Study on the Intelligent Modeling of the Blade Aerodynamic Force in Compressors Based on Machine Learning

Abstract

1. Introduction

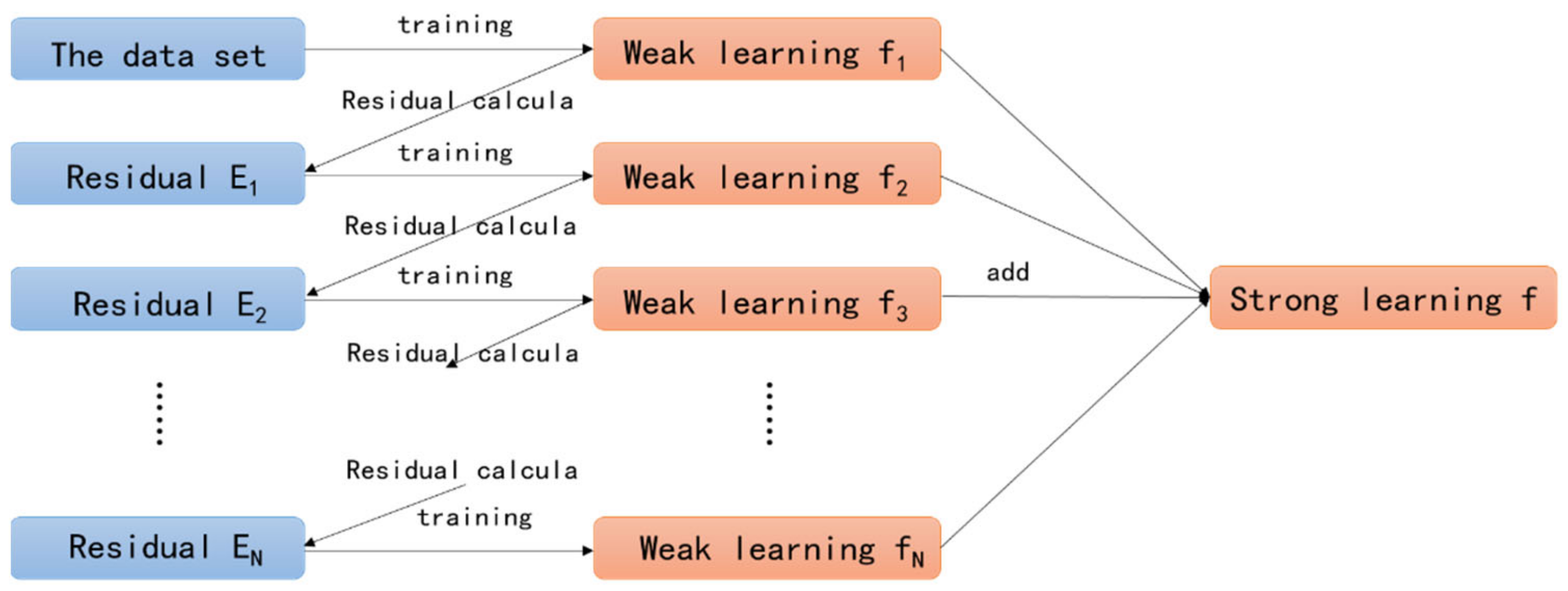

2. Description of the Machine Learning Algorithm

3. Methodology of Aerodynamic Intelligent Model

