1. Introduction

Autonomous mobile robots are everywhere today, providing various services, such as cleaning, logistics, inspection, and security. They reduce the human effort needed to perform repetitive, unhygienic, and unsafe tasks and help to solve labor-related availability, cost, and quality problems. Studies show that there is a vast market for service robots, estimated to be valued at USD 243.9 billion by 2030, compared to USD 36.5 billion in 2021 [

1]. Many research works have been published that enhance the fundamental techniques of robotics, mainly seeking to develop their autonomous behavior and functional performance. Specific aspects include better area coverage [

2,

3], optimized path planning [

4,

5], perception [

6,

7], performance measurement [

8,

9], energy efficiency [

10,

11], human–robot interaction [

12], and fleet management [

13]. Many mobile robots are deployed in human-shared workplaces; hence, the robot’s health and operational safety are vital. In this context, the current studies are more focused on avoiding collisions with static and dynamic large obstacles in their heading direction [

14,

15]. However, research on the various factors causing accelerated system degradation, sources of failure or abnormal operation, condition monitoring (CM) methods, and possible ways to minimize such exposure is rare regarding mobile robots. Towards this goal, we have recently developed three CM frameworks using different sensors, mainly an inertial measurement unit (IMU), a monocular camera, and a combination of an IMU and current sensors [

16,

17,

18] for indoor mobile robots. Uneven, unstructured, and rough terrain are significant but rarely considered factors causing accelerated deterioration in mobile robots. CM studies enable the detection of any potential failure. However, avoiding such terrain-related anomalies is a more productive solution, especially when the robot is deployed in a particular workspace for repetitive tasks, such as inspection, logistics, patrolling, etc. Hence, this study proposes a new path planning strategy to minimize the robot’s traversal over undesirable terrain, thereby enhancing its reliability and operational safety.

1.1. Problem Statement

Manufacturers and contract companies mostly carry out manual supervision and periodic maintenance to monitor and resolve their robots’ system degradation and operational safety-related concerns. However, this consumes time, is skill-set-dependent, and leads to the underutilization of components. The degradation rate or maintenance costs greatly depend on the nature of the deployment environment, mainly in terms of the roughness levels of floors, various floor objects, and imperfections. Although the floor roughness and types of surface imperfections vary from building to building, the current practice involves an hourly or monthly-based fixed rental charge [

19]. In addition, the number of floor imperfections may become worse over time or due to dynamic environmental or climatic changes. To date, various path planning approaches have been studied, considering the area coverage, distance, time, and energy [

4,

20,

21,

22,

23,

24] associated with mobile robots. However, no path planning strategies are available that focus on terrain-induced vibration as a cost factor to minimize system degradation and avoid operational hazards in mobile robots. Hence, a real-time terrain-induced vibration class-aware CM framework is needed, as well as the continuous learning and updating of terrain anomalies due to dynamic changes in the terrain state and the selection of a path by eliminating such terrain features. Towards this goal, this study proposes a novel vibration-aware path planning optimization strategy that avoids the traversal of extremely rough terrain areas to enhance the system’s reliability and operational safety.

Floors, especially those in large workplaces, are usually composed of different materials with varied textures or roughnesses. Various floor components, such as tactile pavements, power pockets, and grip platforms for escalator areas, are also observed. There could also be other floor imperfections, such as cable routing, small steps or slopes due to unevenly paved tiles, and gutters or broken floors due to poor workmanship or maintenance, poor material quality, or aging. All of these factors generate terrain-induced vibration in an indoor mobile robot, which results in faster system degradation and wear, misalignment, wobbling or damage to the drive wheels, shorter life cycles for the payload and other critical parts, imbalanced structures, performance degradation, sensor accuracy errors, unplanned downtime, catastrophic failures, higher maintenance costs, and safety issues. These floor-level objects, imperfections, and floor textures are not captured as obstacles in the 2D LiDAR-generated grid map for robot navigation. In our previous CM case studies [

16,

17,

18] focused on predicting the sources of anomalous vibration in a mobile robot, the robot failed due to severe wheel wobbling in two weeks when deployed on concrete with a small pebble-paved corridor. After one month of continuous running, a similar but minor failure was noticed when tested on a regular concrete floor. Hence, it is essential to create an automated system that is aware of the roughness or imperfections of floors based on the level of vibration induced and to select a path that avoids such vibration-prone areas in its next cycle of operation.

1.2. Research Contributions

The main research contributions of this work are summarized below.

