A Portable Electronic Nose Coupled with Deep Learning for Enhanced Detection and Differentiation of Local Thai Craft Spirits

Abstract

1. Introduction

2. Materials and Methods

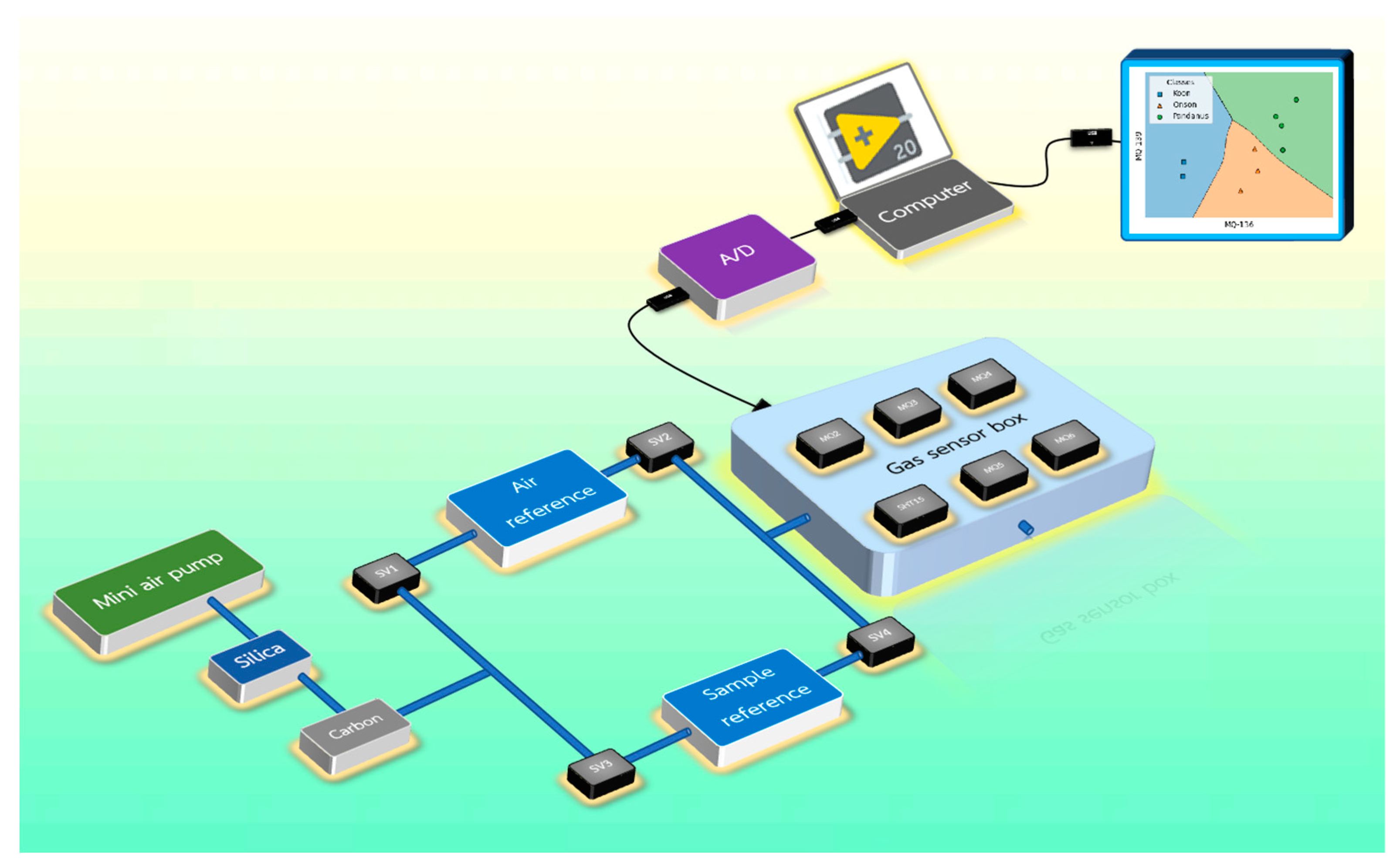

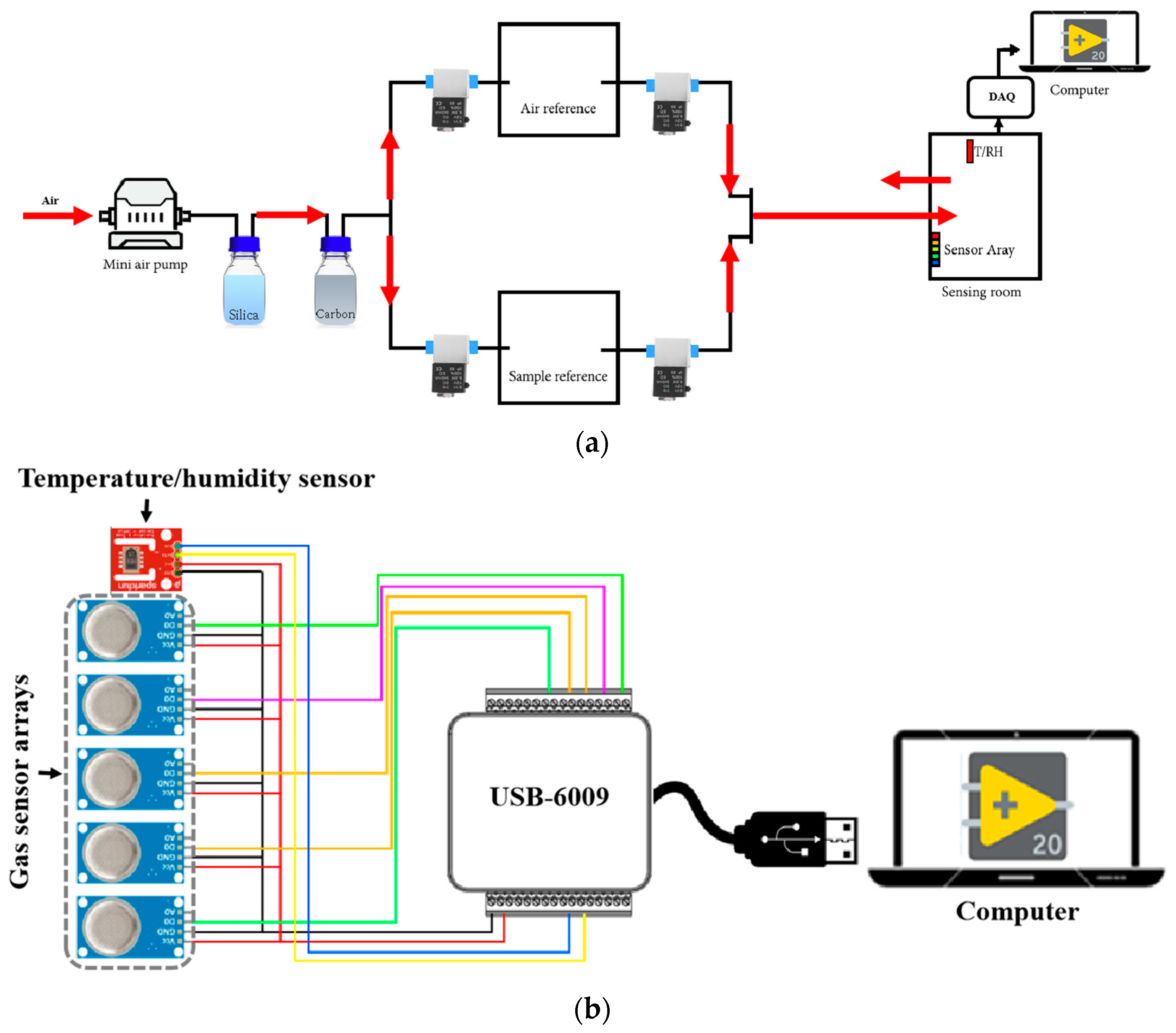

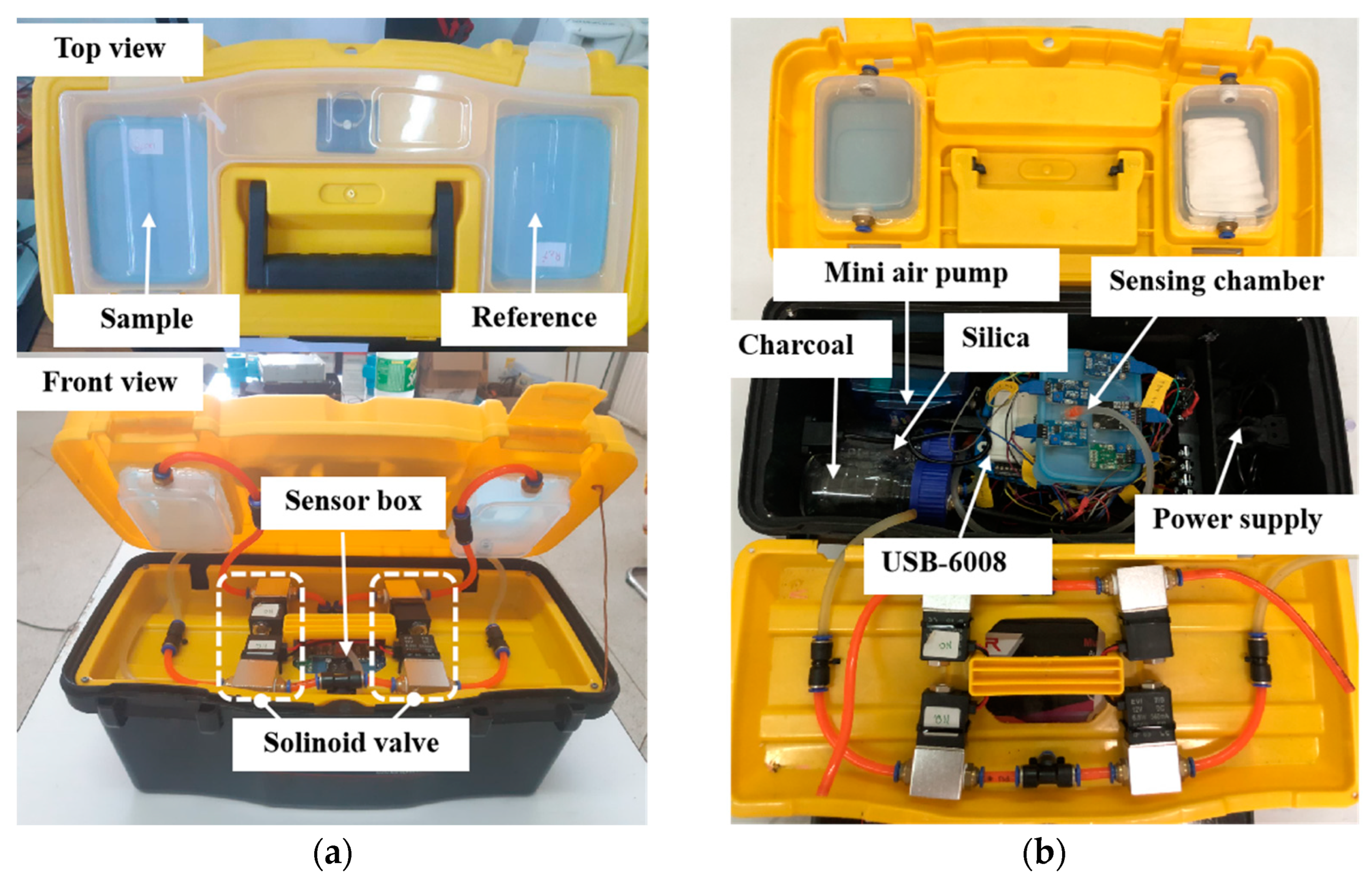

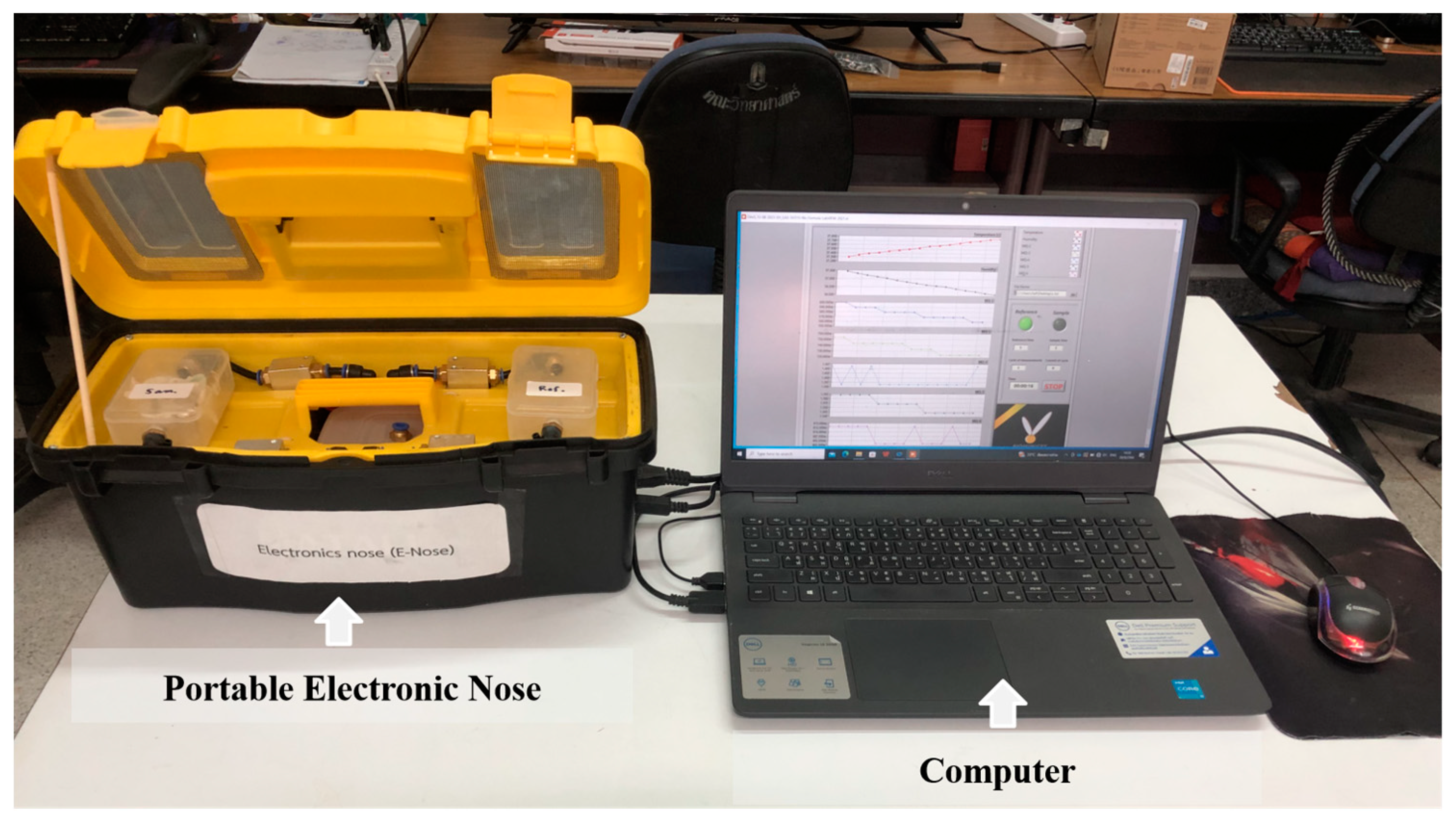

2.1. E-Nose System

2.2. Materials and Analyte Solution Preparation

2.3. Experimental Measurement Set-Up

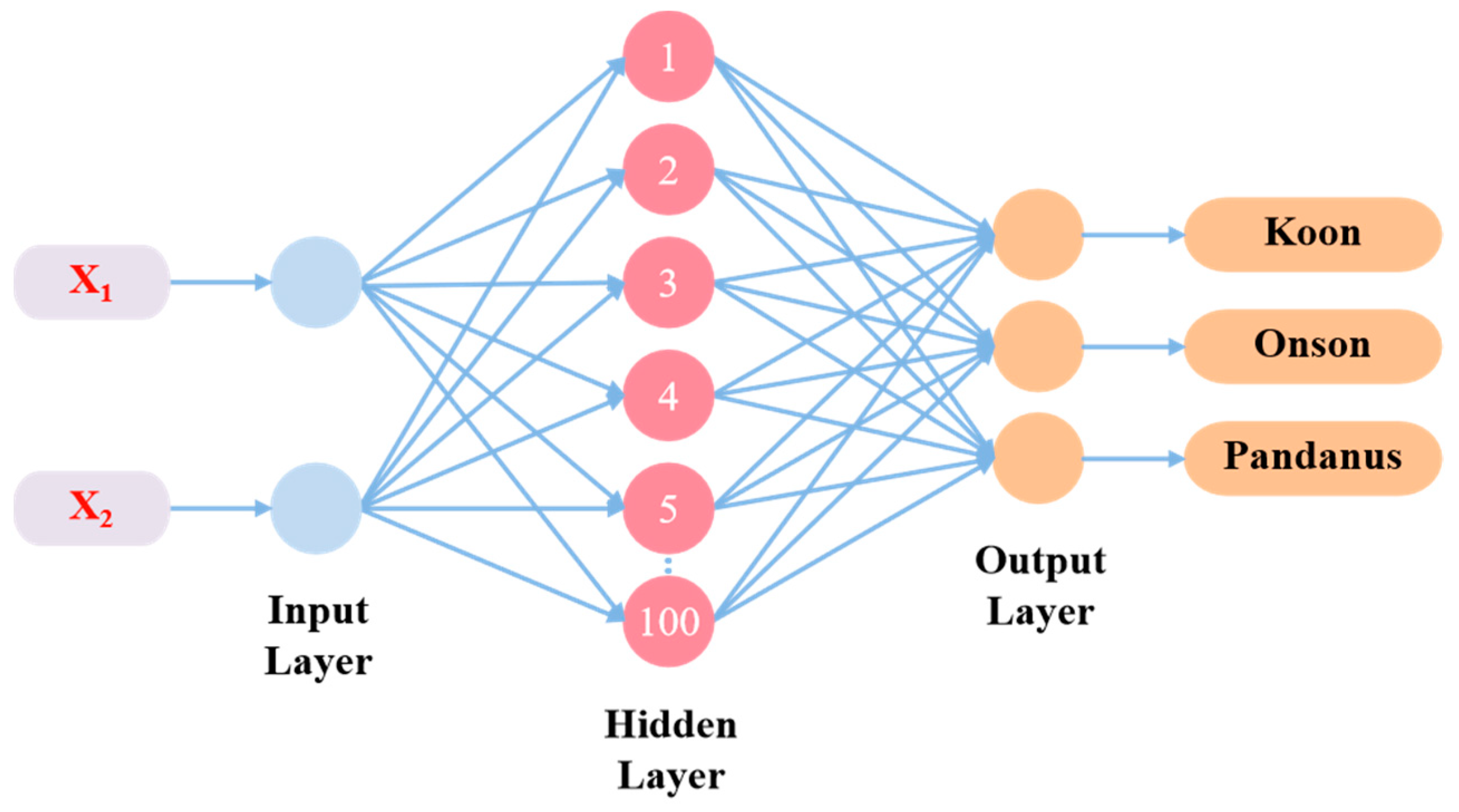

2.4. Data Extraction and Neural Network

3. Results

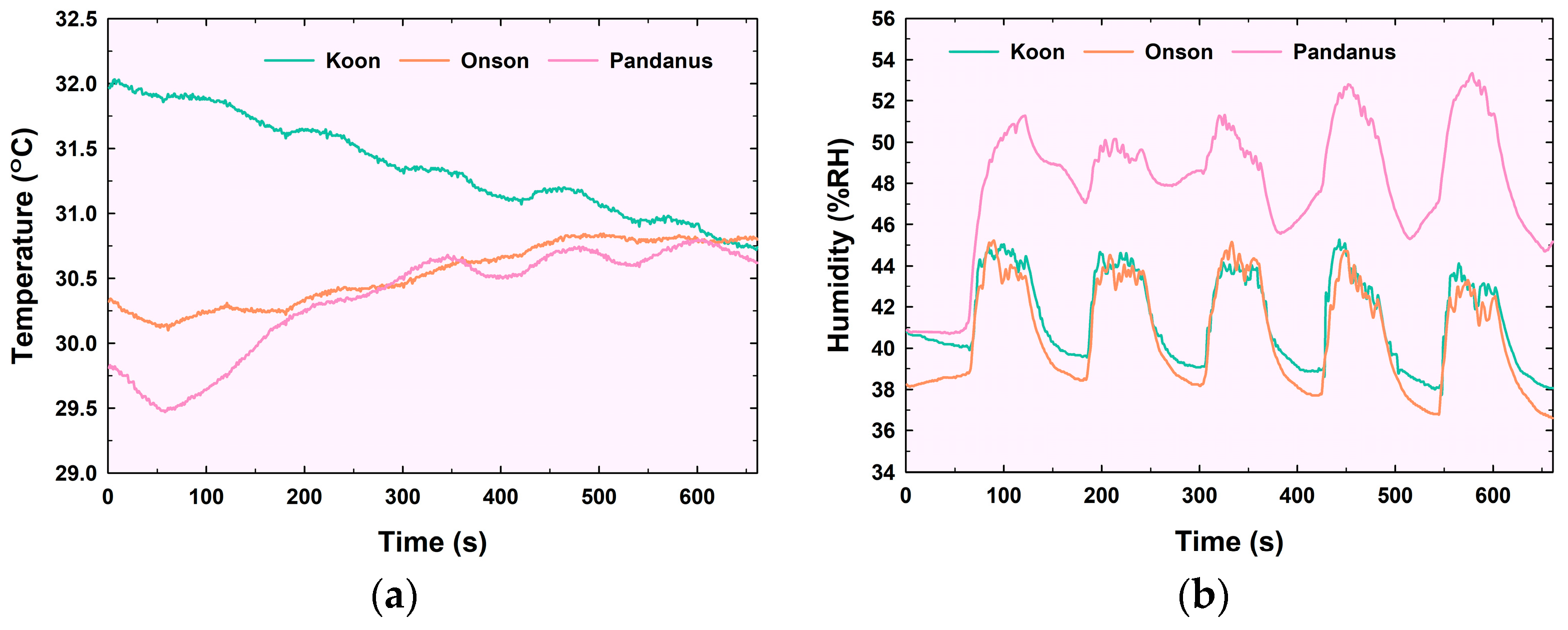

