Abstract

This study aimed to thoroughly investigate the quality differences and influencing factors of Dahongpao tea of different grades. Through sensory evaluation, electronic nose analysis, electronic tongue analysis, biochemical component analysis, and HS-SPME-GC-MS, the taste and aroma characteristics of Dahongpao samples of different grades (superfine, first, and second grades) were comprehensively studied. The results showed that there were significant differences in sensory quality, aroma components, and taste components among Dahongpao of different grades. Superfine Dahongpao has a rich aroma and mellow taste, containing a higher content of esters and aromatic hydrocarbons such as benzaldehyde (2-hydroxy-5-methoxy), hexyl benzoate, and cyclohexanecarboxylic acid 2,3-dichlorophenyl ester, which endow it with fruity, floral, and woody characteristics. In contrast, first- and second-grade Dahongpao contain more alkanes, pyrazines, and furans such as benzene (1-ethyl-1-propenyl), dodecane (2,6,10-trimethyl), and pyrazine (2,6-dimethyl), which impart floral, roasted, and nutty flavors. Moreover, superfine Dahongpao has a more bitter and astringent taste, but the bitterness and astringency dissipate more quickly, while the taste of first- and second-grade Dahongpao is relatively bland. These differences provide a scientific basis for the grade classification of Dahongpao tea and offer references for improving tea quality and standardized production.

1. Introduction

Tea, a traditional Chinese beverage with a rich history and diverse types, varies significantly in quality levels. Among them, Dahongpao, a renowned oolong tea, is celebrated globally for its unique aroma and exceptional quality [1]. Dahongpao, produced in Wuyi Mountain, Fujian Province, is not only a symbol of deep cultural heritage but also a key element of Chinese tea culture. As the tea market continues to evolve and consumer demand for premium teas grows, research into the quality evaluation and grade classification standards of Dahongpao has become increasingly important.

The national standards for Dahongpao define strict guidelines for grade classification, which are closely linked to both its commercial value and the tea-drinking experience of consumers. Variations in grade lead to distinct differences in aroma, taste, and appearance. Therefore, investigating the relationship between grade differences in Dahongpao national standard samples and their quality and aroma is of significant theoretical and practical importance. Such research can enhance tea quality, refine production and processing techniques, and guide consumer choices.

Currently, tea grades are primarily determined through sensory evaluation, with taste and aroma being key factors in this process [2]. The taste quality of tea is judged by analyzing key components in tea liquor, such as tea polyphenols, caffeine, soluble sugars, catechins, and free amino acids, which contribute to bitterness, astringency, sweetness, and umami flavors. The electronic tongue, a multi-sensor system, has proven particularly useful for analyzing liquid-phase foods and has seen significant development over the past decade [3]. Although the electronic tongue has been widely used in tea quality identification, classification, and control, such as grade research and origin identification [4], there has been no significant use of this technology for grade classification of Dahongpao national standard samples. For example, Ren et al. [5] utilized the electronic tongue to differentiate the grades of 700 black tea samples with a correct discrimination rate of 99.14%.

Aroma is equally vital for tea grade classification, particularly for oolong teas like Dahongpao [6]. The aroma is evaluated by analyzing the volatile compounds in tea. Electronic nose technology and gas chromatography (GC)–mass spectrometry (MS) are widely used for characterizing and identifying aroma differences in various foods, including wine [7] and sesame oil [8]. To date, more than 700 volatile compounds have been identified in tea, with over 300 specific to oolong tea [6,9]. Numerous studies have explored the aroma profile of Dahongpao, including investigations into how roasting affects volatile compound content, aroma intensity, and olfactory characteristics [10,11]. While previous studies have explored aroma profiles of Dahongpao under specific processing conditions [10,11] or non-standardized samples [6], systematic investigations on nationally graded teas remain scarce. Prior research has predominantly relied on isolated techniques (e.g., electronic tongue [5], GC-MS [12], or sensory evaluation [13]) for tea quality assessment, often focusing on non-standardized samples. For instance, Ren et al. [5] differentiated 700 black tea grades using electronic tongue alone but lacked chemical validation of sensory differences. Similarly, Lin et al. [12] investigated roasting effects on aroma in single-grade teas but overlooked national standard grading systems. These limitations—dependency on single analytical approaches or non-standardized samples—hinder a comprehensive understanding of the multidimensional factors (chemical, sensory and processing) driving grade differences. To address these gaps, this study uniquely bridges the literature by analyzing Chinese national standard samples (GB/T 23776-2018) through a multimodal framework integrating sensory evaluation, electronic nose/tongue, biochemical profiling, and HS-SPME-GC-MS. The dual objectives of the present study are (1) to establish a robust methodology for grade differentiation and (2) to identify quantifiable chemical markers that support the refinement of tea grading standards.

However, existing studies are limited to single analytical techniques (e.g., e-tongue or GC-MS) or non-standardized samples, lacking systematic investigations of national standard graded samples. This study pioneered the integration of sensory evaluation, electronic nose/tongue, biochemical analysis, and HS-SPME-GC-MS to systematically decode the chemical and sensory basis of grade differences in Dahongpao national standard samples, addressing critical literature gaps and providing scientific support for standard refinement.

2. Materials and Methods

2.1. Sample Collection

Three national standard Dahongpao samples of different grades—superfine (SP), first grade (FT), and second grade (SE)—were provided by the Wuyishan Market Supervision Bureau and the Wuyishan Tea Industry Association. The samples were marked with serial number GSB16-1524-2022, valid from 3 December 2021 to 2 December 2024. All samples were strictly screened according to the sensory quality regulations outlined in the Chinese national standard “Method for Sensory Evaluation of Tea” (GB/T 23776-2018) [13]. Part of each sample was ground through a 0.2 mm sieve, and both ground and unground portions were stored at −20 °C for subsequent experiments.

2.2. Experimental Reagents

C10–C40 (even-numbered) n-alkane standards (50 mg/L, 1 mL; O2si Smart Solutions, Charleston, SC, USA) were purchased from O2si Smart Solutions, a subsidiary of LGC Standards (Charleston, SC, USA). KCl (≥99.0%, Sigma-Aldrich, St. Louis, MO, USA), L-(+)-tartaric acid (≥99.5%, Sigma-Aldrich, St. Louis, MO, USA), Folin–Ciocalteu reagent (Sigma-Aldrich, St. Louis, MO, USA), Na2CO3 (≥99.5%, Sigma-Aldrich, St. Louis, MO, USA), grade acetonitrile (HPLC, Sigma-Aldrich, St. Louis, MO, USA), formic acid (≥98%, Sigma-Aldrich, St. Louis, MO, USA), theanine standard (≥98%, Sigma-Aldrich, St. Louis, MO, USA), ninhydrin (Sigma-Aldrich, St. Louis, MO, USA), caffeine standard (≥99%, Sigma-Aldrich, St. Louis, MO, USA), anthrone (97%, Sigma-Aldrich, St. Louis, MO, USA), D-glucose standard (≥99.5%, Sigma-Aldrich, St. Louis, MO, USA), aluminum chloride hexahydrate (≥99%, Sigma-Aldrich, St. Louis, MO, USA), DVB/CAR/PDMS solid-phase microextraction fiber (50/30 μm, Supelco, Cat. No. 57348-U; Supelco, Bellefonte, PA, USA), and catechin standards: EGCG (≥98%, Solarbio, Beijing, China), EC (≥98%, Solarbio, Beijing, China), C (≥98%,Solarbio, Beijing, China), CG (≥98%, Solarbio, Beijing, China), GC (≥98%, Solarbio, Beijing, China), GCG (≥98%, Solarbio, Beijing, China), ECG (≥98%, Solarbio, Beijing, China), and EGC (≥98%, Solarbio, Beijing, China) were utilized.

2.3. Sensory Evaluation

Following GB/T 23776-2018, “Method for Sensory Evaluation of Tea” [13], 10 qualified tea tasters with extensive experience were invited to perform sensory evaluations on three tea samples. All 10 expert evaluators have national tea sensory evaluation certifications (GB/T 23776-2018), with more than 5 years of experience in Wuyi rock tea evaluation. Prior to the experiment, panelists underwent standardized training using national reference samples (GSB16-1524-2022) to calibrate scoring criteria for appearance, soup color, aroma, taste, and infused leaves. They evaluated and scored the appearance, soup color, aroma, taste, and leaf residue based on a 100-point scale. Samples were presented with randomized three-digit codes, and grade information was concealed during evaluation to prevent bias. The total sensory quality score was calculated using the following formula:

Total Score = Appearance × 20% + Soup Color × 5% + Aroma × 30% + Taste × 35% + Leaf Residue × 10%

2.4. Electronic Nose Analysis

Volatile compounds were analyzed using the PEN3 electronic nose (Airsense Analytics GmbH, Rostock, Germany) using the method described by Xia et al. [14]. Briefly, 10 g of the Dahongpao sample was placed in a 250 mL glass beaker with 10 mL of boiling water. The container was sealed with plastic wrap and allowed to stand for 30 min to ensure gas equilibrium. The measurement was performed for 90 s with a pre-sampling time of 5 s and a gas flow rate of 0.4 L/min. Each sample was triplicated.

