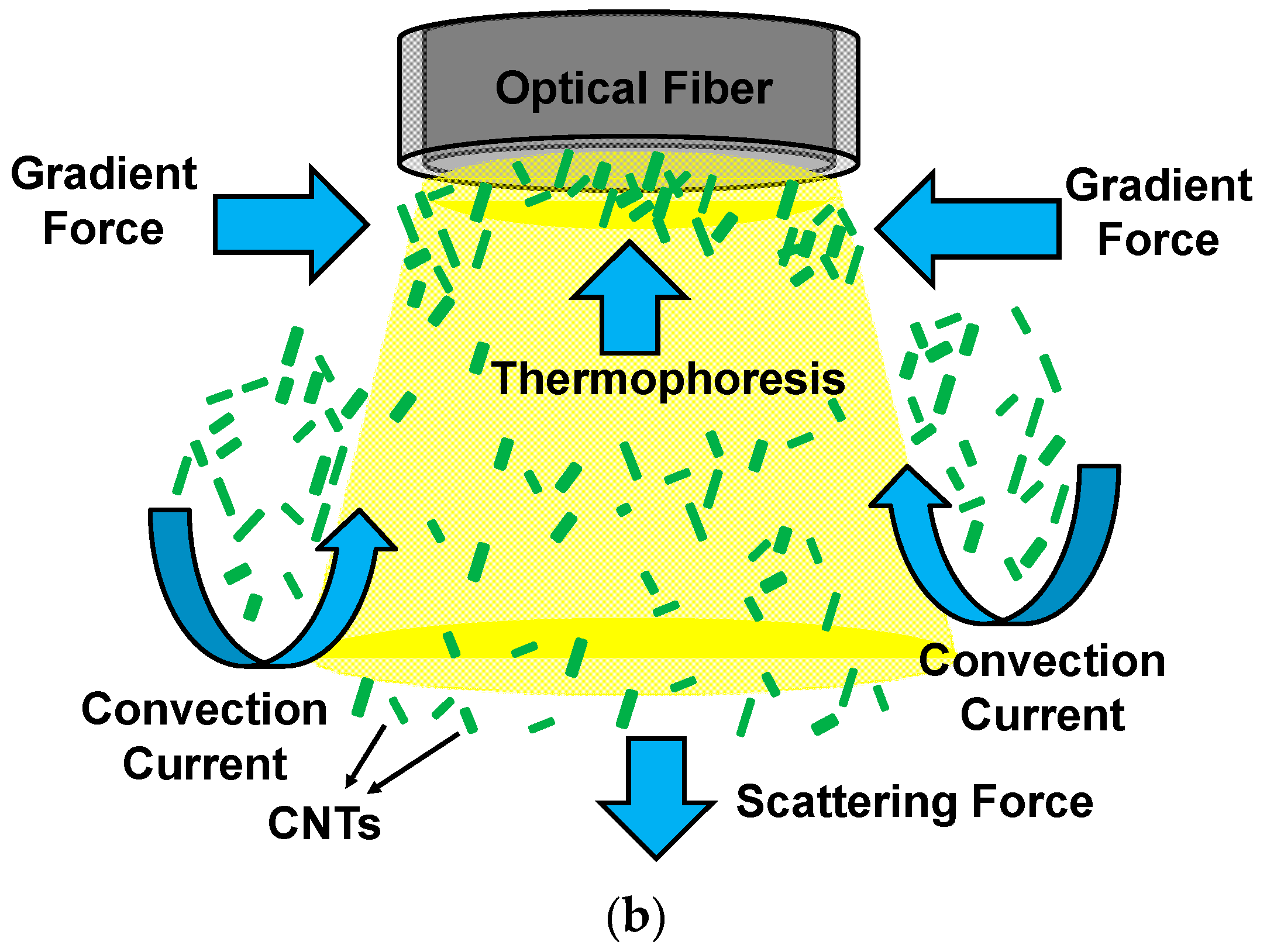

3.3. Optical Deposition

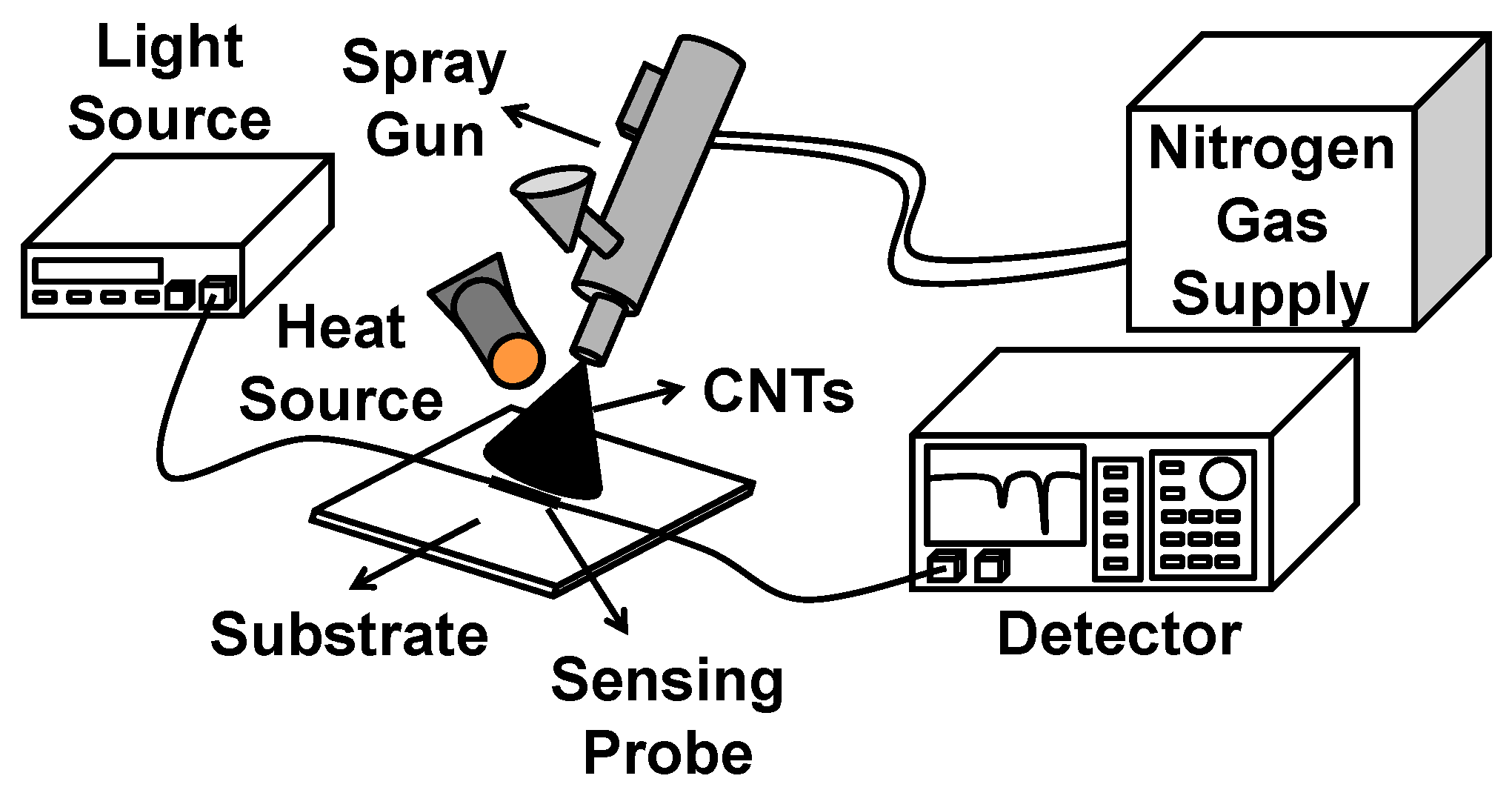

3.4. Spray Coating

4. Chemical Sensing Applications

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Iijima, S.; Ichihashi, T. Single-shell carbon nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef]

- Allen, M.J.; Tung, V.C.; Kaner, R.B. Honeycomb carbon: A review of graphene. Chem. Rev. 2009, 110, 132–145. [Google Scholar] [CrossRef] [PubMed]

- Yamashita, S. A tutorial on nonlinear photonic applications of carbon nanotube and graphene. J. Lightw. Technol. 2012, 30, 427–447. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.; Xie, J.; Jin, Z.; Wang, J.; Li, Y.; Jiang, K.; Fan, S. Fabrication of ultralong and electrically uniform single-walled carbon nanotubes on clean substrates. Nano Lett. 2009, 9, 3137–3141. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Zhang, Y.; Zhang, Q.; Xie, H.; Qian, W.; Wei, F. Growth of half-meter long carbon nanotubes based on Schulz-Flory distribution. ACS Nano 2013, 7, 6156–6161. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 2000, 84, 5552–5555. [Google Scholar] [CrossRef] [PubMed]

