1. Introduction

Assembly is a crucial step to realizing the full functions of a product by constructing a complete structure, which becomes increasingly difficult with an increasing number of parts that make up the product [

1,

2,

3,

4,

5]. Digital modelling and virtual assembly have been widely studied to solve this problem [

6,

7,

8,

9]. Assembly planning is an integral part of virtual assembly [

10,

11,

12,

13], which primarily includes assembly sequence planning (ASP), assembly line balancing (ALB), and assembly path planning (APP) [

14,

15,

16,

17,

18,

19].

APP consumes considerable time when there is a significant number of parts. Thus, some methods have been researched to improve its efficiency [

20]. APP finds collision-free short paths from the initial location to the final position [

20,

21], which is similar to path planning for robots, vehicles, and drones, among other technologies [

22,

23,

24,

25,

26,

27]. Hassan et al. proposed a novel near-optimum APP algorithm based on the particle swarm optimization approach to solve the obstacle-free APP process in a 3D haptic-assisted environment [

28]. Wei et al. proposed a centroidal Voronoi tessellation (CVT) for the intelligent control of self-assembly path planning of swarm robots [

29]. Masehian et al. presented a new simple greedy heuristic method to solve the assembly sequence and path planning problem; the method tries to locally minimize geometric interference between parts being assembled along the main directions in each iteration, and it employs a sampling-based stochastic path planner to arrange short paths for parts while avoiding workspace obstacles [

20]. Morato et al. presented a technique that combines motion planning and part interaction clusters based on multiple rapidly exploring random trees to improve the generation of assembly precedence constraints [

30]. These studies are beneficial for improving the efficiency of path planning. However, most of the APP methods mentioned above involve a large amount of repeated computation, leading to low planning efficiency and high costs when generating the assembly path through all parts.

In these studies, the rapidly exploring random tree (RRT) is a typical random sampling algorithm in path planning which explores free space by generating leaf nodes randomly and uniformly to expand a tree structure. A collision-free path is obtained by backtracking from the leaf node to the parent node in sequence when a leaf node reaches the target area [

30,

31]. The randomness of the sampling points makes it difficult to obtain the optimal path even if the number of sampling points is sufficient. Therefore, the rapidly exploring random tree star (RRT*) algorithm is one algorithm that has been proposed to improve the RRT algorithm, making the path cost lower by improving the nearest point selection strategy [

23,

32]. However, the RRT* algorithm cannot obtain a low-cost assembly path in a short time, or even a valid assembly path, when the number of sampling points is small.

In assembly planning, the final positions of the assembled parts are in close proximity, although their initial positions are different. Hence, most of the assembly paths overlap or partially overlap, meaning that parts of these paths are repeatedly planned. Therefore, finding and reusing the planned paths is a feasible way to reduce repeated planning and improve planning efficiency [

33,

34]. The difference in initial part positions in the assembly presents a challenge for the direct reuse of the planned paths as a whole. Accordingly, the assembly paths must be segmented for effective reuse. Therefore, a hybrid path planning method based on the improved RRT* algorithm is proposed in this paper to plan the motion segments as paths with different starting points and the same target point by reusing the planned paths.

The rest of this paper is organized as follows. The establishment of the configuration space for path planning is introduced in

Section 2. In

Section 3, the static RRT* (S-RRT*) and dynamic RRT* (D-RRT*) algorithms are proposed, and the hybrid path planning method based on the improved RRT* algorithm is illustrated in detail. A case study is provided in

Section 4 to compare and analyze the RRT*, S-RRT*, and D-RRT* algorithms.

Section 5 concludes the paper.

2. Establishment of the Configuration Space for Path Planning

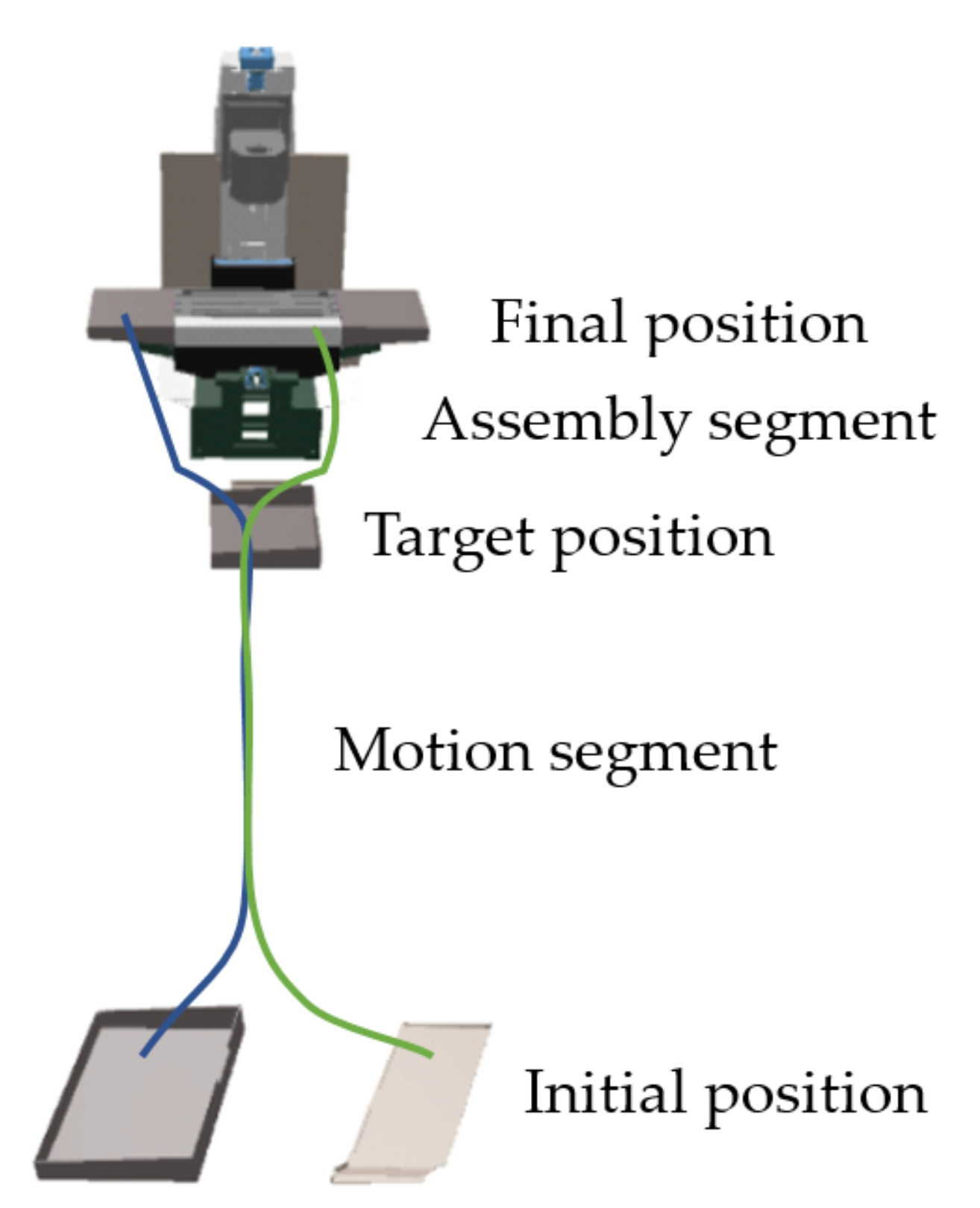

2.1. Segmentation of the Assembly Path

A position near the product assembly is defined as the target position. All the parts are moved from their initial positions to the target position and then assembled in the final positions. Therefore, an assembly path is divided into two segments: a motion segment from the initial position to the target position and an assembly segment from the target position to the final position, as shown in

Figure 1.