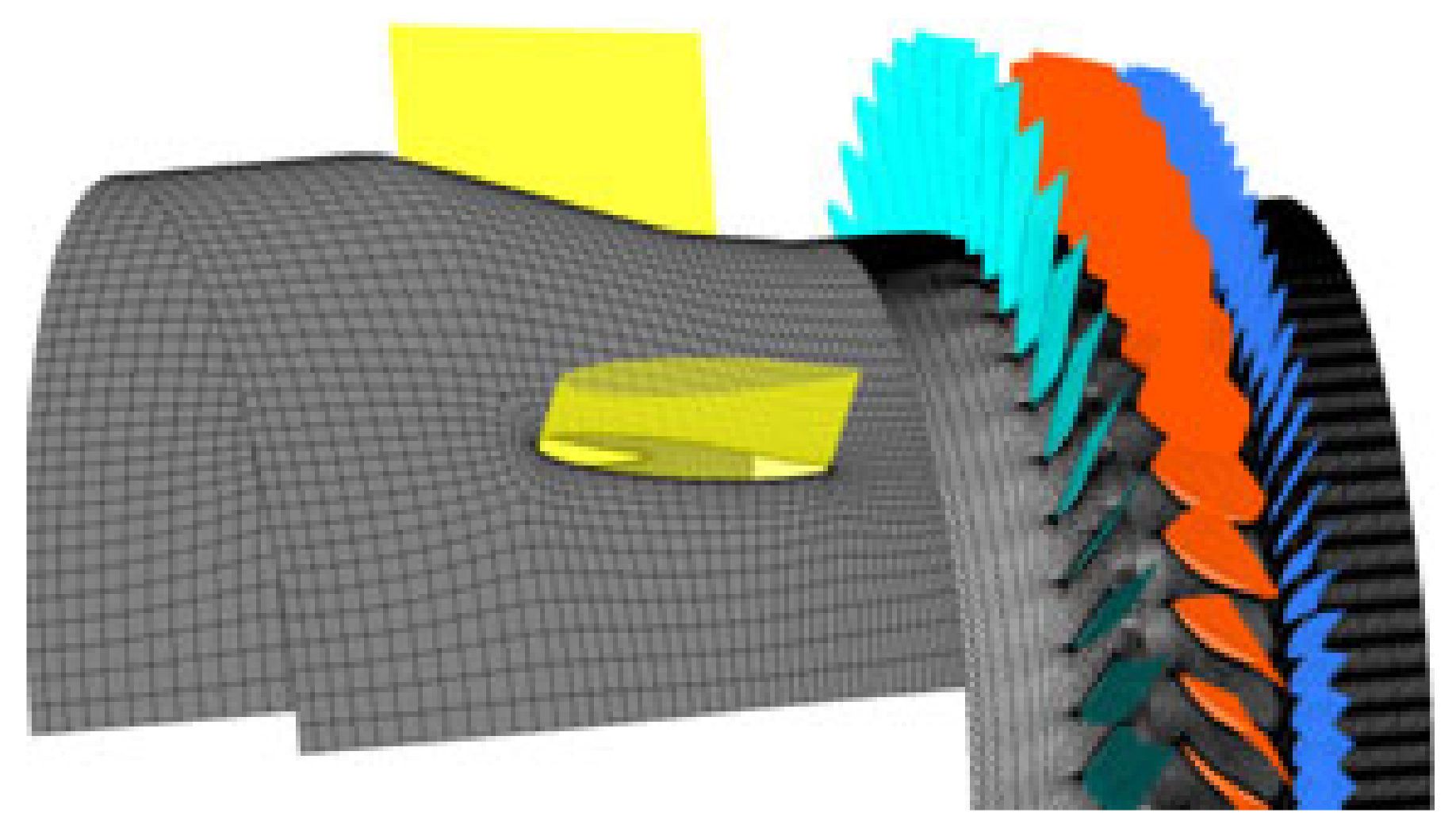

3.1. Data Collection for Machine Learning

3.2. Procedure of Aerodynamic Modeling Based on the XGBoost Algorithm

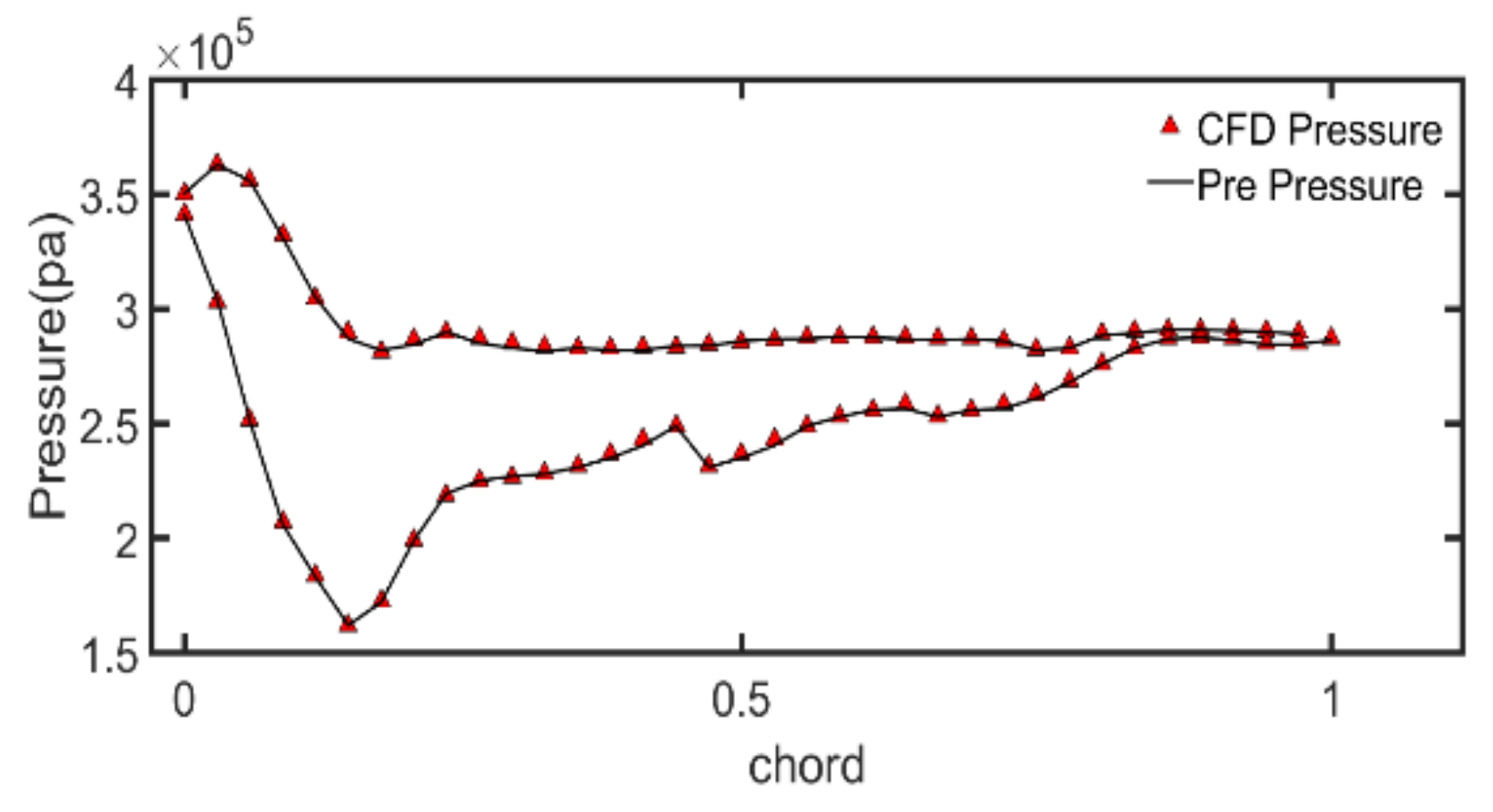

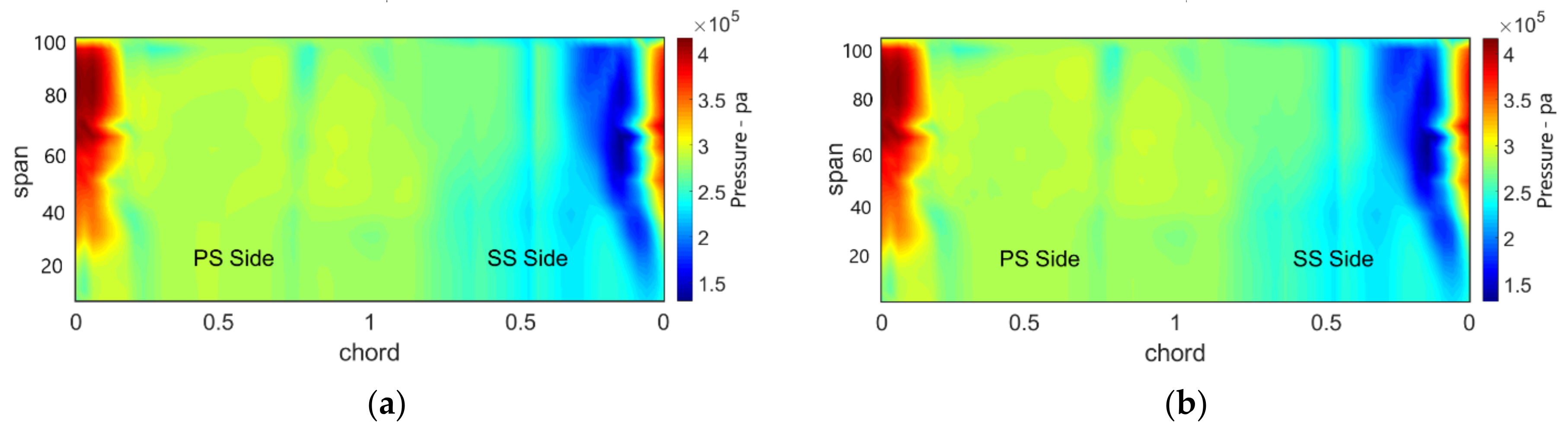

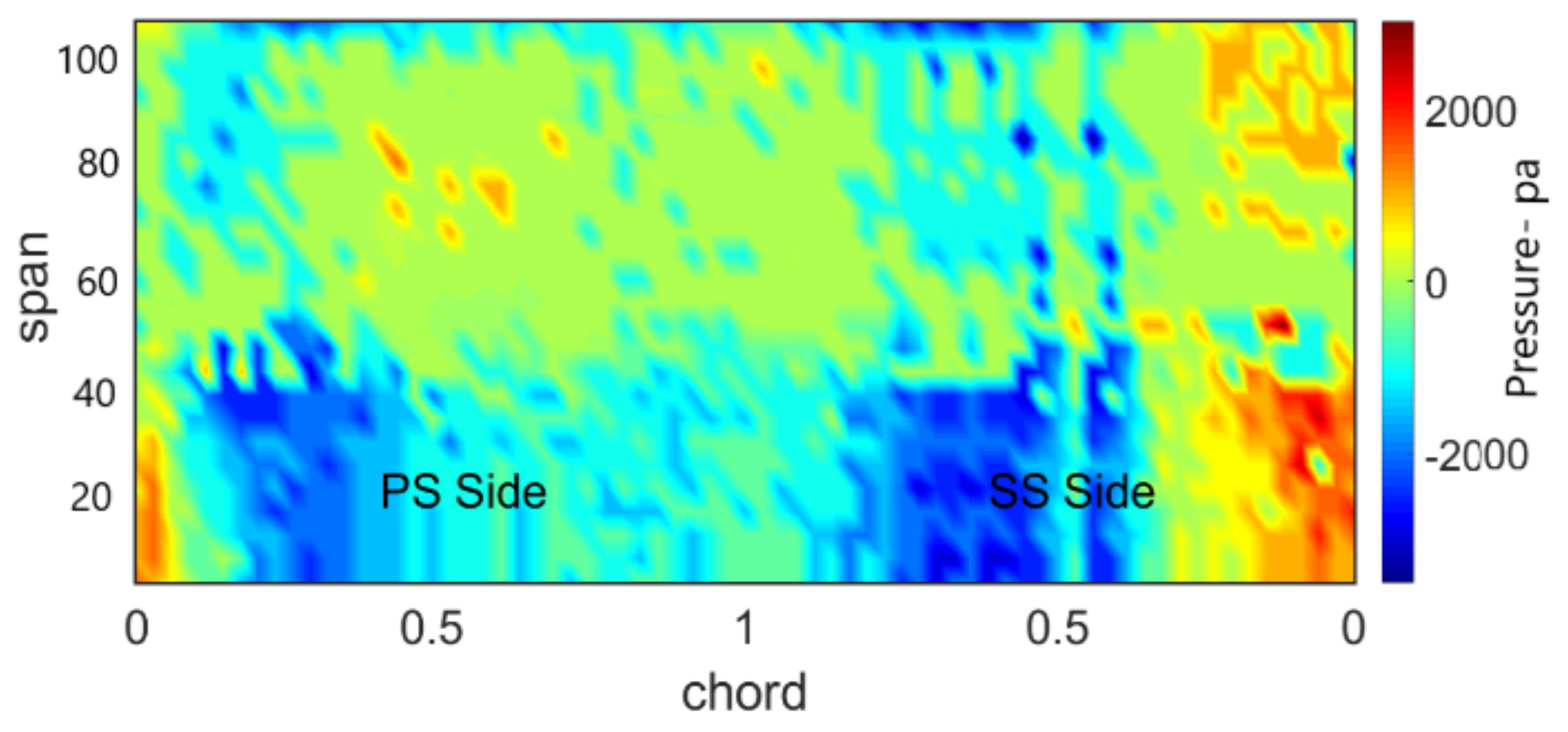

