Materials for Chemical Sensing: A Comprehensive Review on the Recent Advances and Outlook Using Ionic Liquids, Metal–Organic Frameworks (MOFs), and MOF-Based Composites

Abstract

:1. Introduction

2. Sensing Methods: Amperometric Sensors, Fluorescence-Based Sensors, and Chemiresistors

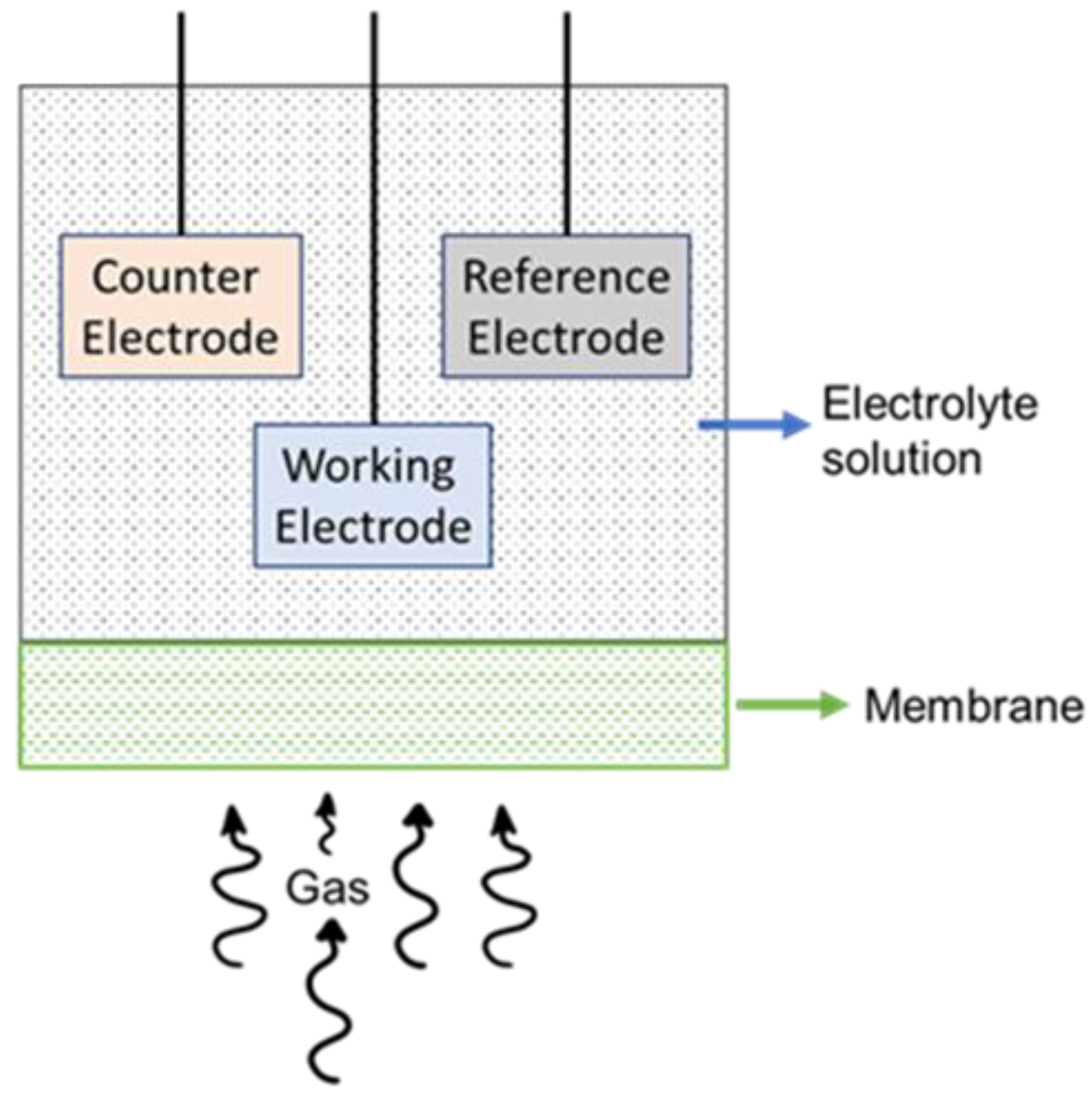

2.1. Amperometric Electrochemical Gas Sensors

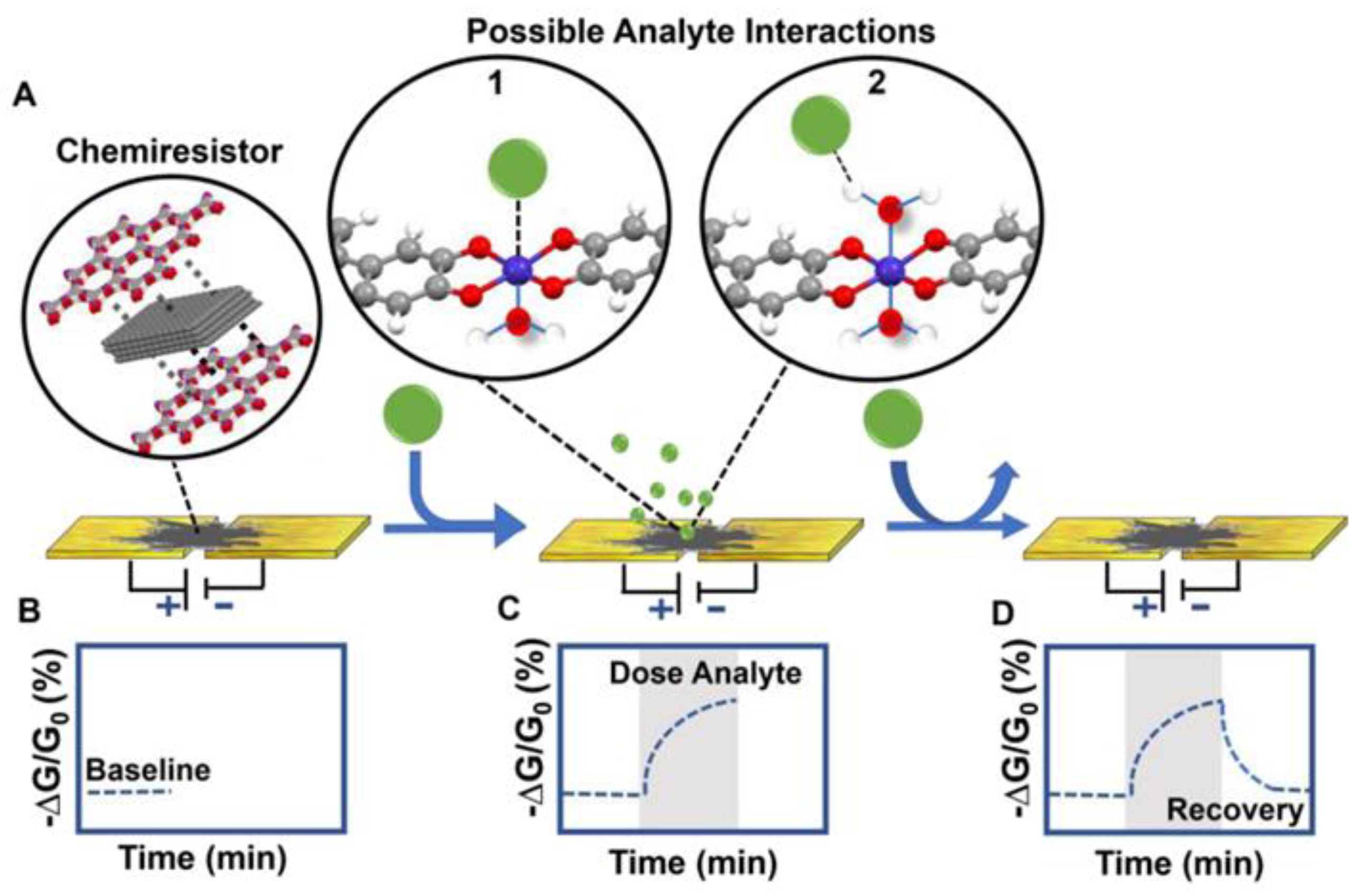

2.2. Chemiresistive Gas Sensors

2.3. Optochemical and Photoluminescence-Based Sensors

3. Ionic Liquids in Amperometric Gas Sensing—Recent Developments

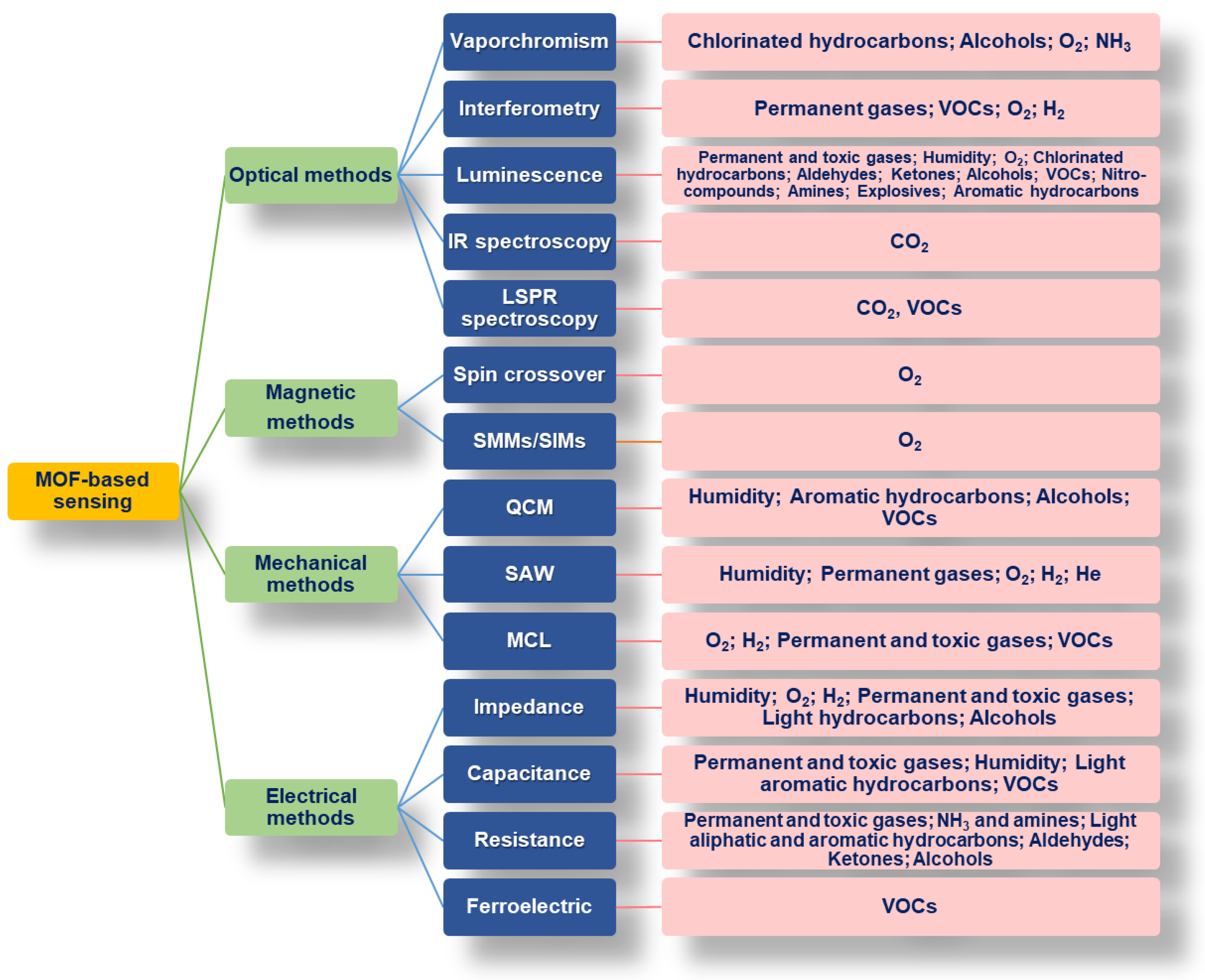

4. Metal–Organic-Framework-Based Composites in Gas Sensing—Recent Developments

4.1. General Properties of Metal–Organic Frameworks

4.2. MOFs in Optical Gas Sensing

4.2.1. Vapochromism

4.2.2. Luminescence

4.2.3. Interferometry

4.2.4. Localized Surface Plasmon Resonance (LSPR)

4.2.5. Infrared Spectroscopy

4.3. MOF-Based Sensors Using Gravimetric and Mechanical Methods

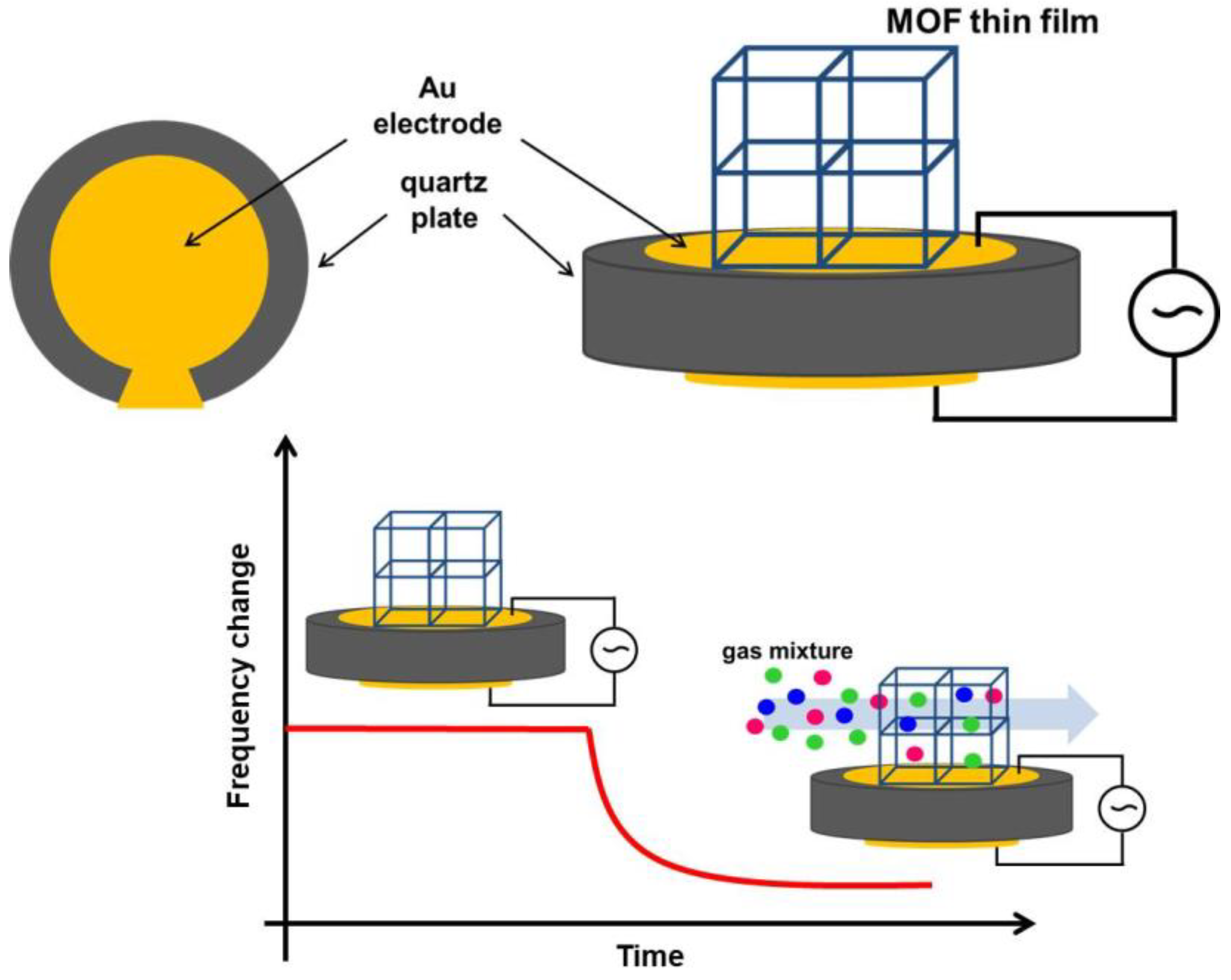

4.3.1. Quartz Crystal Microbalance (QCM)-Based Sensors

4.3.2. Surface Acoustic Wave Sensors (SAWS)

4.3.3. Microcantilever-Based Sensors (MCLs)

4.4. MOF-Based Sensors Using Electrical Methods

4.4.1. Chemoresistors

4.4.2. Chemicapacitive Sensors

4.4.3. Sensors Based on Changes in AC Impedance

4.4.4. Sensors Based on Changes in the Work Function

4.5. Additional Methods

4.5.1. Methods Involving Ferroelectric Properties

4.5.2. Methods Involving Magnetic Properties

4.6. Recent Advances in Gas Sensing Based on MOF-Based Hybrid Organic–Inorganic Composites

4.6.1. Composites of MOFs with Metal Oxides (MOXs)

4.6.2. Composites of MOFs with Noble-Metal Nanoparticles

4.6.3. Composites of MOFs with Carbon-Based Materials

4.6.4. Composites of MOFs with Conducting Polymers

5. Conclusions and Perspectives

- MOF materials employed for hybrid MOFs-MOXs composites are still limited; thus, the size of gas molecules that can be detected at present is also limited. Therefore, it is important to individuate other suitable MOF materials to be used instead of ZIF. Since the choice of MOX is dominated by ZnO due to the synthetic approach implemented, new methods of synthesis involving other MOXs as metal precursors have to be tested and other synthetic approaches have to be developed, also with the hope of improving more the sensing performance for specific gases.

