Abstract

Environmental monitoring plays a key role in understanding and mitigating the effects of climate change, pollution, and resource mismanagement. The growth of printed sensor technologies offers an innovative approach to addressing these challenges due to their low cost, flexibility, and scalability. Printed sensors enable the real-time monitoring of air, water, soil, and climate, providing significant data for data-driven decision-making technologies and policy development to improve the quality of the environment. The development of new materials, such as graphene, conductive polymers, and biodegradable substrates, has significantly enhanced the environmental applications of printed sensors by improving sensitivity, enabling flexible designs, and supporting eco-friendly and disposable solutions. The development of inkjet, screen, and roll-to-roll printing technologies has also contributed to the achievement of mass production without sacrificing quality or performance. This review presents the current progress in printed sensors for environmental applications, with a focus on technological advances, challenges, applications, and future directions. Moreover, the paper also discusses the challenges that still exist due to several issues, e.g., sensitivity, stability, power supply, and environmental sustainability. Printed sensors have the potential to revolutionize ecological monitoring, as evidenced by recent innovations such as Internet of Things (IoT) integration, self-powered designs, and AI-enhanced data analytics. By addressing these issues, printed sensors can develop a better understanding of environmental systems and help promote the UN sustainable development goals.

1. Introduction

Environmental monitoring is essential for the preservation of the quality of the natural environment for future generations and to mitigate the effects of environmental deterioration [1]. Traditional analytical methods are effective; however, their accuracy in monitoring environmental parameters is frequently compromised by the complexity of the process and the limited availability of real-time data [2]. Advanced sensors are becoming increasingly critical in the era of the Internet of Everything, as the demand for rapid and efficient access to reliable information is increasing day by day [3]. The IoT paradigm can enhance understanding and support climate change impact assessments in various sectors, including environmental sustainability and sustainable energy.

The 2030 Agenda for Sustainable Development, adopted by all UN Member States in 2015, outlines 17 Sustainable Development Goals aimed at promoting economic growth while tackling climate change and preserving the ecosystem. Key ecosystems provide essential services to food and agriculture, such as freshwater supply, habitat provision, and habitat for species. The degradation of land and marine ecosystems affects 3.2 billion people and costs about 10% of the global GDP. The UN General Assembly declared the “UN Decade on Ecosystem Restoration 2021–2030” to upscale restoration strategies for degraded ecosystems, aiming to generate USD 9 trillion in ecosystem services and remove 13–26 GT of greenhouse gas emissions. The UN Environment and Food and Agriculture Organization prioritizes areas such as biodiversity, land degradation, marine environment protection, food chain ecological balance, coral reef management, deforestation, nitrogen management, rangelands, sustainable blue economy, and peatland management.

With increasing concerns over air pollution, water contamination, soil degradation, and climate change, it is becoming increasingly critical to employ effective, scalable, and continuous environmental monitoring techniques [4]. Environmental risks pose threats to humans and the environment, with floods being the most frequent. Drinkable water is essential for health, but this is becoming scarce, especially in poorer nations. Water pollution is a global issue due to hazardous pollutants like dyes, pharmaceuticals, heavy metals, fertilizers, and pesticides [5]. We need advanced monitoring techniques to gather evidence about environmental ground and surface water pollutants, protect water quality, and enhance household water supplies.

Air pollution is a major challenge to urban health and environmental sustainability, with 91% of the world’s population living in areas where air quality exceeds safe limits [6]. Comprehensive studies on air quality are vital to understanding the problems associated with it. Air pollution composition has evolved from a local problem to a global problem, with pollutants like particulate matter, ozone, nitrogen dioxide, carbon monoxide, and sulfur dioxide being the most significant [7]. Recent developments in portable, less expensive air pollution sensors have changed the framework for air pollution monitoring [8]. These sensors report data in near-real time at high resolution, improve computational and visualization capabilities, and enable wireless communication and infrastructure. By using advanced sensors, communities and individuals can understand their environmental exposure, develop pollution-reduction plans, and connect to health markers [9].

Soil degradation is an international crisis that represents a risk to food security and the environment. Remote sensing (RS) techniques are employed for studying soil degradation, providing benefits including real-time data acquisition, low-cost monitoring systems, and efficiency. Future research requirements involve the restoration of degraded soil resources, data availability, modeling algorithms, decision support systems, and multi-scale analysis [10]. In addition, human activities, such as the cultivation of livestock and the combustion of fossil fuels, have made our environment vulnerable to climate change [11]. Intelligent agriculture practices are now essential due to the effects of urbanization, water scarcity, climate change, and agricultural land contamination.

Traditional sensors have been utilized for environmental monitoring; however, they have limitations due to a variety of factors, including their cost, size, the need for skilled operators, difficulties in miniaturization, and the utilization of energy. They often have limitations caused by high manufacturing and maintenance costs, which can be impractical for large-scale installations. Conventional monitoring systems are also sometimes limited by spatial coverage and data-processing capabilities [12]. Their high energy requirement is also contrary to the increasing emphasis on low-power IoT devices. The detrimental environmental effect of conventional sensors is also an issue, as their production and disposal often involve non-biodegradable materials and hazardous chemicals, which contribute to electronic waste.

Addressing the environmental impact of sensors is essential to achieving global sustainability goals. Innovations in sensor technology, like printed sensors, present promising alternatives to address these limitations and unlock new applications [13,14,15,16]. Printed sensors have offered an innovative and more efficient solution for continuous real-time environmental monitoring at scale, offering considerable promise in addressing these challenges. Printed electronics is an environmentally friendly additive manufacturing technique that allows for the fabrication of electronic devices on low-cost substrates like paper, plastic films, concrete, and wood. This method can be done in a roll-to-roll manner, reducing product costs. Moreover, we can create advanced devices using biodegradable substrates and inks and produce conformable, flexible, and stretchable devices using lightweight, flexible, and stretchable substrates. Thus, this technology has huge potential for creating sensors for environmental monitoring [17]. Their inherent flexibility and light weight make them easy to incorporate into a wide range of monitoring systems that can be used in both urban and rural areas, as well as in remote areas where traditional monitoring equipment might not be practical or too expensive [18].

The main advantage of printed sensors is their low cost, which allows for large-scale applications. Techniques such as inkjet printing, screen printing, and roll-to-roll printing can manufacture sensors at a fraction of the cost of conventional sensor systems, ensuring high precision and accuracy [19]. The range of applications of these printing technologies has been significantly improved by their ability to fabricate sensors on flexible substrates, which allows for large-scale production. Graphene, carbon nanotubes, and conductive polymers are among the recent advances in sensor materials, which have contributed to the progress of printed sensors. In addition to their electrical properties, these materials have also facilitated the development of printed sensors due to their chemically tunable sensing layers and mechanical flexibility. These materials have also enhanced the sensitivity, durability, and responsiveness of printed sensors to a broad range of environmental factors [20].

Despite their many advantages, printed sensors encounter several shortcomings that limit their broad application in environmental monitoring. These disadvantages include material instability, longevity, mechanical strength, and sensitivity to environmental conditions [21]. A typical problem with printed sensors is their inability to detect low concentrations of pollutants in complicated physical environments like contaminated water and polluted air [22]. Additionally, the stability of printed sensors for a prolonged duration remains a significant challenge, particularly when they are subjected to harsh environmental conditions such as high humidity, extreme temperatures, and UV light [23,24]. Therefore, the this study primarily focuses on the improved reliability and lifespan of printed sensors.

The mechanical strength of most sensors is lower than that of traditional solid-state sensors, which may lead to structural failure and fatigue resistance [25]. The resolution of printed sensors is often lower than those of their higher-end-technology counterparts and requires calibration for their practical application [26]. Another issue is their environmental sensitivity, which may negatively impact signal quality due to factors like electromagnetic interference and losses in noisy environments [27]. Additionally, there are other challenges related to manufacturing consistency and scalability. The management of power and compatibility with existing devices may introduce additional complexity [28]. Hence, it is important to address these limitations in order to improve the reliability and usefulness of printed sensors in real-world scenarios, particularly in harsh environmental conditions.

The disposal and recycling of printed sensors have recently become topics of concern due to their widespread contamination [29]. Conductive inks and polymer materials may complicate the waste management process [30]. Traditional disposal methods often result in landfills, which release harmful emissions and degrade the overall environment [31]. Therefore, improved disposal techniques and recycling methods are crucial to minimizing the environmental footprint of printed sensors. Hence, the utilization of biodegradable materials in printed sensors will be very effective in minimizing e-waste generation.

Moreover, advancements in materials science, printing techniques, and sensor design can help enable the development of sensors with higher sensitivity and greater stability. Additionally, the integration of printed sensors with IoT platforms enables real-time environmental monitoring across diverse areas [32]. This technology improves decision-making in agriculture, urban planning, and disaster management. Artificial intelligence and machine learning algorithms enhance the capabilities of these sensors, enabling accurate predictions and improved resource management [33,34]. The scalability of IoT platforms allows for extensive data collection and remote monitoring.

This review discusses the advancements in printed sensors for environmental monitoring. It also highlights their potential for real-time data collection and informed decision-making in sectors like agriculture, urban planning, and public health. Advances in materials, technologies, and applications have made them more accessible and cost-effective. The use of nanomaterials and polymers expands their functional capabilities, making them suitable for monitoring environmental factors like air quality, soil moisture, and pollutant levels. However, challenges such as durability, performance consistency, and recycling remain. The paper also highlights the need for regulatory frameworks and industry standards to integrate printed sensors into existing monitoring systems. Future research should focus on sensor integration with IoT platforms and AI and machine learning (ML) integration. Collaborative initiatives between industry, academia, and policymakers may foster a better ecosystem for printed sensor management, which can help reduce hazards to the environment and optimize the utilization of resources.

2. Printed Sensor Technology

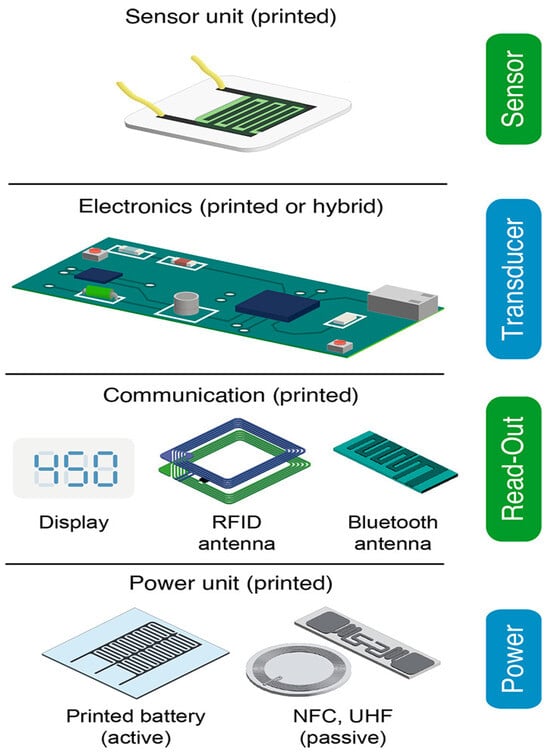

Printed sensor technology has transformed environmental monitoring by enabling cost-effective, scalable, and versatile devices. These sensors convert environmental variables into measurable electrical signals using resistive, capacitive, and piezoelectric methods. With advancements in research and new materials, these sensors are expected to expand their applications and effectiveness in monitoring environmental parameters, contributing to improved ecological management and sustainability efforts. This section explores the principles of printed sensors and the materials used in these sensors and discusses various printing methods in detail.

2.1. Principles of Printed Sensors

Printed sensors are devices that interact with environmental parameters through physical, chemical, and biological mechanisms. Physical interactions involve responses to external input, such as pressure, temperature, or humidity, that affect the electrical characteristics of the sensing materials [35,36]. Chemical interactions involve the absorption or adsorption of analytes onto the sensor surface, affecting the physical properties of the sensing materials. Gas-sensitive materials, for example, detect pollutants by changing their resistance when exposed to specific gases. Biological interactions, such as enzymes, antibodies, or DNA, can also be used for sensing purposes [37]. These interactions generate electrical signals that can be recorded and processed using conventional electronic systems, enabling real-time monitoring and analysis of environmental conditions. Advanced signal processing algorithms can enhance the accuracy and reliability of these readings.

