Abstract

Odors existing in natural environment are typically mixtures of a large variety of chemical compounds in specific proportions. It is a challenging task for an electronic nose to recognize the gas mixtures. Most current research is based on the overall response of sensors and uses relatively simple datasets, which cannot be used for complex mixtures or rapid monitoring scenarios. In this study, a novel electronic nose (E-nose) using a spiking neural network (SNN) model was proposed for the detection and recognition of gas mixtures. The electronic nose integrates six commercial metal oxide sensors for automated gas acquisition. SNN with a simple three-layer structure was introduced to extract transient dynamic information and estimate concentration rapidly. Then, a dataset of mixed gases with different orders of magnitude was established by the E-nose to verify the model’s performance. Additionally, random forests and the decision tree regression model were used for comparison with the SNN-based model. Results show that the model utilizes the dynamic characteristics of the sensors, achieving smaller mean squared error (MSE < 0.01) and mean absolute error (MAE) with less data compared to random forest and decision tree algorithms. In conclusion, the electronic nose system combined with the bionic model shows a high performance in identifying gas mixtures, which has a great potential to be used for indoor air quality monitoring in practical applications.

1. Introduction

The petroleum industry and household activities can generate mixtures of flammable and toxic gases, containing a large variety of chemical compounds in specific proportions, including methane (CH4) and carbon monoxide (CO), and others. When these gases reach specific levels, they exhibit varying degrees of flammability, toxicity, and explosiveness, thereby posing significant risks to human health, safety, and the environment. The toxicity and explosive limits of gases are related to their concentrations. Many regions have established regulations regarding the exposure concentration and detection range of toxic and hazardous gases or flammable and explosive gases. For CO, the Occupational Safety and Health Administration (OSHA) in the United States has set the maximum allowable concentration in the workplace at 50 ppm [1], while the National Institute for Occupational Safety and Health (NIOSH) has set the maximum concentration at 200 ppm [2]. When the concentration of CO in the environment exceeds 100 ppm, individuals may experience mild headaches after 1–2 h; at 1000 ppm, unconsciousness may occur after one hour. For CH4, high concentrations of methane can lead to asphyxiation by displacing oxygen in the blood, potentially causing coma or death. NIOSH recommends a maximum safe methane concentration of 1000 ppm over an 8 h period [3]. When the concentration of CH4 exceeds 50,000 ppm and mixes with air, there is a potential risk of explosion. Therefore, it is essential to detect and distinguish gases from mixtures, particularly for the quantitative detection of target gases within the mixture.

Compared to traditional gas chromatography methods, the artificial olfactory system, known as the electronic nose (E-nose), offers a cost-effective solution for gas analysis by combining sensor arrays with the pattern recognition technology [4]. Sensor arrays of the E-nose are typically composed of a few chemosensors with broad and partially overlapping selectivity. By detecting chemical and physical changes caused by chemical molecules adsorbed on the surface of sensors, sensors obtain gas information and form a specific “fingerprint”. Pattern recognition technology can identify odors by extracting sensor response characteristics and learning the internal relationship of the data. E-noses at present are successfully applied in many fields, including environmental, food, health, security, and others [5,6,7]. To achieve gas component identification in mixed gases, two strategies can be employed: developing sensors with high selectivity and sensitivity [8,9], or employing efficient intelligent identification algorithms. The performance of the gas sensor can be optimized by selecting appropriate materials, dimensionality (0-D, 1-D, 2-D, or 3-D) of the sensing material, and sensor structure according to the detection mechanism.

Despite extensive efforts to find the optimal configurations with various parameters to enhance sensor performance, these improvements remain limited. To address this, researchers have started to employ advanced data processing technologies to further enhance sensor performance. Cho et al. [10] analyzed the binary gas mixtures using a fuzzy adaptive resonance theory map (ARTMAP) classifier and a fuzzy ART-based concentration estimator. However, the mixing ratio used in this study is fixed, so that the recognition accuracy can be improved by the drift correction algorithm. Chen et al. [11] used a least squares support vector machine (LSSVM) algorithm with particle swarm optimization for gas mixture concentration prediction. A public dataset with wind tunnel was used, but there were only three concentrations of each gas. Xu et al. [12] proposed a multivariable relevance vector machine (MVRVM) for the detection of the concentration; the concentration detection average relative errors were 5.58% and 5.38% of the two target gases, respectively. In this study, there were many kinds of gas mixtures, but the concentration range of the two gases was the same. In real-world gas mixtures, there are typically multiple gases present with varying concentration ranges and ratios. However, few studies have been specifically designed to address such complex scenarios. Furthermore, most algorithms identify gases over the entire sensor sampling period, which may not be suitable for short-duration or continuous real-time monitoring.

