Patterning Large-Scale Nanostructured Microarrays on Coverslip for Sensitive Plasmonic Detection of Aqueous Gliadin Traces

Abstract

:1. Introduction

2. Experimental Section

2.1. Chemicals

2.2. Instruments

2.3. Preparation of Gliadin and Antibodies Concentrations

2.4. Choice of Commercial Gluten-Free Products

2.5. Extraction of Gliadin Traces from Selected Foods

2.6. Preparation of the Gold Nanostructured TEM-Microarrays on Glass Coverslip

2.6.1. Cleaning Protocol

2.6.2. Gold Patterning through TEM-Grids

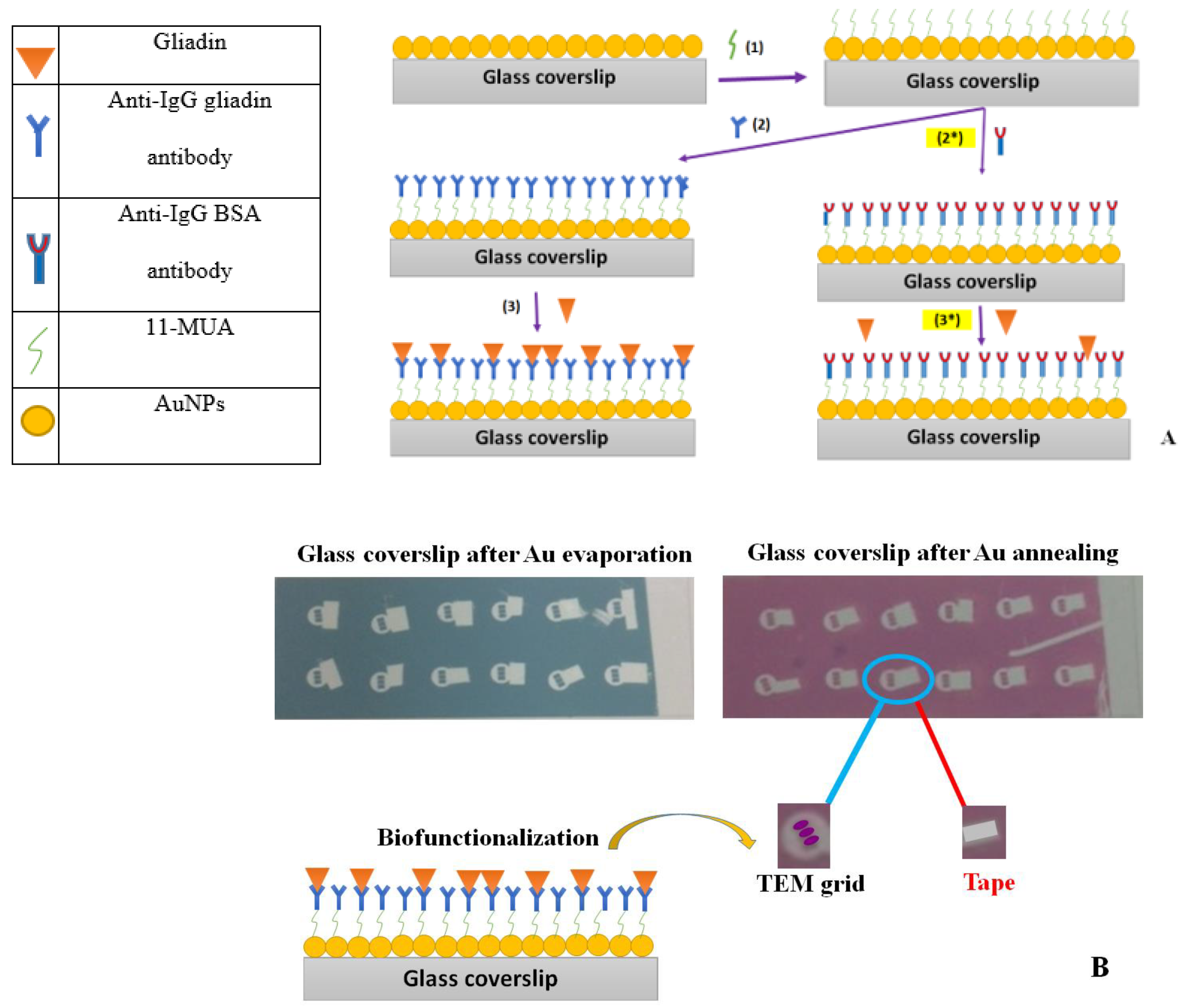

2.6.3. (Bio) Functionalization of Gold Nanostructures and Gliadin Immunosensor

3. Results and Discussion

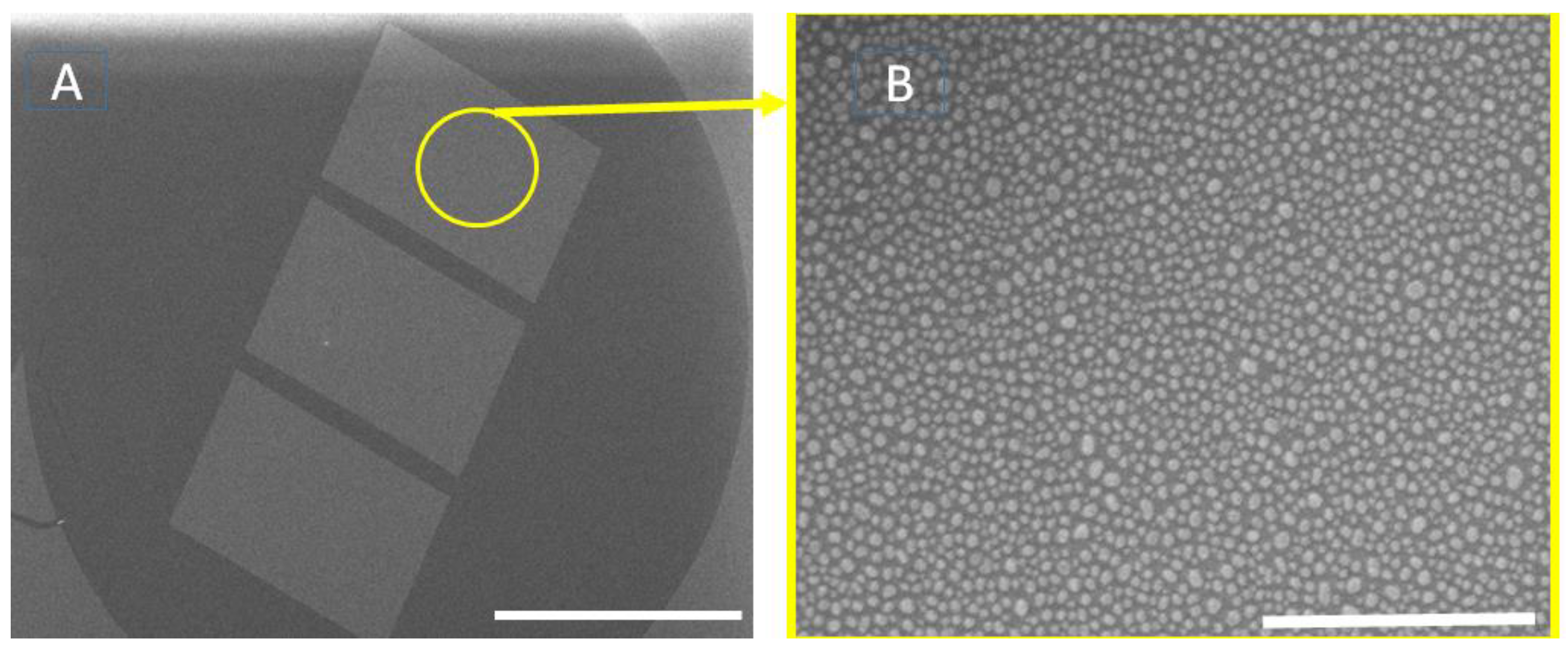

3.1. SEM Characterization of the Gold Nanostructured Microarrays on Coverslip

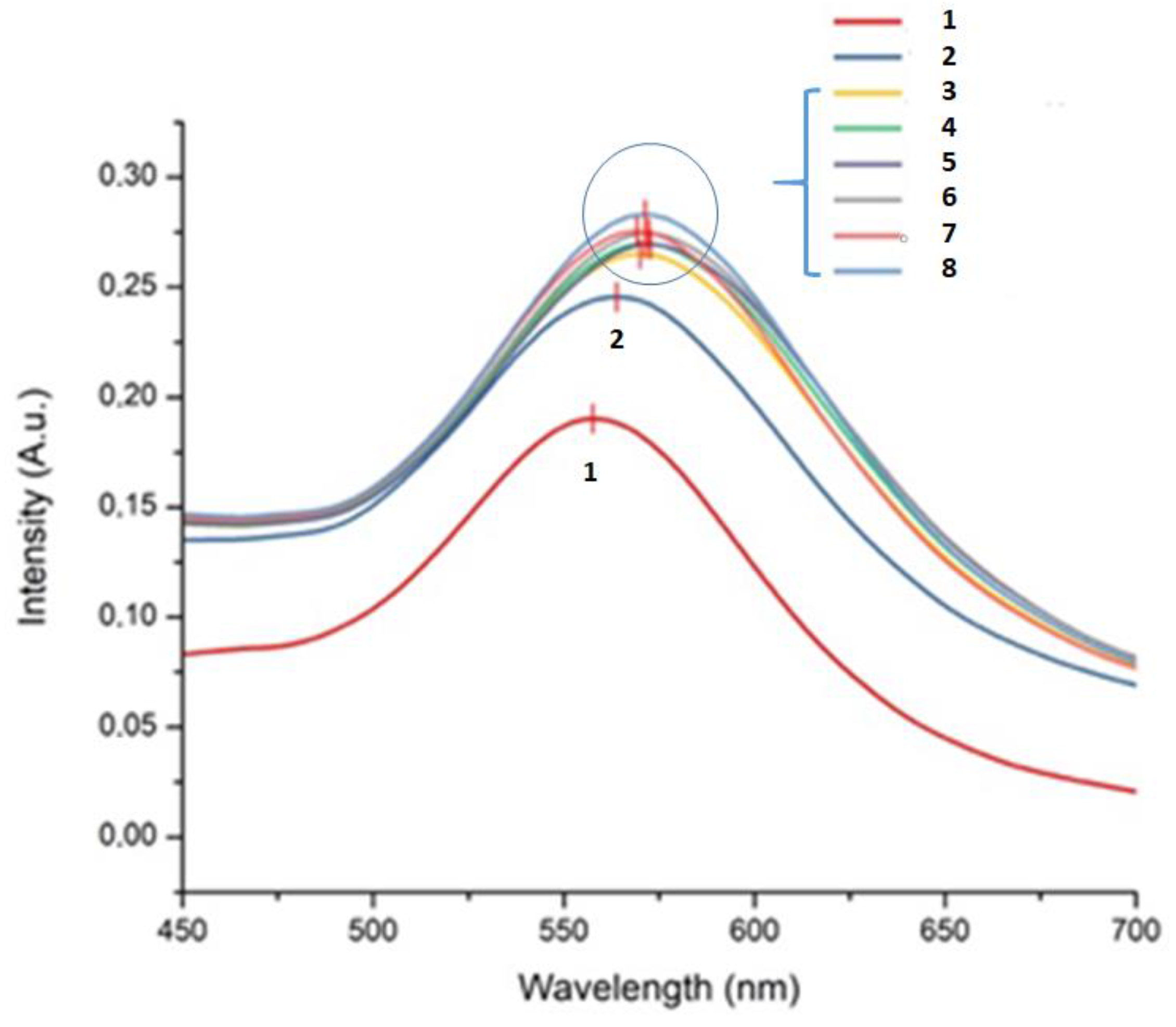

