Review of Helical Magnetic Structures in Magnetic Microwires

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Magneto-Optical Kerr Effect Technique

3. Background: Helical, Elliptical, Spiral and Vortex Magnetic Structures

4. Background: Magnetic Structure in Magnetic Microwires

5. MOKE Study of Helical Magnetic Structures in Microwires

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Garcıa-Martın, J.; Gomez-Gil, J.; Vazquez-Sanchez, E. Non-destructive techniques based on eddy current testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Uzal, E.; Rose, J. The impedance of eddy current probes above layered metals whose conductivity and permeability vary continuously. IEEE Trans. Magn. 1993, 29, 1869–1873. [Google Scholar] [CrossRef]

- Stutzke, N.; Russek, S.; Pappas, P. Low-frequency noise measurements on commercial magnetoresistive magnetic field sensors. J. Appl. Phys. 2005, 97, 10Q107. [Google Scholar] [CrossRef]

- Dogaru, T.; Smith, S.T. Giant magnetoresistence-based eddy-current sensor. IEEE Trans. Magn. 2002, 37, 3831–3838. [Google Scholar] [CrossRef]

- Rifai, D.; Abdalla, A.; Ali, A.; Razali, R. Giant Magnetoresistance Sensors: A Review on Structures and Non-Destructive Eddy Current Testing Applications. Sensors 2016, 16, 298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nair, N.; Melapudi, V.; Hector, J.; Liu, X.; Deng, Y.; Zeng, Z.; Udpa, L.; Thomas, J.; Udpa, S. A GMR-based eddy current system for NDE of aircraft structures. IEEE Trans. Magn. 2016, 42, 3312–3314. [Google Scholar] [CrossRef]

- Yang, G.; Zeng, Z.; Deng, Y.; Liu, X.; Udpa, L.; Tamburrino, A. 3D EC-GMR sensor system for detection of subsurface defects at steel fastener sites. NDT E Int. 2012, 50, 20–28. [Google Scholar] [CrossRef]

- Lo, C.; Nakagawa, N. Evaluation of eddy current and magnetic techniques for inspecting rebars in bridge barrier rails. AIP Conf. Proc. 2013, 1511, 1371–1377. [Google Scholar]

- Yamada, S.; Chomsuwan, K.; Fukuda, Y.; Iwahara, M.; Wakiwaka, H.; Shoji, S. Eddy-current testing probe with spin-valve type GMR sensor for printed circuit board inspection. IEEE Trans. Magn. 2004, 40, 2676–2678. [Google Scholar] [CrossRef]

- Wang, R.; Kawamura, Y. An automated sensing system for steel bridge inspection using GMR sensor array and magnetic wheels of climbing robot. J. Sens. 2016, 1, 1. [Google Scholar] [CrossRef] [Green Version]

- Du, W.; Nguyen, H.; Dutt, A.; Scallion, K. Design of a GMR sensor array system for robotic pipe inspection. In Proceedings of the 2010 IEEE Sensors, Kona, HI, USA, 1–4 November 2010; pp. 2551–2554. [Google Scholar]

- Chen, L.; Que, P.; Jin, T. A giant-magnetoresistance sensor for magnetic-flux-leakage nondestructive testing of a pipe. Russ. J. Nondestruct. Test. 2005, 41, 462–465. [Google Scholar] [CrossRef]

- Kaack, M.; Orth, T.; Fischer, G.; Weingarten, W.; Koka, S.; Arzt, N. Application of GMR sensors for the industrial inspection of seamless steel pipes. In Proceedings of the 11th Symposium on Magnetoresistive Sensors and Magnetic Systems, Wetzlar, Germany, 29–30 March 2011. [Google Scholar]

- Rifai, D.; Abdalla, A.; Razali, R.; Ali, K.; Faraj, M. An eddy current testing platform system for pipe defect inspection based on an optimized eddy current technique probe design. Sensors 2017, 17, 579. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zilberstein, V.; Walrath, K.; Grundy, D.; Schlicker, D.; Goldfine, N.; Abramovici, E.; Yentzer, T. MWM eddy-current arrays for crack initiation and growth monitoring. Int. J. Fatigue 2003, 25, 1147–1155. [Google Scholar] [CrossRef]

- Farea, S.; Hammad, R.; Dawoud, F.; Dossary, S.; Alzarani, S.; Binqorsain, A.; Minachi, A.; Goldfine, N.; Denenberg, S.; Manning, B.; et al. Field Demonstrations of MR-MWM-Array Solution for Detection, Imaging and Sizing of Corrosion under Fireproofing (CUF) with Wire Mesh. In Proceedings of the 15th Middle East Corrosion Conference, Manama, Bahrain, 2–5 February 2014. [Google Scholar]

- Bailey, J.; Long, N.; Hunze, A. Eddy Current Testing with Giant Magnetoresistance (GMR) Sensors and a Pipe-Encircling Excitation for Evaluation of Corrosion under Insulation. Sensors 2017, 17, 2229. [Google Scholar] [CrossRef] [Green Version]

- Brett, C.; de Raad, J. Validation of pulsed eddy current system for measuring wall thinning trough insulation. In Proceedings of the SPIE 2947, Nondestructive Evaluation of Utilities and Pipes, Scottsdale, AZ, USA, 14 November 1996. [Google Scholar]

- Cheng, W. Pulsed Eddy Current Testing of Carbon Steel Pipes Wall-thinning Through Insulation and Cladding. J. Nondestruct. Eval. 2012, 31, 215–224. [Google Scholar] [CrossRef]

- Greiner, M.; Demers-Carpeneter, V.; Rochette, M.; Hardy, F. Pulsed Eddy Current: New Developments for Corrosion under Insulation Examinations. In Proceedings of the 19th World Conference on Non-Destructive Testing, Munich, Germany, 13–17 June 2016. [Google Scholar]

- Majidnia, S.; Rudlin, J.; Nilavalan, R. A pulsed eddy current system for flaw detection using an encircling coil on a steel pipe. In Proceedings of the First International Conference on Welding and Non-Destructive Testing (ICWNDT2014), Karaj, Iran, 25–26 February 2014. [Google Scholar]

- Majidnia, S.; Rudlin, J.; Nilavalan, R. Investigations on a pulsed eddy current system for flaw detection using an encircling coil on a steel pipe. Insight Non Destr. Test. Cond. Monit. 2014, 56, 560–565. [Google Scholar] [CrossRef]

- Heim, E.; Ludwig, F.; Schilling, M. Binding assays with streptavidin-functionalized superparamagnetic nanoparticles and biotinylated analytes using fluxgate magnetorelaxometry. J. Magn. Magn. Mater. 2009, 321, 1628–1631. [Google Scholar] [CrossRef]

- Lee, Y.M.; Jeong, Y.; Kang, H.J.; Chung, S.J.; Chung, B.H. Cascade enzyme-linked immunosorbent assay (CELISA). Biosens. Bioelectron. 2009, 25, 332–337. [Google Scholar] [CrossRef]

- Lee, W.; Joo, S.J.; Sun, U.K.; Rhie, K.W.; Hong, J.K.; Shin, K.H.; Kim, K.H. Magnetic bead counter using a micro-Hall sensor for biological applications. Appl. Phys. Lett. 2009, 94, 153903. [Google Scholar] [CrossRef]