Spiking neural networks (SNNs) are regarded as the third-generation artificial neural network due to their biomimetic properties, which are potentially capable of modeling complex information processing in the brain [13]. Different from traditional networks, SNNs represent and integrate different information dimensions such as time, frequency, and phase by using trains of spikes, similar to the neural coding process by neurons, which makes them have the advantages of high calculation speed, low power consumption, and biological interpretability [14,15]. A classifier inspired by the insect antennal lobe was applied to identifying 20 individual chemical odors and achieved an accuracy of 92% using only the first 10% of the continuous data, showing the advantage of SNNs for continuous data [16]. However, most works so far that utilize SNNs focus on classification tasks [17,18].

In this study, a novel electronic nose combined with an SNN model is proposed for the recognition of mixed gases, specifically targeting mixtures of CO and CH4. Firstly, a miniaturized electronic nose system is used to detect mixed gases, and a dataset of gas mixtures is established, comprising single gases and mixed gases of two types. Subsequently, a concentration recognition model based on SNN is developed for identifying the concentrations of individual components in mixed gases, exploring the recognition effectiveness based on short-term data. Finally, the model is compared with common multi-output regression models to evaluate its performance.

2. Materials and Methods

2.1. Data Acquisition

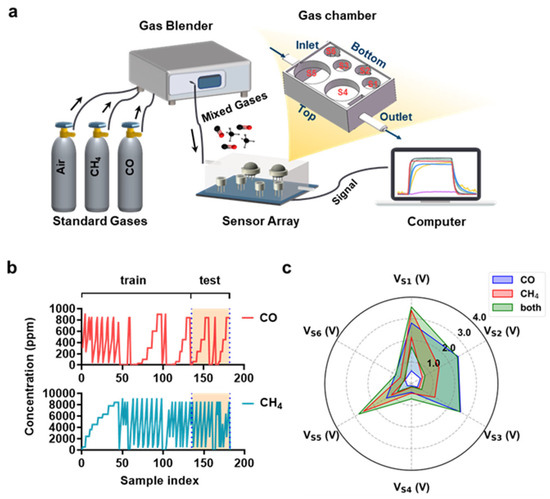

A self-developed E-nose system (Figure 1a) was used for data collection. The gas chamber is a basic rectangular cavity with dimensions of 56 mm × 43 mm × 38 mm. It is designed with an inlet and an outlet, each with a radius of 1.65 mm. The chamber accommodates six sensors and a temperature-humidity sensor, with spaces reserved according to the shape and height of the sensors in the sensor array. A small space is left between the sensor surfaces and the top of the gas chamber to serve as the gas reaction chamber. This design aims to minimize the chamber’s volume and increase the sample density within the shortest time. All gas sensors’ tops are exposed to the gas. When gas enters through the inlet, it flows rapidly across the surfaces of all sensors, ensuring thorough contact with each sensor and facilitating easy cleaning of the chamber. The gas then flows through gaps at the bottom and exits through the outlet. Finally, the sensor array is sealed within the gas chamber. The sensor array includes six commercial metal oxide semiconductor (MOS) sensors (MP-9, MP-4, MP503 from Winsen Electronics Technology Co., Ltd., Zhengzhou, China and TGS821, TGS816, TGS2602 from Figaro Engineering Inc., Osaka, Japan) [5,19]. The sensor models and their gas detection ranges are shown in Table 1. Additionally, a temperature and humidity sensor (SHT20, Sensirion, Stäfa, Switzerland) was used to monitor the gas temperature and humidity in real time. A gas mixer (Gas Blender 6000, MCQ Instruments, Rome, Italy) was used to provide different concentrations of gases for the electronic nose system. The standard air (79% nitrogen and 21% oxygen), CO (3010 ppm, standard air diluted), CH4 (30,100 ppm, standard air diluted) were all provided by Jingong Materials Co., Ltd. (Hangzhou, China).