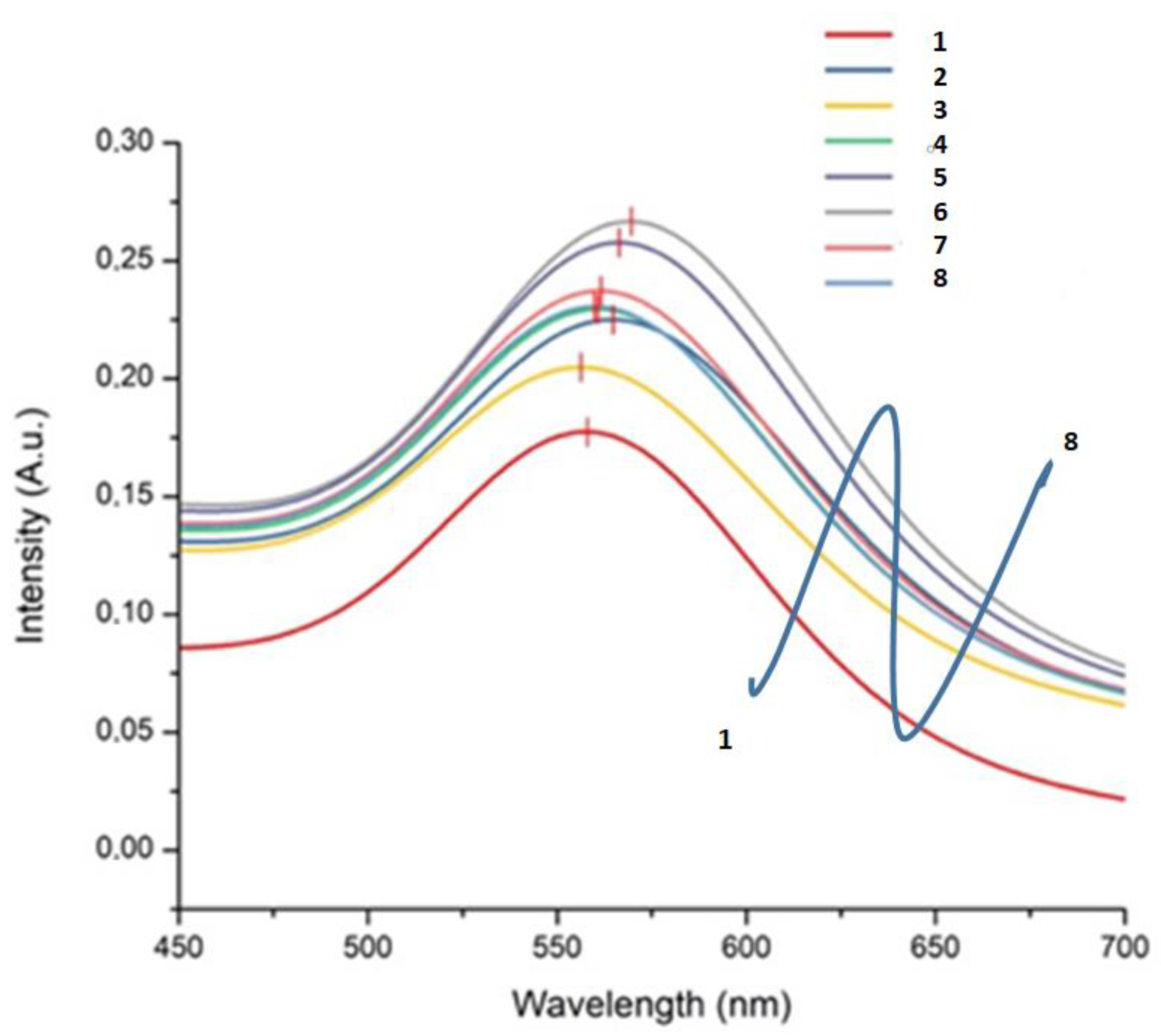

3.2. Diluents of Anti-Gliadin Antibodies and Their Impact on LSPR Performances

3.3. Dose-Response Calibration Curves

3.4. Controls Experiments

3.5. LSPR Spectra of Gliadin Content in Commercial Food Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brouns, F.J.P.H.; van Buul, V.J.; Shewry, P.R. Does Wheat Make Us Fat and Sick? J. Cereal Sci. 2013, 58, 209–215. [Google Scholar] [CrossRef]

- Commission of the European Communities. Commission regulation (EC) no 41/2009 of 20 January 2009 concerning the composition and labelling of foodstuffs suitable for people intolerant to gluten. Off. J. Eur. Union 2009, 16/13–16/15. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32009R0041 (accessed on 27 November 2021).