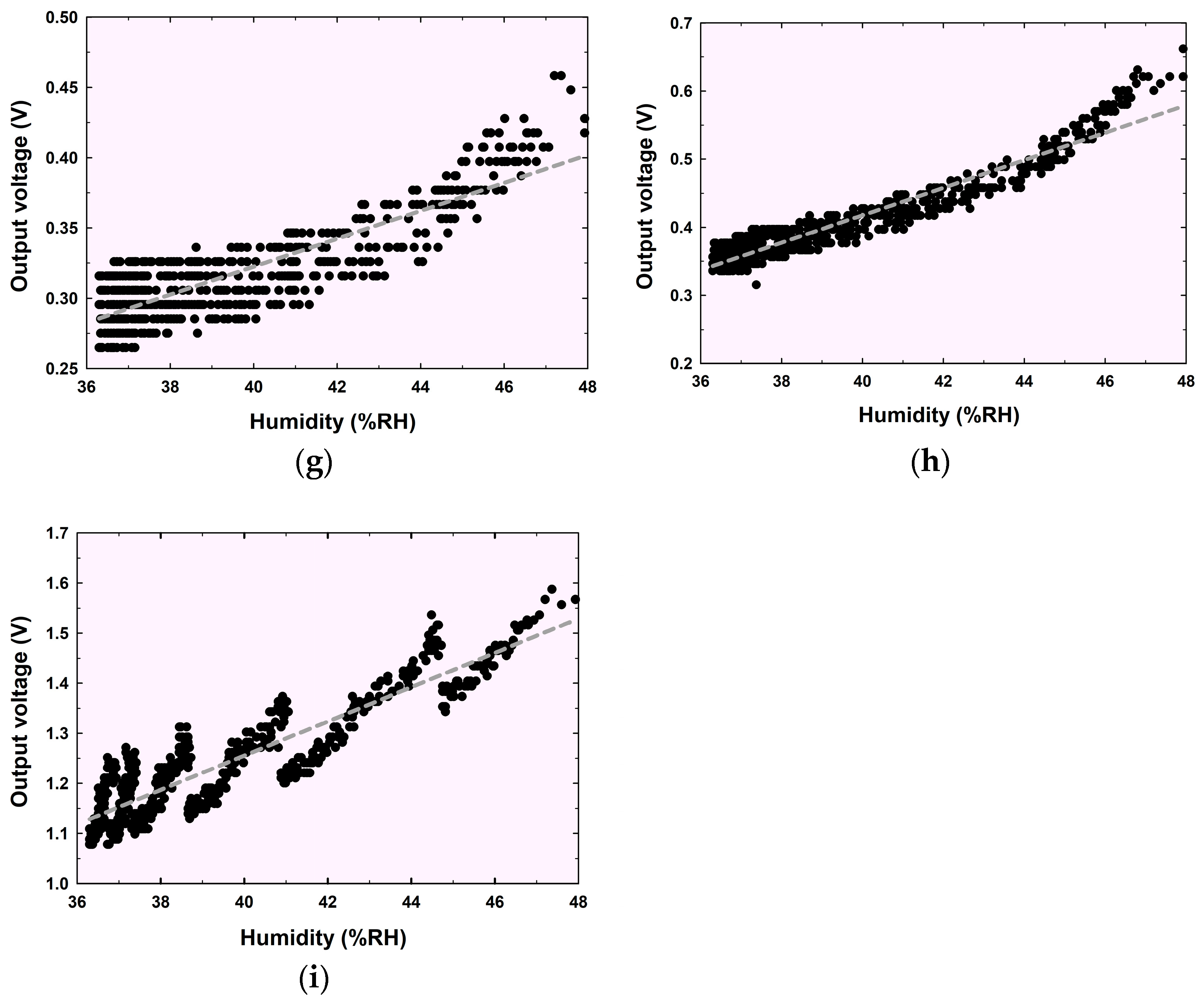

3.1. Temperature and Humidity Sensor Response

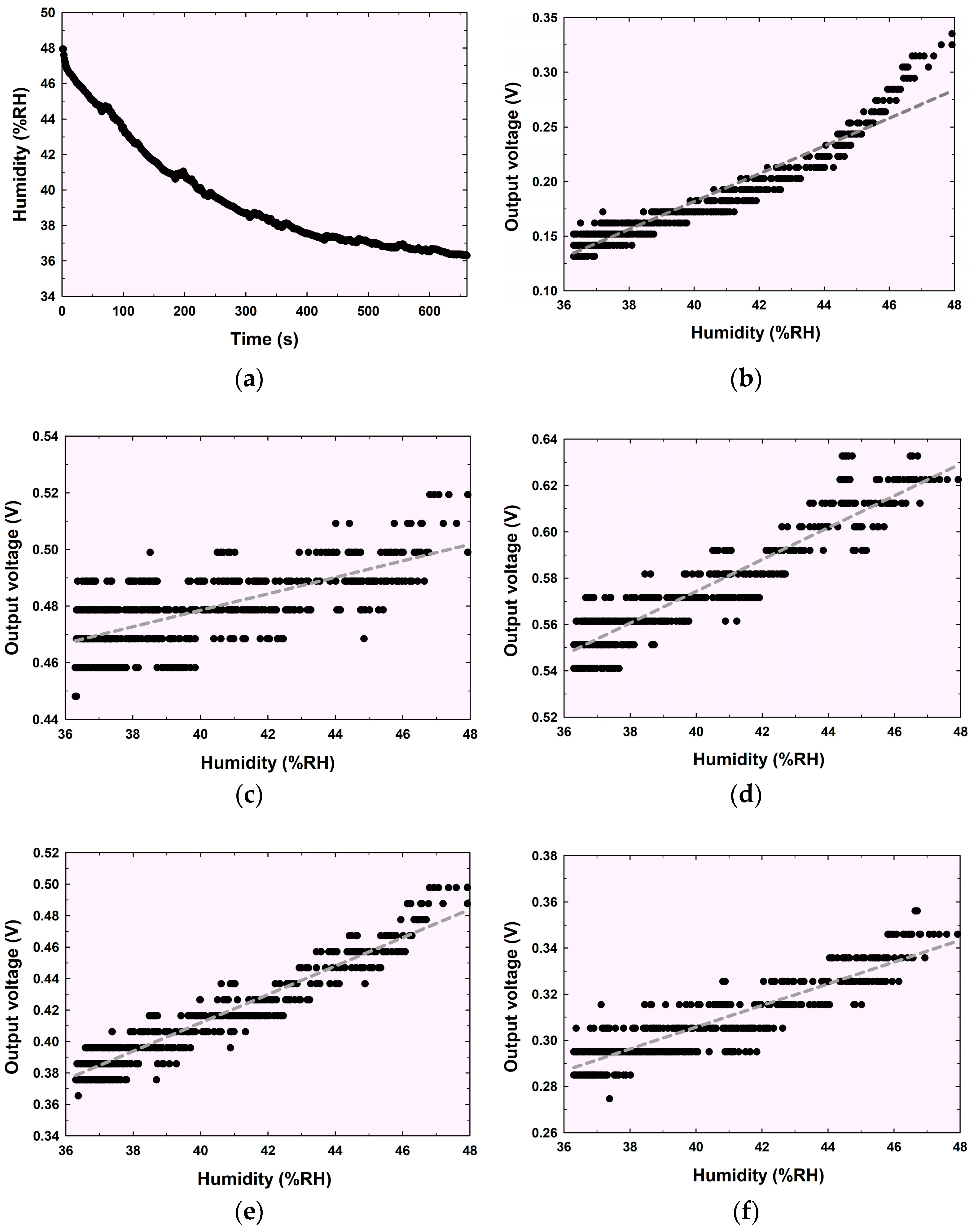

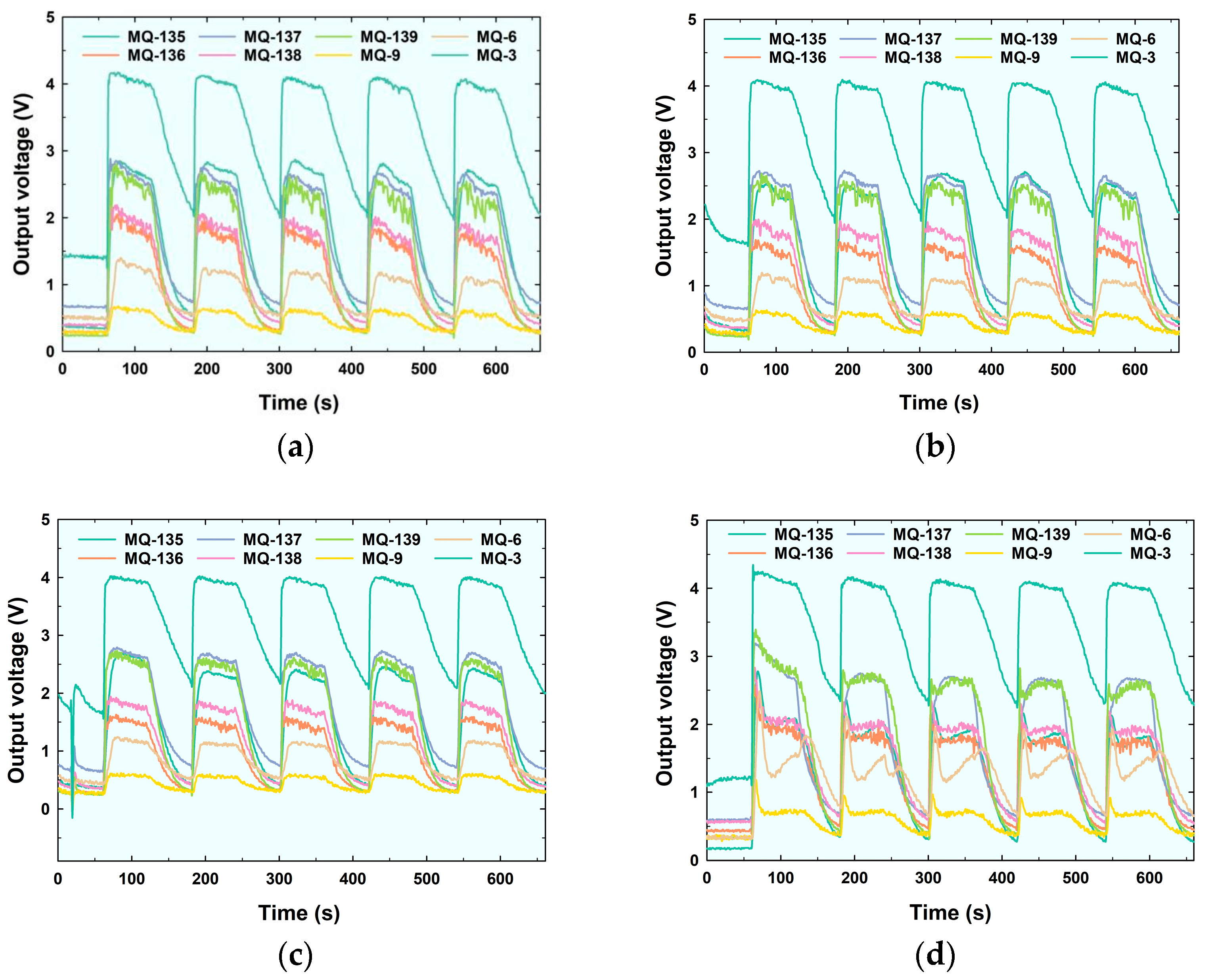

3.2. Gas Sensor Response

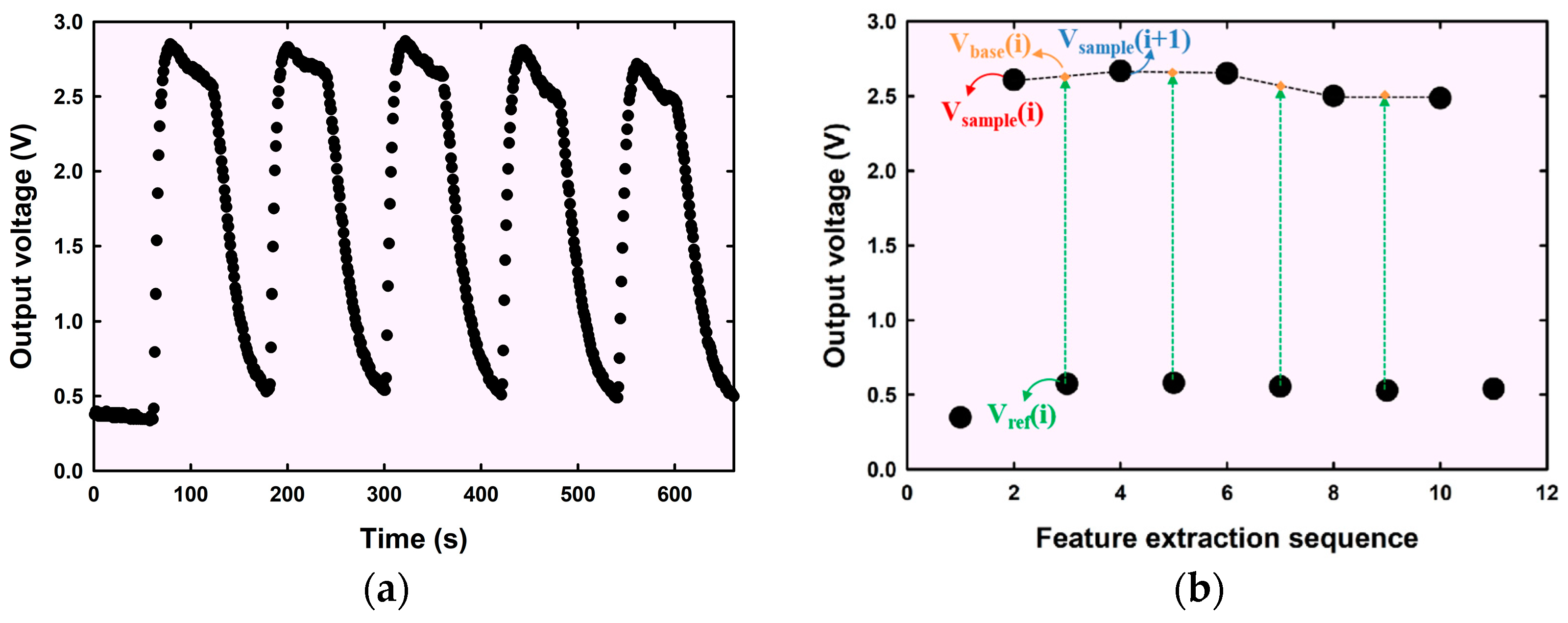

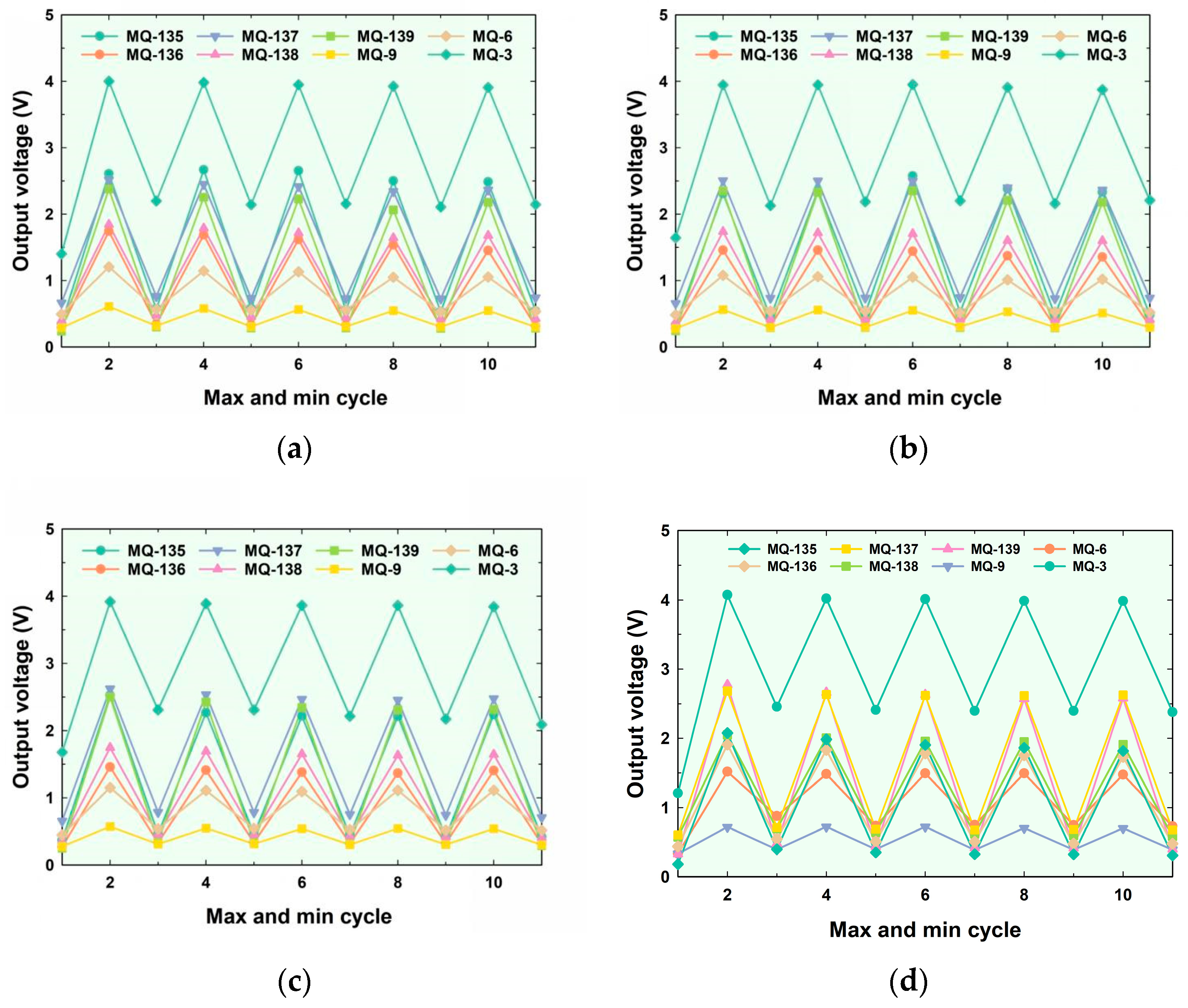

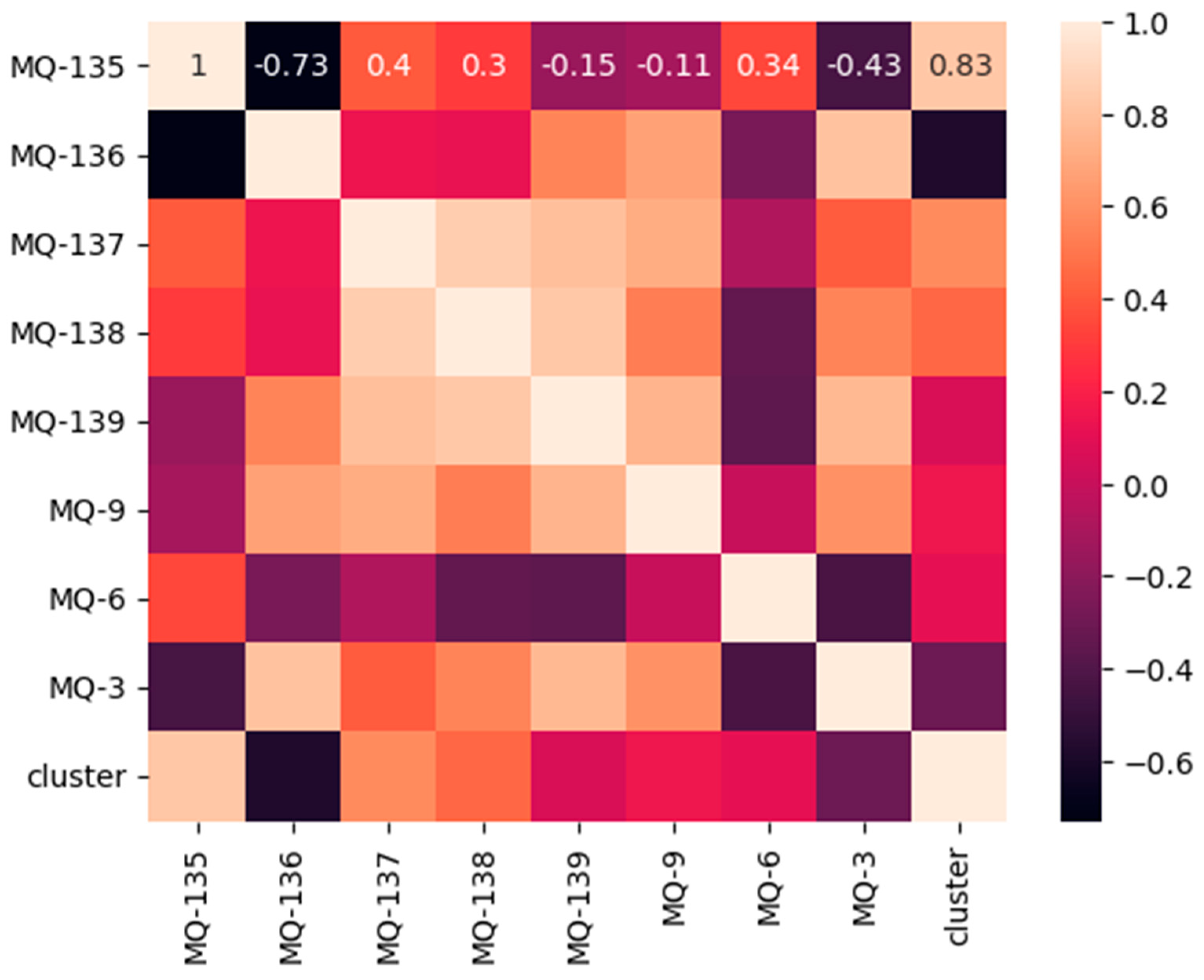

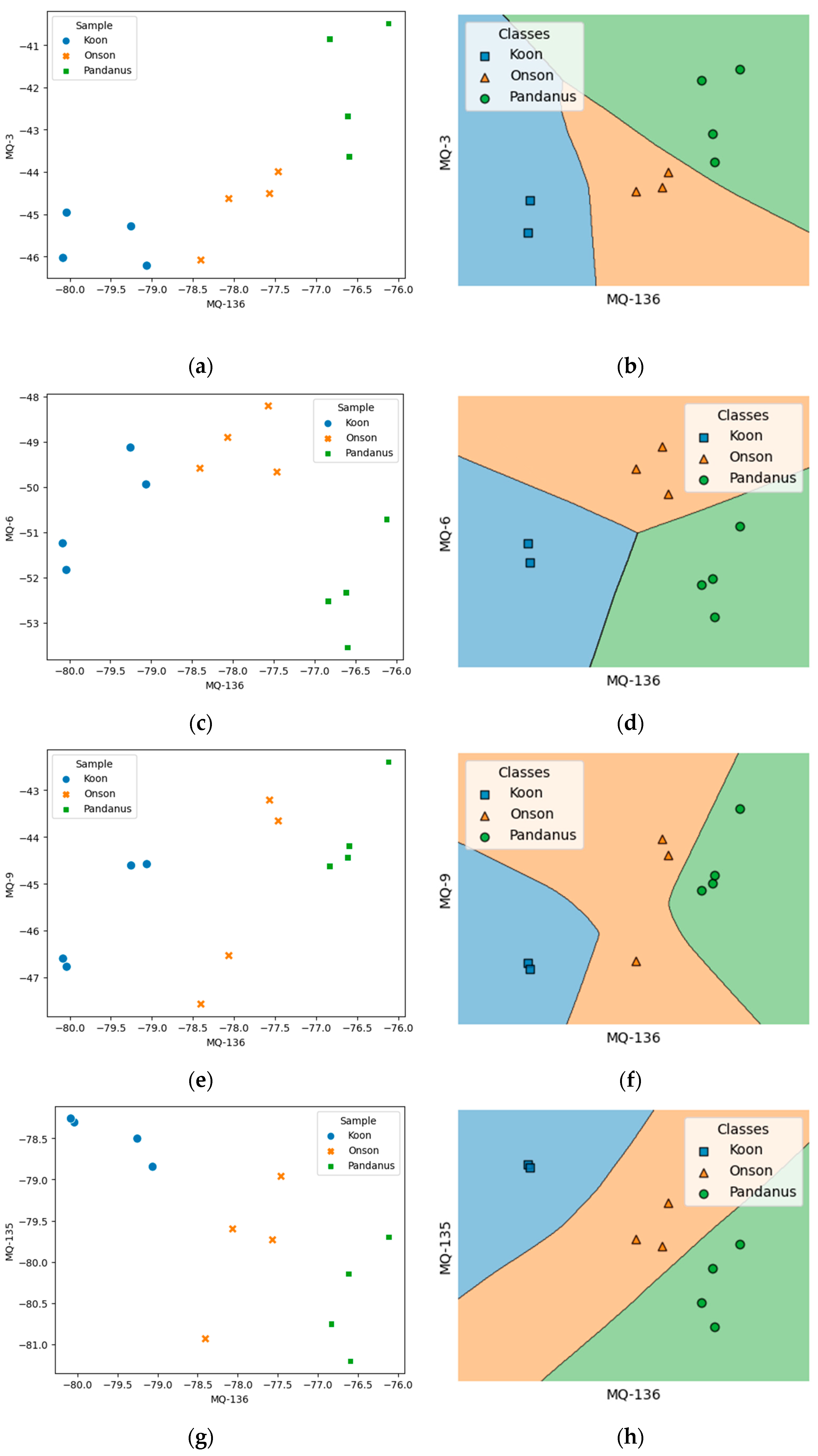

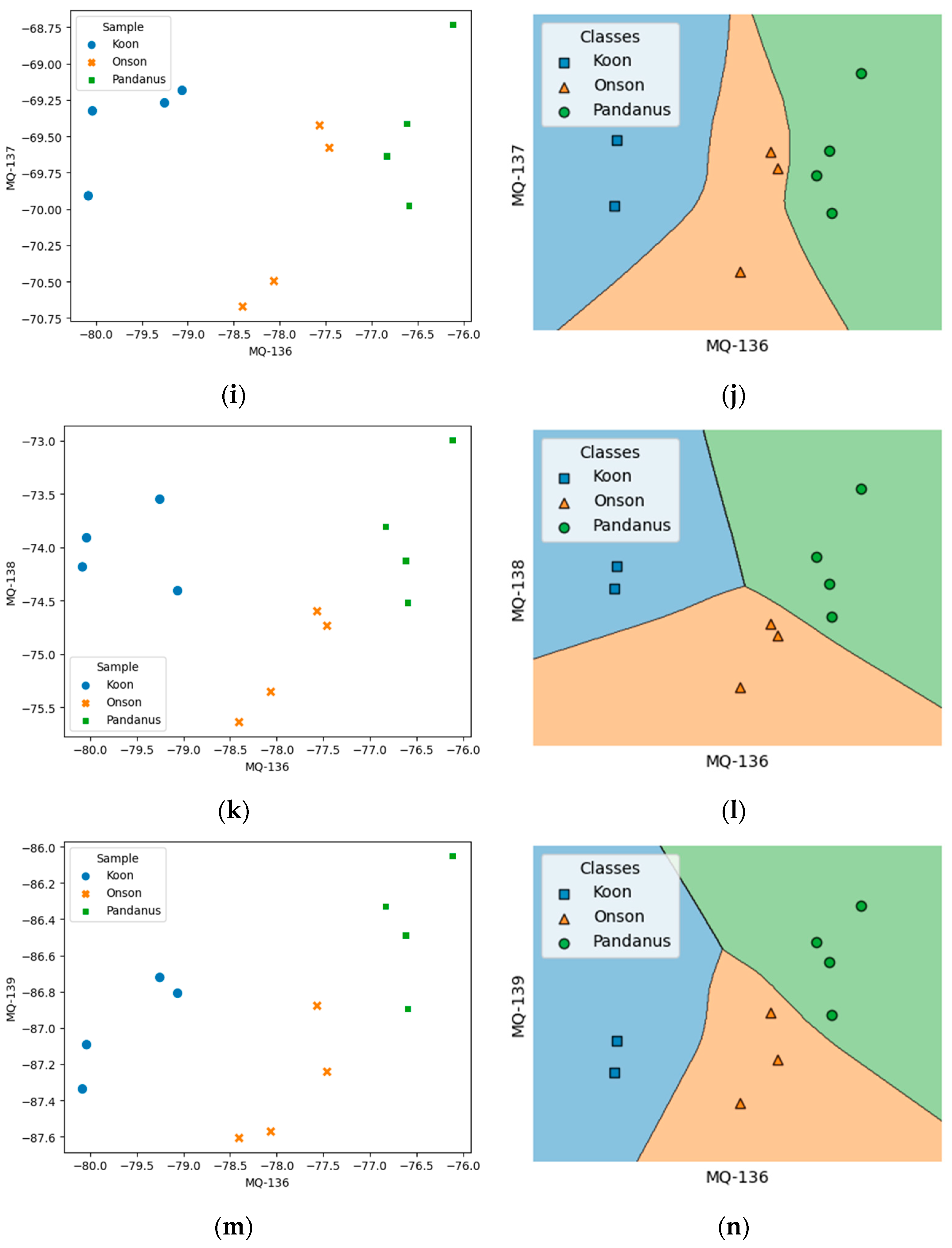

3.3. Maximum and Minimum Data Extraction from Gas Sensor Response

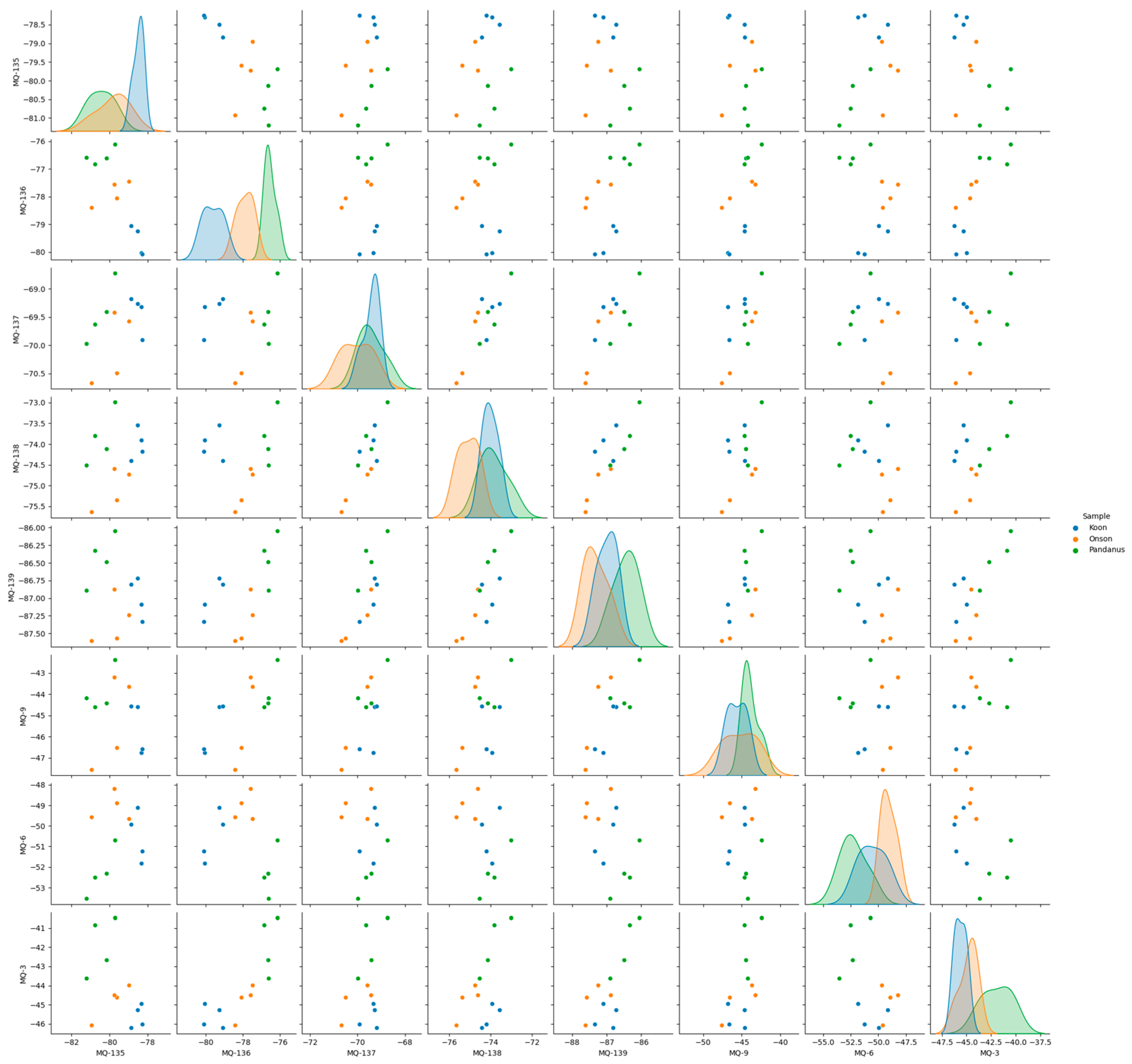

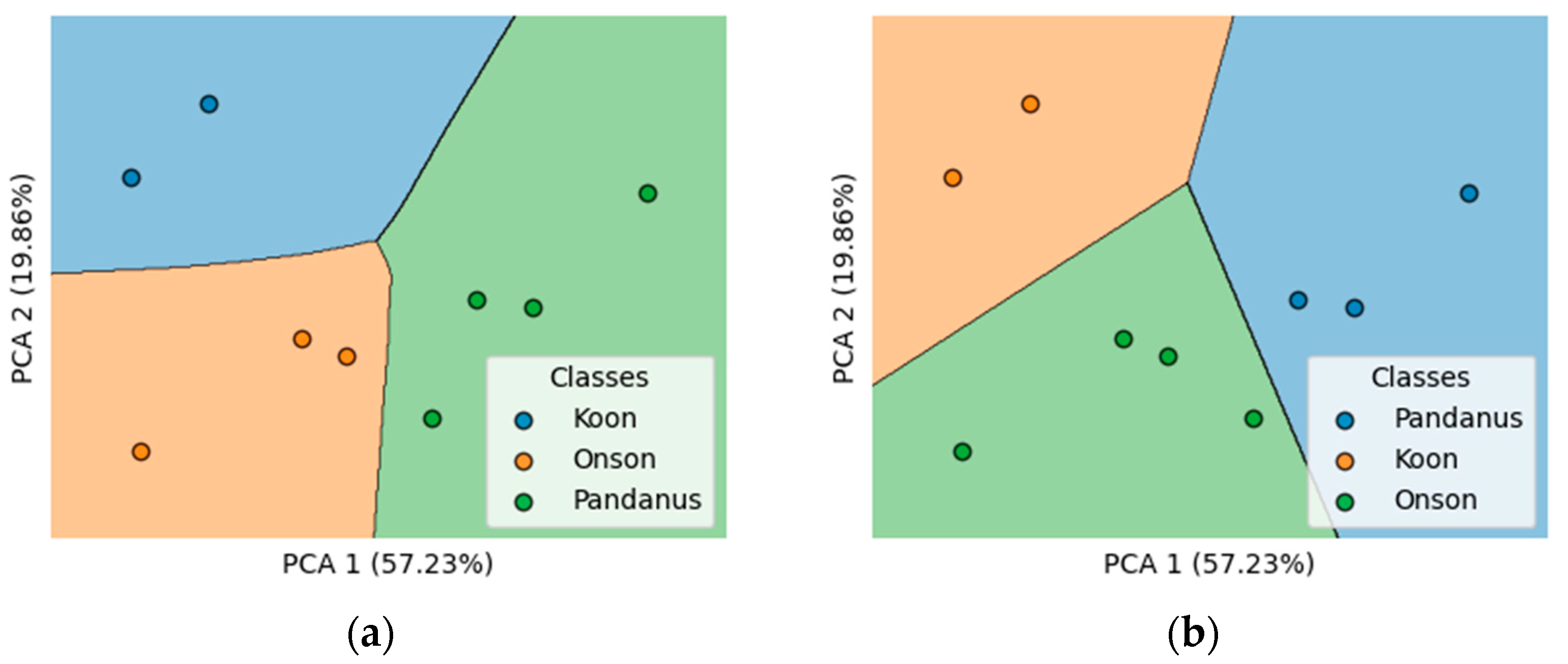

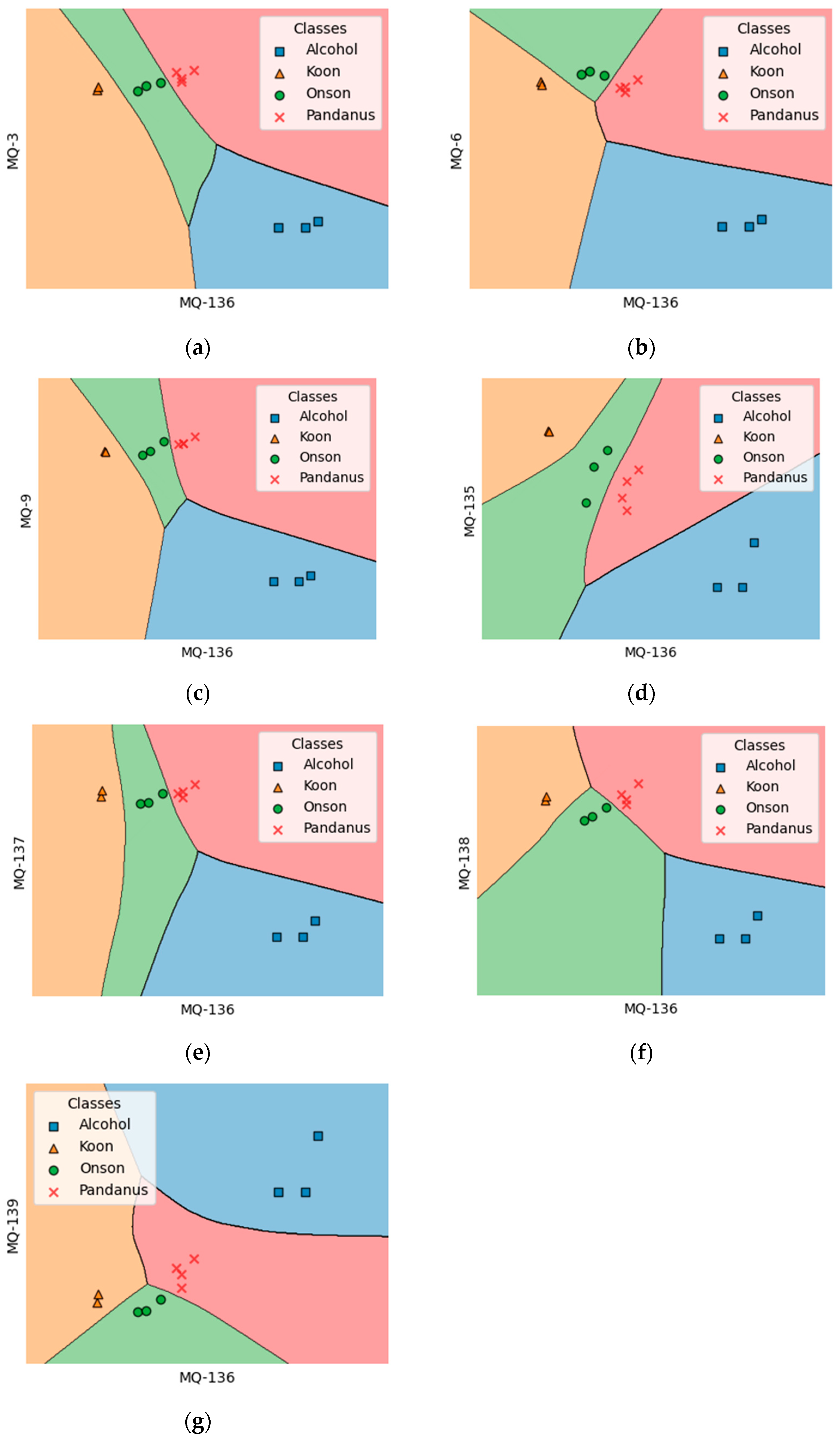