Figure 1.

Sample collection and overview. (a) Electronic nose system diagram; (b) illustration of sample concentration collected; (c) radar chart of sensor response voltage for single and mixed gases.

Table 1.

Sensor models and gas detection ranges.

The electronic nose system was preheated for more than 30 min and cleaned with standard air at 1000 mL/min for 30 min until the voltage of the sensor was stable. The gas was passed through a thermostatic heated pipe before entering the chamber to keep the detected temperature in a constant range. Humidity can affect the sensor response, so to eliminate this interference, the gas output from the cylinder was in a dry state. Dynamic injection method was selected in the experiment. A constant flow rate of 1000 mL/min was set for the 5 min test. This duration was sufficiently long to ensure that most sensors reached a stable state, while also facilitating the later discussion of the possibility of recognition over different durations. Standard air was then used to clean the sensor array again for 5 min, allowing the baseline to return to its initial state, in preparation for the next sample test. The signal was collected at 0.3 Hz, and was uploaded to the computer after analog-to-digital conversion for subsequent analysis and processing.

The data consist of mixed gases with varying concentrations of carbon monoxide (CO) and methane (CH4). The concentration settings for all samples are shown in Figure 1b. According to the standards by Occupational Safety and Health Administration (OSHA) and National Institute for Occupational Safety and Health (NIOSH), the concentration range of CO was set from 0 to 1000 ppm, and the concentration range of CH4 was set from 0 to 10,000 ppm. A total of 182 samples were collected, with 133 designated as training data and 49 as testing data based on collection time. These samples include the presence of only CO, only CH4, and both gases. Figure 1c shows the gas response radar chart. It can be seen that there is an overlap between the range of mixed gases and the ranges of the two individual gases, leading to difficulties in recognizing the concentration of mixed gases.

2.2. Data Preprocessing and Spike Encoding

The raw sensor data obtained are represented as an three-dimensional matrix, where is the number of samples, is the number of sensors, and is the length of the time-series response. Let represent the time-series response of the -th sample of the -th sensor after filtering, where . The baseline response was subtracted from to obtain the response , effectively removing additive noise interference from the background. Due to potential biases in weight updates caused by differences in response intensity during model training, linear normalization was applied to standardize the data. This ensures a consistent magnitude of input variations over time. The normalized response was calculated as follows:

where represents the response of all samples on the -th sensor in the training set. and represent the maximum and minimum values of , respectively. By automatically scaling, the normalized response of each gas sensor falls within the range of (0, 1).

Due to the different concentration ranges of the target gases, with CO concentrations ranging from 0 to 1000 ppm and CH4 concentrations ranging from 0 to 10,000 ppm, it is necessary to scale these values to the range of 0 to 1 to enhance the efficiency and stability of the model training process. This can be achieved by dividing the CO concentrations by 1000 and the CH4 concentrations by 10,000, respectively.

2.3. Sensor Responses Encoding

Since SNNs require spike events as input, an encoding method is necessary to convert external continuous stimulus signals into discrete and sparse spike trains, akin to the neural coding process in biological neurons [20]. The rate encoding method encodes signal strengths by the mean firing rate of spike trains within a time window. However, this method, which relies on steady-state signals, loses information related to the adsorption/desorption kinetics of the sensors. In artificial sensors, the signal magnitude is directly linked to the number of odorant molecules bound in real time at the sensor surface, meaning the sensor response curve reflects the dynamic, time-varying gas process. Studies have shown that analyzing the dynamic response of chemical sensors enhances the discriminability of sensor arrays and can significantly reduce sensor response times [21]. Temporal encoding methods are capable of encoding the precise timing of each spike and can be used for the rapid processing of stimuli. These methods have been widely used for encoding various temporal signals, including speech [22] and EEG signals [23].