- A surprisingly small number of reports is available on gas sensing based on MOF/carbon-based materials, if compared with the high number of studies in which this class of materials is employed as gas adsorbents. Such a limitation is probably partly related to the poor processability and to the synthetic approaches used, so research efforts in such a direction have to be prompted.

- Regarding MOF/polymer composites, there are few applications in gas sensing and the corresponding selection of MOF materials and polymers is also small. Such limitations are related to different aspects: MOFs have a certain pore size, and if the polymer is polymerized and inserted into the MOF pores, the transport of some gas molecules can be hampered and the accessibility of the target analyte to the active sites can be limited; the homogeneous dispersion of polymers in MOFs is, in most cases, far from being achieved and it still needs to be explored and optimized. In addition, the polymer-loading amount plays an important role in defining the final composite properties so various synthetic methods need to be further improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gas and Particle Sensors–Technology and Market Trends 2021. Available online: https://www.i-micronews.com/products/gas-and-particle-sensors-technology-and-market-trends-2021/ (accessed on 9 April 2022).

- Fortune Business Insights Industrial Gas Sensors Market Size, Growth|Industry Report 2026. Available online: https://www.fortunebusinessinsights.com/industry-reports/industrial-gas-sensors-market-101064 (accessed on 9 April 2022).

- Barsan, N.; Koziej, D.; Weimar, U. Metal Oxide-Based Gas Sensor Research: How to? Sens. Actuators B Chem. 2007, 121, 18–35. [Google Scholar] [CrossRef]

- Barsan, N.; Weimar, U. Conduction Model of Metal Oxide Gas Sensors. J. Electroceram. 2001, 7, 143–167. [Google Scholar] [CrossRef]

- Korotcenkov, G. The Role of Morphology and Crystallographic Structure of Metal Oxides in Response of Conductometric-Type Gas Sensors. Mater. Sci. Eng. R Rep. 2008, 61, 1–39. [Google Scholar] [CrossRef]

- Baron, R.; Saffell, J. Amperometric Gas Sensors as a Low Cost Emerging Technology Platform for Air Quality Monitoring Applications: A Review. ACS Sens. 2017, 2, 1553–1566. [Google Scholar] [CrossRef] [PubMed]

- Lin, R.; Liu, S.; Ye, J.; Li, X.; Zhang, J. Photoluminescent Metal–Organic Frameworks for Gas Sensing. Adv. Sci. 2016, 3, 1500434. [Google Scholar] [CrossRef]

- Wagner, T.; Haffer, S.; Weinberger, C.; Klaus, D.; Tiemann, M. Mesoporous Materials as Gas Sensors. Chem. Soc. Rev. 2013, 42, 4036–4053. [Google Scholar] [CrossRef]

- Stetter, J.R.; Li, J. Amperometric Gas SensorsA Review. Chem. Rev. 2008, 108, 352–366. [Google Scholar] [CrossRef] [PubMed]

- Malik, R.; Tomer, V.K.; Mishra, Y.K.; Lin, L. Functional Gas Sensing Nanomaterials: A Panoramic View. Appl. Phys. Rev. 2020, 7, 021301. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, R.; Gardner, J.W.; Guha, P.K. Air Pollution Monitoring Using Near Room Temperature Resistive Gas Sensors: A Review. IEEE Trans. Electron. Devices 2019, 66, 3254–3264. [Google Scholar] [CrossRef]

- Halfaya, Y.; Bishop, C.; Soltani, A.; Sundaram, S.; Aubry, V.; Voss, P.L.; Salvestrini, J.-P.; Ougazzaden, A. Investigation of the Performance of HEMT-Based NO, NO2 and NH3 Exhaust Gas Sensors for Automotive Antipollution Systems. Sensors 2016, 16, 273. [Google Scholar] [CrossRef]

- Wales, D.J.; Grand, J.; Ting, V.P.; Burke, R.D.; Edler, K.J.; Bowen, C.R.; Mintova, S.; Burrows, A.D. Gas Sensing Using Porous Materials for Automotive Applications. Chem. Soc. Rev. 2015, 44, 4290–4321. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, X.; Yip, S.; Meng, Y.; Wang, W.; Li, D.; Liu, C.; Ho, J.C. High-Performance Electrically Transduced Hazardous Gas Sensors Based on Low-Dimensional Nanomaterials. Nanoscale Adv. 2021, 3, 6254–6270. [Google Scholar] [CrossRef]

- Horsfall, L.A.; Pugh, D.C.; Blackman, C.S.; Parkin, I.P. An Array of WO3 and CTO Heterojunction Semiconducting Metal Oxide Gas Sensors Used as a Tool for Explosive Detection. J. Mater. Chem. A 2017, 5, 2172–2179. [Google Scholar] [CrossRef]

- Mirzaei, A.; Leonardi, S.G.; Neri, G. Detection of Hazardous Volatile Organic Compounds (VOCs) by Metal Oxide Nanostructures-Based Gas Sensors: A Review. Ceram. Int. 2016, 42, 15119–15141. [Google Scholar] [CrossRef]

- Leidinger, M.; Sauerwald, T.; Reimringer, W.; Ventura, G.; Schütze, A. Selective Detection of Hazardous VOCs for Indoor Air Quality Applications Using a Virtual Gas Sensor Array. J. Sens. Sens. Syst. 2014, 3, 253–263. [Google Scholar] [CrossRef] [Green Version]

- Chaisiwamongkhol, K.; Batchelor-McAuley, C.; Compton, R.G. Optimising Amperometric PH Sensing in Blood Samples: An Iridium Oxide Electrode for Blood PH Sensing. Analyst 2019, 144, 1386–1393. [Google Scholar] [CrossRef]

- Landini, N.; Anania, G.; Fabbri, B.; Gaiardo, A.; Gherardi, S.; Guidi, V.; Rispoli, G.; Scagliarini, L.; Zonta, G.; Malagù, C. Neoplasms and Metastasis Detection in Human Blood Exhalations with a Device Composed by Nanostructured Sensors. Sens. Actuators B Chem. 2018, 271, 203–214. [Google Scholar] [CrossRef]

- Galstyan, V.; Bhandari, M.P.; Sberveglieri, V.; Sberveglieri, G.; Comini, E. Metal Oxide Nanostructures in Food Applications: Quality Control and Packaging. Chemosensors 2018, 6, 16. [Google Scholar] [CrossRef] [Green Version]

- Pallotti, D.; Orabona, E.; Amoruso, S.; Maddalena, P.; Lettieri, S. Modulation of Mixed-Phase Titania Photoluminescence by Oxygen Adsorption. Appl. Phys. Lett. 2014, 105, 031903. [Google Scholar] [CrossRef] [Green Version]

- Gaiardo, A.; Fabbri, B.; Guidi, V.; Bellutti, P.; Giberti, A.; Gherardi, S.; Vanzetti, L.; Malagù, C.; Zonta, G. Metal Sulfides as Sensing Materials for Chemoresistive Gas Sensors. Sensors 2016, 16, 296. [Google Scholar] [CrossRef]

- Ambrosone, G.; Coscia, U.; Lettieri, S.; Maddalena, P.; Privato, C.; Ferrero, S. Hydrogenated Amorphous Silicon Carbon Alloys for Solar Cells. Thin Solid Film. 2002, 403, 349–353. [Google Scholar] [CrossRef]

- Comini, E. Metal Oxide Nano-Crystals for Gas Sensing. Anal. Chim. Acta 2006, 568, 28–40. [Google Scholar] [CrossRef] [PubMed]

- Setaro, A.; Bismuto, A.; Lettieri, S.; Maddalena, P.; Comini, E.; Bianchi, S.; Baratto, C.; Sberveglieri, G. Optical Sensing of NO2 in Tin Oxide Nanowires at Sub-Ppm Level. Sens. Actuators B Chem. 2008, 130, 391–395. [Google Scholar] [CrossRef]

- Setaro, A.; Lettieri, S.; Diamare, D.; Maddalena, P.; Malagù, C.; Carotta, M.C.; Martinelli, G. Nanograined Anatase Titania-Based Optochemical Gas Detection. New J. Phys. 2008, 10, 053030. [Google Scholar] [CrossRef] [Green Version]

- Bittig, H.C.; Körtzinger, A.; Neill, C.; van Ooijen, E.; Plant, J.N.; Hahn, J.; Johnson, K.S.; Yang, B.; Emerson, S.R. Oxygen Optode Sensors: Principle, Characterization, Calibration, and Application in the Ocean. Front. Mar. Sci. 2018, 4, 429. [Google Scholar] [CrossRef]

- Wang, X.; Wolfbeis, O.S. Optical Methods for Sensing and Imaging Oxygen: Materials, Spectroscopies and Applications. Chem. Soc. Rev. 2014, 43, 3666–3761. [Google Scholar] [CrossRef] [Green Version]

- Quaranta, M.; Borisov, S.M.; Klimant, I. Indicators for Optical Oxygen Sensors. Bioanal. Rev. 2012, 4, 115–157. [Google Scholar] [CrossRef] [Green Version]

- Clark, L.C.; Wolf, R.; Granger, D.; Taylor, Z. Continuous Recording of Blood Oxygen Tensions by Polarography. J. Appl. Physiol. 1953, 6, 189–193. [Google Scholar] [CrossRef]

- Clark, J.L.C. Electrochemical Device for Chemical Analysis. U.S. Patent No. 2,913,386; Washington, DC: U.S. Patent and Trademark Office, 17 November 1959. [Google Scholar]

- Xiong, L.; Compton, R.G. Amperometric Gas Detection: A Review. Int. J. Electrochem. Sci. 2014, 9, 30. [Google Scholar]

- Vogel, W.M.; Lundquist, J.T. Reduction of Oxygen on Teflon-Bonded Platinum Electrodes. J. Electrochem. Soc. 1970, 117, 1512. [Google Scholar] [CrossRef]

- Buzzeo, M.C.; Hardacre, C.; Compton, R.G. Use of Room Temperature Ionic Liquids in Gas Sensor Design. Anal. Chem. 2004, 76, 4583–4588. [Google Scholar] [CrossRef] [PubMed]

- Gębicki, J.; Kloskowski, A.; Chrzanowski, W.; Stepnowski, P.; Namiesnik, J. Application of Ionic Liquids in Amperometric Gas Sensors. Crit. Rev. Anal. Chem. 2016, 46, 122–138. [Google Scholar] [CrossRef] [PubMed]

- Gardecka, A.J.; Bishop, C.; Lee, D.; Corby, S.; Parkin, I.P.; Kafizas, A.; Krumdieck, S. High Efficiency Water Splitting Photoanodes Composed of Nano-Structured Anatase-Rutile TiO2 Heterojunctions by Pulsed-Pressure MOCVD. Appl. Catal. B Environ. 2018, 224, 904–911. [Google Scholar] [CrossRef]

- Preiß, E.M.; Rogge, T.; Krauß, A.; Seidel, H. Tin Oxide-Based Thin Films Prepared by Pulsed Laser Deposition for Gas Sensing. Sens. Actuators B Chem. 2016, 236, 865–873. [Google Scholar] [CrossRef]

- Sanz, M.; Castillejo, M.; Amoruso, S.; Ausanio, G.; Bruzzese, R.; Wang, X. Ultra-Fast Laser Ablation and Deposition of TiO2. Appl. Phys. A 2010, 101, 639–644. [Google Scholar] [CrossRef] [Green Version]

- Sanz, M.; López-Arias, M.; Marco, J.F.; de Nalda, R.; Amoruso, S.; Ausanio, G.; Lettieri, S.; Bruzzese, R.; Wang, X.; Castillejo, M. Ultrafast Laser Ablation and Deposition of Wide Band Gap Semiconductors. J. Phys. Chem. C 2011, 115, 3203–3211. [Google Scholar] [CrossRef]

- Coscia, U.; Ambrosone, G.; Lettieri, S.; Maddalena, P.; Rigato, V.; Restello, S.; Bobeico, E.; Tucci, M. Preparation of Microcrystalline Silicon–Carbon Films. Sol. Energy Mater. Sol. Cells 2005, 87, 433–444. [Google Scholar] [CrossRef]

- Ambrosone, G.; Coscia, U.; Lettieri, S.; Maddalena, P.; Minarini, C. Optical, Structural and Electrical Properties of Μc-Si:H Films Deposited by SiH4+H2. Mater. Sci. Eng. B 2003, 101, 236–241. [Google Scholar] [CrossRef]

- Parashar, M.; Shukla, V.K.; Singh, R. Metal Oxides Nanoparticles via Sol–Gel Method: A Review on Synthesis, Characterization and Applications. J. Mater. Sci. Mater. Electron. 2020, 31, 3729–3749. [Google Scholar] [CrossRef]

- Esposito, S. “Traditional” Sol-Gel Chemistry as a Powerful Tool for the Preparation of Supported Metal and Metal Oxide Catalysts. Materials 2019, 12, 668. [Google Scholar] [CrossRef] [Green Version]

- Liu, N.; Chen, X.; Zhang, J.; Schwank, J.W. A Review on TiO2-Based Nanotubes Synthesized via Hydrothermal Method: Formation Mechanism, Structure Modification, and Photocatalytic Applications. Catal. Today 2014, 225, 34–51. [Google Scholar] [CrossRef]

- Meyyappan, M. Carbon Nanotube-Based Chemical Sensors. Small 2016, 12, 2118–2129. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Huang, D.; Yang, Z.; Xu, S.; He, G.; Li, X.; Hu, N.; Yin, G.; He, D.; Zhang, L. A Review on Graphene-Based Gas/Vapor Sensors with Unique Properties and Potential Applications. Nano. Micro. Lett. 2016, 8, 95–119. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Jiang, C.; Wei, S. Gas Sensing in 2D Materials. Appl. Phys. Rev. 2017, 4, 021304. [Google Scholar] [CrossRef]

- Koo, W.-T.; Jang, J.-S.; Kim, I.-D. Metal-Organic Frameworks for Chemiresistive Sensors. Chem 2019, 5, 1938–1963. [Google Scholar] [CrossRef]

- Yao, M.-S.; Lv, X.-J.; Fu, Z.-H.; Li, W.-H.; Deng, W.-H.; Wu, G.-D.; Xu, G. Layer-by-Layer Assembled Conductive Metal–Organic Framework Nanofilms for Room-Temperature Chemiresistive Sensing. Angew. Chem. Int. Ed. 2017, 56, 16510–16514. [Google Scholar] [CrossRef] [PubMed]

- Ando, M. Recent Advances in Optochemical Sensors for the Detection of H2, O2, O3, CO, CO2 and H2O in Air. TrAC Trends Anal. Chem. 2006, 25, 937–948. [Google Scholar] [CrossRef]

