Unified CACSD Toolbox for Hybrid Simulation and Robust Controller Synthesis with Applications in DC-to-DC Power Converter Control

Abstract

:1. Introduction

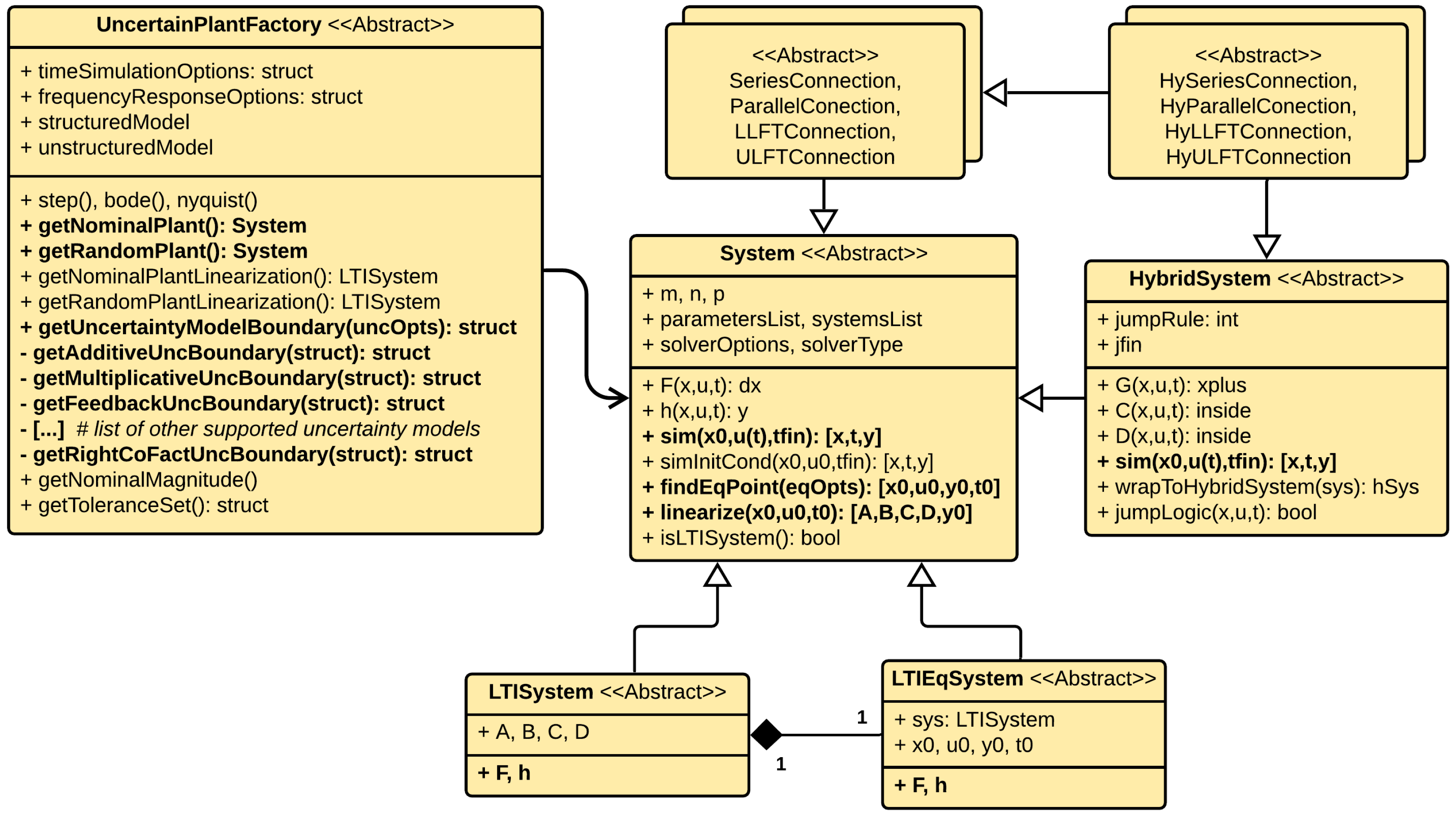

2. Toolbox Structure and Functionalities

2.1. Toolbox Features

- specify finite-dimensional dynamical systems with the general framework from Equation (1) to be used with the MATLAB ode framework; ability to interconnect such systems in series, parallel, and linear-fractional transformations; this functionality is described in Section 2.2.1 and Section 2.2.2;

- specify hybrid dynamical systems in the framework from in [16] as in Equation (4), with the ability to interconnect such systems in series, parallel, and linear-fractional transformations, upper and lower; this feature is described in Section 2.2.3;

- automatically compute equilibrium points numerically, with the possibility to impose certain states, inputs, and/or outputs, while the remaining ones are deduced through numerical optimization; this feature is presented in Section 2.4;