2.5. Electronic Tongue Analysis

The taste of the tea soup was analyzed using the SA402B Puls electronic tongue (Insent Intelligent Sensor Technology, Inc., Kanagawa, Japan) following Ren et al. [5]. Briefly, 0.5 g of tea leaves was weighed (accurate to 0.001 g), and 25 mL of boiling distilled water was added. The mixture was shaken and allowed to steep for 3 min before filtering. The tea soup was then diluted to 250 mL and cooled to room temperature for 20 min. A 40 mL sample was used for electronic tongue analysis, with experiments repeated three times.

For sensor calibration, a solution of 30 mmol/L potassium chloride and 0.3 mmol/L tartaric acid (in a 1:1 volume ratio) was used. The sensor was placed in this reference solution for 30 s to zero the instrument. Each sample was compared with the reference solution, with a cleaning time of 5 min, sample measurement time of 30 s, and an aftertaste evaluation for 30 s. Each sample was triplicated.

2.6. Biochemical Component Analysis

The tea polyphenols were determined according to Chinese national standard GB/T 8313-2018 [15]. Briefly, 0.2 g of tea was extracted with 5 mL of 70% methanol solution preheated in a 70 °C water bath for 10 min. The supernatant was collected, and the process was repeated before combining the extracts and diluting to 10 mL. The absorbance was measured at 765 nm after addition of Folin phenol reagent and sodium carbonate solution.

For catechin content (C, EC, ECG, CG, GC, EGC, GCG, and EGCG), HPLC analysis was conducted using the same GB/T 8313-2018 method [15]. Theanine content was determined using HPLC according to GB/T 23193-2017 [16]. For free amino acid analysis, the ninhydrin colorimetric method outlined in GB/T 8314-2013 was employed [17]. Caffeine content was analyzed following GB/T 8312-2013 [18], where 2 g of tea was extracted with 80 mL boiling distilled water and analyzed spectrophotometrically at 274 nm.

Additionally, the anthrone colorimetric method and aluminum trichloride colorimetric method [19] were used to measure soluble sugar and flavonoid contents, respectively.

2.7. HS-SPME-GC-MS Analysis

Headspace solid-phase microextraction (HS-SPME) combined with gas chromatography–mass spectrometry (GC-MS) was used to analyze volatile compounds in tea [20]. After equilibrating tea samples at room temperature for 1 h, 0.5 g of tea powder was placed in a 20 mL headspace vial, sealed, and held at 60 °C with stirring for 30 min. A 50/30 μm DVB/CAR/PDMS extraction fiber was inserted into the vial for 30 min of headspace extraction, followed by desorption at 240 °C for 5 min. GC-MS separation was performed using an Agilent HP-5MS column (30 m × 0.25 mm, 0.25 μm). The temperature program was set as follows:

Initial temperature: 50 °C for 2 min.

Ramp to 80 °C at 2 °C/min, held for 4 min.

Ramp to 180 °C at 5 °C/min, held for 5 min.

Ramp to 220 °C at 10 °C/min, held for 10 min.

Helium was used as the carrier gas at a flow rate of 1.0 mL/min, with no split injection. Ion source: 230 °C; scan range: m/z 45–500. Volatile compounds were identified by comparing mass spectra with the National Institute of Standards and Technology (NIST) Mass Spectral Library (version 8.0). Compound identification criteria were that the matching degree of NIST 8.0 library was >90%. External standards (C10–C20) were injected under the same GC-MS conditions for compound quantification.

2.8. Statistical Analysis

Data were analyzed using SPSS Version 13 for one-way analysis of variance. Graphical analyses, including heat maps, radar plots, PCA, Venn diagrams, volcano plots, K-means clustering, and OPLS-DA graphics, were generated using R 3.3 software (Boston, MA, USA).

3. Results and Discussion

3.1. Sensory Evaluation and Electronic Nose Analysis of Dahongpao of Different Grades

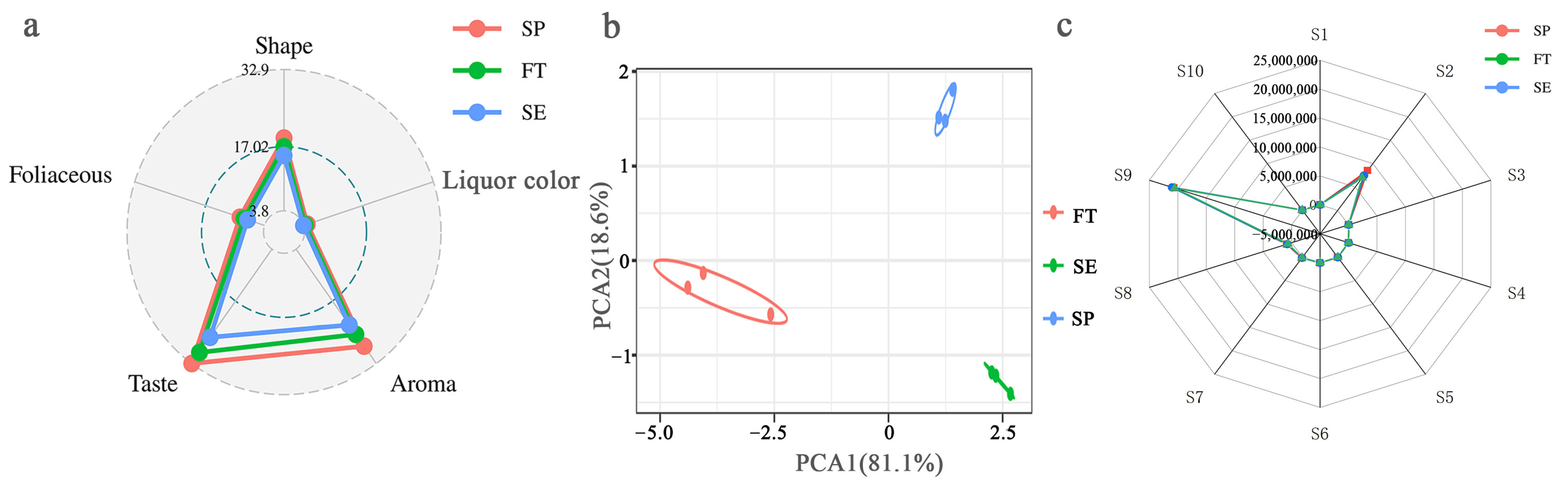

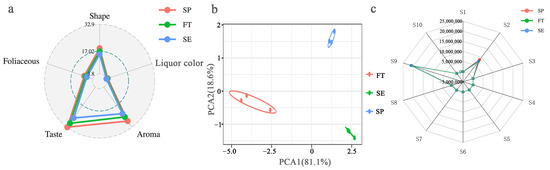

- The sensory evaluation of Dahongpao tea samples of different grades (Figure 1a, Table S1) revealed significant differences in appearance, soup color, aroma, taste, and leaf bottom. Across these five sensory attributes, quality was consistently ranked as SP (special grade) > FT (first grade) > SE (second grade). The average total sensory scores were 94.15 for SP, 85.2 for FT, and 75.95 for SE. Notably, in the sensory evaluation of Wuyi rock tea, aroma and taste were the most influential factors, contributing 30% and 35% to the total score, respectively. This indicates that variations in aroma and taste were the primary determinants of grade differences in Wuyi rock tea;

Figure 1. Sensory evaluation and electronic nose analysis of three grades of Dahongpao. (a) Radar chart showing sensory scores for appearance, soup color, aroma, taste, and leaf bottom. (b) Principal component analysis (PCA) of aroma components based on electronic nose data. (c) Radar chart displaying electronic nose sensor response patterns. SP, FT, and SE represent special grade, first grade, and second grade, respectively.

Figure 1. Sensory evaluation and electronic nose analysis of three grades of Dahongpao. (a) Radar chart showing sensory scores for appearance, soup color, aroma, taste, and leaf bottom. (b) Principal component analysis (PCA) of aroma components based on electronic nose data. (c) Radar chart displaying electronic nose sensor response patterns. SP, FT, and SE represent special grade, first grade, and second grade, respectively. - Electronic nose analysis of Dahongpao tea samples from different grades (Figure 1b,c, Table S2) further supported these findings. The principal component analysis (PCA) of aroma components showed a clear distinction between grades, with PCA1 accounting for 81.1% of the variation and PCA2 for 18.6%. Significant differences were observed in the response values of sensors S2, S8, and S10, which were associated with nitrogen oxides, alcohols, and esters. The concentration of these compounds followed SP > FT > SE of the trend, indicating higher levels of aroma-active alcohols and esters in higher grade teas;

- Previous studies have shown a strong correlation between floral and fruity aromas in Wuyi rock tea and the presence of alcohols and esters [12,21]. This suggests that higher concentrations of these volatile compounds in SP contribute to its more pronounced floral and fruity notes, ultimately leading to higher aroma scores.