- Lettieri, S.; Pallotti, D.K.; Gesuele, F.; Maddalena, P. Unconventional Ratiometric-Enhanced Optical Sensing of Oxygen by Mixed-Phase TiO2. Appl. Phys. Lett. 2016, 109, 031905. [Google Scholar] [CrossRef] [Green Version]

- Popa, D.; Udrea, F. Towards Integrated Mid-Infrared Gas Sensors. Sensors 2019, 19, 2076. [Google Scholar] [CrossRef] [Green Version]

- Nugroho, F.A.A.; Darmadi, I.; Cusinato, L.; Susarrey-Arce, A.; Schreuders, H.; Bannenberg, L.J.; da Silva Fanta, A.B.; Kadkhodazadeh, S.; Wagner, J.B.; Antosiewicz, T.J.; et al. Metal–Polymer Hybrid Nanomaterials for Plasmonic Ultrafast Hydrogen Detection. Nat. Mater. 2019, 18, 489–495. [Google Scholar] [CrossRef] [Green Version]

- Lakowicz, J.R. (Ed.) Mechanisms and Dynamics of Fluorescence Quenching. In Principles of Fluorescence Spectroscopy; Springer: Boston, MA, USA, 2006; pp. 331–351. ISBN 978-0-387-46312-4. [Google Scholar]

- Borbone, F.; Carella, A.; Caruso, U.; Roviello, G.; Tuzi, A.; Dardano, P.; Lettieri, S.; Maddalena, P.; Barsella, A. Large Second-Order NLO Activity in Poly(4-Vinylpyridine) Grafted with PdII and CuII Chromophoric Complexes with Tridentate Bent Ligands Containing Heterocycles. Eur. J. Inorg. Chem. 2008, 2008, 1846–1853. [Google Scholar] [CrossRef]

- Bellani, S.; Ghadirzadeh, A.; Meda, L.; Savoini, A.; Tacca, A.; Marra, G.; Meira, R.; Morgado, J.; Di Fonzo, F.; Antognazza, M.R. Hybrid Organic/Inorganic Nanostructures for Highly Sensitive Photoelectrochemical Detection of Dissolved Oxygen in Aqueous Media. Adv. Funct. Mater. 2015, 25, 4531–4538. [Google Scholar] [CrossRef]

- Li, C.; Ding, S.; Yang, L.; Zhu, Q.; Chen, M.; Tsang, D.C.W.; Cai, G.; Feng, C.; Wang, Y.; Zhang, C. Planar Optode: A Two-Dimensional Imaging Technique for Studying Spatial-Temporal Dynamics of Solutes in Sediment and Soil. Earth Sci. Rev. 2019, 197, 102916. [Google Scholar] [CrossRef]

- Han, C.; Ren, J.; Tang, H.; Xu, D.; Xie, X. Quantitative Imaging of Radial Oxygen Loss from Valisneria Spiralis Roots with a Fluorescent Planar Optode. Sci. Total Environ. 2016, 569, 1232–1240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, Z.; Yu, X.; Hao, Y. Design and Fabrication of a Ratiometric Planar Optode for Simultaneous Imaging of PH and Oxygen. Sensors 2017, 17, 1316. [Google Scholar] [CrossRef] [Green Version]

- Larsen, M.; Borisov, S.M.; Grunwald, B.; Klimant, I.; Glud, R.N. A Simple and Inexpensive High Resolution Color Ratiometric Planar Optode Imaging Approach: Application to Oxygen and PH Sensing.: A Simple RGB Based Planar Optode Imaging Approach. Limnol. Oceanogr. Methods 2011, 9, 348–360. [Google Scholar] [CrossRef]

- Koren, K.; Moßhammer, M.; Scholz, V.V.; Borisov, S.M.; Holst, G.; Kühl, M. Luminescence Lifetime Imaging of Chemical Sensors—A Comparison between Time-Domain and Frequency-Domain Based Camera Systems. Anal. Chem. 2019, 91, 3233–3238. [Google Scholar] [CrossRef]

- Christel, W.; Zhu, K.; Hoefer, C.; Kreuzeder, A.; Santner, J.; Bruun, S.; Magid, J.; Jensen, L.S. Spatiotemporal Dynamics of Phosphorus Release, Oxygen Consumption and Greenhouse Gas Emissions after Localised Soil Amendment with Organic Fertilisers. Sci. Total Environ. 2016, 554, 119–129. [Google Scholar] [CrossRef] [Green Version]

- Pischedda, L.; Cuny, P.; Esteves, J.L.; Poggiale, J.-C.; Gilbert, F. Spatial Oxygen Heterogeneity in a Hediste Diversicolor Irrigated Burrow. Hydrobiologia 2012, 1, 109–124. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Z.; Yu, X.; Zhai, S.; Hao, Y. Ratiometric Dissolved Oxygen Sensors Based on Ruthenium Complex Doped with Silver Nanoparticles. Sensors 2017, 17, 548. [Google Scholar] [CrossRef] [Green Version]

- Chu, C.-S. Optical Oxygen Sensing Properties of Ru(II) Complex and Porous Silica Nanoparticles Embedded in Solgel Matrix. Appl. Opt. AO 2011, 50, E145–E151. [Google Scholar] [CrossRef]

- Cretì, A.; Valerini, D.; Taurino, A.; Quaranta, F.; Lomascolo, M.; Rella, R. Photoluminescence Quenching Processes by NO2 Adsorption in ZnO Nanostructured Films. J. Appl. Phys. 2012, 111, 073520. [Google Scholar] [CrossRef]

- Sanchez-Valencia, J.R.; Alcaire, M.; Romero-Gómez, P.; Macias-Montero, M.; Aparicio, F.J.; Borras, A.; Gonzalez-Elipe, A.R.; Barranco, A. Oxygen Optical Sensing in Gas and Liquids with Nanostructured ZnO Thin Films Based on Exciton Emission Detection. J. Phys. Chem. C 2014, 118, 9852–9859. [Google Scholar] [CrossRef]

- Morandi, S.; Fioravanti, A.; Cerrato, G.; Lettieri, S.; Sacerdoti, M.; Carotta, M.C. Facile Synthesis of ZnO Nano-Structures: Morphology Influence on Electronic Properties. Sens. Actuators B Chem. 2017, 249, 581–589. [Google Scholar] [CrossRef]

- Pallotti, D.K.; Passoni, L.; Gesuele, F.; Maddalena, P.; Di Fonzo, F.; Lettieri, S. Giant O2—Induced Photoluminescence Modulation in Hierarchical Titanium Dioxide Nanostructures. ACS Sens. 2017, 2, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Siedl, N.; Koller, D.; Sternig, A.K.; Thomele, D.; Diwald, O. Photoluminescence Quenching in Compressed MgO Nanoparticle Systems. Phys. Chem. Chem. Phys. 2014, 16, 8339. [Google Scholar] [CrossRef] [Green Version]

- Faglia, G.; Baratto, C.; Sberveglieri, G.; Zha, M.; Zappettini, A. Adsorption Effects of NO2 at Ppm Level on Visible Photoluminescence Response of SnO2 Nanobelts. Appl. Phys. Lett. 2005, 86, 011923. [Google Scholar] [CrossRef]

- Trani, F.; Causà, M.; Lettieri, S.; Setaro, A.; Ninno, D.; Barone, V.; Maddalena, P. Role of Surface Oxygen Vacancies in Photoluminescence of Tin Dioxide Nanobelts. Microelectron. J. 2009, 40, 236–238. [Google Scholar] [CrossRef]

- Lettieri, S.; Causà, M.; Setaro, A.; Trani, F.; Barone, V.; Ninno, D.; Maddalena, P. Direct Role of Surface Oxygen Vacancies in Visible Light Emission of Tin Dioxide Nanowires. J. Chem. Phys. 2008, 129, 244710. [Google Scholar] [CrossRef] [Green Version]

- Lettieri, S.; Setaro, A.; Baratto, C.; Comini, E.; Faglia, G.; Sberveglieri, G.; Maddalena, P. On the Mechanism of Photoluminescence Quenching in Tin Dioxide Nanowires by NO2 Adsorption. New J. Phys. 2008, 10, 043013. [Google Scholar] [CrossRef]

- Lettieri, S.; Gargiulo, V.; Alfè, M.; Amati, M.; Zeller, P.; Maraloiu, V.-A.; Borbone, F.; Pavone, M.; Muñoz-García, A.B.; Maddalena, P. Simple Ethanol Refluxing Method for Production of Blue-Colored Titanium Dioxide with Oxygen Vacancies and Visible Light-Driven Photocatalytic Properties. J. Phys. Chem. C 2020, 124, 3564–3576. [Google Scholar] [CrossRef]

- Lettieri, S.; Gargiulo, V.; Pallotti, D.K.; Vitiello, G.; Maddalena, P.; Alfè, M.; Marotta, R. Evidencing Opposite Charge-Transfer Processes at TiO2 /Graphene-Related Materials Interface through a Combined EPR, Photoluminescence and Photocatalysis Assessment. Catal. Today 2018, 315, 19–30. [Google Scholar] [CrossRef]

- Zhuang, W.; Hachem, K.; Bokov, D.; Javed Ansari, M.; Taghvaie Nakhjiri, A. Ionic Liquids in Pharmaceutical Industry: A Systematic Review on Applications and Future Perspectives. J. Mol. Liq. 2022, 349, 118145. [Google Scholar] [CrossRef]

- Tanner, E.E.L. Ionic Liquids Charge Ahead. Nat. Chem. 2022, 14, 842. [Google Scholar] [CrossRef] [PubMed]

- Buettner, C.S.; Cognigni, A.; Schröder, C.; Bica-Schröder, K. Surface-Active Ionic Liquids: A Review. J. Mol. Liq. 2022, 347, 118160. [Google Scholar] [CrossRef]

- Plechkova, N.V.; Seddon, K.R. Applications of Ionic Liquids in the Chemical Industry. Chem. Soc. Rev. 2008, 37, 123–150. [Google Scholar] [CrossRef]

- Schreiner, C.; Zugmann, S.; Hartl, R.; Gores, H.J. Fractional Walden Rule for Ionic Liquids: Examples from Recent Measurements and a Critique of the So-Called Ideal KCl Line for the Walden Plot. J. Chem. Eng. Data 2010, 55, 1784–1788. [Google Scholar] [CrossRef]

- Ignat’ev, N.V.; Welz-Biermann, U.; Kucheryna, A.; Bissky, G.; Willner, H. New Ionic Liquids with Tris(Perfluoroalkyl)Trifluorophosphate (FAP) Anions. J. Fluor. Chem. 2005, 126, 1150–1159. [Google Scholar] [CrossRef]

- Tang, Y.; Zeng, X. Electrochemical Oxidation of Hydrogen in Bis(Trifluoromethylsulfonyl)Imide Ionic Liquids under Anaerobic and Aerobic Conditions. J. Phys. Chem. C 2016, 120, 23542–23551. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Arrigan, D.W.M.; Silvester, D.S. Achievement of Prolonged Oxygen Detection in Room-Temperature Ionic Liquids on Mechanically Polished Platinum Screen-Printed Electrodes. Anal. Chem. 2016, 88, 5104–5111. [Google Scholar] [CrossRef] [Green Version]

- Hussain, G.; O’Mullane, A.P.; Silvester, D.S. Modification of Microelectrode Arrays with High Surface Area Dendritic Platinum 3D Structures: Enhanced Sensitivity for Oxygen Detection in Ionic Liquids. Nanomaterials 2018, 8, 735. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.; Silvester, D.S. Low-Cost Microarray Thin-Film Electrodes with Ionic Liquid Gel-Polymer Electrolytes for Miniaturised Oxygen Sensing. Analyst 2016, 141, 3705–3713. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gondosiswanto, R.; Gunawan, C.A.; Hibbert, D.B.; Harper, J.B.; Zhao, C. Microcontact Printing of Thiol-Functionalized Ionic Liquid Microarrays for “Membrane-Less” and “Spill-Less” Gas Sensors. ACS Appl. Mater. Interfaces 2016, 8, 31368–31374. [Google Scholar] [CrossRef]

- Liu, X.; Chen, X.; Xu, Y.; Chen, T.; Zeng, X. Effects of Water on Ionic Liquid Electrochemical Microsensor for Oxygen Sensing. Sens. Actuators B Chem. 2019, 285, 350–357. [Google Scholar] [CrossRef]

- Wan, H.; Yin, H.; Mason, A.J. Rapid Measurement of Room Temperature Ionic Liquid Electrochemical Gas Sensor Using Transient Double Potential Amperometry. Sens. Actuators B Chem. 2017, 242, 658–666. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.; Hussain, G.; Banks, C.E.; Silvester, D.S. Screen-Printed Graphite Electrodes as Low-Cost Devices for Oxygen Gas Detection in Room-Temperature Ionic Liquids. Sensors 2017, 17, 2734. [Google Scholar] [CrossRef] [Green Version]

- Gondosiswanto, R.; Hibbert, D.B.; Fang, Y.; Zhao, C. Ionic Liquid Microstrips Impregnated with Magnetic Nanostirrers for Sensitive Gas Sensors. ACS Appl. Mater. Interfaces 2017, 9, 43377–43385. [Google Scholar] [CrossRef]

- Lin, L.; Zeng, X. Toward Continuous Amperometric Gas Sensing in Ionic Liquids: Rationalization of Signal Drift Nature and Calibration Methods. Anal. Bioanal. Chem. 2018, 410, 4587–4596. [Google Scholar] [CrossRef]

- Gondosiswanto, R.; Hibbert, D.B.; Fang, Y.; Zhao, C. Redox Recycling Amplification Using an Interdigitated Microelectrode Array for Ionic Liquid-Based Oxygen Sensors. Anal. Chem. 2018, 90, 3950–3957. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Liu, Q.; Zhang, H.; Li, Z.; Jing, X.; Yuan, Y.; Zhang, H.; Liu, P.; Wang, J. Ionic Liquids Combined with Pt-Modified Ordered Mesoporous Carbons as Electrolytes for the Oxygen Sensing. Sens. Actuators B Chem. 2018, 254, 490–501. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Liu, Q.; Chen, R.; Zhang, H.; Yu, J.; Song, D.; Jing, X.; Zhang, M.; Wang, J. Electrochemical Oxygen Sensor Based on the Interaction of Double-Layer Ionic Liquid Film (DLILF). J. Electrochem. Soc. 2018, 165, B779. [Google Scholar] [CrossRef]

- Yu, L.; Liu, J.; Yin, W.; Yu, J.; Chen, R.; Song, D.; Liu, Q.; Li, R.; Wang, J. Ionic Liquid Combined with NiCo2O4/RGO Enhances Electrochemical Oxygen Sensing. Talanta 2020, 209, 120515. [Google Scholar] [CrossRef] [PubMed]

- Yin, W.; Liu, J.; Liu, Q.; Chen, R.; Yu, J.; Zhang, H.; Song, D.; Fan, M.; Zhang, M.; Wang, J. Ag-CS Enhanced Performance of Pyrrolidone-Based Ionic Liquid Oxygen Sensor. J. Electrochem. Soc. 2020, 167, 067522. [Google Scholar] [CrossRef]

- Wan, H.; Liu, X.; Wang, X.; Chen, Y.; Wang, P.P. Facile Screen-Printed Carbon Nanotube Electrode on Porous Substrate with Gold Nanoparticle Modification for Rapid Electrochemical Gas Sensing. J. Electrochem. Soc. 2021, 168, 067514. [Google Scholar] [CrossRef]

- Yin, W.; Alali, K.T.; Zhang, M.; Liu, J.; Song, D.; Liu, Q.; Yu, J.; Chen, R.; Zhang, H.; Wang, J. A−Fe2O3/RGO Cooperated with Tri-Alkyl-Substituted-Imidazolium Ionic Liquids for Enhancing Oxygen Sensing. Sens. Actuators B Chem. 2021, 341, 130029. [Google Scholar] [CrossRef]

- Doblinger, S.; Hay, C.E.; Tomé, L.C.; Mecerreyes, D.; Silvester, D.S. Ionic Liquid/Poly(Ionic Liquid) Membranes as Non-Flowing, Conductive Materials for Electrochemical Gas Sensing. Anal. Chim. Acta 2022, 1195, 339414. [Google Scholar] [CrossRef]