The motion segment is arranged by reusing the planned path, and the assembly segment is directly planned. Combining the planning results of the two segments reduces repeated planning of the same or similar paths and improves the success ratio.

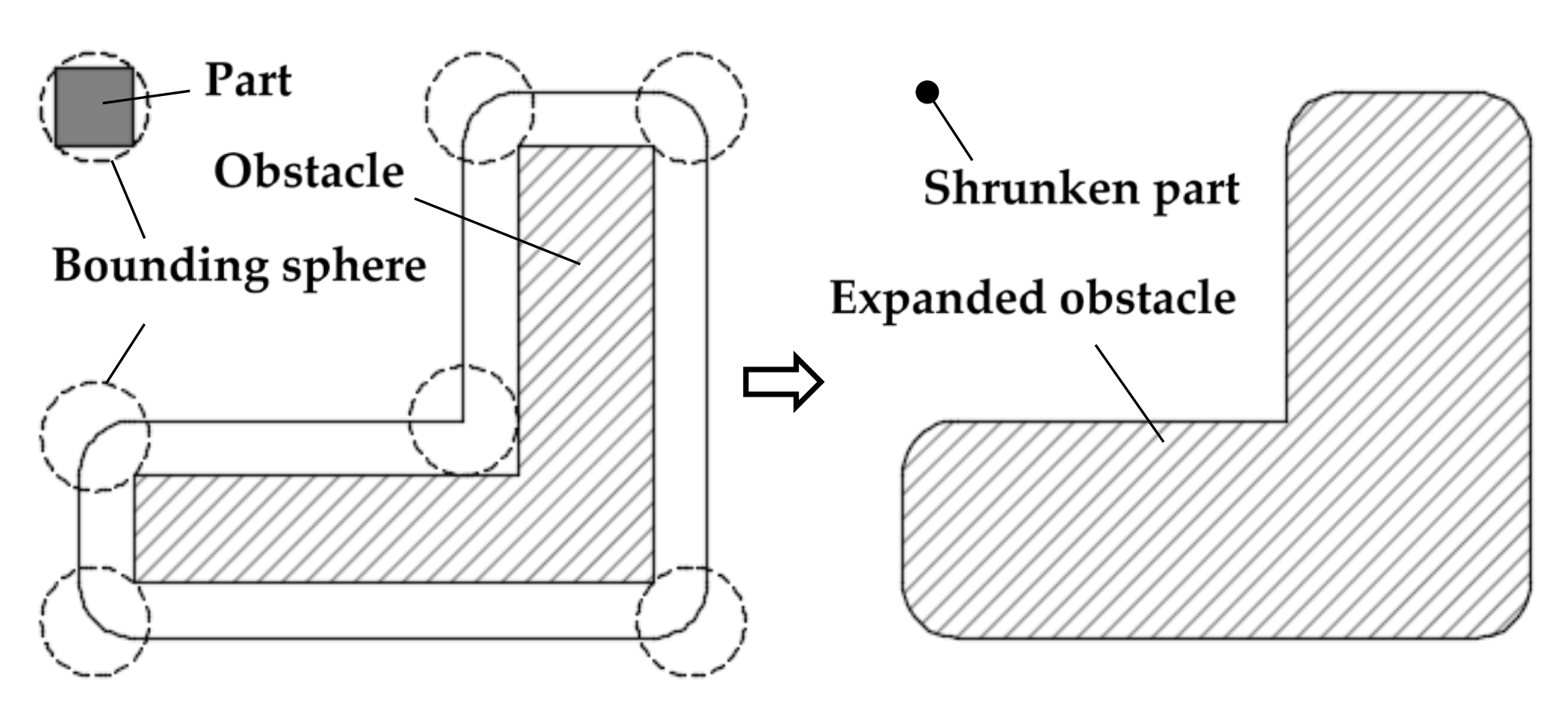

2.2. Part Shrinkage and Obstacle Expansion

There are many parts and obstacles in the assembly space of a complex product, which leads to high-complexity collision detection. Consequently, the assembly space is typically mapped to a configuration space for unified modelling before path planning. However, a substantial number of components with different shapes and sizes makes path planning a sizeable task if a new configuration space is created for each part. Therefore, the configuration space must be constructed reasonably and efficiently to support reusable path planning.

In path planning based on collision detection, a part is typically described with a bounding volume. The circumscribed sphere of a part is selected as its bounding sphere to simplify the description and calculation. In the equivalent transformation from the assembly space to the configuration space, the part shrinks according to the radius of its bounding sphere. All obstacle outlines are correspondingly expanded with the same radius (see

Figure 2). In this way, path planning for a part in the assembly space is transformed into finding a noninterference path in the configuration space.

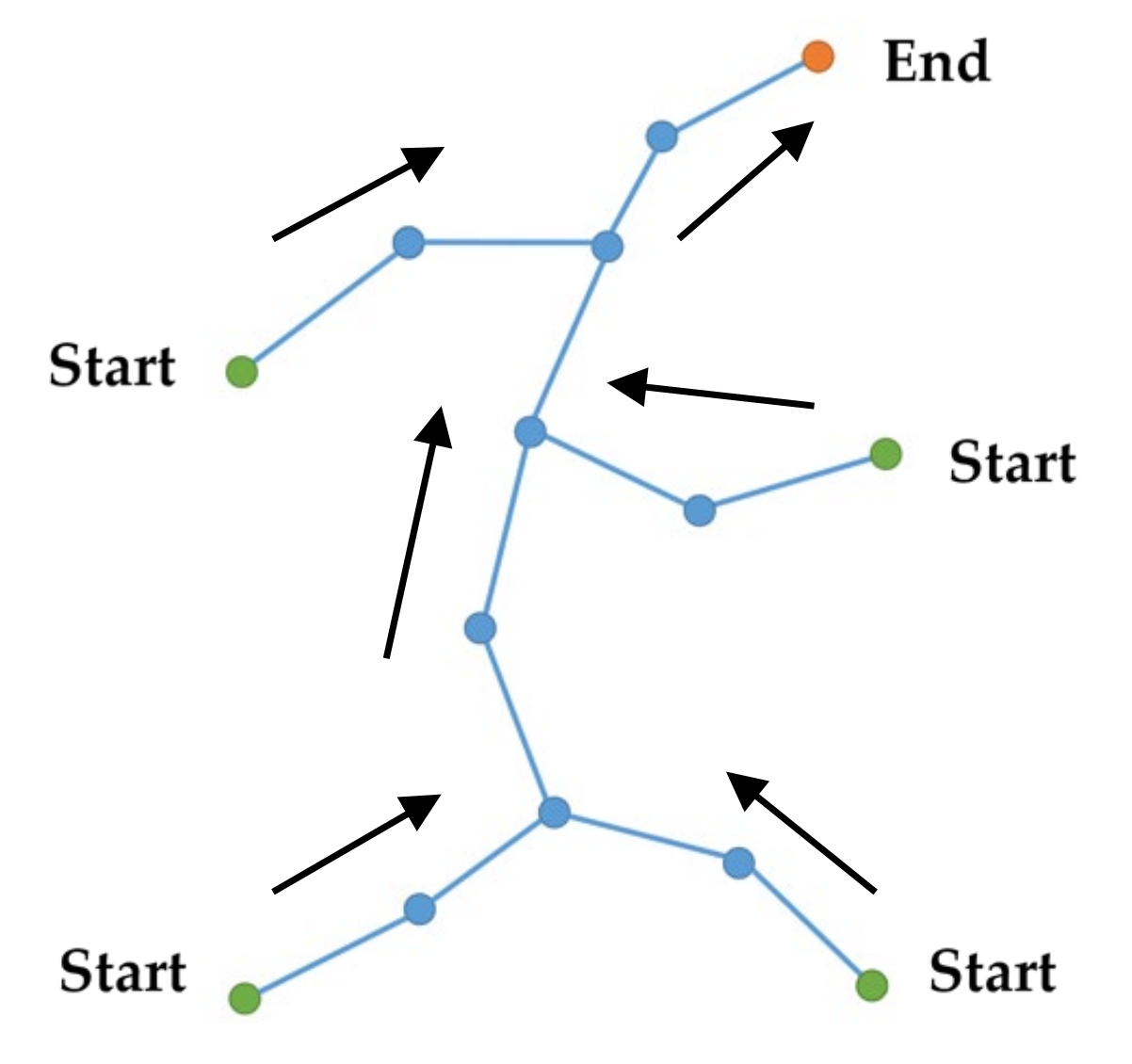

2.3. Establishment of the a Priori Path and a Priori Tree

An a priori path

Pprior is a planned assembly path for a part, which is expressed as a linked list as shown in Equation (1):

where each

pi is a node of the a priori path, and

p1 and

pn are the start and end nodes corresponding to the part’s initial position and target position, respectively.