Therefore, to encode the dynamic response of the sensors, a temporal spike encoding method was used. Step-forward (SF) [24] is a contrast-based temporal encoding method. It calculates differences by iteratively updating baseline values, effectively representing changes in signals. SF encoding has demonstrated robust performance across various data types [20]. We employed the SF method to encode each sensor signal, setting the initial baseline to the first value of the signal. When the signal exceeds , a positive spike is generated and the baseline shifts to . Conversely, if the signal drops below , a negative spike is generated and the baseline shifts to . The threshold value is the only parameter in this encoding method. Selecting the appropriate threshold is crucial because a small threshold will introduce noise, while a large threshold leads to information loss. However, optimizing the threshold parameter for encoding methods typically requires individual calibration for each sensor, which involves significant computation and practical inconvenience. Here, we consider a population encoding method where a series of different thresholds is set for each sensor. With a total of thresholds, the final encoded data size becomes .

2.4. Concentration Identification Model

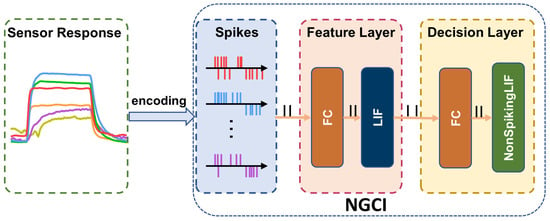

To achieve gas concentration recognition, an SNN-based model named Neural Gas Concentration Identification (NGCI) is proposed. This model employs a three-layer fully connected SNN architecture, as shown in Figure 2: the input layer consists of spike trains encoded from sensors, with neural units; the middle layer serves as a feature layer; and the final layer acts as a decision layer, with 2 neural units.

Figure 2.

Illustration of the proposed SNN computational architecture for sensor-based gas concentration recognition.

In this work, the Leaky Integrated-and-Fire (LIF) model [25] was used because of its computational efficiency and capability of capturing the essential features of information processing. The LIF model is a classic model used to simulate the activity of biological neurons. The model can be mathematically represented as:

where, is the membrane potential of the neuron, is the membrane time constant, is the resting membrane potential of the neuron, is the membrane resistance, is the time-dependent input current or stimuli. Its operation can be summarized as three stages. First, the neuron receives input currents or stimuli from other neurons. These inputs are weighted by certain weights and accumulated on the membrane potential of the neuron. Then, the membrane potential of the neuron gradually leaks and decreases over time with the time constant . Once the membrane potential of the neuron reaches a predefined threshold , the neuron generates an output spike. After firing, the membrane potential is reset to a resting value . For simplicity, and were set to 0, was set to 1 and was set to 1. SNNs are typically used for classification tasks, where in the decision layer, neurons’ firing rates are compared to determine the winning neuron with the highest firing rate. However, concentration prediction involves regression, where the predicted concentration value is continuous. Rates-based decoding yields discrete values, which are not continuous. Therefore, in the decision layer, a non-spiking LIF neuron was used to output floating-point numbers, which is often used in reinforcement learning. Its threshold was set to infinity, preventing it from firing spikes, and the membrane potential at the neuron’s last moment was used as the output value [26].

The model was trained by the end-to-end surrogate gradient learning (SGL) scheme. The losses were calculated by the weighted mean square error (Weighted MSE) loss function that measures the distance between the label and the output of the model. Weighted MSE is a common loss function in deep learning that allows assigning different weights to individual samples or outputs, thereby adjusting the model’s adaptation to various scenarios more effectively.

where is the number of samples and is the number of output units, represents the actual value of the -th sample for the -th output unit, represents the predicted value of the -th sample for the -th output unit. is the given time window. represents the weight of the -th sample for the -th output unit. Adjusting allows for weighting the contribution of different samples to the loss during training, thereby focusing more on specific samples or outputs to achieve a balanced or targeted loss distribution.

2.5. Model Performance Evaluation

To better evaluate the model’s performance, decision trees and random forests were also used for modeling. In order to evaluate the performance of a model, mean absolute error (MAE) and mean squared error (MSE) are commonly used metrics that provide insights into how accurately the model’s predictions align with the actual values. MAE is more robust to outliers because it gives equal weight to all errors, while MSE is more sensitive to outliers due to the squaring operation.