3.2. Electronic Tongue and Quality Index Analysis of Dahongpao of Different Grades

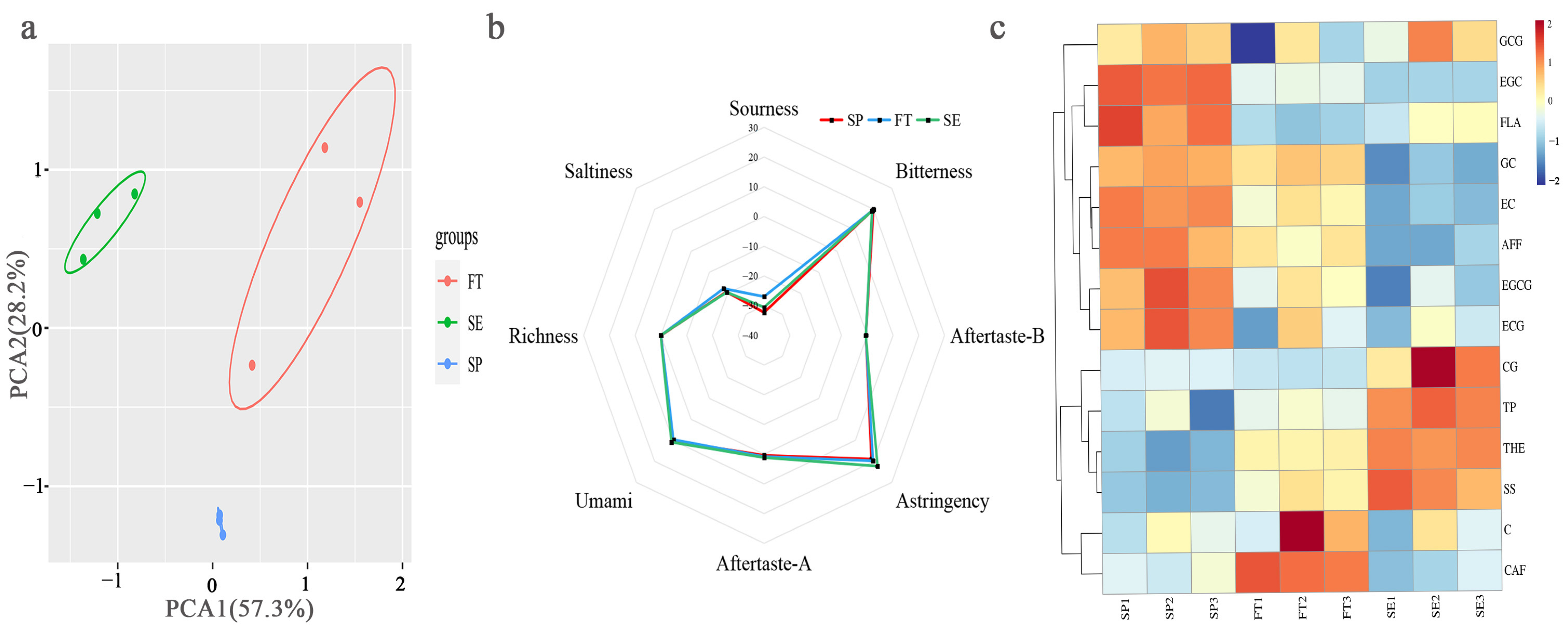

- The taste of tea soup is a significant factor in the sensory evaluation of Wuyi rock tea, with its quality closely related to the chemical composition of tea. Electronic tongues, extensively used for quality analysis of liquid foods, have proven effective in distinguishing grade differences between teas [5,22,23];

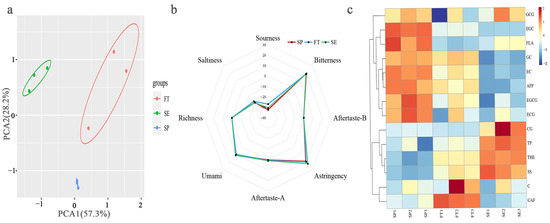

- The analysis of Dahongpao samples of different grades using an electronic tongue is illustrated in Figure 2 and Table S3. Figure 2a demonstrates that the electronic tongue effectively differentiates taste profiles among the grades. Principal component analysis (PCA) revealed that PCA1 accounted for 57.3% of the variance, while PCA2 accounted for 28.2%. Higher-grade Dahongpao teas exhibited increased bitterness yet showed reduced levels of Aftertaste-B, astringency, and Aftertaste-A;

Figure 2. Electronic tongue analysis and quality index of Dahongpao of different grades. (a) Principal component analysis (PCA) of electronic tongue data. (b) Radar map illustrating the electronic tongue analysis. (c) Heatmap of quality index components. TP: tea polyphenol; CAF: caffeine; THE: theanine; SS: soluble sugar; AFF: free amino acid; FLA: flavonoid. SP, FT, and SE represent special grade, first grade, and second grade, respectively.

Figure 2. Electronic tongue analysis and quality index of Dahongpao of different grades. (a) Principal component analysis (PCA) of electronic tongue data. (b) Radar map illustrating the electronic tongue analysis. (c) Heatmap of quality index components. TP: tea polyphenol; CAF: caffeine; THE: theanine; SS: soluble sugar; AFF: free amino acid; FLA: flavonoid. SP, FT, and SE represent special grade, first grade, and second grade, respectively. - Quality index analysis revealed that higher-grade Dahongpao had a higher catechins content, while lower-grade teas contained more tea polyphenols. Previous studies have shown that caffeine, tea polyphenols, and catechins significantly influence the bitterness and astringency of oolong tea [24,25]. These findings suggest that higher-grade Dahongpao teas possess a more intense taste profile, with bitterness and astringency dissipating more readily, contributing to a higher sensory evaluation score for taste.