- Lee, J.; Hussain, G.; López-Salas, N.; MacFarlane, D.R.; Silvester, D.S. Thin Films of Poly(Vinylidene Fluoride-Co-Hexafluoropropylene)-Ionic Liquid Mixtures as Amperometric Gas Sensing Materials for Oxygen and Ammonia. Analyst 2020, 145, 1915–1924. [Google Scholar] [CrossRef]

- Liu, X.; Chen, X.; Ju, J.; Wang, X.; Mei, Z.; Qu, H.; Xu, Y.; Zeng, X. Platinum–Nickel Bimetallic Nanosphere–Ionic Liquid Interface for Electrochemical Oxygen and Hydrogen Sensing. ACS Appl. Nano Mater. 2019, 2, 2958–2968. [Google Scholar] [CrossRef]

- Tang, Y.; He, J.; Gao, X.; Yang, T.; Zeng, X. Continuous Amperometric Hydrogen Gas Sensing in Ionic Liquids. Analyst 2018, 143, 4136–4146. [Google Scholar] [CrossRef]

- Jayanthi, E.; Murugesan, N.; Suneesh, A.S.; Ramesh, C.; Anthonysamy, S. Sensing Behavior of Room Temperature Amperometric H2 Sensor with Pd Electrodeposited from Ionic Liquid Electrolyte as Sensing Electrode. J. Electrochem. Soc. 2017, 164, H5210. [Google Scholar] [CrossRef]

- Zhi, Z.; Gao, W.; Yang, J.; Geng, C.; Yang, B.; Tian, C.; Fan, S.; Li, H.; Li, J.; Hua, Z. Amperometric Hydrogen Gas Sensor Based on Pt/C/Nafion Electrode and Ionic Electrolyte. Sens. Actuators B Chem. 2022, 367, 132137. [Google Scholar] [CrossRef]

- Hussain, G.; Ge, M.; Zhao, C.; Silvester, D.S. Fast Responding Hydrogen Gas Sensors Using Platinum Nanoparticle Modified Microchannels and Ionic Liquids. Anal. Chim. Acta 2019, 1072, 35–45. [Google Scholar] [CrossRef]

- Hussain, G.; Silvester, D.S. Comparison of Voltammetric Techniques for Ammonia Sensing in Ionic Liquids. Electroanalysis 2018, 30, 75–83. [Google Scholar] [CrossRef]

- Hussain, G.; Silvester, D.S. Detection of Sub-Ppm Concentrations of Ammonia in an Ionic Liquid: Enhanced Current Density Using “Filled” Recessed Microarrays. Anal. Chem. 2016, 88, 12453–12460. [Google Scholar] [CrossRef] [PubMed]

- Hussain, G.; Aldous, L.; Silvester, D.S. Preparation of Platinum-Based ‘cauliflower Microarrays’ for Enhanced Ammonia Gas Sensing. Anal. Chim. Acta 2019, 1048, 12–21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ge, M.; Hussain, G.; Hibbert, D.B.; Silvester, D.S.; Zhao, C. Ionic Liquid-Based Microchannels for Highly Sensitive and Fast Amperometric Detection of Toxic Gases. Electroanalysis 2019, 31, 66–74. [Google Scholar] [CrossRef] [Green Version]

- Chi, X.; Tang, Y.; Zeng, X. Electrode Reactions Coupled with Chemical Reactions of Oxygen, Water and Acetaldehyde in an Ionic Liquid: New Approaches for Sensing Volatile Organic Compounds. Electrochim. Acta 2016, 216, 171–180. [Google Scholar] [CrossRef] [Green Version]

- Ge, M.; Gondosiswanto, R.; Zhao, C. Electrodeposited Copper Nanoparticles in Ionic Liquid Microchannels Electrode for Carbon Dioxide Sensor. Inorg. Chem. Commun. 2019, 107, 107458. [Google Scholar] [CrossRef]

- Toniolo, R.; Dossi, N.; Bortolomeazzi, R.; Bonazza, G.; Daniele, S. Volatile Aldehydes Sensing in Headspace Using a Room Temperature Ionic Liquid-Modified Electrochemical Microprobe. Talanta 2019, 197, 522–529. [Google Scholar] [CrossRef]

- Gil-González, N.; Benito-Lopez, F.; Castaño, E.; Morant-Miñana, M.C. Imidazole-Based Ionogel as Room Temperature Benzene and Formaldehyde Sensor. Microchim. Acta 2020, 187, 638. [Google Scholar] [CrossRef]

- Doblinger, S.; Lee, J.; Gurnah, Z.; Silvester, D.S. Detection of Sulfur Dioxide at Low Parts-per-Million Concentrations Using Low-Cost Planar Electrodes with Ionic Liquid Electrolytes. Anal. Chim. Acta 2020, 1124, 156–165. [Google Scholar] [CrossRef] [PubMed]

- Esteves, C.; Palma, S.I.C.J.; Costa, H.M.A.; Alves, C.; Santos, G.M.C.; Ramou, E.; Carvalho, A.L.; Alves, V.; Roque, A.C.A. Tackling Humidity with Designer Ionic Liquid-Based Gas Sensing Soft Materials. Adv. Mater. 2022, 34, 2107205. [Google Scholar] [CrossRef]

- Zuliani, I.; Fattori, A.; Svigelj, R.; Dossi, N.; Grazioli, C.; Bontempelli, G.; Toniolo, R. Amperometric Detection of Ethanol Vapors by Screen Printed Electrodes Modified by Paper Crowns Soaked with Room Temperature Ionic Liquids. Electroanalysis 2022, 34, 1–11. [Google Scholar] [CrossRef]

- Gao, J.; Hua, Z.; Xu, S.; Wan, H.; Zhi, Z.; Chen, X.; Fan, S. Amperometric Gas Sensors Based on Screen Printed Electrodes with Porous Ceramic Substrates. Sens. Actuators B Chem. 2021, 342, 130045. [Google Scholar] [CrossRef]

- Luo, R.; Wu, Y.; Li, Q.; Du, B.; Zhou, S.; Li, H. Rational Synthesis and Characterization of IL-CNTs-PANI Microporous Polymer Electrolyte Film. Synth. Met. 2021, 274, 116720. [Google Scholar] [CrossRef]

- Kuberský, P.; Navrátil, J.; Syrový, T.; Sedlák, P.; Nešpůrek, S.; Hamáček, A. An Electrochemical Amperometric Ethylene Sensor with Solid Polymer Electrolyte Based on Ionic Liquid. Sensors 2021, 21, 711. [Google Scholar] [CrossRef]

- Zhang, S.-Y.; Zhuang, Q.; Zhang, M.; Wang, H.; Gao, Z.; Sun, J.-K.; Yuan, J. Poly(Ionic Liquid) Composites. Chem. Soc. Rev. 2020, 49, 1726–1755. [Google Scholar] [CrossRef] [Green Version]

- Silvester, D.S. New Innovations in Ionic Liquid–Based Miniaturised Amperometric Gas Sensors. Curr. Opin. Electrochem. 2019, 15, 7–17. [Google Scholar] [CrossRef]

- Raptopoulou, C.P. Metal-Organic Frameworks: Synthetic Methods and Potential Applications. Materials 2021, 14, 310. [Google Scholar] [CrossRef]

- Andirova, D.; Cogswell, C.F.; Lei, Y.; Choi, S. Effect of the Structural Constituents of Metal Organic Frameworks on Carbon Dioxide Capture. Microporous Mesoporous Mater. 2016, 219, 276–305. [Google Scholar] [CrossRef]

- Yulia, F.; Nasruddin; Zulys, A.; Ruliandini, R. Metal-Organic Framework Based Chromium Terephthalate (MIL-101 Cr) Growth for Carbon Dioxide Capture: A Review. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 57, 158–174. [Google Scholar]

- Ding, M.; Cai, X.; Jiang, H.-L. Improving MOF Stability: Approaches and Applications. Chem. Sci. 2019, 10, 10209–10230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiao, L.; Seow, J.Y.R.; Skinner, W.S.; Wang, Z.U.; Jiang, H.-L. Metal–Organic Frameworks: Structures and Functional Applications. Mater. Today 2019, 27, 43–68. [Google Scholar] [CrossRef]

- Lee, Y.-R.; Kim, J.; Ahn, W.-S. Synthesis of Metal-Organic Frameworks: A Mini Review. Korean J. Chem. Eng. 2013, 30, 1667–1680. [Google Scholar] [CrossRef]

- Silva, P.; Vilela, S.M.F.; Tomé, J.P.C.; Almeida Paz, F.A. Multifunctional Metal–Organic Frameworks: From Academia to Industrial Applications. Chem. Soc. Rev. 2015, 44, 6774–6803. [Google Scholar] [CrossRef] [Green Version]

- Safaei, M.; Foroughi, M.M.; Ebrahimpoor, N.; Jahani, S.; Omidi, A.; Khatami, M. A Review on Metal-Organic Frameworks: Synthesis and Applications. TrAC Trends Anal. Chem. 2019, 118, 401–425. [Google Scholar] [CrossRef]

- Freund, R.; Zaremba, O.; Arnauts, G.; Ameloot, R.; Skorupskii, G.; Dincă, M.; Bavykina, A.; Gascon, J.; Ejsmont, A.; Goscianska, J.; et al. The Current Status of MOF and COF Applications. Angew. Chem. Int. Ed. 2021, 60, 23975–24001. [Google Scholar] [CrossRef]

- Song, Y.; Li, X.; Sun, L.; Wang, L. Metal/Metal Oxide Nanostructures Derived from Metal–Organic Frameworks. RSC Adv. 2015, 5, 7267–7279. [Google Scholar] [CrossRef]

- Alfè, M.; Gargiulo, V.; Amati, M.; Maraloiu, V.-A.; Maddalena, P.; Lettieri, S. Mesoporous TiO2 from Metal-Organic Frameworks for Photoluminescence-Based Optical Sensing of Oxygen. Catalysts 2021, 11, 795. [Google Scholar] [CrossRef]

- Tan, X.; Wu, Y.; Lin, X.; Zeb, A.; Xu, X.; Luo, Y.; Liu, J. Application of MOF-Derived Transition Metal Oxides and Composites as Anodes for Lithium-Ion Batteries. Inorg. Chem. Front. 2020, 7, 4939–4955. [Google Scholar] [CrossRef]

- Li, H.-Y.; Zhao, S.-N.; Zang, S.-Q.; Li, J. Functional Metal–Organic Frameworks as Effective Sensors of Gases and Volatile Compounds. Chem. Soc. Rev. 2020, 49, 6364–6401. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Xiao, A.-S.; Zou, B.; Zhang, H.-X.; Yan, K.-L.; Lin, Y. Advances of Metal–Organic Frameworks for Gas Sensing. Polyhedron 2018, 154, 83–97. [Google Scholar] [CrossRef]

- Huang, B.; Li, Y.; Zeng, W. Application of Metal-Organic Framework-Based Composites for Gas Sensing and Effects of Synthesis Strategies on Gas-Sensitive Performance. Chemosensors 2021, 9, 226. [Google Scholar] [CrossRef]

- Sosa, J.; Bennett, T.; Nelms, K.; Liu, B.; Tovar, R.; Liu, Y. Metal–Organic Framework Hybrid Materials and Their Applications. Crystals 2018, 8, 325. [Google Scholar] [CrossRef] [Green Version]

- Mandal, S.; Natarajan, S.; Mani, P.; Pankajakshan, A. Post-Synthetic Modification of Metal–Organic Frameworks Toward Applications. Adv. Funct. Mater. 2021, 31, 2006291. [Google Scholar] [CrossRef]

- Alfe, M.; Policicchio, A.; Lisi, L.; Gargiulo, V. Solid Sorbents for CO2 and CH4 Adsorption: The Effect of Metal Organic Framework Hybridization with Graphene-like Layers on the Gas Sorption Capacities at High Pressure. Renew. Sustain. Energy Rev. 2021, 141, 110816. [Google Scholar] [CrossRef]

- Lei, J.; Qian, R.; Ling, P.; Cui, L.; Ju, H. Design and Sensing Applications of Metal–Organic Framework Composites. TrAC Trends Anal. Chem. 2014, 58, 71–78. [Google Scholar] [CrossRef]

- Zhu, Q.-L.; Xu, Q. Metal–Organic Framework Composites. Chem. Soc. Rev. 2014, 43, 5468–5512. [Google Scholar] [CrossRef]

- Kalaj, M.; Bentz, K.C.; Ayala, S.; Palomba, J.M.; Barcus, K.S.; Katayama, Y.; Cohen, S.M. MOF-Polymer Hybrid Materials: From Simple Composites to Tailored Architectures. Chem. Rev. 2020, 120, 8267–8302. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Ying, Y. Recent Advances in Sensing Applications of Metal Nanoparticle/Metal–Organic Framework Composites. TrAC Trends Anal. Chem. 2021, 143, 116395. [Google Scholar] [CrossRef]

- Chen, C.; Li, B.; Zhou, L.; Xia, Z.; Feng, N.; Ding, J.; Wang, L.; Wan, H.; Guan, G. Synthesis of Hierarchically Structured Hybrid Materials by Controlled Self-Assembly of Metal–Organic Framework with Mesoporous Silica for CO2 Adsorption. ACS Appl. Mater. Interfaces 2017, 9, 23060–23071. [Google Scholar] [CrossRef] [PubMed]

- Chronopoulos, D.D.; Saini, H.; Tantis, I.; Zbořil, R.; Jayaramulu, K.; Otyepka, M. Carbon Nanotube Based Metal–Organic Framework Hybrids From Fundamentals Toward Applications. Small 2022, 18, 2104628. [Google Scholar] [CrossRef]

- Zheng, Y.; Zheng, S.; Xue, H.; Pang, H. Metal-Organic Frameworks/Graphene-Based Materials: Preparations and Applications. Adv. Funct. Mater. 2018, 28, 1804950. [Google Scholar] [CrossRef]

- Alfè, M.; Gargiulo, V.; Lisi, L.; Di Capua, R. Synthesis and Characterization of Conductive Copper-Based Metal-Organic Framework/Graphene-like Composites. Mater. Chem. Phys. 2014, 147, 744–750. [Google Scholar] [CrossRef]

- Aguilera-Sigalat, J.; Bradshaw, D. Synthesis and Applications of Metal-Organic Framework–Quantum Dot (QD@MOF) Composites. Coord. Chem. Rev. 2016, 307, 267–291. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Huo, F. Metal–Organic Framework Composites: From Fundamentals to Applications. Nanoscale 2015, 7, 7482–7501. [Google Scholar] [CrossRef] [PubMed]

- Jahan, M.; Bao, Q.; Yang, J.-X.; Loh, K.P. Structure-Directing Role of Graphene in the Synthesis of Metal–Organic Framework Nanowire. J. Am. Chem. Soc. 2010, 132, 14487–14495. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Z.; Xiao, W.; Deng, S.; Chen, C.; Zhang, N. Mechanochemistry-Assisted Encapsulation of Metal Nanoparticles in MOF Matrices via a Sacrificial Strategy. J. Mater. Chem. A 2019, 7, 14504–14509. [Google Scholar] [CrossRef]

- Chen, L.; Chen, H.; Luque, R.; Li, Y. Metal−organic Framework Encapsulated Pd Nanoparticles: Towards Advanced Heterogeneous Catalysts. Chem. Sci. 2014, 5, 3708–3714. [Google Scholar] [CrossRef]

- Hu, M.-L.; Razavi, S.A.A.; Piroozzadeh, M.; Morsali, A. Sensing Organic Analytes by Metal–Organic Frameworks: A New Way of Considering the Topic. Inorg. Chem. Front. 2020, 7, 1598–1632. [Google Scholar] [CrossRef]

- Small, L.J.; Schindelholz, M.E.; Nenoff, T.M. Hold on Tight: MOF-Based Irreversible Gas Sensors. Ind. Eng. Chem. Res. 2021, 60, 7998–8006. [Google Scholar] [CrossRef]

- Zhang, R.; Lu, L.; Chang, Y.; Liu, M. Gas Sensing Based on Metal-Organic Frameworks: Concepts, Functions, and Developments. J. Hazard. Mater. 2022, 429, 128321. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Deep, A.; Kim, K.-H. Metal Organic Frameworks for Sensing Applications. TrAC Trends Anal. Chem. 2015, 73, 39–53. [Google Scholar] [CrossRef]

