Multiscale 1D-CNN for Damage Severity Classification and Localization Based on Lamb Wave in Laminated Composites

Abstract

1. Introduction

2. Proposed Methodology

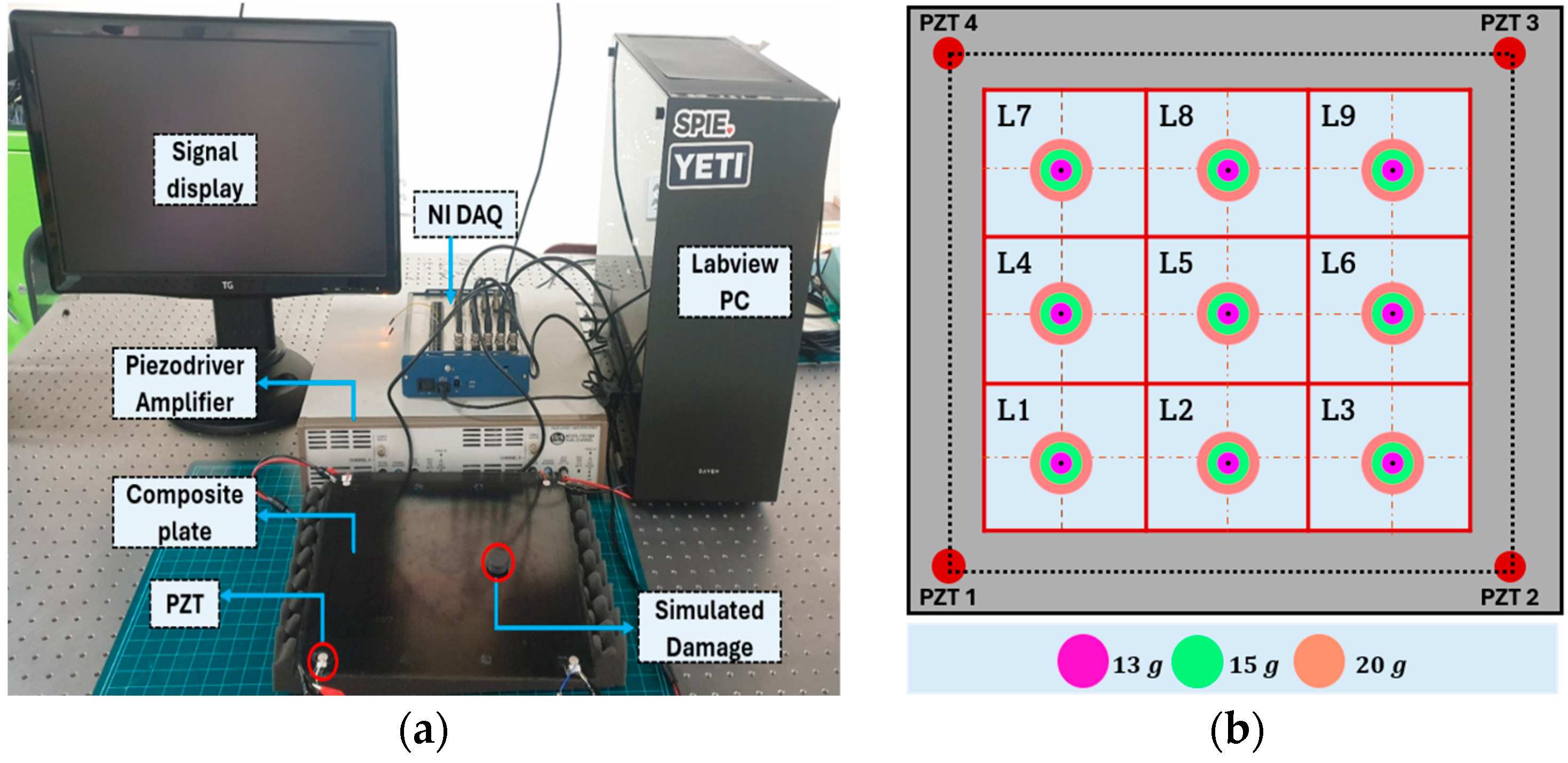

2.1. Material Preparation