- Collins, P.G.; Avouris, P. Nanotubes for electronics. Sci. Am. 2000, 283, 62–69. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.Q.; Headrick, R.J.; Bengio, E.A.; Myint, S.M.; Khoshnevis, H.; Jamali, V.; Duong, H.M.; Pasquali, M. Purification and Dissolution of Carbon Nanotube Fibres Spun from Floating Catalyst Method. ACS Appl. Mater. Interfaces 2017, 9, 37112–37119. [Google Scholar] [CrossRef] [PubMed]

- Khoshnevis, H.; Tran, T.Q.; Mint, S.M.; Zadhoush, A.; Duong, H.M.; Youssefi, M. Effect of alignment and packing density on the stress relaxation process of carbon nanotube fibres spun from floating catalyst chemical vapor deposition method. Colloid Surf. A 2018, 558, 570–578. [Google Scholar] [CrossRef]

- Zaporotskova, I.V.; Boroznina, N.P.; Parkhomenko, Y.N.; Kozhitiv, L.V. Carbon nanotubes: sensor properites. A review. Mod. Electron. Mater. 2016, 2, 95–105. [Google Scholar] [CrossRef]

- Meyer, M.S.; Eesley, G.L. Optical fibre refractometer. Rev. Sci. Instrum. 1987, 58, 2047–2048. [Google Scholar] [CrossRef]

- Othonos, A.; Kalli, K. Fibre Bragg Gratings: Fundamentals and Applications in Telecommunications and Sensing; Artech House: Norwood, MA, USA, 1999. [Google Scholar]

- Kersey, A.D.; Davis, M.A.; Patrick, H.J.; LeBlanc, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fibre grating sensors. J. Lightw. Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Vengsarkar, A.M.; Lemaire, P.J.; Judkins, J.B.; Bhatia, V.; Erdogan, T.; Sipe, J.E. Long-period fibre gratings as band-rejection filters. J. Lightw. Technol. 1996, 14, 58–65. [Google Scholar] [CrossRef]

- Bhatia, V.; Vengsarkar, A.M. Optical fibre long-period grating sensors. Opt. Lett. 1996, 21, 692–694. [Google Scholar] [CrossRef] [PubMed]

- Kieu, K.Q.; Mansuripur, M. Biconical fibre taper sensors. IEEE Photonics Technol. Lett. 2006, 18, 2239–2241. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, Y.H.; Park, K.S.; Eom, J.B.; Kim, M.J.; Rho, B.S.; Choi, H.Y. Interferometric fibre optic sensors. Sensors 2012, 12, 2467–2486. [Google Scholar] [CrossRef] [PubMed]

- Jha, R.; Villatoro, J.; Badenes, G. Ultrastable in reflection photonic crystal fibre modal interferometer for accurate refractive index sensing. Appl. Phys. Lett. 2008, 93, 1911061–1911063. [Google Scholar] [CrossRef]

- Silva, S.; Frazão, O.; Santos, J.L.; Malcata, F.X. A reflective optical fibre refractometer based on multimode interference. Sens. Actuators B 2012, 161, 88–92. [Google Scholar] [CrossRef]

- Gupta, B.D.; Dodeja, H.; Tomar, A.K. Fibre optic evanescent field absorption sensor based on a U-shaped probe. Opt. Quantum Electron. 1996, 28, 1629–1639. [Google Scholar] [CrossRef]

- Banerjee, A.; Mukherjee, S.; Verma, R.K.; Jana, B.; Khan, T.K.; Chakroborty, M.; Das, R.; Biswas, S.; Saxena, A.; Singh, V.; et al. Fibre optic sensing of liquid refractive index. Sens. Actuators B 2007, 123, 594–605. [Google Scholar] [CrossRef]

- Margulis, V.A.; Gaiduk, E.A. Nature of near-infrared absorption in single-wall carbon nanotubes. Phys. Lett. A 2001, 281, 52–58. [Google Scholar] [CrossRef]

- Sreekumar, T.V.; Liu, T.; Kumar, S. Single-wall carbon nanotube films. Chem. Mater. 2002, 15, 175–178. [Google Scholar] [CrossRef]

- Spotnitz, M.E.; Ryan, D.; Stone, H.A. Dip coating for the alignment of carbon nanotubes on curved surfaces. J. Mater. Chem. 2004, 14, 1299–1302. [Google Scholar] [CrossRef]

- Jang, E.Y.; Kang, T.J.; Im, H.W.; Kim, D.W.; Kim, Y.H. Single-walled carbon-nanotube networks on large-area glass substrate by the dip-coating method. Small 2008, 4, 2255–2261. [Google Scholar] [CrossRef] [PubMed]