3.3. Analysis of Volatiles in Dahongpao of Different Grades

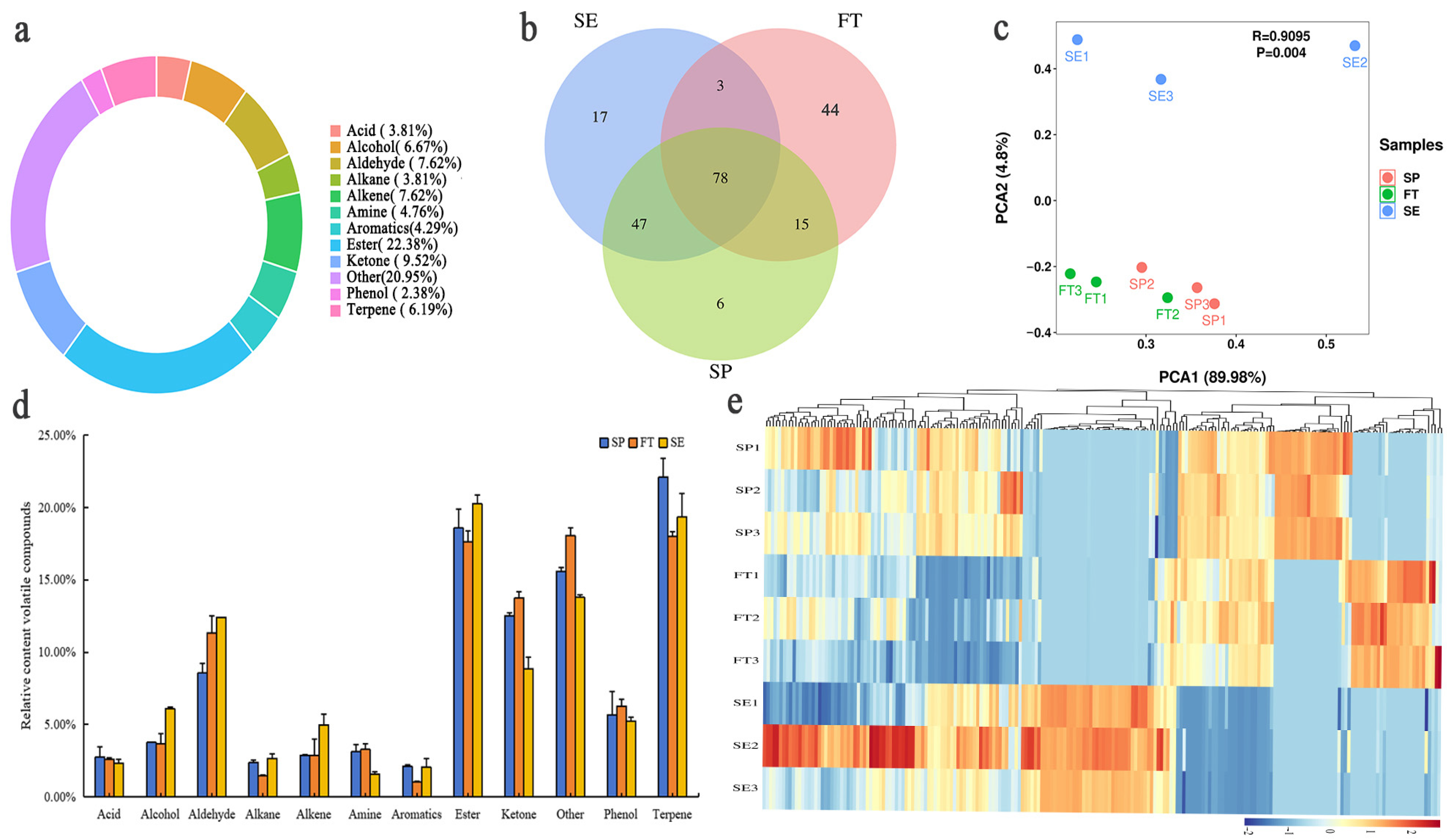

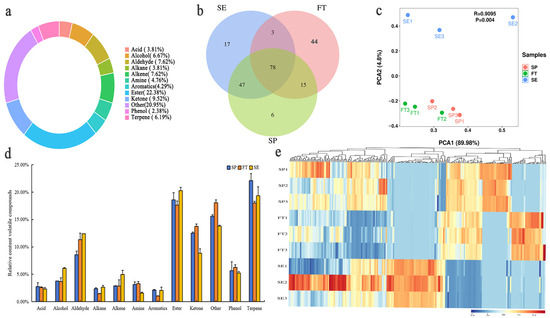

- A comprehensive analysis of 210 volatile compounds in Dahongpao of various grades was conducted using GC-MS. The identified compounds included alcohols (14 types), amines (10 types), aromatic hydrocarbons (9 types), phenols (5 types), aldehydes (16 types), carboxylic acids (8 types), terpenes (13 types), ketones (20 types), alkanes (8 types), esters (47 types), and alkenes (16 types) (Figure 3a). Among these, FT had the greatest diversity in aroma components, with 44 unique compounds, while SE had 17 and SP had only 6 (Figure 3b);

Figure 3. Volatile compound and classification analysis of three grades of Dahongpao. (a) Doughnut chart showing the number of volatile compounds classified in all Dahongpao samples. (b) Venn diagram depicting the shared and unique volatile compounds among SP, FT, and SE. (c) Principal component analysis (PCA) showing the distribution of volatile compounds across different grades. (d) Relative content of different volatile compounds in SP, FT, and SE. (e) Heatmap visualizing the normalized relative content of each volatile compound. SP, FT, and SE represent special grade, first grade, and second grade, respectively. Each row in the heatmap corresponds to a tea sample, and each column represents a volatile compound.

Figure 3. Volatile compound and classification analysis of three grades of Dahongpao. (a) Doughnut chart showing the number of volatile compounds classified in all Dahongpao samples. (b) Venn diagram depicting the shared and unique volatile compounds among SP, FT, and SE. (c) Principal component analysis (PCA) showing the distribution of volatile compounds across different grades. (d) Relative content of different volatile compounds in SP, FT, and SE. (e) Heatmap visualizing the normalized relative content of each volatile compound. SP, FT, and SE represent special grade, first grade, and second grade, respectively. Each row in the heatmap corresponds to a tea sample, and each column represents a volatile compound. - Principal component analysis (PCA) revealed that SP and FT had similar aroma profiles, as they occupied the same quadrant in the PCA plot, whereas SE was clearly separated (Figure 3c). This suggests that while SP and FT share some common aroma characteristics, SE has a markedly different profile. The analysis further indicated that terpene compounds were the most abundant across all grades, followed by esters, aldehydes, and ketones (Figure 3d);

- To further explore the quality differences between Dahongpao grades, a cluster analysis based on heatmap was performed on aroma components. The results highlight a notable enrichment of terpenes, esters, and alkenes in SP (Figure 3e). Previous studies reported that terpenes and esters contribute fruity, floral, or sweet aromas to oolong tea [26]. Specifically, terpenes are associated with floral, fruity, and woody characteristics [27], while alkenes are associated with green, floral, or fruity notes [28,29]. SP was particularly rich in terpenes with floral and fruity aromas, such as β-myrcene, cyclohexene, and α-farnesene [29,30,31,32]. FT also contained ketones with floral and fruity notes, including 3,5-octadien-2-one and bicyclo[3.3.1]nonan-2-one [33,34]. SE featured ester compounds with similar floral and fruity aromas, such as ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propane-2-yl carbonate and phthalic acid butyl hept-3-yl ester [35,36,37,38,39,40,41];

- In summary, the analysis indicates that Dahongpao of different grades has significant variations in volatile compounds, with the highest concentration of terpenes, followed by esters and ketones. These compounds are closely related to floral and fruity characteristics. Differences in aroma profiles between grades were evident; however, further research was deemed necessary to identify and characterize the key volatile compounds responsible for these differences.

3.4. Screening of Different Volatiles

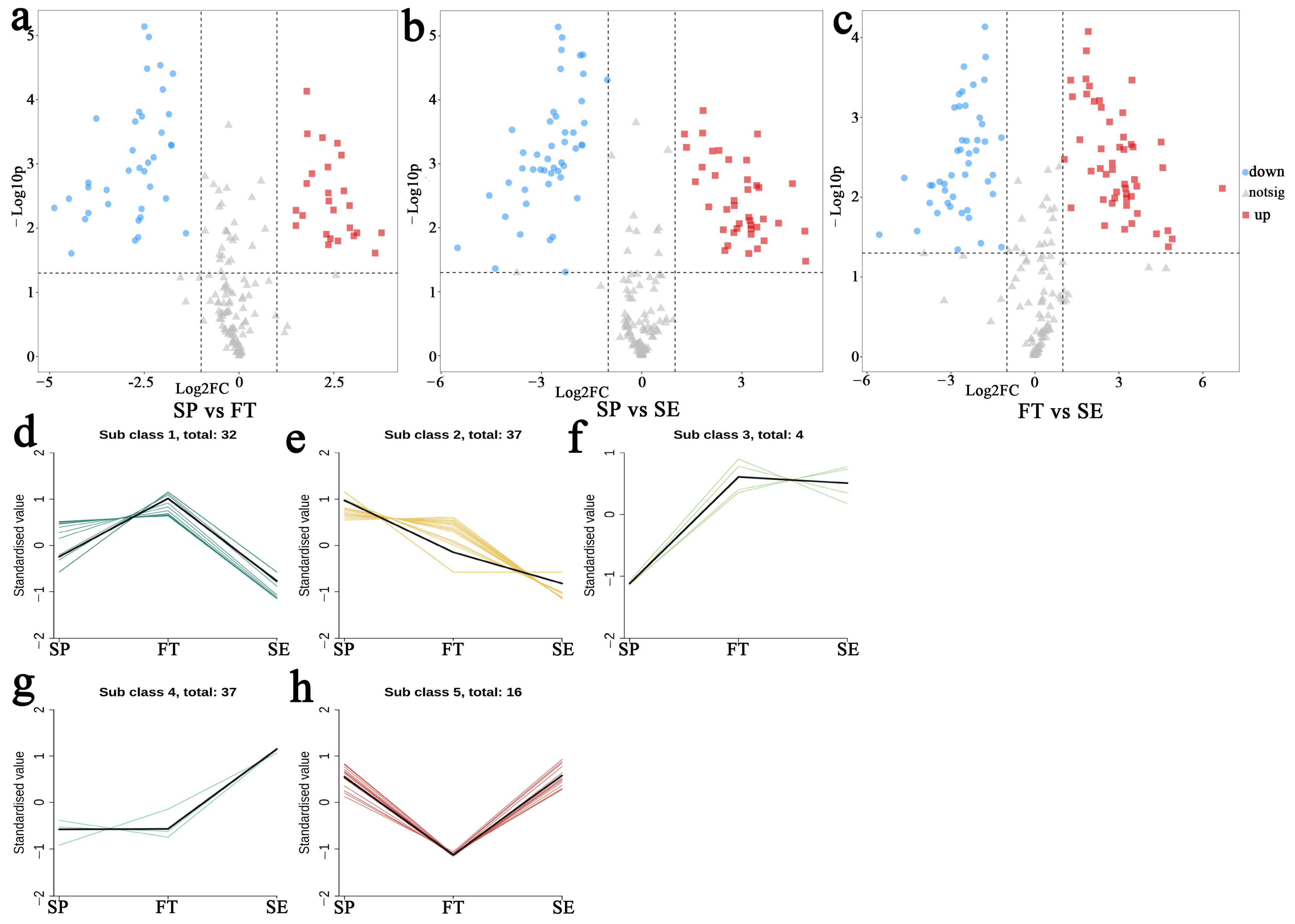

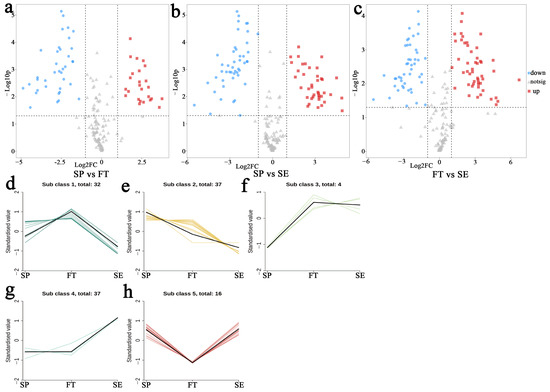

- To identify volatile compounds that differentiate Dahongpao of various grades, a volcano plot was employed to analyze the relative abundance of volatiles across grades. The analysis revealed that SP had 119 up-regulated and 57 down-regulated volatile compounds compared to FT. Conversely, FT showed 74 up-regulated and 116 down-regulated compounds when compared to SE (Figure 4a,b);