A priori paths with different start nodes and the same end node form an a priori tree, where the leaf node is the start node of each path, the root node is the end node of all paths, and a branch from the leaf node to the root node is an a priori path, as shown in

Figure 3. The reuse of an a priori path can be transformed into the search for an appropriate node of the a priori tree.

A node on the a priori tree may belong to different paths, and the number of such paths reflects its “importance”, which is defined as the weight of the node. The weight increases as the number of paths increases. The weight

wi of node

pi is defined as

where

ni is the number of a priori paths crossing node

pi, and

n is the total number of a priori paths. As shown in Equation (2), when the number of a priori paths crossing node

pi becomes bigger, the weight of node

pi also becomes bigger, which means that node

pi becomes more “important” among all the a priori paths.

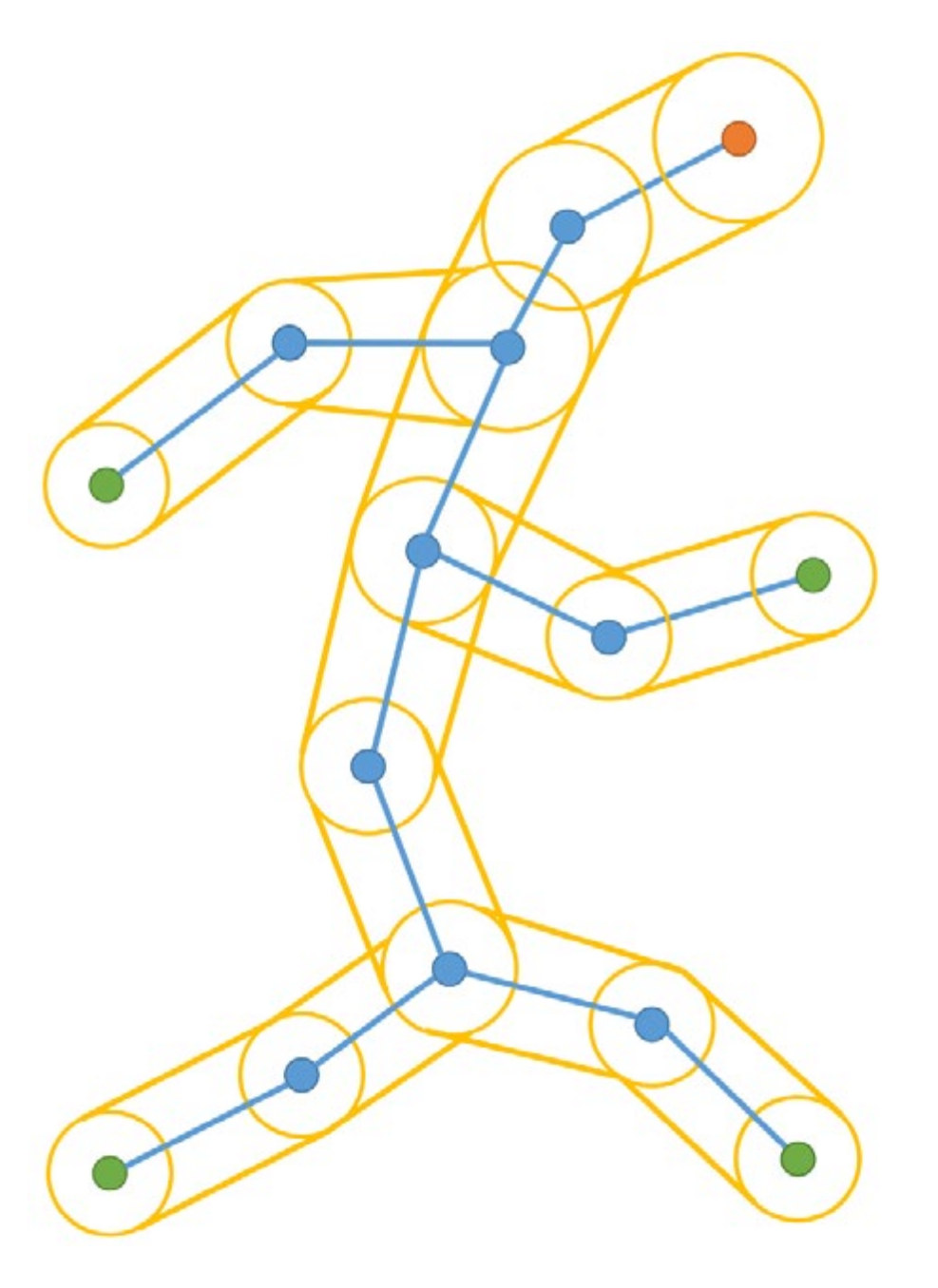

2.4. Expansion of the a Priori Space

The path planning algorithm based on random sampling extends the path by generating random points in the configuration space. If the a priori tree is only described using its nodes, the probability that the sampling points generated randomly coincide with the nodes is notably small, which makes finding and reusing the planned paths challenging. To solve this problem, the a priori tree is converted to an a priori space by expanding its nodes and branches, improving the reusability of the a priori paths.

Since the weight of a node expresses its “importance”, the expansion radius

ri of node

pi is positively related to its weight; that is,

where

d is the minimum distance between the nodes of the a priori path. According to Equation (3), when the weight of a node increases, this means that the number of a priori paths crossing node

pi increases, the radius of node

pi is greater, and the part of the a priori space of this node is larger.

Node

pi is expanded by constructing a circle with

pi as the center and

ri as the radius. External common tangents of every two adjacent circles are connected in turn.

Figure 4 displays the space composed of all circles and common external tangents, which is the a priori space expanded from the a priori tree.

3. Algorithms for Path Reuse

The RRT algorithm is widely used in path planning; it randomly generates sampling points in the configuration space based on a tree structure and explores the configuration space according to the given steps. In theory, any point in the configuration space can be reached through the nodes of the tree in a specific sequence. Therefore, the RRT algorithm was used as the basis of the algorithms studied in this paper.

It is difficult for the RRT algorithm to find the optimal path due to the randomness of the sampling points. As a result, the RRT* algorithm was proposed to lower the path cost by improving the nearest point selection strategy [

31] of the RRT algorithm. The basic process of the RRT* algorithm is consistent with that of the RRT algorithm, and the main improvement is the strategy of adding new nodes and branches to the exploration tree.

In the early stage of APP, the RRT* algorithm is adopted because there is no a priori path to be reused. The key steps of the RRT* algorithm are as follows:

- Step 1:

Point prand is randomly generated in the configuration space C.

- Step 2:

Node pnear closest to prand is selected from the exploration tree with a connecting line, and a point on this line with a distance s (extension step of the exploration tree) from pnear is subsequently taken as a new leaf node, pnew.