Printing sensor technology integrates electronic components and sensing mechanisms to produce compact, lightweight devices that are suitable for a wide range of applications. The lightweight, flexible materials make them particularly convenient to transport, deploy, and handle, especially in remote regions, and for environmental applications.

2.2. Types of Printed Sensors

Printed sensors are devices that have been designed to address the requirements of environmental monitoring, which includes the monitoring of ecological factors, i.e., variations in humidity levels, temperatures, and air quality. Their flexibility facilitates the development of a broad variety of sensor types, thereby enhancing their application in monitoring environments.

This section categorizes printed sensors according to their targeted applications, including temperature and humidity monitoring, biosensing, and gas sensing. This classification was selected to highlight the practical applications of printed sensors in everyday environments. While it has been recognized that numerous sensors share similar transduction mechanisms (e.g., electrochemical), the application-based approach was chosen to correspond with the functional context in which these sensors are most frequently employed.

2.2.1. Gas Sensors

Gas sensors are essential in air quality monitoring due to their compact design, portability, and ability to provide real-time data. They are suitable for detecting toxic gases like carbon monoxide (CO) and nitrogen oxides (NOx), metal oxide semiconductor (MOS) sensors (which employ oxides like tin dioxide (SnO2)), and volatile organic compounds (VOCs) [38,39]. They offer advantages such as real-time monitoring, cost-effectiveness, and the ability to be integrated into IoT systems. However, challenges such as environmental conditions, calibration, and cross-sensitivity can affect their reliability and efficacy. Regular calibration is crucial for ensuring measurement accuracy, while cross-sensitivity is a critical limitation in mixed-gas environments. Gas sensors are used in various applications, including indoor air quality monitoring, occupational health monitoring, and environmental compliance reporting [40]. Advances in nanostructured materials and sensor design have enhanced the sensitivity and selectivity of gas sensors, allowing for more efficient operation under varying conditions.

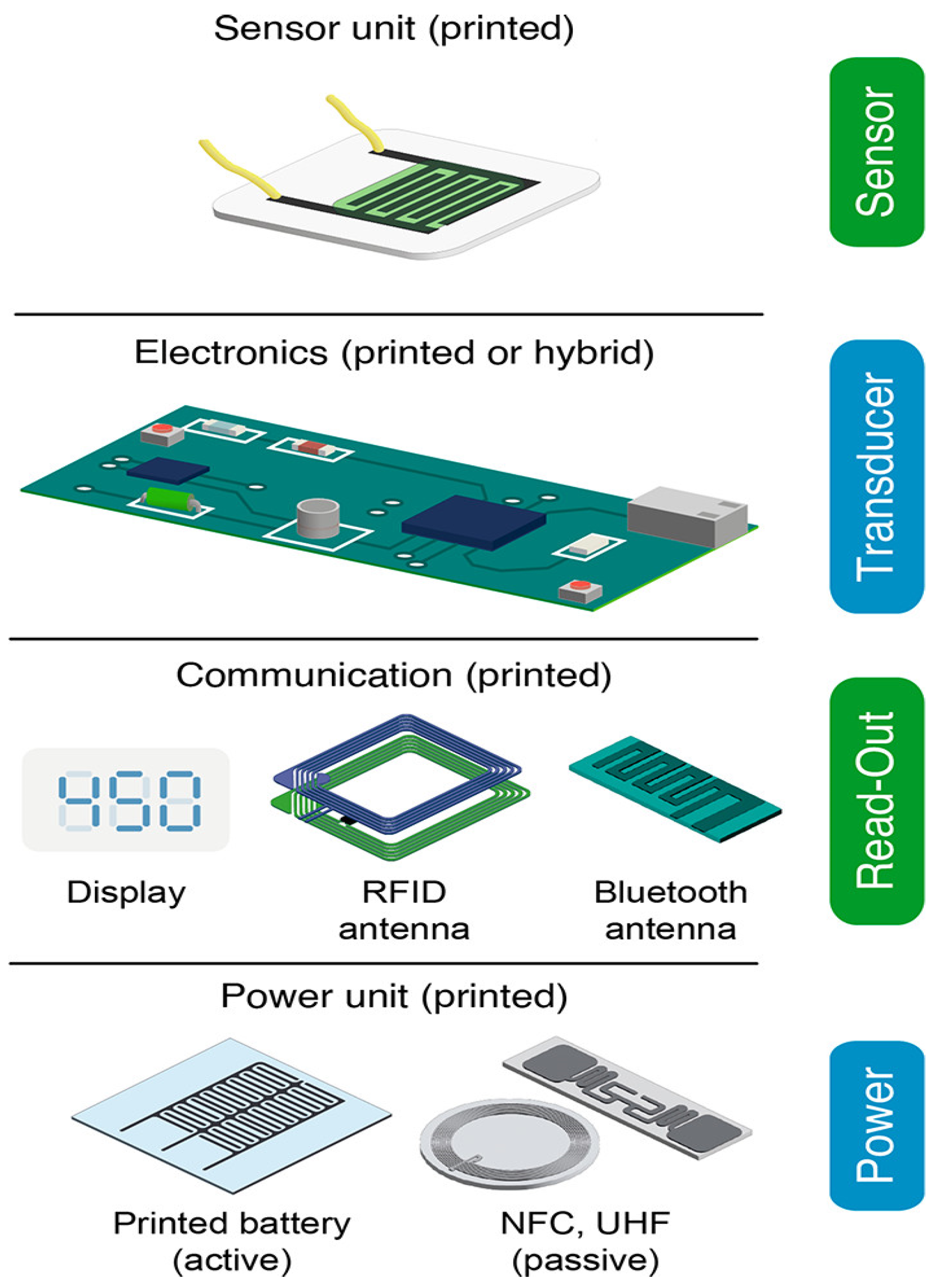

Printed gas sensors are highly regarded for their flexibility, which enables their deployment in wearable gadgets, portable sensors, or permanent installations. Typical components of a printed gas-sensor system are shown in Figure 1. Advanced equipment enables large-scale, high-speed, cost-effective device fabrication on rigid and flexible substrates. This allows for the development and incorporation of device configurations and functional materials. To achieve optimal performance, printed gas sensors require a review of the substrates, inks, and printing methods, all of which are interdependent and influence the material type, printing scale, and manufacturing scale. Emerging techniques utilize traditional printing methods for multilayer devices, demonstrating the ongoing evolution of printing technologies.

Figure 1.

Components of printed gas-sensing devices [41].

The current generation of gas sensors is based on conducting polymers and related composites. Additionally, gaseous compounds may interact with polymers through relatively weak forces between molecules or undergo chemical reactions. Gas-induced charge doping can alter the electrical properties of conducting polymers upon gas adsorption. For example, p-type polypyrrole (PPy) may be exposed to a reducing gas such as NH3. Theoretical explanations for gas-sensing phenomena in conducting polymers have also been proposed, including proton doping/de-doping through acid/base reactions. The abundant adsorption sites on polymeric chains and the strong affinity of the majority of volatile organic compounds (VOCs) toward polymers can result in structural changes and modifications to electrical properties. The significant consumption of VOC molecules in a polymer film can also result in a mass increase, which enables the detection of various types of VOCs and yields additional output signals.

2.2.2. Electrochemical Sensors

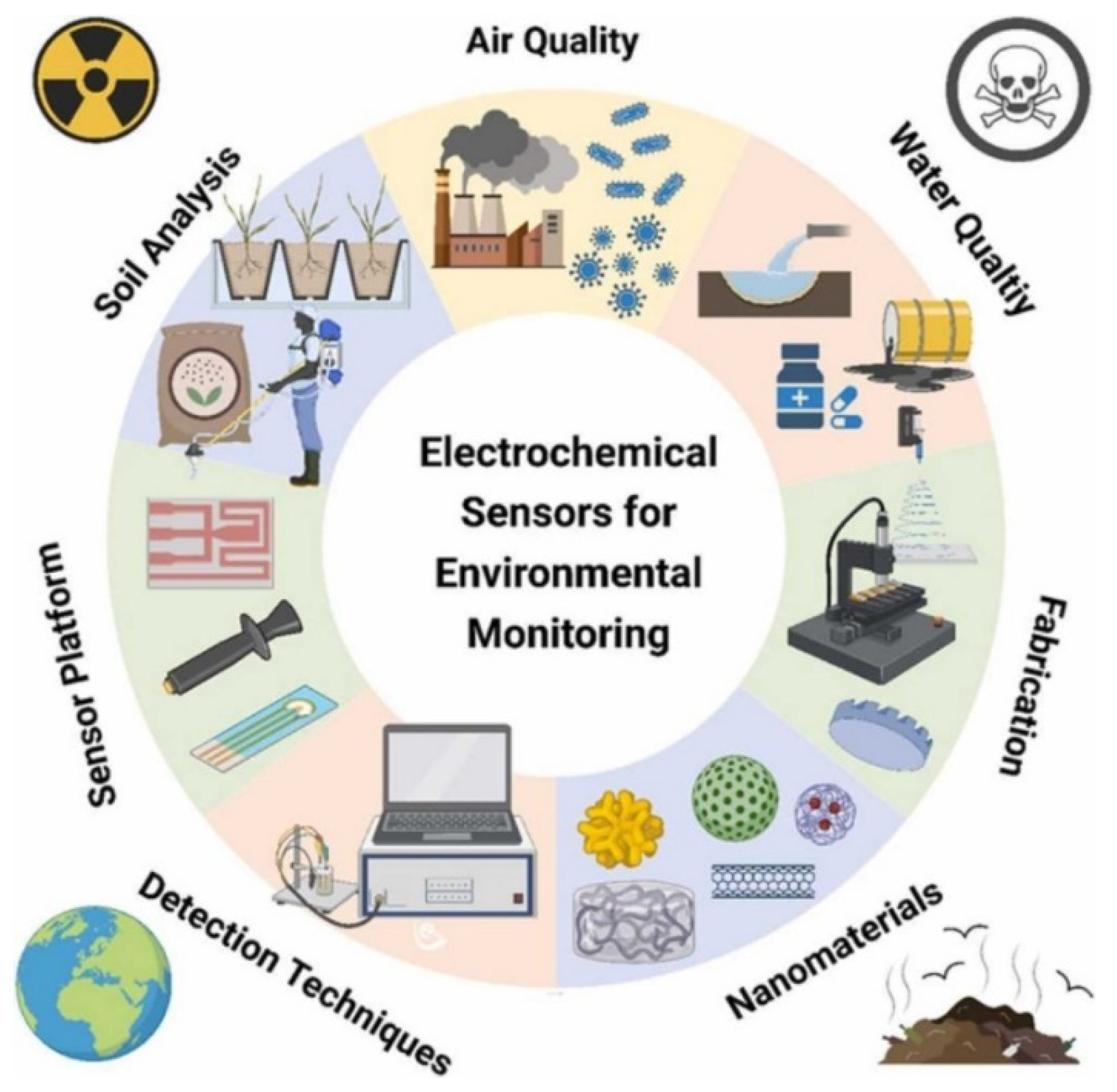

Electrochemical technology is a crucial field for various industries due to its environmental and green benefits. It has applications in energy, environmental monitoring, biochemical sensing, and wastewater treatment. The fabrication of sensitive and robust electronic devices for electrochemical sensors is critical to addressing these issues. Recent developments in electrochemical sensors include disposable, mobile, implantable, and self-powered devices. The environmental monitoring market is crucial for monitoring water quality, air pollutants, and soil quality, as shown in Figure 2. Portable electrochemical sensors have been used by He et al. [42] for the real-time detection of contaminants at low concentrations in water. However, the challenge is to create inexpensive and user-friendly sensors that do not require expensive lab techniques or trained staff. The demand for portable electrochemical sensors for real-time soil monitoring is expected to grow in the near future.

Figure 2.

Overview and applications of electrochemical sensors [43].