- Wang, K.; Lu, F.; Li, Z.; Zhad, L.; Han, C. Recent Developments in Gluten-free Bread Baking Approaches: A review. Food Sci. Technol. 2017, 37, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Rai, S.; Kaur, A.; Chopra, C.S. Gluten-free Products for Celiac Susceptible People. Front. Nutr. 2018, 5, 116. [Google Scholar] [CrossRef]

- Sabenca, C.; Ribeiro, M.; de Sousa, T.; Poeta, P.; Bagulho, A.S.; Igrejas, G. Wheat/Gluten-related Disorders and Gluten-free Diet Misconceptions: A Review. Foods 2021, 10, 1765. [Google Scholar] [CrossRef]

- Ortiz, C.; Valenzuela, R.; Lucero, A.Y. Celiac Disease, Non celiac Gluten Sensitivity and Wheat Allergy: Comparison of 3 Different Diseases Triggered by the Same Food. Rev. Chil. Pediatr. 2017, 88, 417–423. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Caio, G.; Volta, U.; Sapone, A.; Leffler, D.A.; De Giogio, R.; Catassi, C.; Fasano, A. Celiac disease: A comprehensive current review. BMC Med. 2019, 17, 142. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barbaro, M.R.; Cremon, C.; Wrona, D.; Fuschi, D.; Marasco, G.; Stanghellini, V.; Barbara, G. Non-celiac Gluten Sensitivity in the Context of Functional Gastrointestinal Disorders. Nutrients 2021, 12, 3735. [Google Scholar] [CrossRef]

- Roszkowska, A.; Pawlicka, M.; Mroczek, A.; Balabuszek, K.; Nieradko-Iwanicka, B. Non-celiac Gluten Sensitivity: A Review. Medicina 2019, 55, 222. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sergi, C.; Villanacci, V.; Carroccio, A. Non-celiac wheat sensitivity: Rationality and irrationality of a gluten-free diet in individuals affected with non-celiac disease: A review. BMC Gastroenterol. 2021, 21, 5. [Google Scholar] [CrossRef]