- Step 3:

The nearest node set psnear is constructed with the nodes of the exploration tree in a certain range centered on pnew.

- Step 4:

Node pmin is found as the parent of pnew by traversing psnear, through which pnew is connected to the exploration tree with the minimum path cost.

- Step 5:

pnew and pmin are added to the node set, and the branch connecting them is added to the branch set.

Compared to the RRT algorithm, it is similarly difficult for the RRT* algorithm to plan an assembly path with lower cost in a short time due to the excessive calculations.

- 2.

S-RRT* algorithm for static reuse of a priori paths

In the assembly of a new part, if there is an assembled part whose bounding sphere is not smaller than that of the new part, its configuration space can be utilized for path planning of the new part without any modification. Therefore, the path of the part can be directly reused as an a priori path to improve the planning efficiency. An S-RRT* algorithm (an improved RRT* algorithm statically reusing the a priori paths) is proposed in this case.

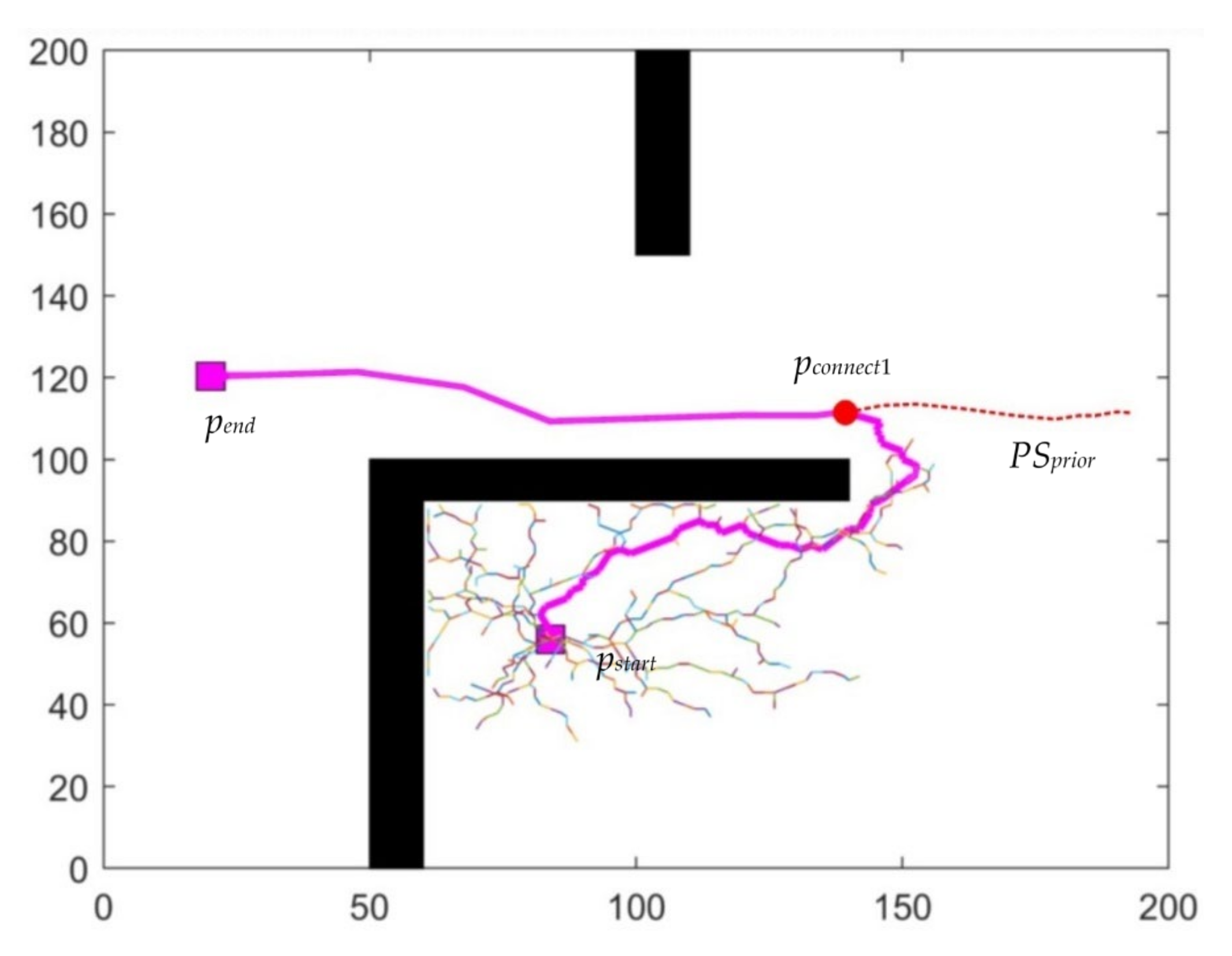

The main improvement of the S-RRT* algorithm is reusing the a priori paths after the exploration tree Texplore is extended to the a priori space Cprior. The S-RRT* algorithm aside from this reuse is consistent with the RRT* algorithm. The main steps of the S-RRT* algorithm are as follows:

- Step 1:

A new leaf node pnew is generated on the line that connects the random point prand and its nearest node pnear, with a distance of s (expansion step) from pnear.

- Step 2:

pnew is checked to confirm whether it is in the obstacle space Cobstacle. If so, the algorithm returns to Step 1; otherwise, the algorithm continues to the next step.

- Step 3:

pnew is checked to verify whether it is in Cprior. If so, the exploration tree has been extended to the a priori space, and the algorithm goes to the next step; otherwise, the algorithm returns to Step 1.

- Step 4:

Two nodes pconnect1 and pconnect2 are selected from the a priori tree Tprior and the exploration tree Texplore, respectively, according to pnew to connect the two trees.

- Step 5:

The new branch Enew connecting pconnect1 and pconnect2 is added to Texplore, and a new path pnew is planned by backtracking from the end node pend to the start node pstart and added to the a priori path set PSprior.

- Step 6:

After sampling N times, the cost of each new path in PSprior is calculated, and the path with the lowest cost Pmin is selected as the final path.

The pseudo-code of the S-RRT* algorithm is shown in Algorithm 1.

| Algorithm 1 The static rapidly exploring random tree star (S-RRT*) algorithm. |

| Input: Cplan, Cobstacle, Cprior, pstart, pend, S, N, Tprior, Texplore |

| Result: A path Pmin with the minimum cost from pstart to pend |

| Texplore.init (); |

| PSprior.init (); |

| for n = 1 to N do |

| { |

| prand←Sample (Cplan); |

| pnear←Near (prand, Texplore); |

| pnew←Steer (prand, pnear, S); |

| if CollisionFree(Cobstacle, pnew) then |

| { |

| Pnear←Near (xnew, Texplore); |

| pmin←SelectParentNode (Pnear, pnear, pnew); |

| Texplore.AddEdge (Edge (xmin, pnew)); |

| Texplore.Rewire(); |

| if InPriorSpace (Cprior, pnew) then |

| { |

| pconnect1, pconnect2←ConnectNode (Texplore, Tprior, pnew); |

| Enew.AddEdge (pconnect1, pconnect2); |

| pnew←PathBacktrack (Texplore, Tprior, pconnect1, pconnect2) |

| PSprior.AddPath (pnew); |

| } |

| } |

| } |

| Pmin←MinCostPath (PSprior); |

| return Pmin; |

A path planned using the S-RRT* algorithm is shown in

Figure 5. In this figure, a new assembly path is established, the part of the a priori path from

pconnect1 to

pend is reused, and the path from

pstart through

pconnect1 to

pend is the final path generated by the S-RRT* algorithm. Compared with the RRT* algorithm, the S-RRT* algorithm generates a path with fewer sampling times by reusing the a priori path, which helps to improve the efficiency and success ratio of APP for complex products.

