Numerical Approach for Detecting the Resonance Effects of Drilling during Assembly of Aircraft Structures †

Abstract

:1. Introduction

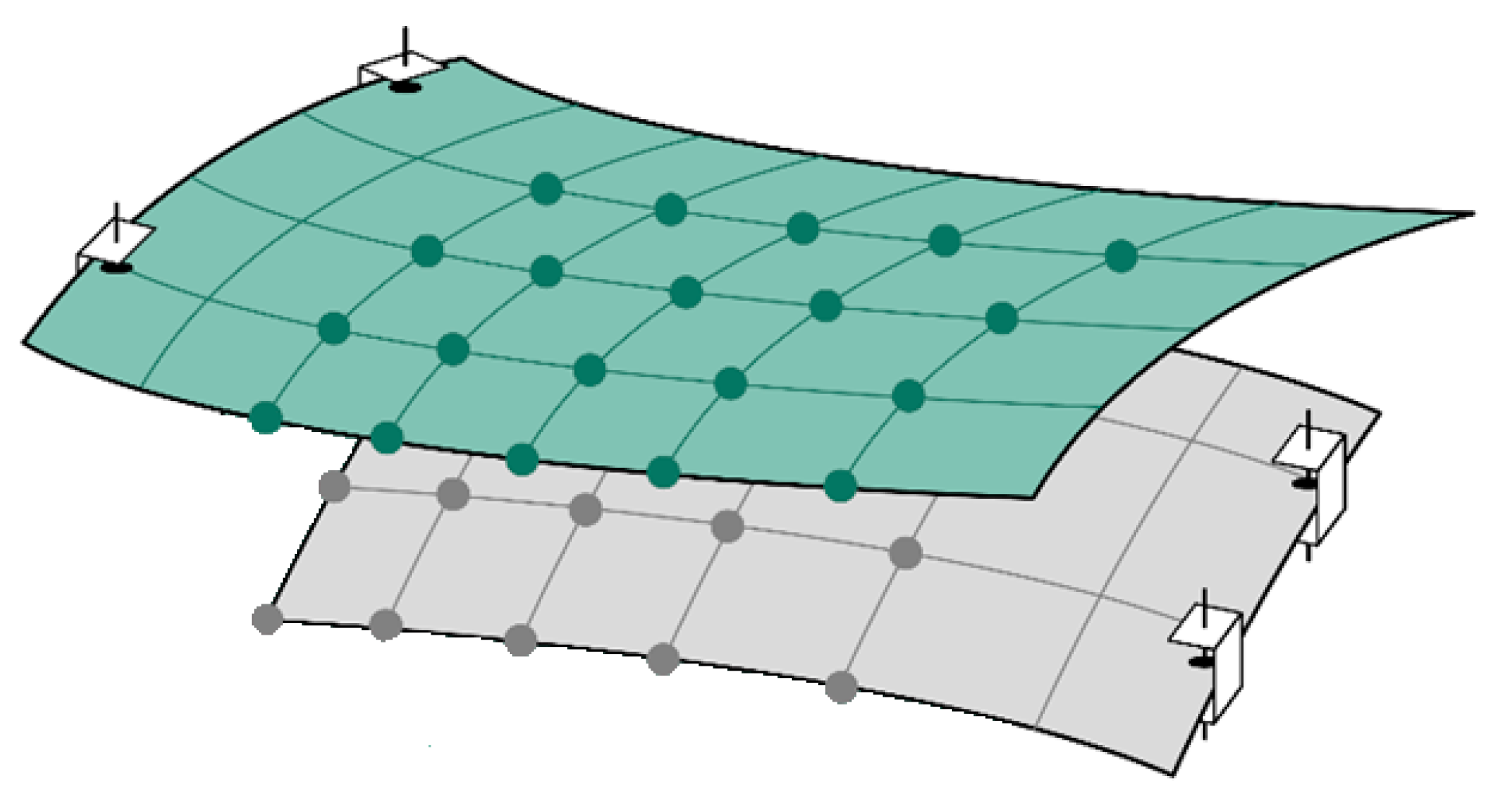

2. Numerical Approach

2.1. Guyan Reduction

2.2. Time Discretization Algorithm

2.3. Basic Assumptions of the Numerical Algorithm

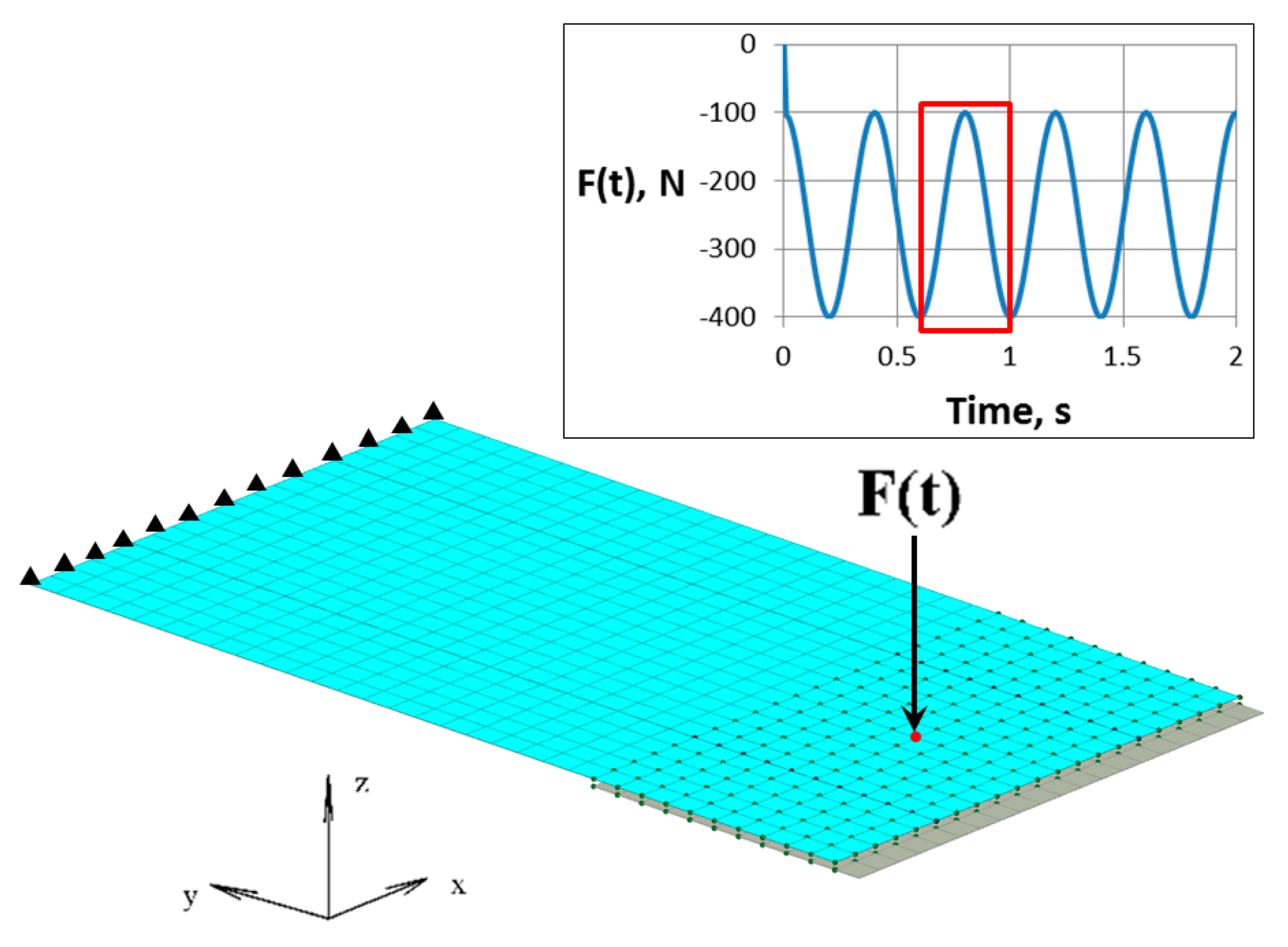