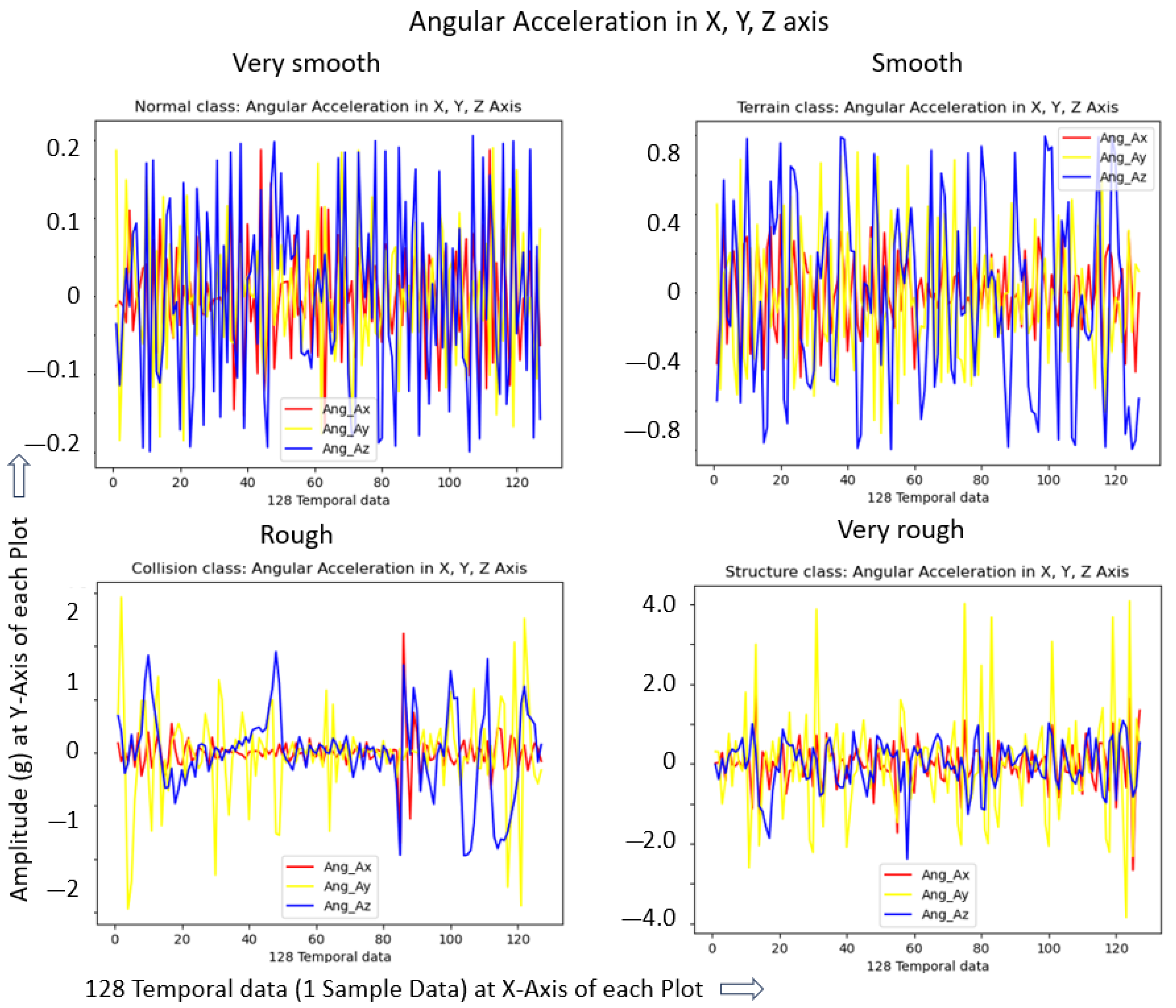

The change in the robot’s linear and angular motion due to extremely rough terrain is captured using an onboard IMU sensor and modeled as vibration-indicated data.