- Bhardwaj, S.K.; Bhardwaj, N.; Kaur, R.; Mehta, J.; Sharma, A.L.; Kim, K.-H.; Deep, A. An Overview of Different Strategies to Introduce Conductivity in Metal–Organic Frameworks and Miscellaneous Applications Thereof. J. Mater. Chem. A 2018, 6, 14992–15009. [Google Scholar] [CrossRef]

- Razavi, S.A.A.; Masoomi, M.Y.; Morsali, A. Stimuli-Responsive Metal-Organic Framework (MOF) with Chemo-Switchable Properties for Colorimetric Detection of CHCl3. Chem. Eur. J. 2017, 23, 12559–12564. [Google Scholar] [CrossRef]

- Wang, H.; Lustig, W.P.; Li, J. Sensing and Capture of Toxic and Hazardous Gases and Vapors by Metal–Organic Frameworks. Chem. Soc. Rev. 2018, 47, 4729–4756. [Google Scholar] [CrossRef]

- Diamantis, S.A.; Margariti, A.; Pournara, A.D.; Papaefstathiou, G.S.; Manos, M.J.; Lazarides, T. Luminescent Metal–Organic Frameworks as Chemical Sensors: Common Pitfalls and Proposed Best Practices. Inorg. Chem. Front. 2018, 5, 1493–1511. [Google Scholar] [CrossRef]

- Mahata, P.; Mondal, S.K.; Singha, D.K.; Majee, P. Luminescent Rare-Earth-Based MOFs as Optical Sensors. Dalton Trans. 2017, 46, 301–328. [Google Scholar] [CrossRef]

- Huangfu, M.; Wang, M.; Lin, C.; Wang, J.; Wu, P. Luminescent Metal–Organic Frameworks as Chemical Sensors Based on “Mechanism–Response”: A Review. Dalton Trans. 2021, 50, 3429–3449. [Google Scholar] [CrossRef]

- Chen, L.; Liu, D.; Peng, J.; Du, Q.; He, H. Ratiometric Fluorescence Sensing of Metal-Organic Frameworks: Tactics and Perspectives. Coord. Chem. Rev. 2020, 404, 213113. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuan, S.; Day, G.; Wang, X.; Yang, X.; Zhou, H.-C. Luminescent Sensors Based on Metal-Organic Frameworks. Coord. Chem. Rev. 2018, 354, 28–45. [Google Scholar] [CrossRef]

- Zhu, C.; Gerald, R.E.; Huang, J. Metal-Organic Framework Materials Coupled to Optical Fibers for Chemical Sensing: A Review. IEEE Sens. J. 2021, 21, 19647–19661. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.-J.; Lu, P.; Culp, J.T.; Ohodnicki, P.R. Metal–Organic Framework Thin Film Coated Optical Fiber Sensors: A Novel Waveguide-Based Chemical Sensing Platform. ACS Sens. 2018, 3, 386–394. [Google Scholar] [CrossRef] [PubMed]

- Kreno, L.E.; Hupp, J.T.; Van Duyne, R.P. Metal−Organic Framework Thin Film for Enhanced Localized Surface Plasmon Resonance Gas Sensing. Anal. Chem. 2010, 82, 8042–8046. [Google Scholar] [CrossRef]

- He, C.; Liu, L.; Korposh, S.; Correia, R.; Morgan, S.P. Volatile Organic Compound Vapour Measurements Using a Localised Surface Plasmon Resonance Optical Fibre Sensor Decorated with a Metal-Organic Framework. Sensors 2021, 21, 1420. [Google Scholar] [CrossRef]

- Na Songkhla, S.; Nakamoto, T. Overview of Quartz Crystal Microbalance Behavior Analysis and Measurement. Chemosensors 2021, 9, 350. [Google Scholar] [CrossRef]

- Wang, L. Metal-Organic Frameworks for QCM-Based Gas Sensors: A Review. Sens. Actuators A Phys. 2020, 307, 111984. [Google Scholar] [CrossRef]

- Ma, Z.; Yuan, T.; Fan, Y.; Wang, L.; Duan, Z.; Du, W.; Zhang, D.; Xu, J. A Benzene Vapor Sensor Based on a Metal-Organic Framework-Modified Quartz Crystal Microbalance. Sens. Actuators B Chem. 2020, 311, 127365. [Google Scholar] [CrossRef]

- Mandal, D.; Banerjee, S. Surface Acoustic Wave (SAW) Sensors: Physics, Materials, and Applications. Sensors 2022, 22, 820. [Google Scholar] [CrossRef]

- Paschke, B.; Wixforth, A.; Denysenko, D.; Volkmer, D. Fast Surface Acoustic Wave-Based Sensors to Investigate the Kinetics of Gas Uptake in Ultra-Microporous Frameworks. ACS Sens. 2017, 2, 740–747. [Google Scholar] [CrossRef] [Green Version]

- Devkota, J.; Greve, D.W.; Hong, T.; Kim, K.-J.; Ohodnicki, P.R. An 860 MHz Wireless Surface Acoustic Wave Sensor with a Metal-Organic Framework Sensing Layer for CO2 and CH4. IEEE Sens. J. 2020, 20, 9740–9747. [Google Scholar] [CrossRef]

- Vanotti, M.; Poisson, S.; Blondeau-Patissier, V.; André, L.; Brandès, S.; Desbois, N.; Gros, C.P. SAW Based CO2 Sensor: Influence of Functionalizing MOF Crystal Size on the Sensor’s Selectivity. In Proceedings of the International Conference on Advances in Sensors, Actuators, Metering and Sensing, Nice, France, 18–22 July 2021. [Google Scholar]

- Vashist, D.S.K.; Tewari, R.; Bajpai, D.R.P.; Bharadwaj, D.L.M.; Raiteri, R. A Review of Microcantilevers for Sensing Applications. J. Nanotechnol. 2007, 3, 15. [Google Scholar] [CrossRef]

- Cai, S.; Li, W.; Xu, P.; Xia, X.; Yu, H.; Zhang, S.; Li, X. In Situ Construction of Metal–Organic Framework (MOF) UiO-66 Film on Parylene-Patterned Resonant Microcantilever for Trace Organophosphorus Molecules Detection. Analyst 2019, 144, 3729–3735. [Google Scholar] [CrossRef] [PubMed]

- Yim, C.; Lee, M.; Yun, M.; Kim, G.-H.; Kim, K.T.; Jeon, S. CO2-Selective Nanoporous Metal-Organic Framework Microcantilevers. Sci. Rep. 2015, 5, 10674. [Google Scholar] [CrossRef]

- Ellern, I.; Venkatasubramanian, A.; Lee, J.H.; Hesketh, P.J.; Stavilla, V.; Allendorf, M.D.; Robinson, A.L. Characterization of Piezoresistive Microcantilever Sensors with Metal Organic Frameworks for the Detection of Volatile Organic Compounds. ECS Trans. 2013, 50, 469–476. [Google Scholar] [CrossRef]

- Ko, M.; Aykanat, A.; Smith, M.; Mirica, K. Drawing Sensors with Ball-Milled Blends of Metal-Organic Frameworks and Graphite. Sensors 2017, 17, 2192. [Google Scholar] [CrossRef] [Green Version]

- Chen, E.-X.; Yang, H.; Zhang, J. Zeolitic Imidazolate Framework as Formaldehyde Gas Sensor. Inorg. Chem. 2014, 53, 5411–5413. [Google Scholar] [CrossRef]

- Chidambaram, A.; Stylianou, K.C. Electronic Metal–Organic Framework Sensors. Inorg. Chem. Front. 2018, 5, 979–998. [Google Scholar] [CrossRef]

- Liu, J.; Sun, F.; Zhang, F.; Wang, Z.; Zhang, R.; Wang, C.; Qiu, S. In Situ Growth of Continuous Thin Metal–Organic Framework Film for Capacitive Humidity Sensing. J. Mater. Chem. 2011, 21, 3775. [Google Scholar] [CrossRef]

- Sapsanis, C.; Omran, H.; Chernikova, V.; Shekhah, O.; Belmabkhout, Y.; Buttner, U.; Eddaoudi, M.; Salama, K. Insights on Capacitive Interdigitated Electrodes Coated with MOF Thin Films: Humidity and VOCs Sensing as a Case Study. Sensors 2015, 15, 18153–18166. [Google Scholar] [CrossRef]

- Assen, A.H.; Yassine, O.; Shekhah, O.; Eddaoudi, M.; Salama, K.N. MOFs for the Sensitive Detection of Ammonia: Deployment of Fcu-MOF Thin Films as Effective Chemical Capacitive Sensors. ACS Sens. 2017, 2, 1294–1301. [Google Scholar] [CrossRef] [PubMed]

- Yassine, O.; Shekhah, O.; Assen, A.H.; Belmabkhout, Y.; Salama, K.N.; Eddaoudi, M. H2S Sensors: Fumarate-Based Fcu-MOF Thin Film Grown on a Capacitive Interdigitated Electrode. Angew. Chem. Int. Ed. 2016, 55, 15879–15883. [Google Scholar] [CrossRef] [PubMed]

- Homayoonnia, S.; Zeinali, S. Design and Fabrication of Capacitive Nanosensor Based on MOF Nanoparticles as Sensing Layer for VOCs Detection. Sens. Actuators B Chem. 2016, 237, 776–786. [Google Scholar] [CrossRef]

- Achmann, S.; Hagen, G.; Kita, J.; Malkowsky, I.; Kiener, C.; Moos, R. Metal-Organic Frameworks for Sensing Applications in the Gas Phase. Sensors 2009, 9, 1574–1589. [Google Scholar] [CrossRef] [Green Version]

- Weiss, A.; Reimer, N.; Stock, N.; Tiemann, M.; Wagner, T. Screening of Mixed-Linker CAU-10 MOF Materials for Humidity Sensing by Impedance Spectroscopy. Microporous Mesoporous Mater. 2016, 220, 39–43. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Zhang, Y.; Cong, H.; Fu, B.; Wen, S.; Ruan, S. A Novel Humidity Sensor Based on NH2-MIL-125(Ti) Metal Organic Framework with High Responsiveness. J. Nanopart. Res. 2013, 15, 2014. [Google Scholar] [CrossRef]

- D’Amico, A.; Di Natale, C.; Paolesse, R.; Mantini, A.; Goletti, C.; Davide, F.; Filosofi, G. Chemical Sensing Materials Characterization by Kelvin Probe Technique. Sens. Actuators B Chem. 2000, 70, 254–262. [Google Scholar] [CrossRef]

- Davydovskaya, P.; Pentyala, V.; Yurchenko, O.; Hussein, L.; Pohle, R.; Urban, G.A. Work Function Based Sensing of Alkanes and Alcohols with Benzene Tricarboxylate Linked Metal Organic Frameworks. Sens. Actuators B Chem. 2014, 193, 911–917. [Google Scholar] [CrossRef]

- Pentyala, V.; Davydovskaya, P.; Pohle, R.; Urban, G.; Yurchenko, O. Mg-MOF74 and Co-MOF74 as Sensing Layers for CO2 Detection. Procedia Eng. 2014, 87, 1071–1074. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Xiong, R.-G. Ferroelectric Metal–Organic Frameworks. Chem. Rev. 2012, 112, 1163–1195. [Google Scholar] [CrossRef]

- Han, S.; Kim, H.; Kim, J.; Jung, Y. Modulating the Magnetic Behavior of Fe(II)–MOF-74 by the High Electron Affinity of the Guest Molecule. Phys. Chem. Chem. Phys. 2015, 17, 16977–16982. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Behboodian, R.; Bagnall, D.; Taheri, M.; Nasiri, N. Metal-Organic-Frameworks: Low Temperature Gas Sensing and Air Quality Monitoring. Chemosensors 2021, 9, 316. [Google Scholar] [CrossRef]

- Huang, X.; Gong, Z.; Lv, Y. Advances in Metal-Organic Frameworks-Based Gas Sensors for Hazardous Substances. TrAC Trends Anal. Chem. 2022, 153, 116644. [Google Scholar] [CrossRef]

- Majhi, S.M.; Ali, A.; Rai, P.; Greish, Y.E.; Alzamly, A.; Surya, S.G.; Qamhieh, N.; Mahmoud, S.T. Metal–Organic Frameworks for Advanced Transducer Based Gas Sensors: Review and Perspectives. Nanoscale Adv. 2022, 4, 697–732. [Google Scholar] [CrossRef]

- Olorunyomi, J.F.; Geh, S.T.; Caruso, R.A.; Doherty, C.M. Metal–Organic Frameworks for Chemical Sensing Devices. Mater. Horiz. 2021, 8, 2387–2419. [Google Scholar] [CrossRef] [PubMed]

- Drobek, M.; Kim, J.-H.; Bechelany, M.; Vallicari, C.; Julbe, A.; Kim, S.S. MOF-Based Membrane Encapsulated ZnO Nanowires for Enhanced Gas Sensor Selectivity. ACS Appl. Mater. Interfaces 2016, 8, 8323–8328. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Xiong, S.; Mao, Z.; Hu, S.; Long, X. A Designed ZnO@ZIF-8 Core-Shell Nanorod Film as a Gas Sensor with Excellent Selectivity for H 2 over CO. Chem. Eur. J. 2017, 23, 7969–7975. [Google Scholar] [CrossRef] [Green Version]

- Cui, F.; Chen, W.; Jin, L.; Zhang, H.; Jiang, Z.; Song, Z. Fabrication of ZIF-8 Encapsulated ZnO Microrods with Enhanced Sensing Properties for H2 Detection. J. Mater. Sci. Mater. Electron. 2018, 29, 19697–19709. [Google Scholar] [CrossRef]

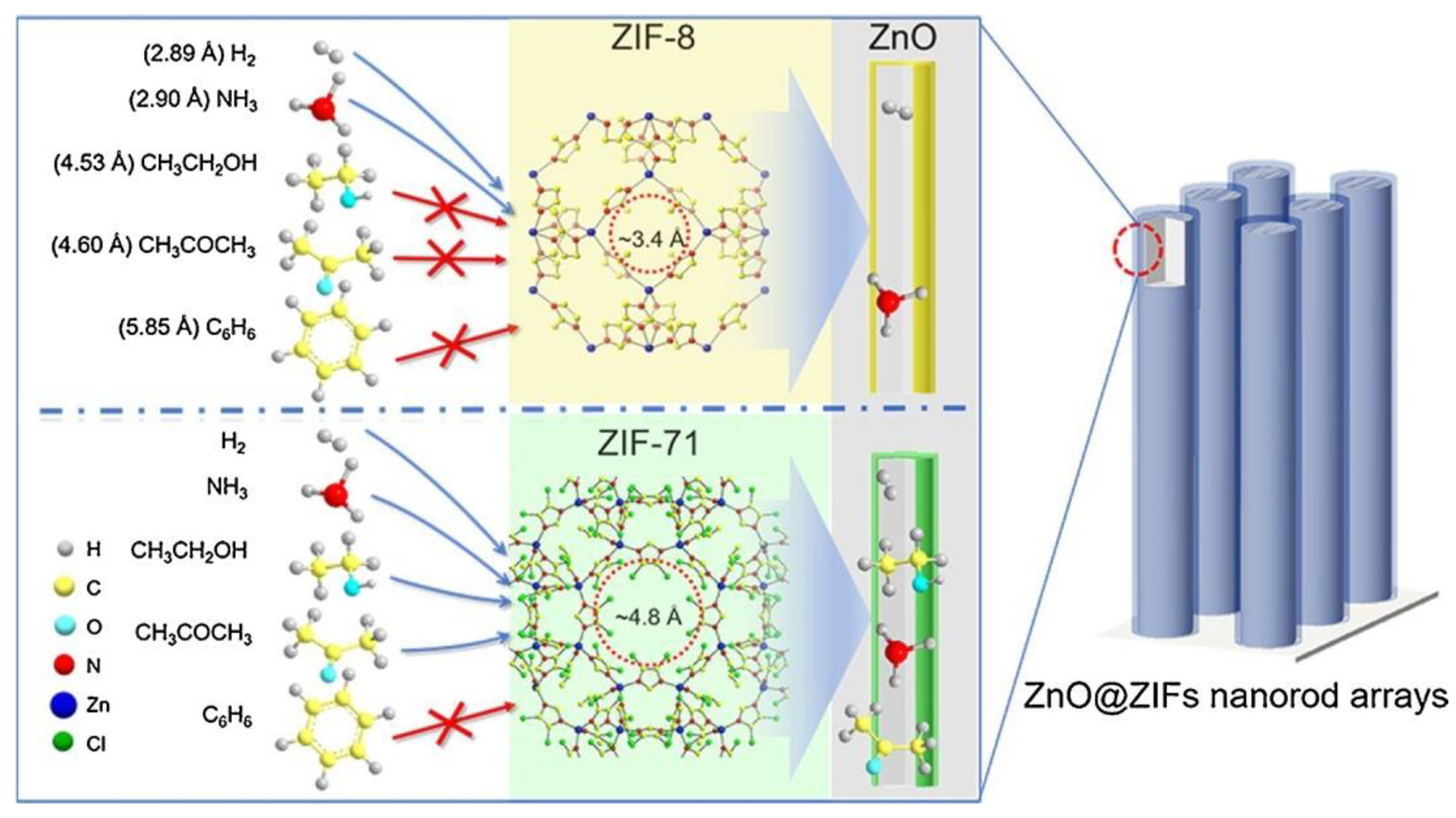

- Zhou, T.; Sang, Y.; Wang, X.; Wu, C.; Zeng, D.; Xie, C. Pore Size Dependent Gas-Sensing Selectivity Based on ZnO@ZIF Nanorod Arrays. Sens. Actuators B Chem. 2018, 258, 1099–1106. [Google Scholar] [CrossRef]