- Pannetier, L.M.; Parkkonen, L.; Sergeeva, C.N.; Polovy, H.; Fermon, C.; Fowley, C. Magnetocardiography with sensors based on giant magnetoresistance. Appl. Phys. Lett. 2011, 98, 153705. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, H.A.; Graham, D.L.; Freitas, P.P.; Cabral, J.M.S. Biodetection using magnetically labeled biomolecules and arrays of spin valve sensors. J. Appl. Phys. 2003, 93, 7281–7286. [Google Scholar] [CrossRef]

- Vacher, F.; Alves, F.; Gilles, C. Eddy current nondestructive testing with giant magneto-impedance sensor. NDT EInt. 2007, 40, 439–442. [Google Scholar] [CrossRef]

- Phan, M.H.; Peng, H.X. Giant magnetoimpedance materials: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 323–420. [Google Scholar] [CrossRef]

- Tehranchi, M.M.; Ranjbaran, M.; Eftekhari, H. Double core giant magneto-impedance sensors for the inspection of magnetic flux leakage from metal surface cracks. Sens. Actuators A 2011, 170, 55–61. [Google Scholar] [CrossRef]

- Moulin, J.; Shahosseini, I.; Alves, F.; Mazaleyrat, F. Ultrasoft Finemet thin films for magneto-impedance microsensors. J. Micromech. Microeng. 2011, 21, 074010–074017. [Google Scholar] [CrossRef]

- Panina, L.V.; Mohri, K. Magneto-impedance effect in amorphous wires. Appl. Phys. Lett. 1994, 65, 1189–1191. [Google Scholar] [CrossRef]

- Panina, L.V.; Mohri, K.; Uchiyama, T.; Noda, M. Giant magneto-impedance in Co-rich amorphous wires and films. IEEE Trans. Magn. 1995, 31, 1249–1260. [Google Scholar] [CrossRef]

- Jackson, J.D. Classical Electrodynamics; John Wiley &Sons, Inc.: Hoboken, NJ, USA, 1975. [Google Scholar]

- Qin, F.X.; Peng, H.X.; Phan, M.H. Wire-length effect on GMI in Co70.3Fe3.7B10Si13Cr3 amorphous glass-coated microwires. Mater. Sci. Eng. 2010, 167, 129–132. [Google Scholar] [CrossRef]

- Ripka, P.; Kraus, L. Magnetic Sensors and Magnetometers; Artech House: Boston, MA, USA, 2001; pp. 350–358. [Google Scholar]

- Zhou, Y.; Yu, J.Q.; Zhao, X.L.; Cai, B.C. Simulation of giant magnetoimpedance in single layer and sandwiched thin films. J. Appl. Phys. 2001, 89, 1816–1819. [Google Scholar] [CrossRef]

- Peksoz, A.; Kaya, Y.; Taysioglu, A.A.; Derebasi, N.; Kaynak, G. Giant magneto-impedance effect in diamagnetic organic thin film coated amorphous ribbons. Sens. Actuators A 2010, 159, 69–72. [Google Scholar] [CrossRef]

- NazariNejad, S.; Fomani, A.A.; Mansour, R. Giant Magneto-Impedance Thin Film Magnetic Sensor. IEEE Trans. Magn. 2013, 49, 3874–3877. [Google Scholar] [CrossRef]

- Dwevedi, S.; Markandeyulu, G. Giant magnetoimpedance effect in nanocrystalline ribbons for sensitive magnetic sensors. J. Appl. Phys. 2010, 107, 09A328. [Google Scholar] [CrossRef]

- Laurita, N.; Chaturvedi, A.; Bauer, C.; Jayathilaka, P.; Leary, A.; Miller, C.; Phan, M.H.; McHenry, M.E.; Srikanth, H. Enhanced giant magnetoimpedance effect and field sensitivity in Co-coated soft ferromagnetic amorphous ribbons. J. Appl. Phys. 2011, 109, 07C706. [Google Scholar] [CrossRef] [Green Version]

- Chiriac, H.; Tibu, M.; Moga, A.; Herea, D. Magnetic GMI sensor for detection of biomolecules. J. Magn. Magn. Mater. 2005, 293, 671–676. [Google Scholar] [CrossRef]

- Chiriac, H.; Herea, D.; Corodeanu, S. Microwire array for giant magneto-impedance detection of magnetic particles for biosensor prototype. J. Magn. Magn. Mater. 2007, 311, 425–428. [Google Scholar] [CrossRef]

- Chiriac, H.; Herea, D. Magneto-impedance sensor for biomedical applications. Int. J. Appl. Electromagn. Mech. 2007, 25, 453–459. [Google Scholar] [CrossRef]

- Kim, D.; Kim, H.; Park, S.; Lee, W.; Jeung, W.Y. Operating Field Optimization of Giant Magneto Impedance (GMI) Devices in Micro Scale for Magnetic Bead Detection. IEEE Trans. Magn. 2008, 44, 3985–3988. [Google Scholar]

- Blanc-Béguin, F.; Nabily, S.; Gieraltowski, J.; Turzo, A.; Querellou, S.; Salaun, P. Cytotoxicity and GMI bio-sensor detection of maghemite nanoparticles internalized into cells. J. Magn. Magn. Mater. 2009, 321, 192–197. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Hayashi, M.; Thomas, L. Magnetic domain-wall racetrack memory. Science 2008, 320, 190. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, W.; Klein, J.O.; Claude Chappert, C.; Ravelosona, D. Peristaltic perpendicuar-magnetic anisotropy racetrack memory based on chiral domain wall motions. J. Phys. D Appl. Phys. 2015, 48, 105001. [Google Scholar] [CrossRef]

- Bläsing, R.; Khan, A.A.; Filippou, P.C.; Garg, C.; Hameed, F.; Castrillon, J.; Parkin, S.S.P. From physics to the cusp of applications within a decade. Proc. IEEE 2020, 108, 1303. [Google Scholar] [CrossRef]

- Honda, S.; Sonobe, Y.; Greaves, S.J. Transforming domain motion for 3D racetrack memory with perpendicular magnetic anisotropy. J. Phys. D Appl. Phys. 2021, 54, 135002. [Google Scholar] [CrossRef]

- Chizhik, A.; Gonzalez, J. Magnetic Microwires. A Magneto-Optical Study; Pan Stanford Publishing: Singapore, 2014. [Google Scholar]

- Melo, L.G.C.; Menard, D.; Ciureanu, P.; Yelon, A.; Cochrane, R.W. Coupled core–shell model of magnetoimpedance in wires. J. Appl. Phys. 2004, 95, 1331. [Google Scholar] [CrossRef]

- Torrejon, J.; Thiaville, A.; Adenot-Engelvin, A.L.; Vazquez, M.; Acher, O. Cylindrical magnetization model for glass-coated microwires with circular anisotropy: Statics. J. Magn. Magn. Mater. 2011, 323, 283. [Google Scholar] [CrossRef]