Conventional manufacturing techniques used in the fabrication of these sensors, like electrodeposition, laser cutting, and photolithography, are very expensive. Hence, printing electrode technologies are rapidly growing, enabling the production of low-cost, integrated electrodes for sensing applications by eliminating complex fabrication processes, improving their compatibility with affordable materials, reducing material waste, and supporting scalable and simple manufacturing methods. In addition, the integration of nanomaterials such as CNTs and graphene with printing technology offers a unique area for manufacturing high-performance and flexible electrodes. Godja et al. [44] used a nanomaterials-based electromechanical system to detect environmental contaminants of emerging concern. These nanomaterials formed modified electrodes that allowed for the selective detection of specific analytes. Moreover, polymer nanocomposites have been used in the development of electrochemical sensors due to their promising features, such as good electrocatalytic behavior and higher electrical conductivity [45]. Researchers are also investigating hybrid nanocomposites consisting of nanomaterials and biomolecules for applications in sensors, electronics, nanotechnology, and biotechnology [46]. These nanocomposite materials improve conductivity by uniformly dispersing metal nanoparticles throughout a polymer matrix, thereby demonstrating efficacy in the chemical and biological sensing of various analytes. The flexibility of conducting polymers offers a higher degree of stability, making metal/conducting polymers an optimal choice for biosensors and chemosensors. Hybrid nanomaterials are also used in optical sensors for environmental monitoring. These sensors have advanced significantly in recent years, particularly for detecting air pollutants, particulate matter, VOCs, water pollutants, and industrial chemicals.

2.2.3. Biosensors

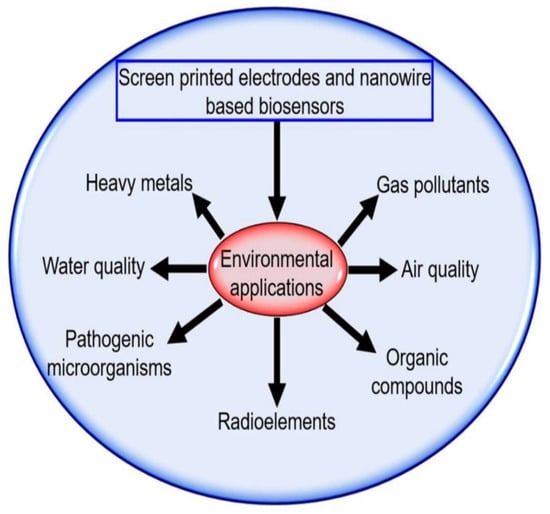

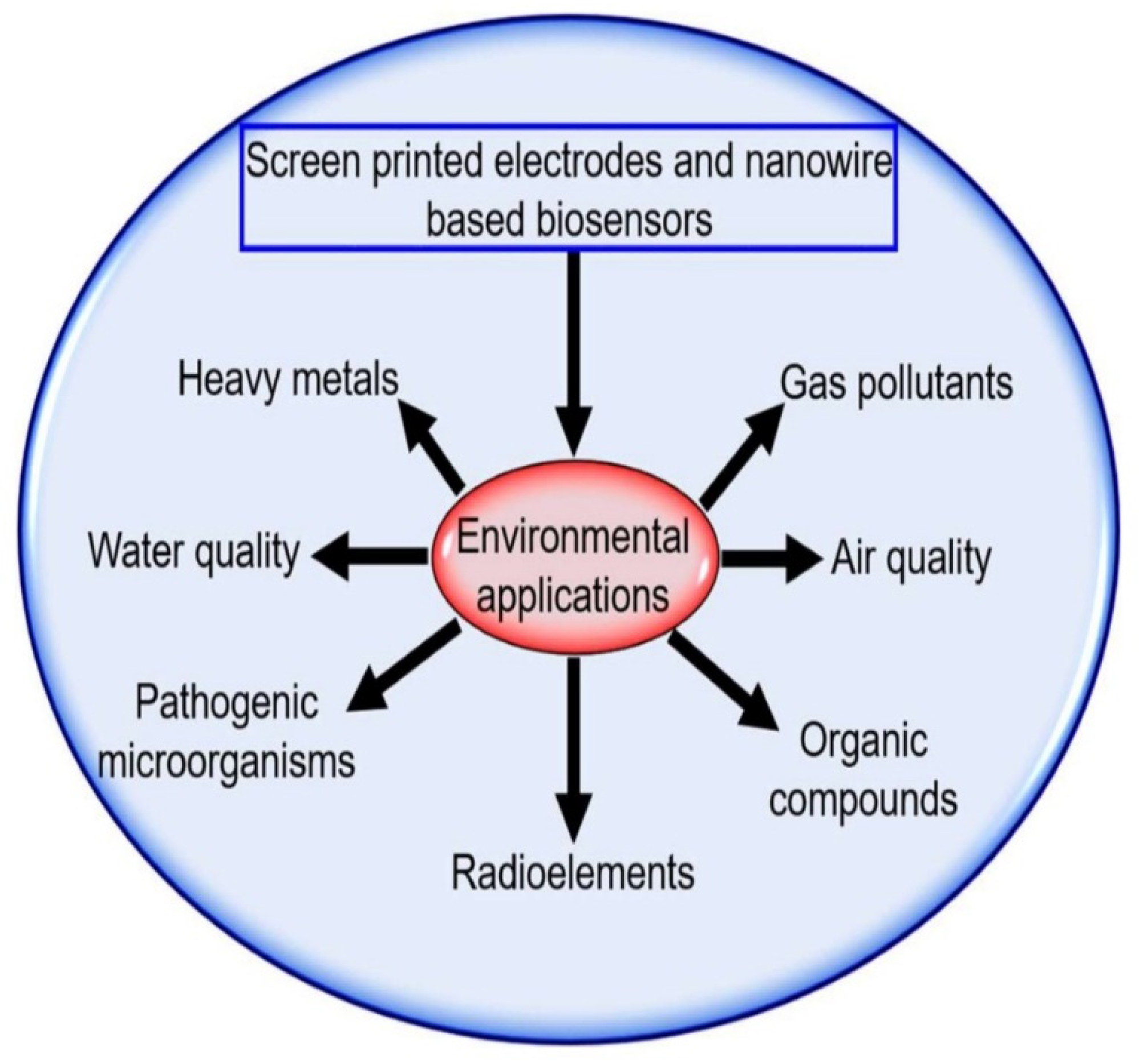

Biosensors are the preferred technology for monitoring environmental pollutants due to their ability to provide fast and reliable data. These self-contained devices, which are usually small, are integrated with a biological recognition element and a transduction element that can provide information about biological effects and distinguish the bioavailable fraction of pollutants from the total sample content [47]. Figure 3 depicts various environmental applications of screen-printed biosensors. The primary concept underpinning these sensors is the ability to generate an electrochemical reaction between a detectable analyte and a sensor material. This reaction is then converted into current, voltage, and impedance, which are subsequently processed and stored by an electronic system. These sensors require three electrodes: a reference electrode, a counter or auxiliary electrode, and a working electrode [48].

Biosensors are used to monitor reactive oxygen species and antioxidants, detect heavy metals and phenolic compounds in water, and assess food safety through the identification of contaminants and pathogens. Further applications include the monitoring of heavy metal concentrations in environmental samples, such as water and soil, including of lead, chromium, zinc, mercury, cadmium, copper, arsenic, and nickel. Biosensors are also used for measuring biodegradable organic material in water (BOD or BOD5), being particularly useful for rapid determination in industrial effluents and river waters. Biosensors determine levels of nitrites (used in food preservation and soil fertilization) and nitrates (found in groundwater and surface water) in water.

Three-dimensional (3D)-printing technologies have revolutionized the development of biosensors, which have numerous applications in environmental safety monitoring [49]. These biosensors detect pollutants and assess environmental matrices, such as herbicide detection in water, serotonin quantification in synthetic urine, and catechol determination in water. They also enable in situ monitoring of uranium in groundwater by using SLAM Bioprinting to pattern microbes in hydrogel constructs. A membraneless single-chamber microbial fuel-cell-based biosensor was developed using Material Jetting 3D printing to detect a mixture of freshwater pollutants, specifically Ni(II) and Cr(III), at concentrations above 2 mg/L. These biosensors offer reduced manufacturing costs and broad applications in monitoring water pollution. Janmohammadi et al. [50] presented a 3D-printed microbial fuel-cell design for detecting nitrate in synthetic wastewater and environmental samples. The optimized parameters, including organic matter concentration, external resistance, and flow rate, demonstrated high sensitivity and potential for real-world water quality monitoring. Pan et al. [51] examined the application of 3D-printing technology in creating electrochemical sensors for environmental monitoring and various applications, including the detection of heavy metals, pathogens, antibiotics, and organophosphates.

Figure 3.

Environmental applications of biosensors [52].

Figure 3.

Environmental applications of biosensors [52].

2.2.4. Temperature Sensors

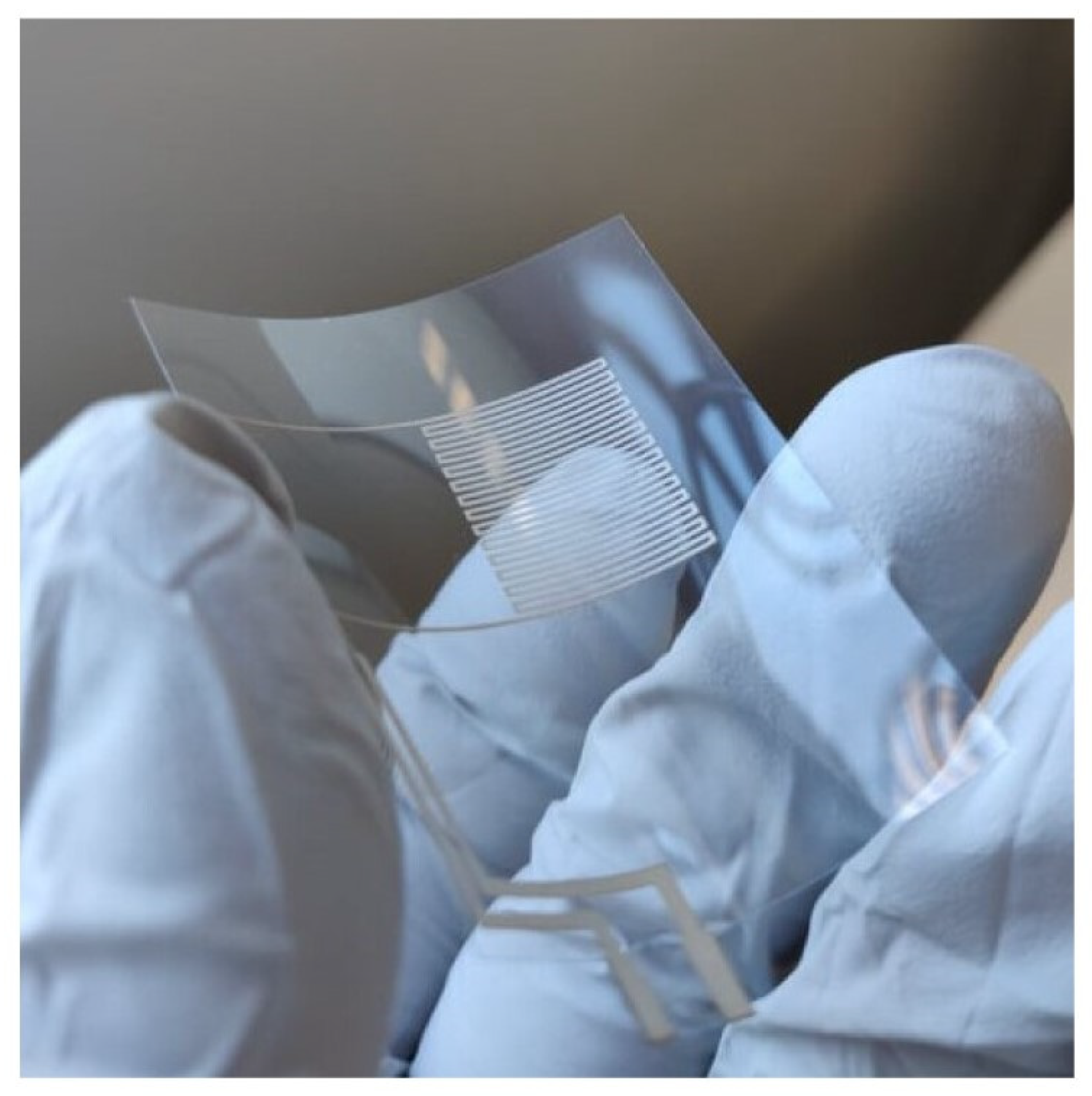

Temperature is a crucial parameter in human physiology and industrial processes, and low-cost, reliable temperature sensors are essential for wearable smart electronics and Internet of Things-powered devices. Printed temperature sensors typically employ thermosensitive or thermoelectric materials that exhibit expected changes in their electrical properties as temperature variations occur. These sensors can monitor temperature and heat flux in electronic circuit boards, detect potential overheating areas, and measure the cooling devices’ performance [53]. Printed temperature sensors are mostly resistance temperature sensors that rely on their electrical resistance. They typically have positive or negative resistance–temperature relationships, with the latter having a faster response but a smaller sensing range. Typical sensors use expensive inorganic metals or printable inks containing metallic micro- or nano-objects. Figure 4 depicts screen-printed sensors offering a cheap alternative to conventional platinum sensors.