- Osorio, C.E.; Mejias, J.H.; Rustgi, S. Gluten Detection Methods and Their Critical Role in Assuring Safe Diets for Celiac Patients. Nutrients 2019, 11, 2920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Melini, F.; Melina, V. Immunological Methods in Gluten Risk Analysis: A Snapshot. Safety 2018, 4, 56. [Google Scholar] [CrossRef] [Green Version]

- Ciaurriz, P.; Fernández, F.; Tellechea, E.; Moran, J.F.; Asensio, A.C. Comparison of Four Functionalization Methods of Gold Nanoparticles for Enhancing the Enzyme-Linked Immunosorbent Assay (ELISA). Beilstein J. Nanotechnol. 2017, 8, 244–253. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.M.; Lee, J.H.; Park, J.-D.; Choi, Y.-S.; Sung, J.-M.; Jang, H.W. Analyzing Gluten Content in Various Food Products Using Different Types of ELISA Test Kits. Foods 2021, 10, 108. [Google Scholar] [CrossRef] [PubMed]

- Codex Alimentarius Commission. Review of Cereals, Pulses and Legumes Methods, Joint FAO/WHO Food Standards Programme Codex Committee on Methods of Analysis and Sampling. 2019. CX/MAS 19/40/3-Add.2. Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FMeetings%252FCX-715-40%252Fma40_03_add2e.pdf (accessed on 27 November 2021).

- Hahn, S.M. Food Labeling; Gluten-Free Labeling of Fermented or Hydrolyzed Food. Fed. Regist. 2020, 85, 49240–49261. [Google Scholar]

- From Polyclonal Sera to Recombinant Antibodies: A Review of immunological Detection of Gluten in Foodstuff. Foods 2021, 10, 66.

- Schalk, K.; Koehler, P.; Scherf, K.A. Targeted liquid chromatography tandem mass spectrometry to quantitate wheat gluten using well-defined reference proteins. PLoS ONE 2018, 13, e0192804. [Google Scholar] [CrossRef] [Green Version]

- Panda, R.; Garber, A.E. Western Blot Analysis of Fermented-Hydrolyzed Foods Utilizing Gluten-Specific Antibodies Employed in a Novel Multiplex Competitive ELISA. Anal. Bioanal. Chem. 2019, 411, 5159–5174. [Google Scholar] [CrossRef]

- Bromilow, S.N.L.; Gethings, L.A.; Langridge, J.I.; Shewry, P.R.; Buckley, M.; Bromley, M.J.; Mills, E.N.C. Comprehensive Proteomic Profiling of Wheat Gluten Using a Combination of Data-Independent and Data-Dependent Acquisition. Front. Plant 2017, 7, 2020. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, N.; Meng, M. Detection of Gluten-Rich Cereals in Processed Foods with Enhanced Sensitivity by Targeting Mitochondrial DNA Using PCR. Food Anal. Methods 2019, 12, 811–825. [Google Scholar] [CrossRef]

- Mujico, J.R.; Lombardía, M.; Mena, M.C.; Méndez, E.; Albar, J.P. A highly sensitive real-time PCR system for quantification of wheat contamination in gluten-free food for celiac patients. Food Chem. 2011, 128, 795–801. [Google Scholar] [CrossRef]

- Rossella, S.; Nicolò, D.; Rosanna, T.; Rebeca, M.C.; de-los-Santos, I.N.; Jesffls, M.L. Selection of Anti-gluten DNA Aptamers in a Deep Eutectic Solvent. Angew. Chem. 2018, 130, 13032–13036. [Google Scholar]

- Miranda-Castro, R.; de-los-Santos-Álvarez, N.; Miranda-Ordieres, A.J.; Lobo-Castañón, M.J. Harnessing Aptamers to Overcome Channenges in Gluten Detection. Biosensors 2016, 6, 16. [Google Scholar] [CrossRef] [PubMed]

- Perumal, V.; Hashim, U. Advances in biosensors: Principle, architecture and applications. J. Appl. Biomed. 2014, 12, 1–15. [Google Scholar] [CrossRef]

- Gupta, S.; Kaushal, A.; Kumar, A.; Kumar, D. Recent Advances in Biosensors for Diagnosis of Celiac Disease: A Review. Biotechnol. Bioeng. 2019, 116, 444–451. [Google Scholar] [CrossRef]

- Pasinszki, T.; Krebsz, M. Biosensors for Non-invasive Detection of Celiac Disease Biomarkers in Body Fluids. Biosensors 2018, 8, 55. [Google Scholar] [CrossRef] [Green Version]