3. Results and Discussion

3.1. Preprocessing and Encoding Results

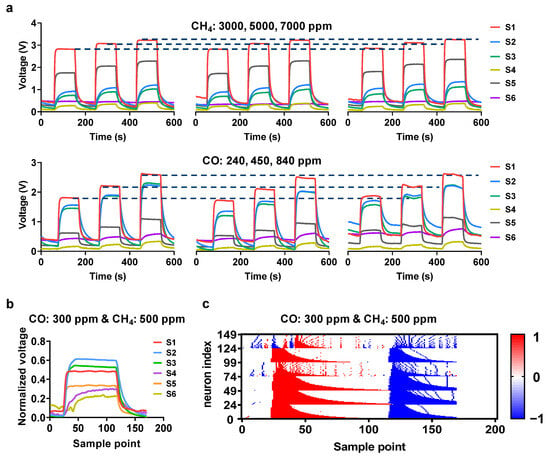

Figure 3a shows the concentration gradient and repeatability tests of the sensor array for two different gases (CO and CH4). It presents the results for CH4 concentrations at 3000, 5000, and 7000 ppm, and CO concentrations at 240, 450, and 840 ppm. The results indicate that the sensor response increases with higher concentrations. The two gases exhibit different gradient patterns. Additionally, the three repeatability tests demonstrate good consistency. These results lay the foundation for subsequent identification. Figure 3b shows a normalized results of a typical sensor response result for a sample, captured across 170 sampling points. The sample is a mixture with concentrations of 300 ppm CO and 500 ppm CH4. The sensor responses exhibit a distinct three-phase pattern. In this initial phase (first 25 sampling points), the sensors operated without exposure to the target substance, maintaining a stable response that reflects background noise and baseline readings. During the subsequent phase (26–115 sampling points), the sensors were exposed to the target substance, revealing varied responses among different sensors: sensor S1, S2, S3, and S5 stabilize quickly, whereas sensor S4 and S6 show a continuous increase throughout the phase, suggesting that they do not reach a stable value within this timeframe. In this final washing phase (116–170 sampling points), the target substance was removed. The sensor responses typically return to the baseline or near it, indicating recovery after exposure. Normalization plays a crucial role in ensuring the comparability of sensor responses across different sensors. This process standardizes responses to a common scale, facilitating clearer distinctions and similarities in sensor behaviors.

Figure 3.

Preprocessing and encoding results. (a) Concentration gradient and repeatability tests for CH4 and CO; (b) normalized response signal of typical response signal for a sample (CO: 300 ppm and CH4: 500 ppm); (c) encoded results corresponding to (b).

Further analysis involved spiking encoding of the normalized responses, utilizing a specific threshold range illustrated in Figure 3c. Thresholds ranged from 0.005 to 0.03, incremented by 0.001. As a result, responses from the six sensors were encoded into 150 spike trains (6 × 25). The SF encoding results are depicted in bipolar colors of red and blue in Figure 3c. During exposure to the target substance, positive neurons exhibit increased spiking activity, while during the washing phase, negative neurons show heightened activity. Lower neuron index corresponds to lower thresholds for each sensor, influencing spike generation accordingly. The data clearly illustrate that smaller thresholds lead to increased spike counts, whereas larger thresholds result in fewer spikes.

3.2. Recognition of Gas Mixtures

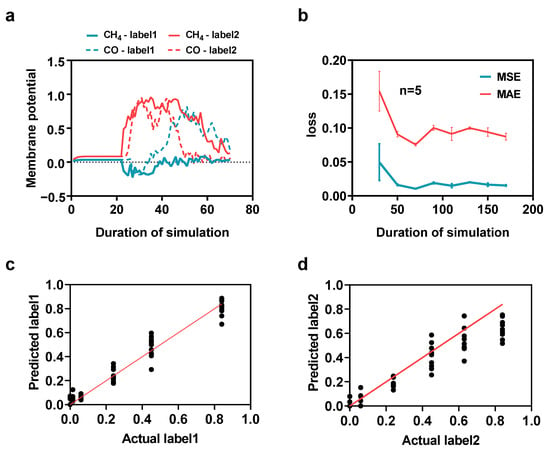

The membrane potential changes in the last layer of the model are depicted in Figure 4a. The solid line represents samples of methane gas at 2400 ppm, while the dashed line represents samples of CO at 240 ppm. The blue line signifies output label 1, indicating the predicted concentration of CO, while the red line corresponds to output label 2, representing the predicted concentration of CH4. It is evident that samples of the two gases exhibit distinct membrane potential changes. Despite this, due to the identical predicted normalized concentration, the endpoint of the solid red line closely aligns with that of the dashed blue line, and similarly, the endpoint of the dashed red line closely aligns with that of the solid blue line. This suggests that the concentration information has been accurately identified.