Figure 4.

Screen-printed temperature sensor [54].

Printed temperature sensors are crucial in environmental monitoring, serving in weather stations, agriculture, and industrial processes [55,56]. They offer cost-effectiveness, flexibility, and a lightweight design, making them suitable for non-standard environments. However, they face challenges such as sensitivity, stability, and calibration needs. Future research is focusing on developing improved materials that enhance sensitivity while maintaining flexibility and durability and on integrating these sensors with IoT technologies for real-time data monitoring and the remote management of environmental conditions [57]. Despite these challenges, printed temperature sensors have the potential to revolutionize environmental monitoring.

2.2.5. Humidity Sensors

Humidity is crucial in various aspects of life and in industrial processes, and precise humidity sensors are essential for monitoring and controlling conditions. These sensors are used in intelligent systems for irrigation, corrosion detection, and civil engineering [58]. Measurement of humidity is difficult due to human interactions (such as with fungal or bacterial growth) and the likelihood of oxidation. Ceramic materials are extensively studied for use in gas sensing, particularly humidity sensing, due to their grain boundaries and crystal grains [59]. Researchers are exploring various conduction mechanisms, including electronic and ionic, to improve sensor performance. However, complex chemical reactions and environmental exposure can lead to degradation.

Advancements in humidity sensor technologies focus on improving transducer performance, structure design, mechanism principles, and fabrication technologies. Key features include semiconductor materials, suitable manufacturing technologies, geometrical properties, surface optimization, ease of production flow, and reduced investment expenses [60]. Sensor performance also relies on the substrate material, with materials like paper, cotton fabrics, and polyimides used for flexibility, bendability, and foldability [61]. Paper and cotton fabrics are advantageous for electrode formations but cannot withstand high-humidity environments [62]. Polyethylene terephthalate (PET) is widely used due to its transparency, high sensor sensitivity, and ease of processing with roll-to-roll technology.

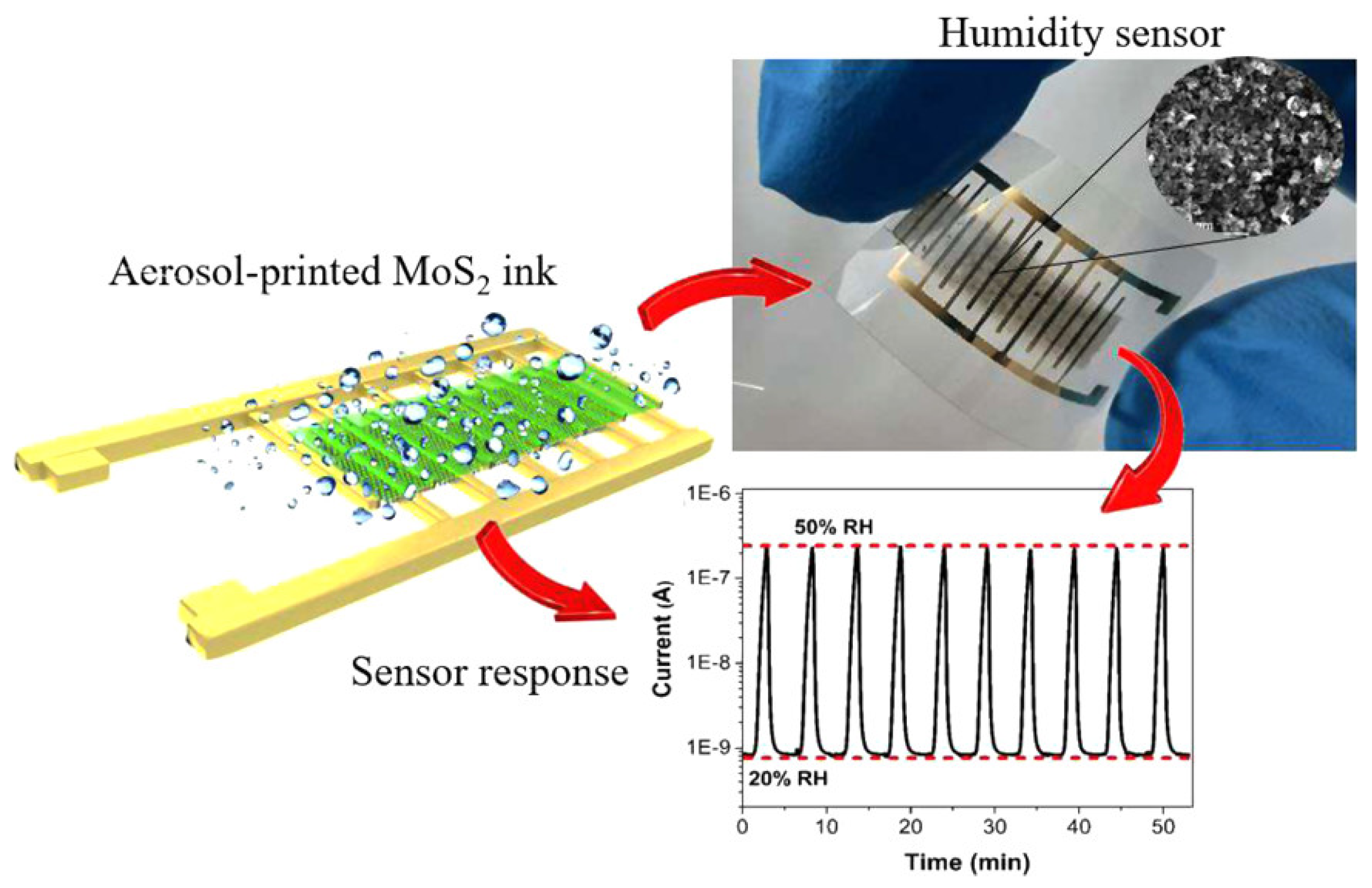

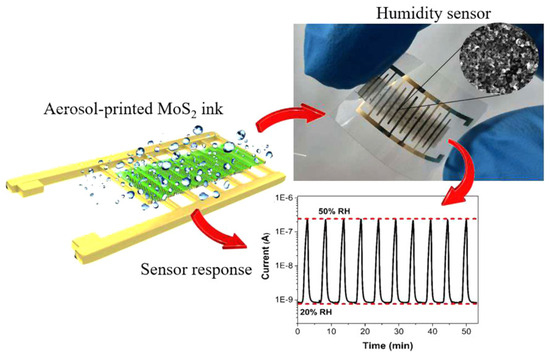

Sensor performance depends on the fabrication methodology, with contact techniques like gravure and flexography being popular. In contrast, non-contact techniques like screen printing, slot-die, and inkjet printing are increasingly popular due to their speed, adaptability, and low amounts of material waste. Printing technologies are increasingly being used to create ultra-low-cost electronic components, particularly humidity sensors, for applications like biomonitoring, wearables, and environmental monitoring. Two-dimensional (2D) transition metal dichalcogenides like MoS2 are crucial for sensing applications. However, developing sustainable and inexpensive inks with functional materials is still in the early stages. The aerosol-printed MoS2 sensor, as shown in Figure 5, exhibits high sensitivity, good response/recovery times, and excellent repeatability. The device can significantly influence the application of MoS2 ink in humidity sensors.

Figure 5.

Aerosol-printed humidity sensor [54].

3. Materials Used in Printed Sensors

The selection of materials (like conductive inks), substrate type, and functionalization technique is crucial in printed electronics for creating environmental sensors. There are various types of inks, including conducting, semiconducting, dielectric, and light-emitting inks [63]. Functional inks should form homogeneous layers and be compatible with other inks. Metal particles are commonly used instead of pigments. Conducting materials are synthesized as nanoparticles, dissolved organometallic compounds, or conductive polymers. Metal nanoparticles and metal–organic decomposition inks are popular for their high conductivity and resistance to oxidation. Semiconducting inks are formulated from polymer blends and solvents, while dielectric inks are used as insulator and capacitor layers. This section reviews these materials and their roles in advanced printed sensors.

3.1. Conductive Inks

Conductive inks are crucial in printed sensor technology for creating conductive pathways, electrodes, and sensing elements. They combine electronic qualities into flexible materials by utilizing adhesives and solvents. The performance of conductive inks is influenced by their electrical conductivity and viscosity and by the printing technique used. Also, their conductivity varies based on their composition and the processing techniques used; e.g., silver inks have higher conductivities than carbon-based inks [64]. Viscosity is crucial for printing, with low-viscosity inks being easier to print, especially for finer details [65]. Adhesion and flexibility are essential for creating durable sensors, especially for environmental sensors that may be subjected to bending or stretching [66]. These inks are used to monitor environmental parameters like temperature, humidity, and gas concentrations.

3.1.1. Metal-Based Inks

Metal-based inks are essential for printed electronics, enabling the fabrication of electronic components on flexible substrates. These inks are composed of metal nanoparticles, complexes, or metallo-organic compounds, which enable the production of conductive patterns through various printing and sintering techniques. Metal-based conductive inks, such as Au, Ag, Pt, and Cu, have gained significant attention due to their high electrical conductivity after sintering. The synthesis of metal nanoparticles is crucial for achieving the desired ink properties, as carefully selecting parameters such as shape, particle size, surface chemistry, and dispersion profile directly affects the ink’s viscosity, print uniformity, stability, and final electrical conductivity. Common methods include chemical reduction, physical vapor deposition, and template-assisted methods.

Metal-based inks are essential for creating flexible electronic devices, such as RFID antennas, OLED displays, and smart packaging and labels. Their advantages include cost efficiency, scalability, and compatibility with various substrates. Challenges include oxidation stability, viscosity control, and sinter compatibility. To overcome these challenges, advanced sintering techniques, such as near-infrared (NIR) sintering, flash sintering, and intensive pulsed light (IPL) sintering techniques, have been developed. These techniques enable rapid processing at reduced temperatures, minimizing thermal damage and maintaining electrical conductivity, making them ideal for flexible electronics manufacturing. Flexible printed electronics use functional inks to create electronic circuits on flexible substrates [67]. Low-temperature sintering techniques reduce the thermal impact, ensuring high-quality device fabrication. Metallic nanoparticle inks are utilized due to their superior electrical conductivity, ease of synthesis, and biocompatibility. Flexible electronics have extensively implemented near-infrared (NIR) sintering technology, which enables the selective heating of Ag nano-inks without substrate deformation and reduces the sintering time [68].

