Development of Preform for Simulation of Cold Forging Process of A V8 Engine Camshaft Free from Flash & Under-Filling

Abstract

1. Introduction

2. Methodology

- —strain velocity, , , are deformation velocities

- —Strain velocity component

- —Materials rate of formability change; —force on boundary surface ; —deformation velocity on boundary surface

- —Surface on which force applied; —deformed surface

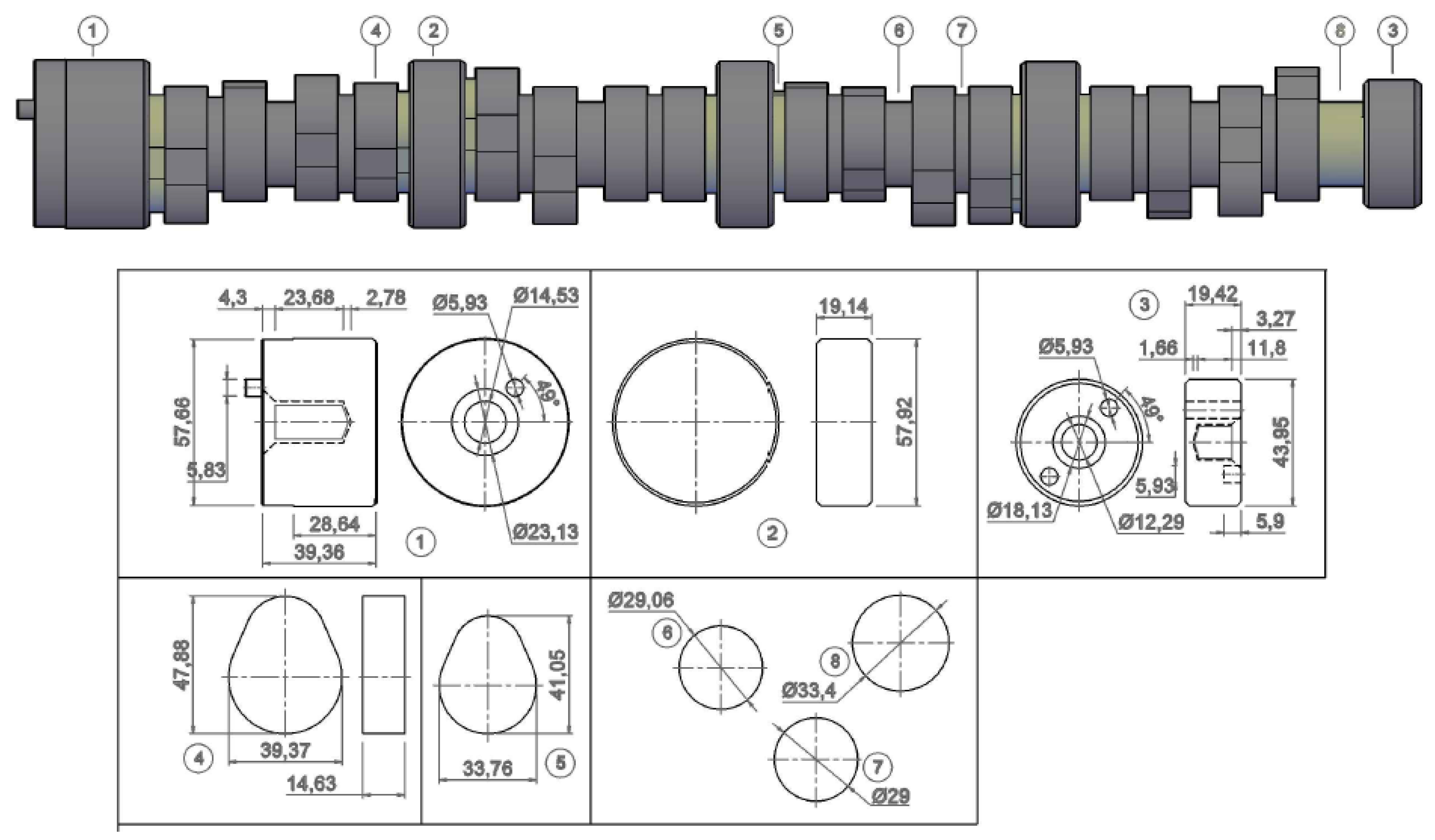