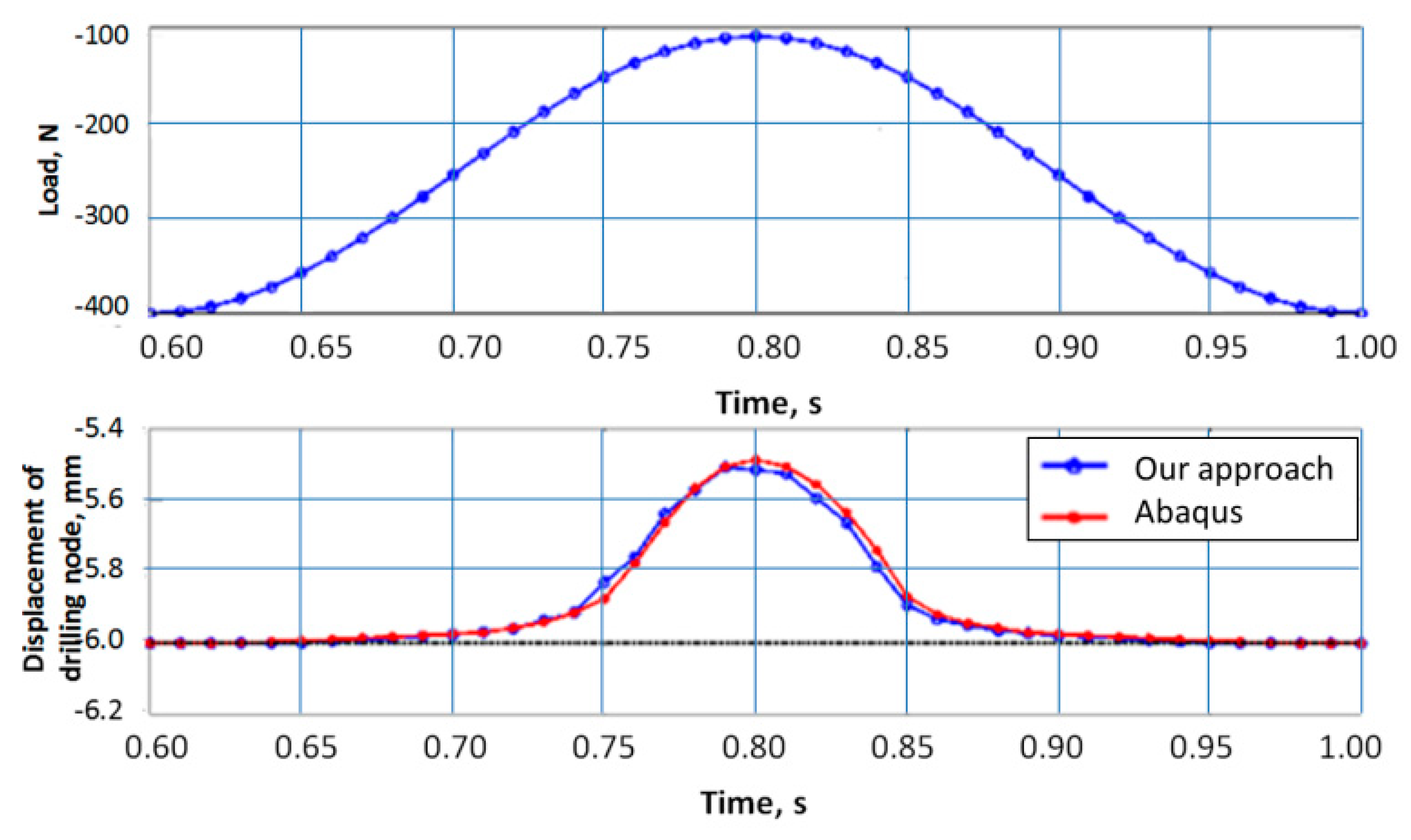

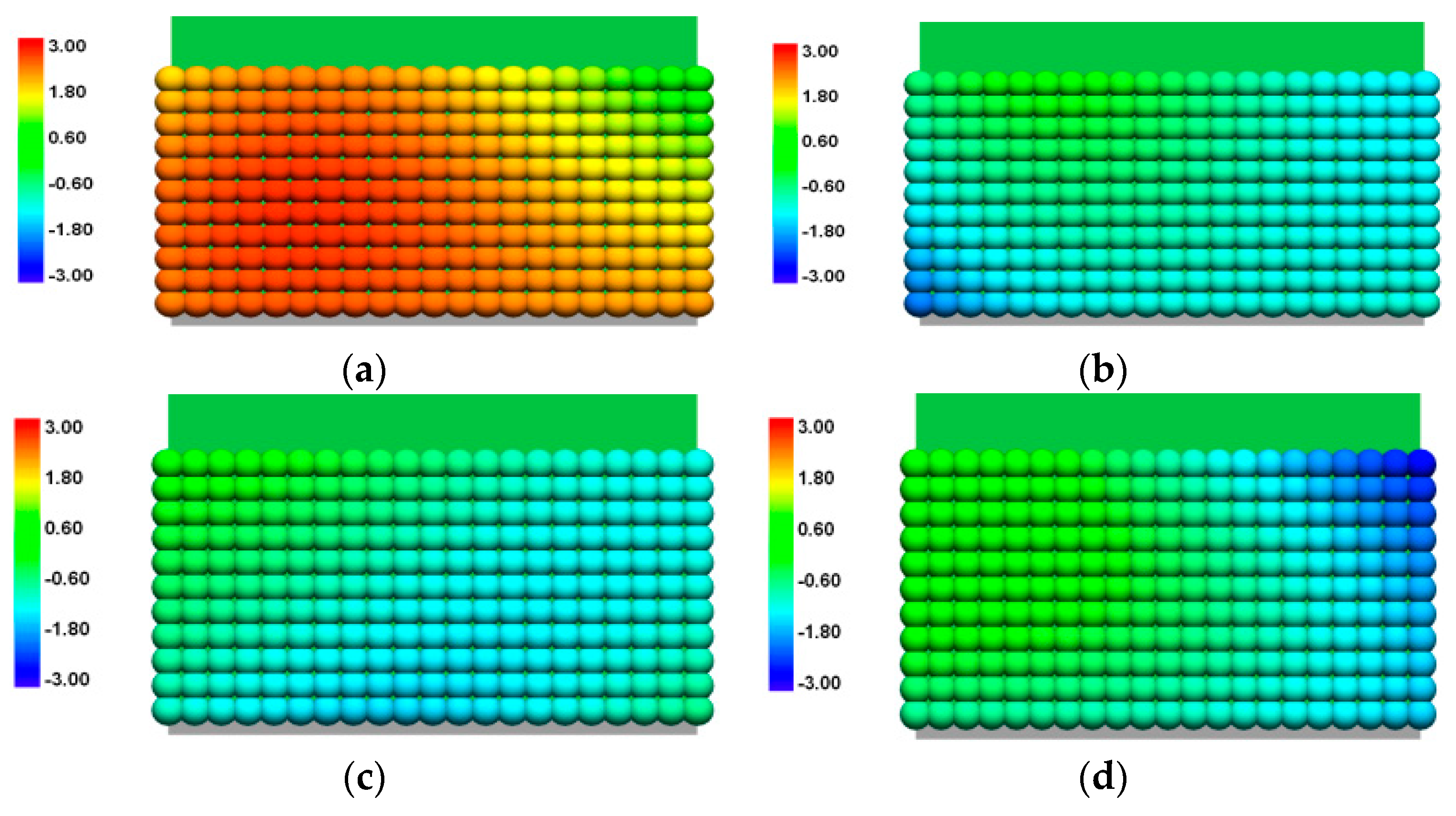

3. Verification with Abaqus

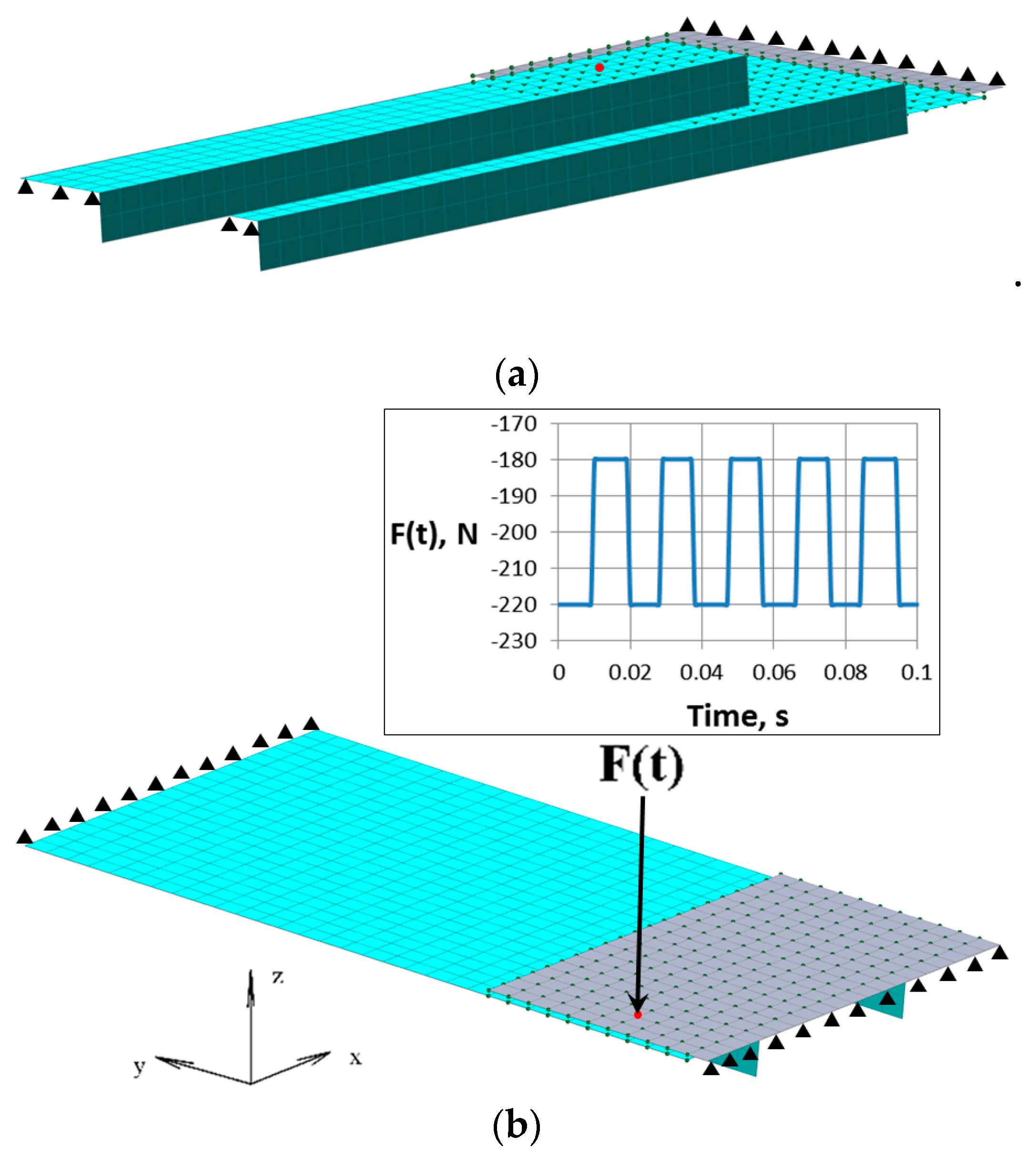

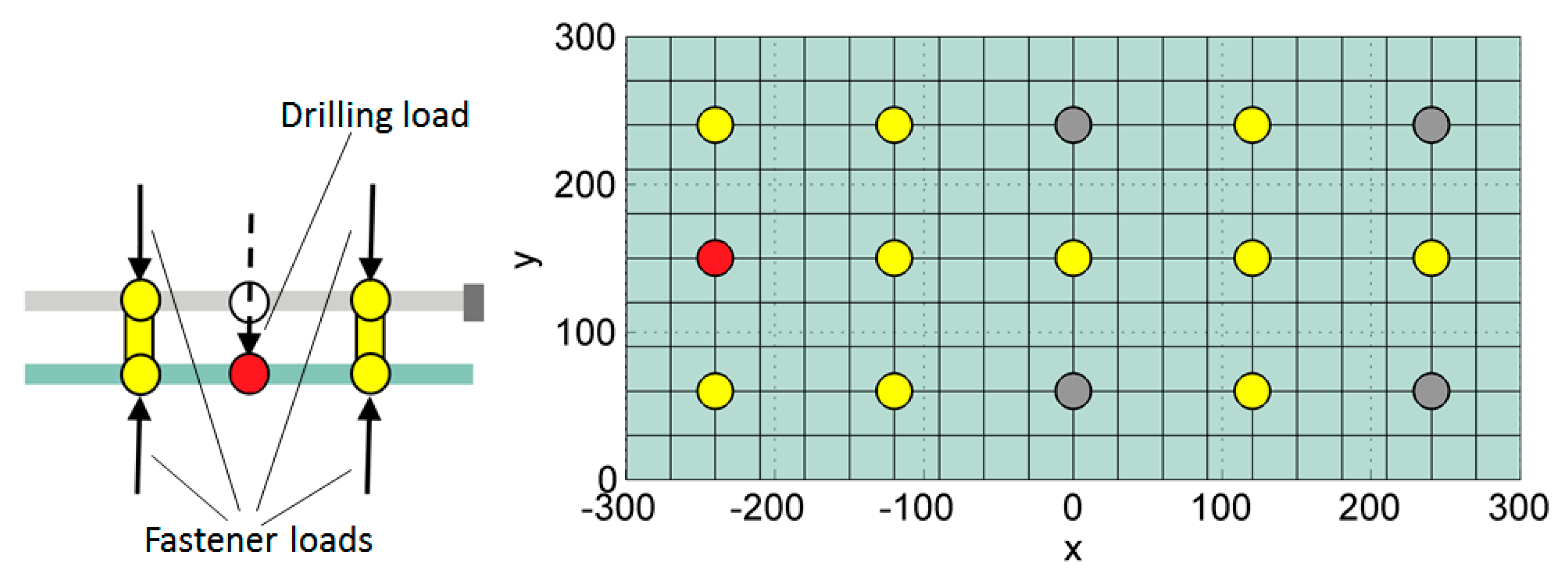

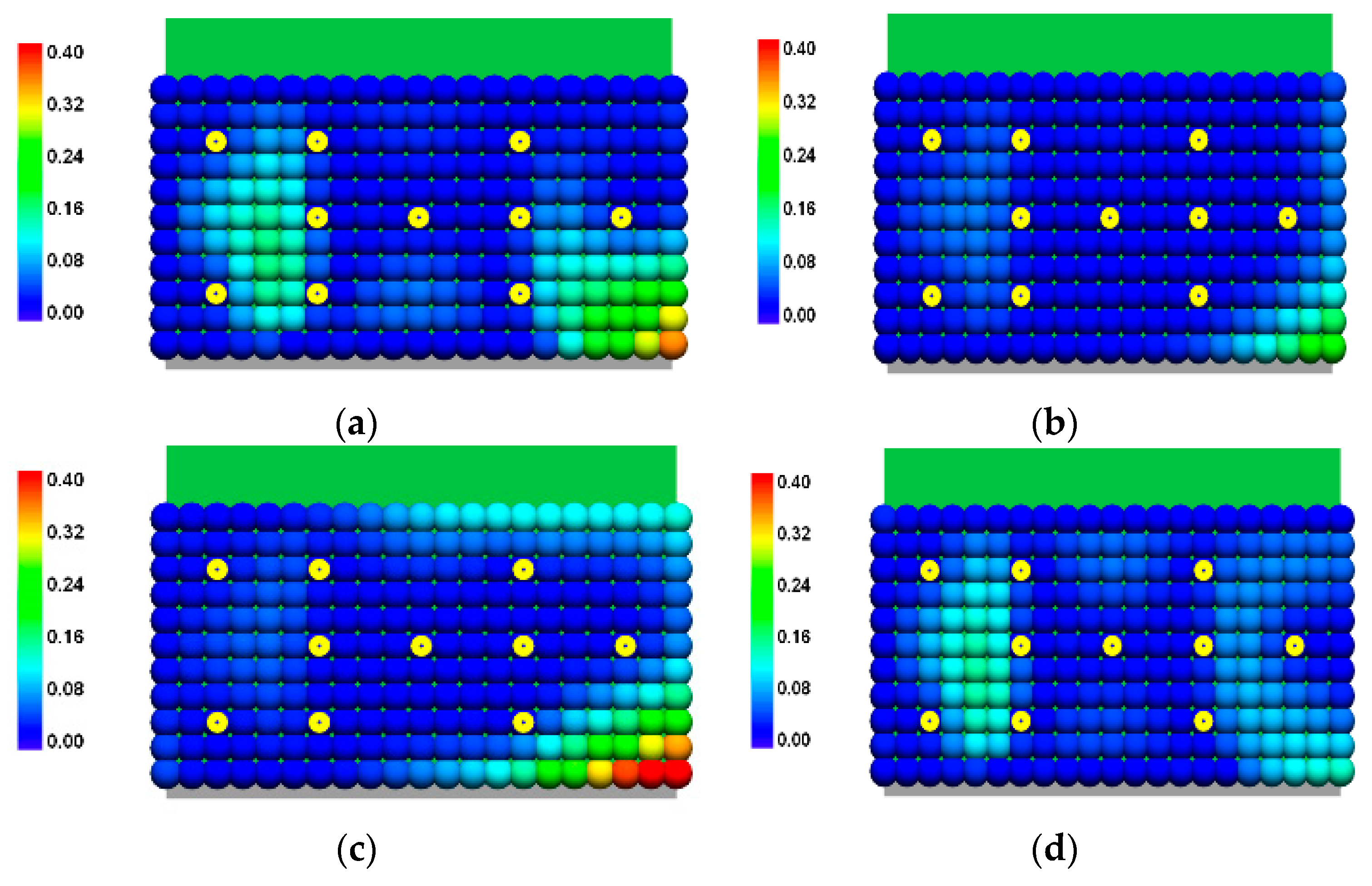

4. Drilling Process Simulation

5. Search for Resonance Effects