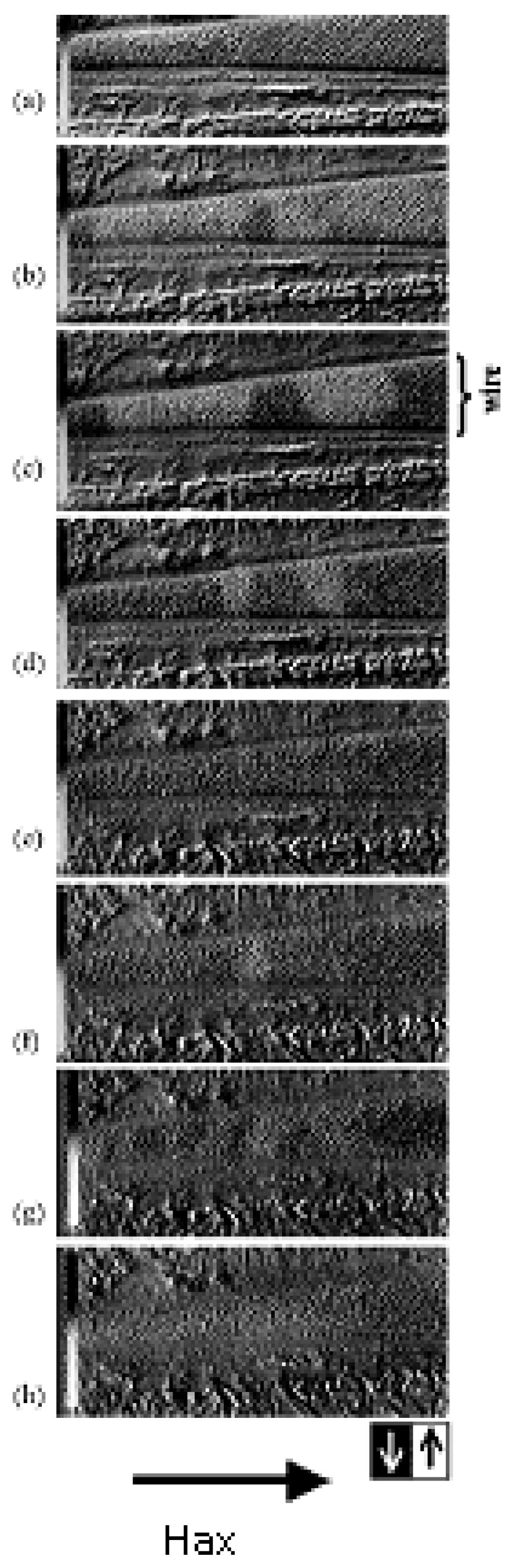

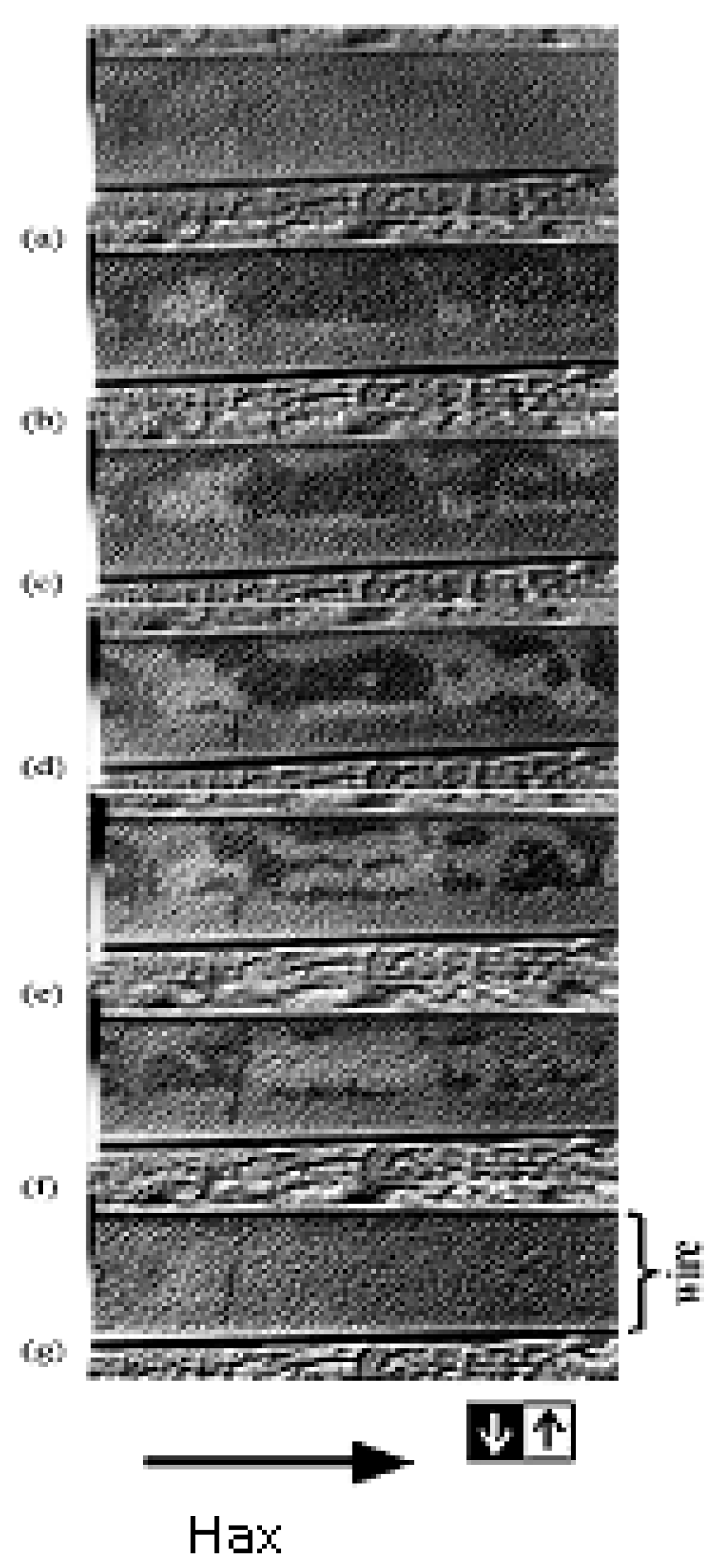

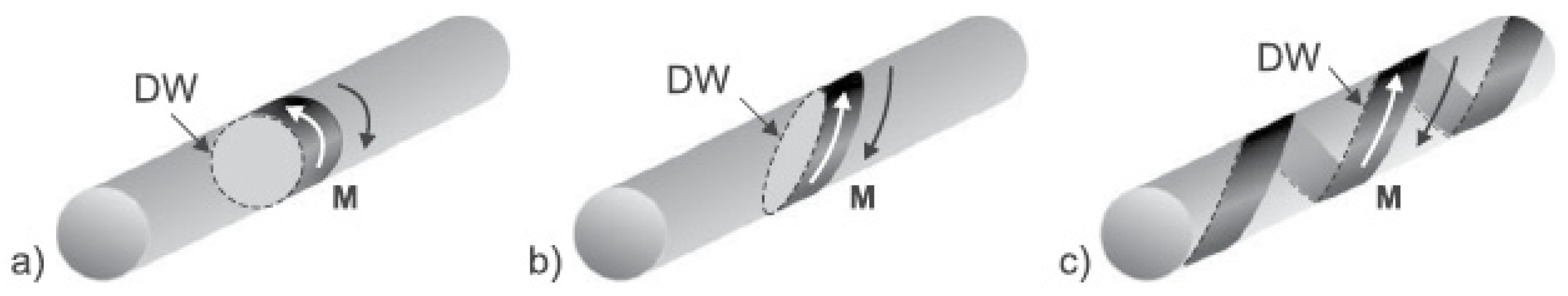

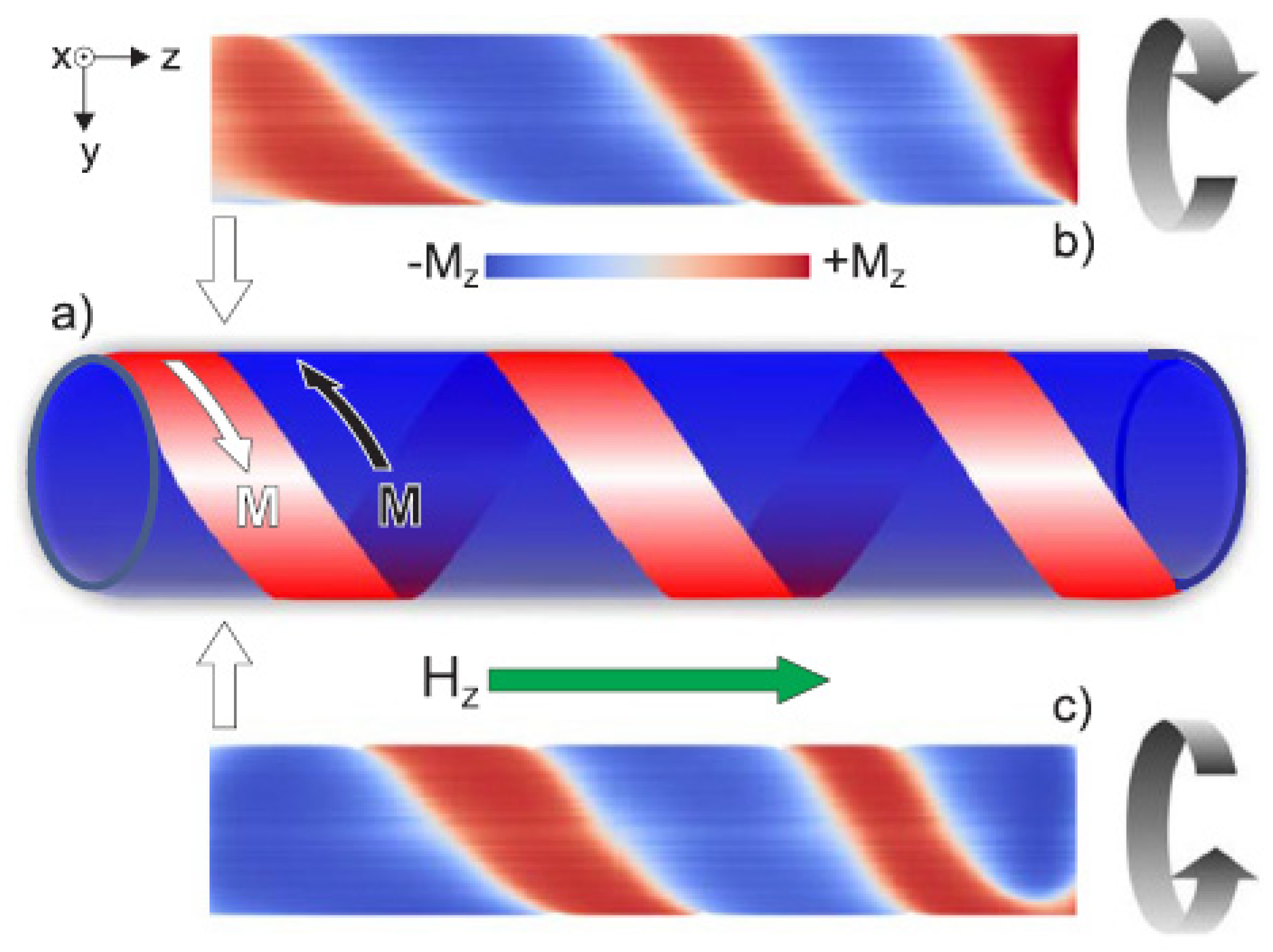

- Chizhik, A.; Zhukov, A.; Gonzalez, J.; Gawronski, P.; Kułakowski, K.; Stupakiewicz, A. Spiral magnetic domain structure in cylindrically-shaped microwires. Sci. Rep. 2018, 8, 15090. [Google Scholar] [CrossRef] [Green Version]

- Zhukov, A.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Hernando, B.; Gonzalez-Legarreta, L.; Suñol, J.J.; Zhukova, V. Correlation of Crystalline Structure with Magnetic and Transport Properties of Glass-Coated Microwires. Crystals 2017, 7, 41. [Google Scholar] [CrossRef]

- Baranov, S.A.; Larin, V.S.; Torcunov, A.V. Technology, Preparation and Properties of the Cast Glass-Coated Magnetic Microwires. Crystals 2017, 7, 136. [Google Scholar] [CrossRef]