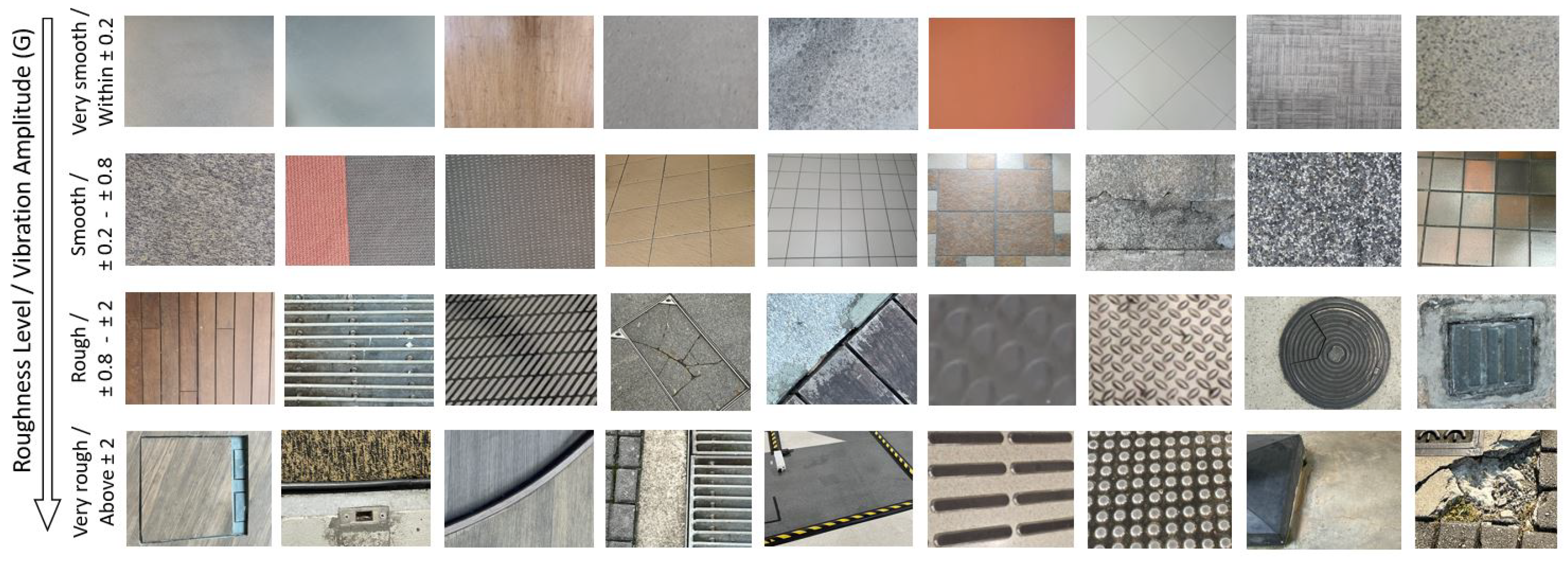

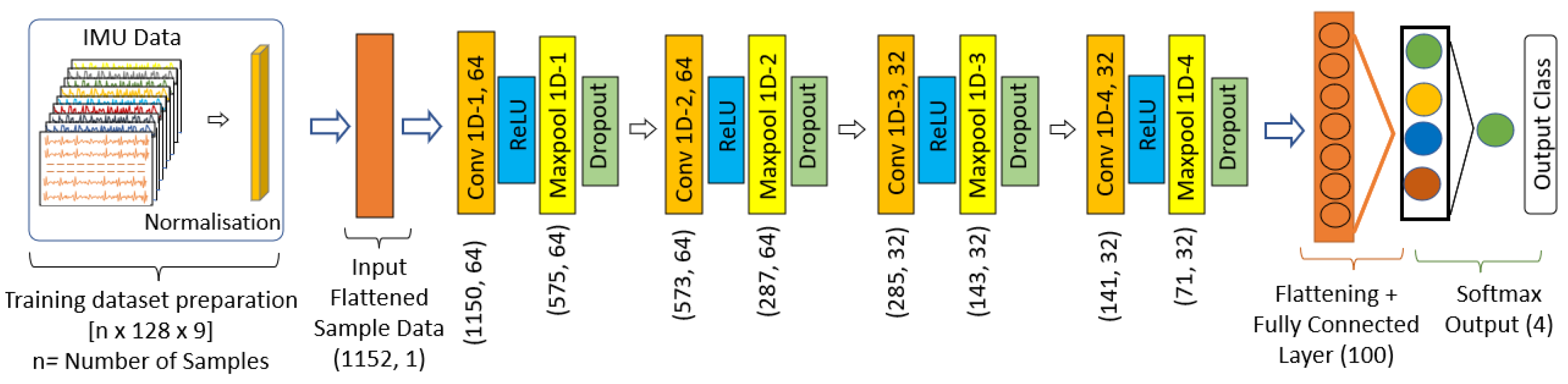

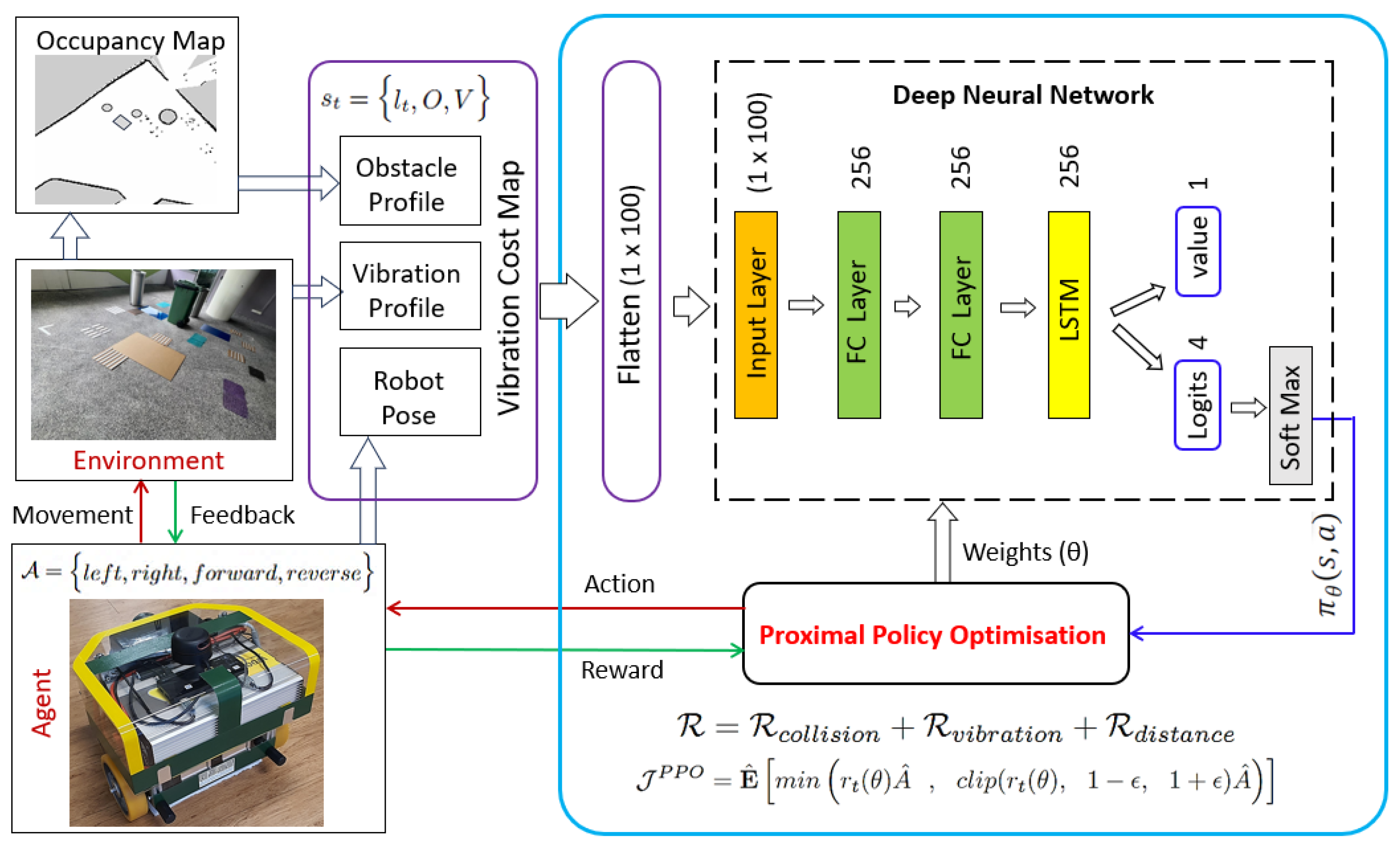

The robot’s vibrations due to rough terrain features are classified into four levels, from very smooth to very rough and from safe to unsafe, and a real-time vibration class prediction model is developed, adapting a 1D CNN-based model.