Figure 4. Two-by-two analysis of volatile differential metabolites in three grades of Dahongpao. (a) Volcano map showing the variability between SP and FT. (b) Volcano map showing the variability between FT and SE. (c–h) K-means clustering analysis of differential volatile compounds across different grades of Dahongpao. SP, FT, and SE represent special grade, first grade, and second grade, respectively.

Figure 4. Two-by-two analysis of volatile differential metabolites in three grades of Dahongpao. (a) Volcano map showing the variability between SP and FT. (b) Volcano map showing the variability between FT and SE. (c–h) K-means clustering analysis of differential volatile compounds across different grades of Dahongpao. SP, FT, and SE represent special grade, first grade, and second grade, respectively. - Further analysis using K-means clustering on the relative content changes of volatile metabolites across grades demonstrated distinct patterns (Figure 4c–g). The first subclass showed a relationship of SP ≈ FT < SE, primarily involving compounds that did not fit into the categorized groups. The second subclass and third subclass exhibited SP > FT > SE and SP > FT ≈ SE, respectively. This latter analysis identified a total of 41 substances, predominantly esters and terpenes with fruity and floral aromas. Notable compounds included hexanoic acid, tridec-2-ynyl ester, phthalic acid di(2-phenylethyl) ester, benzoic acid-hexyl ester, cyclohexanecarboxylic acid, 2,3-dichlorophenyl ester, β-myrcene, cyclohexene, 3-methyl-6-(1-methylethenyl)-(3R-trans)-, and α-farnesene;

- These findings highlight substantial differences in volatile profiles among Dahongpao grades, with specific esters and terpenes contributing significantly to differentiation. This analysis underscores the importance of these compounds in distinguishing between different grades of Dahongpao tea;

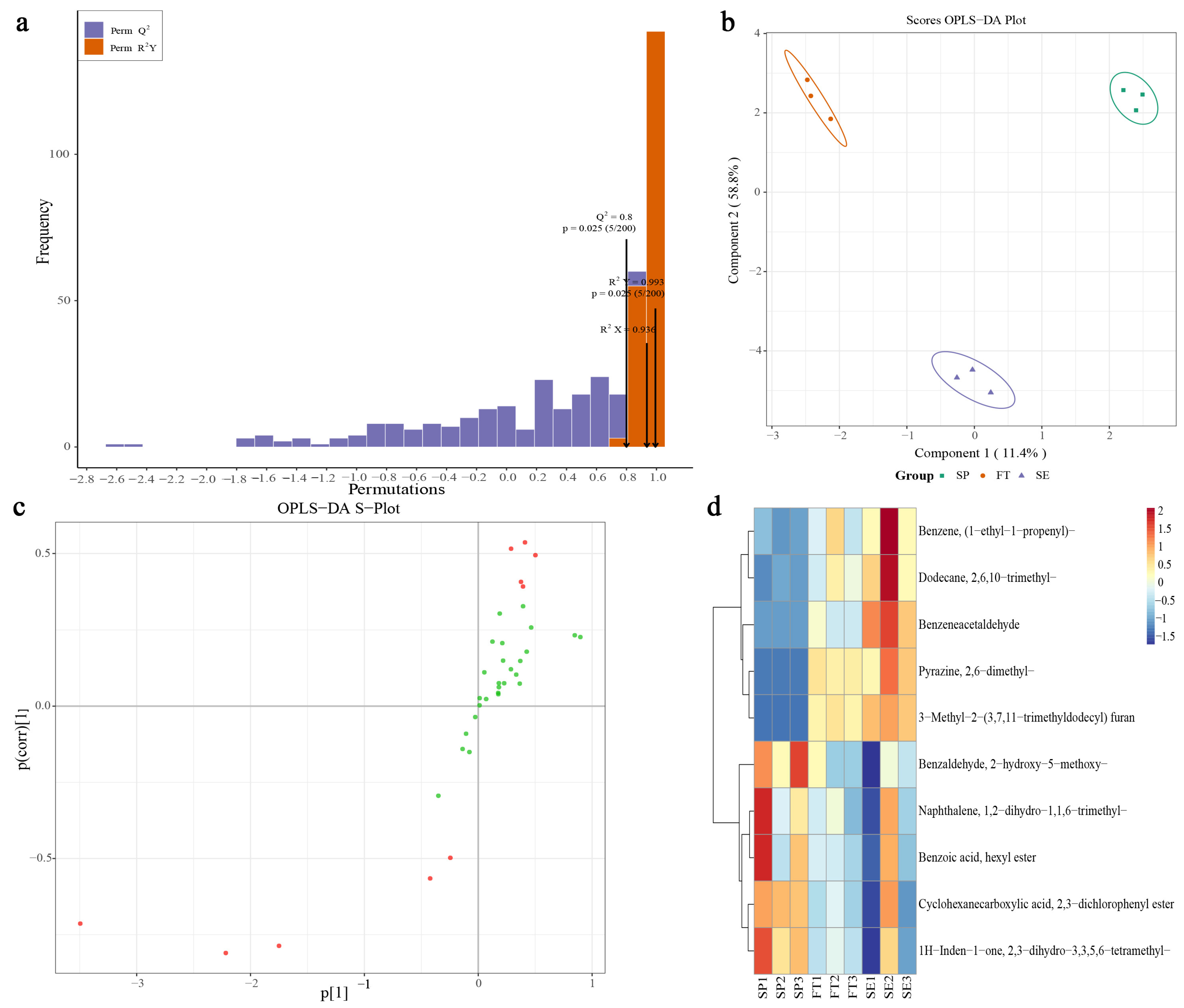

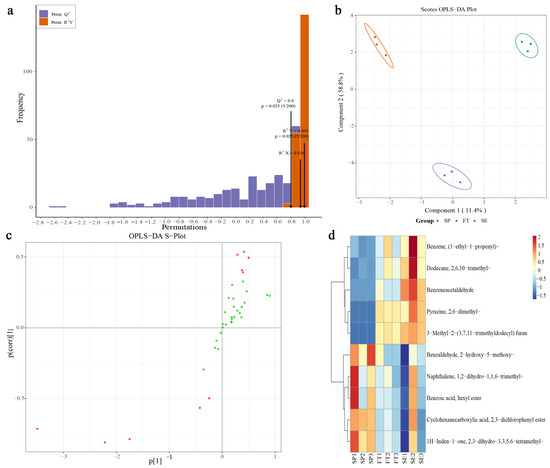

- Further analysis using OPLS-DA was conducted to identify differential substances within the first, second, and third subclasses. The results indicate that after 200 random simulations, the model demonstrated high goodness of fit (R2Y = 0.993, p < 0.025) and predictability (Q2 = 0.8, p < 0.025), suggesting robust performance (Figure 5a). The model effectively distinguished between different samples, with component 1 accounting for 11.4% of the variance and component 2 accounting for 58.8%, supporting its usefulness for further analysis (Figure 5b);

Figure 5. Screening for differentially volatile metabolites in SP, FT, and SE comparisons. (a) OPLS−DA model fit assessment for SP, FT, and SE. (b) OPLS−DA analysis and validation for the three grades of Dahongpao. (c) OPLS−DA loading plot for volatile metabolites in SP, FT, and SE. Red dots represent significantly different metabolites, while green dots represent non-significantly different metabolites. (d) Heatmap of differential metabolites across SP, FT, and SE grades. SP, FT, and SE represent special grade, first grade, and second grade, respectively.