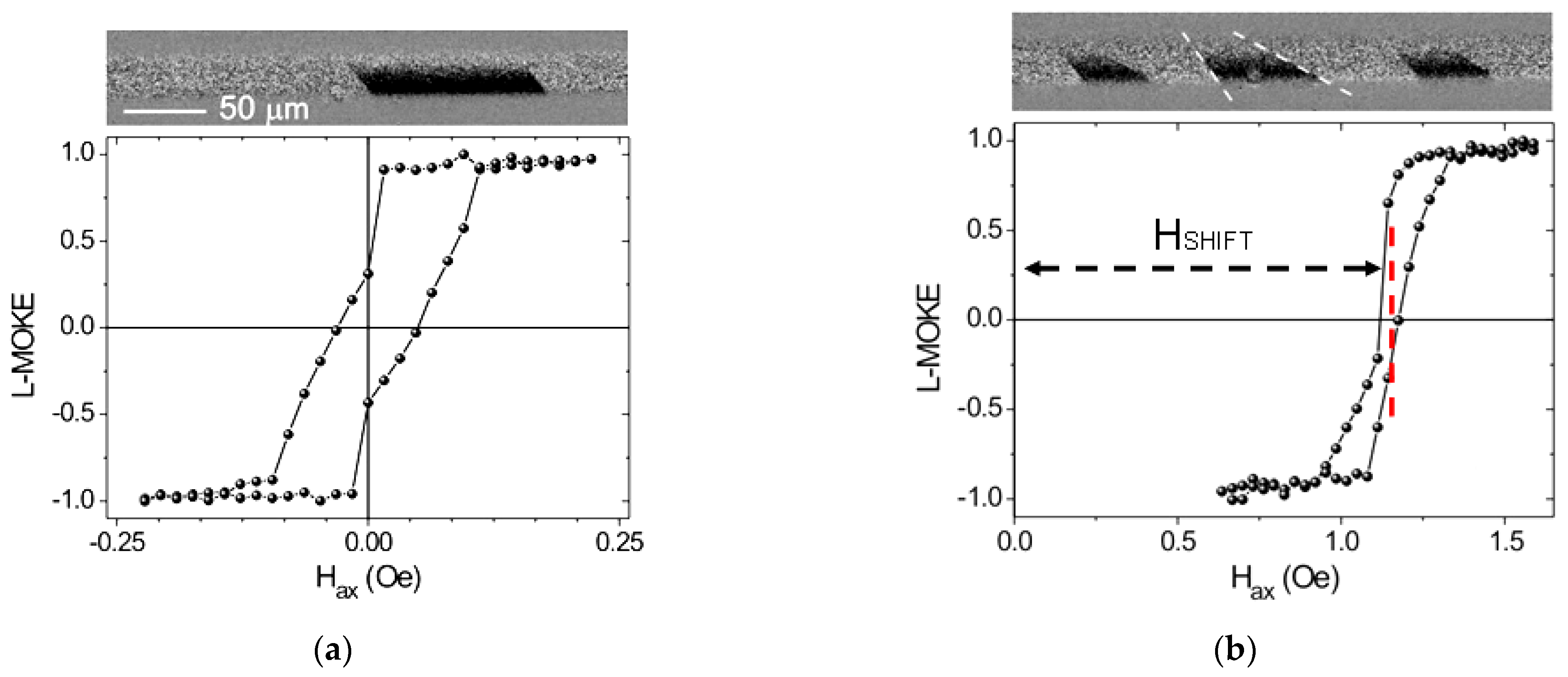

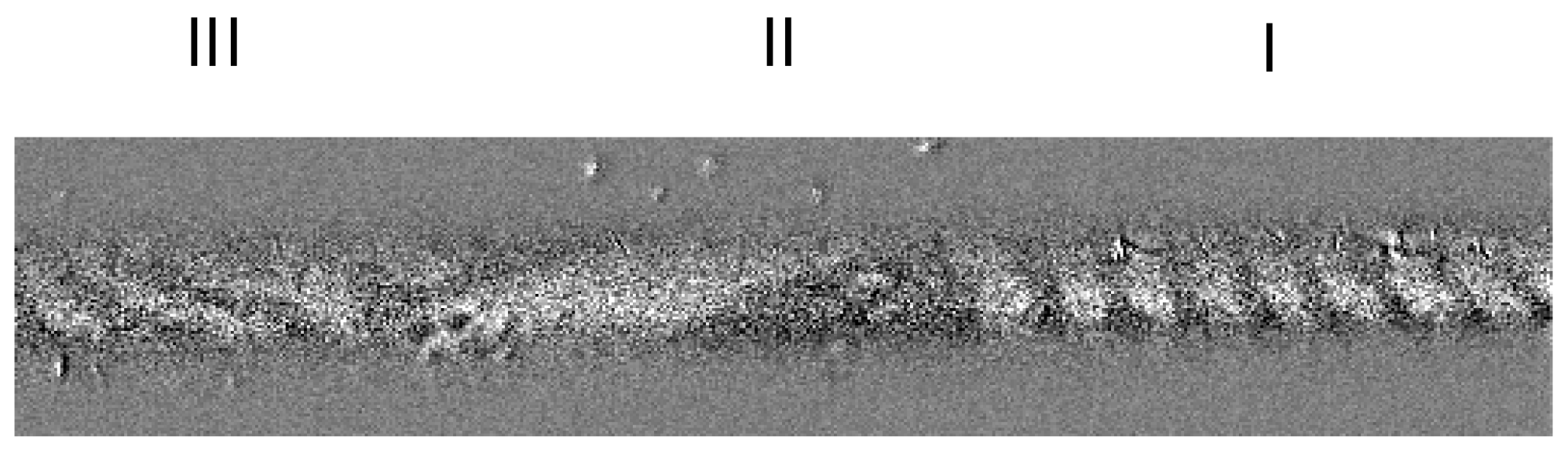

- Stupakiewicz, A.; Chizhik, A.; Tekielak, M.; Zhukov, A.; Gonzalez, J.; Maziewski, A. Direct imaging of the magnetization reversal in microwires using all-MOKE microscopy. Rev. Sci. Instrum. 2014, 85, 103702. [Google Scholar] [CrossRef]

- Vock, S.; Hengst, C.; Wolf, M.; Tschulik, K.; Uhlemann, M.; Sasvari, Z.; Makarov, D.; Schmidt, O.G.; Schultz, L.; Neu, V. Magnetic vortex observation in FeCo nanowires by quantitative magnetic force microscopy. Appl. Phys. Lett. 2014, 105, 172409. [Google Scholar] [CrossRef]

- Moreno, J.; Bran, C.; Vazquez, M.; Kosel, J. Cylindrical magnetic nanowires applications. IEEE Trans. Magn. 2021, 57, 800317. [Google Scholar] [CrossRef]

- Geng, L.D.; Jin, Y.M. Magnetic vortex racetrack memory. J. Magn. Magn. Mater. 2017, 423, 84. [Google Scholar] [CrossRef] [Green Version]

- Janutka, A.; Brzuszek, K. Giant magnetoreactance in magnetic nanowires. J. Magn. Magn. Mater. 2020, 515, 167297. [Google Scholar] [CrossRef]

- Richter, K.; Kostyk, Y.; Varga, R.; Zhukov, A.; Larin, V. Domain Wall Dynamics in Amorphous Microwires. Acta Physica Polonica A 2008, 113, 7. [Google Scholar] [CrossRef]

- Andersen, I.M.; Rodríguez, L.A.; Bran, C.; Marcelot, C.; Joulie, S.; Hungria, T.; Vazquez, M.; Gatel, C.; Snoeck, E. Exotic Transverse-Vortex Magnetic Configurations in CoNi Nanowires. ACS Nano 2020, 14, 1399. [Google Scholar] [CrossRef] [PubMed] [Green Version]