- Martín-Fernández, B.; De-Los-Santos-Álvarez, N.; Martín-Clemente, J.P.; Lobo-Castañón, M.J.; López-Ruiz, B. Challenging Genosensors in Food Samples: The Case of Gluten Determination in Highly Processed Samples. Talanta 2016, 146, 490–495. [Google Scholar] [CrossRef]

- Marín-Barroso, E.; Messina, G.A.; Bertolino, F.A.; Raba, J.; Pereira, S.V. Electrochemical Immunosensor Modified with Carbon Nanofibers Coupled to a Paper Platform for the Determination of Gliadins in Food Samples. Anal. Methods 2019, 11, 2170–2178. [Google Scholar] [CrossRef]

- Bariani, G.C.; Zhou, L.; Poggesi, S.; Mittapalli, R.; Manzano, M.; Ionescu, R.E. Acoustic Multi-detection of Gliadin using QCM Crystals Patterned with Controlled Sectors of TEM Grid and Annealed Nanoislands on Gold Electrode. Nanomaterials 2020, 10, 790. [Google Scholar] [CrossRef]

- Jia, K.; Bijeon, J.L.; Adam, P.M.; Ionescu, R.E. Large Scale Fabrication of Gold Nano-Structured Substrates via High Temperature Annealing and Their Direct Use for the LSPR Detection of Atrazine. Plasmonics 2013, 8, 143–151. [Google Scholar] [CrossRef]

- Kharati, M.; Rabiee, M.; Rostami-Nejad, M.; Aghamohammadi, E.; Asadzadeh-aghdaei, H.; Zali, M.R.; Rabiee, N.; Farahi, Y.; Bagherzadeh, M.; Webster, T.J. Development of a Nano Biosensor for Anti-gliadin detection for Celiac disease based on suspension microarray. Biomed. Phys. Eng. Express 2020, 6, 055015. [Google Scholar] [CrossRef] [PubMed]

- Ren, B.; Liu, G.K.; Lian, X.B.; Yang, Z.L.; Tian, Z.Q. Raman Spectroscopy on Transition Metals. Anal. Bioanal. Chem. 2007, 388, 29–45. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hua, Z.; Yu, T.; Liu, D.; Xianyu, Y. Recent Advances in Gold Nanoparticles-based Biosensors for Food Safety Detection. Biosens. Bioelectron. 2021, 179, 113076. [Google Scholar] [CrossRef] [PubMed]

- Chu, P.-T.; Lin, C.-S.; Chen, W.-J.; Chen, C.-F.; Wen, H.-W. Detection of Gliadin in Foods Using a Quartz Crystal Microbalance Biosensor that Incorporates Gold Nanoparticles. J. Agric. Food Chem. 2012, 60, 6483–6492. [Google Scholar] [CrossRef] [Green Version]

- Kang, X.; Sui, J.; Zhang, X.; Wei, G.; Wang, B.; Liu, P.; Qui, L.; EL-Banna, H.A.; Cui, B.; Abd El-Aty, A.M. The Impact of Gliadin and Glutenin on the Formation and Structure of Starch-Lipid Complexes. Food Chem. 2022, 371, 131095. [Google Scholar] [CrossRef]

| PBS 0.1 M | Water | Ethanol 70% | ||||

|---|---|---|---|---|---|---|

| Gliadin | Intensity | Wavelength | Intensity | Wavelength | Intensity | Wavelength |