Figure 5. Screening for differentially volatile metabolites in SP, FT, and SE comparisons. (a) OPLS−DA model fit assessment for SP, FT, and SE. (b) OPLS−DA analysis and validation for the three grades of Dahongpao. (c) OPLS−DA loading plot for volatile metabolites in SP, FT, and SE. Red dots represent significantly different metabolites, while green dots represent non-significantly different metabolites. (d) Heatmap of differential metabolites across SP, FT, and SE grades. SP, FT, and SE represent special grade, first grade, and second grade, respectively. - S-Plot analysis of the OPLS-DA model identified differential substances with VIP values > 1, resulting in the screening of 10 key compounds (Figure 5c,d). Among these, substances with the highest content in SP included benzaldehyde (2-hydroxy-5-methoxy), benzoic acid hexyl ester, cyclohexanecarboxylic acid, 2,3-dichlorophenyl ester, 1H-Inden-1-one, and 2,3-dihydro-3,3,5,6-tetramethyl, all noted for their fruity and floral aromas [32,42]. Additionally, naphthalene (1,2-dihydro-1,1,6-trimethyl) contributes a woody aroma [43]. In contrast, SE was characterized by higher levels of benzene (1-ethyl-1-propenyl), dodecane (2,6,10-trimethyl), pyrazine (2,6-dimethyl), benzeneacetaldehyde, and 3-methyl-2-(3,7,11-trimethyldodecyl) furan, which are associated with floral, roasted, or nutty flavors [44,45,46]. The high abundance of hexyl benzoate in SP (Figure 5d) aligned with its low odor threshold [25], which amplified floral perception even at trace concentrations. This mechanistic link explains the superior aroma scores of superfine-grade tea;

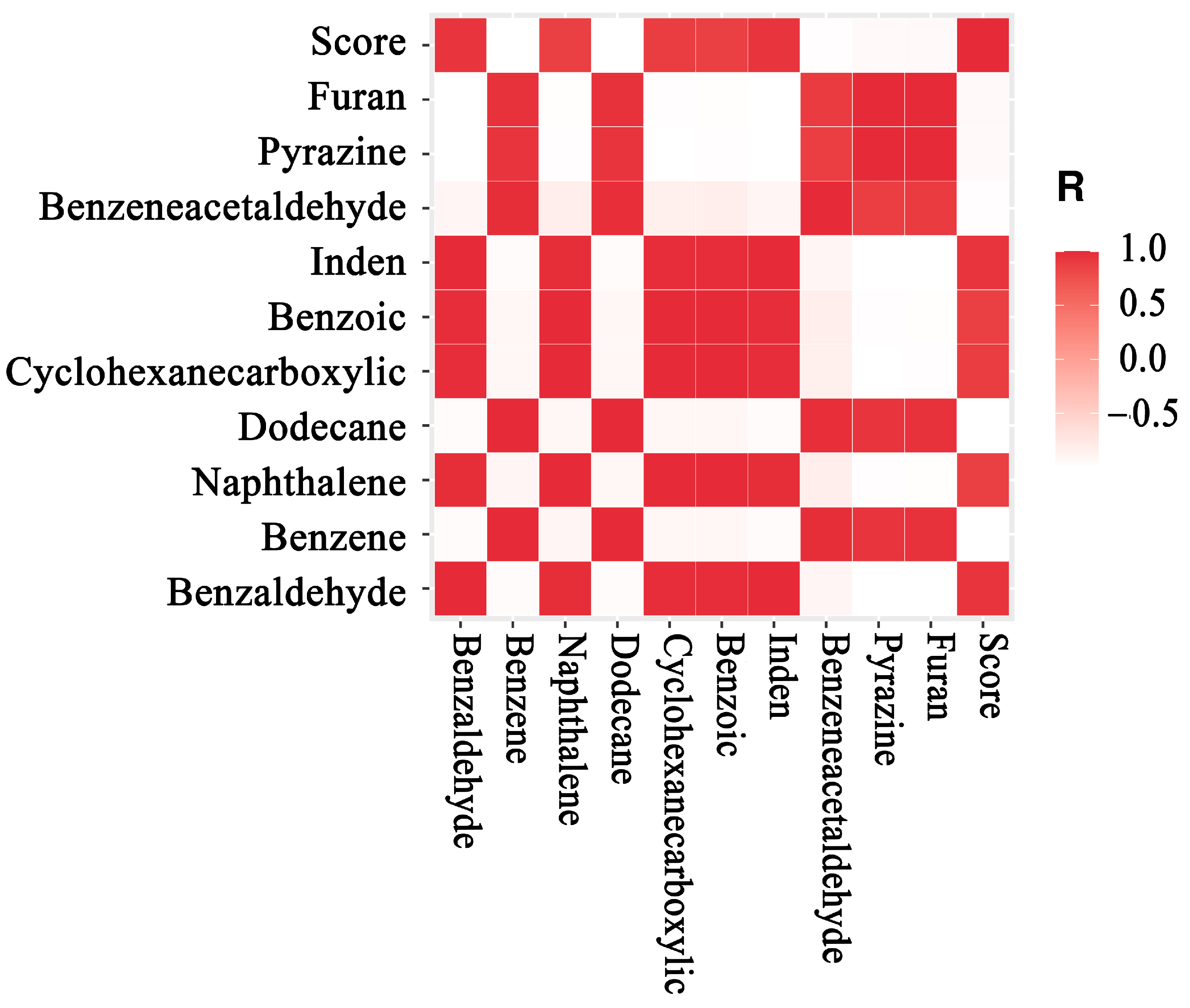

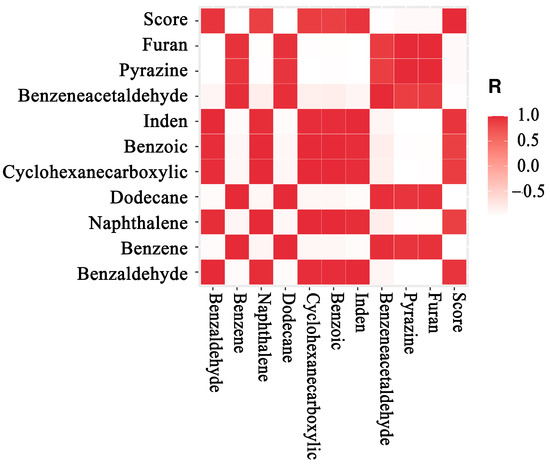

- The correlation analysis (Figure 6) indicated that compounds such as benzaldehyde (2-hydroxy-5-methoxy), benzoic acid hexyl ester, cyclohexanecarboxylic acid 2,3-dichlorophenyl ester, 1H-inden-1-one (2,3-dihydro-3,3,5,6-tetramethyl), and naphthalene (1,2-dihydro-1,1,6-trimethyl) showed a significant positive correlation with sensory evaluation scores (p < 0.05). This suggests these compounds are closely associated with enhancing the sensory attributes of the evaluated samples. Conversely, benzene (1-ethyl-1-propenyl), dodecane (2,6,10-trimethyl), pyrazine (2,6-dimethyl), benzeneacetaldehyde, and 3-methyl-2-(3,7,11-trimethyldodecyl) furan were significantly negatively correlated with sensory scores (p < 0.05). This suggests these compounds are critical in influencing the aroma profile of Dahongpao;

Figure 6. Correlation analysis between key differentiating substances and sensory evaluation scores. Metabolites are identified as follows: Benzaldehyde: Benzaldehyde and 2-hydroxy-5-methoxy-; Benzoic: Benzoic acid and hexyl ester; Cyclohexanecarboxylic: Cyclohexanecarboxylic acid; 2,3-Dichlorophenyl ester: 2,3-Dichlorophenyl ester; Inden: 1H-Inden-1-one and 2,3-dihydro-3,3,5,6-tetramethyl-; Naphthalene: Naphthalene and 1,2-dihydro-1,1,6-trimethyl; Benzene: Benzene, (1-ethyl-1-propenyl); Dodecane: Dodecane and 2,6,10-trimethyl; Pyrazine: Pyrazine and 2,6-dimethyl; Furan: 3-Methyl-2-(3,7,11-trimethyldodecyl) furan.

Figure 6. Correlation analysis between key differentiating substances and sensory evaluation scores. Metabolites are identified as follows: Benzaldehyde: Benzaldehyde and 2-hydroxy-5-methoxy-; Benzoic: Benzoic acid and hexyl ester; Cyclohexanecarboxylic: Cyclohexanecarboxylic acid; 2,3-Dichlorophenyl ester: 2,3-Dichlorophenyl ester; Inden: 1H-Inden-1-one and 2,3-dihydro-3,3,5,6-tetramethyl-; Naphthalene: Naphthalene and 1,2-dihydro-1,1,6-trimethyl; Benzene: Benzene, (1-ethyl-1-propenyl); Dodecane: Dodecane and 2,6,10-trimethyl; Pyrazine: Pyrazine and 2,6-dimethyl; Furan: 3-Methyl-2-(3,7,11-trimethyldodecyl) furan. - Baking is a crucial processing step for Wuyi rock tea, inducing Maillard reactions that impact tea quality [47]. Research by Lin et al. [12] indicated that lower-grade Wuyi Shuixian tea often exhibits more pronounced baking and sweet flavors. Similarly, this study found that lower-grade Wuyi Dahongpao contained higher levels of nutty and roasted compounds, likely due to Maillard reactions during baking, which affect the tea’s aroma components;

- In summary, the aroma profiles of Dahongpao across different grades vary significantly. Higher-grade Dahongpao is enriched with esters and aromatic hydrocarbons, contributing fruity, floral, and woody aromas. In contrast, lower-grade Dahongpao contains more alkanes, pyrazines, and furans, imparting floral, roasted, and nutty flavors.