3.4. Classification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Persaud, K.C.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 352–355. [Google Scholar] [CrossRef] [PubMed]

- Bonah, E.; Huang, X.; Aheto, J.H.; Osae, R. Application of electronic nose as a non-invasive technique for odor fingerprinting and detection of bacterial foodborne pathogens: A review. J. Food Sci. Technol. 2020, 57, 1977–1990. [Google Scholar] [CrossRef] [PubMed]

- Persaud, K. Electronic Noses and Tongues in the Food Industry. In Electronic Noses and Tongues in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–12. ISBN 978-0-12-800243-8. [Google Scholar]

- Aouadi, B.; Zaukuu, J.Z.; Vitális, F.; Bodor, Z.; Fehér, O.; Gillay, Z.; Bazar, G.; Kovacs, Z. Historical evolution and food control achievements of near infrared spectroscopy, Electronic nose, and electronic tongue-critical overview. Sensors 2020, 20, 5479. [Google Scholar] [CrossRef] [PubMed]

- John, A.T.; Murugappan, K.; Nisbet, D.R.; Tricoli, A. An outlook of recent advances in chemiresistive sensor-based electronic nose systems for food quality and environmental monitoring. Sensors 2021, 1, 2271. [Google Scholar] [CrossRef]

- Seesaard, T.; Wongchoosuk, C. Recent progress in electronic noses for fermented foods and beverages applications. Fermentation 2022, 8, 302. [Google Scholar] [CrossRef]

- Munekata, P.E.S.; Finardi, S.; de Souza, C.K.; Meinert, C.; Pateiro, M.; Hoffmann, T.G.; Domínguez, R.; Bertoli, S.L.; Kumar, M.; Lorenzo, J.M. Applications of electronic nose, electronic eye and electronic tongue in quality, safety and shelf life of meat and meat products: A review. Sensors 2023, 23, 672. [Google Scholar] [CrossRef]