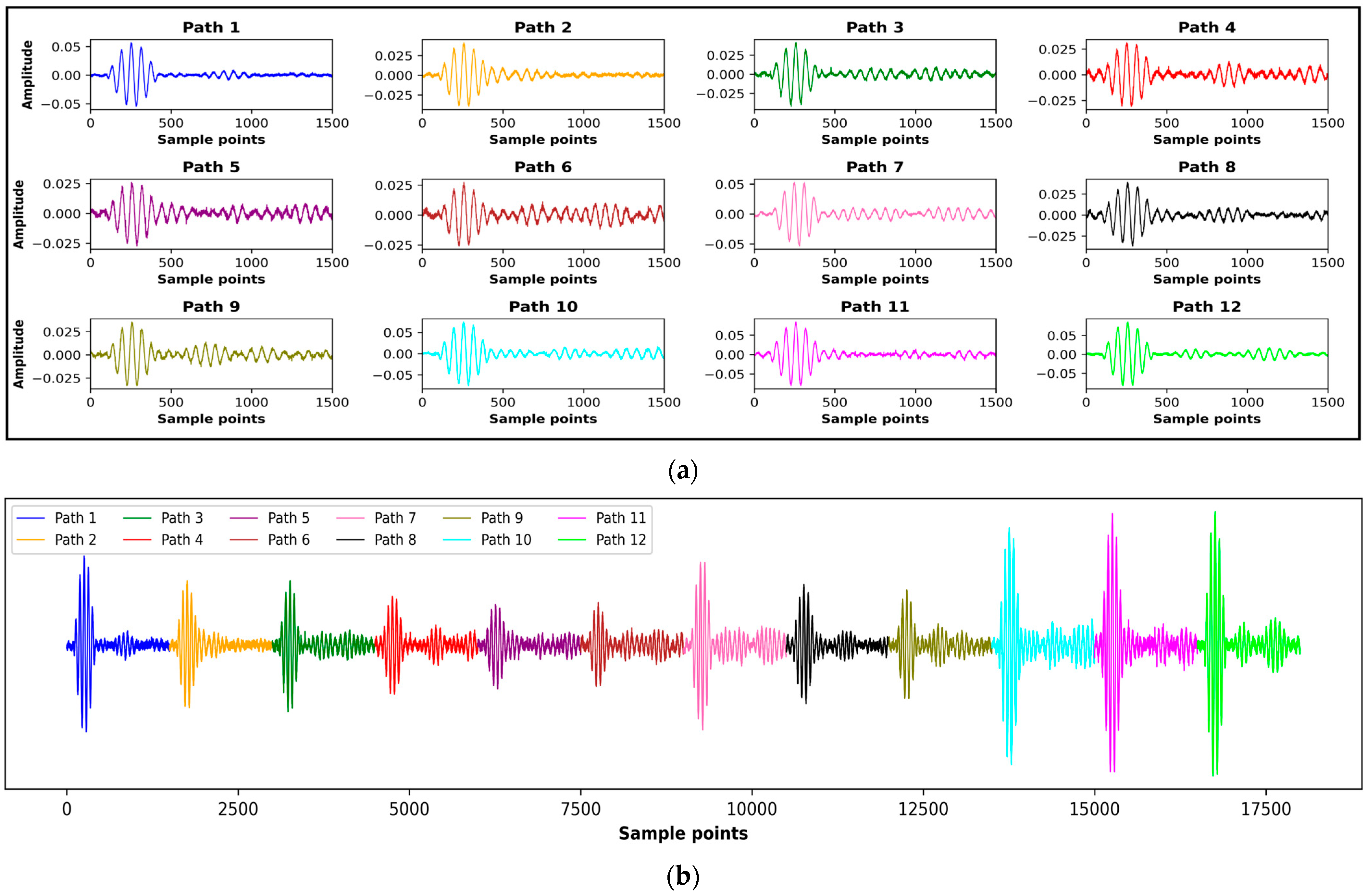

2.2. Lamb Wave Signal Acquisition

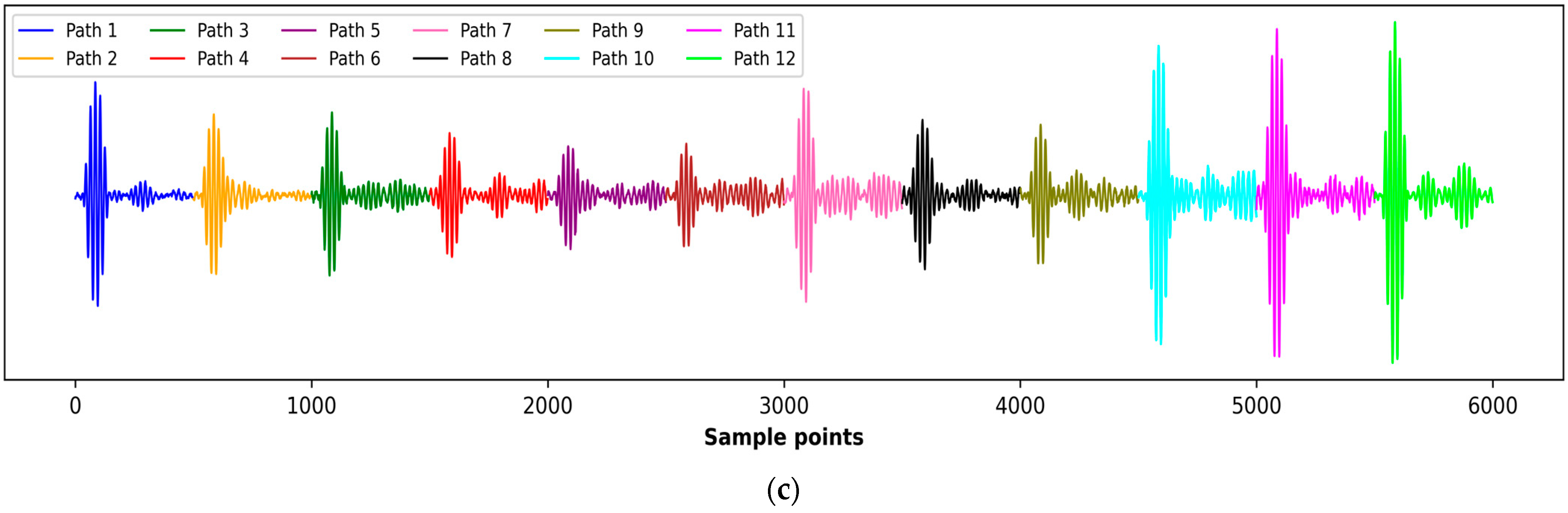

2.3. Data Preprocessing

2.4. ANNs

2.5. SVM

2.6. Fully Convolutional Networks (FCNs)