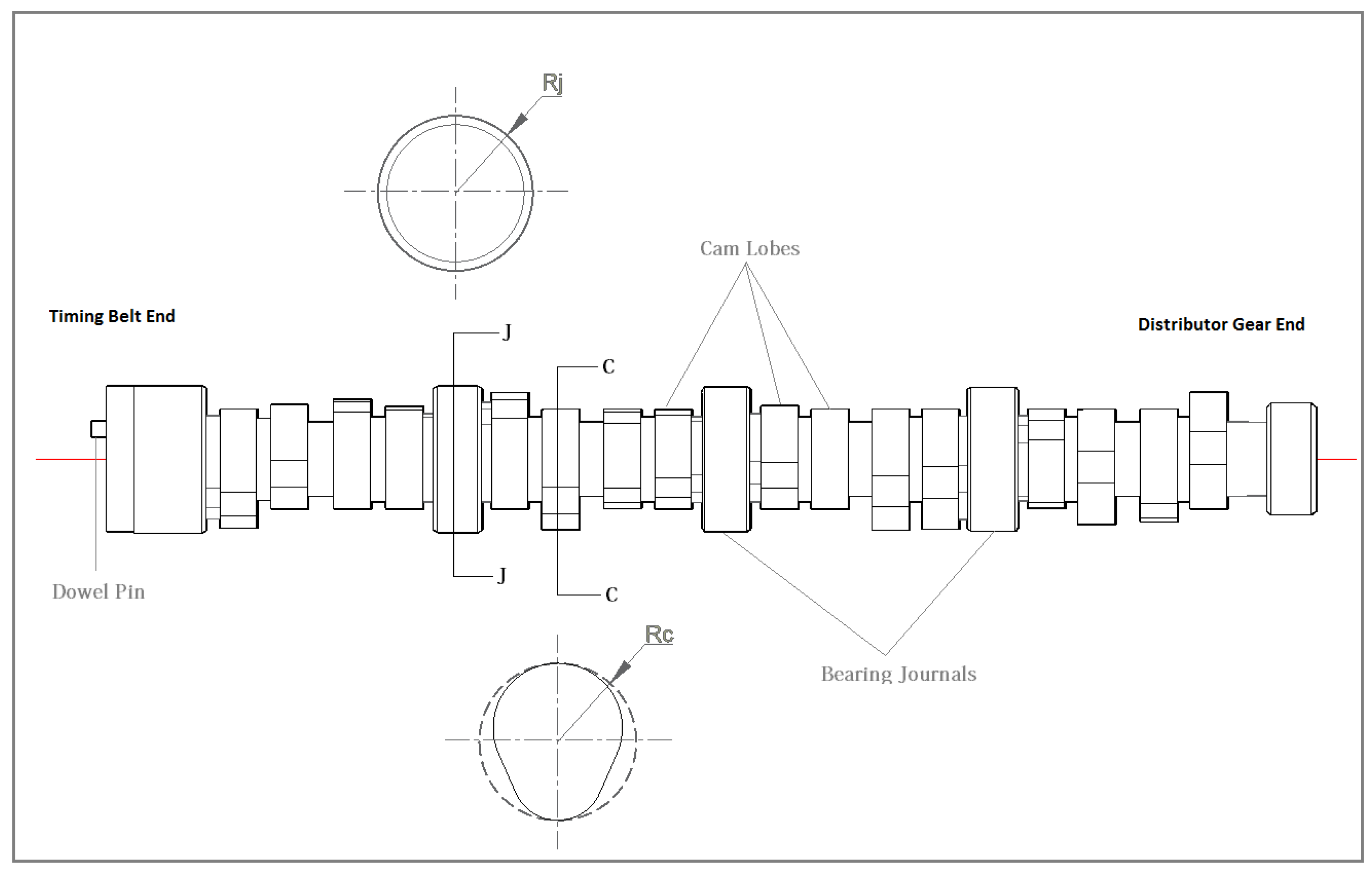

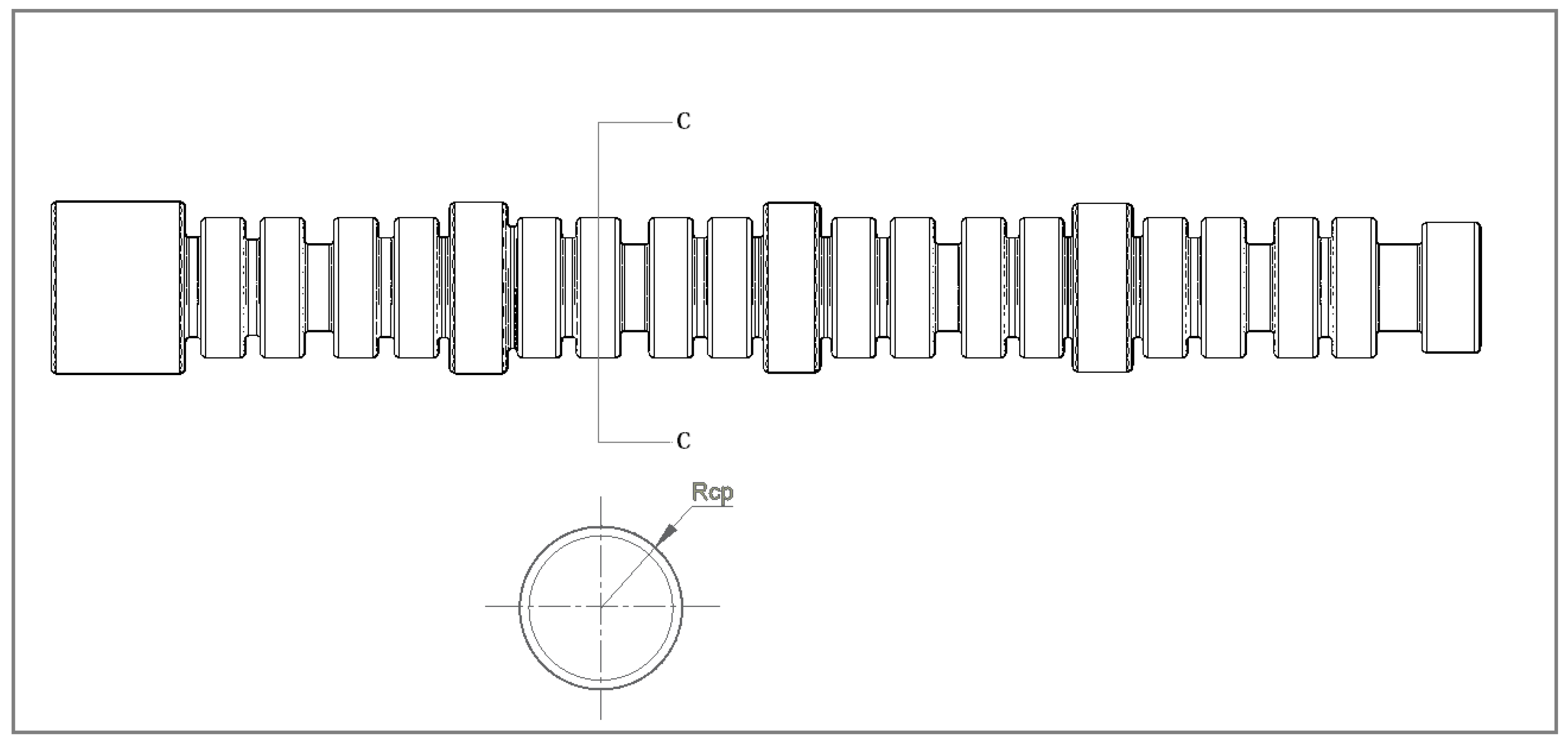

2.1. Pre-Form Dimensional Analysis

2.2. Dimensional Analysis of Cam-Shafts Resulting from Simulations

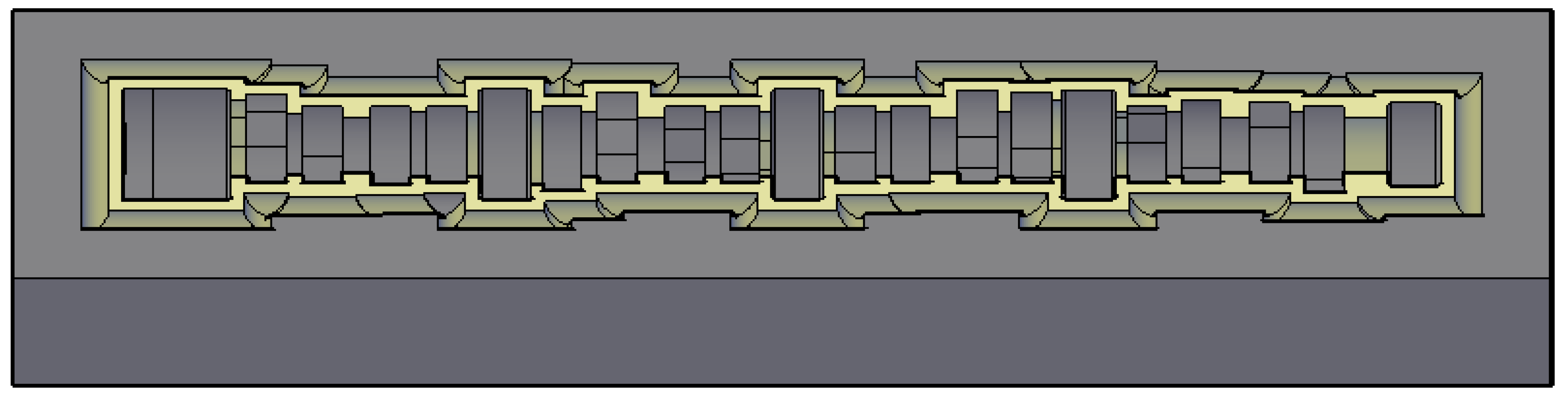

2.3. Finite Element Modeling and Material Specification

2.4. Discretization Details

2.5. Process Parameters

3. Results

3.1. Volumetric Analysis of Effect of Variation in Preform Geometry