- Krstic, V.; Duesberg, G.S.; Muster, J.; Burghard, M.; Roth, S. Langmuir-Blodgett films of matrix-diluted single-walled carbon nanotubes. Chem. Mater. 1998, 10, 2338–2340. [Google Scholar] [CrossRef]

- Guo, Y.; Wu, J.; Zhang, Y. Manipulation of single-wall carbon nanotubes into aligned molecular layers. Chem. Phys. Lett. 2002, 362, 314–318. [Google Scholar] [CrossRef]

- Kim, Y.; Minami, N.; Zhu, W.; Kazaoui, S.; Azumi, R.; Matsumoto, M. Langmuir-Blodgett films of single-wall carbon nanotubes: layer-by-layer deposition and in-plane orientation of tubes. Jpn. J. Appl. Phys. 2003, 42, 7629–7634. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Wang, X.; Shimoyama, I.; Sun, X.; Seo, W.S.; Dai, H. Langmuir-Blodgett assembly of densely aligned single-walled carbon nanotubes from bulk materials. J. Am. Chem. Soc. 2007, 129, 4890–4891. [Google Scholar] [CrossRef] [PubMed]

- Nicholson, J.W.; Windeler, R.S.; DiGiovanni, D.J. Optically driven deposition of single-walled carbon-nanotube saturable absorbers on optical fibre end-faces. Opt. Express 2007, 15, 9176–9183. [Google Scholar] [CrossRef] [PubMed]

- Kashiwagi, K.; Yamashita, S.; Set, S.Y. Optically Manipulated Deposition of Carbon Nanotubes onto Optical Fibre End. Jpn. J. Appl. Phys. 2007, 46, 988–990. [Google Scholar] [CrossRef]

- McNab, G.S.; Meisen, A. Thermophoresis in liquids. J. Colloid Interfaces Sci. 1973, 44, 339–346. [Google Scholar] [CrossRef]

- Set, S.Y.; Yaguchi, H.; Tanaka, Y.; Jablonski, M. Laser mode locking using a saturable absorber incorporating carbon nanotubes. J. Lightw. Technol. 2004, 22, 51–56. [Google Scholar] [CrossRef]

- Song, Y.W.; Morimune, K.; Set, S.Y.; Yamashita, S. Polarization insensitive all-fibre mode-lockers functioned by carbon nanotubes deposited onto tapered fibres. Appl. Phys. Lett. 2007, 90, 0211011–0211013. [Google Scholar] [CrossRef]

- Chow, K.K.; Yamashita, S.; Set, S.Y. Four-wave-mixing-based wavelength conversion using a single-walled carbon-nanotube-deposited planar lightwave circuit waveguide. Opt. Lett. 2010, 35, 2070–2072. [Google Scholar] [CrossRef] [PubMed]

- Penza, M.; Cassano, G.; Aversa, P.; Antolini, F.; Cusano, A.; Cutolo, A.; Giordano, M.; Nicolais, L. Alcohol detection using carbon nanotubes acoustic and optical sensors. Appl. Phys. Lett. 2004, 85, 2379–2381. [Google Scholar] [CrossRef]

- Penza, M.; Cassano, G.; Aversa, P.; Cusano, A.; Consales, M.; Giordano, M.; Nicolais, L. Carbon nanotube acoustic and optical sensors for volatile organic compound detection. Nanotechnology 2005, 16, 2536. [Google Scholar] [CrossRef]

- Penza, M.; Cassano, G.; Aversa, P.; Cusano, A.; Consales, M.; Giordano, M.; Nicolais, L. Acoustic and Optical VOCs Sensors incorporating carbon nanotubes. IEEE Sens. J. 2006, 6, 867–875. [Google Scholar] [CrossRef]

- Consales, M.; campopiano, S.; Cutolo, A.; Penza, M.; Aversa, P.; Cassano, G.; Giordano, M.; Cusano, A. Carbon nanotubes thin films fibre optic and acoustic VOCs sensors: performance analysis. Sens. Actuators B Chem. 2006, 118, 232–242. [Google Scholar] [CrossRef]

- Consales, M.; Cutolo, A.; Penza, M.; Aversa, P.; Cassano, G.; Giordano, M.; Cusano, A. Carbon nanotubes coated acoustic and optical VOCs sensors: Towards the tailoring of the sensing performances. IEEE Trans. Nanotechnol. 2007, 6, 601–612. [Google Scholar] [CrossRef]

- Consales, M.; Crescitelli, A.; Penza, M.; Aversa, P.; Veneri, P.D.; Giordano, M.; Cusano, A. SWCNT nano-composite optical sensors for VOC and gas trace detection. Sens. Actuators B Chem. 2009, 138, 351–361. [Google Scholar] [CrossRef]