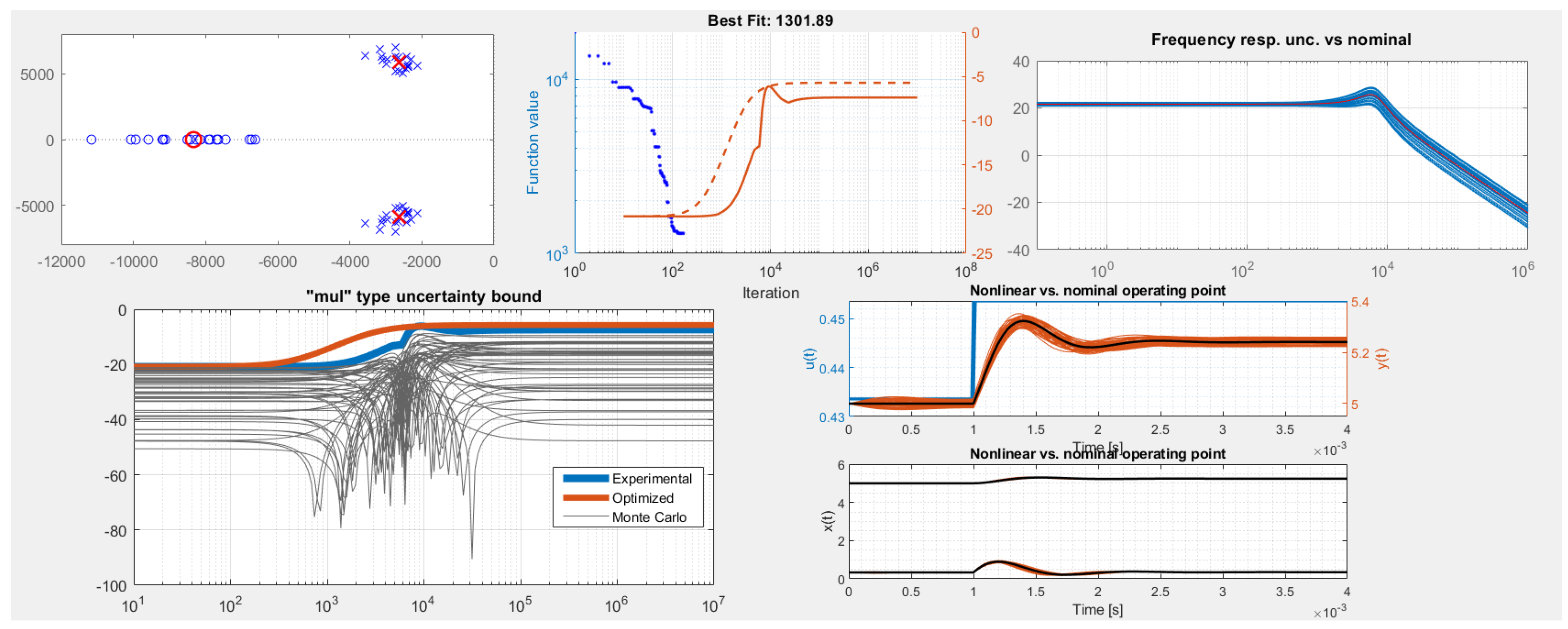

- automatically compute the uncertainty model as requested alongside a nominal plant: additive, inverse additive, input and output multiplicative, etc. using a global optimization algorithm, such as particle swarm optimization, to be directly used as necessary for robust synthesis methods; removes the burden for the control engineer to manually do this process for each plant; this feature is presented in Section 2.5;

- flexible and scalable, all features are implemented through MATLAB code and does not need the use of Simulink, which can become cumbersome when treating families of plants and not a single, specific, plant at a time; also, to account for the operating point in the case of linearized, nonlinear, and hybrid systems, alike, the same interface for Model-in-the-Loop simulation is provided in the toolbox, as shown in Section 2.2 and Section 2.3;

- besides the automatic validation of the frequency response for the desired operating point of the linearized plant family, the toolbox runs tests accounting for the uncertainty behavior of the desired nonlinear plant, not only on the linearization which the controller has been designed for. Every specification imposed in the designed phase will be automatically tested for the entire nonlinear system family, as illustrated in the case studies from Section 3.

