1. Introduction

There is a growing demand for energy to meet the requirements of continuous industrial development and modern civilization. In parallel, there is a growing concern about the depletion of traditional energy sources such as fossil fuel and drawbacks of continuous consumption of fossil fuel such as climate change [

1]. Indeed, a recent study expected that future energy demands might exceed the limits of current energy systems [

2]. Moreover, the increasing global energy demands and consumption of fossil fuel will escalate the emissions of greenhouse gases and other toxic air pollutants. Therefore, alternative sources of energy such as renewable energy have earned significant attention in the recent decades. In particular, fuel cell is among the power generation systems that can deliver environmentally friendly quality energy with great energy conversion efficiency. Furthermore, fuel cell has a great potential in power delivery for stationary and movable applications compared to other storage technologies [

3,

4,

5,

6,

7]. Other remarkable features of fuel cell over other energy alternatives include lower fuel oxidation temperature and reduced emissions [

8]. Solid oxide fuel cell (SOFC) and polymer composites-based electrolyte fuel cell represent the most attractive types of fuel cell for a wide range of applications. A growing effort is made to deliver a model that can predict the performance of fuel cell over steady state or dynamics operating environmental conditions [

9,

10,

11,

12]. In fact, appropriate model identification requires feeding accurate input parameters to the governing equations that encompass physical and chemical properties of the cell, where the modelling methodologies can be empirical, semi-empirical, or theoretical [

13,

14,

15,

16].

The parameter extraction of the fuel cell model plays an important role in the simulation, evaluation, control, and optimization of a fuel cell system. The voltage drops in SOFC are mainly reliant on the parameters associated with the chemical processes inside SOFC [

17,

18]. Several methods were used to identify the accurate parameters of SOFC. Among these methods, the metaheuristic optimization-based methodologies were superior in resolving the SOFC parameter estimation problem due to their reliability, robustness, and simplicity. Shi et al. [

19] proposed a strategy, Converged Grass Fibrous Root, to determine the best parameters of the SOFC model. Both temperature and pressure variation are considered. During the optimization process, seven parameters are assigned to be decision variables: the standard potential, the current limitation density, the Tafel line slope, a constant depends on the operating state of SOFC, the area-specific resistance, the anode exchange current density, and the cathode exchange current density. El-Hay et al. [

10] suggested a methodology based on an interior search algorithm to estimate the steady state and transient parameters of SOFC. A proportional-integral controller is integrated with the dynamic model to enhance its performance throughout transient disturbances. A similar study also carried by the same authors based on Satin Bowerbird Optimizer was conducted [

9]. During the optimization process, the decision variables are represented by the unknown parameters of SOFC, whereas the cost function is represented by mean squared deviations between experimental data and estimated SOFC voltages. In the same direction, Yousri et al. [

20] proposed a modified algorithm called comprehensive learning dynamic multi-swarm marine predators to determine both static and dynamic parameters of SOFC. During the optimization process, the mean squared error between the experimental data and estimated SOFC voltage is used as the objective function that is required to be minimum. Nassef et al. [

21] used the radial movement optimization algorithm (RMOA) to determine the best parameters of the SOFC model. The model of SOFC was created using a neural network. During the optimization process, four parameters, including electrolyte thickness, cathode interlayer thickness, anode porosity, and anode support layer thickness, are used as decision variables; in contrast, the objective function is represented by the power density of SOFC. By using the RMOA, the power density was increased by 17.28% compared with the genetic algorithm. In the same direction, Fathy et al. [

22] suggested a methodology based on the moth-flame optimization algorithm (MFOA). The power density of SOFC using the MFOA was improved. It was increased by 18.92% and 5.56% compared to the genetic algorithm and RMOA, respectively.

The contribution of the current research work can be summarized as follows:

A novel approach based on Equilibrium Optimizer (EO) is suggested to determine the optimal parameters of the SOFC-based model.

The suggested methodology is validated through both steady-state and dynamic-state models of SOFC with the changing of the operational conditions.

A comprehensive comparison with previous works and other programs of the Archimedes optimization algorithm (AOA), Heap-based optimizer (HBO), Seagull Optimization Algorithm (SOA), Student Psychology Based Optimization Algorithm (SPBO), Marine predator algorithm (MPA), and Manta ray foraging optimization (MRFO).

The superiority and reliability of the suggested EO-based strategy in solving the SOFC parameter determination problem is verified.

The rest of the paper is organized as follows: The mathematical model of SOFC is illustrated in

Section 2.

Section 3 presents an overview about main aspects of the equilibrium optimizer. Then, the suggested optimization problem and solution methodology are explained in

Section 4.