- Consales, M.; Crescitelli, A.; Campopiano, S.; Cutolo, A.; Penza, M.; Aversa, P.; Giordano, M.; Cusano, A. Chemical detection in water by single-walled carbon nanotubes-based optical fibre sensors. IEEE Sens. J. 2007, 7, 1004–1005. [Google Scholar] [CrossRef]

- Cusano, A.; Consales, M.; Cutolo, A.; Penza, M.; Aversa, P.; Giordano, M.; Guemes, A. Optical probes based on optical fibres and single-walled carbon nanotubes for hydrogen detection at cryogenic temperatures. Appl. Phys. Lett. 2006, 89. [Google Scholar] [CrossRef]

- Mannivannan, S.; Saranya, A.M.; Renganathan, B.; Sastikumar, D.; Gobi, G.; Park, K.C. Single-walled carbon nanotubes wrapped poly-methyl methacrylate fibre optic sensor for ammonia, ethanol and methanol vapors at room temperature. Sens. Actuators B Chem. 2012, 171, 634–638. [Google Scholar] [CrossRef]

- Shivananju, B.N.; Yamadagni, S.; Fazuldeen, R.; Kumar, A.K.S.; Nithin, S.P.; Varma, M.M.; Asokan, S. Highly Sensitive Carbon Nanotubes Coated Etched Fibre Bragg Grating Sensor for Humidity Sensing. IEEE Sens. J. 2014, 14, 2615–2619. [Google Scholar] [CrossRef]

- Shabaneh, A.A.; Girei, S.H.; Arasu, P.T.; Rashid, S.A.; Yunusa, Z.; Mahdi, M.A.; Paiman, S.; Ahmad, M.Z.; Yaacob, M.H. Reflectance response of optical fibre coated with carbon nanotubes for aqueous ethanol sensing. IEEE Photonics J. 2014, 6, 68029101–680291010. [Google Scholar] [CrossRef]

- Batumalay, M.; Ahmad, F.; Lokman, A.; Jasim, A.A.; Harun, S.W.; Ahmad, H. Tapered plastic optical fibre coated with single wall carbon nanotubes polyethylene oxide composite for measurement of uric acid concentration. Sens. Rev. 2014, 34, 75–79. [Google Scholar] [CrossRef]

- Tan, Y.C.; Ji, W.B.; Mamidala, V.; Chow, K.K.; Tjin, S.C. Carbon-nanotube-deposited long period fibre grating for continuous refractive index sensor applications. Sens. Actuators B Chem. 2014, 196, 260–264. [Google Scholar] [CrossRef]

- Tan, Y.C.; Tou, Z.Q.; Mamidala, V.; Chow, K.K.; Chan, C.C. Continuous refractive index sensing based on carbon-nanotube-deposited photonic crystal fibres. Sens. Actuators B Chem. 2014, 202, 1097–1102. [Google Scholar] [CrossRef]

- Tan, Y.C.; Huang, J.Y.; Chow, K.K. Continuous Refractive Index Sensing based on Carbon-nanotube-deposited joint single-mode multi-mode fibre segment. In Proceedings of the 2015 IEEE Photonics Conference, Reston, VA, USA, 4–8 October 2015. [Google Scholar]

- Allsop, T.; Arif, R.; Neal, R.; Kalli, K.; Kundrát, V.; Rozhin, A.; Culverhouse, P.; Webb, D.J. Photonic gas sensors exploiting directly the optical properties of hybrid carbon nanotube localized surface plasmon structures. Light Sci. Appl. 2016, 5, e16036. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.C. Chemical Sensing Applications of Carbon Nanotube-Deposited Optical Fibre Sensors. Chemosensors 2018, 6, 55. https://doi.org/10.3390/chemosensors6040055

Tan YC. Chemical Sensing Applications of Carbon Nanotube-Deposited Optical Fibre Sensors. Chemosensors. 2018; 6(4):55. https://doi.org/10.3390/chemosensors6040055

Chicago/Turabian StyleTan, Yung Chuen. 2018. "Chemical Sensing Applications of Carbon Nanotube-Deposited Optical Fibre Sensors" Chemosensors 6, no. 4: 55. https://doi.org/10.3390/chemosensors6040055

APA StyleTan, Y. C. (2018). Chemical Sensing Applications of Carbon Nanotube-Deposited Optical Fibre Sensors. Chemosensors, 6(4), 55. https://doi.org/10.3390/chemosensors6040055