5.1. Determination of Natural Frequencies

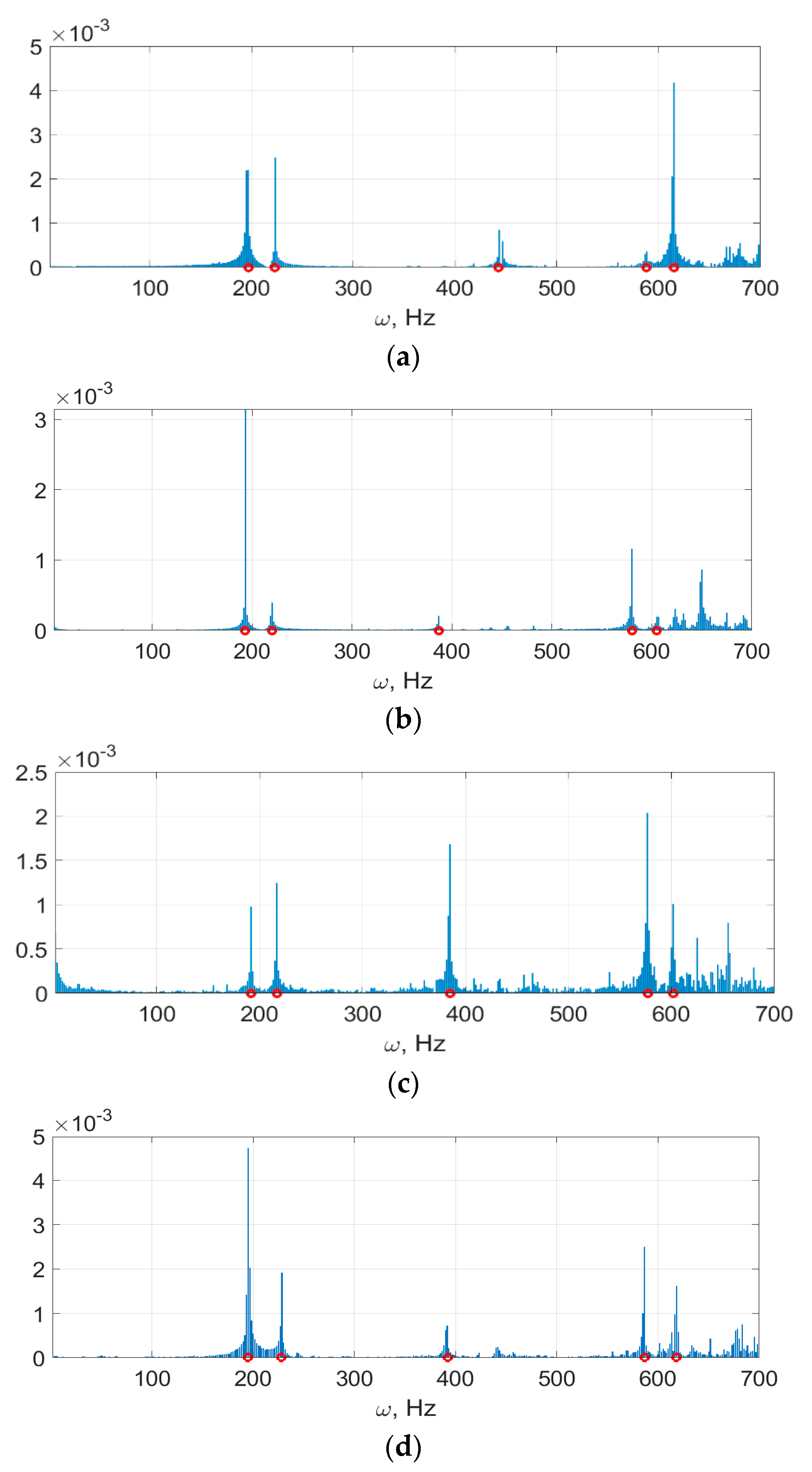

- The upper panel is affected by a sudden impulse to the drilling node (indicated by the red circle in Figure 5). The impulse causes free oscillations of both panels in the assembly. The damping is set to zero, so the oscillations do not decay. These oscillations are simulated by solving Equation (13) with initial conditions corresponding to the installed fasteners, as it was described in the previous section.

- The frequency response function is obtained as a Fourier transform of the computed residual gap in the drilling node.

- The natural frequencies of the assembly correspond to the local maxima of .