Figure 4.

Model outputs, optimization, and recognition results. (a) Membrane potential outputs of different gas samples; (b) optimization of simulation duration; (c) recognition results for CO concentration; (d) recognition results for CH4 concentration.

The simulation duration is a critical parameter in SNN models. A longer simulation duration captures the dynamic behavior and learning processes of the neural network. However, longer durations require more computational resources and time. Therefore, we evaluated the model with simulation durations ranging from 30 to 170 timesteps, with intervals of 20, as shown in the Figure 4b. As the first 25 sampling points serve as the baseline, this setup ensures that the timesteps cover the entire gas detection process. The curve in the figure initially shows a rapid decrease in loss as the simulation duration increases, reaching its lowest point at 70 timesteps. After this, the loss fluctuates within a certain range despite further increases in simulation duration. This behavior might be related to the encoding process. As observed in the previous figures (Figure 3c), spikes are densely emitted during the sensor’s rising phase. This may mean that only sensor data used in the rise stage can identify the concentration. This lays the foundation for rapid gas identification. Due to the signal being encoded using time encoding methods, shortening the simulation duration is equivalent to utilizing only the effective information from the first 70 data points. The recognition results using a model with a simulation duration of 70 are shown in Figure 4c,d. Figure 4c shows the recognition results for label 1 (CO), and Figure 4d shows the recognition results for label 2 (CH4). Since the output values are continuous variables, some values below 0 are observed. However, the target variable, representing concentration, should theoretically be greater than or equal to 0. Therefore, we have applied a simple method to set recognition results below 0 to 0. From the results, it is apparent that recognition of high concentrations of CH4 tends to be lower. This could be attributed to sensor responses nearing saturation at higher concentrations.

Finally, the sensor data curve of the first 70 points of the sensors are used as the input of the random forest and the decision tree to perform multiple input–multiple output regression prediction. The results are shown in Table 2. NGCI achieved the smallest MSE and MAE, compared with other algorithms.

Table 2.

Results of different models.

4. Conclusions and Discussion

In this study, a miniaturized electronic nose combined with an SNN model is proposed for identifying gas mixtures. The electronic nose was used to construct a dataset of mixed gases, encompassing varying concentrations of CO and CH4 gas mixtures. The range of gas concentrations is determined based on relevant regulations governing exposure limits and explosion limits. Subsequently, an SNN-based model for gas concentration identification named NGCI was proposed for gas concentration identification. The model adopts a three-layer fully connected structure, the first layer employs population-based contrastive temporal encoding to process sensor signals. By using a series of different thresholds, high-contrast events and low-contrast events are effectively encoded. The encoded results are fed into a feature extraction layer to extract important information from the encoded signals. Finally, a non-spiking LIF model was used to estimate the continuous numerical values of normalized gas concentration. Compared with the commonly used two kinds of multi-output regression models, the proposed model is able to estimate the concentration using a small amount of data, achieving a smaller MSE of 0.0099 and MAE of 0.0723 than other algorithms.

Future research can further optimize the model structure, explore the recognition capabilities for more mixed gas components, and consider deployment in practical engineering and environmental monitoring. The current experiment only considered the recognition of gas mixture concentrations under dry conditions. In practical applications, gases are often present under varying humidity conditions. However, the humidity interference can be mitigated by externally attaching a drying tube in front of the chamber. Therefore, this method can be implemented in practical applications by modifying the system configuration without altering the network itself.