| (ppm) | (A.u.) | (nm) | (A.u.) | (nm) | (A.u.) | (nm) |

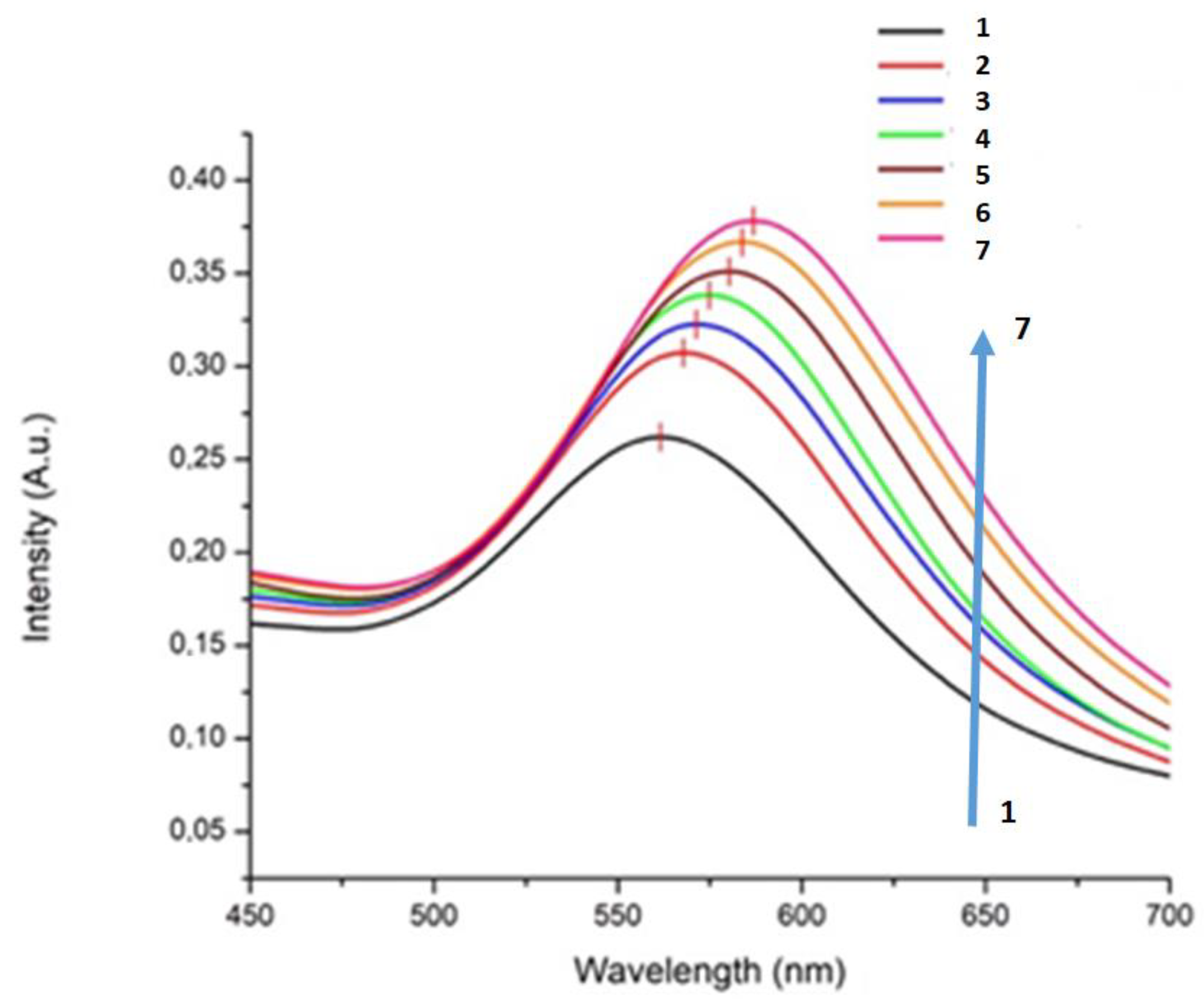

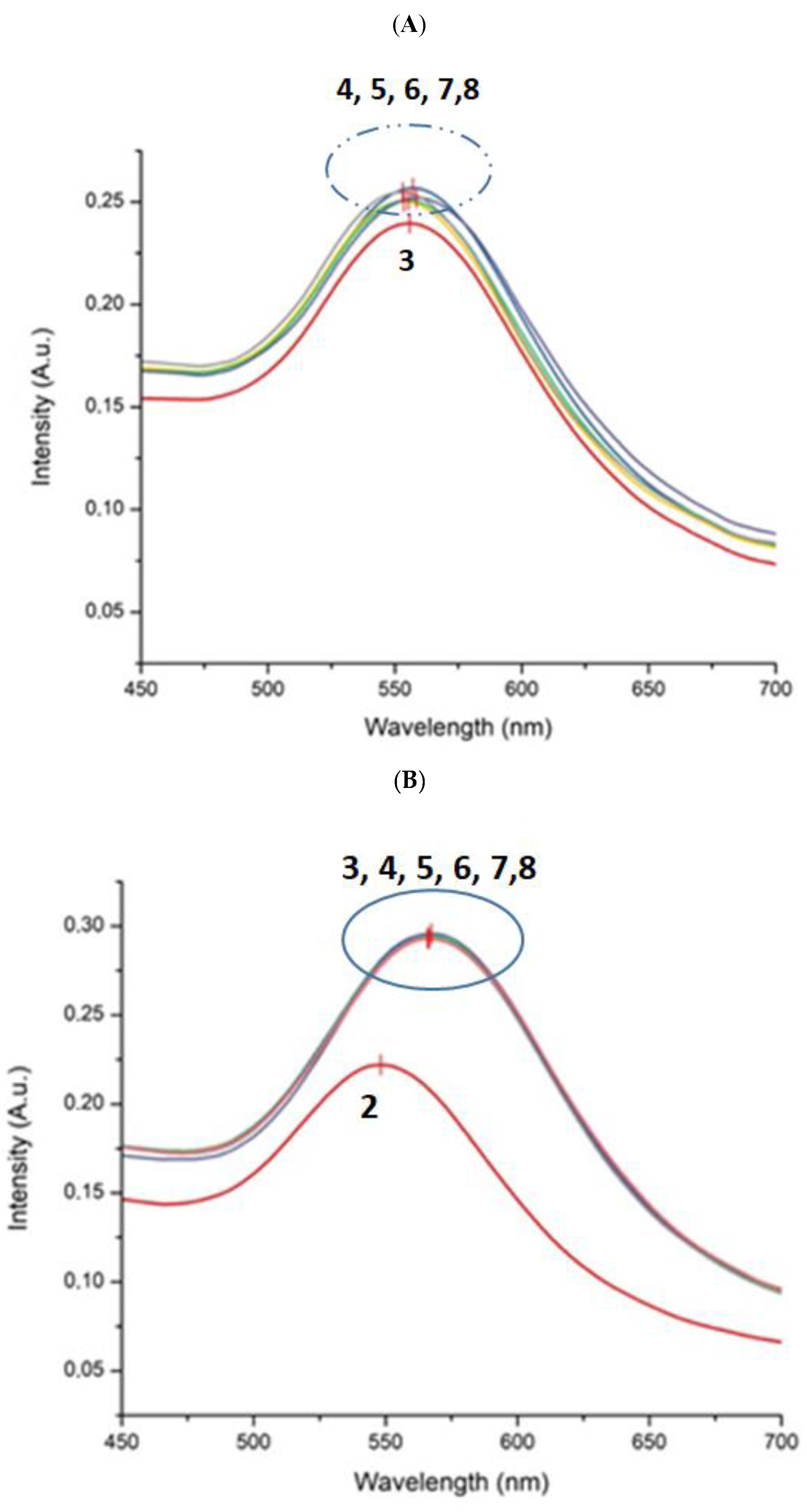

| 0.1 | 0.270 ± 0.012 | 573 | 0.323 ± 0.001 | 570 | 0.229 ± 0.019 | 557 |

| 1 | 0.269 ± 0.008 | 580 | 0.338 ± 0.001 | 576 | 0.258 ± 0.012 | 564 |

| 10 | 0.274 ± 0.010 | 581 | 0.351 ± 0.000 | 581 | 0.267 ± 0.022 | 576 |

| 100 | 0.275 ± 0.007 | 569 | 0.367 ± 0.002 | 585 | 0.237 ± 0.005 | 560 |

| 1000 | 0.283 ± 0.012 | 575 | 0.378 ± 0.001 | 591 | 0.231 ± 0.010 | 559 |

| c (ppm) | Δy Assimilated to Standard Deviation | Δc (ppm) |

|---|---|---|

| 0.10 | 0.0009 | 0.01 |

| 1.00 | 0.0008 | 0.13 |

| 10.00 | 0.0004 | 0.66 |

| 100 | 0.0015 | 25 |

| 1000 | 0.0012 | 198 |

| c (ppm) | Δy Assimilated to the Spectrometer Accuracy (nm) | Δc (ppm) |

|---|---|---|

| 0.1 | 0.2 | 0.009 |

| 1 | 0.09 | |

| 10 | 0.9 | |

| 100 | 9 | |

| 1000 | 90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casari Bariani, G.; Zhou, L.; Poggesi, S.; Manzano, M.; Ionescu, R.E. Patterning Large-Scale