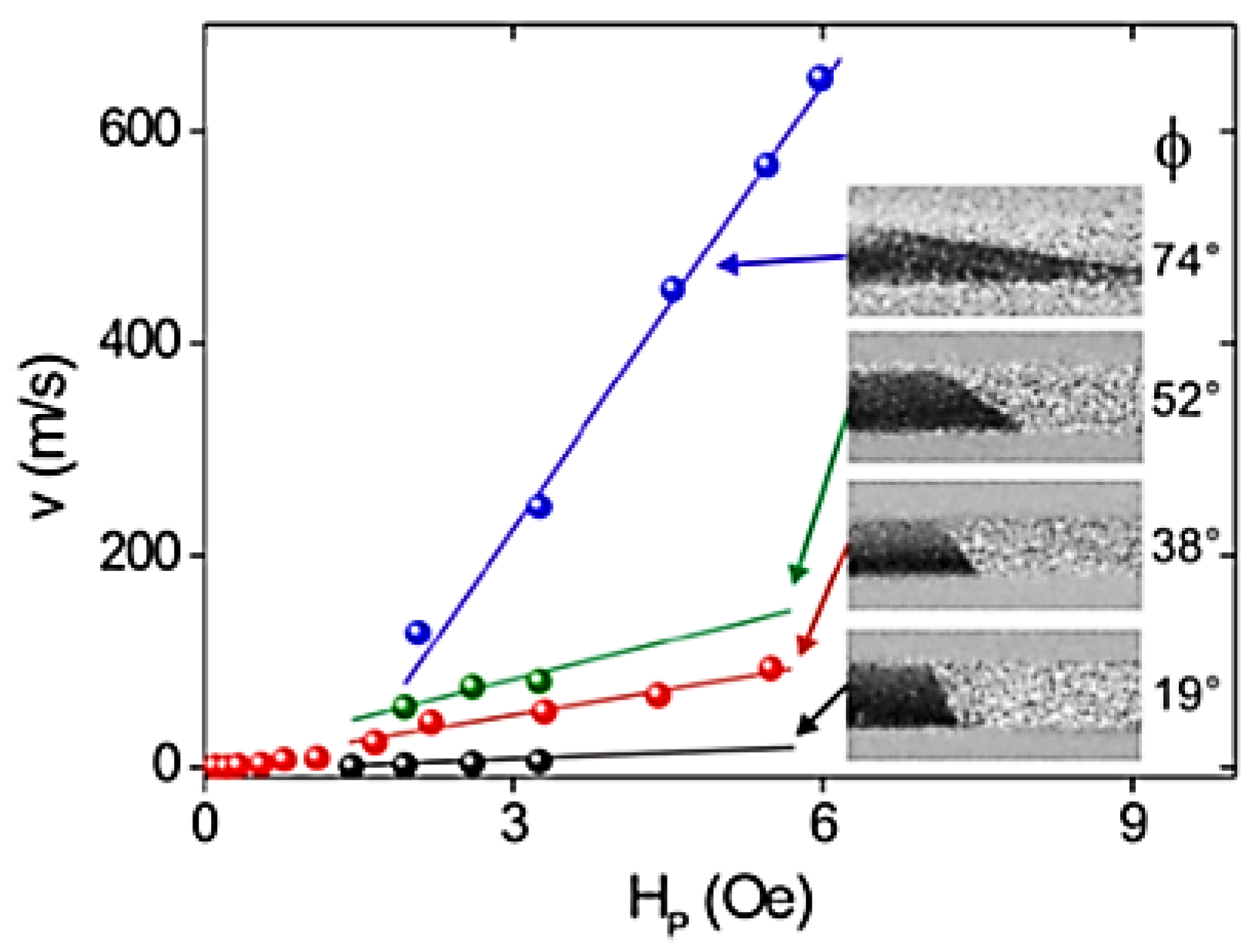

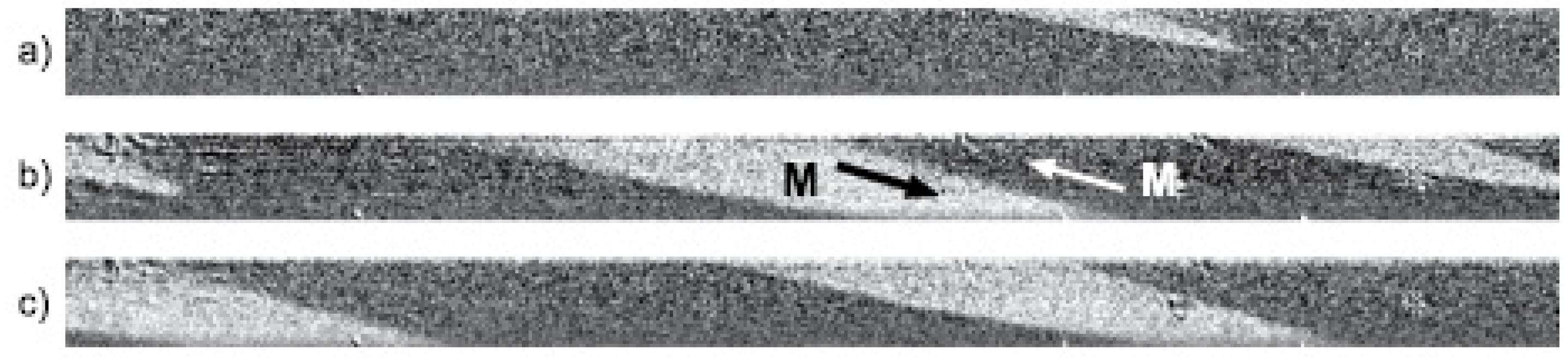

- Richter, K.; Thiaville, A.; Varga, R.; McCord, J. The role of uniaxial magnetic anisotropy distribution on domain wall tilting in amorphous glass-coated microwires. J. Appl. Phys. 2020, 127, 193905. [Google Scholar] [CrossRef]

- Fernandez-Roldan, J.A.; del Real, R.P.; Bran, C.; Vazquez, M.; Chubykalo-Fesenko, O. Electric current and field control of vortex structures in cylindrical magnetic nanowires. Phys. Rev. B 2020, 102, 024421. [Google Scholar] [CrossRef]

- Andersen, I.M.; Wolf, D.; Rodriguez, L.A.; Lubk, A.; Oliveros, D.; Bran, C.; Niermann, T.; Rößler, U.K.; Vazquez, M.; Gatel, C.; et al. Field tunable three-dimensional magnetic nanotextures in cobalt-nickel nanowires. Phys. Rev. Res. 2021, 3, 033085. [Google Scholar] [CrossRef]

- Fernandez-Roldan, J.A.; Ivanov, Y.P.; Chubykalo-Fesenko, O. 4—Micromagnetic modeling of magnetic domain walls and domains in cylindrical nanowires. In Magnetic Nano- and Microwires. (Second Edition) Design, Synthesis, Properties and Applications; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Cambridge, UK, 2020; pp. 403–426. [Google Scholar]

- Mohri, K.; Humphrey, F.B.; Yamasaki, J.; Kinoshita, F. Large barkhausen effect and matteucci effect in amorphous magnetostrictive wires for pulse generator elements. IEEE Trans. Magn. 1985, 21, 2017. [Google Scholar] [CrossRef]

- Takajo, M.; Yamasaki, J.; Humphrey, F.B. Domain observations of Fe and Co based amorphous wires. IEEE Trans. Magn. 1993, 29, 3484. [Google Scholar] [CrossRef]

- Yamasaki, J.; Humphrey, F.B.; Mohri, K.; Kawamura, H.H. Takamur, H.; Mälmhäll, R. Large Barkhausen discontinuities in Co-based amorphous wires with negative magnetostriction. J. Appl. Phys. 1988, 63, 3949. [Google Scholar] [CrossRef]

- Chizhik, A.; Gonzalez, J.; Yamasaki, J.; Zhukov, A.; Blanco, J.M. Vortex-type domain structure in Co-rich amorphous wires. J. Appl. Phys. 2004, 95, 2933. [Google Scholar] [CrossRef] [Green Version]

- Chizhik, A.; Yamasaki, J.; Zhukov, A.; Gonzalez, J.; Blanco, J.M. Magnetization reversal and magnetic domain structure in glass-covered Co-rich microwires in presence of tensile stress. J. Magn. Magn. Mater. 2004, 272–276, e499–e500. [Google Scholar] [CrossRef]

- Ivanov, Y.P.; del Real, R.P.; Chubykalo-Fesenko, O.; Vazquez, M. Vortex magnetic structure in circularly magnetized microwires as deduced from magneto-optical Kerr measurements. J. Appl. Phys. 2014, 115, 063909. [Google Scholar] [CrossRef] [Green Version]

- Richter, K.; Thiaville, A.; Varga, R. Magneto-optical study of the surface reversal process in amorphous glass-coated microwires with positive magnetostriction. IEEE Trans. Magn. 2014, 50, 2501404. [Google Scholar] [CrossRef]

- Chiriac, H.; Lostun, M.; Óvári, T.A. Surface Magnetization Processes in Amorphous Microwires. IEEE Trans. Magn. 2010, 46, 383. [Google Scholar] [CrossRef]

- Hernando, B.; Sánchez, M.L.; Prida, V.M.; Santos, J.D.; Olivera, J.; Belzunce, F.J.; Badini, G.; Vázquez, M. Magnetic domain structure of amorphous Fe73.5Si13.5B9Nb3Cu1 wires under torsional stress. J. Appl. Phys. 2008, 103, 07E716. [Google Scholar] [CrossRef]

- Chiriac, H.T.; Óvári, T.A.; Ţibu, M. Effect of surface domain structure on wall mobility in amorphous microwires. J. Appl. Phys. 2009, 105, 07A310. [Google Scholar] [CrossRef]