Author Contributions

Conceptualization, H.W., L.Z. and P.W.; methodology, Y.X., C.C., W.Y., L.Z. and P.W.; software, S.M. and C.C.; validation, W.Y.; formal analysis, C.C.; investigation, S.M. and W.Y.; resources, H.W. and L.Z.; data curation, Y.X.; writing—original draft preparation, Y.X.; writing—review and editing, Y.X., S.M. and P.W.; visualization, Y.X.; supervision, H.W., L.Z. and P.W.; project administration, H.W., L.Z. and P.W.; funding acquisition, P.W. and C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by National Key Research and Development Program of China (No. 2021YFC3300303), National Natural Science Foundation of China (No. 62120106004, 32250008) and Scientific Research Fund of Zhejiang Provincial Education Department (Y202353232).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest, financial or otherwise.

References

- Occupational Safety and Health Administration (OSHA). Carbon Monoxide in Workplace Atmospheres. 1991. Available online: https://www.osha.gov/sites/default/files/methods/osha-id210.pdf (accessed on 15 June 2024).

- National Institute for Occupational Safety and Health. Occupational Exposure to Carbon Monoxide. 1972. Available online: https://stacks.cdc.gov/view/cdc/19324 (accessed on 15 June 2024).

- Macasaet, D.; Bandala, A.; Illahi, A.A.; Dadios, E.; Lauguico, S. Hazard Classification of Toluene, Methane and Carbon Dioxide for Bomb Detection Using Fuzzy Logic. In Proceedings of the 2019 IEEE 11th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Laoag, Philippines, 29 November–1 December 2019. [Google Scholar] [CrossRef]

- Chen, H.; Huo, D.X.; Zhang, J.L. Gas Recognition in E-Nose System: A Review. IEEE Trans. Biomed. Circuits Syst. 2022, 16, 169–184. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Xue, Y.; Sun, Q.; Zhang, T.; Chen, Y.; Yu, W.; Xiong, Y.; Wei, X.; Yu, G.; Wan, H. A miniaturized electronic nose with artificial neural network for anti-interference detection of mixed indoor hazardous gases. Sens. Actuators B Chem. 2021, 326, 128822. [Google Scholar] [CrossRef]

- Karakaya, D.; Ulucan, O.; Turkan, M. Electronic nose and its applications: A survey. Int. J. Autom. Comput. 2020, 17, 179–209. [Google Scholar] [CrossRef]

- Ali, M.M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Principles and recent advances in electronic nose for quality inspection of agricultural and food products. Trends Food Sci. Technol. 2020, 99, 1–10. [Google Scholar]

- Nag, S.; Castro, M.; Choudhary, V.; Feller, J.F. Sulfonated poly(ether ether ketone) [SPEEK] nanocomposites based on hybrid nanocarbons for the detection and discrimination of some lung cancer VOC biomarkers. J. Mater. Chem. B 2017, 5, 348–359. [Google Scholar] [CrossRef] [PubMed]

- Freddi, S.; Gonzalez, M.C.R.; Casotto, A.; Sangaletti, L.; De Feyter, S. Machine-Learning-Aided NO2 Discrimination with an Array of Graphene Chemiresistors Covalently Functionalized by Diazonium Chemistry. Chem. Eur. J. 2023, 29, e202302154. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.H.; Kim, Y.W.; Na, K.J.; Jeon, G.J. Wireless electronic nose system for real-time quantitative analysis of gas mixtures using micro-gas sensor array and neuro-fuzzy network. Sens. Actuat. B-Chem. 2008, 134, 104–111. [Google Scholar] [CrossRef]

- Chen, Y.S.; Xia, W.Y.; Chen, D.Y.; Zhang, T.Y.; Song, T.T.; Zhao, W.J.; Song, K. A Qualitative and Quantitative Analysis Strategy for Continuous Turbulent Gas Mixture Monitoring. Chemosensors 2022, 10, 499. [Google Scholar] [CrossRef]

- Xu, Y.H.; Zhao, X.; Chen, Y.S.; Zhao, W.J. Research on a Mixed Gas Recognition and Concentration Detection Algorithm Based on a Metal Oxide Semiconductor Olfactory System Sensor Array. Sensors 2018, 18, 3264. [Google Scholar] [CrossRef] [PubMed]