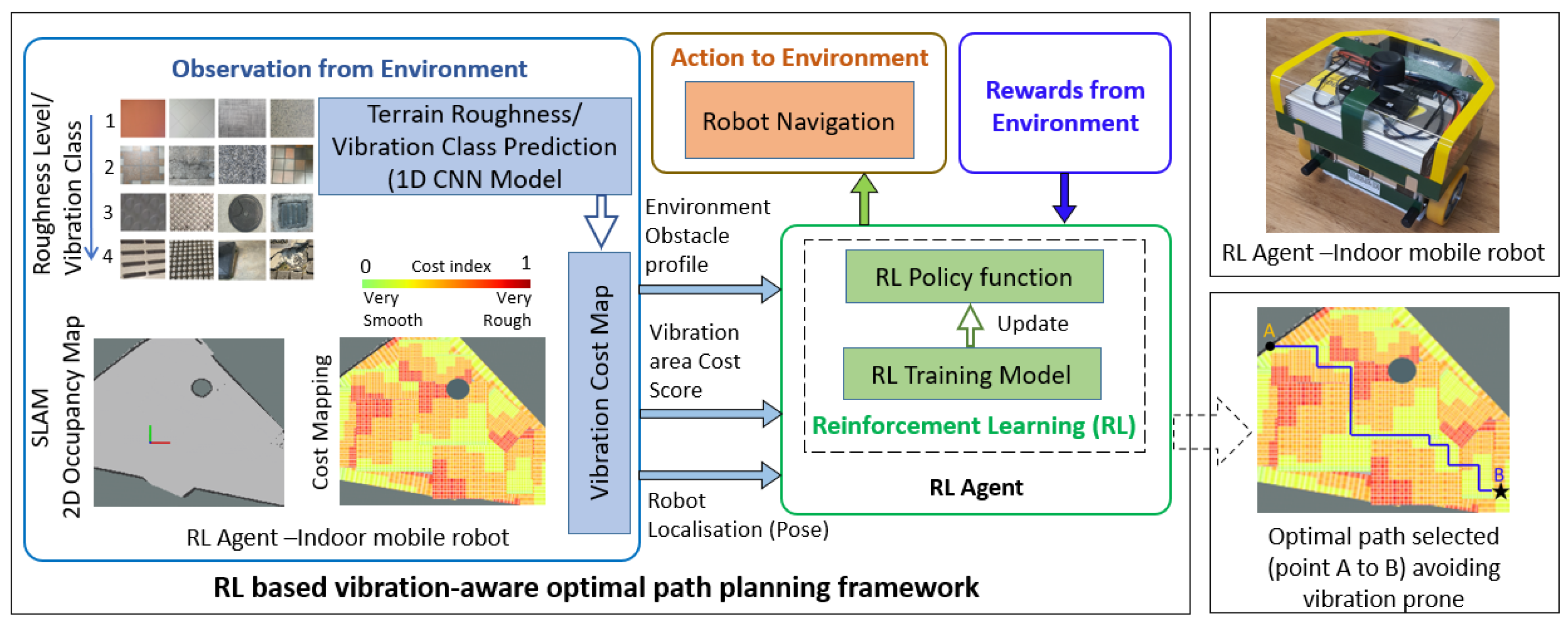

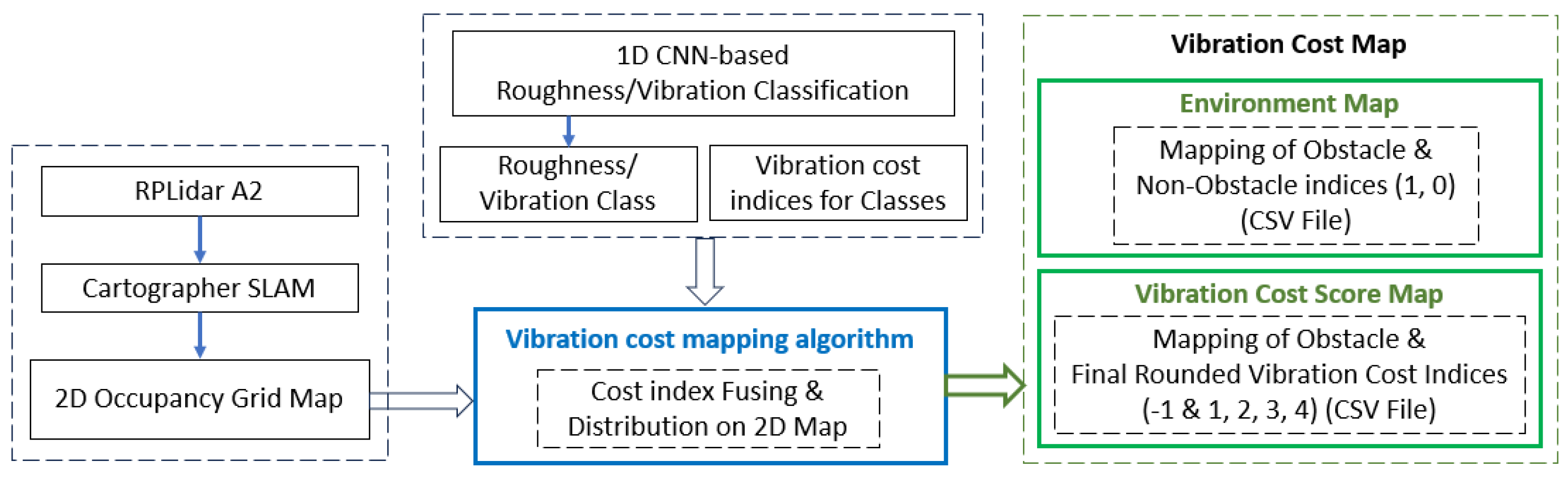

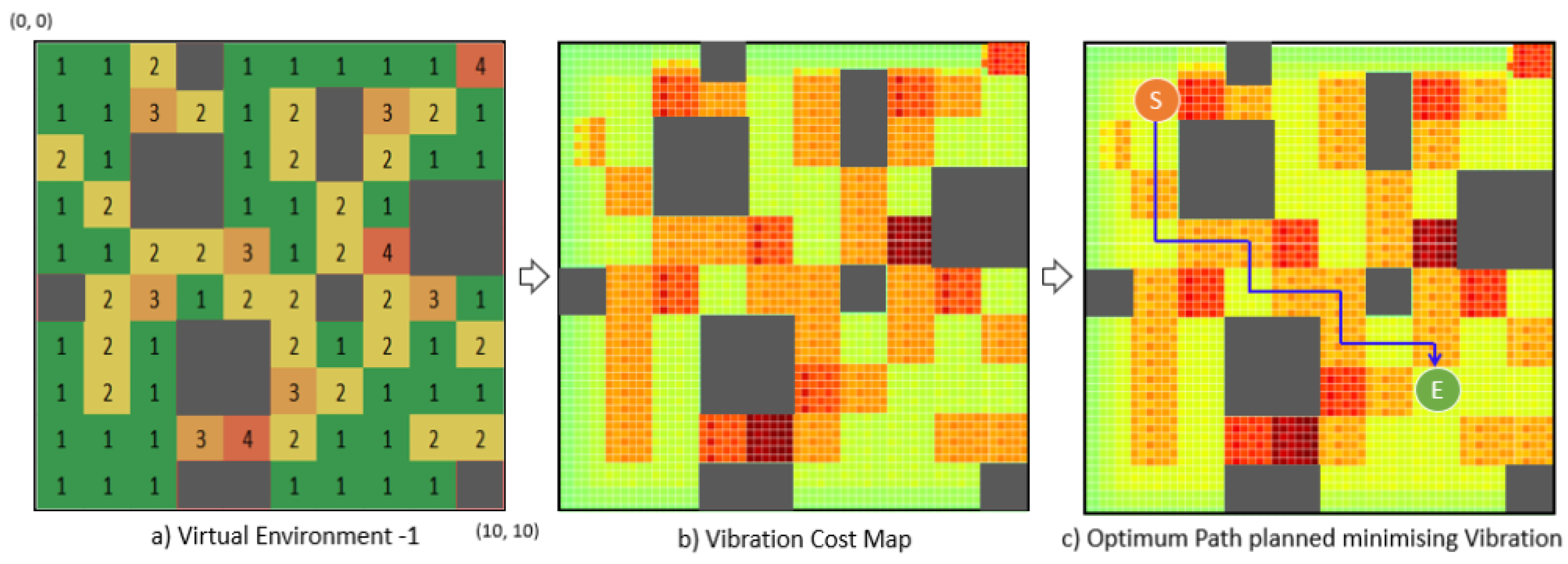

An algorithm is formulated to fuse the vibration cost, assigned to each vibration class predicted for every footprint of the robot, and a 2D occupancy grid map of the robot’s workspace, and we develop a vibration cost map. This map contains profiles of obstacles, the roughness score of the workspace at a unit area, and the robot’s pose for navigation.

A novel RL-based vibration-aware path planning strategy for indoor mobile robots is proposed, using the vibration cost map as input and aiming to minimize system deterioration by avoiding traversal through extremely rough terrain. This is realized by

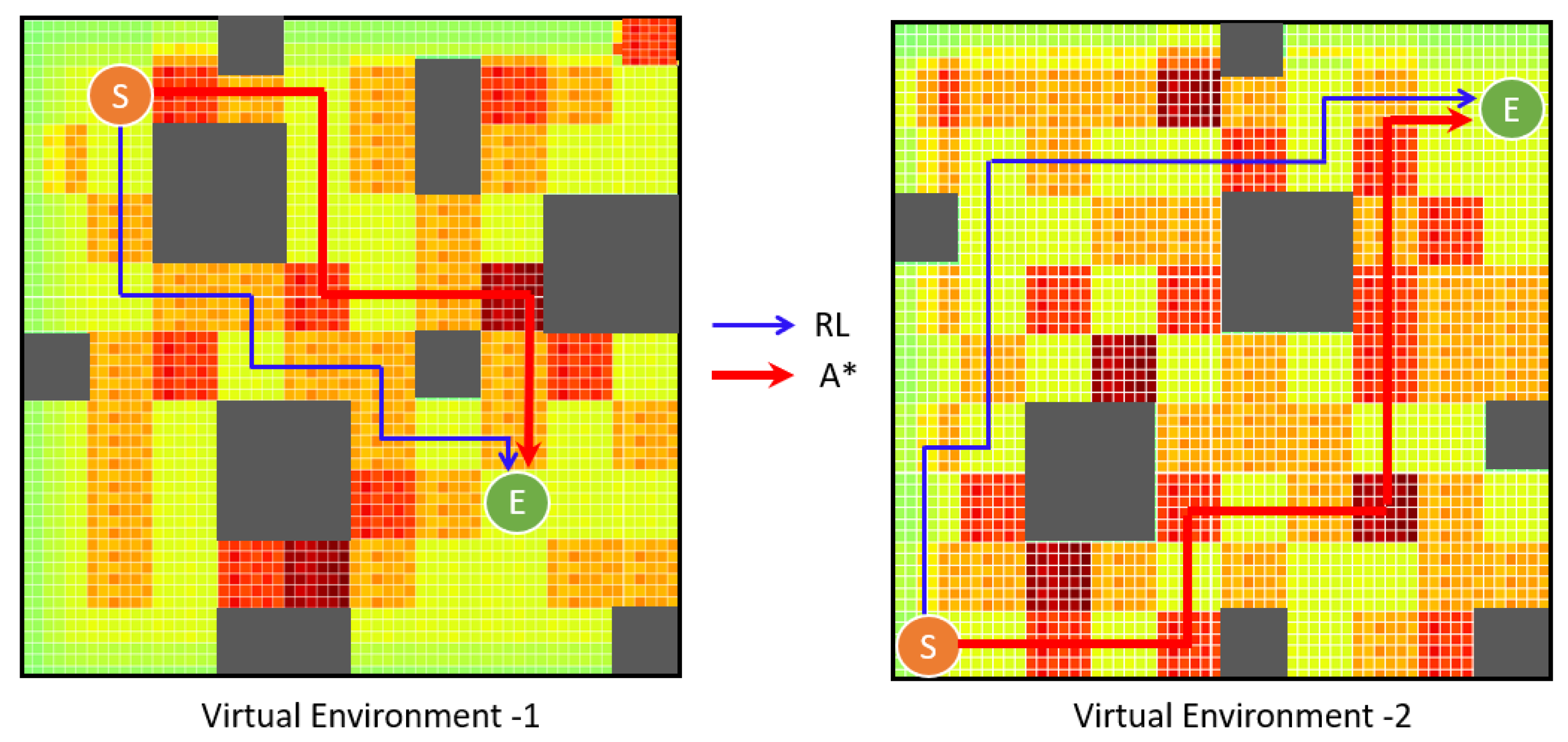

We validate the proposed framework through virtual and real-time case studies with an in-house-developed autonomous mobile robot. In addition, we compare it with the robot’s existing A*-based path planning strategy by proposing a performance index in terms of the total movement (distance) and roughness scores.

The outline of this paper is as follows.

Section 2 explains the related works published.

Section 3 provides an overview of the proposed system, consisting of a terrain-induced vibration classification model, vibration cost map generation, and an RL framework.

Section 4 elaborates on the training models, evaluations, and results.

Section 5 explains the real-time field case studies and results. Finally,

Section 6 summarizes the present work.