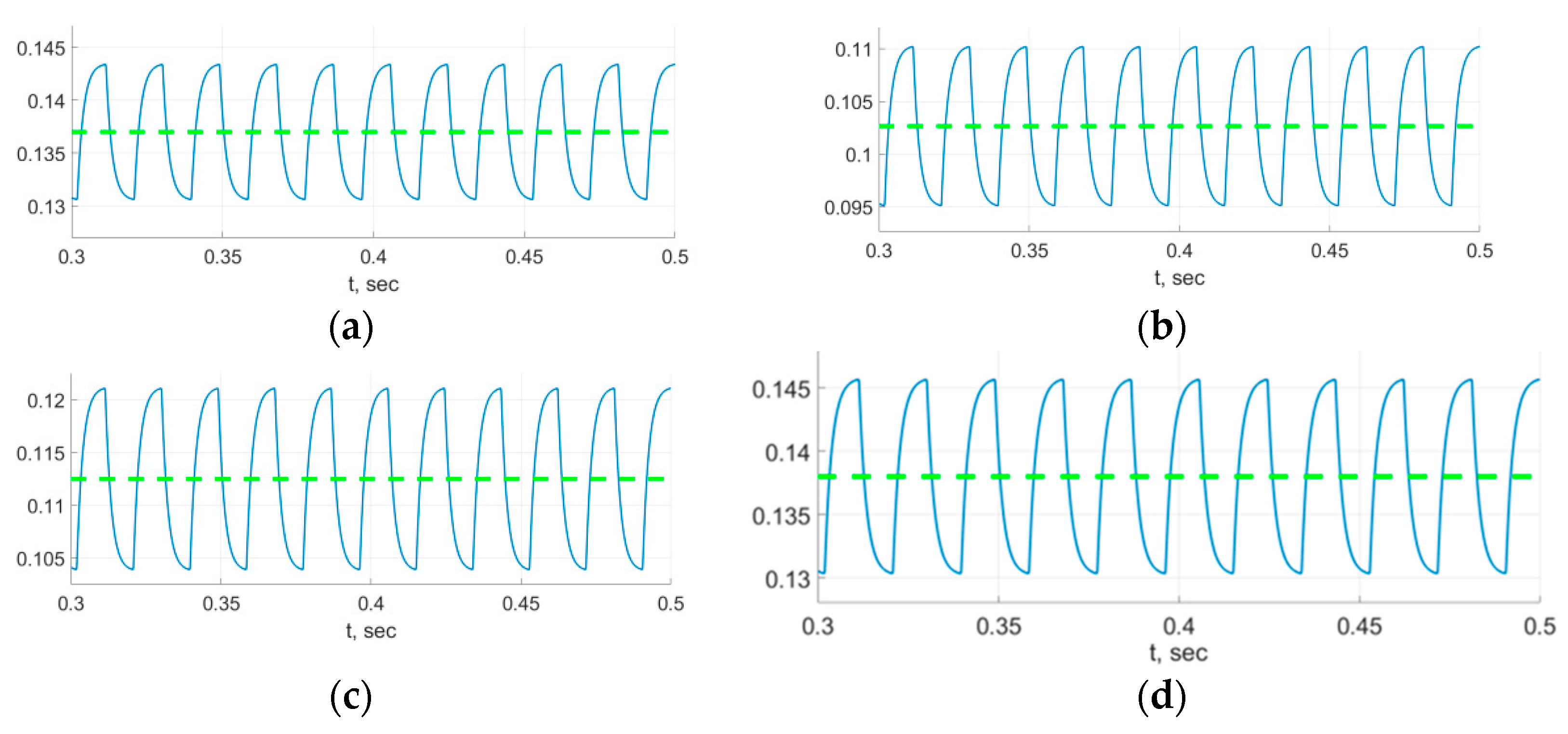

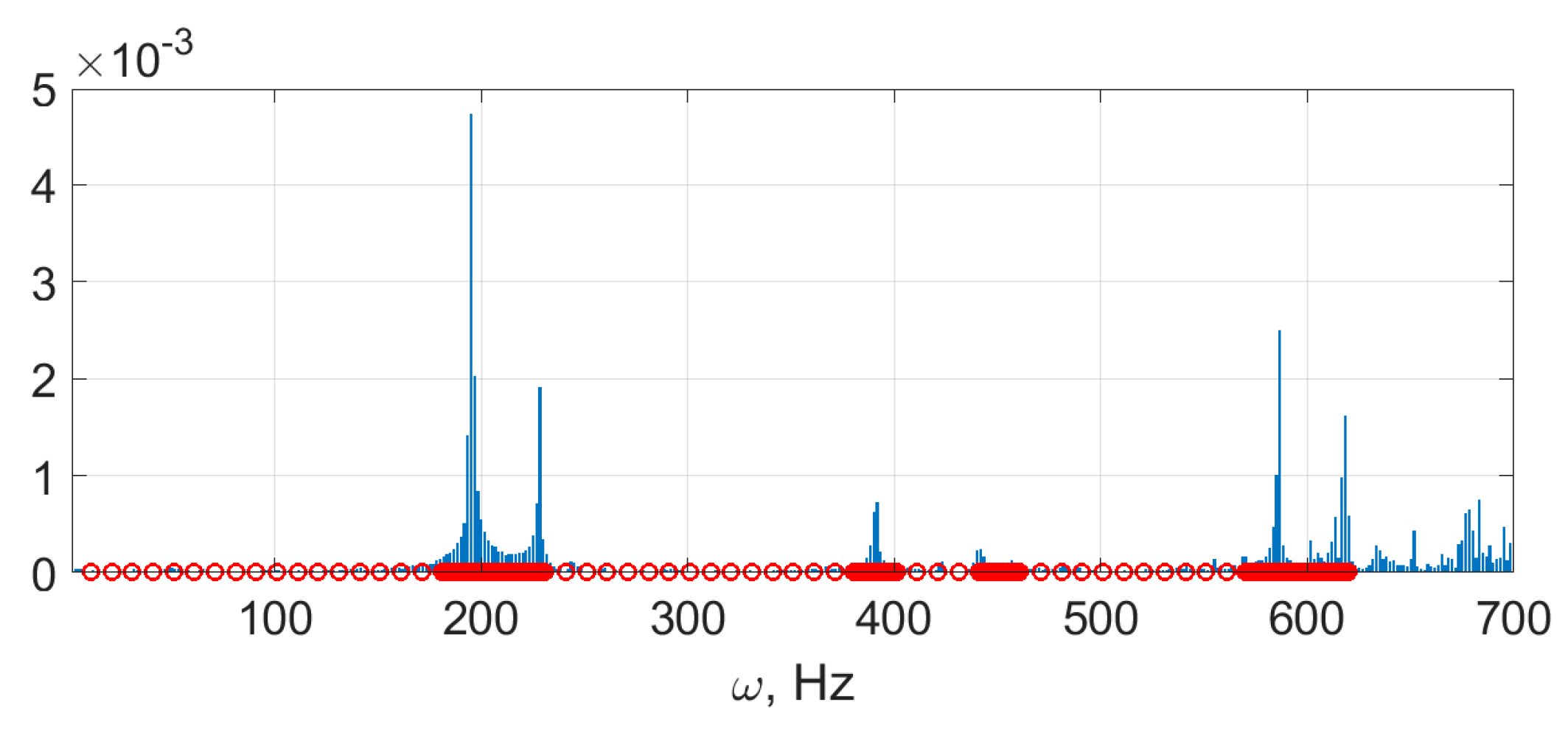

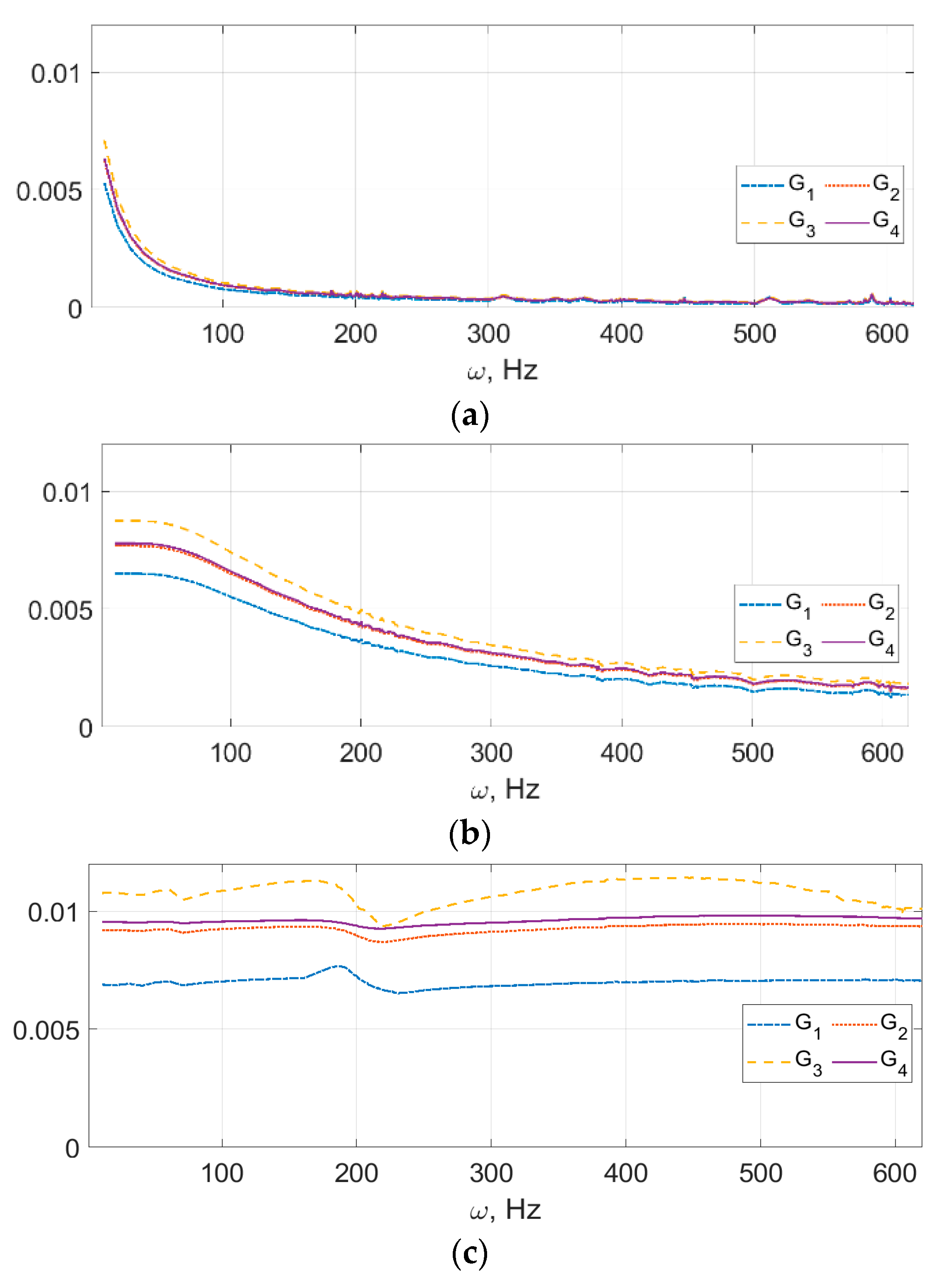

5.2. Building the Dependence of the Vibration Amplitude on the Drill Rotational Speed by Massive Computations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MIC | Method of influence coefficients |