4. Modeling of Blade Aerodynamic Pressure Based on Machine Learning

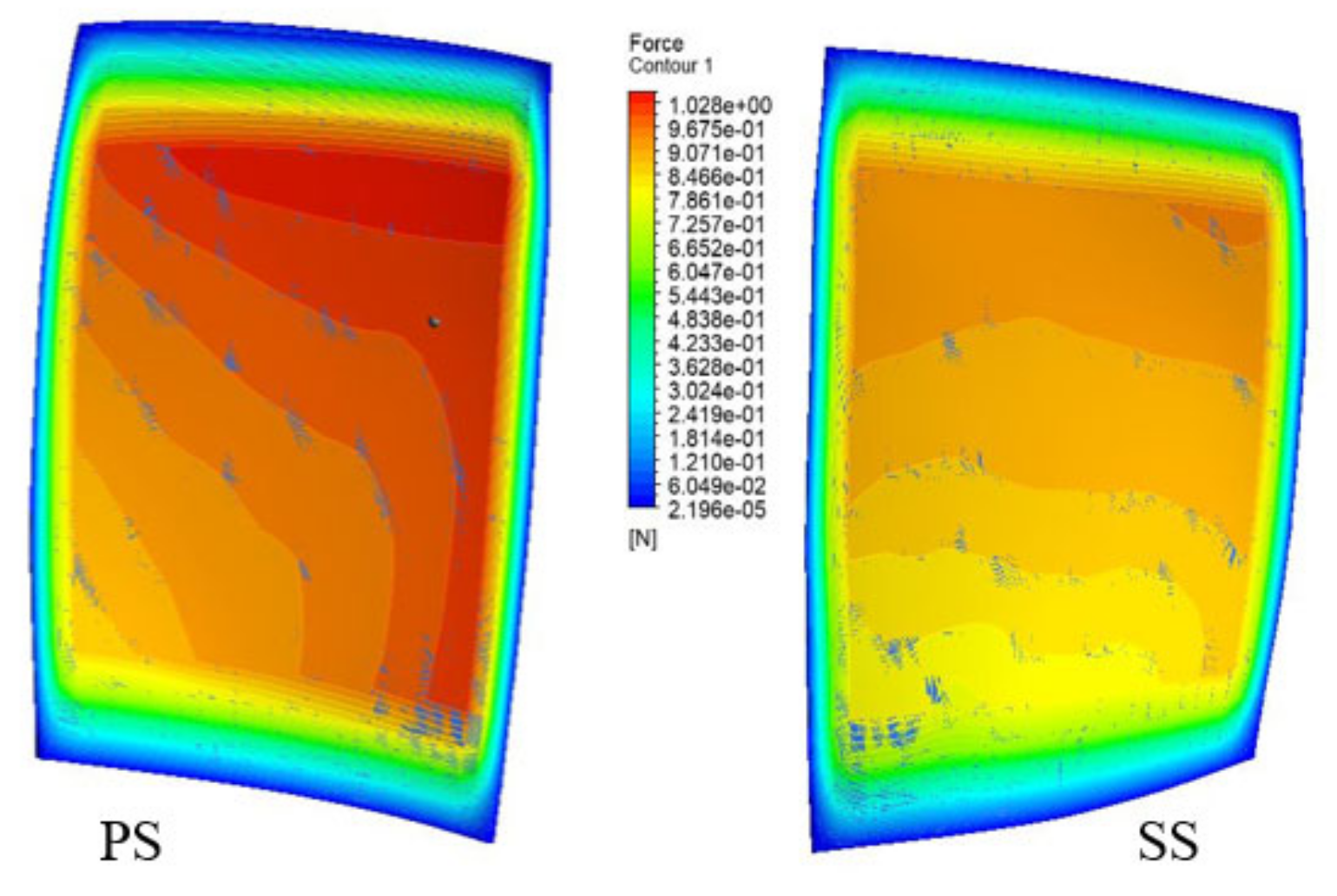

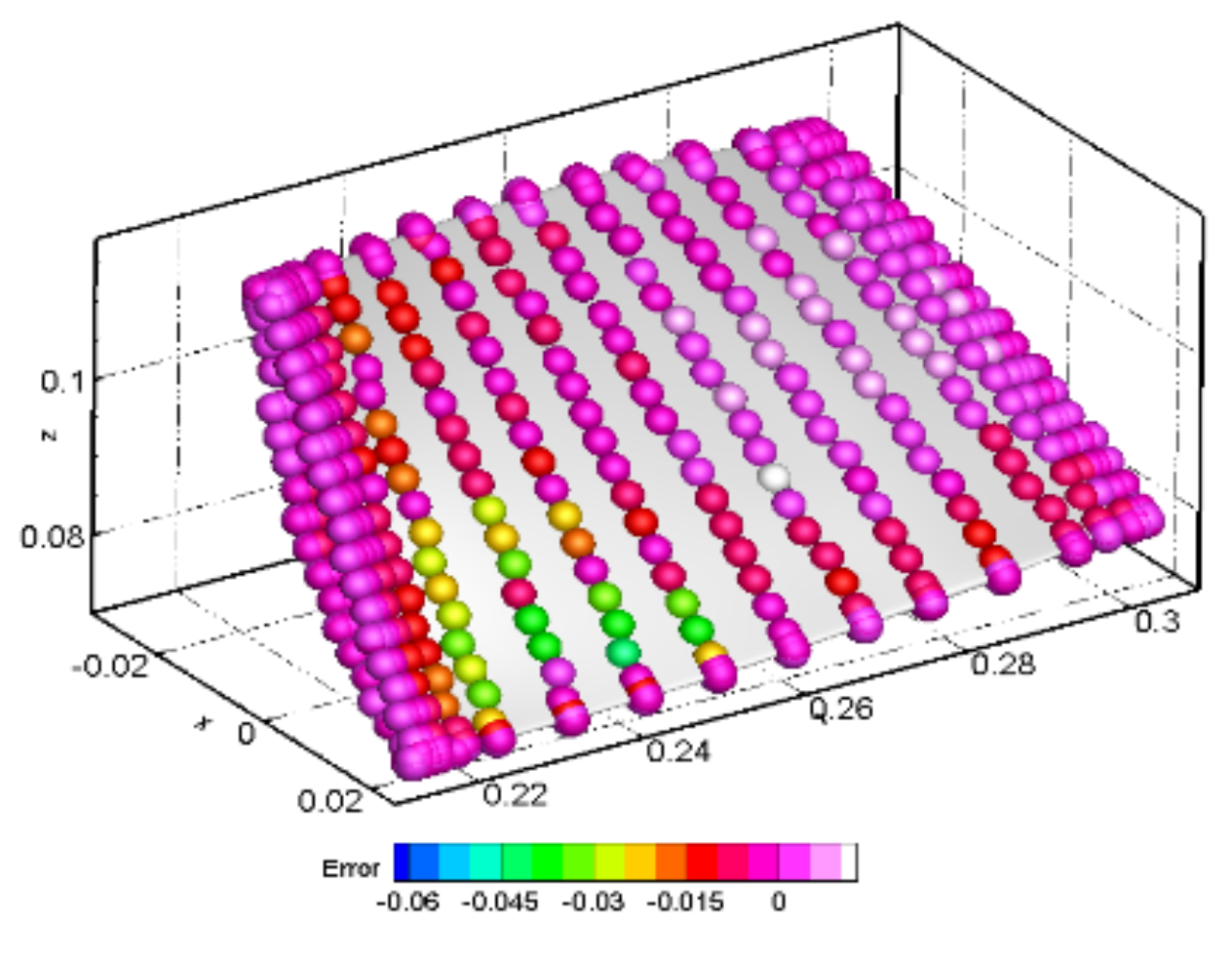

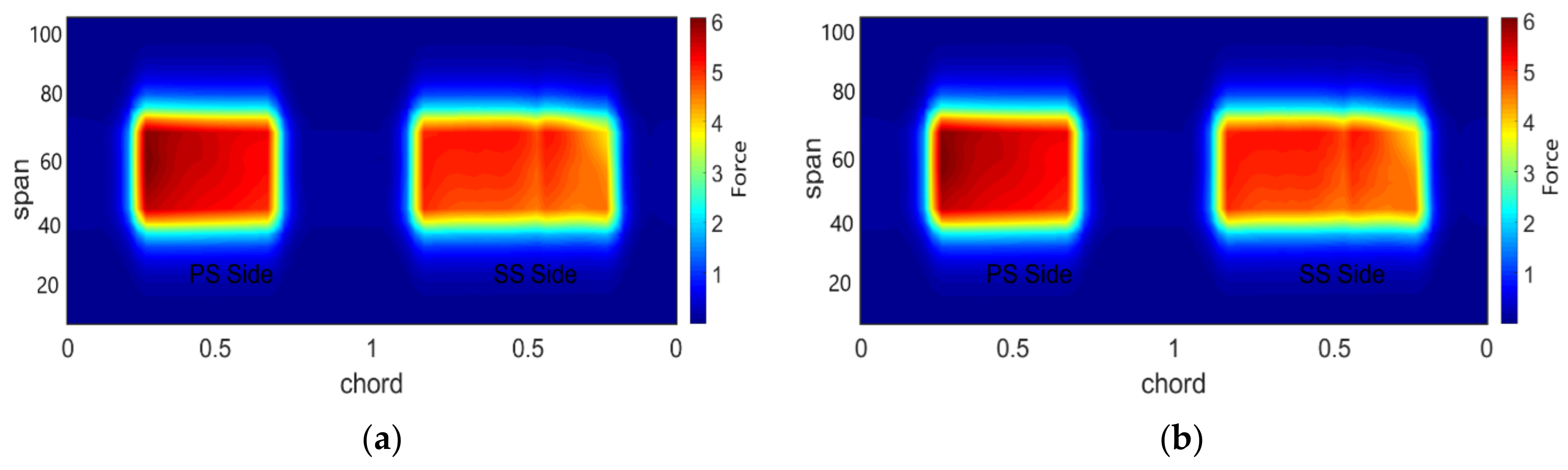

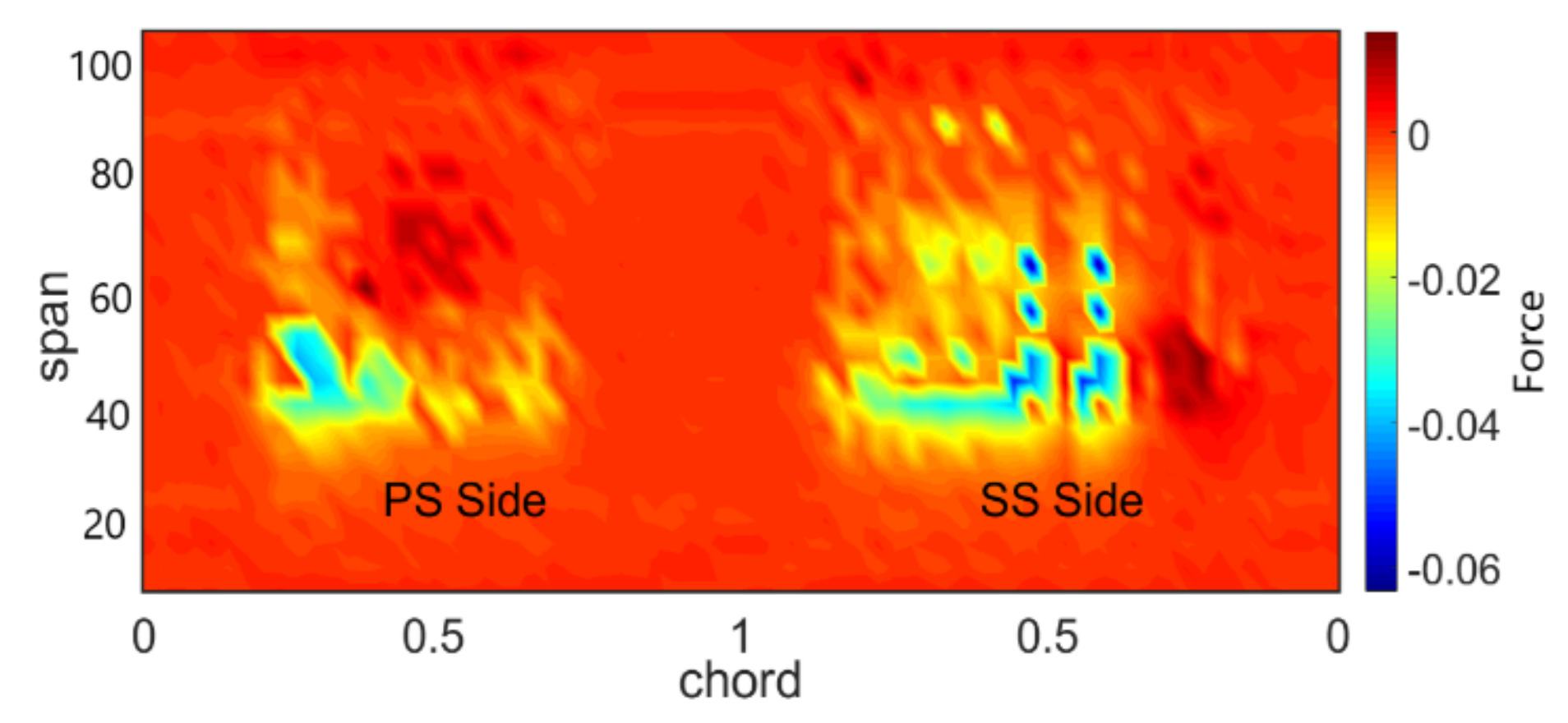

5. Modeling of Blade Aerodynamic Force Based on Machine Learning

6. Discussion

7. Conclusions

- (1)

- With the combination of the intelligent algorithm in machine learning and CFD technology, the modeling for the aerodynamic force can be performed for a three-dimensional blade of compressor in vibration. Also, the procedure for aerodynamic modeling based on the XGBoost algorithm was established, which is described as data collection, data preprocessing, training set construction, model training and parameter adjustment.

- (2)

- The high-fidelity data for model training can be set up by solving the complex Navier-Stokes equations once for the flow field. Then the information of the unsteady flow can be effectively captured based on the XGBoost model training for the mathematical mapping between the input and output. The rapid identification was achieved for the three-dimensional aerodynamic force on the blade, which improves the efficiency of calculation.