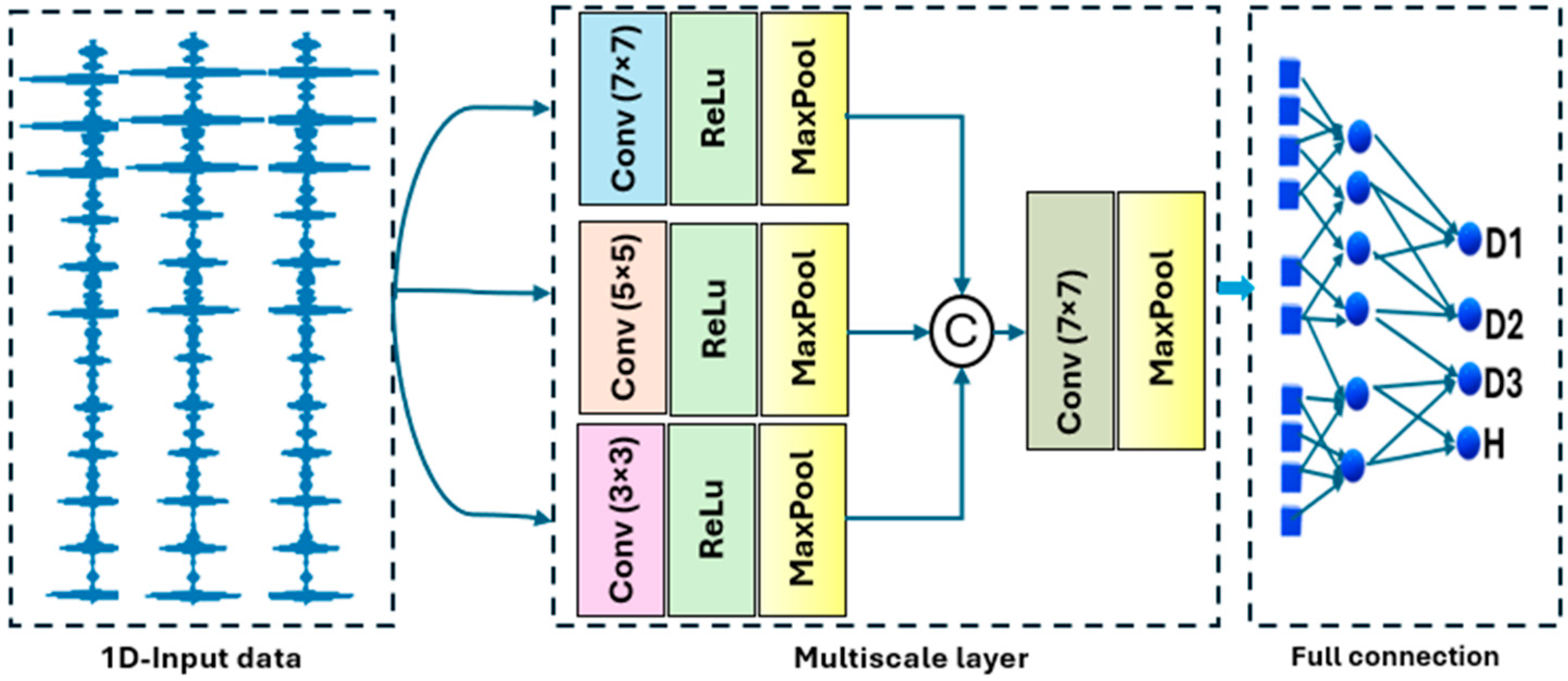

2.7. MS-1D-CNN

2.8. Performance Evaluation Metrics

3. Damage Severity Classification

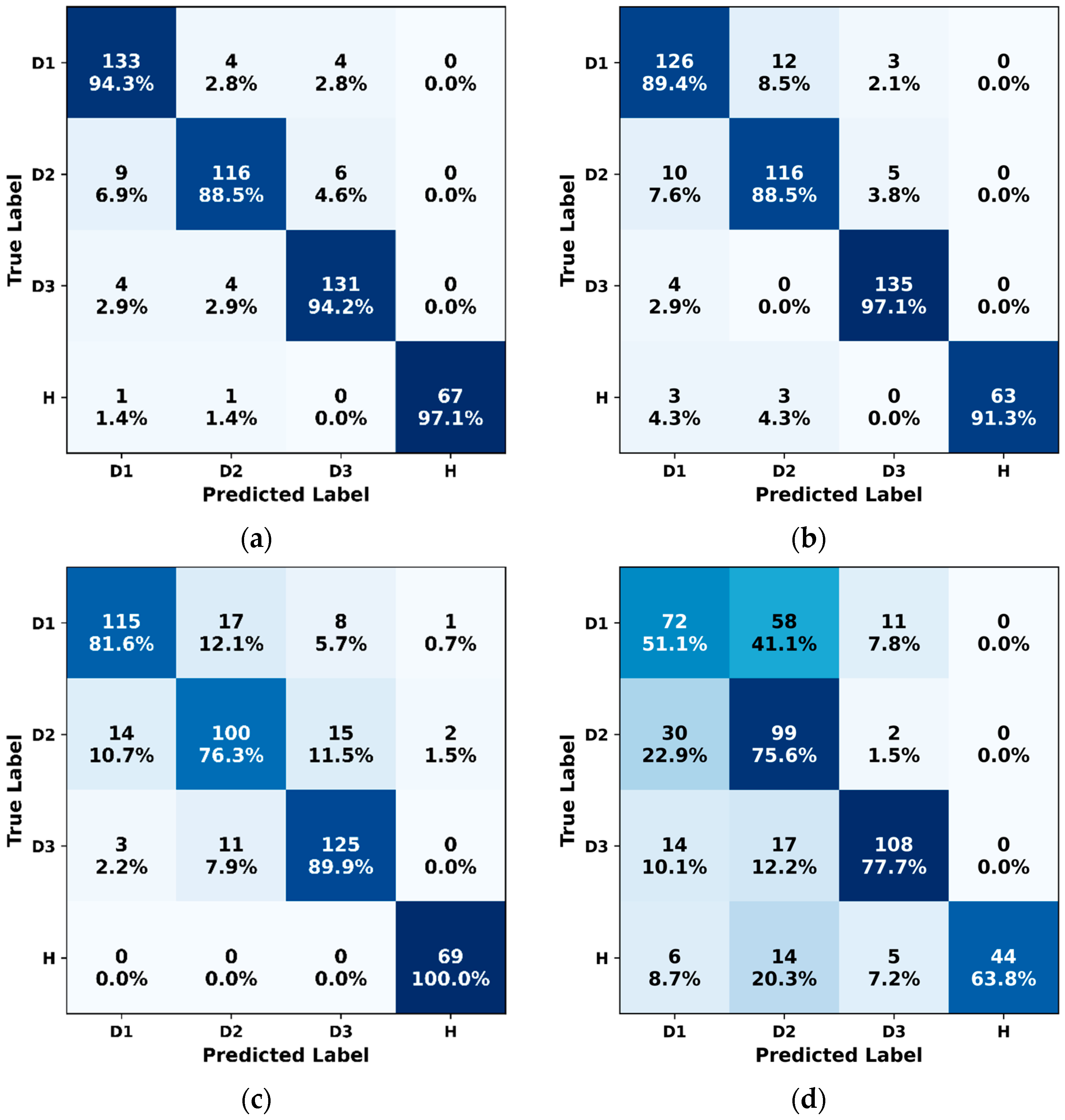

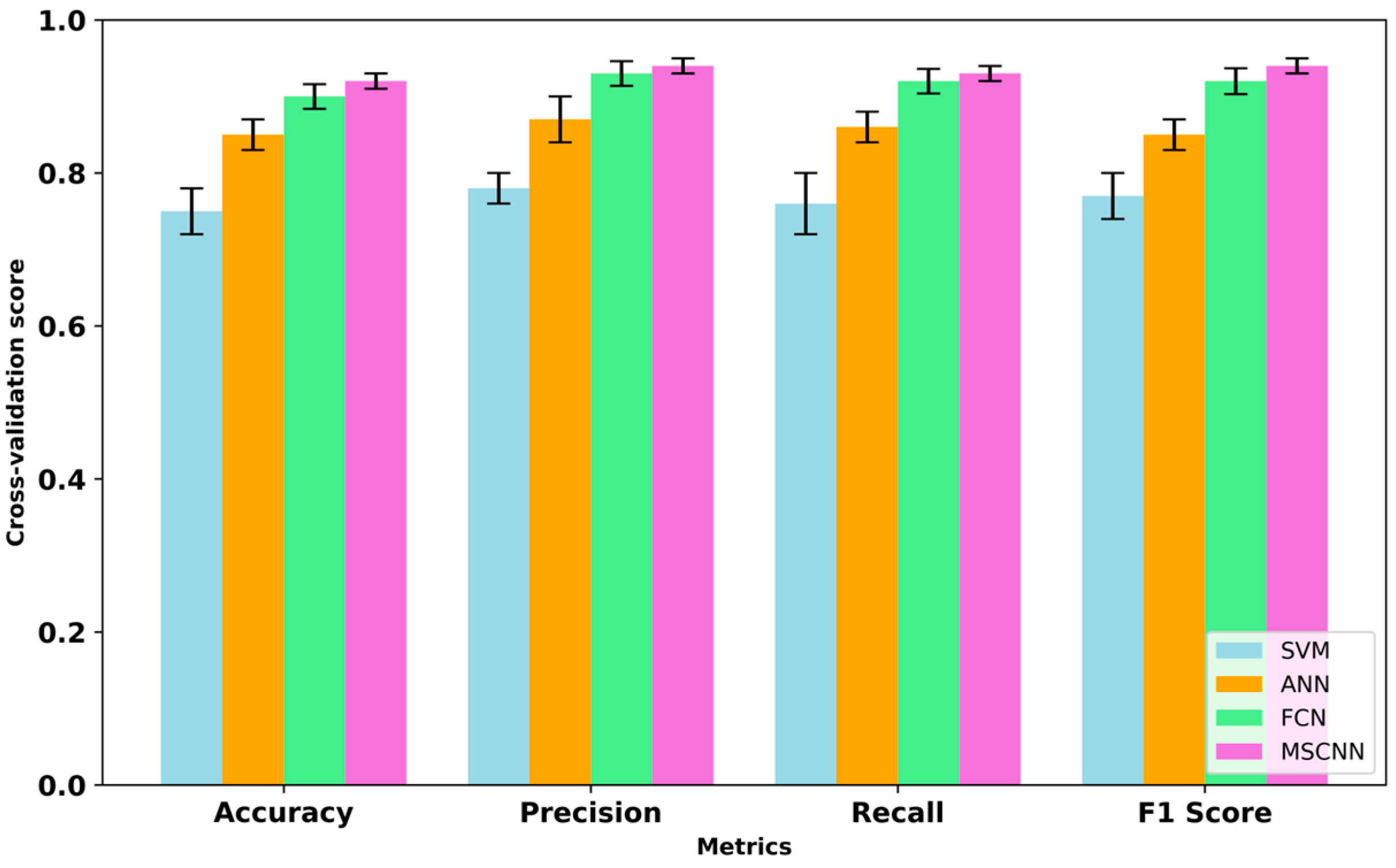

3.1. Performance Comparison with Various Models

3.2. Damage Localization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Hasan, M.; Zhao, J.; Jiang, Z. Micromanufacturing of composite materials: A review. Int. J. Extrem. Manuf. 2019, 1, 12004. [Google Scholar] [CrossRef]

- Singh, H.; Brar, G.S.; Kumar, H.; Aggarwal, V. A review on metal matrix composite for automobile applications. Mater. Today Proc. 2020, 43, 320–325. [Google Scholar] [CrossRef]

- Salama, A.; El-Sakhawy, M. Polysaccharides/propolis composite as promising materials with biomedical and packaging applications: A review. Biomass Convers. Biorefinery 2022, 14, 4555–4565. [Google Scholar] [CrossRef]