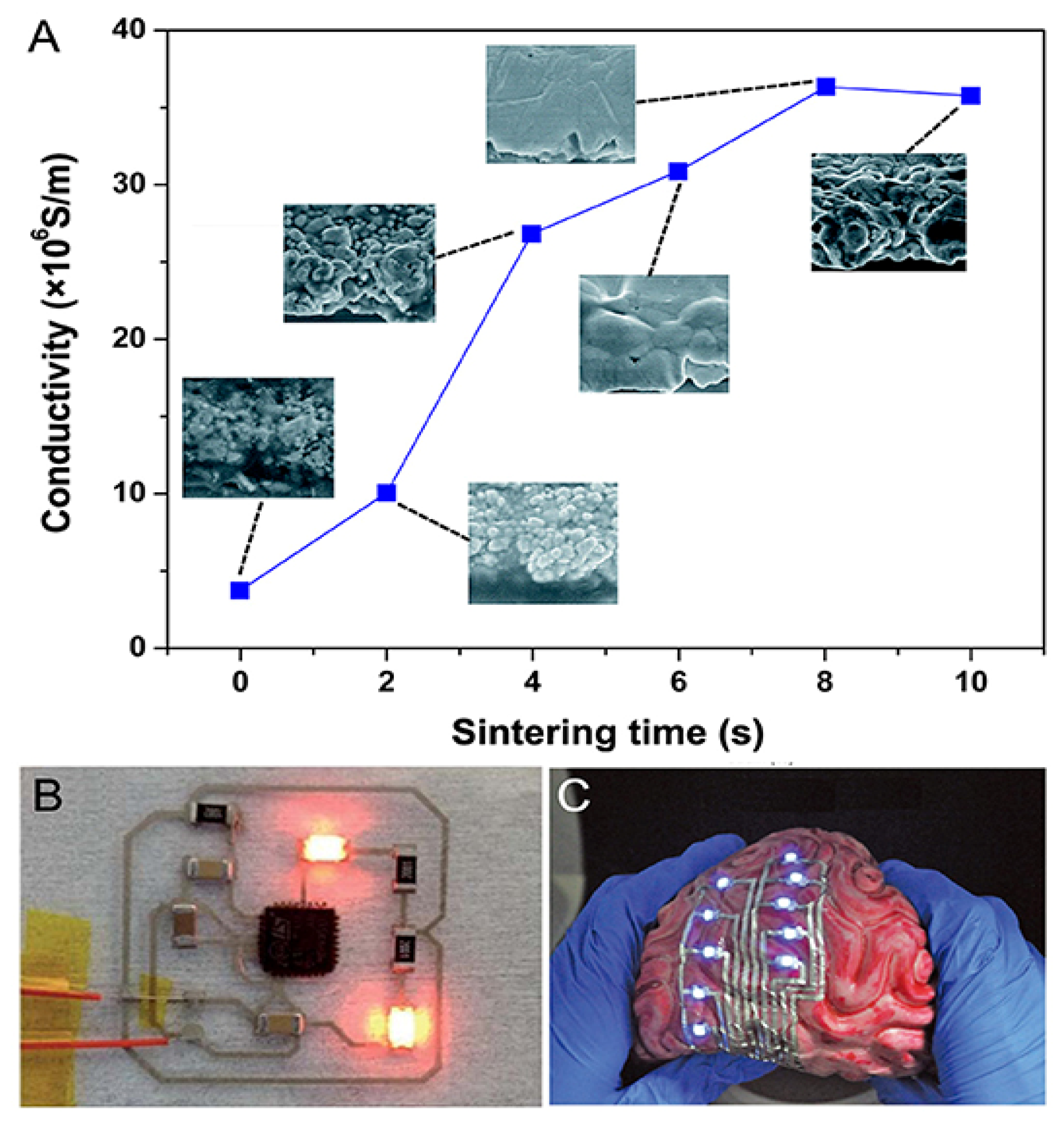

A flexible hybrid circuit has been developed by integrating the electronic components on a terephthalate (PET) substrate, followed by screen printing and sintering with NIR [69,70,71]. As shown in Figure 6, Tavakoli et al. [70] presented a method for coating silver nanoparticle ink with eutectic gallium–indium (EGaIn), which enhances the electrical conductivity and tensile-strain tolerance. This process involves a room-temperature “sintering” process, forming a continuous conductive trace. The resulting ultrathin and hydrographically transferable electronics are flexible, functional, and can even maintain their functionality when deformed, supporting strains exceeding 80%. This low-cost process eliminates the need for cleanroom fabrication, enabling functionalities such as electronic tattoos and 3D hydrographic transfer. Future prospects in printed electronics include sustainability research, integration with IoT, and the use of advanced nanomaterials.

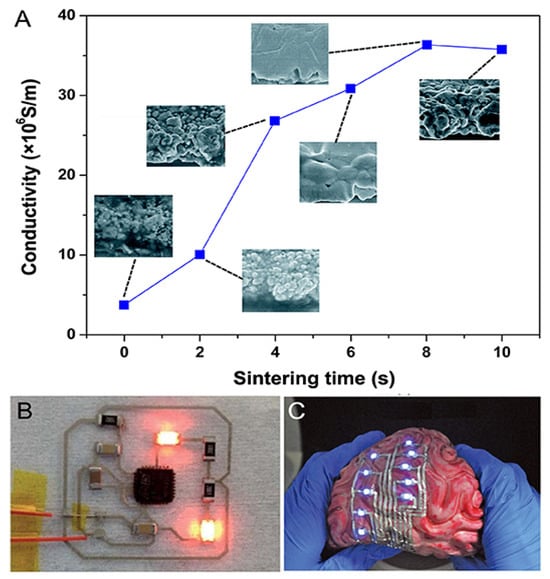

Figure 6.

(A) SEM images of Ag nanoparticles (AgNPs) sintered by NIR at different times; (B) a flexible hybrid integrated circuit on a PET substrate (screen-printed with AgNP ink); (C) and an inkjet-printed sensor on a soft brain-shaped toy (with AgNP-Ga-In ink) [69,70,71].

3.1.2. Carbon-Based Inks

Carbon-based conductive inks, including graphite, carbon black, and newer materials like graphene and carbon nanotubes, offer advantages such as cost, stability, and resistance. However, these materials face challenges due to their high resistivity and poor humidity response, making them unsuitable for integrated circuits. Graphene and carbon nanotubes exhibit superior properties, such as high carrier mobility, thermal conductivity, electromigration resistance, and tensile strength.

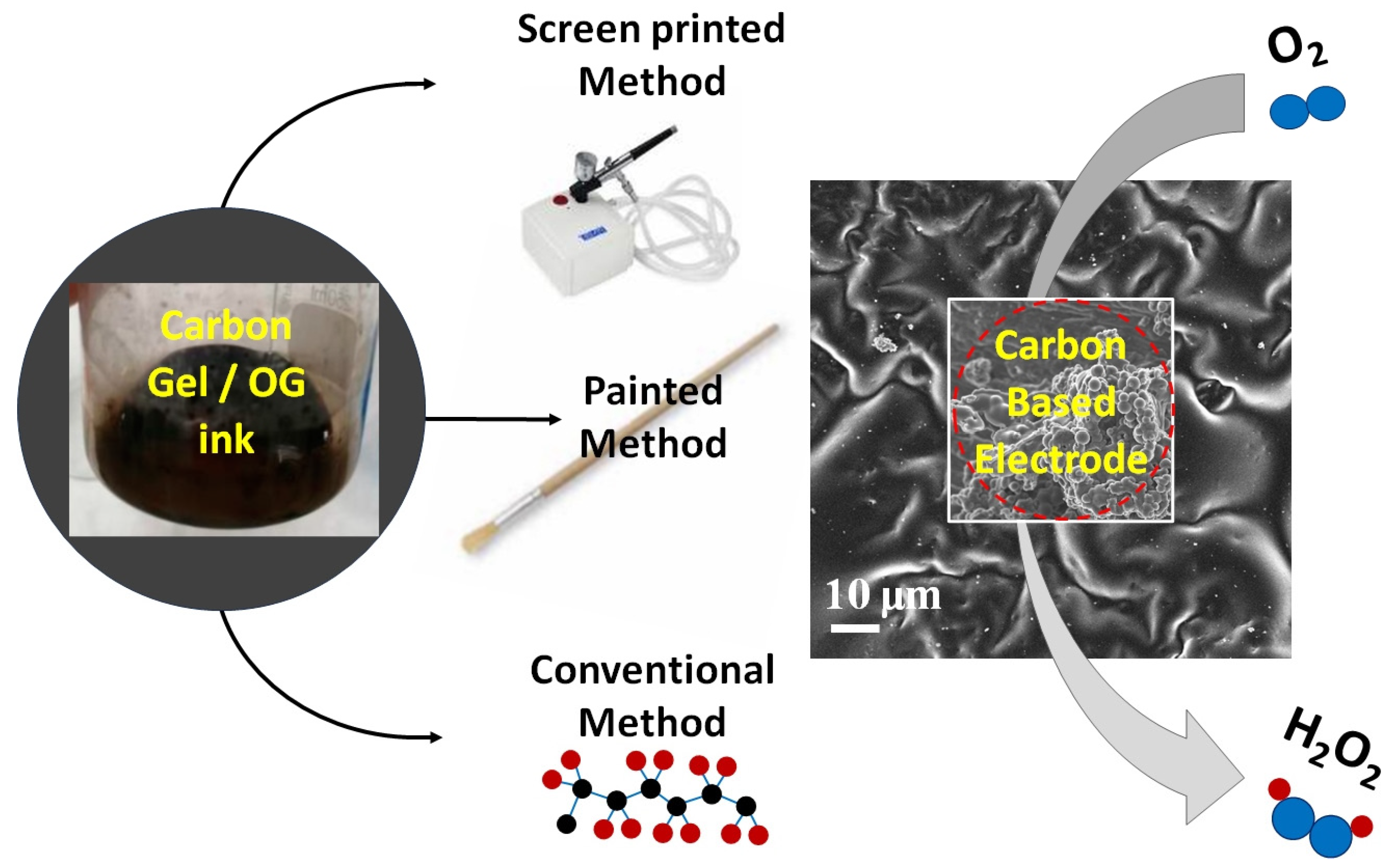

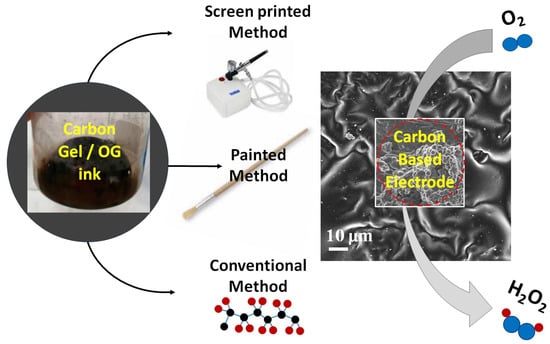

Gao et al. utilized ultrasonic-assisted supercritical CO2 to exfoliate graphite, maintaining high electrical conductivity [72]. Valencia et al. synthesized metal-free electrocatalysts based on carbon gels doped with graphene oxide for the electro-Fenton process, which generates hydroxyl radicals from hydroxide peroxide. As shown in Figure 7, these catalysts were prepared from organic-gel-based inks using painted and screen-printed methods and compared with conventional pasted methods on graphite supports. The best-performing catalyst was the brush-painted one, which exhibited nearly 90% degradation of amoxicillin under optimal conditions. This shows that carbon-gel-based electrocatalysts are effective and can be adhered to graphite without binders.

Figure 7.

Catalyst preparation using carbon gel/OG ink using painted and screen-printed methods [73].

Tran et al. [74] employed poly [2-(3-thienyl)ethyloxy-4-butylsulfonate] sodium salt (PTEBS) to exfoliate graphite without the use of excessive dispersants. This method enables the production of self-dispersible pristine graphene, which can be further processed into dry, water-dispersible graphene powders. Aqueous graphene inks that are highly concentrated have been developed for the purpose of printing flexible conductive circuits. These inks exhibit exceptional conductivity without the need for heat treatment.

Graphene, carbon nanotubes, and their composite materials exhibit exceptional mechanical, electrical, thermal, and corrosion properties. Highly efficient carbon-based conductive inks can be attained by modifying the solvent content and adjusting the preparation process [60]. In contrast, conjugated conductive polymers can improve electrical conductivity, while aromatic polymers can decrease the need for additional dispersants and enhance the hydrophilic characteristics of graphene [75].