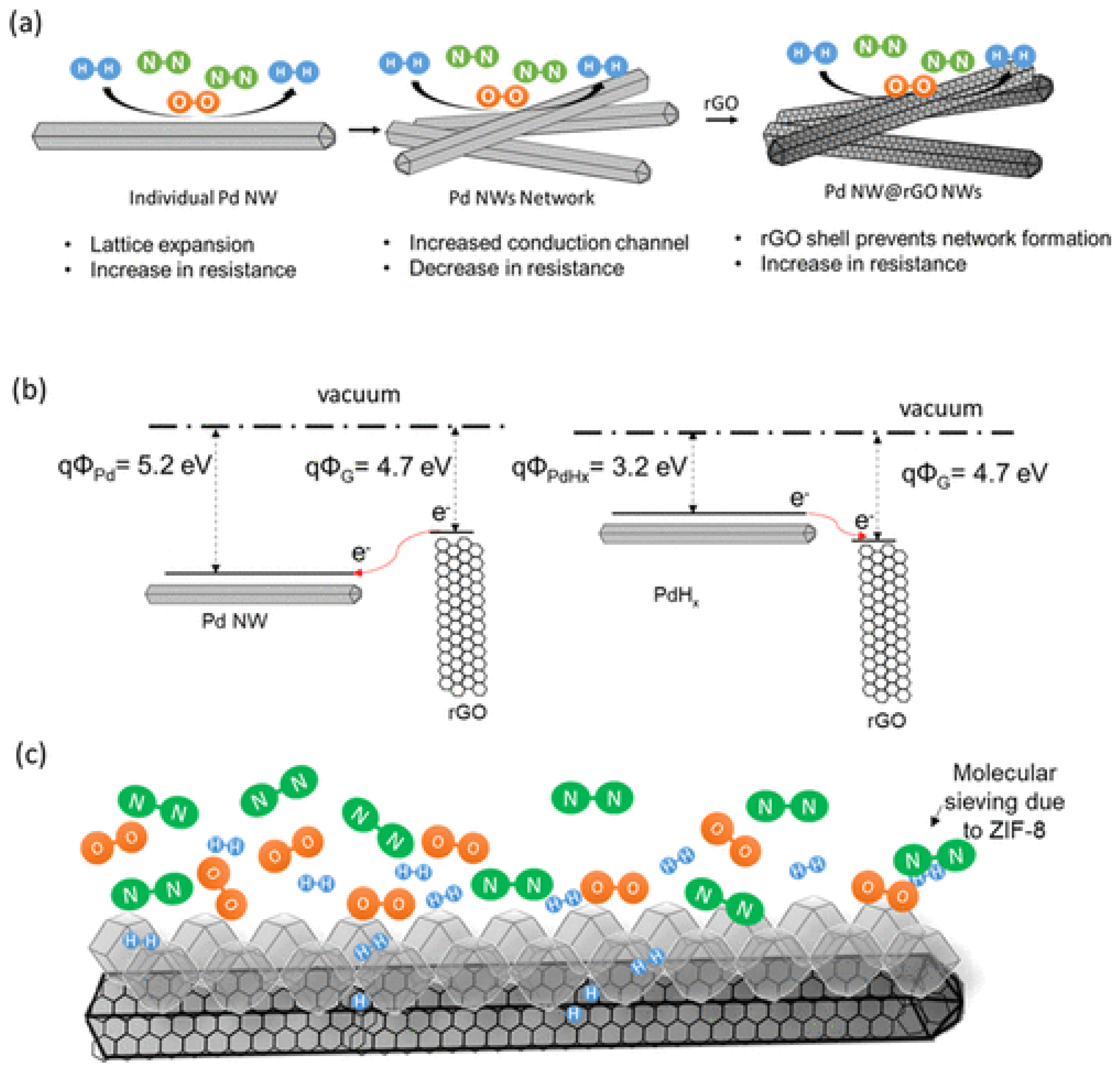

- Koo, W.-T.; Qiao, S.; Ogata, A.F.; Jha, G.; Jang, J.-S.; Chen, V.T.; Kim, I.-D.; Penner, R.M. Accelerating Palladium Nanowire H2 Sensors Using Engineered Nanofiltration. ACS Nano 2017, 11, 9276–9285. [Google Scholar] [CrossRef]

- Weber, M.; Kim, J.-H.; Lee, J.-H.; Kim, J.-Y.; Iatsunskyi, I.; Coy, E.; Drobek, M.; Julbe, A.; Bechelany, M.; Kim, S.S. High-Performance Nanowire Hydrogen Sensors by Exploiting the Synergistic Effect of Pd Nanoparticles and Metal–Organic Framework Membranes. ACS Appl. Mater. Interfaces 2018, 10, 34765–34773. [Google Scholar] [CrossRef]

- Kumar, A.; Mohammadi, M.M.; Zhao, Y.; Liu, Y.; Liu, J.; Thundat, T.; Swihart, M.T. Reduced Graphene Oxide-Wrapped Palladium Nanowires Coated with a Layer of Zeolitic Imidazolate Framework-8 for Hydrogen Sensing. ACS Appl. Nano Mater. 2021, 4, 8081–8093. [Google Scholar] [CrossRef]

- Lv, R.; Zhang, Q.; Wang, W.; Lin, Y.; Zhang, S. ZnO@ZIF-8 Core-Shell Structure Gas Sensors with Excellent Selectivity to H2. Sensors 2021, 21, 4069. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Alzamly, A.; Greish, Y.E.; Bakiro, M.; Nguyen, H.L.; Mahmoud, S.T. A Highly Sensitive and Flexible Metal–Organic Framework Polymer-Based H2S Gas Sensor. ACS Omega 2021, 6, 17690–17697. [Google Scholar] [CrossRef] [PubMed]

- Xie, B.; Ding, B.; Mao, P.; Wang, Y.; Liu, Y.; Chen, M.; Zhou, C.; Wen, H.; Xia, S.; Han, M.; et al. Metal Nanocluster—Metal Organic Framework—Polymer Hybrid Nanomaterials for Improved Hydrogen Detection. Small 2022, 18, 2200634. [Google Scholar] [CrossRef]

- Hwang, S.I.; Sopher, E.M.; Zeng, Z.; Schulte, Z.M.; White, D.L.; Rosi, N.L.; Star, A. Metal–Organic Frameworks on Palladium Nanoparticle–Functionalized Carbon Nanotubes for Monitoring Hydrogen Storage. ACS Appl. Nano Mater. 2022. [Google Scholar] [CrossRef]

- DMello, M.E.; Sundaram, N.G.; Kalidindi, S.B. Assembly of ZIF-67 Metal-Organic Framework over Tin Oxide Nanoparticles for Synergistic Chemiresistive CO 2 Gas Sensing. Chem. Eur. J. 2018, 24, 9220–9223. [Google Scholar] [CrossRef]

- Jayaramulu, K.; Esclance DMello, M.; Kesavan, K.; Schneemann, A.; Otyepka, M.; Kment, S.; Narayana, C.; Kalidindi, S.B.; Varma, R.S.; Zboril, R.; et al. A Multifunctional Covalently Linked Graphene–MOF Hybrid as an Effective Chemiresistive Gas Sensor. J. Mater. Chem. A 2021, 9, 17434–17441. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, R.; Zhang, T.; Liu, S.; Fei, T. Zeolitic Imidazolate Framework-8 (ZIF-8)-Coated In2O3 Nanofibers as an Efficient Sensing Material for Ppb-Level NO2 Detection. J. Colloid Interface Sci. 2019, 541, 249–257. [Google Scholar] [CrossRef]

- Jo, Y.-M.; Lim, K.; Yoon, J.W.; Jo, Y.K.; Moon, Y.K.; Jang, H.W.; Lee, J.-H. Visible-Light-Activated Type II Heterojunction in Cu3 (Hexahydroxytriphenylene)2/Fe2O3 Hybrids for Reversible NO2 Sensing: Critical Role of π–Π* Transition. ACS Cent. Sci. 2021, 7, 1176–1182. [Google Scholar] [CrossRef]

- Koo, W.; Kim, S.; Jang, J.; Kim, D.; Kim, I. Catalytic Metal Nanoparticles Embedded in Conductive Metal–Organic Frameworks for Chemiresistors: Highly Active and Conductive Porous Materials. Adv. Sci. 2019, 6, 1900250. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.-O.; Koo, W.-T.; Kim, H.; Park, C.; Lee, T.; Hutomo, C.A.; Choi, S.Q.; Kim, D.S.; Kim, I.-D.; Park, S. Large-Area Synthesis of Nanoscopic Catalyst-Decorated Conductive MOF Film Using Microfluidic-Based Solution Shearing. Nat. Commun. 2021, 12, 4294. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Zhang, W.; Wu, H.; Zhao, Y. Zn–Co Zeolitic Imidazolate Framework Nanoparticles Intercalated in Graphene Nanosheets for Room-Temperature NO2 Sensing. ACS Appl. Nano Mater. 2021, 4, 3998–4006. [Google Scholar] [CrossRef]

- Le Ouay, B.; Boudot, M.; Kitao, T.; Yanagida, T.; Kitagawa, S.; Uemura, T. Nanostructuration of PEDOT in Porous Coordination Polymers for Tunable Porosity and Conductivity. J. Am. Chem. Soc. 2016, 138, 10088–10091. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zhou, T.; Zhang, Y.; Tang, L.; Guo, Q.; Wang, M.; Xie, C.; Zeng, D. Synthesis of Core-Shell Flower-like WO3@ZIF-71 with Enhanced Response and Selectivity to H2S Gas. Solid State Ion. 2020, 350, 115278. [Google Scholar] [CrossRef]

- Wu, X.; Xiong, S.; Gong, Y.; Gong, Y.; Wu, W.; Mao, Z.; Liu, Q.; Hu, S.; Long, X. MOF-SMO Hybrids as a H2S Sensor with Superior Sensitivity and Selectivity. Sens. Actuators B Chem. 2019, 292, 32–39. [Google Scholar] [CrossRef]

- Tan, J.; Hussain, S.; Ge, C.; Zhan, M.; Liu, J.; Liu, S.; Liu, G.; Qiao, G. Construction of Hierarchical Trimetallic Organic Framework Leaf-like Nanostructures Derived from Carbon Nanotubes for Gas-Sensing Applications. J. Hazard. Mater. 2020, 400, 123155. [Google Scholar] [CrossRef]

- Travlou, N.A.; Singh, K.; Rodríguez-Castellón, E.; Bandosz, T.J. Cu–BTC MOF–Graphene-Based Hybrid Materials as Low Concentration Ammonia Sensors. J. Mater. Chem. A 2015, 3, 11417–11429. [Google Scholar] [CrossRef]

- Yin, Y.; Zhang, H.; Huang, P.; Xiang, C.; Zou, Y.; Xu, F.; Sun, L. Inducement of Nanoscale Cu–BTC on Nanocomposite of PPy–RGO and Its Performance in Ammonia Sensing. Mater. Res. Bull. 2018, 99, 152–160. [Google Scholar] [CrossRef]

- Khan, F.U.; Mehmood, S.; Zhao, X.; Yang, Y.; Pan, X. Ultra-Sensitive Bimetallic Alloy Loaded with Porous Architecture MOF for Ammonia Detection at Room Temperature. In Proceedings of the 2021 IEEE International Symposium on Circuits and Systems (ISCAS), Daegu, Korea, 22–28 May 2021; IEEE: Piscataway, NJ, USA; pp. 1–5. [Google Scholar]

- Bhardwaj, S.K.; Mohanta, G.C.; Sharma, A.L.; Kim, K.-H.; Deep, A. A Three-Phase Copper MOF-Graphene-Polyaniline Composite for Effective Sensing of Ammonia. Anal. Chim. Acta 2018, 1043, 89–97. [Google Scholar] [CrossRef]

- Garg, N.; Kumar, M.; Kumari, N.; Deep, A.; Sharma, A.L. Chemoresistive Room-Temperature Sensing of Ammonia Using Zeolite Imidazole Framework and Reduced Graphene Oxide (ZIF-67/RGO) Composite. ACS Omega 2020, 5, 27492–27501. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Jia, X.; Yang, J.; Li, Y.; Wang, S.; Song, H. One-Pot Synthesis of Core–Shell ZIF-8@ZnO Porous Nanospheres with Improved Ethanol Gas Sensing. J. Mater. Sci. Mater. Electron. 2020, 31, 22534–22545. [Google Scholar] [CrossRef]

- Sachdeva, S.; Koper, S.J.H.; Sabetghadam, A.; Soccol, D.; Gravesteijn, D.J.; Kapteijn, F.; Sudhölter, E.J.R.; Gascon, J.; de Smet, L.C.P.M. Gas Phase Sensing of Alcohols by Metal Organic Framework–Polymer Composite Materials. ACS Appl. Mater. Interfaces 2017, 9, 24926–24935. [Google Scholar] [CrossRef] [PubMed]

- Jafari, N.; Zeinali, S. Highly Rapid and Sensitive Formaldehyde Detection at Room Temperature Using a ZIF-8/MWCNT Nanocomposite. ACS Omega 2020, 5, 4395–4402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jafari, N.; Zeinali, S.; Shadmehr, J. Room Temperature Resistive Gas Sensor Based on ZIF-8/MWCNT/AgNPs Nanocomposite for VOCs Detection. J. Mater. Sci. Mater. Electron. 2019, 30, 12339–12350. [Google Scholar] [CrossRef]

- Tian, H.; Fan, H.; Li, M.; Ma, L. Zeolitic Imidazolate Framework Coated ZnO Nanorods as Molecular Sieving to Improve Selectivity of Formaldehyde Gas Sensor. ACS Sens. 2016, 1, 243–250. [Google Scholar] [CrossRef]

- Jagan Mohan Reddy, A.; Katari, N.K.; Nagaraju, P.; Hussain Reddy, K.; Surendra Babu, M.S. Fabrication and Deployment of Nanodisc ZnO@ZIF-8, ZnO@NA and ZnO@INA Core–Shell MOFs: Enhanced NH3 and HCHO Gas Sensing. J. Mater. Sci. Mater. Electron. 2021, 32, 7827–7840. [Google Scholar] [CrossRef]

- Wang, D.; Li, Z.; Zhou, J.; Fang, H.; He, X.; Jena, P.; Zeng, J.-B.; Wang, W.-N. Simultaneous Detection and Removal of Formaldehyde at Room Temperature: Janus Au@ZnO@ZIF-8 Nanoparticles. Nano-Micro Lett. 2018, 10, 4. [Google Scholar] [CrossRef] [Green Version]