- 3.

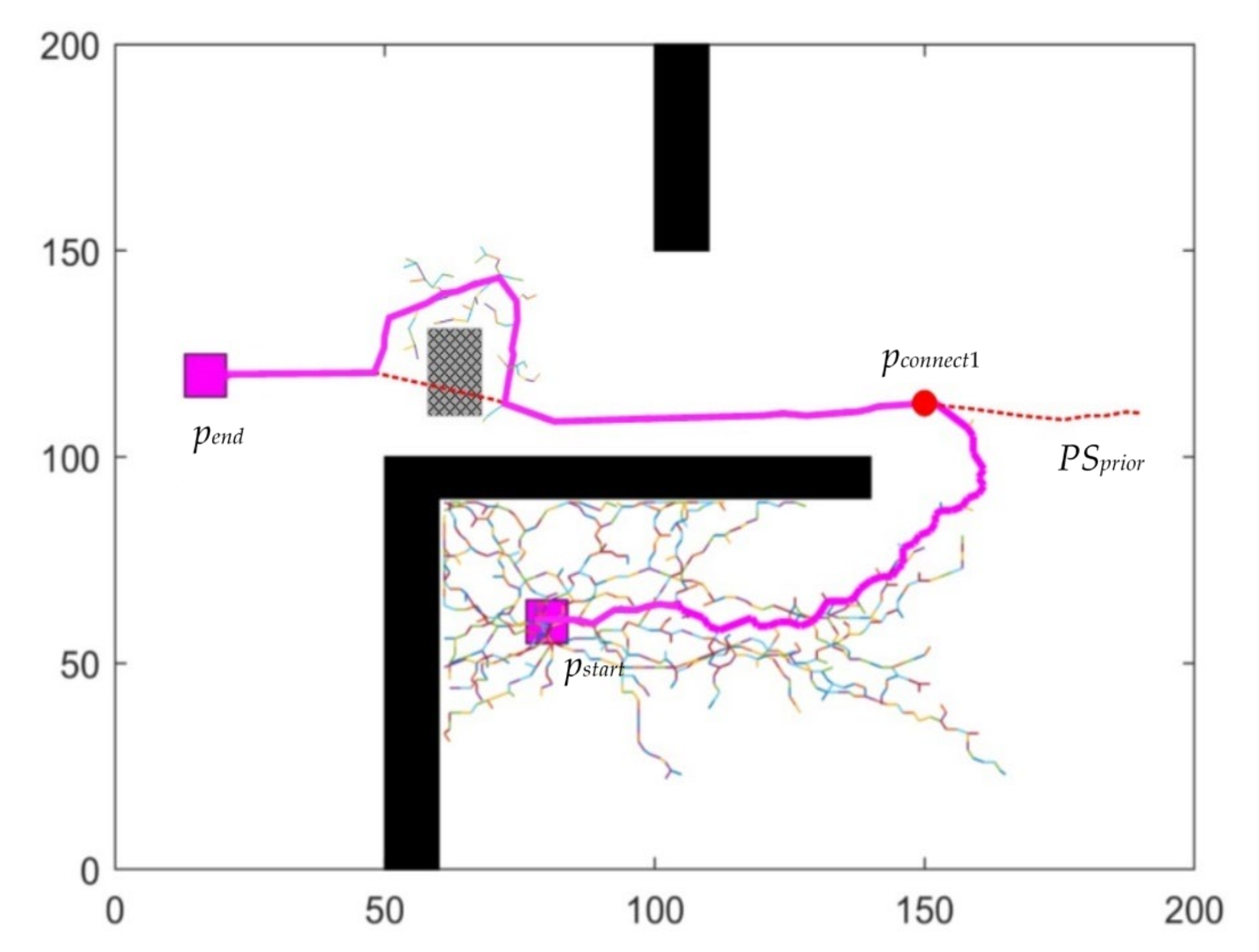

D-RRT* algorithm for dynamic reuse of a priori paths

When assembling a new part, if the bounding sphere of the assembled part is smaller than that of the new part, its configuration space cannot be used for path planning of the new part. This is because the expansion of the new part’s obstacles is more extensive than that of the assembled part. The more formidable obstacles may interfere with the a priori path and lead to the failure of path planning using the S-RRT* algorithm. Therefore, a D-RRT* algorithm (an improved RRT* algorithm dynamically reusing the a priori path) is proposed to solve this problem. The main improvement of the D-RRT* algorithm is the utilization of the dynamic window approach [

32] and further extension of the exploration tree to avoid interference between the a priori path and the obstacles after the connection node pair is found. The a priori path is reused non-continuously through dynamic backtracking to obtain the new path. The main steps of the dynamic backtracking of the a priori path are as follows:

- Step 1:

Two connection nodes pconnect1 and pconnect2 are selected from the a priori tree Tprior and the exploration tree Texplore, respectively, as for the S-RRT* algorithm.

- Step 2:

pconnect1 and its parent node pparent are connected with a line to check whether the line interferes with obstacles. If there is no interference, pparent is added to the new path, and the algorithm goes to Step 4; otherwise, the algorithm proceeds to Step 3.

- Step 3:

The local path from pconnect1 to pparent is planned and added to the new path.

- Step 4:

pconnect1 and pparent are updated with pparent and its parent node, respectively, which expands the exploration tree along the a priori path.

- Step 5:

pconnect2 is checked to determine whether it is the end node. If the end node is identified, a new path Pnew is planned by backtracking from the end node pend to the start node pstart; otherwise, the algorithm returns to Step 2.

The pseudo-code of the dynamic backtracking of the a priori path is shown in Algorithm 2.

| Algorithm 2 Dynamic backtracking of the a priori path. |

| Input: Tprior, Texplore, pconnect1, pconnect2, Cobstacle, S |

| Result: A path Pnew without collision from pconnect1 to pconnect2 |

| DynamicBacktracking(Tprior, Texplore, pconnect1, pconnect2, Cobstacle, S) { |

| pcurrent←pconnect1; |

| pparent←pcurrent.parentNodeInPriorTree (); |

| for j = 1 to N do { |

| if CollisionFree (Creusable, Cobstacle, pcurrent, pparent) then{ |

| Pprior.addNode (pcurrent, pparent); |

| Pprior.addEdge (Edge (pcurrent, pparent)); |

| } |

| else{ |

| Plocal←LocalPath (pcurrent, pparent); |

| Pprior←addLocalPath (Plocal); |

| } |

| pcurrent←pparent; |

| pparent←pparent. parentNodeInPriorTree (); |

| if pparent = pconnect2 then { |

| return Pprior; |

| } |

| } |

| } |

A path planned using the D-RRT* algorithm is shown in

Figure 6. There is an obstacle in

Figure 6 that did not appear in

Figure 5, which occurs in the part of the a priori path from

pconnect1 to

pend, and the D-RRT* algorithm can establish new assembly paths in this situation. Thus, a new assembly path was generated by D-RRT* from

pstart through

pconnect1 to

pend. The D-RRT* algorithm avoids obstacles by using dynamic backtracking and local path planning, which helps efficiently obtain an optimal assembly path without additional interference.

- 4.