Furthermore, integrated circuit designs can be printed onto flexible and rigid substrates employing carbon-based conductive inks, resulting in the production of high-resolution integrated circuit patterns and flexible conductive films [76]. They are the optimal choice for gas, electrochemical, flexible, and eco-friendly sensor designs due to their exceptional electrical, thermal, and mechanical properties.

3.1.3. Conductive Polymer Inks

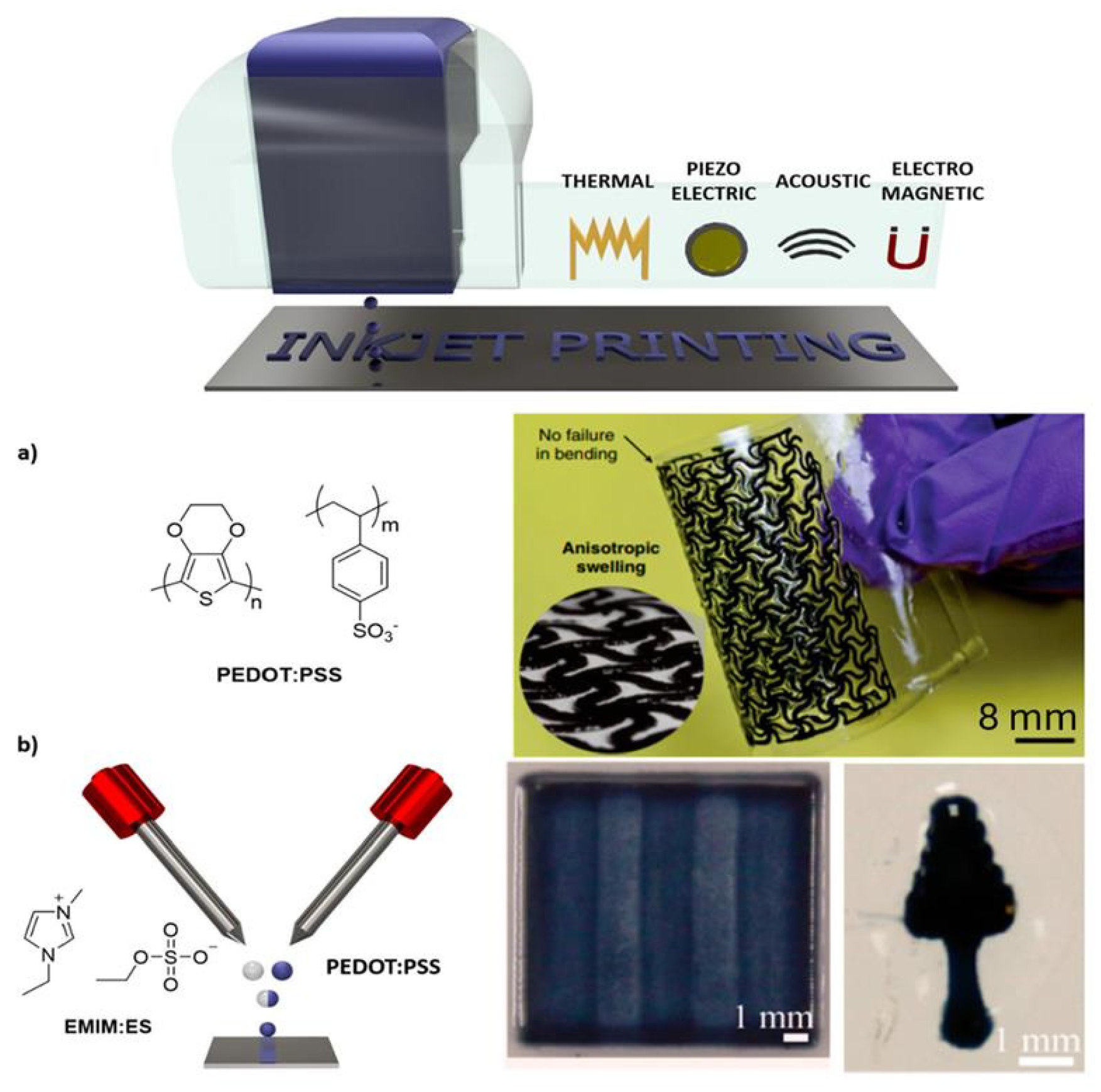

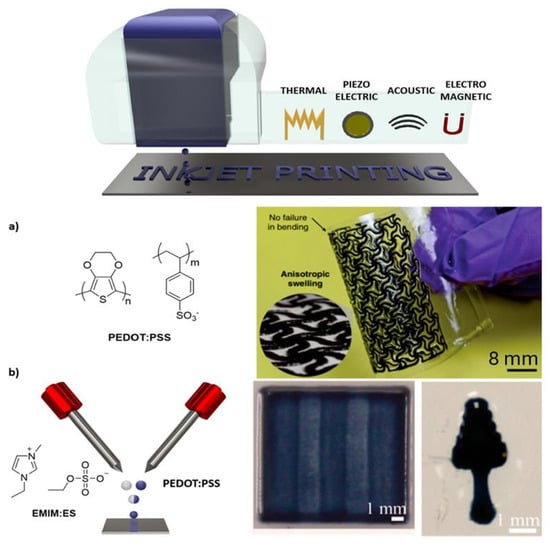

Polymer-based conductive inks use electrically conducting polymers like polythiophene (PTh), polyaniline (PANI), polypyrrole (PPy), and poly(3,4-ethylenedioxythiophene)/poly(styrene sulfonate) (PEDOT/PSS) [77]. As shown in Figure 8, the droplets generated from thermal, piezoelectric, or electromagnetic stimuli from the inkjet printer are deposited onto a surface to fabricate a 3D conductive structure. These polymers have advantages like moderate electrical conductivity, stability, and solubility in organic solvents. However, their application in conductive inks is limited due to their insolubility [78].

Figure 8.

Inkjet printing (top); (bottom) (a) PEDOT:PSS/DMSO ink on PET substrate; (b) PEDOT:PSS droplets for manufacturing 3D structures [79].

To improve the ink’s electrical conductivity and stability, researchers usually dope it with different available techniques. A study by Cao et al. [80] demonstrates that doping polyaniline with various organic solvents improves conductivity and increases solubility, making them suitable for use as inks. The researchers systematically dissolved doped polyaniline in these solvents and analyzed the conductivity of the films formed from each solution. Conductively filled polymers are insulating structures that contain conjugated conducting structures or other conductive solids. The solvents in which they are dissolved help in enhancing their conductivity. The films cast from the solvents achieved conductivities of up to 300 S/cm, which are significantly higher than the initial 10 S/cm of PANI powder. To improve the ink’s electrical conductivity and stability, researchers have used nanoscale conductive carbon black, resulting in a wide range of applications [81].

Recent studies have explored modified carbon-black structures to improve performance metrics, including surface treatments and hybrid composites with carbon nanotubes [82]. Innovative manufacturing techniques like electrospinning and spray coating have been used to create conductive composites with nanoscale carbon black [83]. Environmental and health concerns include toxicity and safety, and sustainable practices are crucial. Future research is focusing on exploring alternative fillers and enhancing computational models to predict nanocomposite performance, enhancing designs for flexible electronics, sensors, and energy storage technologies [84].

3.2. Substrates

This section studies the substrates used in printed electronics, including their properties, manufacturing techniques, applications, and challenges.

3.2.1. Rigid Substrates

Rigid substrates are essential components in printed electronics, providing structural stability and support for various applications. They are characterized by their stability, durability, and ability to withstand mechanical stress during operation and handling. There are three main types of rigid substrates: glass, ceramic, and plastics (polyimide and polystyrene). Glass substrates are characterized by their excellent dielectric properties and mechanical strength, making them suitable for high-temperature applications. Ceramic substrates are ideal for applications requiring stringent reliability standards. Polyimide, often used in flexible applications, can also be molded into rigid forms due to its high thermal stability. Polystyrene is economically favorable and provides decent mechanical properties.

Rigid substrates have key mechanical properties, such as tensile strength, bending resistance, electrical properties, and thermal properties. Manufacturing processes for rigid substrates include cutting and sanding, surface treatment, and screen printing. They are widely used in printed circuit boards (PCBs) for consumer electronics, automotive applications, and telecommunications, as well as in displays and optical devices. They also play a vital role in the development of high-performance sensors for automotive, aerospace, and medical applications.

However, rigid substrates face challenges such as weight and bulkiness, higher manufacturing costs, and compatibility with printed inks. Future trends in rigid substrates include advanced materials development, integration with smart technologies, and sustainable practices.

3.2.2. Flexible Substrates

Flexible substrates are crucial in printed electronics, enabling the development of lightweight, bendable, and portable electronic devices [85]. They are characterized by their ability to bend, fold, and twist without compromising functionality. Various types of flexible substrates exist, including polymer-based substrates like polyethylene terephthalate (PET), thermoplastic polyurethanes (TPU), polyimide (PI), poly (PDMS), and polyethylene naphthalate (PEN) [86]. Paper-based substrates, particularly those with coatings, have gained attention for their biodegradability and low cost [87].

Mechanical properties of flexible substrates include tensile strength, flexibility, and durability under bending and twisting. Electrical properties include their dielectric constant, conductivity, and thermal stability. These sensors can work on irregular surfaces or be integrated into wearable devices, making them popular in air quality monitoring. Various polymers have been proposed as flexible substrates, including semi-crystalline and amorphous types. Their selection must meet chemical, physical, thermal, mechanical, and optical requirements, as shown in Table 1.

Table 1.

Main properties of flexible polymeric substrates [85,88,89,90,91].

Flexible substrates have catalyzed the production of novel applications such as wearable electronics, smart textiles, and flexible displays. However, challenges such as adhesion issues, environmental resistance, and material cost remain. Adhesion issues can lead to delamination under stress or environmental exposure, while environmental resistance requires the substrate to demonstrate resistance to moisture, UV light, and temperature fluctuations. Material costs can also be a concern.

Future trends in flexible substrates include advanced materials with enhanced properties, hybrid approaches that combine different materials and functionalities within a single substrate, and integration with IoT. As the Internet of Things continues to grow, flexible substrates will play a key role in enabling connected devices by allowing for their seamless integration into various environments.

3.3. Sensor Functionalization

Sensor functionalization is a crucial process that enhances the sensitivity and selectivity of sensors, enabling them to respond more effectively to specific analytes or varying environmental conditions. This technique is applied in diverse areas, including environmental monitoring, healthcare, and industrial processes [92,93]. The primary goal of sensor functionalization is to enhance the interaction between sensor materials and target analytes, enabling accurate and reliable measurements that are crucial for timely decision-making and resource management. Techniques such as incorporating specific chemical groups, using nanomaterials, and applying advanced surface modifications can enhance the sensor’s response to specific environmental conditions. The use of biomolecules for sensor functionalization introduces a biocompatible element that can drastically increase selectivity, making it essential in environmental monitoring [94].

Advancements in printing technologies, such as screen printing and inkjet printing, facilitate the efficient application of functionalized inks onto sensor substrates, promoting accessibility to custom sensor designs. This integration not only streamlines manufacturing but also fosters sustainability practices in sensor design. As the demand for precise and responsive sensors continues to grow, investments in functionalization strategies will play a pivotal role in shaping the future of sensor technologies, ultimately leading to enhanced monitoring and management of environmental and public health challenges.

Surface functionalization with nanomaterials is a crucial advancement in materials science, impacting various applications such as electronics, environmental preservation, and biomedical technologies. This process involves modifying the surface properties of nanomaterials to improve their functionality, stability, and interaction with other substances. Nanomaterials, including nanoparticles, nanocomposites, and nanosheets, exhibit unique behaviors due to their nanoscale dimensions, leading to their enhanced chemical reactivity [95,96,97]. Functionalization with nanomaterials has revolutionized environmental remediation technologies by improving their interaction with specific pollutants [98]. Nanoparticles, such as titanium dioxide, exhibit unique behaviors due to their nanoscale dimensions, such as increased chemical reactivity and larger surface area. Surface functionalization enhances these properties, allowing for optimized functionalities such as increased reactivity, selectivity, and stability. Covalent functionalization techniques create strong chemical bonds between nanomaterials and reactive surface groups, enhancing their adsorption characteristics and chemical resistance [99,100]. Non-covalent functionalization uses softer interactions, allowing for dynamic capture and release mechanisms for environmental monitoring [101]. Surface-functionalized nanomaterials have significant impacts in environmental remediation, such as the efficient removal of hazardous materials from wastewater streams through magnetic separation techniques. A comparative analysis is provided in Table 2 for specific applications, and the performance, cost, and fabrication complexity of printed sensors are significantly influenced by the choice of functionalization method.