- Taherkhani, A.; Belatreche, A.; Li, Y.H.; Cosma, G.; Maguire, L.P.; McGinnity, T.M. A review of learning in biologically plausible spiking neural networks. Neural Netw. 2020, 122, 253–272. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.B.; Chua, Y.S.; Zhang, M.L.; Li, G.Q.; Li, H.Z.; Tan, K.C. A Tandem Learning Rule for Effective Training and Rapid Inference of Deep Spiking Neural Networks. Ieee Trans. Neural Netw. Learn. Syst. 2023, 34, 446–460. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.D.; Perez-Gonzalez, D.; Rees, A.; Erwin, H.; Wermter, S. A biologically inspired spiking neural network model of the auditory midbrain for sound source localisation. Neurocomputing 2010, 74, 129–139. [Google Scholar] [CrossRef]

- Diamond, A.; Schmuker, M.; Berna, A.Z.; Trowell, S.; Nowotny, T. Classifying continuous, real-time e-nose sensor data using a bio-inspired spiking network modelled on the insect olfactory system. Bioinspir. Biomim. 2016, 11, 026002. [Google Scholar] [CrossRef] [PubMed]

- Imam, N.; Cleland, T.A. Rapid online learning and robust recall in a neuromorphic olfactory circuit. Nat. Mach. Intell. 2020, 2, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Zheng, Y.G. Robust gas recognition with mixed interference using a spiking neural network. Meas. Sci. Technol. 2022, 33, 015105. [Google Scholar] [CrossRef]

- Zhang, J.; Xue, Y.; Zhang, T.; Chen, Y.; Wei, X.; Wan, H.; Wang, P. Detection of Hazardous Gas Mixtures in the Smart Kitchen Using an Electronic Nose with Support Vector Machine. J. Electrochem. Soc. 2020, 167, 147519. [Google Scholar] [CrossRef]

- Petro, B.; Kasabov, N.; Kiss, R.M. Selection and Optimization of Temporal Spike Encoding Methods for Spiking Neural Networks. IEEE Trans. Neural Netw. Learn. Syst. 2020, 31, 358–370. [Google Scholar] [CrossRef] [PubMed]

- Magna, G.; Martinelli, E.; Paolesse, R.; Di Natale, C. Bio-inspired encoding for a real-time and stable single component odor detection with a highly-redundant optical artificial olfactory system. Sens. Actuat. B-Chem. 2022, 373, 132719. [Google Scholar] [CrossRef]

- Stewart, K.; Shea, T.M.; Pacik-Nelson, N.; Gallo, E.; Danielescu, A. Speech2Spikes: Efficient Audio Encoding Pipeline for Real-time Neuromorphic Systems. In Proceedings of the 2023 Annual Neuro-Inspired Computational Elements Conference, Nice 2023, San Antonio, TX, USA, 11–14 April 2023; pp. 71–78. [Google Scholar] [CrossRef]

- Tan, C.; Sarlija, M.; Kasabov, N. NeuroSense: Short-term emotion recognition and understanding based on spiking neural network modelling of spatio-temporal EEG patterns. Neurocomputing 2021, 434, 137–148. [Google Scholar] [CrossRef]

- Guo, W.Z.; Fouda, M.E.; Eltawil, A.M.; Salama, K.N. Neural Coding in Spiking Neural Networks: A Comparative Study for Robust Neuromorphic Systems. Front. Neurosci. 2021, 15, 638474. [Google Scholar] [CrossRef] [PubMed]

- Li, W.S.; Chen, H.T.; Guo, J.Y.; Zhang, Z.Y.; Wang, Y.H. Brain-inspired Multilayer Perceptron with Spiking Neurons. In Proceedings of the 2022 Ieee/Cvf Conference on Computer Vision and Pattern Recognition (Cvpr 2022), New Orleans, LA, USA, 18–24 June 2022; pp. 773–783. [Google Scholar] [CrossRef]

- Guerrero, E.; Quintana, F.M.; Guerrero-Lebrero, M.P. Event-Based Regression with Spiking Networks. In International Work-Conference on Artificial Neural Networks; Springer: Cham, Switzerland, 2023; Volume 14135, pp. 617–628. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).