- (3)

- Based on the data of blade vibration in CFD simulation, an intelligent model based on the XGBoost algorithm was established for the prediction of the three-dimensional unsteady aerodynamic pressure and force. With the comparison to the CFD data, it showed a good accuracy and reliability on the prediction in the XGBoost intelligent method. The distribution of an unsteady aerodynamic load on the blade can be accurately predicted on the basis of any spatial position in the blade vibration process. It provides a new perspective for the analysis of blade nonlinear dynamics. The aerodynamic intelligent model based on the machine learning is worthy of further integration with fluid mechanics for evaluating the blade vibration stability.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| XGBoost | eXterme Gradient Boosting |

| CFD | Computation Fluid Dynamics |

| R2 | the Coefficient of Determination |

| RMSE | the Root Mean Square Error |

| POD | Proper Orthogonal Decomposition |

| DMD | Dynamic Mode Decomposition |

| DNN | Deep Neural Networks |

| DNS | Direct Numerical Simulation |

| CNN | Convolutional Neural Network |

| LSTM | Long Short-Term Memory network |

| ASA | Adaptive Simulated Annealing |

| RRBF | Recursive Radial Basis Function network |

| CART | Classification and Regression Trees |

| PS | Pressure Side |

| SS | Suction Side |

References

- Chao, D.; Wang, P. Numerical Calculation of Three-Dimensional Flow Field in Blade Row of Turbomachine. Therm. Power Eng. 1994, 9, 230–233. [Google Scholar]

- Zhang, Z.; Liu, X. Numerical Simulation of Unsteady Flow in Three-Dimensional Oscillating Cascades. In Proceedings of the 2009 Chinese Society of Engineering Thermophysics, Aerothermodynamics and Fluid Machinery Academic Conference, Dalian, China, 18–20 October 2009. [Google Scholar]

- Hu, Y.; Zhou, X. Numerical Analysis and Application of Unsteady Aerodynamic Forces in Vibrating Cascades. J. Appl. Mech. 2004, 21, 49–52. [Google Scholar]

- Chen, G.; Li, Y. Research Progress and Prospect of reduced-order Model of unsteady flow Field and its Application. Prog. Mech. 2011, 41, 686–701. [Google Scholar]

- Kou, J.; Zhang, W. Modal Analysis of Transonic Chattering based on POD and DMD. Chin. J. Aeronaut. 2016, 37, 2679–2689. [Google Scholar]

- Qiu, R.; Huang, R.; Wang, Y.; Huang, C. Dynamic Mode Mecomposition and Reconstruction of Transient Cavitating Flows around a Clark-Y Hydrofoil. Theor. Appl. Mech. Lett. 2020, 10, 327–332. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L. Dynamic Mode Decomposition of Cavitating Flow around ALE 15 Hydrofoil. Renew. Energy 2019, 139, 214–227. [Google Scholar] [CrossRef]

- Li, C.Y.; Tse, T.K.; Hu, G. Dynamic Mode Decomposition on Pressure Flow Field Analysis: Flow Field Reconstruction, Accuracy, and Practical Significance. J. Wind Eng. Ind. Aerodyn. 2020, 205, 104278. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Y.; Liu, H. Comparison of Modal Decomposition Methods for Unsteady Flow Separation in Compressor Cascades. J. Northwest. Polytech. Univ. 2020, 38, 121–129. [Google Scholar] [CrossRef]

- Cowan, T.; Arena, A.; Gupta, K. Accelerating Computational Fluid Dynamics Based Aeroelastic Predictions Using System Identification. J. Aircr. 2001, 38, 81–87. [Google Scholar] [CrossRef]

- Su, D.; Zhang, W.; Zhang, C.; Ye, Z. Unsteady Aerodynamic Modeling Method of Turbine Based on System Identification Technology. Aeronaut. J. 2012, 33, 242–248. [Google Scholar]

- Zhang, J.; Li, L.; Yuan, M. Aerodynamic Order Reduction Model Optimization of Airfoils Parameterized by Radial Basis Function. Appl. Math. Mech. J. 2019, 40, 250–258. [Google Scholar]

- Brunton, S.L.; Noack, B.R.; Koumoutsakos, P. Machine Learning for Fluid Mechanics. Annu. Rev. Fluid Mech. 2020, 52, 477–508. [Google Scholar] [CrossRef]

- Kutz, J.N. Deep Learning in Fluid Dynamics. J. Fluid Mech. 2017, 814, 1–4. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, X.; Ye, S. Application of Deep Learning Method to Reynolds Stress Models of Channel Flow Based on Reduced-Order Modeling of DNS Data. J. Hydrodyn. 2019, 31, 58–65. [Google Scholar] [CrossRef]

- Wang, Y.; Li, D.; Chen, G. A Reduced-Order Model of Aerodynamic Deep Learning Based on Flow Field Characteristics. In Proceedings of the 4th National Conference on Unsteady Aerodynamics, Hefei, China, 10–13 May 2018. [Google Scholar]

- Han, R.; Wang, Y.; Zhang, Y.; Chen, G. A Novel Spatial-Temporal Prediction Method for Unsteady Wake Flows Based on Hybrid Deep Neural Network. Phys. Fluids 2019, 31, 127101. [Google Scholar]

- Hasegawa, K.; Fukami, K.; Murata, T.; Fukagata, K. Machine-Learning-Based Reduced-Order Modeling for Unsteady Flows around Bluff Bodies of Various Shapes. Theor. Comput. Fluid Dyn. 2020, 1–17. [Google Scholar]

- Kou, J.; Zhang, W. Multi-Fidelity Modeling Framework for Nonlinear Unsteady Aerodynamics of Airfoils. Appl. Math. Model. 2019, 76, 832–855. [Google Scholar] [CrossRef]