| FEM | Finite element model |

| DOFs | Degrees of freedom |

| The vector of displacements and rotations in all nodes of the FEM | |

| The number of degrees of freedom | |

| The time | |

| T | The maximal time |

| The mass matrix | |

| The damping matrix | |

| The stiffness matrix | |

| The vector of the applied load | |

| The vector of the initial displacement | |

| The vector of the initial velocity | |

| The set of indices of nodes with restricted degrees of freedom | |

| The vector of the initial gap in the junction area | |

| The number of nodes in the junction area | |

| The vector of constrained degrees of freedom | |

| . | The vector of unconstrained degrees of freedom |

| The diagonal blocks of the mass matrix | |

| The off-diagonal blocks of the mass matrix | |

| The diagonal blocks of the damping matrix | |

| The off-diagonal blocks of the damping matrix | |

| The diagonal blocks of the stiffness matrix | |

| The off-diagonal blocks of the stiffness matrix | |

| The vector of the load applied to constrained degrees of freedom | |

| The vector of the load applied to unconstrained degrees of freedom | |

| The reduced mass matrix | |

| The reduced damping matrix | |

| The reduced stiffness matrix | |

| The time step | |

| The number of time steps | |

| The discrete time | |

| The discrete displacement | |

| The discrete velocity | |

| The discrete acceleration | |

| α, , κ, φ | The parameters of the generalized α method |

| The equivalent matrix of stiffness | |

| The equivalent load vector | |

| The initial gaps | |

| The residual gap | |

| Rayleigh damping mass matrix scale factor | |

| Rayleigh damping stiffness matrix scale factor | |

| The damping factors |

References

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Nosrati, A. Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: A review. Int. J. Adv. Manuf. Technol. 2019, 105, 2289–2308. [Google Scholar] [CrossRef]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Vafadar, A. A review: Drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Bañon, F.; Sambruno, A.; Fernandez-Vidal, S.; Fernandez-Vidal, S.R. One-Shot Drilling Analysis of Stack CFRP/UNS A92024 Bonding by Adhesive. Materials 2019, 12, 160. [Google Scholar] [CrossRef] [Green Version]

- Hassan, M.H.; Abdullah, J.; Franz, G.; Shen, C.Y.; Mahmoodian, R. Effect of Twist Drill Geometry and Drilling Parameters on Hole Quality in Single-Shot Drilling of CFRP/Al7075-T6 Composite Stack. J. Compos. Sci. 2021, 5, 189. [Google Scholar] [CrossRef]

- Melkote, S.N.; Newton, T.R.; Hellstern, C.; Morehouse, J.B.; Turner, S. Interfacial Burr Formation in Drilling of Stacked Aerospace Materials. In Burrs—Analysis, Control and Removal; Aurich, J.C., Dornfeld, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 89–98. ISBN 978-3-642-00567. [Google Scholar]

- Giasin, K.; Ayvar-Soberanis, S. An investigation of burrs, chip formation, hole size, circularity and delamination during drilling operation of GLARE using ANOVA. Compos. Struct. 2017, 159, 745–760. [Google Scholar] [CrossRef]

- Habib, N.; Sharif, A.; Hussain, A.; Aamir, M.; Giasin, K.; Pimenov, D.Y.; Ali, U. Analysis of Hole Quality and Chips Formation in the Dry Drilling Process of Al7075-T6. Metals 2021, 11, 891. [Google Scholar] [CrossRef]

- Lee, J.H.; Ge, J.C.; Song, J.H. Study on Burr Formation and Tool Wear in Drilling CFRP and Its Hybrid Composites. Appl. Sci. 2021, 11, 384. [Google Scholar] [CrossRef]

- Xi, F.-F.; Yu, L.; Tu, X.W. Framework on robotic percussive riveting for aircraft assembly automation. Adv. Manuf. 2013, 1, 112–122. [Google Scholar] [CrossRef] [Green Version]

- Ni, J.; Tang, W.C.; Pan, M.; Qiu, X.; Xing, Y. Assembly sequence optimization for minimizing the riveting path and overall dimensional error. In Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture; SAGE Publications: Thousand Oaks, CA, USA, 2018; Volume 232, pp. 2605–2615. [Google Scholar]

- Gulivindala, A.K.; Bahubalendruni, M.R.; Varupala, S.V.P.; Sankaranarayanasamy, K. A heuristic method with a novel stability concept to perform parallel assembly sequence planning by subassembly detection. Assem. Autom. 2020. [Google Scholar] [CrossRef]

- Lupuleac, S.; Shinder, J.; Churilova, M.; Zaitseva, N.; Khashba, V.; Bonhomme, E.; Montero-Sanjuan, P. Optimization of Automated Airframe Assembly Process on Example of A350 S19 Splice Joint. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Luo, H.; Fu, J.; Wu, T.; Chen, N.; Li, H. Numerical Simulation and Experimental Study on the Drilling Process of 7075-t6 Aerospace Aluminum Alloy. Materials 2021, 14, 553. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhao, A.; Wan, P.; Huiyue, D.; Yunbo, B. Modeling and Optimization of Bidirectional Clamping Forces in Drilling of Stacked Aluminum Alloy Plates. Materials 2020, 13, 2866. [Google Scholar] [CrossRef]

- Tinkloh, S.; Wu, T.; Tröster, T.; Niendorf, T. The Effect of FiberWaviness on the Residual Stress State and Its Prediction by the Hole Drilling Method in Fiber Metal Laminates: A Global-Local Finite Element Analysis. Metals 2021, 11, 156. [Google Scholar] [CrossRef]

- Savilov, A.V.; Pyatykh, A.S.; Timofeev, S.A. Vibration suppression methods at high performance drilling. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 632, p. 012108. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, C.; Qian, F.; Dhupia, J.S.; Wu, M. A Variable Parameter Ambient Vibration Control Method Based on Quasi-Zero Stiffness in Robotic Drilling Systems. Machines 2021, 9, 67. [Google Scholar] [CrossRef]

- Lonfier, J.; De Castelbajac, C. A Comparison between Regular and Vibration-Assisted Drilling in CFRP/Ti6Al4V Stack. SAE Int. J. Mater. Manuf. 2015, 8, 18–26. [Google Scholar] [CrossRef]

- Bleicher, F.; Wiesinger, G.; Kumpf, C.; Finkeldei, D.; Baumann, C.; Lechner, C. Vibration assisted drilling of CFRP/metal stacks at low frequencies and high amplitudes. Prod. Eng. 2018, 12, 289–296. [Google Scholar] [CrossRef] [Green Version]

- Bisua, C.; Cherifb, M.; Knevezb, J.-Y. Dynamic analysis of the forced vibration drilling process. Procedia CIRP 2018, 67, 290–295. [Google Scholar] [CrossRef]