Section 5 presents a detailed discussion of the obtained results and a comparative study with other methods. Finally, the main findings and the future work are outlined in

Section 6.

3. Overview of Equilibrium Optimizer

Equilibrium optimizer (EO) is a recent algorithm that was proposed by Faramarzi et al. in 2020 [

25]. The core idea of the EO is extracted from the control volume mass balance models. During the optimization process of the EO, the particles and positions are assigned to the solutions and concentrations, respectively. The details explanations about the inspiration, mathematical model, and algorithm of the EO can be found in [

25]. The mass balance formula is expressed as follows.

where

C denotes the concentration of the control volume;

denotes the changing rate of the mass;

Q denotes the flow rate;

Ceq denotes the concentration at the balance state; and

G denotes the mass generation rate.

By integration over time and rearranged with the above formula, the following relation can be used to express the concentration of the control volume.

where

λ denotes the turnover rate (

) and

, and

t0 and

C0 denote the initial time and concentration, respectively.

The time

t is decreasing with increasing the number of iterations as follows:

where

I and

z are the current iteration and maximum number of iterations, respectively.

a1 and

a2 are constants.

is a random vector in range [0, 1].

Considering Equation (16), there are three sections describing the updating process for particles. The first section represents the equilibrium concentration. It represents the optimum solutions arbitrarily chosen from a pool. The second section is related to the concentration variations between a particle and the equilibrium state. The last section is related to the generation rate. It is mainly performing the role of an exploiter. The equilibrium state is the final convergence state of the EO optimization process. The equilibrium pool can be represented as follows.

During the first iteration, the particle modifies the concentration using

whereas it is uses

with other iterations. The generation rate is defined as follows.

where

G0 is the initial value, and

k denotes a decay constant (

k =

λ).

where

r1 and

r2 are random variables in range [0, 1], and

GCP is a parameter that controls the generation rate.

The addition of memory saving helps each particle to save its coordinates in the search space. Moreover, it informs its fitness function value. The fitness function related to a particular particle in the ongoing iteration is compared with the previous one; then, the updating process is placed if it reaches better fit. This action enhances the exploitation phase. The optimization process of EO is illustrated in

Figure 1.

5. Numerical Analysis

The analysis is performed on two modes of the SOFC operation which are steady-state and dynamic-state. Both of them are investigated under variable-operating conditions. The commercial SOFC, which is manufactured by Siemens [

30], is employed in steady-state analysis. In such a case, four measured datasets are recorded at temperatures of 1073, 1173, 1213, and 1273 K, where the proposed EO size of population is assigned as 50, and the number of iterations is selected as 100. The population-based approach presented in this work has some difficulty, such as getting premature and local optima, and the authors take into consideration this problem by performing the approach with 50 independent runs, and the best one is selected as global optima. This action minimizes the problem of falling in local optima. Other metaheuristic approaches are implemented and compared to the proposed EO; these algorithms are the Archimedes optimization algorithm (AOA), Heap-based optimizer (HBO), Seagull Optimization Algorithm (SOA), Student Psychology Based Optimization Algorithm (SPBO), Marine predator algorithm (MPA), Manta ray foraging optimization (MRFO), and comprehensive learning dynamic multi-swarm marine predators algorithm CLDMMPA [

20].

Table 1 shows the obtained optimal parameters of SOFC operated at 1073 K via the proposed EO and the others. The proposed approach succeeded in achieving a fitness function of 2.6906 × 10

−6 which is the same obtained via CLDMMPA. However, the CLDMMPA is complex in construction; moreover, the proposed EO consumes only 272.198102 s, which is the best compared to the others. The measured and calculated polarization curves obtained via the proposed EO are shown in

Figure 3. Both curves are closely converged. Moreover,

Figure 4 shows the estimated polarization curves obtained via the other approaches and the measured ones. Furthermore, the performance of each optimizer during the iterative process is shown in

Figure 5. It is clear that the EO performance is the best compared to the others.

The optimal parameters of the SOFC steady-state based model at 1173, 1213, and 1273 K obtained via the proposed EO and the others are tabulated in

Table 2,

Table 3 and

Table 4. Regarding the obtained results at 1173 K, the best fitness function is 1.5527 × 10

−6 obtained via the proposed EO while CLDMMPA comes in the second rank with a SMSE of 1.5529 × 10

−6. On the other hand, the worst approach is SOA with a fitness function of 3.1657 × 10

−6. Moreover, during the operation at 1213 K, the EO outperformed the others in terms of elapsed time and fitness function. The reader can see that during operation at 1273 K, the proposed EO achieved a SMSE of 2.2995 × 10

−6, which is the best compared to the others.