- Cavallari, M.R.; Izquierdo, J.E.E.; Braga, G.S.; Dirani, E.A.T.; Pereira-da-Silva, M.A.; Rodríguez, E.F.G.; Fonseca, F.J. Enhanced sensitivity of gas sensor based on poly(3-hexylthiophene) thin-film transistors for disease diagnosis and environment monitoring. Sensors 2015, 15, 9592–9609. [Google Scholar] [CrossRef]

- Wilson, A.D. Review of electronic-nose technologies and algorithms to detect hazardous chemicals in the environment. Procedia Technol. 2012, 1, 453–463. [Google Scholar] [CrossRef]

- Wilson, A.D.; Baietto, M. Advances in electronic-nose technologies developed for biomedical applications. Sensors 2011, 11, 1105–1176. [Google Scholar] [CrossRef]

- Voss, A.; Schroeder, R.; Schulz, S.; Haueisen, J.; Vogler, S.; Horn, P.; Stallmach, A.; Reuken, P. Detection of liver dysfunction using a wearable electronic nose system based on semiconductor metal oxide sensors. Biosensors 2022, 12, 70. [Google Scholar] [CrossRef]

- Epping, R.; Koch, M. On-site detection of volatile organic compounds (vocs). Molecules 2023, 28, 1598. [Google Scholar] [CrossRef] [PubMed]

- Mansurova, M.; Ebert, B.E.; Blank, L.M.; Ibáñez, A.J. A breath of information: The volatilome. Curr. Genet. 2018, 64, 959–964. [Google Scholar] [CrossRef] [PubMed]