- Chizhik, A.; Gonzalez, J.; Zhukov, A.; Blanco, J.M. Circular magnetic bistability in Co-rich amorphous microwires. J. Phys. D Appl. Phys. 2003, 36, 419. [Google Scholar] [CrossRef]

- Ipatov, M.; Chizhik, A.; Zhukova, V.; Gonzalez, J.; Zhukov, A. Correlation of surface domain structure and magneto-impedance in amorphous microwires. J. Appl. Phys. 2011, 109, 113924. [Google Scholar] [CrossRef]

- Chiriac, H.; Óvári, T.A. Amorphous glass-covered magnetic wires: Preparation, properties, applications. Prog. Mater. Sci. 2011, 40, 333. [Google Scholar] [CrossRef]

- Sanchez, M.L.; Santos, J.D.; Olivera, J.; Prida, V.M.; Hernando, B. Influence of magnetic field and torsional stress on the skin penetration depth of Finemet wires. J. Magn. Magn. Mater. 2007, 316, 475. [Google Scholar] [CrossRef]

- McCord, J. Progress in magnetic domain observation by advanced magneto-optical microscopy. J. Phys. D Appl. Phys. 2015, 48, 333001. [Google Scholar] [CrossRef]

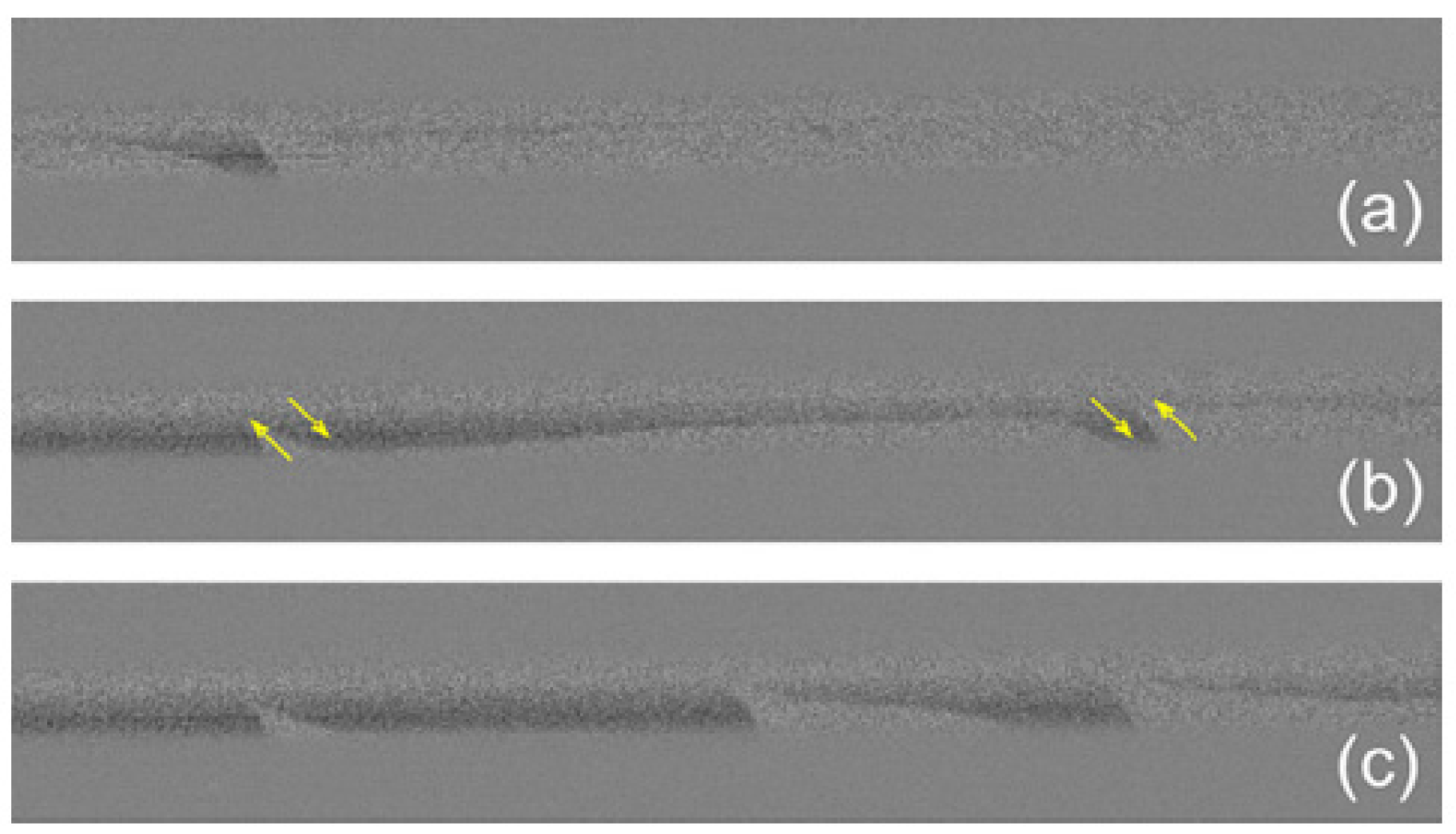

- Vahovsky, O.; Richter, K.; Varga, R.; McCord, J. Local distortions of surface domain walls in cylindrical microwires observed by magneto-optics. J. Magn. Magn. Mater. 2021, 537, 168168. [Google Scholar] [CrossRef]

- Ye, J.; del Real, R.P.; Infante, G.; Vázquez, M. Local magnetization profile and geometry magnetization effects in microwires as determined by magneto-optical Kerr effect. J. Appl. Phys. 2013, 113, 043904. [Google Scholar] [CrossRef] [Green Version]

- Aksenov, O.I.; Aronin, A.S. Investigation of the Domain Structure of Co-Based Microwires by Magneto-Optical Indicator Films Method. Phys. Solid State 2021, 63, 513. [Google Scholar] [CrossRef]

- Menard, D.; Frankland, D.; Ciureanu, P.; Yelon, A.; Rouabhi, M.; Cochrane, R.W.; Chiriac, H.; Ovari, T.A. Modeling of domain structure and anisotropy in glass-covered amorphous wires. J. Appl. Phys. 1998, 83, 6566. [Google Scholar] [CrossRef]

- Torrejon, J.; Thiaville, A.; Adenot-Engelvin, A.L.; Vazquez, M. Cylindrical magnetization model for glass-coated microwires with circumferencial anisotropy: Dynamics. J. Magn. Magn. Mater. 2013, 333, 144. [Google Scholar] [CrossRef] [Green Version]

- Chizhik, A.; Gonzalez, J.; Zhukov, A.; Blanco, J.M. Transformation of surface domain structure in Co-rich amorphous wires. Sens. Actuators B 2007, 126, 235. [Google Scholar] [CrossRef]

- Chizhik, A.; Stupakiewicz, A.; Zhukov, A.; Maziewski, A.; Gonzalez, J.; Zablotskii, V. Manipulation of Magnetic Domain Structures with Helical Magnetization in Magnetic Microwires. IEEE Trans. Magn. 2014, 50, 2005903. [Google Scholar] [CrossRef]

- Chizhik, A.; Stupakiewicz, A.; Zhukov, A.; Gonzalez, J. On mechanisms of domain switching in amorphous glass-coated wires. Phys. Status Solidi A 2016, 213, 350. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukov, A.; Gonzalez, J.; Stupakiewicz, A. Control of the domain wall motion in cylindrical magnetic wires. A. Appl. Phys. Lett. 2016, 109, 052405. [Google Scholar] [CrossRef]