2. Related Works

Several vibration data-based studies have been conducted for applications such as monitoring abnormal working conditions in various systems and traversability assessment for mobile robots. Vibrations induced by different indoor floors—ceramic tiles, linoleum, carpet, and terrazzo—were classified using an IMU sensor and linear Bayes normal classifier model to ensure the smooth operation of wheeled mobile robots in [

25]. Similarly, a terrain classification study on terrain obstacles in the human environment was conducted in [

26] to distinguish traversable regions based on 2D LiDAR data and the support vector data description (SVDD) technique. However, the majority of the terrain-based classification studies [

27,

28,

29] have been conducted for the maneuverability assessment of outdoor mobile robots and autonomous ground vehicles, distinguishing between concrete, sand, gravel, grass, and mud. Meanwhile, studies on the classification of the roughness and imperfection levels of indoor floors for the optimization of path planning are rare in terms of indoor mobile robots. Developing a suitable AI classification model based on the nature of raw data, with high training accuracy and fast and easy execution for real-time applications, is critical. The 1D CNN model is widely used in vibration data-based studies, especially for CM applications, due to its low computational complexity and ease of configuration [

30]. For instance, it has been examined regarding the abnormal operation of bearings [

31], motors [

32], structural systems [

33], and industrial robots [

34].

Feasible and optimal path planning is essential for the efficient performance of mobile robots. Graph search algorithms, such as Dijkstra’s algorithm [

35] and A* [

36], are popular in terms of obtaining the path with the lowest cost. Furthermore, extensions of the A* algorithm, such as D* [

37] and D* Lite [

38], have been developed, which incorporate any changes in the path planning graph using heuristics for fast replanning. Voronoi diagram-based path planning for mobile robots [

39,

40] is helpful for shorter paths and unknown static obstacles, enabling real-time path planning. However, the work in [

41] shows the limitations of the above typical algorithms, such as slow speeds (Dijkstra), proximity to obstacles (A*), and not considering vehicle constraints (Voronoi). Sampling-based algorithms such as Probabilistic Roadmaps (PRM) [

42] and Rapidly Exploring Random Trees (RRT) [

43] work well in solving path planning problems in high-dimensional configuration spaces, by connecting a set of points sampled from an obstacle-free space and delivering a graph of feasible trajectories. As PRM is based on random sampling, there are possibilities for unconnected graphs at narrow passages, unless the number of nodes increases, bringing a higher computational cost. The standard RRT algorithm also shows limitations, like poor performance in narrow passages. The kinematically feasible path is equally as important as the minimum path cost in mobile robots. For instance, the Lattice planner [

44,

45] is a graph-based path planning algorithm that sets a search space (state lattice) for constrained motion planning and enables the uniform discretization of vertices, extending to the equivalent positions and headings to form feasible motion primitives. Compared to classical methods, evolutionary methods such as the genetic algorithm (GA) [

46], ant colony optimization (ACO) [

47], particle swarm optimization (PSO) [

48], and simulated annealing (SA) [

49] are found to be faster in solving path planning problems. However, the dynamically changing terrain-related features are not considered in these approaches as a cost factor in view of the robot’s health.

In recent years, the exploration of unstructured and dynamically changing unknown environments using RL techniques has been widely conducted regarding the application of motion planning in mobile robots [

50,

51,

52,

53]. This intelligent learning-based path planning approach helps in reducing the programming complexity and eliminates the slow convergence and dependency on prior environmental knowledge compared to traditional graph, sampling, and evolutionary path planning methods. A deep Q-network (DQN)-based global path planning method is presented in [

54] for mobile robots in dense environments, using RGB images as input to the DQN. The authors compared the model’s efficiency with that of the A* and Dijkstra algorithms and found that it was much faster due to inferring the optimal path and avoiding obstacles. As per [

55], the DQN approach is limited to discrete action spaces; hence, they proposed a soft actor–critic (SAC) algorithm for mobile robots, with continuous numerical values and a potential energy function for improved rewards. This avoids static and dynamic obstacles without prior knowledge in complex environments. The Reconfigurable Structure of Deep Deterministic Policy Gradient (RS-DDPG) was applied for mobile robots in unknown dynamic environments in [

56]. Here, the authors used an event-triggered reconfigurable actor–critic network to avoid overestimating the action value, improved the time convergence with a minor valuation deviation, added an adaptive reward mechanism due to the lack of sample information, and used a sample pretreatment method for better learning efficiency. A visual-guided tracking task issue in a snake-like robot with many joints was solved using a model-free RL algorithm in [

57], mapping the vision space to a joint space. For this perception to action control task, Proximal Policy Optimization (PPO) was adopted to train the network, as PPO is easy to implement and performs better in continuous action spaces [

58]. Besides perception and navigation, the RL approach was applied for a search and rescue task in [

59], where an A3C network with frontier exploration was used.

Studies on obtaining a smooth path in an unstructured environment constitute another emerging area in path planning approaches. Considering the unstructured characteristics of the environment, an improved A*-based local motion planning algorithm was proposed in [

60] for autonomous vehicles. Similarly, an improved A* algorithm suitable for long-distance off-road path planning was developed using a terrain data map in [

61]. A human-like motion planning tool suitable for mobile robots deployed in indoor complex environments was introduced in [

62], where it ensured foreseeability, flexibility, velocity-adjustable trajectory planning, addressing the constraints of both the robot and environment. An energy-aware path planner for mobile robots deployed in uneven terrain environments was proposed in [

63], where the sequential context of traversed terrain was captured using a 1D CNN and correlated with the assessed terrain point clouds to determine the energy used.

The above works show that many path planning and optimization algorithms and their improved or hybrid versions have been developed, including AI-supported terrain classification works focusing on mobile robots. These mainly focus on the minimum path length, time, energy, computational costs, avoidance of obstacles, and plausible trajectories. However, there are no vibration-based path planning strategies for indoor mobile robots considering degradation due to the dynamically changing roughness and imperfections of various floors in large workplaces. Thus, the goal of this study was to develop a deep reinforcement learning (DRL)-based feasible path planning strategy, avoiding dynamically changing and unknown terrain-induced abnormal vibrations, for an autonomous indoor mobile robot. This enables the minimization of accelerated system degradation, reduced maintenance costs, and the avoidance of operational hazards due to unexpected wheel wear or damage, wobbling, and loose sensor assemblies.