2.2. Systems Specification

2.2.1. Nonlinear Systems

2.2.2. Linear Systems

2.2.3. Hybrid Systems

2.3. System Interconnections

2.4. Automatic Equilibrium Point Computation

2.5. Automatic Least Conservative Uncertainty Bound Computation

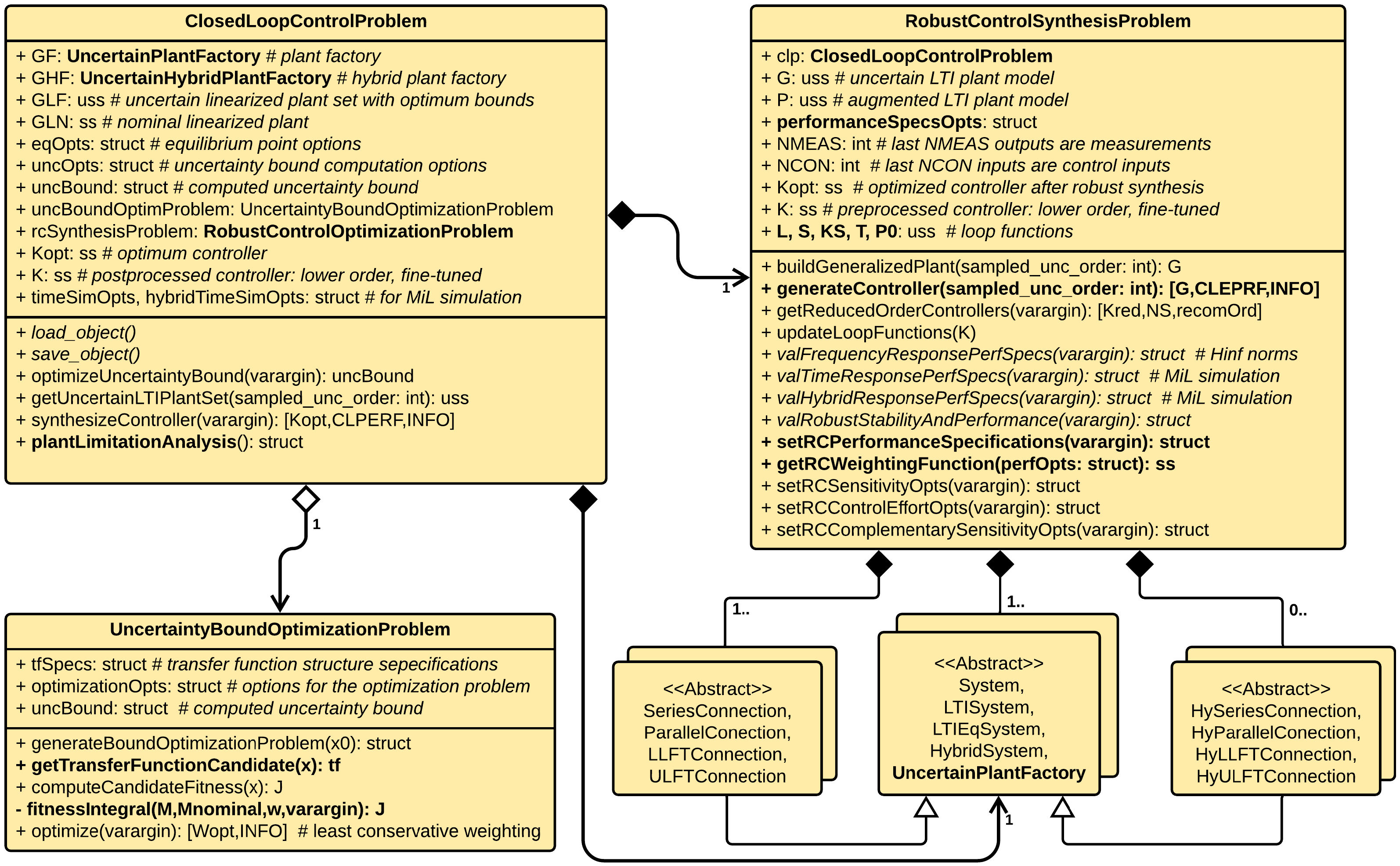

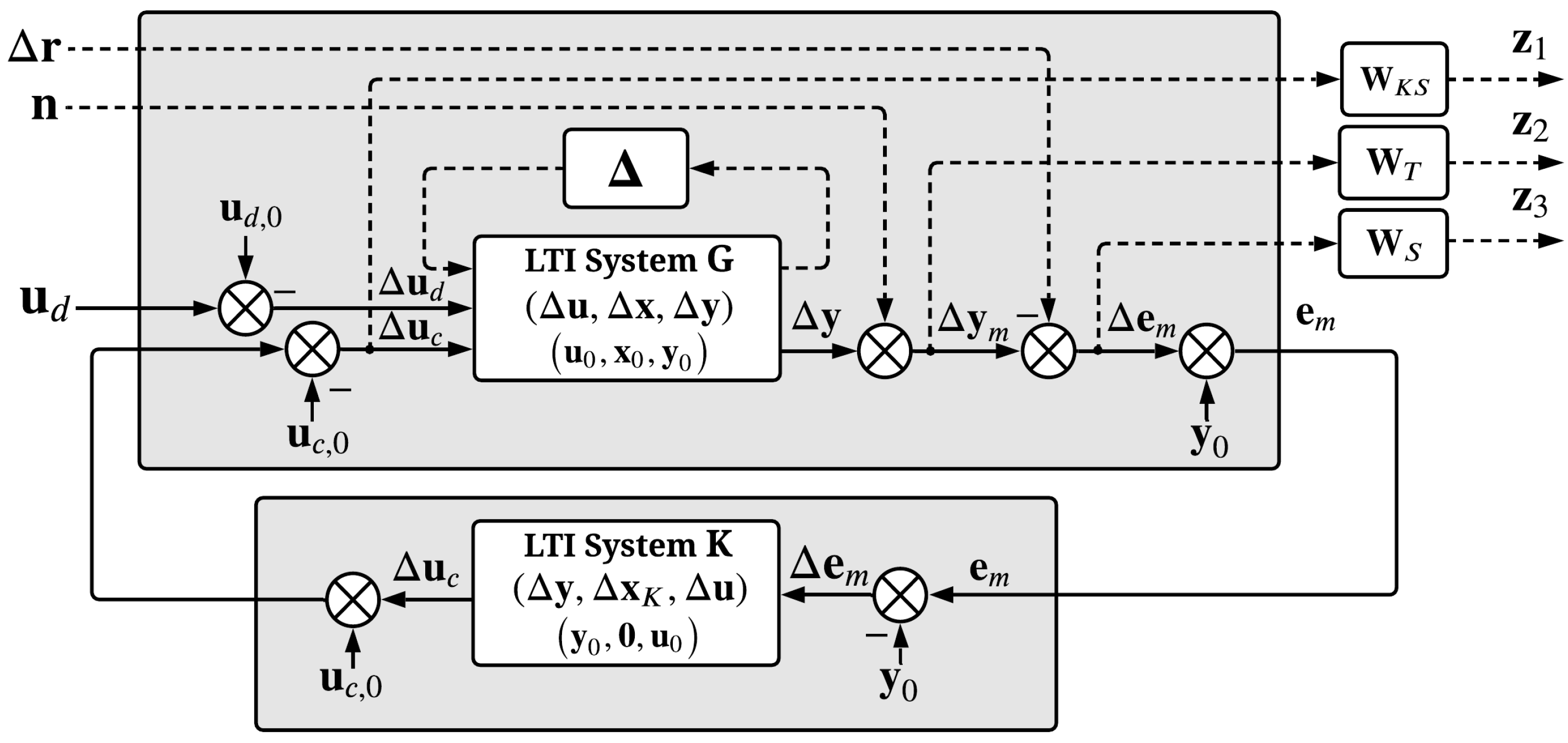

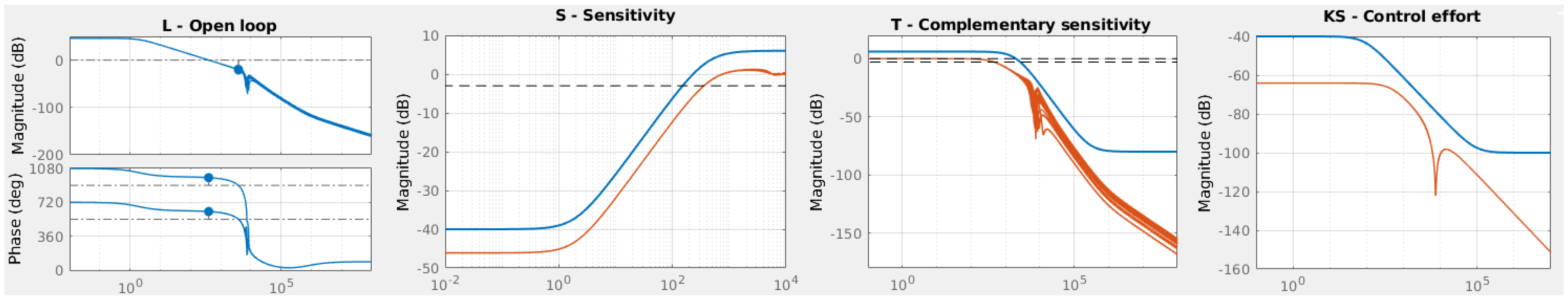

2.6. Robust Synthesis and Closed Loop Validation

3. Results

3.1. Mathematical Modeling

- : switching device, usually a transistor, and : switching device, usually a diode or transistor;

- L, , : converter inductors;

- C, , , : converter capacitors;

- R: (variable) output load resistance;

- E: external source voltage;

- , , : resistances associated with the inductors;

- , , , : capacitors parasitic resistances;

- , : resistances associated with the ON state of the switching devices (usually drain source);

- , : constant voltage drops associated with the conducting phase of and ;

- : normalized duty cycle applied to ; complementary to the PWM signal applied to .