- Chizhik, A.; Gonzalez, J.; Zhukov, A.; Stupakiewicz, A. Torsion stress induced magnetic switching in amorphous microwires. IEEE Magn. Lett. 2017, 8, 5106805. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukova, V.; Zhukov, A.J.; Gonzalez, J.; Gawronski, P.; Kułakowski, K.; Stupakiewicz, A. Surface magnetic structures induced by mechanical stresses in Co-rich Microwires. J. Alloys Compd. 2018, 735, 1449. [Google Scholar] [CrossRef]

- Vazquez, M.; Gomez Polo, C.; Velazquez, J.; Hernando, A. Bending stresses and bistable behavior in Fe-rich amorphous wire. J. Appl. Phys. 1994, 75, 5791. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukov, A.; Corte-León, P.; Blanco, J.M.; Gonzalez, J.; Gawroński, P. Torsion induced acceleration of domain wall motion in magnetic microwires. J. Magn. Magn. Mater. 2019, 489, 165420. [Google Scholar]

- Chizhik, A.; Zhukov, A.; Gonzalez, J.; Stupakiewicz, A. Basic study of magnetic microwires for sensor applications: Variety of magnetic structures. J. Magn. Magn. Mater. 2017, 422, 299. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukov, A.; Gonzalez, J.; Stupakiewicz, A. Control of reversible magnetization switching by pulsed circular magnetic field in glass-coated amorphous microwires. Appl. Phys. Lett. 2018, 112, 072407. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukov, A.; Blanco, J.M.; Gonzalez, J.; Gawronski, P. Experimental determination of limit angle of helical anisotropy in amorphous magnetic microwires. J. Magn. Magn. Mater. 2009, 321, 803. [Google Scholar] [CrossRef]

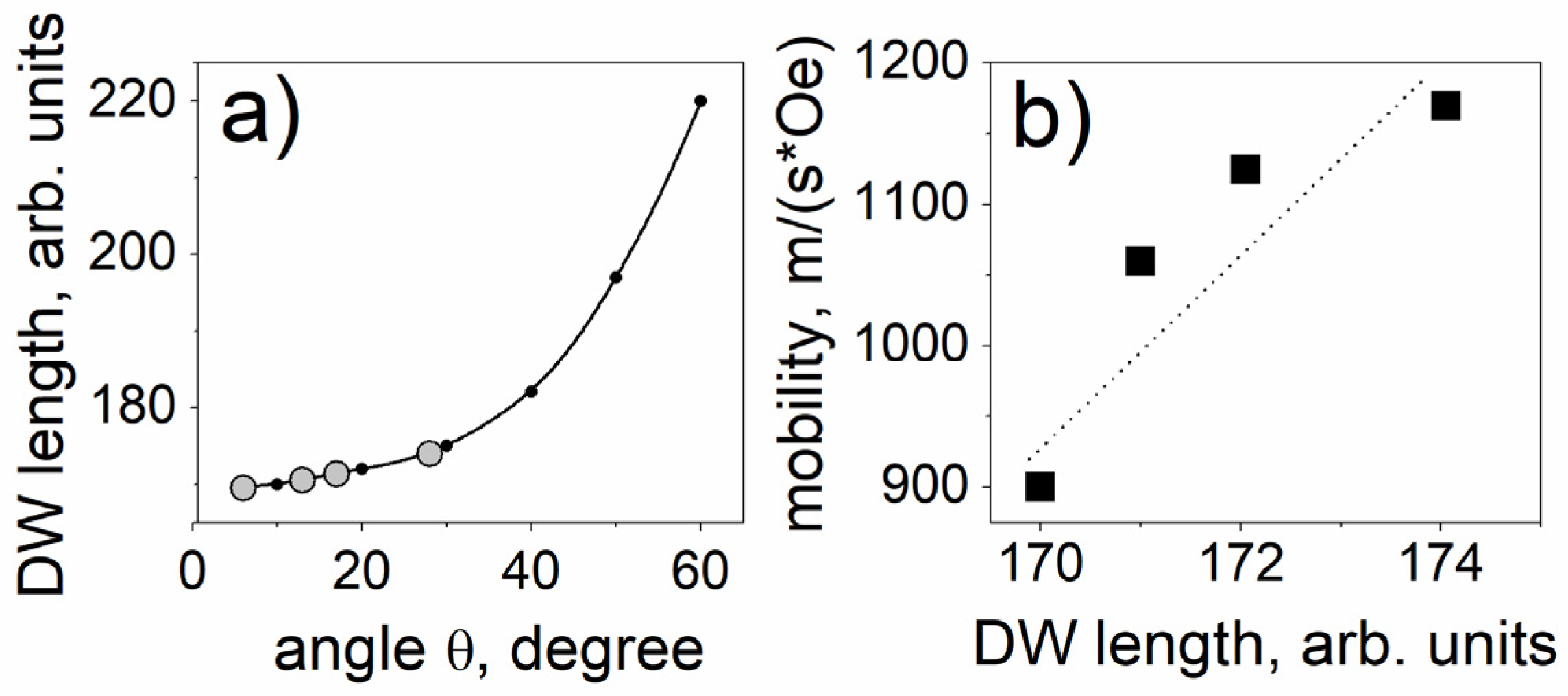

- Chizhik, A.; Zhukov, A.; Gonzalez, J.; Gawronski, P. Study of length of domain walls in cylindrical magnetic microwires. J. Magn. Magn. Mater. 2020, 512, 167060. [Google Scholar] [CrossRef]

- Vansteenkiste, A.; Leliaert, J.; Dvornik, M.; Helsen, M.; Garcia-Sanchez, F.; Van Waeyenberge, B. The design and verification of mumax3. AIP Adv. 2014, 4, 107133. [Google Scholar] [CrossRef] [Green Version]

- Hudak, J.; Blazek, J.; Cverha, A.; Gonda, P.; Varga, R. Improved Sixtus–Tonks method for sensing the domain wall propagation direction. Sens. Actuators A 2009, 156, 292. [Google Scholar] [CrossRef]

- Calle, E.; Jiménez, A.; Vázquez, M.; del Real, R.P. Time-resolved velocity of a domain wall in a magnetic microwire. J. Alloys Compd. 2018, 767, 106. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chizhik, A.; Gonzalez, J.; Zhukov, A.; Gawronski, P. Review of Helical Magnetic Structures in Magnetic Microwires. Chemosensors 2022, 10, 291. https://doi.org/10.3390/chemosensors10080291

Chizhik A, Gonzalez J, Zhukov A, Gawronski P. Review of Helical Magnetic Structures in Magnetic Microwires. Chemosensors. 2022; 10(8):291. https://doi.org/10.3390/chemosensors10080291

Chicago/Turabian StyleChizhik, Alexander, Julian Gonzalez, Arcady Zhukov, and Przemyslaw Gawronski. 2022. "Review of Helical Magnetic Structures in Magnetic Microwires" Chemosensors 10, no. 8: 291. https://doi.org/10.3390/chemosensors10080291

APA StyleChizhik, A., Gonzalez, J., Zhukov, A., & Gawronski, P. (2022). Review of Helical Magnetic Structures in Magnetic Microwires. Chemosensors, 10(8), 291. https://doi.org/10.3390/chemosensors10080291