- Veiga, F.; Suárez, A.; Del Val, A.A.G.; Penalva, M.; Lopez de Lacalle, L.N. Evaluation on advantages of low frequency assisted drilling (LFAD) aluminium alloy Al7075. Int. J. Mechatron. Manuf. Syst. 2020, 13, 230–246. [Google Scholar] [CrossRef]

- Zaitseva, N.; Pogarskaia, T.; Minevich, O.; Shinder, J.; Bonhomme, E. Simulation of Aircraft Assembly via ASRP Software. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Liu, S.C.; Hu, S.J. Variation simulation for deformable sheet metal assemblies using finite element methods. ASME J. Manuf. Sci. Eng. 1997, 119, 368–374. [Google Scholar] [CrossRef]

- Wärmefjord, K.; Lindkvist, L.; Söderberg, R. Tolerance simulation of compliant sheet metal assemblies using automatic node-based contact detection. In ASME 2008 International Mechanical Engineering Congress and Exposition; ASME: New York, NY, USA, 2008; Volume 14, pp. 35–44. [Google Scholar]

- Lupuleac, S.; Kovtun, M.; Rodionova, O.; Marguet, B. Assembly simulation of riveting process. SAE Int. J. Aerosp. 2008, 2, 193–198. [Google Scholar] [CrossRef]

- Galin, L.A.; Moss, H.; Sneddon, N. Contact Problems in the Theory of Elasticity; North Carolina State College: Raleigh, NC, USA, 1961; p. 233. [Google Scholar]

- Tu, Y.; Gazis, D. The contact problem of a plate pressed between two spheres. J. Math Ind. 1964, 31, 659–666. [Google Scholar] [CrossRef]

- Lions, J.L.; Stampacchia, G. Variational Inequalities. Commun. Pure Appl. Math 1967, 20, 493–519. [Google Scholar] [CrossRef] [Green Version]

- Kinderlehrer, D.; Stampacchia, G. An Introduction to Variational Inequalities and Their Applications; SIAM: Philadelphia, PA, USA, 1980. [Google Scholar]

- Turner, M.J.; Clough, R.W.; Martin, H.C.; Topp, L.J. Stiffness and deflection analysis of complex structures. J. Aero. Sci. 1956, 23, 805–823. [Google Scholar] [CrossRef]

- Guyan, R.J. Reduction of stiffness and mass matrix. AIAA J. 1965, 3, 380. [Google Scholar] [CrossRef]

- Wriggers, C.P. Computational Contact Mechanics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Lupuleac, S.; Smirnov, A.; Churilova, M.; Shinder, J.; Zaitseva, N.; Bonhomme, E. Simulation of body force impact on the assembly process of aircraft parts. In ASME 2019 International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar]

- Lupuleac, S.; Zaitseva, N.; Stefanova, M.; Berezin, S.; Shinder, J.; Petukhova, M.; Bonhomme, E. Simulation of the wing-to-fuselage assembly process. ASME J. Manuf. Sci. Eng. 2019, 141, 061009. [Google Scholar] [CrossRef]

- Lorin, S.; Lindau, B.; Lindkvist, L.; Söderberg, R. Efficient compliant variation simulation of spot-welded assemblies. ASME J. Comput. Inf. Sci. Eng. 2019, 19, 011007. [Google Scholar] [CrossRef]

- Lupuleac, S.; Pogarskaia, T.; Churilova, M.; Kokkolaras, M.; Bonhomme, E. Optimization of fastener pattern in airframe assembly. Assem. Autom. 2020, 40. [Google Scholar] [CrossRef]

- Petukhova, M.; Lupuleac, S.; Shinder, Y.; Smirnov, A.; Yakunin, S.; Bretagnol, B. Numerical approach for airframe assembly simulation. J. Math. Ind. 2014, 4, 8. [Google Scholar] [CrossRef] [Green Version]

- Flodén, O.; Persson, K.; Sandberg, G. Reduction methods for the dynamic analysis of substructure models of lighweight building structures. Comput. Struct. 2014, 138, 49–61. [Google Scholar] [CrossRef] [Green Version]

- Chung, J.; Hulbert, G.M. A time integration algorithm for structural dynamics with improved numerical dissipation: The generalized-α method. J. Appl. Mech. 1993, 60, 371–375. [Google Scholar] [CrossRef]

- Lupuleac, S.; Petukhova, M.; Shinder, J.; Bretagnol, B. Methodology for solving contact problem during riveting process. SAE Int. J. Aerosp. 2011, 4, 952–957. [Google Scholar] [CrossRef]

- Vasiliev, A.; Minevich, O.; Lapina, E.; Shinder, J.; Lupuleac, S.; Barboule, J. A Novel Approach to Dynamic Contact Analysis in the Course of Aircraft Assembly Simulation. In Proceedings of the AeroTech® Digital Summit, Online, 9–11 March 2021. [Google Scholar] [CrossRef]

- Lupuleac, S.; Smirnov, A.; Shinder, J.; Petukhova, M.; Churilova, M.; Victorov, E.; Bouriquet, J. Complex fastener model for simulation of airframe assembly process. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2020. [Google Scholar] [CrossRef]

- Nastran In-CAD 2019 for Inventor Help. Available online: http://help.autodesk.com/view/NINCAD/2019/ENU/?guid=GUID-6D2ABB14-6285-441B-883F-358F9E37FA8E (accessed on 10 May 2021).

| Initial Gap | Mean Residual Gap (μm) | Mean Amplitude (μm) |

|---|---|---|

| 137.0 | 6.4 | |

| 102.7 | 7.6 | |

| 112.5 | 8.6 | |

| 138.0 | 7.7 |

| Initial Gap | Natural Frequencies (Hz) | ||||

|---|---|---|---|---|---|

| 193 | 220 | 387 | 580 | 615 | |

| 197 | 223 | 443 | 588 | 605 | |

| 192 | 217 | 385 | 577 | 602 | |

| 195 | 228 | 392 | 587 | 618 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasiliev, A.; Lupuleac, S.; Shinder, J. Numerical Approach for Detecting the Resonance Effects of Drilling during Assembly of Aircraft Structures. Mathematics 2021, 9, 2926. https://doi.org/10.3390/math9222926

Vasiliev A, Lupuleac S, Shinder J. Numerical Approach for Detecting the Resonance Effects of Drilling during Assembly of Aircraft Structures. Mathematics. 2021; 9(22):2926. https://doi.org/10.3390/math9222926

Chicago/Turabian StyleVasiliev, Alexey, Sergey Lupuleac, and Julia Shinder. 2021. "Numerical Approach for Detecting the Resonance Effects of Drilling during Assembly of Aircraft Structures" Mathematics 9, no. 22: 2926. https://doi.org/10.3390/math9222926

APA StyleVasiliev, A., Lupuleac, S., & Shinder, J. (2021). Numerical Approach for Detecting the Resonance Effects of Drilling during Assembly of Aircraft Structures. Mathematics, 9(22), 2926. https://doi.org/10.3390/math9222926