3.2. Toolbox Workflow

- inherit class System to define the nonlinear model of the process as in Equation (1) and Figure 1;

- define equilibrium point specifications as in (11)–(13);

- inherit class UncertainPlantFactory and overload method getRandomPlant;

- define uncertainty options, including transfer function structure for all particles, and execute the methods from class UncertaintyBoundOptimizationProblem in order to minimize the functional from Equation (21), obtaining ;

- run optimization to compute the uncertainty weight as in Table 1;

- synthesize robust controller based on Figure 6;

- apply order-reducing methods on the resulting controller;

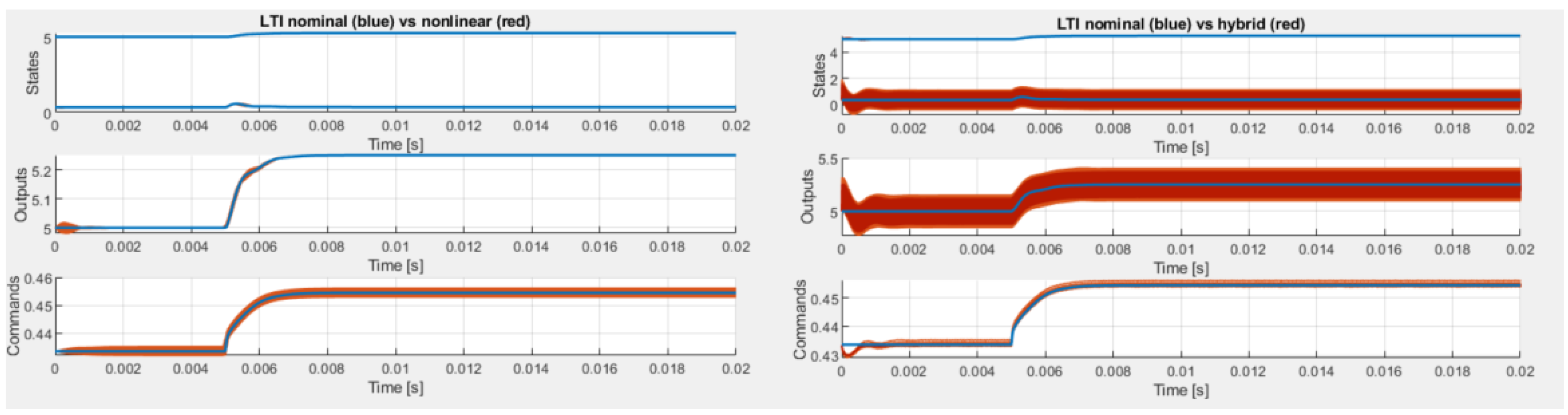

- validate frequency and time-response performance specifications using the nonlinear system at operating point through Model-in-the-Loop simulations;

- optionally, inherit the classes HybridSystem and UncertainPlantFactory, respectively, to validate time-response performance specifications using the corresponding hybrid plant model at operating point; for DC-to-DC converter control, the last step should be adapted for CCM or DCM operation.