The polarization curves of the measured data and calculated data obtained via the proposed EO for the steady-state SOFC based model at 1173, 1213, and 1273 K are shown in

Figure 6. The curves confirm the matching between the experimental and calculated data.

It is important to investigate the performance of each optimizer via calculating the statistical parameters, which include the best, worst, mean, median, variance, and standard deviation after 50 independent runs. These data are calculated and tabulated in

Table 5. The proposed EO gives acceptable statistical parameters compared to the others.

The obtained results confirmed the superiority and reliability of the proposed methodology incorporating EO in identifying the optimal parameters of the SOFC steady-state based model.

It is important to confirm the availability of the presented approach in a dynamic/transient-based model of SOFC. Therefore, a 100 kW stack with specifications given in

Table 6 is modeled in a dynamic-state model subjected to variable load disturbances. At the beginning, the proposed EO is applied to identify the optimal parameters of a 100 kW SOFC stack operated at 1273 K; the obtained parameters are tabulated in

Table 7 in comparison to those obtained by the others. Regarding the obtained results, the proposed EO outperformed the others, achieving the minimum SMSE with a value of 1.0406. MRFO comes in the second rank with a fitness function of 1.0775, and then CLDMMPA achieves an SMSE of 1.3204 and comes in the third rank.

Figure 7 shows the measured and calculated polarization curves obtained via the EO, and both curves are closely converged. However,

Figure 8 shows the polarization curves obtained via MPA, HBO, SOA, and MRFO. The statistical parameters of all optimizers in such cases are calculated and tabulated in

Table 8, where the best parameters are obtained by the proposed EO.

Figure 9 shows the performance of each optimizer during implementing the iterative process. The performance of the proposed EO is confirmed to be better than the others.