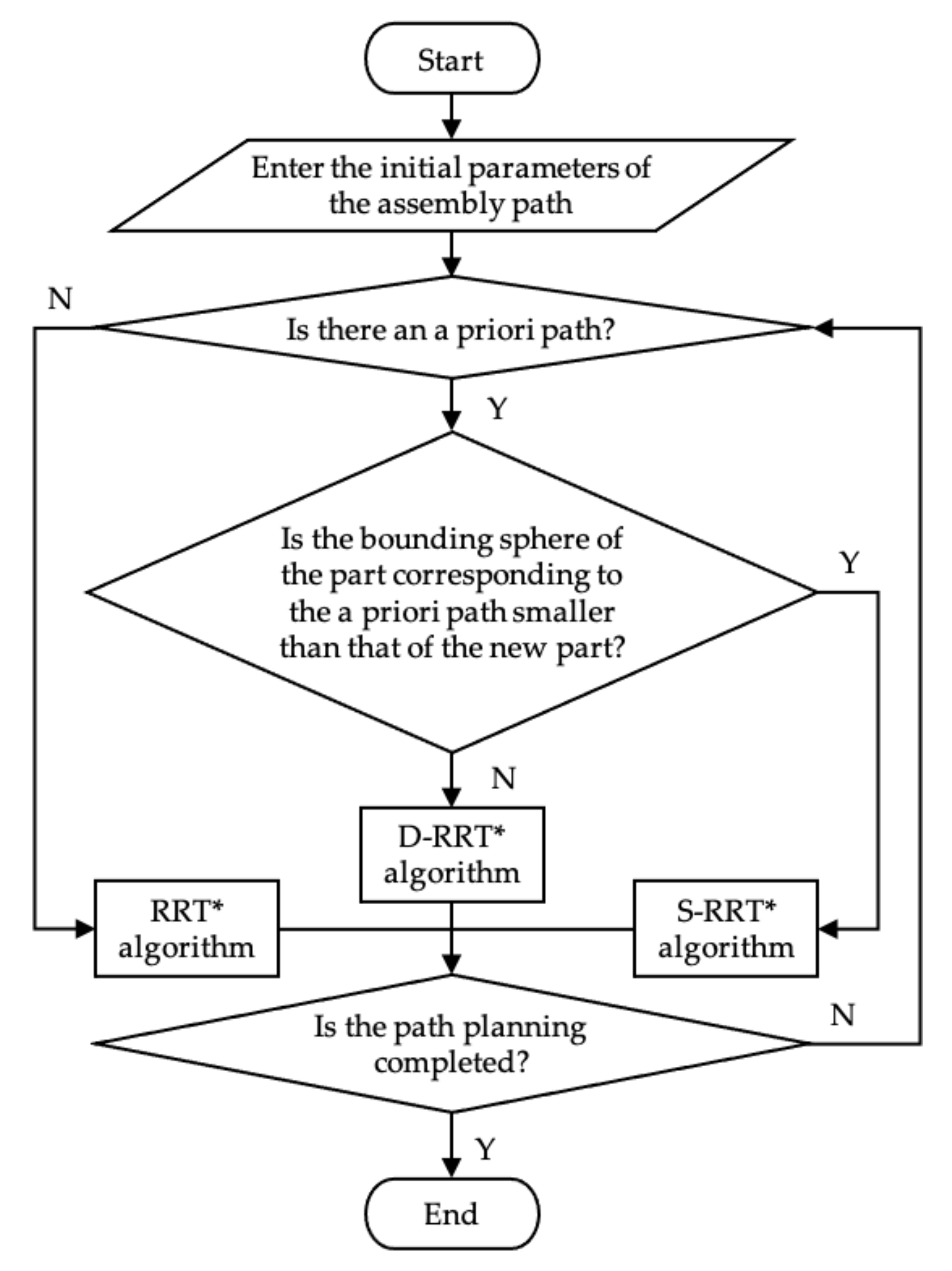

Hybrid process of the three algorithms

Using the three abovementioned algorithms, a hybrid process based on a priori path reuse was designed for assembly path planning, as presented in

Figure 7.

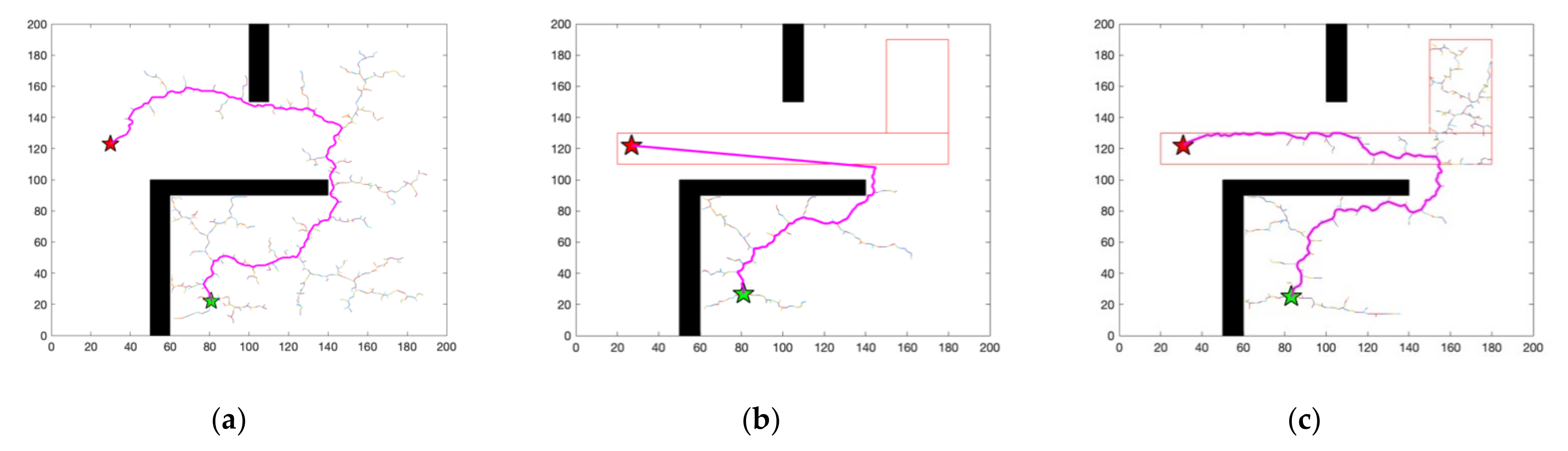

4. Comparison and Analysis

To analyze the performance of the RRT*, S-RRT*, and D-RRT* algorithms in the same case, a comparison is provided in this section. D-RRT* can also be applied in a situation in which there is no obstacle in the prior path, since it is an algorithm based on S-RRT* which can establish new path plans in the presence of obstacles, illustrated in detail in

Section 3. Thus, a suitable case must be prepared to test the performance and make comparisons for the three algorithms. Assuming some a priori paths in the configuration space, the three algorithms mentioned above were used to plan the assembly path from the same starting point to the same endpoint, and one of the results is shown in

Figure 8. Information relating to

Figure 8 is presented in

Table 1.

The randomness of sampling points in the three algorithms leads to large differences in the results of path planning, even with the same start and end points. Therefore, each algorithm was executed 100 times, and the averages of the minimum number of sampling points, the path length, and the running time of the three algorithms were compared, as illustrated in

Table 2.

Table 2 demonstrates that the minimum numbers of sampling points for the S-RRT* algorithm and the D-RRT* algorithm were only 1/4 and 1/3 that for the RRT* algorithm, respectively, and their path length and running time were also less than those of the RRT* algorithm. The performance of the D-RRT* algorithm means that it is not as useful as the S-RRT* algorithm due to the additional sampling strategy.