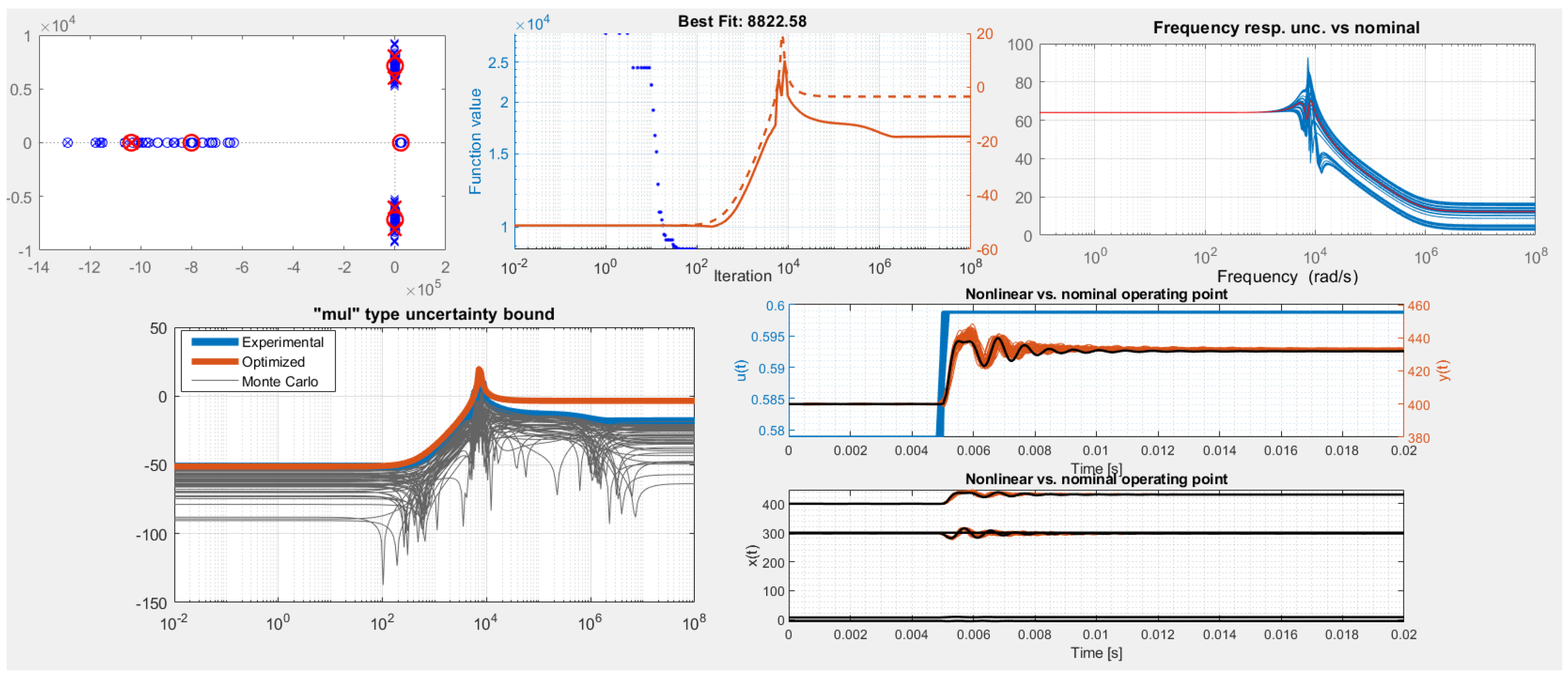

3.3. Numerical Results

3.3.1. SEPIC Converter

3.3.2. Buck Converter

3.3.3. Boost Converter

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

Sample Availability

Abbreviations

| CACSD | Computer-Aided Control System Design |

| CCM | Continuous Conduction Mode |

| DAE | Differential-Algebraic Equation |

| DC | Direct Current |

| DCM | Discontinuous Conduction Mode |

| DOF | Degree of Freedom |

| HyEQ | Hybrid Equations Toolbox |

| LLFT | Lower Linear Fractional Transformation |

| LMI | Linear Matrix Inequality |

| LTI | Linear Time-Invariant |

| MiL | Model-in-the-Loop |

| ODE | Ordinary Differential Equation |

| PSO | Particle Swarm Optimization |

| RCP | Rapid Control Prototyping |

| SEPIC | Single-ended primary-inductor converter |

| ULFT | Upper Linear Fractional Transformation |

References

- Balas, G.; Chiang, R.; Packard, A.; Safonov, M. Robust Control Toolbox, Reference for MATLAB; The MathWorks, Inc.: Natick, MA, USA, 2020. [Google Scholar]

- Global Optimization Toolbox, User’s Guide for MATLAB; The MathWorks, Inc.: Natick, MA, USA, 2020.

- Feyel, P.; Duc, G.; Sandou, G. Optimal tuning of ∞ fixed-structure robust controller against multiple high-level requirements using evolutionary computation. Int. J. Robust Nonlinear Control 2019, 29, 949–972. [Google Scholar] [CrossRef]

- Blackwell, C.; Sastry, M.K.S. Multivar - A MATLAB based MIMO Control System Design Application. In Proceedings of the 8th International Conference on Computational Intelligence and Communication Networks, Tehri, India, 23–25 December 2016. [Google Scholar]

- Keller, P. Robust and optimal ∞ control in LabVIEW. IEEE Conf. Control. Technol. Appl. (CCTA) 2017. [Google Scholar] [CrossRef]

- Jacobs, L.; Verbandt, M.; De Preter, A.; Anthonis, J.; Swevers, J.; Pipeleers, G. A Toolbox for Robust Control Design: An Illustrative Case Study; IEEE: Tokyo, Japan, 2018. [Google Scholar]

- Sadeghpour, M.; de Oliveira, V.; Karimi, A. A Toolbox for Robust PID Controller Tuning Using Convex Optimization. IFAC Proc. Vol. 2012, 45, 158–163. [Google Scholar] [CrossRef] [Green Version]