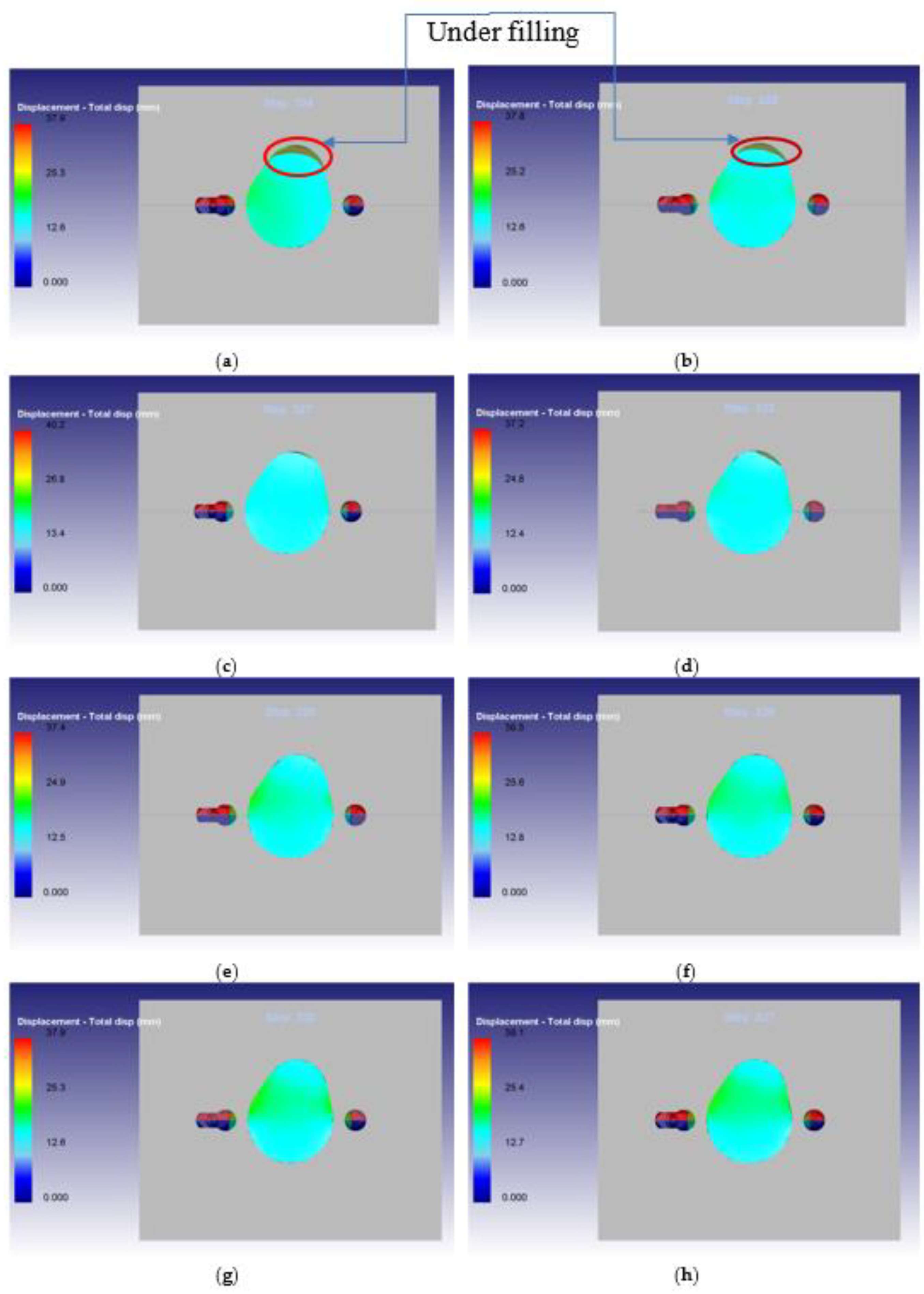

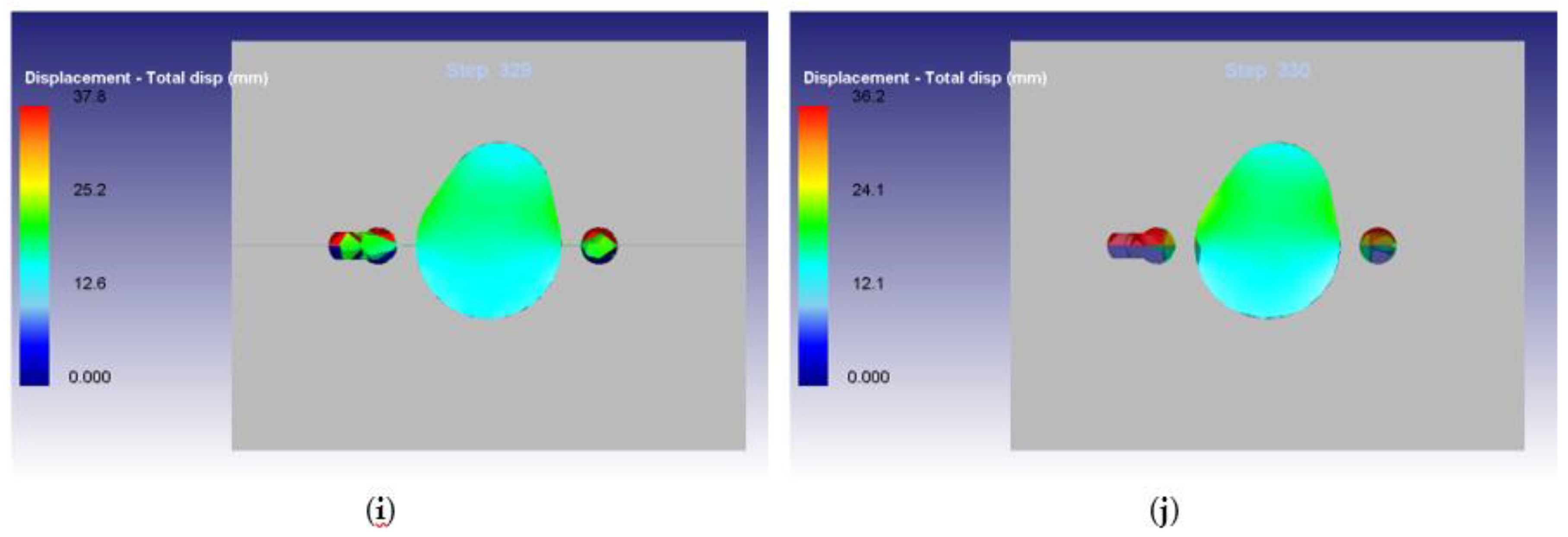

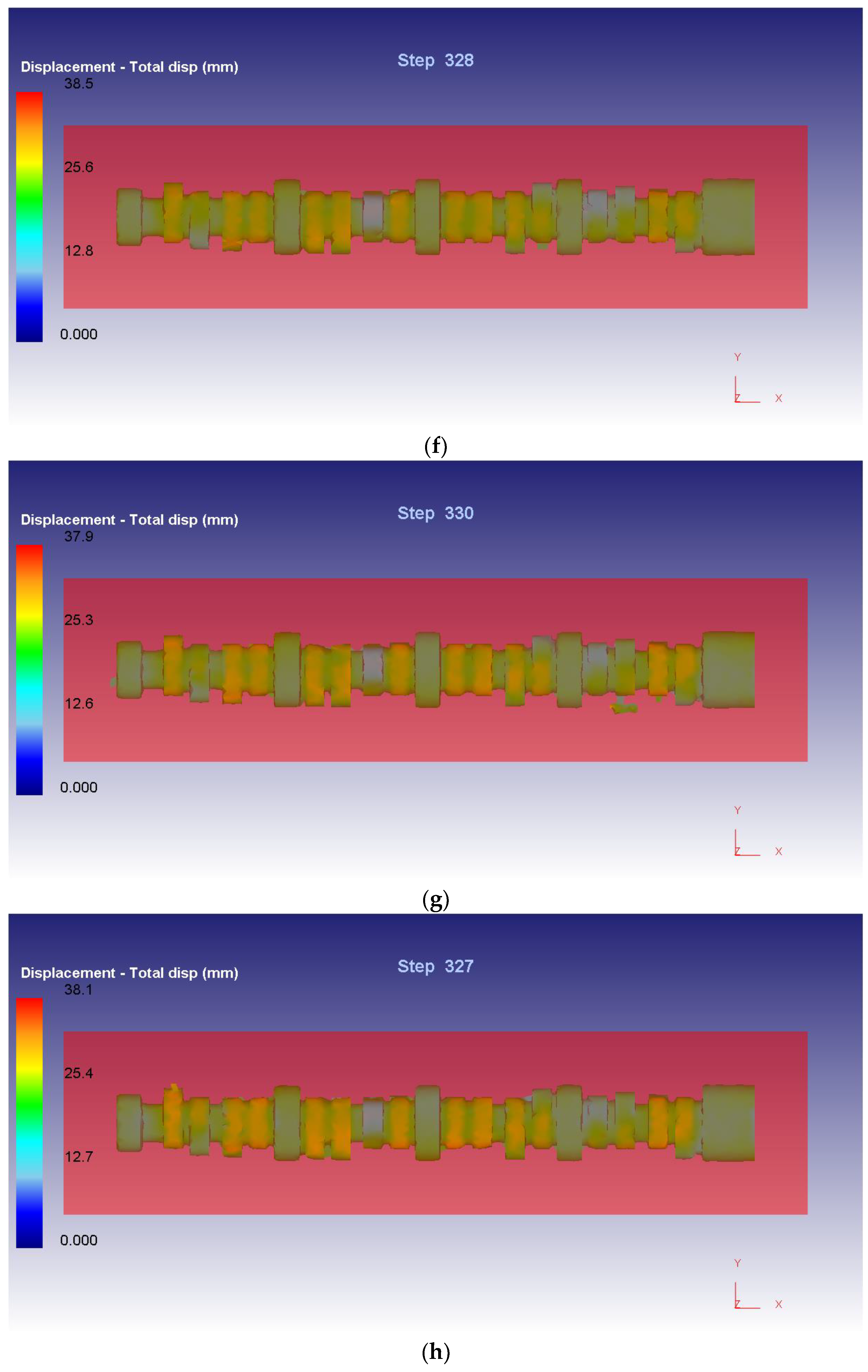

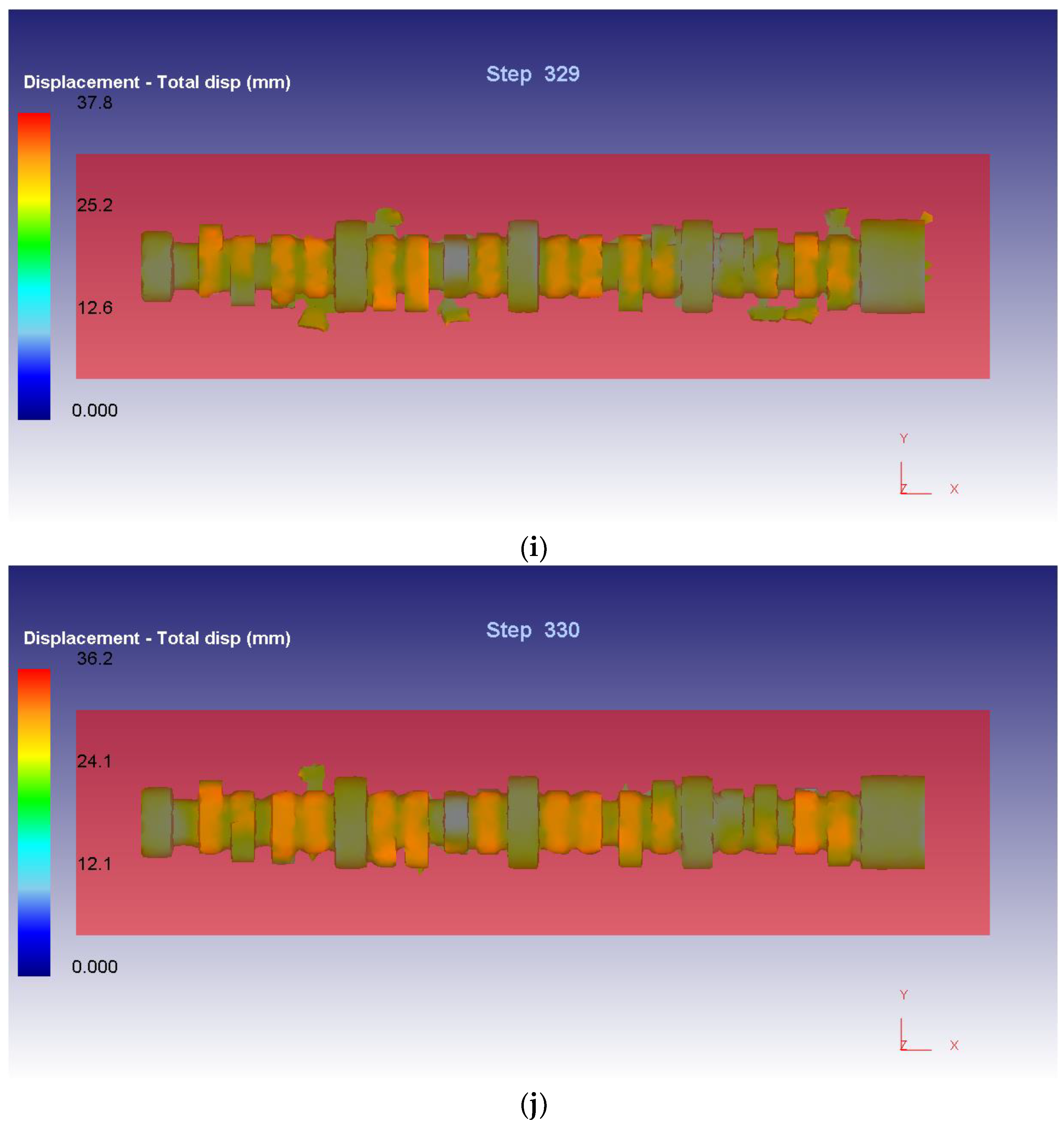

3.2. Effect of Preform Geometry on Simulation

3.3. Under-Fill and Flash

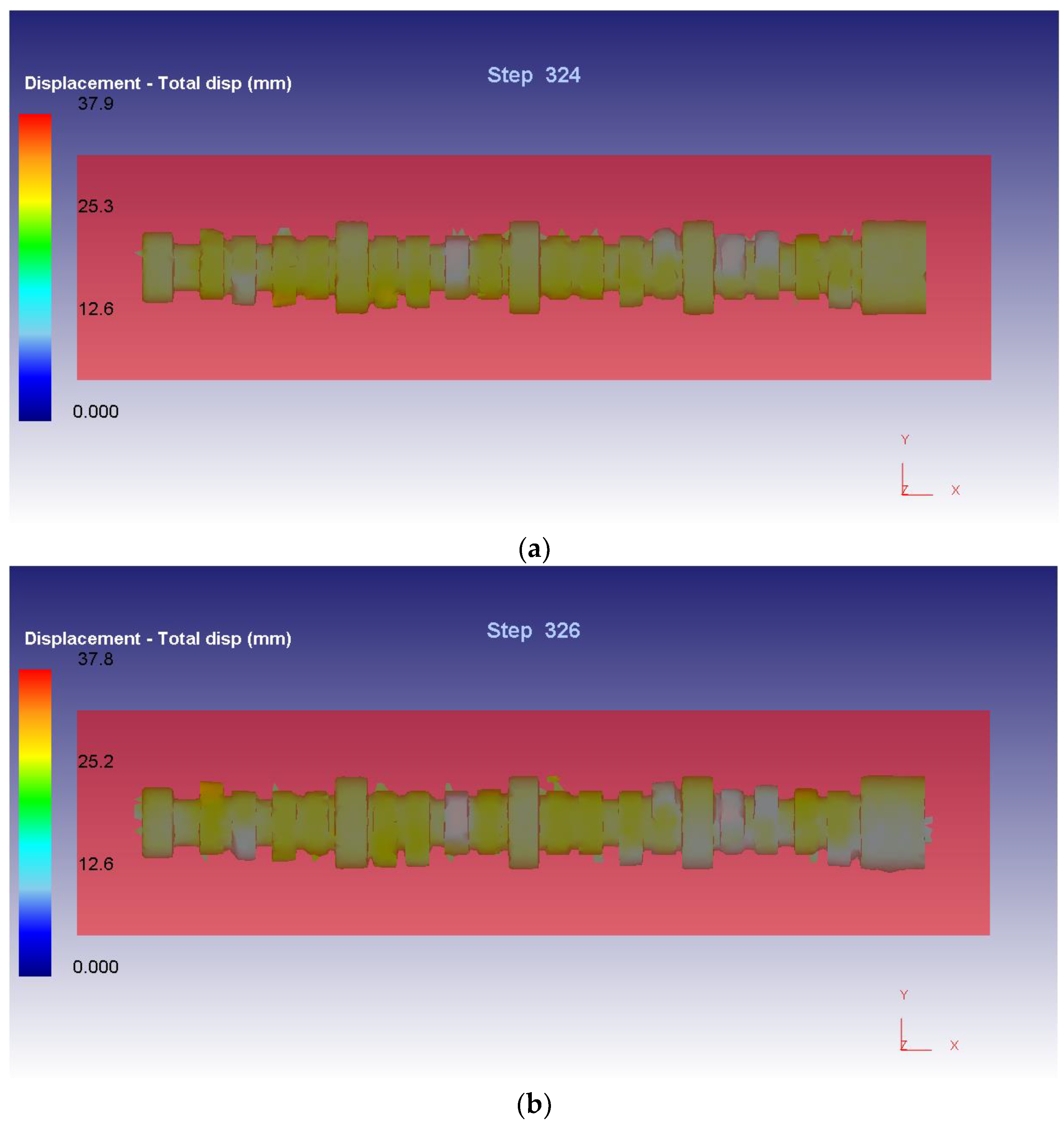

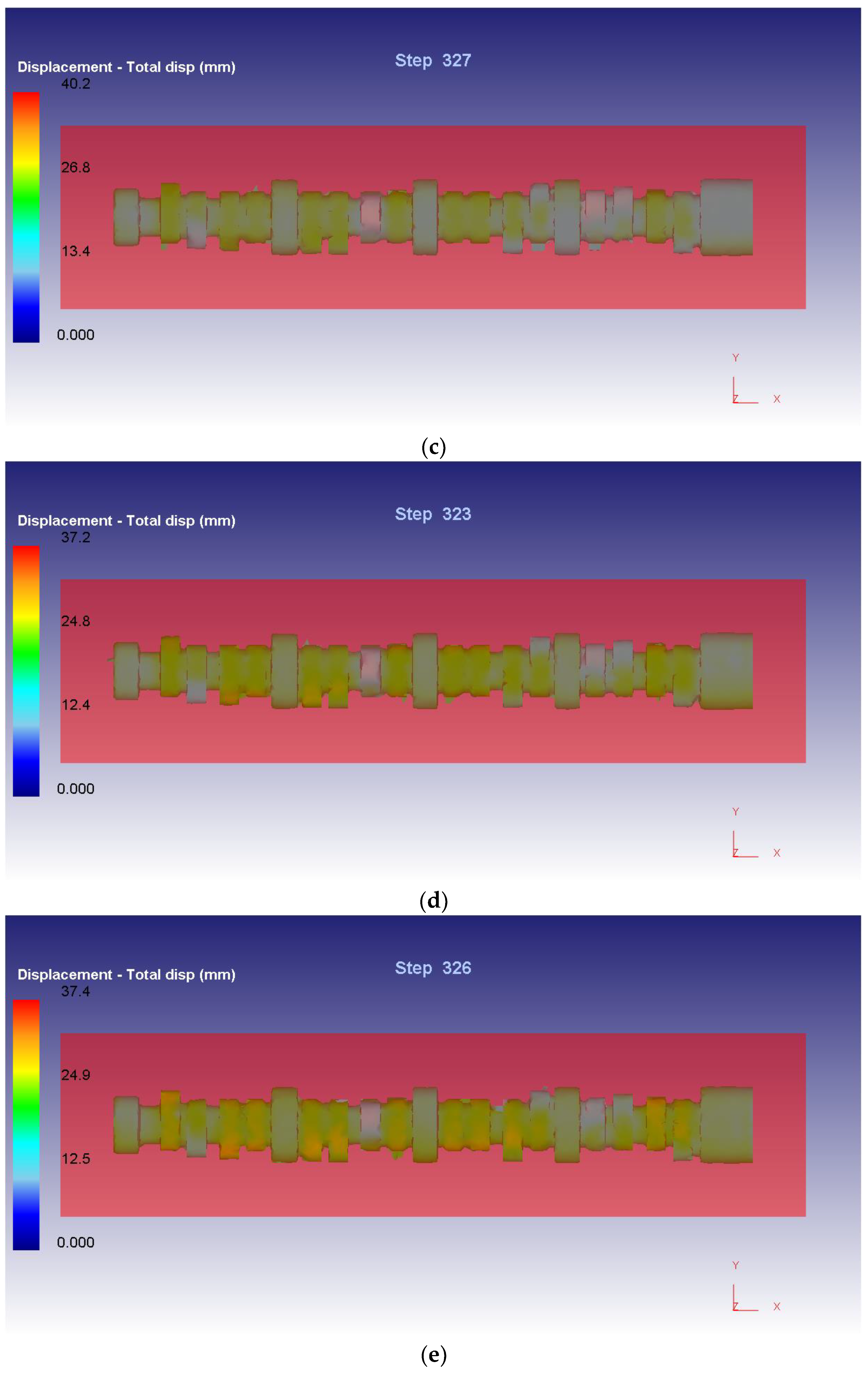

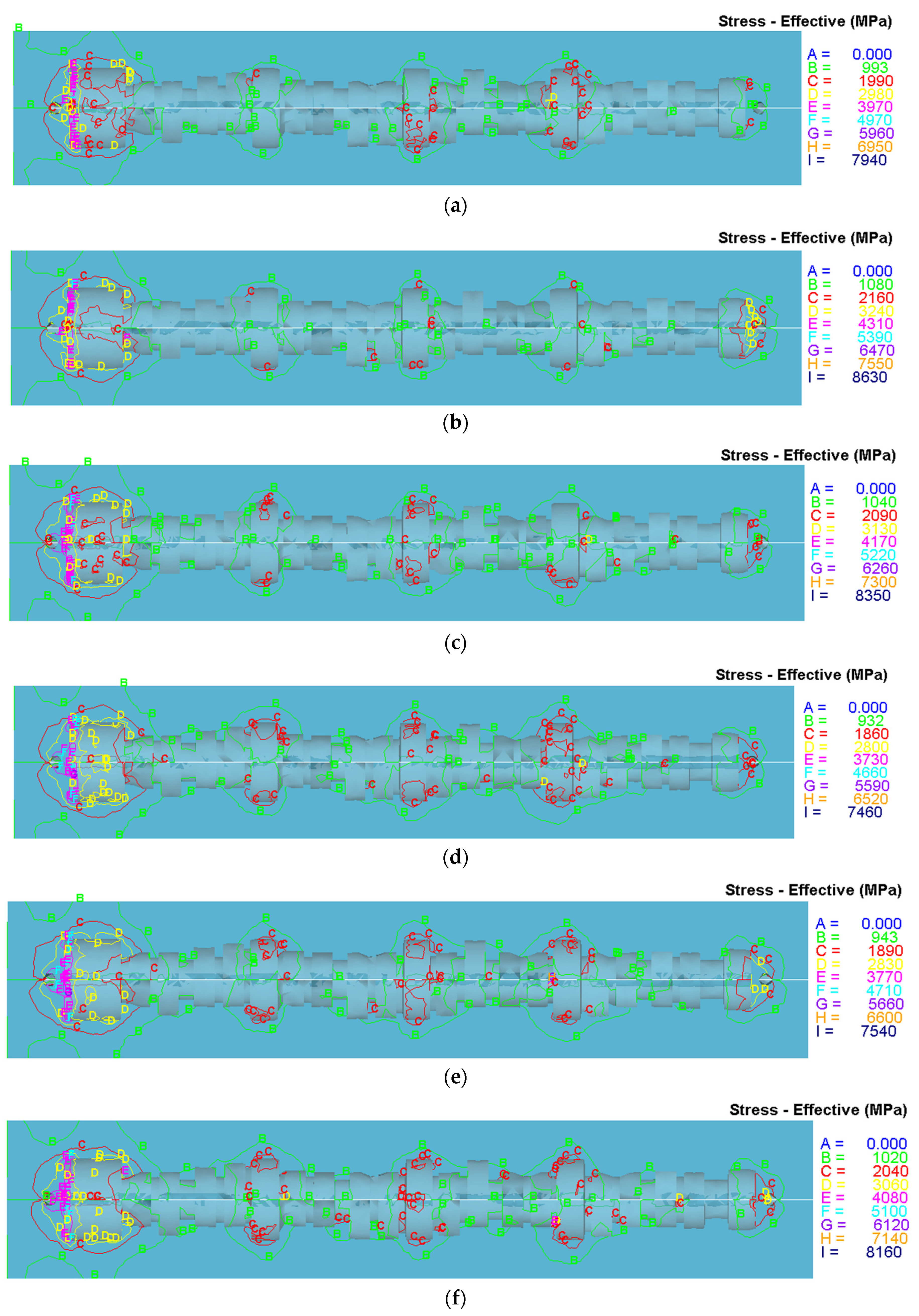

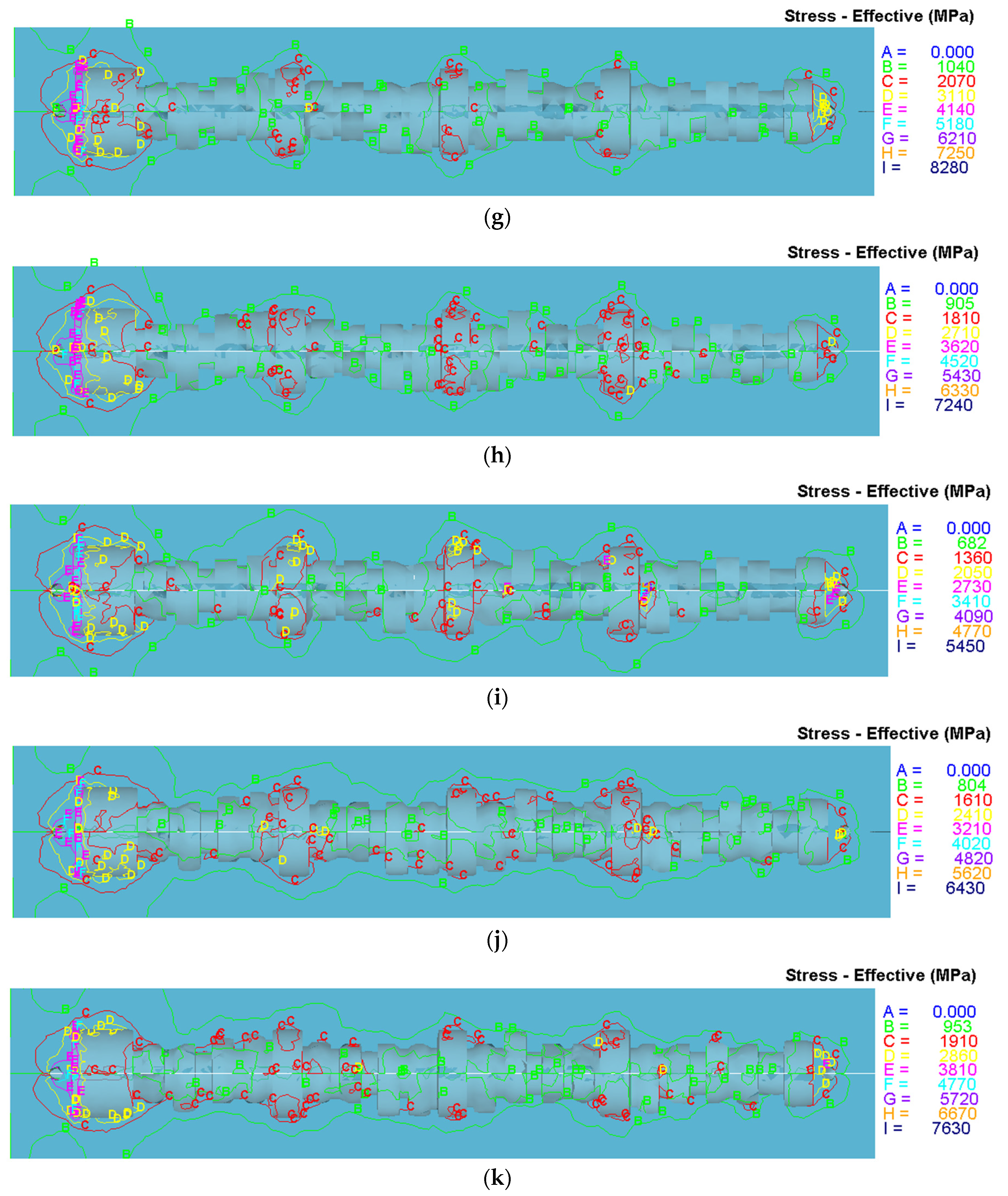