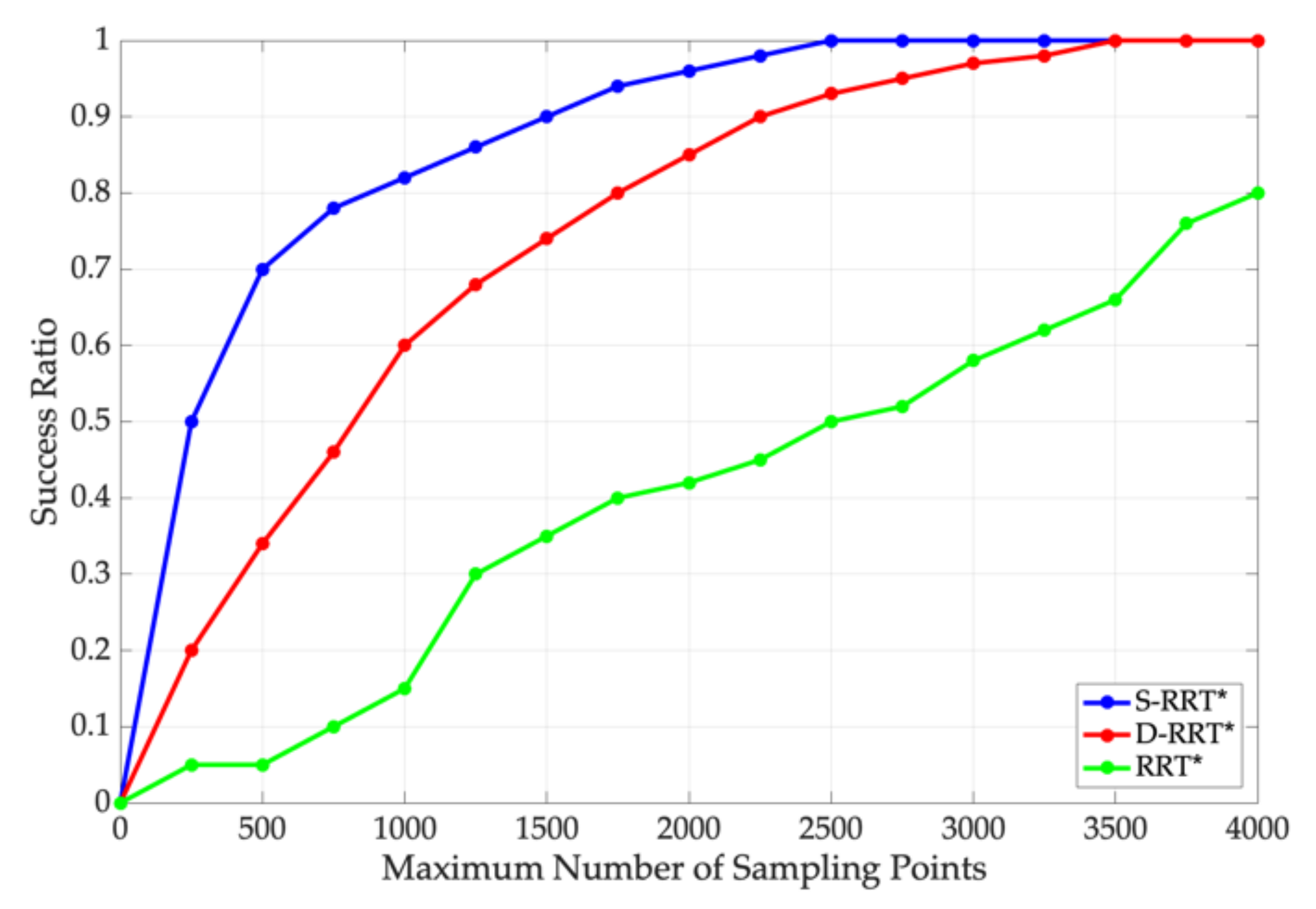

Considering that the start position of each part of a complex product is different in the assembly space, 50 starting points were randomly generated in the configuration space for the path planning simulation. The RRT*, S-RRT*, and D-RRT* algorithms were used to plan the assembly path for each starting point with different maximum numbers of sampling points. The number of successfully planned paths was used to calculate the path planning success ratio for multiple starting positions with the specified maximum number of sampling points, as shown in

Table 3.

Table 3 confirms that as the maximum number of sampling points increased, the success ratios of the three algorithms also increased. When the maximum number of sampling points was small, the success ratios of the S-RRT* algorithm and the D-RRT* algorithm were considerably greater than those of the RRT* algorithm. The success ratios of these three algorithms are also shown in

Figure 9.

The minimum numbers of sampling points and the total running times of the three algorithms are specified in

Table 4 for the aforementioned path plans.

Table 4 shows that the minimum numbers of sampling points and the total running times of the S-RRT* and D-RRT* algorithms in APP for batch parts are much smaller than those of the RRT* algorithm.

Thus, the results of the figures and tables above can explain the advantages and disadvantages of RRT*, S-RRT*, and D-RRT*. The RRT* algorithm is employed to establish an assembly path without any a priori data, which requires many more sampling points and much more computing time than S-RRT* and D-RRT*. The S-RRT* algorithm is the fastest and the most efficient when compared to RRT* and D-RRT*, but it strictly demands a priori paths and stability in the sizes of new parts. The D-RRT* algorithm can establish assembly paths when there are new obstacles interfering with the a priori paths. However, D-RRT* still needs more sampling data and calculating time than S-RRT*, and a priori paths are required as well.

5. Conclusions

APP for complex products is tedious and repetitive work. A hybrid planning method that reuses a priori paths was proposed in this paper to improve the efficiency and success ratio of path planning. In this method, the assembly path is divided into motion segments and assembly segments to improve the reusability of the path, and the feasibility of the motion segment is analyzed. An a priori path set is established according to the planned assembly paths; on this basis, an a priori tree is established. An a priori space is created by expanding the a priori tree according to the bounding sphere of the part to be assembled, which establishes a foundation for path reuse.

Three algorithms improving upon the RRT algorithm were examined for path planning based on a priori path reuse. The RRT* algorithm establishes the exploration tree of the new path in the early planning stage when there is no a priori path to reuse. The S-RRT* and D-RRT* algorithms are utilized after the exploration tree of the new path is extended to the a priori space according to a comparison of bounding spheres between the part to be assembled and the part corresponding to the a priori path. If the former’s bounding sphere is not greater than the latter’s, the S-RRT* algorithm finds a pair of connection points to establish a connection between the exploration tree and the a priori tree and obtain a new path through direct backtracking from the endpoint to the starting point. Otherwise, the D-RRT* algorithm extends the exploration tree via the dynamic window approach after finding the connection point pair to avoid interference between the a priori path and the obstacles, and a new path is obtained through dynamic and non-continuous backtracking.

The RRT*, S-RRT*, and D-RRT* algorithms were compared in terms of their minimum number of sampling points, path length, and running time in single-start assembly path planning. The success ratio, minimum number of sampling points, and running time in multistart assembly path planning were also compared. The results show that the S-RRT* and D-RRT* algorithms are significantly better than the RRT* algorithm due to the reuse of the a priori paths. Therefore, hybrid path planning combining the three algorithms is helpful to improving the efficiency and success ratio of the assembly path planning of complex products.