- Ljung, L. System Identification Toolbox, Reference for MATLAB; The MathWorks, Inc.: Natick, MA, USA, 2020. [Google Scholar]

- Karimi, A.S. Frequency-Domain Robust Control Toolbox. In Proceedings of the 52nd IEEE Conference on Decision and Control, Firenze, Italy, 10–13 December 2013. [Google Scholar] [CrossRef] [Green Version]

- Sadeghzadeh, A.; Karimi, A.S. Fixed-structure 2 controller design for polytopic systems via LMIs. Optim. Control Appl. Meth. 2014. [Google Scholar] [CrossRef] [Green Version]

- Verbandt, M.; Swevers, J.; Pipeleers, G. An LTI control toolbox—Simplifying optimal feedback controller design. In Proceedings of the 2016 European Control Conference (ECC), Aalborg, Denmark, 29 June–1 July 2016. [Google Scholar] [CrossRef]

- Şuşcă, M. Solving Algebraic Riccati Equations Using Proper Deflating Subspaces for 2/∞ Synthesis. Master’s Thesis, Technical University of Cluj-Napoca, Cluj-Napoca, Romania, 2019. [Google Scholar] [CrossRef]

- Şuşcă, M.; Mihaly, V.; Stănese, M.; Dobra, P. Iterative Refinement Procedure for Solutions to Algebraic Riccati Equations. In Proceedings of the 2020 IEEE International Conference on Automation, Quality and Testing, Robotics (AQTR), Cluj-Napoca, Romania, 21–23 May 2020. [Google Scholar] [CrossRef]

- Mihaly, V. General Purpose Linear Matrix Inequality Solver With Applications in Robust and Nonlinear Control. Master’s Thesis, Technical University of Cluj-Napoca, Cluj-Napoca, Romania, 2020. [Google Scholar]

- Gumussoy, S.; Henrion, D.; Millstone, M.; Overton, M.L. Multiobjective Robust Control with HIFOO 2.0. In Proceedings of the 6th IFAC Symposium on Robust Control Design, Haifa, Israel, 16–18 June 2009. [Google Scholar]

- Sanfelice, R.G.; Copp, D.A.; Nanez, P. Hybrid Equations (HyEQ) Toolbox v2.04—A Toolbox for Simulating Hybrid Systems in MATLAB/Simulink®; MathWorks®: Natick, MA, USA, 2017. [Google Scholar]

- Goebel, R.; Sanfelice, R.G.; Teel, A.R. Hybrid Dynamical Systems: Modeling, Stability, and Robustness; Princeton University Press: Princeton, NJ, USA, 2012. [Google Scholar]

- Griewank, A.; Walther, A. Evaluating Derivatives: Principles and Techniques of Algorithmic Differentiation, 2nd ed.; SIAM: Philadelphia, PA, USA, 2008. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar] [CrossRef]

- Doyle, J.C.; Glover, K.; Khargonekar, P.P.; Francis, B.A. State-Space Solutions to Standard 2 and ∞ Control Problems. IEEE Trans. Autom. Control. 1989, 34, 831–847. [Google Scholar] [CrossRef]

- Fortuna, L.; Frasca, M. Optimal and Robust Control—Advanced Topics with MATLAB; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Gahinet, P.; Apkarian, P. A Linear Matrix Inequality Approach to ∞ Control. Int. J. Robust Nonlinear Control. 1994, 4, 421–448. [Google Scholar] [CrossRef]

- Ionescu, V.; Oară, C.; Weiss, M. Generalized Riccati Theory and Robust Control: A Popov Function Approach; John Wiley & Sons Ltd.: Chichester, UK, 1999. [Google Scholar]

- Zhou, K.; Doyle, J.C.; Glover, K. Robust and Optimal Control; Prentice Hall: Englewood Cliffs, NJ, USA, 1996. [Google Scholar]

- Packard, A.; Doyle, J.; Balas, G. Linear, Multivariable Robust Control With a μ Perspective. J. Dyn. Syst. Meas. Control. 1993, 115, 426–438. [Google Scholar] [CrossRef]

- Skogestad, S.; Postlethwaite, I. Multivariable Feedback Control: Analysis and Design, 2nd ed.; John Wiley & Sons Ltd.: Chichester, UK, 2005. [Google Scholar]

- Raghavendra, K.V.G.; Zeb, K.; Muthusamy, A.; Krishna, T.N.V.; Kumar, S.V.S.; Kim, D.-H.; Kim, M.-S.; Cho, H.-G.; Kim, H.-J. A Comprehensive Review of DC–DC Converter Topologies and Modulation Strategies with Recent Advances in Solar Photovoltaic Systems. Electronics 2020, 9, 31. [Google Scholar] [CrossRef] [Green Version]