- Wongchoosuk, C.; Lutz, M.; Kerdcharoen, T. Detection and classification of human body odor using an electronic nose. Sensors 2009, 9, 7234–7249. [Google Scholar] [CrossRef] [PubMed]

- Voss, A.; Witt, K.; Kaschowitz, T.; Poitz, W.; Ebert, A.; Roser, P.; Bär, K.J. Detecting cannabis use on the human skin surface via an electronic nose system. Sensors 2014, 14, 13256–13272. [Google Scholar] [CrossRef] [PubMed]

- Tang, K.T.; Chiu, S.W.; Pan, C.H.; Hsieh, H.Y.; Liang, Y.S.; Liu, S.C. Development of a portable electronic nose system for the detection and classification of fruity odors. Sensors 2010, 10, 9179–9193. [Google Scholar] [CrossRef]

- Pan, C.H.; Hsieh, H.Y.; Tang, K.T. An analog multilayer perceptron neural network for a portable electronic nose. Sensors 2012, 13, 193–207. [Google Scholar] [CrossRef]

- Macías Macías, M.; Agudo, J.E.; García Manso, A.; García Orellana, C.J.; González Velasco, H.M.; Gallardo Caballero, R. A compact and low cost electronic nose for aroma detection. Sensors 2013, 13, 5528–5541. [Google Scholar] [CrossRef]

- Macías, M.M.; Manso, A.G.; Orellana, C.J.; Velasco, H.M.; Caballero, R.G.; Chamizo, J.C. Acetic acid detection threshold in synthetic wine samples of a portable electronic nose. Sensors 2012, 13, 208–220. [Google Scholar] [CrossRef]

- Hernández, E.; Pelegrí-Sebastiá, J.; Sogorb, T.; Chilo, J. Evaluation of red wine acidification using an e-nose system with venturi tool sampling. Sensors 2023, 23, 2878. [Google Scholar] [CrossRef]

- Han, F.; Zhang, D.; Aheto, J.H.; Feng, F.; Duan, T. Integration of a low-cost electronic nose and a voltammetric electronic tongue for red wines identification. Food Sci. Nutr. 2020, 8, 4330–4339. [Google Scholar] [CrossRef]

- Liu, R.; Liu, Y.; Zhu, Y.; Kortesniemi, M.; Zhu, B.; Li, H. Aromatic characteristics of passion fruit wines measured by e-nose, gc-quadrupole ms, gc-orbitrap-ms and sensory evaluation. Foods 2022, 11, 3789. [Google Scholar] [CrossRef] [PubMed]

- Fuentes, S.; Summerson, V.; Gonzalez Viejo, C.; Tongson, E.; Lipovetzky, N.; Wilkinson, K.L.; Szeto, C.; Unnithan, R.R. Assessment of smoke contamination in grapevine berries and taint in wines due to bushfires using a low-cost e-nose and an artificial intelligence approach. Sensors 2020, 20, 5108. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez Viejo, C.; Fuentes, S. Digital assessment and classification of wine faults using a low-cost electronic nose, near-infrared spectroscopy and machine learning modelling. Sensors 2022, 22, 2303. [Google Scholar] [CrossRef]

- Aleixandre, M.; Santos, J.P.; Sayago, I.; Cabellos, J.M.; Arroyo, T.; Horrillo, M.C. A wireless and portable electronic nose to differentiate musts of different ripeness degree and grape varieties. Sensors 2015, 15, 8429–8443. [Google Scholar] [CrossRef] [PubMed]

- Macías, M.M.; Agudo, J.E.; Manso, A.G.; Orellana, C.J.; Velasco, H.M.; Caballero, R.G. Improving short term instability for quantitative analyses with portable electronic noses. Sensors 2014, 14, 10514–10526. [Google Scholar] [CrossRef]

- Huang, Y.; Doh, I.J.; Bae, E. Design and validation of a portable machine learning-based electronic nose. Sensors 2021, 21, 3923. [Google Scholar] [CrossRef]

- Kiani, S.; Minaei, S.; Ghasemi-Varnamkhasti, M. A portable electronic nose as an expert system for aroma-based classification of saffron. Chemometr. Intell. Lab. 2016, 156, 148–156. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, H.; Sun, W.; Lu, N.; Yan, M.; Wu, Y.; Hua, Z.; Fan, S. Development of a low-cost portable electronic nose for cigarette brands identification. Sensors 2020, 20, 4239. [Google Scholar] [CrossRef]

- Gonzalez Viejo, C.; Tongson, E.; Fuentes, S. Integrating a low-cost electronic nose and machine learning modelling to assess coffee aroma profile and intensity. Sensors 2021, 21, 2016. [Google Scholar] [CrossRef]

- Tyagi, H.; Daulton, E.; Bannaga, A.S.; Arasaradnam, R.P.; Covington, J.A. Non-invasive detection and staging of colorectal cancer using a portable electronic nose. Sensors 2021, 21, 5440. [Google Scholar] [CrossRef]

- Vanarse, A.; Osseiran, A.; Rassau, A.; van der Made, P. Application of neuromorphic olfactory approach for high-accuracy classification of malts. Sensors 2022, 22, 440. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Gonzalez Viejo, C.; Vaghefi, N.; Taylor, P.W.J.; Tongson, E.; Fuentes, S. Early detection of fusarium oxysporum infection in processing tomatoes (Solanum lycopersicum) and pathogen-soil interactions using a low-cost portable electronic nose and machine learning modeling. Sensors 2022, 22, 8645. [Google Scholar] [CrossRef] [PubMed]

- Meléndez, F.; Arroyo, P.; Gómez-Suárez, J.; Palomeque-Mangut, S.; Suárez, J.I.; Lozano, J. Portable electronic nose based on digital and analog chemical sensors for 2,4,6-trichloroanisole discrimination. Sensors 2022, 22, 3453. [Google Scholar] [CrossRef] [PubMed]

- Santos, J.P.; Sayago, I.; Sanjurjo, J.L.; Perez-Coello, M.S.; Díaz-Maroto, M.C. Rapid and non-destructive analysis of corky off-flavors in natural cork stoppers by a wireless and portable electronic nose. Sensors 2022, 22, 4687. [Google Scholar] [CrossRef]

- Aznan, A.; Gonzalez Viejo, C.; Pang, A.; Fuentes, S. Rapid detection of fraudulent rice using low-cost digital sensing devices and machine learning. Sensors 2022, 22, 8655. [Google Scholar] [CrossRef]

- Gardner, J.W.; Hines, E.L.; Wilkinson, M. Application of artificial neural networks to an electronic olfactory system. Meas. Sci. Technol. 1990, 1, 446–451. [Google Scholar] [CrossRef]

- Gardner, J.W. Detection of vapours and odours from a multisensor array using pattern recognition. Part I. Principal component and cluster analysis. Sens. Actuators B 1991, 4, 109–116. [Google Scholar] [CrossRef]

- Gardner, J.W.; Hines, E.L.; Tang, H.C. Detection of vapours and odours from a multisensor array using pattern-recognition techniques Part 2. Artificial neural networks. Sens. Actuators B 1992, 9, 9–15. [Google Scholar] [CrossRef]

- Craven, M.A.; Gardner, J.W.; Bartlett, P.N. Electronic noses—Development and future prospects. Trends Anal. Chem. 1996, 15, 486–493. [Google Scholar] [CrossRef]

- Hines, E.L.; Llobet, E.; Gardner, J.W. Electronic noses: A review of signal processing techniques. IEE Proc.-Circuits Devices Sys. 1999, 146, 297–310. [Google Scholar] [CrossRef]

- Vorakhutttanon, K.; Widtayakornbundit, S.; Sawangwong, S. Thai distilled spirit as cultural product for local tourism development in thailand. AJPU 2023, 14, 225–239. [Google Scholar]

| Sensor | Types of Gases That Can Be Measured |

|---|---|

| MQ-3 | Alcohol, ethanol, and smoke |

| MQ-6 | LPG and butane gas |

| MQ-9 | Carbon monoxide and flammable gases |

| MQ-135 | Carbon monoxide, benzene, ammonia, alcohol, and smoke |

| MQ-136 | Hydrogen sulfide |

| MQ-137 | Ammonia |

| MQ-138 | Benzene, toluene, alcohol, acetone, propane, formaldehyde, and hydrogen |

| MQ-139 | Freon |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harnsoongnoen, S.; Babpan, N.; Srisai, S.; Kongkeaw, P.; Srisongkram, N. A Portable Electronic Nose Coupled with Deep Learning for Enhanced Detection and Differentiation of Local Thai Craft Spirits. Chemosensors 2024, 12, 221. https://doi.org/10.3390/chemosensors12100221

Harnsoongnoen S, Babpan N, Srisai S, Kongkeaw P, Srisongkram N. A Portable Electronic Nose Coupled with Deep Learning for Enhanced Detection and Differentiation of Local Thai Craft Spirits. Chemosensors. 2024; 12(10):221. https://doi.org/10.3390/chemosensors12100221

Chicago/Turabian StyleHarnsoongnoen, Supakorn, Nantawat Babpan, Saksun Srisai, Pongsathorn Kongkeaw, and Natthaphon Srisongkram. 2024. "A Portable Electronic Nose Coupled with Deep Learning for Enhanced Detection and Differentiation of Local Thai Craft Spirits" Chemosensors 12, no. 10: 221. https://doi.org/10.3390/chemosensors12100221

APA StyleHarnsoongnoen, S., Babpan, N., Srisai, S., Kongkeaw, P., & Srisongkram, N. (2024). A Portable Electronic Nose Coupled with Deep Learning for Enhanced Detection and Differentiation of Local Thai Craft Spirits. Chemosensors, 12(10), 221. https://doi.org/10.3390/chemosensors12100221