4. Conclusions

This study confirmed that Dahongpao samples aligned with Chinese national standards. Sensory evaluation results indicated that higher-grade Dahongpao consistently received higher scores. Analyses revealed that FT and SE had lower levels of nitrogen oxides, alcohols, and esters than SP, which negatively affects their aroma profiles;In terms of taste, higher-grade Dahongpao exhibited increased bitterness and astringency, although these characteristics tended to dissipate more quickly. There were differences in aroma components among the three grades of Dahongpao tea. Higher-grade Dahongpao was characterized by elevated levels of compounds such as benzaldehyde (2-hydroxy-5-methoxy), benzoic acid hexyl ester, cyclohexanecarboxylic acid, 2,3-dichlorophenyl ester, 1H-Inden-1-one, 2,3-dihydro-3,3,5,6-tetramethyl-, and naphthalene (1,2-dihydro-1,1,6-trimethyl), which contribute to fruity, floral, and woody aromas. Conversely, lower-grade Dahongpao contained higher levels of benzene (1-ethyl-1-propenyl), dodecane (2,6,10-trimethyl), pyrazine (2,6-dimethyl), benzeneacetaldehyde, and 3-methyl-2-(3,7,11-trimethyldodecyl) furan, which impart floral, roasted, and nutty flavors;These compounds were significantly correlated with sensory evaluation scores (p < 0.05), highlighting their role as key markers for distinguishing Dahongpao grades. This research enhances our understanding of the grade-related differences in Dahongpao and provides a scientific foundation for the grading criteria outlined in Chinese national standards. However, these findings were based on a limited set of national standard samples (SP/FT/SE) and did not fully account for processing variations. Future studies should validate the generalizability through expanded sampling (e.g., diverse regions/grades) and controlled experiments (e.g., spiking target compounds).

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/chemosensors13040134/s1. Table S1: Sensory evaluation scores of different grades of dahongpao tea assessed by ten expert evaluators; Table S2: Electronic nose analysis of three grades of Dahongpao; Table S3: Electronic tongue analysis of Dahongpao of different grades; Table S4: Volatile compounds identified in special grade Dahongpao tea samples; Table S5: Volatile compounds identified in first grade Dahongpao tea samples; Table S6: Volatile compounds identified in second grade Dahongpao tea samples.

Author Contributions

X.P., J.Z. and P.M., methodology, validation, investigation, formal analysis, data curation, and writing—original draft; W.C., Z.Z. and H.W., formal analysis, data curation, and writing—original draft; X.J. and Y.L., validation, formal analysis, and data curation; J.Y. and Q.Z., methodology, validation, resources, conceptualization, formal analysis, writing—review and editing, supervision, and project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Natural Science Foundation of Fujian Province (2021J011137, 2024N0009, and 2020J01369), the Nanping City Science and Technology Plan Project development fund (NP2021KTS06 and NP2021KTS05), the Innovation and Entrepreneurship Training Program for College Students (S202210397033, 202310397003, 202410397014, and 202310397013), Scientific Research Project of Introducing Talents, Wuyi University (YJ201909), and the faculty and students co-creation team of Wuyi University (2021-SSTD-01 and2021-SSTD-05).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Institutional Review Board of Wuyi University (No. 20230520005 and 20 May 2023).

Informed Consent Statement

Verbal informed consent was obtained from the participants. Verbal consent was obtained rather than written because in China, the sensory evaluation of tea is a widely used method for evaluating tea quality. The Chinese National Standard “Methodology for sensory evaluation of tea” (GB/T 23776-2018) specifies sensory.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, J.; Li, M.; Wang, H.; Huang, W.; Li, F.; Wang, L.; Ho, C.T.; Zhang, Y.; Zhang, L.; Zhai, X.; et al. Decoding the specific roasty aroma Wuyi rock tea (Camellia sinensis: Dahongpao) by the sensomics approach. J. Agric. Food Chem. 2022, 70, 10571–10583. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Yang, Y.; Cheng, X.; Thangaraj, K.; Arkorful, E.; Chen, X.; Li, X. Prediction of suitable brewing cuppages of Dahongpao tea based on chemical composition, liquor colour and sensory quality in different brewing. Sci. Rep. 2020, 10, 945. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Zhao, J.; Vittayapadung, S. Identification of the green tea grade level using electronic tongue and pattern recognition. Food Res. Int. 2008, 41, 500–504. [Google Scholar]

- He, W.; Hu, X.; Zhao, L.; Liao, X.; Zhang, Y.; Zhang, M.; Wu, J. Evaluation of Chinese tea by the electronic tongue: Correlation with sensory properties and classification according to geographical origin and grade level. Food Res. Int. 2009, 42, 1462–1467. [Google Scholar]

- Ren, G.; Li, T.; Wei, Y.; Ning, J.; Zhang, Z. Estimation of Congou black tea quality by an electronic tongue technology combined with multivariate analysis. Microchem. J. 2021, 163, 105899. [Google Scholar] [CrossRef]

- Zhai, X.; Zhang, L.; Granvogl, M.; Ho, C.T.; Wan, X. Flavor of tea (Camellia sinensis): A review on odorants and analytical techniques. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3867–3909. [Google Scholar] [CrossRef]

- Capone, S.; Tufariello, M.; Francioso, L.; Montagna, G.; Casino, F.; Leone, A.; Siciliano, P. Aroma analysis by GC/MS and electronic nose dedicated to Negroamaro and Primitivo typical Italian Apulian wines. Sens. Actuat. B Chem. 2013, 179, 259–269. [Google Scholar] [CrossRef]

- Aghili, N.S.; Rasekh, M.; Karami, H.; Edriss, O.; Wilson, A.D.; Ramos, J. Aromatic fingerprints: VOC analysis with E-nose and GC-MS for rapid detection of adulteration in sesame oil. Sensors 2023, 23, 6294. [Google Scholar] [CrossRef]

- Wilson, K.C.; Clifford, M.N. (Eds.) Tea Cultivation to Consumption; Chapman and Hall: London, UK, 1992; pp. 603–647. [Google Scholar]

- Yang, P.; Wang, H.; Cao, Q.; Song, H.; Xu, Y.; Lin, Y. Aroma-active compounds related to Maillard reaction during roasting in Wuyi Rock tea. J. Food Compos. Anal. 2023, 115, 104954. [Google Scholar]

- Wang, B.; Yu, M.; Tang, Y.; Wang, Y.; Xia, T.; Song, H. Characterization of odor-active compounds in Dahongpao Wuyi Rock Tea (Camellia sinensis) by sensory-directed flavor analysis. J. Food Compos. Anal. 2023, 123, 105612. [Google Scholar]

- Lin, Y.; Huang, Y.; Liu, X.; Pan, Y.; Feng, X.; Guo, H.; Li, X.; Tao, Y.; Chen, P.; Chu, Q. Uncovering the Shuixian tea grades hierarchy in Chinese national standard: From sensory evaluation to microstructure and volatile compounds analysis. Food Chem. 2024, 459, 140342. [Google Scholar] [CrossRef] [PubMed]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 23776-2018; Methodology for Sensory Evaluation of Tea. China Standards Press: Beijing, China, 2018; pp. 1–28. (In Chinese)

- Xia, H.; Chen, W.; Hu, D.; Miao, A.; Qiao, X.; Qiu, G.; Liang, J.; Guo, W.; Ma, C. Rapid discrimination of quality grade of black tea based on near-infrared spectroscopy (NIRS), electronic nose (E-nose) and data fusion. Food Chem. 2024, 440, 138242. [Google Scholar] [CrossRef] [PubMed]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 8313-2018; Determination of Tatal Polyphenols and Catechins Content in Tea. China Standards Press: Beijing, China, 2018; pp. 1–8. (In Chinese)

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GBT23193-2017; Determination of Theanine in Tea-Usiing High Performance Liquid Chromatography. China Standards Press: Beijing, China, 2017; pp. 1–8. (In Chinese)

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 8314-2013; Determination of Total Free Amino Acids. China Standards Press: Beijing, China, 2017; pp. 1–5. (In Chinese)

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GBT8312-2013; Tea-Determination of Caffeine Content. Method Using High-Performance Liquid Chromatography. China Standards Press: Beijing, China, 2013; pp. 1–5. (In Chinese)

- Wang, H.B.; Lin, L.W.; Wang, Y.H. Technical Specification for Tea Production, Processing and Safety Inspection; Xiamen University Press: Xiamen, China, 2020. [Google Scholar]