- Chang, E.-C.; Cheng, C.-A.; Wu, R.-C. Robust Optimal Tracking Control of a Full-Bridge DC-AC. Converter. Appl. Sci. 2021, 11, 1211. [Google Scholar] [CrossRef]

- Garcia, G.; Lopez Santos, O. A Unified Approach for the Control of Power Electronics Converters. Part I—Stabilization and Regulation. Appl. Sci. 2021, 11, 631. [Google Scholar] [CrossRef]

- Mihaly, V.; Şuşcă, M.; Dobra, P. Passivity-Based Controller for Nonideal DC-to-DC Boost Converter. In Proceedings of the 2019 22nd International Conference on Control Systems and Computer Science (CSCS), Bucharest, Romania, 28–30 May 2019; pp. 30–35. [Google Scholar] [CrossRef]

- Repecho, V.; Biel, D.; Olm, J.M.; Fossas, E. Robust sliding mode control of a DC/DC Boost converter with switching frequency regulation. J. Frankl. Inst. 2018, 355, 5367–5383. [Google Scholar] [CrossRef]

- Lunze, I.; Lagarrigue, F.L. Handbook of Hybrid Systems Control: Theory, Tools, Applications; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Feng, Y.; Yagoubi, M. Robust Control of Linear Descriptor Systems; Studies in Systems, Decision and Control 102; Springer: Singapore, 2017. [Google Scholar]

- Liu, K.-Z.; Yao, Y. ROBUST CONTROL—Theory and Applications; John Wiley & Sons (Asia) Pte Ltd.: Singapore, 2016. [Google Scholar]

- Zamboni, W.; Petrone, G. (Eds.) ELECTRIMACS 2019, Selected Papers—Volume 1; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Zamboni, W.; Petrone, G. (Eds.) ELECTRIMACS 2019, Selected Papers–Volume 2; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Ascher, U.M.; Petzold, L.R. Computer Methods for Ordinary Differential Equations and Differential-Algebraic Equations; SIAM: Philadelphia, PA, USA, 1998. [Google Scholar]

- Brenan, K.E.; Campbell, S.L.; Petzold, L.R. Numerical Solution of Initial-Value Problems in Differential-Algebraic Equations; SIAM Classics in Applied Mathematics: Philadelphia, PA, USA, 1996. [Google Scholar]

- Milano, F.; Dassios, I.; Liu, M.; Tzounas, G. Eigenvalue Problems in Power Systems; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

| Uncertainty Type | Definition | Implementation |

|---|---|---|

| Additive | ||

| Inverse additive | ||

| Input multiplicative | ||

| Output multiplicative | ||

| Inverse input multiplicative | ||

| Inverse output multiplicative | ||

| Left coprime factor | ||

| Right coprime factor |

| Param. | Val. | Tol. | Param. | Val. | Tol. |

|---|---|---|---|---|---|

| [mH] | 1.71[mH] | ||||

| 130 [m] | 110 [m] | ||||

| [] | 80 [m] | ||||

| [μF] | [μF] | ||||

| 270 [m] | 350 [m] | ||||

| [μF] | 270 [m] | ||||

| [V] | [V] |

| Param. | Val. | Tol. | Param. | Val. | Tol. |

|---|---|---|---|---|---|

| L | 40 [μH] | 10 [m] | |||

| C | 600 [μF] | [] | |||

| [] | [] | ||||

| [V] | [V] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Şuşcă, M.; Mihaly, V.; Stănese, M.; Morar, D.; Dobra, P. Unified CACSD Toolbox for Hybrid Simulation and Robust Controller Synthesis with Applications in DC-to-DC Power Converter Control. Mathematics 2021, 9, 731. https://doi.org/10.3390/math9070731

Şuşcă M, Mihaly V, Stănese M, Morar D, Dobra P. Unified CACSD Toolbox for Hybrid Simulation and Robust Controller Synthesis with Applications in DC-to-DC Power Converter Control. Mathematics. 2021; 9(7):731. https://doi.org/10.3390/math9070731

Chicago/Turabian StyleŞuşcă, Mircea, Vlad Mihaly, Mihai Stănese, Dora Morar, and Petru Dobra. 2021. "Unified CACSD Toolbox for Hybrid Simulation and Robust Controller Synthesis with Applications in DC-to-DC Power Converter Control" Mathematics 9, no. 7: 731. https://doi.org/10.3390/math9070731

APA StyleŞuşcă, M., Mihaly, V., Stănese, M., Morar, D., & Dobra, P. (2021). Unified CACSD Toolbox for Hybrid Simulation and Robust Controller Synthesis with Applications in DC-to-DC Power Converter Control. Mathematics, 9(7), 731. https://doi.org/10.3390/math9070731