3.4. Die Stress Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ishinaga, N. An advanced press design for cold forging. J. Mater. Process. Technol. 1997, 71, 100–104. [Google Scholar] [CrossRef]

- Yanagimoto, J.; Sugiyama, S.Y.; Anagida, A.; Iwamura, N.; Ishizuka, M. Control of ultrafine microstructure by single-pass heavy deformation and cold forging of metal. J. Mater. Process. Technol. 2009, 209, 679–685. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, Y.; Ruan, X. A web based cold forging process generation system. J. Mater. Process. Technol. 2004, 145, 1–6. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Kubota, S.; Yamanaka, M. Application of CAE in cold forging and heat treatment processes for manufacturing of precision helical gear part. J. Mater. Process. Technol. 2008, 201, 25–31. [Google Scholar] [CrossRef]

- Deng, X.; Hua, L.; Han, X.; Song, Y. Numerical and experimental investigation of cold rotary forging of a 20CrMnTi alloy spur bevel gear. Mater. Des. 2011, 32, 1376–1389. [Google Scholar] [CrossRef]

- Ku, T.-W.A. A Study on Two-Stage Cold Forging for a Drive Shaft with Internal Spline and Spur Gear Geometries. Metals 2018, 8, 953. [Google Scholar] [CrossRef]

- Huang, H.-S.; Hsia, S.-Y. New design of process for cold forging to improve multi-stage gas fitting. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef]

- Samołyk, G.; Winiarski, G. Analysis of single-operation cold forging of a hollow ball from a tubular billet. Int. J. Adv. Manuf. Technol. 2019, 103, 3045–3056. [Google Scholar] [CrossRef]

- Samad, Z.; Abdullah, A.B.; Khaleed, H.M.T.; Abu-Bakar, M.H.; Arshad, M.R. A novel manufacturing method of propeller for autonomous underwatwer vehicle (auv) using cold forging. Indian J. Geo-Mar. Sci. 2012, 41, 242–248. [Google Scholar]