5. Real-Time Field Case Studies and Validation

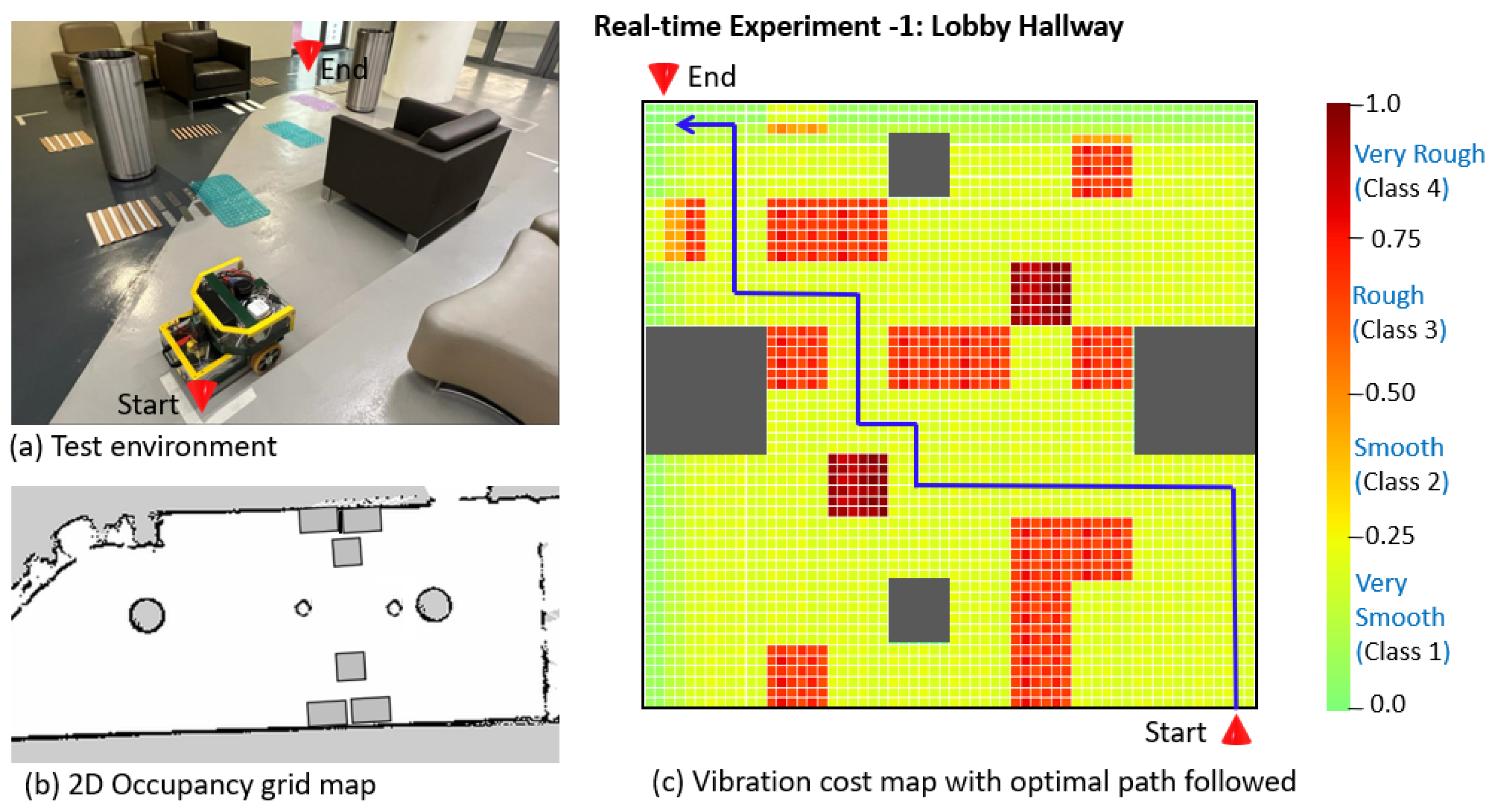

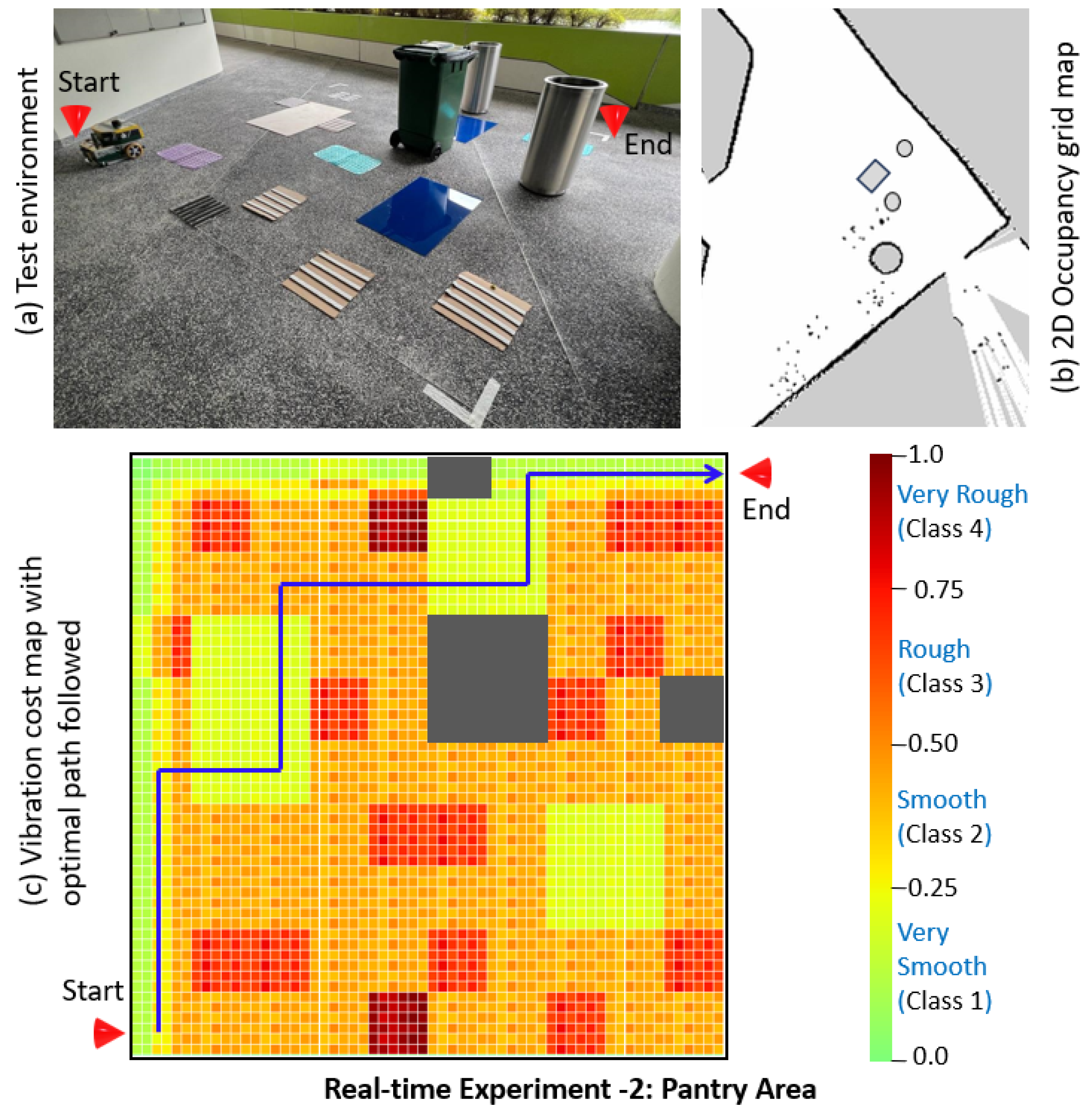

The effectiveness of the proposed vibration-aware RL-based path planning framework is evaluated using the virtual environments from the previous section. However, the framework’s performance needs to be validated in real-world scenarios to ensure real-time application. Hence, this section details two real-time experiments conducted by selecting two different environments and using the indoor mobile robot test platform described in the above section. The use of a single area representing all four roughness classes was one of the limitations in selecting the environment for real-time tests; hence, different types representing the typical terrain features were included, covering all classes for both experiments. This included hard bubbled mats, uniformly paved metal strips, and hard rubber strips of various thicknesses, kept at varied gaps. We used thin mica sheets to simulate the very smooth class. All floor objects were firmly fixed, with the floors similar to the built-in setup, and we ensured no shaking or breakage when the robot traveled on these objects during 2D occupancy grid mapping/scanning. A total of 4 m × 4 m was selected, and a 10 × 10 matrix was used for both case studies, similar to the virtual environments. A lobby hallway was chosen for the first case study (Real-Time Experiment 1) as the environment. This was a well-maintained concrete floor with a painted smooth finish, representing class 1 (very smooth). For the second case study (Real-Time Experiment 2), a pantry area was selected, where the floor was paved with small pebbles, which represented roughness class 2. Meanwhile, for the smooth class, thin mica sheets were used. We added sofas and large trash bins as obstacles. The testbed setups for Experiments 1 and 2 are shown in

Figure 13a and

Figure 14a, respectively.

First, the 2D occupancy grid map was generated for both environments, using the onboard RP LiDAR scanner and Cartographer SLAM algorithm, as shown in

Figure 13b and

Figure 14b, generating the obstacle profiles. Further, using the inference engine algorithm, the roughness classes of both environments were predicted by covering the whole 4 m × 4 m area in a zig-zag pattern. The robot’s linear speed was set at 0.08 m/s, and the IMU subscription rate was 100 Hz, as per the vibration cost mapping algorithm. Hence, a new roughness class was predicted at every 0.1 m, and the roughness levels were distributed per footprint as per the vibration cost mapping framework, as explained in the previous section, generating the vibration profile. Finally, the robot’s start and end point coordinates were assigned, generating the vibration cost map as input to the RL-based network. The PPO rollout generated a path, minimizing the traversal through the vibration prone-area and calculating the shortest path, as marked on the vibration cost map in

Figure 13c and

Figure 14c for Experiments 1 and 2, respectively.