- Yao, M.-S.; Tang, W.-X.; Wang, G.-E.; Nath, B.; Xu, G. MOF Thin Film-Coated Metal Oxide Nanowire Array: Significantly Improved Chemiresistor Sensor Performance. Adv. Mater. 2016, 28, 5229–5234. [Google Scholar] [CrossRef]

- Zhou, T.; Sang, Y.; Sun, Y.; Wu, C.; Wang, X.; Tang, X.; Zhang, T.; Wang, H.; Xie, C.; Zeng, D. Gas Adsorption at Metal Sites for Enhancing Gas Sensing Performance of ZnO@ZIF-71 Nanorod Arrays. Langmuir 2019, 35, 3248–3255. [Google Scholar] [CrossRef]

- Zhou, T.; Dong, W.; Qiu, Y.; Chen, S.; Wang, X.; Xie, C.; Zeng, D. Selectivity of a ZnO@ZIF-71@PDMS Nanorod Array Gas Sensor Enhanced by Coating a Polymer Selective Separation Membrane. ACS Appl. Mater. Interfaces 2021, 13, 54589–54596. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.; Xie, J.; Liu, S.; Bai, Y. Selective Methanol-Sensing of SnS-Supported Ultrathin ZIF-8 Nanocomposite with Core-Shell Heterostructure. Sens. Actuators B Chem. 2022, 368, 132230. [Google Scholar] [CrossRef]

- Nair, S.S.; Illyaskutty, N.; Tam, B.; Yazaydin, A.O.; Emmerich, K.; Steudel, A.; Hashem, T.; Schöttner, L.; Wöll, C.; Kohler, H.; et al. ZnO@ZIF-8: Gas Sensitive Core-Shell Hetero-Structures Show Reduced Cross-Sensitivity to Humidity. Sens. Actuators B Chem. 2020, 304, 127184. [Google Scholar] [CrossRef]

- Cao, R.; Ding, H.; Kim, K.-J.; Peng, Z.; Wu, J.; Culp, J.T.; Ohodnicki, P.R.; Beckman, E.; Chen, K.P. Metal-Organic Framework Functionalized Polymer Coating for Fiber Optical Methane Sensors. Sens. Actuators B Chem. 2020, 324, 128627. [Google Scholar] [CrossRef]

- Hong, T.; Culp, J.; Kim, K.-J.; Ohodnicki, P.R. Polymer/Metal–Organic Framework Composite Sensors for Gas Detection. Meet. Abstr. 2019, MA2019-01, 2028. [Google Scholar] [CrossRef]

- Zheng, L.; Keppler, N.; Zhang, H.; Behrens, P.; Roth, B. Planar Polymer Optical Waveguide with Metal-Organic Framework Coating for Carbon Dioxide Sensing. Adv Mater. Technol. 2022, 2200395. [Google Scholar] [CrossRef]

- Kong, Y.; Zhao, Z.; Wang, Y.; Yang, S.; Huang, G.; Wang, Y.; Liu, C.; You, C.; Tan, J.; Wang, C.; et al. Integration of a Metal–Organic Framework Film with a Tubular Whispering-Gallery-Mode Microcavity for Effective CO2 Sensing. ACS Appl. Mater. Interfaces 2021, 13, 58104–58113. [Google Scholar] [CrossRef]

- Chong, X.; Kim, K.; Zhang, Y.; Li, E.; Ohodnicki, P.R.; Chang, C.-H.; Wang, A.X. Plasmonic Nanopatch Array with Integrated Metal–Organic Framework for Enhanced Infrared Absorption Gas Sensing. Nanotechnology 2017, 28, 26LT01. [Google Scholar] [CrossRef]

- Zhang, J.; Yue, D.; Xia, T.; Cui, Y.; Yang, Y.; Qian, G. A Luminescent Metal-Organic Framework Film Fabricated on Porous Al2O3 Substrate for Sensitive Detecting Ammonia. Microporous Mesoporous Mater. 2017, 253, 146–150. [Google Scholar] [CrossRef]

- Wong, D.; Abuzalat, O.; Mostafa, S.; Park, S.S.; Kim, S. Intense Pulsed Light-Based Synthesis of Hybrid TiO2–SnO2 /MWCNT Doped Cu-BTC for Room Temperature Ammonia Sensing. J. Mater. Chem. C 2020, 8, 7567–7574. [Google Scholar] [CrossRef]

- Chappanda, K.N.; Shekhah, O.; Yassine, O.; Patole, S.P.; Eddaoudi, M.; Salama, K.N. The Quest for Highly Sensitive QCM Humidity Sensors: The Coating of CNT/MOF Composite Sensing Films as Case Study. Sens. Actuators B Chem. 2018, 257, 609–619. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.-Y.; Yan, B. Eu(III)-Functionalized ZnO@MOF Heterostructures: Integration of Pre-Concentration and Efficient Charge Transfer for the Fabrication of a Ppb-Level Sensing Platform for Volatile Aldehyde Gases in Vehicles. J. Mater. Chem. A 2017, 5, 2215–2223. [Google Scholar] [CrossRef]

- Zhai, L.; Yang, Z.-X.; Zhang, W.-W.; Zuo, J.-L.; Ren, X.-M. Dual-Emission and Thermochromic Luminescence Alkaline Earth Metal Coordination Polymers and Their Blend Films with Polyvinylidene Fluoride for Detecting Nitrobenzene Vapor. J. Mater. Chem. C 2018, 6, 7030–7041. [Google Scholar] [CrossRef]

- Kouser, S.; Hezam, A.; Khadri, M.J.N.; Khanum, S.A. A Review on Zeolite Imidazole Frameworks: Synthesis, Properties, and Applications. J. Porous Mater. 2022, 29, 663–681. [Google Scholar] [CrossRef]

- Yao, M.-S.; Cao, L.-A.; Tang, Y.-X.; Wang, G.-E.; Liu, R.-H.; Kumar, P.N.; Wu, G.-D.; Deng, W.-H.; Hong, W.-J.; Xu, G. Gas Transport Regulation in a MO/MOF Interface for Enhanced Selective Gas Detection. J. Mater. Chem. A 2019, 7, 18397–18403. [Google Scholar] [CrossRef]

- Wang, A.; Wang, C.; Fu, L.; Wong-Ng, W.; Lan, Y. Recent Advances of Graphitic Carbon Nitride-Based Structures and Applications in Catalyst, Sensing, Imaging, and LEDs. Nano Micro Lett. 2017, 9, 47. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, J.; Wang, Y. Strategies for the Performance Enhancement of Graphene-Based Gas Sensors: A Review. Talanta 2021, 235, 122745. [Google Scholar] [CrossRef]

- Han, T.; Nag, A.; Chandra Mukhopadhyay, S.; Xu, Y. Carbon Nanotubes and Its Gas-Sensing Applications: A Review. Sens. Actuators A Phys. 2019, 291, 107–143. [Google Scholar] [CrossRef]

- Gargiulo, V.; Alfano, B.; Di Capua, R.; Alfé, M.; Vorokhta, M.; Polichetti, T.; Massera, E.; Miglietta, M.L.; Schiattarella, C.; Di Francia, G. Graphene-like Layers as Promising Chemiresistive Sensing Material for Detection of Alcohols at Low Concentration. J. Appl. Phys. 2018, 123, 024503. [Google Scholar] [CrossRef]

- Villani, F.; Loffredo, F.; Alfano, B.; Miglietta, M.L.; Verdoliva, L.; Alfè, M.; Gargiulo, V.; Polichetti, T. Graphene-Like Based-Chemiresistors Inkjet-Printed onto Paper Substrate. In Sensors; Andò, B., Baldini, F., Di Natale, C., Ferrari, V., Marletta, V., Marrazza, G., Militello, V., Miolo, G., Rossi, M., Scalise, L., et al., Eds.; Lecture Notes in Electrical Engineering; Springer International Publishing: Cham, Germany, 2019; Volume 539, pp. 337–343. ISBN 978-3-030-04323-0. [Google Scholar]

- Bai, H.; Shi, G. Gas Sensors Based on Conducting Polymers. Sensors 2007, 7, 267–307. [Google Scholar] [CrossRef] [Green Version]

| Sensor Type | Examples | Principle of Operation |

|---|---|---|

| Electrochemical | Amperometric, ChemFET | Analyte molecules are involved in the redox reaction at the working electrode of an electrochemical cell, modulating the electrical current. |

| Electrical | Chemoresistors | Adsorbed molecules of the target gas interact with oxygen species adsorbed on the surface of a nanoparticulated semiconductor, modifying its charge depletion regions and its electrical conductivity. |

| Gravimetric | Surface acoustic waves, piezoelectric | A vibration resonance frequency is modified due to the adsorption of the target analyte. The shift in resonance frequency quantifies the analyte concentration. |

| Thermochemical | Catalytic bead sensors | The target gas is burnt, causing a temperature rise that changes the resistance of the detecting element of the sensor proportional to the concentration of combusted gas. |

| Optical | Absorptive Reflective Fluorescence-based | Adsorbed molecules of the target gas modify in several ways the optical properties of the sensing material (e.g., reflectivity, optical transmission, fluorescence spectrum and/or lifetime, etc.). |

| Analyte | Ionic Liquid | Electrode | Analyte Concentration | Ref. | |

|---|---|---|---|---|---|

| O2 | |||||

| [C4mpyrr][NTf2] | Clark-type sensor with polycrystalline Pt gauze | 1–20% | [83] | ||

| [C2mim][NTf2] and [C4mpyrr][NTf2] | Screen-printed (SP) electrodes | 10–100% and 0.1–5% | [84] | ||

| [N8,2,2,2][NTf2] | Pt MATFE | 10–100% | [85] | ||

| [C2mim][NTf2] | Pt microdisk and Pt MATFE | 0.1–100% | [86] | ||

| [MOmim][PF6] | Au microchannel electrode | 5000–25,000 ppm | [87] | ||

| [Bmim][BF4] | Au interdigitated electrodes | 20–100% | [88] | ||

| [C4mpyrr][NTf2] | Au on porous PTFE substrate | 5–20% | [89] | ||

| [C2mim][NTf2] and [C4mim][PF6] | SP electrodes (graphite) | 0.1–20% and 100% | [90] | ||

| [C4mpyrr][NTf2] | Au microchannel electrode | 50–400 ppm and 2000–5000 ppm | [91] | ||

| [C4mpyrr][NTf2] | Clark-type sensor with polycrystalline Pt gauze | 5–20% | [92] | ||

| [C4mpyrr][NTf2] | Interdigitated electrodes | 1400–4800 ppm | [93] | ||

| [C4mim][PF6], [C2mim][PF6] and [C5mim][PF6] | Pt interdigitated electrodes | 0–100% | [94] | ||

| [C4mim][BF4] | Planar electrodes | 20–100% | [95] | ||

| [Bmim][BF6] | Pt planar electrodes modified by NiCo2O4/rGO/[Bmim][BF6] composite | 20–100% | [96] | ||

| [C4mpn][Br] | Pt microelectrodes, 1% Ag-coated chitosan added to the IL | 20–100% | [97] | ||

| [Bmim][BF4] | SPE, solid polymer electrolyte (PTFE/Carbon nanotubes/IL) | 2.1–12.6% | [98] | ||

| [Emmim][TFSI] and [Bmim][TFSI] | Pt electrodes, IL + reduced graphene (rGO) + α-Fe2O3 electrolyte | 20–100% | [99] | ||

| [C2mim][NTf2] | IL membrane on Au-TFE | 20–100% | [100] | ||

| [C2mim][NTf2] added with Poly[DADMA][NTf2] | IL/poly(IL) membrane on Au-TFE | 20–100% | [100] | ||

| O2 and NH3 | [C2mim][BF4] and [C4mim][BF4] | Gel polymer electrolyte (ILs in PVDF) between planar electrodes | 1–20% for O2; 1–10 ppm for NH3 | [101] | |

| O2 and H2 | [Bmpy][NTf2] | Planar Pt-Ni alloy electrodes | 500–5000 ppm for O2; 500–6250 ppm for H2 | [102] | |

| H2 | |||||

| [C4mim][NTf2] and [C4mpyrr][NTf2] | Clark-type sensor with polycrystalline Pt gauze | 0.05–1.25% | [103] | ||

| [C4mim]Cl | Pd deposited on carbon gas diffusion electrode | 1–5% | [104] | ||

| [Bmpy][NTf2] | [Bmpy][NTf2] on Pt/C/Nafion screen-printed electrode | 2000–10,000 ppm | [105] | ||

| [C2mim][NTf2] | Au microchannel electrodes with electrodeposited Pt nanoparticles | 0.1–10% | [106] | ||

| NH3 | |||||

| [C2mim][NTf2] | Pt SPE, TFE, MATFE, and microdisk | 10–100 ppm | [107] | ||

| [C2mim][NTf2] | SP electrode, thin-film electrode (TFE), microarray thin-film electrode (MATFE), and microdisk. | 10–100 ppm | [108] | ||

| [C2mim][NTf2] | Pt MATFE | 10–100 ppm | [109] | ||

| [C2mim][NTf2] | Pt-based MATFE (with different morphologies) | 1–2 ppm LODs (depending on the morphology) | [109] | ||

| NH3 and HCl | [C2mim][NTf2] and [C4mpyrr][NTf2] | Au microchannel electrodes | 20–100 ppm | [110] | |

| VOC (in air) | [C4mpyrr][NTf2] | Clark-type sensor with polycrystalline Pt gauze | 200–3000 ppm of acetaldehyde | [111] | |

| CO2 | [Bmpy][NTf2] | Au microchannel electrodes with electrodeposited Cu nanoparticles | 0.14–11% | [112] | |

| Hexanaldehyde (HA) | [Bmim][OH] | Pt microelectrodes | 2–300 ppm (HA in squalene) | [113] | |

| C6H6 and HCHO | [C2mim][EtSO4] | IL and ionogel (IL in poly(N-isopropylacrylamide)) between interdigitated electrodes | 10–50 ppm | [114] | |

| SO2 | [C4mpyrr][NTf2] | TFEs and MATFEs | 1–10 ppm | [115] | |

| H2O (humidity) | [Bmim][DCA] | IL incorporated in gels on interdigitated electrodes | 30–70% RH | [116] | |

| Ethanol | [Bmim][HSO4] | IL on Au screen-printed electrode | 1–10% | [117] | |

| NO2 | [Bmim][NTf2] | Solid polymer electrolyte (PVDF + IL) on screen-printed electrodes | 1–10 ppm | [118] | |

| [Bmim][BF4] | Solid polymer electrolyte (ionic liquid (IL), carbon nanotubes + polyaniline + IL) on SP electrodes | 0–700 ppm | [119] | ||

| Ethylene (C2H4) | [Bmim][NTf2] | Solid polymer electrolyte (PVDF + IL) on SP electrodes | 100–500 ppm | [120] | |

| Analyte | Material | T (°C) | Conc. | Response | Ref |

|---|---|---|---|---|---|

| H2 | |||||

| ZnO@ZIF-8 | 300 | 50 ppm | 1.44 (R0/Rg) | [201] | |

| ZnO@ZIF-8 | 250 | 50 ppm | 3.28 (R0/Rg) | [202] | |

| ZnO@ZIF-8 | 125 | 10 ppm | ~5 (R0/Rg) | [203] | |

| ZnO@ZIF-8 | 250 | 50 ppm | ~80% (ΔI/I0) | [204] | |

| ZnO@ZIF-71 | 250 | 50 ppm | ~80% (ΔI/I0) | [204] | |

| Pd nanowires@ZIF-8 (4 h) | RT | 0.1% | 0.7% (ΔR/R0) | [205] | |

| ZnO@Pd@ZIF-8 nanowires | 200 | 50 ppm | 6.6 (R0/Rg) | [206] | |

| Pd NWs@rGO@ZIF-8 | RT | 100 ppm | 2.2% (ΔR/R0) | [207] | |

| ZnO@ZIF-8 | 290 | 1000 ppm | ~6 (R0/Rg) | [208] | |

| MOF-5/CS/IL | RT | 100 ppm | ~0.1 (R0/Rg) | [209] | |

| Pd/ZIF-67 | RT | 3000 ppm | 9% (ΔI/I0) | [210] | |

| Pd/ZIF-67/PMMA | RT | 3000 ppm | 7% (ΔI/I0) | [210] | |

| HKUST-1/Pd NP/SWCNT | N.A. | 10 ppm | (not defined) | [211] | |

| CO2 | SnO2@ZIF-67 | 205 | 5000 ppm | 16% (ΔR/R0) | [212] |

| GA@UiO-66-NH2 | 200 | 5% to 100% | 2% to 8% (ΔR/R0) | [213] | |

| NO2 | |||||

| In2O3/ZIF-8 (4:1) | 140 | 1 ppm | 16.4 (Rg/R0) | [214] | |

| Cu3(HHTP)2/Fe2O3 | RT | 5 ppm | 63% (ΔR/R0) | [215] | |

| Pd@Cu3(HHTP)2 | RT | 5 ppm | 62% (ΔR/R0) | [216] | |

| Pt@Cu3(HHTP)2 | RT | 5 ppm | 57% (ΔR/R0) | [216] | |

| Pt@Cu3(HHTP)2 | RT | 3 ppm | 90% (ΔR/R0) | [217] | |

| ZnCo-ZIF/graphene nanoplatelets | 22 °C, 30% RH | 100 ppm | ~30 (R0/Rg) | [218] | |