Table 2.

Comparative analysis of sensor functionalization methods.

Additionally, nanomaterials are used in eco-friendly inks for printing technologies, promoting real-time monitoring of environmental conditions and pollutant levels. Advancements in printing techniques, such as inkjet and screen printing, have revolutionized the application of surface-functionalized nanomaterials, enabling the development of sensitive and selective platforms for environmental monitoring.

3.4. Material Selection Challenges and Future Directions

Environmental monitoring is a critical field that requires careful material selection for effective and sustainable solutions. The multifactorial criteria for material selection include sensitivity to target analytes, compatibility with printing methods, mechanical flexibility, durability under environmental conditions, and cost-effectiveness [102]. Environmental factors like temperature fluctuations, humidity, and potential exposure to corrosive substances can significantly impact sensor performance and reliability [41]. Engineers and designers must navigate these trade-offs to achieve a balanced material profile that meets performance criteria without incurring prohibitive costs or compromising sustainability. Moreover, smart materials and nanomaterials can enhance sensor performance and improve sensitivity and response times [103].

In addition to performance, materials must be sustainable and have minimal negative effects on the environment throughout their life cycle, so sustainability is an important factor to consider. Another constraint is the requirement for biocompatible or non-toxic materials. Advancements in materials science, including in nanomaterials and smart materials, should be the primary focus of future material selection [104]. These advanced materials must demonstrate enhanced properties that are more closely aligned with the present environmental monitoring requirements.

To overcome material selection challenges and promote sustainable practices, advanced manufacturing techniques like 3D printing and additive manufacturing are also helpful [105]. The integration of AI into material selection also presents an exciting opportunity to enhance material selection processes in printed sensor development [106]. AI can optimize data analysis by processing large datasets on material properties, performance characteristics, and environmental impacts. Hence, the integration of AI technology and materials science facilitates the design of environmental monitoring systems that are more intelligent and responsive to changing conditions.

4. Printing Techniques

Sensor design has grown significantly with the introduction of printed sensors, which are fabricated using advanced printing techniques like 3D printing, inkjet printing, aerosol jet printing, screen printing, gravure printing, roll-to-roll printing, and hybrid printing [63]. These techniques offer cost-effectiveness, flexibility, adaptability, high resolution, and environmental sustainability. Traditional methods often involve extensive materials, complex processes, and specialized equipment, leading to increased production costs. Printed sensors can be created using additive manufacturing methods, which help in reducing material wastage and overhead costs. Hence, they contribute to environmental sustainability by minimizing waste and employing recyclable materials and environmentally friendly inks [107].

Printed sensor techniques are highly versatile and adaptable, allowing for quick design modifications. This, in turn, helps researchers and manufacturers to work on more efficient designs [108]. Inkjet printing and aerosol jet printing are two examples of high-resolution, precision printing techniques that can be used to create sensors with sophisticated patterns and that combine different materials. Moreover, printing sensors allow for their integration with other devices and systems, like hybrid printing, which improves performance and functionality in constrained areas. Additionally, printed sensors can be easily connected to digital technologies like the Internet of Things (IoT), enabling real-time data collection and analysis.

4.1. Inkjet Printing

Inkjet printing is a contactless, high-precision technique that allows for the direct deposition of functional ink droplets onto substrates, offering control over patterning and material usage. It offers high-resolution and low-cost solutions for creating environmental sensors, allowing for complex sensor patterns and the integration of various functional materials. Vyas et al. [109] presented inkjet-printed flexible sensors on paper that are used for low-cost mass production of RFID Tags and wireless sensor nodes, offering a green, eco-friendly solution. These sensors could be used in microwave and wireless applications, potentially paving the way for future convergent networks. Krebsbach et al. [110] explored inkjet printing of flexible humidity sensors using bio-sourced and biodegradable materials. The sensors, made from black-soldier-fly melanin, show improved sensing performance and reduced hysteresis. The sensor’s reusability and degradability make it suitable for wearable or agricultural applications. Wu et al. [111] utilized PEDOT:PSS as the sensing material to create a flexible temperature sensor array. In comparison with other sensors, the sensor array exhibited low hysteresis and a sensitivity of −0.50% °C. The accuracy of the temperature measurement was enhanced by an array correction algorithm, which reduced the error from 0.80% to less than 0.50%.

Inkjet printing is cost-effective for prototyping and low-volume production, making it attractive for sensor design development. However, it faces challenges in optimizing ink properties such as viscosity and surface tension. The smallest achievable droplet size, nozzle size, ink characteristics, substrate effects, and material compatibility issues influence the resolution of printed features. It also struggles with integration into larger monitoring networks due to the lack of standardized processes and ink formulations. It also has limitations in scalability and production speed, and its potential for mass production is limited. Additionally, the selection of appropriate functional materials remains a challenge, necessitating further research and innovation in materials science.

4.2. Screen Printing

Screen printing is a widely used technique for producing cost-effective environmental sensors, particularly in high-volume production. This method produces thick, uniform layers, making it suitable for applications requiring robust, long-lasting sensors. Its simplicity and efficiency enable the mass production of sensors, such as electrochemical sensors for water quality monitoring or gas sensors for air quality analysis. Beniwal et al. [112] developed a flexible and disposable humidity sensor on a paper substrate. Their screen-printed ink-based sensor demonstrates good sensing performance, stability, short response time, and good reproducibility. It is used for spatial humidity and soil moisture monitoring, as well as real-time humidity monitoring via wireless transmission to a smartphone. Asad et al. [113] presented a screen-printed flexible soil-moisture sensor array for precision agriculture. It has a high sensitivity for relative humidity and soil-moisture sensing, with a response of 144–1760 pF for 20–100% RH and a response of 40.7% pF/MC for soil-moisture content. The sensor is cost-effective, biodegradable, and offers maintenance-free monitoring for precise irrigation practices. Pranjale et al. [114] presented a low-cost, three-electrode electrochemical sensor for detecting potassium in soil, focusing on plant growth. The sensor, fabricated using screen-printing, uses 63 PET sheets with valinomycin as the ion-sensitive membrane (ISM) for K+ ions with high sensitivity.

Screen printing, while a popular technique, has several limitations that can affect its effectiveness and application. One major constraint is the resolution, which is determined by the mesh count of the screens used; higher mesh counts can achieve finer details but may also hinder ink flow and lead to clogging. This makes it challenging to reproduce highly intricate designs accurately. Material compatibility poses another challenge, as not all inks adhere well to every surface, necessitating careful selection of materials and potential pre-treatment for proper adhesion. Durability can also vary based on factors such as the type of ink and the curing process. Furthermore, scalability is an issue, as screen printing often involves significant setup costs for each color and design, making it less economical for small runs. Production time can increase with complex designs, further complicating scalability. Lastly, screen printing is not well suited for edge-to-edge printing, which can limit its versatility in specific applications.

4.3. Aerosol Jet Printing

Aerosol jet printing (AJP), a precise technique, can deposit functional inks onto substrates, enabling the creation of high-resolution patterns. This technology is particularly useful for wearable and implantable sensors, as well as for multi-functional sensors. This technique allows for the fabrication of conformal and multi-layered sensors, enabling the precise deposition of functional materials onto various substrates and facilitating in situ environmental monitoring. Tousignant et al. [115] utilized AJP to produce fully printed capacitive temperature sensors that are composed of biodegradable dielectric materials. The sensors were characterized at temperatures ranging from 22 °C to 80 °C. These capacitors demonstrated a 43 ± 6% increase in areal capacitance at 80 °C and a frequency of 501 Hz. The AJP method has been employed to deposit ruthenium dioxide (RuO2) onto graphene oxide (GO) for pH sensing [116]. The sensor exhibits a high sensitivity and rapid response time within the pH range of 4–10. This novel technique provides a cost-effective alternative to conventional rigid pH electrodes. In Fapanni et al.’s paper [117], AJP was used in microstructural techniques to increase the electrode active area and the electrochemical sensor sensitivity. The active surface area of the 3D-printed microstructures was increased by up to 130% without affecting the occupancy of the substrate. The method was adaptable and could be used in an infinite number of construction geometries.

AJP faces several challenges, including the ability to achieve high resolution and to control complex particle size and distribution, and it requires careful parameter optimization. Substrate properties, overspray, and environmental factors must be carefully controlled to maintain print quality. AJP requires specific inks and requires careful control of temperature and humidity. Scalability is another significant hurdle, as optimizing processes can be time-consuming and often relies on trial-and-error methods. The throughput of AJP is limited, necessitating strategies to enhance deposition rates without compromising quality. Consistent performance across large production volumes is also a challenge, and the costs associated with scaling AJP for mass production are substantial, emphasizing the need for cost-effective solutions. AJP’s slow throughput limits its use for large-scale production and its use in high-end, specialized applications. Moreover, the selection of suitable materials is crucial for ensuring sensor functionality while minimizing the environmental impact.

4.4. Roll-to-Roll Printing

Roll-to-roll printing presents a viable approach for mass-producing sustainable and cost-effective environmental sensors. It allows for high-volume production, enabling sensors that can conform to various surfaces while reducing energy consumption and waste generation. Environmental sensors are increasingly being produced with reduced manufacturing costs and time, making them ideal for wide-area monitoring systems like air quality or climate monitoring networks. Phung et al. [118] proposed a hybrid device-fabrication process using roll-to-roll (R2R) printing methods for the efficient and eco-friendly mass production of devices. The device consists of four layers of polymer insulating and conductive circuit layers screen-printed onto a PET film. Registration control methods are used to ensure the substrate’s integrity. The device is designed for personal environmental monitoring, a crucial aspect of human welfare and sustainable development. A monitoring system has been developed to collect and process data, which can be used for local or global monitoring, paving the way for big data analysis and forecasting. Phung et al. [119] showed the utilization of R2R printing in the production of an IoT device, which can decrease mass production costs and expedite the fabrication process. Easy assembly and Bluetooth communication with end-user devices are enabled by the device’s four-layer circuit platform, solder paste layer, and conductive layers. This procedure could be implemented in a variety of electronic applications that are more customizable.

Roll-to-roll (R2R) printing faces limitations in producing high-quality electronic and optoelectronic devices. Resolution constraints, material compatibility issues, scalability, and precise control over parameters are significant challenges. Inks and substrates can limit fine-line printing, while material compatibility and scalability are also significant considerations. Moreover, maintaining high resolution and consistent material deposition remains a technical challenge, which affects the reliability and accuracy of R2R-printed sensors [120]. Despite these challenges, R2R printing offers a cost-effective solution for monitoring environmental conditions.

4.5. Gravure Printing

Gravure printing is a high-throughput technique for mass-producing low-cost, disposable sensors, particularly for environmental monitoring. This technique transfers functional inks onto a substrate, producing thin, uniform layers with precise control over their thickness. Sharma et al. [121] substituted a water-based ink for a solvent-based ink in gravure printing to mitigate volatile organic compound emissions and the carbon footprint without compromising quality. By employing laser-engraved cylinders, the cost of printing polyethylene terephthalate film was reduced by USD 1.85, resulting in a decrease in volatile organic compound emissions from 3373 ppm to 2478 ppm and a reduction in the carbon footprint of 3.04 kg. In gravure printing applications, this research proposed a standard for green manufacturing systems. Robust and precise screen and gravure printing techniques have been employed to create a humidity sensor that is based on porous paper (PPHS) [58]. PPHS exhibits high sensitivity, repeatability, stability, and insensitivity to mild temperature fluctuations. The device’s high sensitivity is a result of its robust printing and large specific surface area, rendering it suitable for a variety of applications, including humidity sensing, breath detection, proximity detection, and non-touch switches.