- Hu, W.; Wang, G.; Lin, S.; Liu, Z.; Wang, P.; Li, J.; Zhang, Q.; He, H. Digital evaluation of aroma intensity and odor characteristics of tea with different types—Based on OAV-splitting method. Foods 2022, 11, 2204. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.; Yu, M.; Song, H.; Xu, Y.; Lin, Y.; Granvogl, M. Characterization of key aroma-active compounds in rough and moderate fire Rougui Wuyi rock tea (Camellia sinensis) by sensory-directed flavor analysis and elucidation of the influences of roasting on aroma. J. Agric. Food Chem. 2021, 70, 267–278. [Google Scholar] [CrossRef]

- Raj, D.R.K.; da Silva Ferreira, M.V.; Braunger, M.L.; Riul Jr, A.; Thomas, J.; Barbin, D.F. Exploration of an impedimetric electronic tongue and chemometrics for characterization of black tea from different origins. J. Food Compos. Anal. 2023, 123, 105535. [Google Scholar]

- Kovács, Z.; Dalmadi, I.; Lukács, L.; Sipos, L.; Szántai-Kőhegyi, K.; Kókai, Z.; Fekete, A. Geographical origin identification of pure Sri Lanka tea infusions with electronic nose, electronic tongue and sensory profile analysis. J. Chemometr. 2010, 24, 121–130. [Google Scholar]

- Wang, Z.; Gan, S.; Sun, W.; Chen, Z. Quality characteristics of Oolong tea products in different regions and the contribution of thirteen phytochemical components to its taste. Horticulturae 2022, 8, 278. [Google Scholar] [CrossRef]

- Zhang, L.; Cao, Q.Q.; Granato, D.; Xu, Y.Q.; Ho, C.T. Association between chemistry and taste of tea: A review. Trends Food Sci. Technol. 2020, 101, 139–149. [Google Scholar] [CrossRef]

- Zeng, L.; Fu, Y.Q.; Liu, Y.Y.; Huang, J.S.; Chen, J.X.; Yin, J.F.; Jin, S.; Sun, W.J.; Xu, Y.Q. Comparative analysis of different grades of Tieguanyin oolong tea based on metabolomics and sensory evaluation. LWT 2023, 174, 114423. [Google Scholar]

- Chai, K.; Chen, S.; Wang, P.; Kong, W.; Ma, X.; Zhang, X. Multiomics analysis reveals the genetic basis of volatile terpenoid formation in oolong tea. J. Agric. Food Chem. 2023, 71, 19888–19899. [Google Scholar]

- Zhu, J.C.; Chen, F.; Wang, L.Y.; Niu, Y.W.; Xiao, Z.B. Evaluation of the synergism among volatile compounds in Oolong tea infusion by odour threshold with sensory analysis and E-nose. Food Chem. 2017, 221, 1484–1490. [Google Scholar] [PubMed]

- Chen, J.; Yang, Y.; Deng, Y.; Liu, Z.; Shen, S.; Zhu, J.; Yuan, H.; Jiang, Y. Characterization of the key differential volatile components in different grades of Dianhong Congou tea infusions by the combination of sensory evaluation, comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry, and odor activity value. LWT 2022, 165, 113755. [Google Scholar]

- Li, Z.; Zhao, L.; Xie, F.; Yang, C.; Jayamanne, V.S.; Tan, H.; Jiang, X.; Yang, H. Study of assessment of green tea’grades in GC-MS determination of aromatic components based on principal component analysis (PCA). J. Food Process. Preserv. 2021, 45, e15047. [Google Scholar]

- Li, X.; Shi, C.; Wang, S.; Wang, S.; Wang, X.; Lü, X. Uncovering the effect of Moringa oleifera Lam. leaf addition to Fuzhuan Brick Tea on sensory properties, volatile profiles and anti-obesity activity. Food Funct. 2023, 14, 2404–2415. [Google Scholar]

- He, C.; Li, Y.; Zhou, J.; Yu, X.; Zhang, D.; Chen, Y.; Ni, D.; Yu, Z. Study on the suitability of tea cultivars for processing oolong tea from the perspective of aroma based on olfactory sensory, electronic nose, and GC-MS data correlation analysis. Foods 2022, 11, 2880. [Google Scholar] [CrossRef]

- Dai, Q.; Jin, H.; Gao, J.; Ning, J.; Yang, X.; Xia, T. Investigating volatile compounds’ contributions to the stale odour of green tea. Int. J. Food Sci. Technol. 2020, 55, 1606–1616. [Google Scholar]

- Lan, X.; Liu, Z.; Wang, D.; Zhan, S.; Chen, W.; Su, W.; Sun, Y.; Ni, L. Characterization of volatile composition, aroma-active compounds and phenolic profile of Qingxin oolong tea with different roasting degrees. Food Biosci. 2022, 50, 101985. [Google Scholar]

- Wang, H.; Hua, J.; Jiang, Y.; Yang, Y.; Wang, J.; Yuan, H. Influence of fixation methods on the chestnut-like aroma of green tea and dynamics of key aroma substances. Food Res. Int. 2020, 136, 109479. [Google Scholar]

- Li, R.; Ru, Y.; Wang, Z.; He, X.; Kong, K.W.; Zheng, T.; Zhang, X. Phytochemical composition, antioxidant activity, and enzyme inhibitory activities (α-glucosidase, xanthine oxidase, and acetylcholinesterase) of Musella lasiocarpa. Molecules 2021, 26, 4472. [Google Scholar] [CrossRef]

- Ityo, S.D.; Anhwange, B.A.; Okoye, P.C.; Feka, P.D. Sensory, GC-MS and ftir analysis of aqueous extract of hibiscus sabdarriffa and vernonia amygdalina herbal tea with blends of ginger and lemon zest. J. Chem. Soc. Nigeria 2023, 48, 662–676. [Google Scholar]

- Ouyang, W.; Yu, Y.; Wang, H.; Jiang, Y.; Hua, J.; Ning, J.; Yuan, H. Analysis of volatile metabolite variations in strip green tea during processing and effect of rubbing degree using untargeted and targeted metabolomics. Food Res. Int. 2022, 162, 112099. [Google Scholar] [PubMed]

- Zhu, B.; Zhang, J.; Li, J.; Fang, S.; Zhang, Z.Z.; Wang, R.; Deng, W.W. Aroma profile of Jimudan tea produced using Camellia sinensis, cultivar Jimudan using solid-phase microextraction, gas chromatography–mass spectrometry, and chemometrics. Eur. Food Res. Technol. 2021, 247, 1061–1082. [Google Scholar]

- Wen, S.; Sun, L.; Zhang, S.; Chen, Z.; Chen, R.; Li, Z.; Lai, X.; Zhang, Z.; Cao, J.; Li, Q.; et al. The formation mechanism of aroma quality of green and yellow teas based on GC-MS/MS metabolomics. Food Res. Int. 2023, 172, 113137. [Google Scholar] [PubMed]

- Wang, B.; Chen, H.; Qu, F.; Song, Y.; Di, T.; Wang, P.; Zhang, X. Identification of aroma-active components in black teas produced by six Chinese tea cultivars in high-latitude region by GC–MS and GC–O analysis. Eur. Food Res. Technol. 2021, 248, 647–657. [Google Scholar]

- Yue, C.; Cao, H.; Zhang, S.; Hao, Z.; Wu, Z.; Luo, L.; Zeng, L. Aroma characteristics of Wuyi rock tea prepared from 16 different tea plant varieties. Food Chem. X 2023, 17, 100586. [Google Scholar]

- Liu, X.; Liu, Y.; Li, P.; Yang, J.; Wang, F.; Kim, E.; Wu, Y.; He, P.; Li, B.; Tu, Y. Chemical characterization of Wuyi rock tea with different roasting degrees and their discrimination based on volatile profiles. Rsc Adv. 2021, 11, 12074–12085. [Google Scholar]

- Qu, F.F.; Li, X.H.; Wang, P.Q.; Han, Y.H.; Wu, Y.; Hu, J.H.; Zhang, X.F. Effect of thermal process on the key aroma components of green tea with chestnut-like aroma. J. Sci. Food Agric. 2023, 103, 657–665. [Google Scholar]

- Shimoda, M.; Shigematsu, H.; Shiratsuchi, H.; Osajima, Y. Comparison of volatile compounds among different grades of green tea and their relations to odor attributes. J. Agric. Food Chem. 1995, 43, 1621–1625. [Google Scholar]

- Gotti, R.; Leoni, A.; Fiori, J. Evaluation of roasting effect on selected green tea volatile flavor compound and pyrazine content by HS-SPME GC-MS. Appl. Sci. 2021, 11, 8217. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, Y.; Luo, L.; Zeng, L. Effects of baking degrees on quality characteristics of Wuyi rock tea. Food Mach. 2017, 33, 41–46. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).