Nanostructured Microarrays on Coverslip for Sensitive Plasmonic Detection of Aqueous Gliadin Traces. Chemosensors 2022, 10, 38. https://doi.org/10.3390/chemosensors10020038

Casari Bariani G, Zhou L, Poggesi S, Manzano M, Ionescu RE. Patterning Large-Scale Nanostructured Microarrays on Coverslip for Sensitive Plasmonic Detection of Aqueous Gliadin Traces. Chemosensors. 2022; 10(2):38. https://doi.org/10.3390/chemosensors10020038

Chicago/Turabian StyleCasari Bariani, Giuliocesare, Lan Zhou, Simone Poggesi, Marisa Manzano, and Rodica Elena Ionescu. 2022. "Patterning Large-Scale Nanostructured Microarrays on Coverslip for Sensitive Plasmonic Detection of Aqueous Gliadin Traces" Chemosensors 10, no. 2: 38. https://doi.org/10.3390/chemosensors10020038

APA StyleCasari Bariani, G., Zhou, L., Poggesi, S., Manzano, M., & Ionescu, R. E. (2022). Patterning Large-Scale Nanostructured Microarrays on Coverslip for Sensitive Plasmonic Detection of Aqueous Gliadin Traces. Chemosensors, 10(2), 38. https://doi.org/10.3390/chemosensors10020038