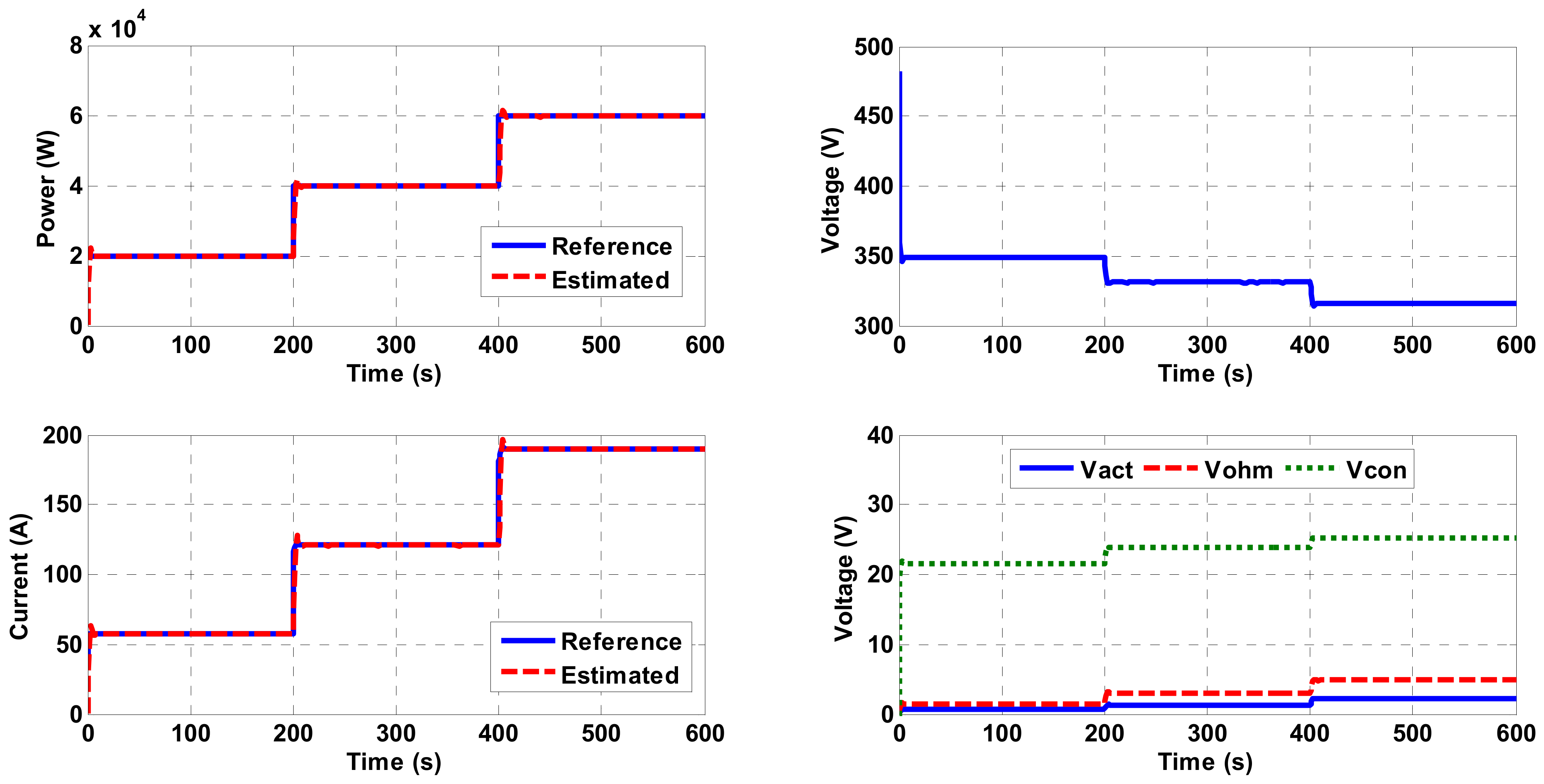

After identifying the parameters of the transient-state based model of SOFC, the model of fuel cell is implemented in Simulink/Matlab, and two load disturbances are applied to the model. The first disturbance is shown in

Figure 10 (1st graph), the power is changed from 30 kW to 60 kW at a time of 300 sec., and given the identified parameters via the proposed EO and the stack output power plotted with the load disturbance, it is clear that they are closely matched, this means that the EO succeeded in extracting the correct parameters of the SOFC dynamic model. Moreover, the load current of the constructed model is closely converged to the disturbance current (3rd graph,

Figure 10). Moreover, the terminal voltage (2nd graph) and the voltage drops occur inside the stack (4th graph), and they are shown in

Figure 10. The constructed model via the proposed EO succeeded in tracking the changes in the load power. Moreover, a second disturbance is applied on the dynamic model in which the load power has two variations; as shown in

Figure 11 (1st graph), the load power changes from 20 kW to 40 kW at 200 s and then changes again to 60 kW at 400 s on the same graph. The output power from the constructed model with identified parameters via the proposed EO is given, and both curves are converged. The terminal voltage, the corresponding current, and the voltage drops are shown in

Figure 11 (2nd graph, 3rd graph, and 4th graph, respectively).

Finally, it can be concluded that the proposed methodology incorporating the EO is reliable, superior, and efficient over other employed approaches in constructing a reliable model of the SOFC-based model operated under either steady-state or dynamic-state modes.

6. Conclusions

This work introduces a new methodology based on a new metaheuristic approach named equilibrium optimizer (EO) to estimate the optimal parameters of a solid oxide fuel cell (SOFC) model. This is achieved with the aid of experimental datasets of the fuel cell polarization curves. The sum squared error difference between the cell experimental and computed voltages is selected as the fitness function to be minimized. The work investigates two operating modes of FC, which are steady- and dynamic-states models under altering operating conditions. In the first model, the parameters are estimated at four temperatures via the recorded measured polarization curves at them. In the dynamic model, two load power disturbances are investigated after identifying the parameters via the proposed EO. The obtained results via the proposed EO are compared to those obtained by the Archimedes optimization algorithm (AOA), Heap-based optimizer (HBO), Seagull Optimization Algorithm (SOA), Student Psychology Based Optimization Algorithm (SPBO), Marine predator algorithm (MPA), Manta ray foraging optimization (MRFO), and comprehensive learning dynamic multi-swarm marine predators algorithm. In the case of the SOFC steady-state model, the proposed EO succeeded in achieving the best (minimum) fitness function of 2.6906 × 10−6, 1.5527 × 10−6, 2.6809 × 10−6, and 2.2995 × 10−6 at operating temperature of 1073 K, 1173 K, 1213 K, and 1273 K, respectively. The corresponding standard deviations in the four studied cases obtained via the proposed EO are 9.15673 × 10−7, 1.63132 × 10−6, 3.36081 × 10−6, and 2.2119 × 10−6. Regarding the obtained results of the SOFC dynamic-state model, the proposed EO outperformed the others, achieving the minimum SMSE with a value of 1.0406; the MRFO comes in the second rank with a fitness function of 1.0775, and then the CLDMMPA achieves a SMSE of 1.3204 and comes in the third rank. The proposed EO succeeded in achieving a variance of 0.02264 and a standard deviation of 0.15048 in this studied case. The findings of this study demonstrate the superiority and reliability of the proposed approach in constructing a good-performance model that converges to the real one.