Gravure printing, despite its high-resolution potential in electronics manufacturing, faces limitations such as resolution constraints, material compatibility issues, and scalability. These issues arise from proximity effects, material compatibility, and a lack of understanding of the underlying physics of the gravure printing process. Moreover, the high initial setup cost for gravure-printing engraved cylinders can be a challenge for small-scale or customized production. Gravure printing also presents a challenge due to the nature of low-viscosity inks and formulations, which render layer functionality difficult, particularly for composite materials such as electrodes [122]. Additionally, it is necessary to conduct new research on the formulation and preparation process of gravure ink in order to influence material changes. Despite its potential, gravure printing is particularly effective for large-area sensor networks.

4.6. 3D Printing

Three-dimensional (3D) printing is a transformative technology in sensor fabrication, offering design freedom and material versatility. It is particularly useful for creating integrated sensor systems for environmental monitoring, such as self-contained IoT-enabled devices. Three-dimensional (3D)-printed gas sensors with porous structures enhance gas diffusion and sensitivity. A room-temperature ammonia gas sensor was developed by 3D printing it with an n-type copper oxide semiconductor [123]. Fused deposition modeling and sintering were employed to fabricate the sensor, which exhibited high stability, good repeatability, low humidity dependency, high sensitivity, and selectivity toward ammonia. There was a linear increase in the sensor response as the concentration of NH3 increased. On the basis of resistance change or direct electron transfer between ammonia molecules and CuO, the sensor’s sensing mechanism was proposed. Kalsoom et al. [124] developed a 3D-printable composite material for a humidity sensor by combining boron-doped diamond (BDD) and LiCl in acrylonitrile butadiene styrene (ABS). A low-cost fused deposition modeling (FDM) 3D printer was employed to rapidly fabricate a one-piece humidity sensor using the material. The sensor exhibited excellent sensitivity, rapid response, and recovery time. The evaluation also included an assessment of its long-term stability and repeatability. The material was also employed to develop a sensor that was specifically designed to monitor the humidity of the N2 supply.

Additive manufacturing offers design flexibility and customization but has limitations. Three-dimensional (3D)-printing machinery, which produces layer-by-layer 3D assemblies, can revolutionize industries by reducing fabrication costs, allowing customer control, and minimizing international transit [125]. It also impacts logistics by allowing logistics departments to manage the entire process. Moreover, challenges like slower production speeds and higher costs of specialized materials pose challenges for its widespread adoption in large-scale environmental monitoring networks.

4.7. Hybrid Printing Techniques

Hybrid printing techniques combine multiple printing methods, allowing for the creation of multi-functional sensors with optimized performance and versatility. For instance, combining screen printing for bulk layers with inkjet printing for fine details allows for the creation of sensors that are both durable and precise. Similarly, integrating 3D printing with aerosol jet printing facilitates the production of complex, multi-layered sensors for advanced applications. This integration enables the development of sensors that incorporate complex circuitry, diverse materials, and multiple functionalities, potentially leading to more robust and versatile environmental monitoring solutions. Verma et al. [126] designed a piezoresistive pressure sensor that was fully printed and created using hybrid printing, i.e., using aerosol jet printing and screen printing. Electromechanical testing was conducted on the sensor to assess its sensitivity, reproducibility, hysteresis, and time drift. The sensor indicated two sensitive regions, with an average sensitivity of 106 ω/MPa and a low sensitivity of 7.6 ω/MPa. As a smart prosthetics guide, the sensor’s performance caters to the requirements of biomedical applications. Moreover, the early stages of hybrid additive manufacturing systems, which combine fused deposition modeling (FDM) with inkjet printing, have enabled the color patterning of 3D-printed structures [127]. These systems are scalable, capable of producing structures with hundreds of layers, and have well-defined filament/ink and formulation requirements. The work illustrated the potential for the integration of bioelectronics and neuromorphic behavior into personalized, multilayer devices by demonstrating the rapid fabrication of neuromorphic transistors using commercially available materials.

Hybrid printed sensors are revolutionizing environmental applications, particularly in air quality monitoring. These sensors can detect harmful gases like NO2 and VOCs with high accuracy, providing real-time data for regulatory compliance and urban planning [44,128]. They also measure water quality parameters like pH and heavy metals, preventing health hazards from contaminated drinking water. However, challenges include sensitivity and specificity issues, environmental stability, and scalability. Ensuring long-term reliability and consistent manufacturing processes is crucial for the success of these sensors. Additionally, variability in sensor performance may complicate their deployment in larger-scale monitoring networks.

4.8. Future Prospects of Printing Techniques

The evolution of printing methods is transforming the field of environmental monitoring, enabling the development of sensors with higher sensitivity and accuracy. Table 3 presents a comparative analysis of six printing techniques used in the fabrication of sensors for environmental monitoring applications, considering key performance factors such as resolution, scalability, material compatibility, sensor durability, speed, and application suitability. Inkjet printing and aerosol jet printing are distinguished by their high resolution, enabling the production of fine, detailed sensor patterns, making them ideal for miniaturized and high-sensitivity applications, such as portable or wearable sensors. In contrast, screen printing and gravure printing are more suited for large-scale production of durable sensors with moderate resolution and high scalability, making them appropriate for industrial or outdoor environmental monitoring systems. Roll-to-roll printing offers very high scalability for continuous processing, allowing for cost-effective mass production but with medium resolution, making it suitable for large-area sensor networks. Additionally, 3D printing provides exceptional material flexibility and the ability to integrate multi-material structures, which is advantageous for creating customized, complex sensor designs. However, its speed and scalability remain more limited. Overall, the choice of printing method depends on the specific requirements of the environmental monitoring application, balancing factors such as sensor sensitivity, production scale, and material compatibility.

Table 3.

Comparison of printing techniques.

The integration of printing technologies with smart manufacturing systems and real-time monitoring will lead to the production of next-generation sensors tailored to diverse environmental challenges. Hybrid printing methods, for example, can balance durability, precision, and functionality, providing comprehensive data for environmental monitoring networks. The demand for highly customizable, scalable, and cost-effective devices will shape the future of printed sensors for environmental monitoring. The combination of advanced printing techniques and sensor technology will pave the way for more efficient, sustainable, and comprehensive environmental monitoring systems, contributing to more efficient and sustainable solutions for addressing global environmental challenges.

4.8.1. Integration with IoT and AI Technologies

AI has emerged as a potential solution to environmental problems as technology has seen a significant evolution. AI is a critical tool in environmental engineering due to the adaptability and generalization that machine learning and deep learning models provide. Nevertheless, the process of data collection is time-consuming and tedious [118]. The Internet of Things (IoT) is also transforming various sectors, including industry and everyday life, requiring a focus on sustainability [136]. The use of flexible, printed, or wearable electronics is crucial for providing a green power supply and for ensuring the satisfaction of the present generation’s needs without compromising future generations’ potential. Sustainability is centered on ecology and the environment, and everyone contributes to this development model. The IoT technology, which powers various sectors, has the potential to optimize production processes, manage services, and reduce resource consumption. However, the increasing connectivity of IoT devices and systems also raises environmental concerns. The use of eco-compatible materials, such as flexible electronics, is gaining popularity due to their portability, wearability, and low cost, making them a promising solution for an increasingly green IoT.

The integration of printed sensor technology with the Internet of Things and artificial intelligence has revolutionized environmental monitoring. This allows for real-time monitoring of environmental parameters across various areas, enabling rapid decision-making and timely interventions. AI-integrated IoT-based flexible electronics, including RFID, sensors, memories, and energy harvesters, are being developed using biodegradable materials and eco-friendly structures [137]. Both organic and inorganic materials are promising for the sustainability of electronics, but further development is needed to improve their stability, functionality, and environmental sustainability. Moreover, AI and machine learning algorithms also enhance the processing and analysis of large data volumes, enabling the detection of patterns and predicting future environmental trends. This combination holds great promise for developing adaptive, responsive, and real-time environmental monitoring systems.

4.8.2. Self-Powered Printed Sensors

Printable techniques for self-powered sensors have gained interest due to their potential to revolutionize flexible and mobile electronics. Materials like conductive inks, CNTs, and metal nanoparticles are used for electrodes and conductive paths, while flexible substrates provide mechanical flexibility. Energy harvesting and storage technologies like printable batteries and supercapacitors enable self-powered sensor systems. Modern technologies, such as inkjet and 3D printing, allow for precise control of geometric shapes and the design of sensors.

Remote monitoring applications have been significantly enhanced by self-powered environmental sensors, which can extract energy from the environment through various methods such as solar, thermal, or vibrational harvesting. These sensors are particularly well suited for regions that lack conventional power sources; e.g., they can continuously monitor air quality without external power. Power consumption is a critical and challenging design consideration in the development of sensors in an environmental monitoring system. Lee et al. [138] proposed low-cost environmental monitoring systems by employing polymer composites for humidity and CO2 sensing due to their high sensitivity, low cost, and low power consumption. Wu et al. [139] developed a self-sustaining multi-sensor device for indoor environmental monitoring that employs organic materials to detect CO2 and humidity. The platform operates at room temperature without the use of infrared transceivers or heating, resulting in a reduction in power consumption to 10 µW and 5 µW, respectively. A CMOS system-on-chip (SoC) has been developed to amplify and read out numerous sensor signals with low power consumption, thereby demonstrating a valid self-powered device for prolonged operations.

Since large-area monitoring is not feasible by employing conventional sensors due to their cost, printed electronics offer an economical solution for environmental monitoring of large areas. Farooqui et al. [140] presented a disposable, compact, and dispersible 3D-printed wireless sensor node with integrated microelectronics for large-area environmental monitoring. The sensor nodes can work in conjunction with fixed nodes, detecting temperature, humidity, and H2S levels, which are crucial for forest fires and industrial leaks. The combination of 3D printing and inkjet printing creates a low-cost, fully integrated wireless sensor node.

However, the advancement of printable manufacturing for entirely integrated and self-powered electronic sensors still faces numerous challenges. These include optimizing printing resolution, further developing manufacturing processes, and ensuring material and substrate compatibility [28].

5. Applications of Printed Sensors for Environmental Monitoring

Printed sensors are being considered a paradigm shift in environmental monitoring due to their scalability, low cost, and versatility. Climate monitoring, soil analysis, water quality testing, and air quality monitoring are among the numerous domains in which these sensors have been successfully implemented. In addition to offering valuable insights for both policymakers and the public, printed sensors facilitate proactive responses to environmental issues by providing real-time, on-site measurements. In the context of global sustainability initiatives, this section examines the numerous applications of printed sensors in environmental monitoring, emphasizing their benefits, obstacles, and the increasing necessity for continuous data.

5.1. Air Quality Monitoring

Air pollution is a global environmental issue that significantly impacts various health issues, such as premature deaths, heart diseases, and lung diseases [141]. Although standard air quality monitoring stations are effective, their deployment in developing countries or remote areas is often restricted by their high cost and the requirements for extensive infrastructure. However, printed sensors offer a cost-effective alternative that can be implemented in extensive networks to guarantee continuous air quality monitoring, even in regions where conventional methods are unfeasible.

Common pollutants, including nitrogen dioxide (NO2), carbon monoxide (CO), particulate matter PM2.5, PM10, sulfur dioxide (SO2), and ozone (O3), are frequently monitored using printed gas sensors [142]. Recent advancements in sensing technologies, such as porphyrin- and graphene-based electrochemical sensors, enable rapid and sensitive detection of pollutants like organic pollutants, biological contaminants, and heavy metals [143]. These sensors are ideal for environmental monitoring applications and are well suited for real-time monitoring in urban areas due to their ability to detect trace levels of gases at low concentrations. Won et al. [144] reported a fully printed ZnO/reduced graphene oxide (rGO) gas sensor for NH3, that exhibited fast response/recovery times, as well as a good linear response at 40–80 ppm. Khan et al. [145] fabricated a direct-ink-printed graphene oxide/alkali lignin chemiresistor for NO2, achieving high sensitivity at room temperature. Table 4 shows the performance parameters comparison of the sensors.

Table 4.

Comparison of air quality monitoring sensors.