| MIL-101(Cr)-PEDOT(45) | RT | 1 ppm to 10 ppm | 1–30 (ΔG/G0) | [219] | |

| H2S | |||||

| MOF-5/CS/IL | RT | 100 ppm | 0.91 (R0/Rg) | [209] | |

| WO3@ZIF-71 | 250 | 20 ppm | 19% (ΔR/R0) | [220] | |

| ZIF-8/ZnO | 25 | 10 ppm | 52% (ΔR/R0) | [221] | |

| Co-Zn-MOF@CNT | 325 | 100 ppm | ~60 (Rg/R0) | [222] | |

| NH3 | |||||

| ZnO@ZIF-8 | 250 | 50 ppm | ~25% (ΔI/I0) | [204] | |

| ZnO@ZIF-71 | 250 | 50 ppm | ~25% (ΔI/I0) | [204] | |

| Cu-BTC/GO (25) | RT | 500 ppm | 7% (ΔR/R0) | [223] | |

| Cu-BTC/PPy-rGO | 25, 50% RH | 50 ppm | 12.4% (ΔR/R0) | [224] | |

| Pd-Co@IRMOF1 | RT | 90 ppm | ~80 (R0/Rg) | [225] | |

| SiO2CuOF-graphene-PAni | N.A. | 200 ppm | 150% (ΔR/R0) | [226] | |

| ZIF-67/rGO | rt | 50 ppm | 5.8 (R0/Rg) | [227] | |

| ZIF-8@ZnO porous nanospheres | 220 | 50 ppm | ~6 (R0/Rg) | [228] | |

| ZnCo-ZIF/graphene nanoplatelets | 25, 30% RH | 1000 ppm | ~1.1 (R0/Rg) | [218] | |

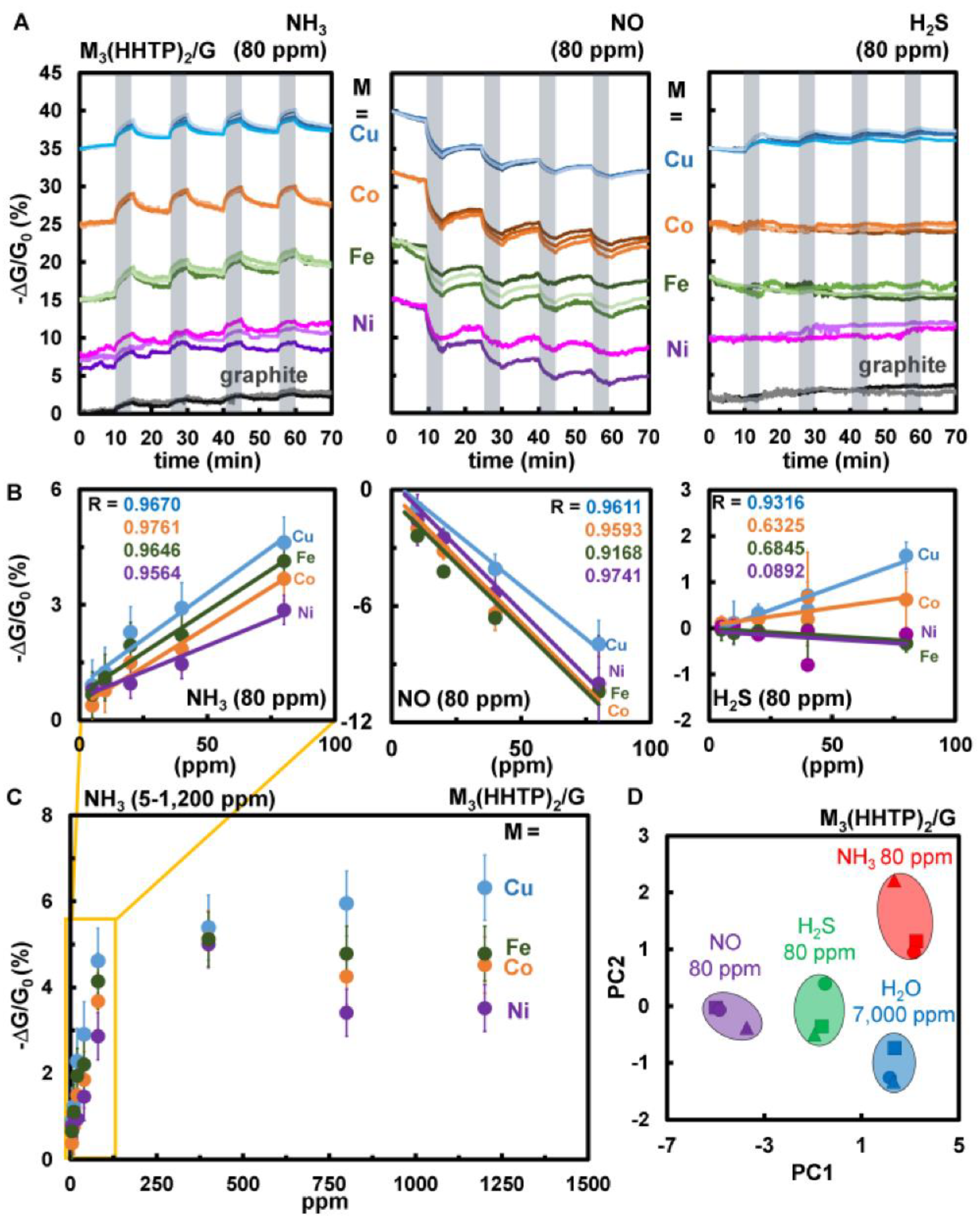

| Cu3(HHTP)2/graphite | RT | 80 ppm | 5% (ΔG/G0) | [181] | |

| Co3(HHTP)2/graphite | RT | 80 ppm | 4% (ΔG/G0) | [181] | |

| Fe3(HHTP)2/graphite | RT | 80 ppm | 4% (ΔG/G0) | [181] | |

| Ni3(HHTP)2/graphite | RT | 80 ppm | 3% (ΔG/G0) | [181] | |

| CO | |||||

| MOF-5/CS/IL | RT | 100 ppm | ~8% (R0/Rg) | [209] | |

| ZnCo-ZIF/graphene nanoplatelets | 22, 30% RH | 1000 ppm | ~1.4 (R0/Rg) | [218] | |

| CH4 | |||||

| ZnCo-ZIF/graphene nanoplatelets | 22, 30% RH | 1000 ppm | ~1.5 (R0/Rg) | [218] | |

| NO | |||||

| Cu3(HHTP)2/graphite | RT | 80 ppm | 8% (ΔG/G0) | [181] | |

| Fe3(HHTP)2/graphite | RT | 80 ppm | 11% (ΔG/G0) | [181] | |

| Ni3(HHTP)2/graphite | RT | 80 ppm | 10% (ΔG/G0) | [181] | |

| H2O | |||||

| Matrimid-NH2-MIL-53(Al) | 28 | 2% | 12% (ΔG/G0) | [229] | |

| ZIF-8/MWCNT | 25; 20% RH | 100 ppm | 11% (ΔR/R0) | [230] | |

| ZIF-8/MWCNTs/AgNPs | RT | 1% | 2.5% (ΔR/R0) | [231] | |

| CH2O (Formaldehyde) | |||||

| ZnO@ZIF-8 | 300, 10% RH | 100 ppm | ~13.5 (R0/Rg) | [232] | |

| ZnO@ZIF-8 | RT | 5 ppm to 100 ppm | 7 to 210 (R0/Rg) | [233] | |

| Janus Au@ZnO@ZIF-8 | 25 | 50 ppm | 5–20 (R0/Rg, sample dependent) | [234] | |

| ZIF-8/MWCNT | 25; 20% RH | 100 ppm | 200% (ΔR/R0) | [230] | |

| ZIF-8@ZnO porous nanospheres | 220 | 50 ppm | ~9.7 (R0/Rg) | [228] | |

| Pd-Co@IRMOF1 | RT | 90 ppm | ~10 (R0/Rg) | [225] | |

| CH3COCH3 (Acetone) | |||||

| ZnO@5nmZIF-CoZn | 260 | 10 ppm | 28 (R0/Rg) | [235] | |

| ZnO@ZIF-8 | 250 | 50 ppm | ~20% (ΔI/I0) | [204] | |

| ZnO@ZIF-71 | 250 | 50 ppm | ~240% (ΔI/I0) | [204] | |

| ZnO@ZIF-71 | 150 | 5 ppm | 39% (ΔI/I0) | [236] | |

| ZIF-8/MWCNTs/Ag NPs | rt | 1% | 2.3% (ΔR/R0) | [231] | |

| ZIF-8/MWCNT | 25; 20% RH | 100 ppm | 4.6% (ΔR/R0) | [230] | |

| ZnO@ZIF-8 | 290 | 50 ppm | ~2 (R0/Rg) | [208] | |

| ZIF-8@ZnO porous nanospheres | 220 | 50 ppm | ~8 (R0/Rg) | [228] | |

| Pd-Co@IRMOF1 | RT | 90 ppm | ~8 (R0/Rg) | [225] | |

| Pd/ZIF-67 | RT | 3000 ppm | 0.5% (ΔI/I0) | [210] | |

| CH3CH2OH (Ethanol) | |||||

| ZnO@ZIF-8 | 250 | 50 ppm | ~40% (ΔI/I0) | [203] | |

| ZnO@ZIF-71 | 250 | 50 ppm | ~325% (ΔI/I0) | [203] | |

| ZnO@ZIF-71 | 150 | 10 ppm | 13.4% (ΔI/I0) | [236] | |

| ZIF-8/MWCNTs/Ag NPs | RT | 1% | 12% (ΔR/Ra) | [231] | |

| ZnO@ZIF-71@PDMS | 250 | 10 ppm | 500% (ΔI/I0) | [237] | |

| Matrimid-NH2-MIL-53(Al) | 28 | 2% | ~8% (ΔG/G0) | [229] | |

| ZIF-8/MWCNT | 25; 20% RH | 100 ppm | 26.4% (ΔR/R0) | [230] | |

| ZnO@ZIF-8 | 290 | 100 ppm | ~2 (R0/Rg) | [208] | |

| ZIF-8@ZnO porous nanospheres | 220 | 50 ppm | 13.8 (R0/Rg) | [228] | |

| Pd-Co@IRMOF1 | RT | 90 ppm | 20 (R0/Rg) | [225] | |

| CH3OH (Methanol) | |||||

| ZIF-8/MWCNTs/Ag NPs | RT | 1% | 8% (ΔR/R0) | [231] | |

| Matrimid-NH2-MIL-53(Al) | 28 | 20,000 ppm | 8% (ΔG/G0) | [229] | |

| ZIF-8/MWCNT | 25–27, 20% RH | 100 ppm | 20% (ΔR/R0) | [230] | |

| ZIF-8@ZnO porous nanospheres | 220 | 50 ppm | 8 (R0/Rg) | [228] | |

| Cu3(HHTP)2/graphite | RT | 500 ppm | 2% (ΔG/G0) | [181] | |

| SnS/ZIF-8 | 25 | 10 ppm | ~60 (ΔG/G0) | [238] | |

| C2H4 (ethene) | ZnO@ZIF-8 | 350 °C, 25% RH | 250 ppm | 20% (ΔG/G0) | [239] |

| C3H6 (propene) | ZnO@ZIF-8 | 350 °C, 25% RH | 250 ppm | 60% (ΔG/G0) | [239] |

| Analyte | Method | Material | Conc. | Response | Ref. |

|---|---|---|---|---|---|

| CH4 | Optical-fiber transmittance | ZIF8/PDMS | 20% to 50% (in N2) | 1.05–1.15 (I/I0) | [240] |

| CH4 | Optical-fiber transmittance | SBS/Fe(Pyz)Ni(CN)4 (50%) | 100% to 20% | Little % transmittance | [241] |

| CO2 | Optical-fiber transmittance | SBS/Fe(Pyz)Ni(CN)4 (50%) | 100% to 10% | Little % transmittance | [241] |

| CO2 | Optical-fiber transmittance | PMMA/ZIF-8 | 0% to 100% | Up to 30% transmittance reduction | [242] |

| CO2 | Interference fringe shift in cavity | ZIF8-decorated WGM microcavity | 25% to 100% | per % of CO2 concentration | [243] |

| CO2 | IR absorption | Plasmonic nanopatch array-ZIF-8 | 20% to 35% | ~4 × 102 (enhancement factor of the IR absorption) | [244] |

| NH3 | Optical | MIL-124@Eu3+/Al2O3 | 500 ppm | 14% (ΔI/I0) | [245] |

| NH3 | QCM | TiO2-SnO2/MWCNTs@Cu-BTC | 40 ppm | 0.8, see table caption for the definition | [246] |

| H2O | QCM | CNT-HKUST-1 | 5% to 75% RH | 2.5 × 10−5 of (Δf/f) per percent of humidity | [247] |

| CH2O | PL | Eu(III)-functionalized ZnO@MOF | 10 ppm | 5.5, defined as I (614 nm)/I (470 nm) | [248] |

| C6H6 | PL | Eu(III)-functionalized ZnO@MOF | 10 ppm | 2.4, defined as I (614 nm)/I (470 nm) | [248] |

| Ethyl-benzene | PL | Eu(III)-functionalized ZnO@MOF | 10 ppm | 2.4, defined as above | [248] |

| Toluene | PL | Eu(III)-functionalized ZnO@MOF | 10 ppm | 2.3, defined as above | [248] |

| Nitrobenzene | PL | [Ca(H2EBTC)(DMF)2]@PVDF | 50 ppm | 1.3 (I0/I) | [249] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gargiulo, V.; Alfè, M.; Giordano, L.; Lettieri, S. Materials for Chemical Sensing: A Comprehensive Review on the Recent Advances and Outlook Using Ionic Liquids, Metal–Organic Frameworks (MOFs), and MOF-Based Composites. Chemosensors 2022, 10, 290. https://doi.org/10.3390/chemosensors10080290

Gargiulo V, Alfè M, Giordano L, Lettieri S. Materials for Chemical Sensing: A Comprehensive Review on the Recent Advances and Outlook Using Ionic Liquids, Metal–Organic Frameworks (MOFs), and MOF-Based Composites. Chemosensors. 2022; 10(8):290. https://doi.org/10.3390/chemosensors10080290

Chicago/Turabian StyleGargiulo, Valentina, Michela Alfè, Laura Giordano, and Stefano Lettieri. 2022. "Materials for Chemical Sensing: A Comprehensive Review on the Recent Advances and Outlook Using Ionic Liquids, Metal–Organic Frameworks (MOFs), and MOF-Based Composites" Chemosensors 10, no. 8: 290. https://doi.org/10.3390/chemosensors10080290

APA StyleGargiulo, V., Alfè, M., Giordano, L., & Lettieri, S. (2022). Materials for Chemical Sensing: A Comprehensive Review on the Recent Advances and Outlook Using Ionic Liquids, Metal–Organic Frameworks (MOFs), and MOF-Based Composites. Chemosensors, 10(8), 290. https://doi.org/10.3390/chemosensors10080290