- Hu, J.; Liu, H.; Wang, Y. Reduced Order Model for Unsteady Aerodynamic Performance of Compressor Cascade Based on Recursive RBF. Chin. J. Aeronaut. 2020, 8, 22. [Google Scholar] [CrossRef]

- Li, K.; Kou, J.; Zhang, W. Deep Neural Network for Unsteady Aerodynamic and Aeroelastic Modeling across Multiple Mach Numbers. Nonlinear Dyn. 2019, 96, 2157–2177. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference, San Francisco, CA, USA, 13–17 August 2016. [Google Scholar]

- Liu, Y.; Qiao, M. Prediction of Heart Disease Based on Clustering and XGboost Algorithm. Comput. Syst. Appl. 2019, 28, 228–232. [Google Scholar]

- Ye, Q.; Rao, H.; Ji, M. Commercial Sales Forecast Based on Xgboost. J. Nanchang Univ. Sci. Ed. 2017, 41, 275–281. [Google Scholar]

- Huang, Q.; Zheng, Y.; Deng, Y. Research on Traffic Forecast of Holiday Road Network based on XGBoost. Highway 2018, 63, 234–238. [Google Scholar]

- Ma, X.; Sha, J.; Wang, D.; Yu, Y.; Yang, Q.; Niu, X. Study on a Prediction of P2P Network Loan Default Based on the Machine Learning Light GBM and XGboost Algorithms According to Different High Dimensional Data Cleaning. Electron. Commer. Res. Appl. 2018, 31, 24–39. [Google Scholar] [CrossRef]

- Zhou, R.; Peng, H.; Li, X.; Yan, Y. Prediction Model of Credit Default Based on XGBoost Algorithm. Bond 2019, 10, 61–68. [Google Scholar]

- Wang, X.; Wang, L.; Wang, S.; Chen, J.; Wu, C. An XGBoost-Enhanced Fast Constructive Algorithm for Food Delivery Route Planning Problem. Comput. Ind. Eng. 2020, 152, 107029. [Google Scholar] [CrossRef]

- Shi, X.; Wong, Y.; Li, M.; Palanisamy, C.; Chai, C. A Feature Learning Approach Based on XGBoost for Driving Assessment and Risk Prediction. Accid. Anal. Prev. 2019, 129, 170–179. [Google Scholar] [CrossRef]

- Budholiya, K.; Shrivastava, S.; Sharma, V. An Optimized XGBoost Based Diagnostic System for Effective Prediction of Heart Disease. J. King Saud Univ. Comput. Inf. Sci. 2020, 10, 13. [Google Scholar] [CrossRef]

- Shen, C. XGBoost Principle and its Application. Comput. Prod. Circ. 2019, 3, 086. [Google Scholar]

- Zhang, D.; Gong, Y. Predictive Diagnosis of Acute Liver Failure by XGBoost Compared with Neural Network and Stochastic Forest Coupling Factor Analysis. Pract. Underst. Math. 2020, 13, 141–152. [Google Scholar]

- Dong, W.; Huang, Y.; Lehane, B.; Ma, G. XGBoost Algorithm-Based Prediction of Concrete Electrical Resistivity for Structural Health Monitoring. Autom. Constr. 2020, 114, 103155. [Google Scholar] [CrossRef]

- Zhang, M.; Hou, A. Investigation on the Flow Field Entropy Structure of Non-Synchronous Blade Vibration in an Axial Turbocompressor. Entropy 2020, 22, 1372. [Google Scholar] [CrossRef]

- Zhang, M.; Hou, A.; Zhou, S.; Yang, X. Analysis on Flutter Characteristics of Transonic Compressor Blade Row by a Fluid-Structure Coupled Method. In Proceedings of the ASME Turbo Expo 2012, Copenhagen, Denmark, 11–15 June 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012. [Google Scholar]

- Zhang, M.; Hou, A.; Li, J. Analysis of Blade Vibration Response Induced by Rotating Stall in Axial Compressor. J. Aerosp. Power 2012, 27, 2269–2277. [Google Scholar]

- Du, C. Study on Unsteady Aerodynamic Force of Vibratory Blade in Turbine. J. Appl. Mech. 1997, 14, 25–29. [Google Scholar]

| Max-Depth | Learning-Rate | n-Estimators | Objective |

|---|---|---|---|

| 40 | 0.35 | 60 | Reg:gamma |

| Max-Depth | Learning-Rate | n-Estimators | Objective |

|---|---|---|---|

| 19 | 0.1 | 160 | Reg:gamma |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Hao, S.; Hou, A. Study on the Intelligent Modeling of the Blade Aerodynamic Force in Compressors Based on Machine Learning. Mathematics 2021, 9, 476. https://doi.org/10.3390/math9050476

Zhang M, Hao S, Hou A. Study on the Intelligent Modeling of the Blade Aerodynamic Force in Compressors Based on Machine Learning. Mathematics. 2021; 9(5):476. https://doi.org/10.3390/math9050476

Chicago/Turabian StyleZhang, Mingming, Shurong Hao, and Anping Hou. 2021. "Study on the Intelligent Modeling of the Blade Aerodynamic Force in Compressors Based on Machine Learning" Mathematics 9, no. 5: 476. https://doi.org/10.3390/math9050476

APA StyleZhang, M., Hao, S., & Hou, A. (2021). Study on the Intelligent Modeling of the Blade Aerodynamic Force in Compressors Based on Machine Learning. Mathematics, 9(5), 476. https://doi.org/10.3390/math9050476