Author Contributions

Methodology, G.Y. and Y.C.; investigation, G.Y. and H.H.; software and validation, C.Z. and H.H.; writing—original draft preparation, C.Z. and H.H.; writing—review and editing, G.Y. and Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China, grant number 2018YFB1701300, the National Natural Science Foundation of China, grant number 51875515, the Key Research and Development Program of Zhejiang Province, grant number 2020C0409, and the Science and Technology Project of Beijing, grant number Z191100001419014.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Demoly, F.; Yan, X.-T.; Eynard, B.; Rivest, L.; Gomes, S. An assembly oriented design framework for product structure engineering and assembly sequence planning. Robot. Comput. -Integr. Manuf. 2011, 27, 33–46. [Google Scholar] [CrossRef]

- Demoly, F.; Toussaint, L.; Eynard, B.; Kiritsis, D.; Gomes, S. Geometric skeleton computation enabling concurrent product engineering and assembly sequence planning. Comput. -Aided Des. 2011, 43, 1654–1673. [Google Scholar] [CrossRef]

- Tsutsumi, D.; Gyulai, D.; Kovács, A.; Tipary, B.; Ueno, Y.; Nonaka, Y.; Fujita, K. Joint optimization of product tolerance design, process plan, and production plan in high-precision multi-product assembly. J. Manuf. Syst. 2020, 54, 336–347. [Google Scholar] [CrossRef]

- Wallis, R.; Erohin, O.; Klinkenberg, R.; Deuse, J.; Stromberger, F. Data Mining-supported Generation of Assembly Process Plans. Procedia CIRP 2014, 23, 178–183. [Google Scholar] [CrossRef]

- Matei, O.; Contraş, D.; Pop, P.; Vǎlean, H. Design and comparison of two evolutionary approaches for automated product design. Soft Comput. 2016, 20, 4257–4269. [Google Scholar] [CrossRef]

- Sierla, S.; Kyrki, V.; Aarnio, P.; Vyatkin, V. Automatic assembly planning based on digital product descriptions. Comput. Ind. 2018, 97, 34–46. [Google Scholar] [CrossRef]

- Yang, Q.; Wu, D.L.; Zhu, H.M.; Bao, J.S.; Wei, Z.H. Assembly operation process planning by mapping a virtual assembly simulation to real operation. Comput. Ind. 2013, 64, 869–879. [Google Scholar] [CrossRef]

- Qiu, C.; Zhou, S.; Liu, Z.; Gao, Q.; Tan, J. Digital assembly technology based on augmented reality and digital twins: A review. Virtual Real. Intell. Hardw. 2019, 1, 597–610. [Google Scholar] [CrossRef]

- Yoon, J. Assembly simulations in virtual environments with optimized haptic path and sequence. Robot. Comput. -Integr. Manuf. 2011, 27, 306–317. [Google Scholar] [CrossRef]

- Li, T.; Lockett, H.; Lawson, C. Using requirement-functional-logical-physical models to support early assembly process planning for complex aircraft systems integration. J. Manuf. Syst. 2020, 54, 242–257. [Google Scholar] [CrossRef]

- Hui, W.; Dong, X.; Guanghong, D.; Linxuan, Z. Assembly planning based on semantic modeling approach. Comput. Ind. 2007, 58, 227–239. [Google Scholar] [CrossRef]

- Kardos, C.; Váncza, J. Application of Generic CAD Models for Supporting Feature Based Assembly Process Planning. Procedia CIRP 2018, 67, 446–451. [Google Scholar] [CrossRef]

- Gruhier, E.; Demoly, F.; Gomes, S. A spatiotemporal information management framework for product design and assembly process planning reconciliation. Comput. Ind. 2017, 90, 17–41. [Google Scholar] [CrossRef]

- Ghandi, S.; Masehian, E. Review and taxonomies of assembly and disassembly path planning problems and approaches. Comput. -Aided Des. 2015, 67–68, 58–86. [Google Scholar] [CrossRef]

- Chen, W.-C.; Hsu, Y.-Y.; Hsieh, L.-F.; Tai, P.-H. A systematic optimization approach for assembly sequence planning using Taguchi method, DOE, and BPNN. Expert Syst. Appl. 2010, 37, 716–726. [Google Scholar] [CrossRef]

- Kardos, C.; Kovacs, A.; Vancza, J. A constraint model for assembly planning. J. Manuf. Syst. 2020, 54, 196–203. [Google Scholar] [CrossRef]

- Ghandi, S.; Masehian, E. A breakout local search (BLS) method for solving the assembly sequence planning problem. Eng. Appl. Artif. Intell. 2015, 39, 245–266. [Google Scholar] [CrossRef]

- Wang, H.; Rong, Y.; Xiang, D. Mechanical assembly planning using ant colony optimization. Comput. -Aided Des. 2014, 47, 59–71. [Google Scholar] [CrossRef]

- Chen, R.-S.; Lu, K.-Y.; Tai, P.-H. Optimizing assembly planning through a three-stage integrated approach. Int. J. Prod. Econ. 2004, 88, 243–256. [Google Scholar] [CrossRef]

- Masehian, E.; Ghandi, S. ASPPR: A New Assembly Sequence and Path Planner/Replanner for Monotone and Nonmonotone Assembly Planning. Comput. -Aided Des. 2020, 123, 102828. [Google Scholar] [CrossRef]

- Ladeveze, N.; Fourquet, J.-Y.; Puel, B. Interactive path planning for haptic assistance in assembly tasks. Comput. Graph. 2010, 34, 17–25. [Google Scholar] [CrossRef]

- Yuan, C.; Liu, G.; Zhang, W.; Pan, X. An efficient RRT cache method in dynamic environments for path planning. Robot. Auton. Syst. 2020, 131, 103595. [Google Scholar] [CrossRef]

- Li, Y.; Wei, W.; Gao, Y.; Wang, D.; Fan, Z. PQ-RRT*: An improved path planning algorithm for mobile robots. Expert Syst. Appl. 2020, 152, 113425. [Google Scholar] [CrossRef]

- Zhong, M.; Yang, Y.; Dessouky, Y.; Postolache, O. Multi-AGV scheduling for conflict-free path planning in automated container terminals. Comput. Ind. Eng. 2020, 142, 106371. [Google Scholar] [CrossRef]

- Fransen, K.J.C.; van Eekelen, J.A.W.M.; Pogromsky, A.; Boon, M.A.A.; Adan, I.J.B.F. A dynamic path planning approach for dense, large, grid-based automated guided vehicle systems. Comput. Oper. Res. 2020, 123, 105046. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, S.; Sutton, R.; Hatton, D.; Khan, A. A constrained A* approach towards optimal path planning for an unmanned surface vehicle in a maritime environment containing dynamic obstacles and ocean currents. Ocean Eng. 2018, 169, 187–201. [Google Scholar] [CrossRef]

- Zhao, Y.; Zheng, Z.; Liu, Y. Survey on computational-intelligence-based UAV path planning. Knowl. -Based Syst. 2018, 158, 54–64. [Google Scholar] [CrossRef]

- Hassan, S.; Yoon, J. Haptic assisted aircraft optimal assembly path planning scheme based on swarming and artificial potential field approach. Adv. Eng. Softw. 2014, 69, 18–25. [Google Scholar] [CrossRef]

- Wei, H.X.; Mao, Q.; Guan, Y.; Li, Y.D. A centroidal Voronoi tessellation based intelligent control algorithm for the self-assembly path planning of swarm robots. Expert Syst. Appl. 2017, 85, 261–269. [Google Scholar] [CrossRef]

- Morato, C.; Kaipa, K.N.; Gupta, S.K. Improving assembly precedence constraint generation by utilizing motion planning and part interaction clusters. Comput. -Aided Des. 2013, 45, 1349–1364. [Google Scholar] [CrossRef]

- Wang, W.; Deng, H.; Wu, X. Path planning of loaded pin-jointed bar mechanisms using Rapidly-exploring Random Tree method. Comput. Struct. 2018, 209, 65–73. [Google Scholar] [CrossRef]

- Chao, N.; Liu, Y.-K.; Xia, H.; Peng, M.-J.; Ayodeji, A. DL-RRT* algorithm for least dose path Re-planning in dynamic radioactive environments. Nucl. Eng. Technol. 2019, 51, 825–836. [Google Scholar] [CrossRef]

- Yan, Y.; Poirson, E.; Bennis, F. An interactive motion planning framework that can learn from experience. Comput. -Aided Des. 2015, 59, 23–38. [Google Scholar] [CrossRef]

- Gaisbauer, F.; Lehwald, J.; Agethen, P.; Otto, M.; Rukzio, E. A Motion Reuse Framework for Accelerated Simulation of Manual Assembly Processes. Procedia CIRP 2018, 72, 398–403. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).