- Abdullah, A.B.; Sapuan, S.M.; Samad, Z.; Khaleed, H.M.T.; Aziz, N.A. Manufacturing of AA6061 propeller for AUV application using cold forging process. Sci. Res. Essays 2012, 7, 170–176. [Google Scholar]

- Khaleed, H.M.T.; Samad, Z.; Othman, A.R.; Mujeebu, M.A.; Badarudin, A.; Abdullah, A.B.; Ab-Kadir, A.R.; Badruddin, I.A.; Ahmed, N.J.S. Computer-Aided FE Simulation for Flashless Cold Forging of Connecting Rod without Underfilling. Arab. J. Sci. Eng. 2011, 36, 855–865. [Google Scholar] [CrossRef]

- Rathore, S.S.; Salve, M.M.; Dabhade, V.V. Dabhade, Effect of molybdenum addition on the mechanical properties of sinter-forged Fe-Cu-C alloys. J. Alloys Compd. 2015, 649, 988–995. [Google Scholar] [CrossRef]

- Kim, Y.S.; Son, H.S.; Kim, C.I. Rigid-plastic finite element simulation for process design of impeller hub forming. J. Mater. Process. Technol. 2003, 143–144, 729–734. [Google Scholar] [CrossRef]

- Kim, D.J.; Kim, B.M. Application of neural network and FEM for metal forming processes. Int. J. Mach. Tools Manuf. 2000, 40, 911–925. [Google Scholar] [CrossRef]

- Khaleed, H.M.T.; Samad, Z.; Othman, A.R.; Mujeebu, M.A.; Abdullah, A.B.; Zihad, M.M. Work-piece optimization and thermal analysis for flash-less cold forging of AUV propeller hubs—FEM simulation and experiment. J. Manuf. Process. 2011, 13, 41–49. [Google Scholar] [CrossRef]

| Intake/Exhaust Durations: |

|

| Maximum lift | 0.340”/0.330” |

| Lobe Separation Angle | 117.5° |

| Intake Centre Line of Camshaft | 121.5° |

| Case | No. of Elements | ||

|---|---|---|---|

| Pre-Form | Punch | Die | |

| V | 103266 | 50190 | 51441 |

| Property | Preform | Die/Punch |

|---|---|---|

| Category | Steel | Steel |

| Class | Alloy Steel | Tool Steel |

| Common Name | Nickel-chromium-molybdenum steel | Tungsten Hot Work Steel |

| Density (×1000 kg/m3) | 7.7–8.03 | 8.67 |

| Poisson’s Ratio | 0.27–0.30 | 0.27–0.30 |

| Elastic Modulus (GPa) | 190–210 | 190–210 |

| Tensile Strength (Mpa) | 536.4 | 650–880 |

| Yield Strength (Mpa) | 385.4 | 350–550 |

| Hardness (HB) | 149 | 545–560 |

| Cases | RC (mm) | RJ (mm) | Preform Vol. (mm3) | Product Vol. (mm3) [A] | Target Vol.(mm3) [B] | Under-Filling (% of Target Volume) | Flash (% of Preform Volume) |

|---|---|---|---|---|---|---|---|

| I | 21.335 | 29 | 721,592 | 691,113 | 719,223 | 3.91 | 4.22 |

| II | 22 | 29 | 731,953 | 697,838 | 719,223 | 2.97 | 4.66 |

| III | 22.5 | 29 | 747,960 | 702,868 | 719,223 | 2.27 | 6.03 |

| IV | 23 | 29 | 768,428 | 706,056 | 719,223 | 1.83 | 8.12 |

| V | 23.5 | 29 | 785,252 | 701,589 | 719,223 | 2.45 | 10.65 |

| VI | 24 | 29 | 802,439 | 706,727 | 719,223 | 1.74 | 11.93 |

| VII | 24.5 | 29 | 819,989 | 704,722 | 719,223 | 2.02 | 14.06 |

| VIII | 25 | 29 | 838,737 | 705,113 | 719,223 | 1.96 | 15.93 |

| IX | 25.5 | 29 | 857,012 | 708,054 | 719,223 | 1.55 | 17.38 |

| X | 26 | 29 | 877,166 | 705,342 | 719,223 | 1.93 | 19.58 |

| Case | Target Area mm2 | Recorded Area mm2 | Percentage Deviation |

|---|---|---|---|

| I | 1433.77 | 1346.36 | 6.10 |

| II | 1372.03 | 4.31 | |

| III | 1378.48 | 3.86 | |

| IV | 1417.98 | 1.10 | |

| V | 1429.16 | 0.32 | |

| VI | 1430.32 | 0.24 | |

| VII | 1430.5 | 0.23 | |

| VIII | 1428.66 | 0.36 | |

| IX | 1429.16 | 0.32 | |

| X | 1424.85 | 0.62 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saquib, A.N.; Khaleed, H.M.T.; Badruddin, I.A.; Algahtani, A.; Addas, M.F.; Abdullah, A.B.; Athani, A.; Kamangar, S.; Khan, T.M.Y. Development of Preform for Simulation of Cold Forging Process of A V8 Engine Camshaft Free from Flash & Under-Filling. Mathematics 2019, 7, 1026. https://doi.org/10.3390/math7111026

Saquib AN, Khaleed HMT, Badruddin IA, Algahtani A, Addas MF, Abdullah AB, Athani A, Kamangar S, Khan TMY. Development of Preform for Simulation of Cold Forging Process of A V8 Engine Camshaft Free from Flash & Under-Filling. Mathematics. 2019; 7(11):1026. https://doi.org/10.3390/math7111026

Chicago/Turabian StyleSaquib, A.N., H.M.T. Khaleed, Irfan Anjum Badruddin, Ali Algahtani, M.F. Addas, A.B. Abdullah, Abdulgaphur Athani, Sarfaraz Kamangar, and T.M. Yunus Khan. 2019. "Development of Preform for Simulation of Cold Forging Process of A V8 Engine Camshaft Free from Flash & Under-Filling" Mathematics 7, no. 11: 1026. https://doi.org/10.3390/math7111026

APA StyleSaquib, A. N., Khaleed, H. M. T., Badruddin, I. A., Algahtani, A., Addas, M. F., Abdullah, A. B., Athani, A., Kamangar, S., & Khan, T. M. Y. (2019). Development of Preform for Simulation of Cold Forging Process of A V8 Engine Camshaft Free from Flash & Under-Filling. Mathematics, 7(11), 1026. https://doi.org/10.3390/math7111026