Further, the efficiency of the proposed RL-based vibration-aware path planning algorithm compared to the existing A* path planning algorithm is assessed based on the two real-time experiments conducted. Accordingly, the performance indices (PIs) for Experiments 1 and 2 are 1.22 and 1.41, respectively. Here, the two models finished with the same number of movements for both experiments, i.e., 18. The roughness scores for Experiment 1 were 27 and 17 for A* and RL, respectively. Similarly, for Experiment 2, they were 38 and 27 for A* and RL, respectively, as given in

Table 4. Hence, the effectiveness of the proposed R-based vibration-aware path planning framework is validated for real-time applications in real-world scenarios, being able to enhance the robot’s health and operational safety by eliminating the extremely rough areas of the floor. As the roughness levels of floors will change over time, the 1D CNN-based inference engine will keep the roughness classes updated. Based on the updated vibration cost map, this change in the environment will further update the RL policy, which will roll out updated path plans. This RL-based approach enhances the robot’s health irrespective of the changes in the roughness levels of the floor (environment) over time.

6. Conclusions

Terrain-induced vibration is one of the critical sources of system deterioration in mobile robots, and the terrain features change based on the external and environmental conditions. Hence, in this work, we propose a new type of path planning strategy, adding extremely rough terrain features as a cost factor and a reinforcement learning-based path planning strategy for the self-learning of the changes in terrain features. The typical terrain features based on the vibration level generated are classified into four classes—very smooth, smooth, rough, and very rough—and classified by adopting a 1D CNN-based model for real-time prediction, yielding high accuracy (97%). A vibration cost mapping algorithm is developed to generate a vibration cost map containing the environment’s obstacle profile, the vibration profile, and the robot’s pose. It is used as input for the RL-based path planning framework to update the RL policy. An RL policy function is modeled for vibration state rewards as a Markov Decision Process (MDP), and a deep RL training model is developed to fine-tune the policy via Proximal Policy Optimization (PPO). An in-house-developed autonomous indoor robot is used as an RL agent. The proposed path planning framework, minimizing the traversal through anomalous terrain features, is evaluated using two virtual environments and validated by testing with two real-world environments. A comparison study with the existing path planning approach (A*) is conducted, and a performance index is proposed to measure the proposed framework’s effectiveness. The RL policy exhibits the same number of movements (total distance traveled) and significantly reduces the roughness score by choosing a path that avoids anomalous terrain areas.

The results demonstrate that the proposed RL approach to path planning for mobile robots, which avoids extremely rough areas, enhances the robot’s reliability and operational safety, reduces the maintenance costs, and facilitates corrective actions for terrain anomalies. In future work, we plan to test this model against other existing path planning methods, such as Dijkstra, RRT, and state lattice, for comparison purposes. Additionally, we aim to explore an RL-based, terrain-induced, vibration-aware path planning approach for outdoor mobile robots.