- Chi, H.; He, W.; Zhao, D.; Ma, R.; Zhang, Y.; Jiang, Z. Recent progress of dielectric polymer composites for bionics. Sci. China Mater. 2023, 66, 22–34. [Google Scholar] [CrossRef]

- Cao, H.; Ma, Y.; Wu, L.; Yu, L.; Elbadry, E.A.; Yang, W.; Huang, X.; Yan, X. Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites. Rev. Adv. Mater. Sci. 2021, 60, 352–364. [Google Scholar] [CrossRef]

- Kidangan, R.T.; Krishnamurthy, C.V.; Balasubramaniam, K. Identification of the fiber breakage orientation in carbon fiber reinforced polymer composites using induction thermography. NDT E Int. 2021, 122, 102498. [Google Scholar] [CrossRef]

- Humer, C.; Höll, S.; Kralovec, C.; Schagerl, M. Damage identification using wave damage interaction coefficients predicted by deep neural networks. Ultrasonics 2022, 124, 106743. [Google Scholar] [CrossRef]

- Jeon, J.Y.; Miao, Y.; Park, G.; Flynn, E. Compressive laser scanning with full steady state wavefield for structural damage detection. Mech. Syst. Signal Process. 2022, 169, 108626. [Google Scholar] [CrossRef]

- Giannakeas, I.N.; Khodaei, Z.S.; Aliabadi, F.M.H.H. Effect of detection and localization uncertainty on damage size estimation using guided wave based SHM. Procedia Struct. Integr. 2024, 52, 655–666. [Google Scholar] [CrossRef]

- Ullah, S.; Ijjeh, A.A.; Kudela, P. Deep learning approach for delamination identification using animation of Lamb waves. Eng. Appl. Artif. Intell. 2023, 117, 105520. [Google Scholar] [CrossRef]

- Wang, J.; Schmitz, M.; Jacobs, L.J.; Qu, J. Deep learning-assisted locating and sizing of a coating delamination using ultrasonic guided waves. Ultrasonics 2024, 141, 107351. [Google Scholar] [CrossRef] [PubMed]

- Ijjeh, A.A.; Kudela, P. Deep learning-based segmentation using full wavefield processing for delamination identification: A comparative study. Mech. Syst. Signal Process. 2022, 168, 108671. [Google Scholar] [CrossRef]

- Pineda Allen, J.C.; Ng, C.T. Damage detection in composite laminates using nonlinear guided wave mixing. Compos. Struct. 2023, 311, 116805. [Google Scholar] [CrossRef]

- Zeng, X.; Zhao, B.; Liu, X.; Yu, Y.; Guo, J.; Qing, X. Lamb wave-based damage assessment for CFRP composite structures using a CHMM-based damage localization algorithm and a damage quantitative expression. Mech. Syst. Signal Process. 2023, 184, 109750. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, J.; Xu, H.; Yang, L.; Ma, S.; Wu, Z. Phased array system for damage detection in plate-like structures based on single Lamb wave mode extraction. J. Aerosp. Eng. 2023, 36, 04023004. [Google Scholar] [CrossRef]

- Wang, Y.; Liao, Y.; Cui, X.; Huang, Y.; Qing, X. A heterogeneous decision voting-based transfer domain adaptation method for damage localization of CFRP composite structures. Mech. Syst. Signal Process. 2025, 224, 112015. [Google Scholar] [CrossRef]

- Cha, Y.J.; Ali, R.; Lewis, J.; Büyük, O. Deep learning-based structural health monitoring. Autom. Constr. 2024, 161, 105328. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, H.; Tian, T.; Deng, D.; Hu, M.; Ma, J.; Gao, D.; Zhang, J.; Ma, S.; Yang, L.; et al. A review in guided-ultrasonic-wave-based structural health monitoring: From fundamental theory to machine learning techniques. Ultrasonics 2023, 133, 107014. [Google Scholar] [CrossRef] [PubMed]

- Perfetto, D.; Rezazadeh, N.; Aversano, A.; De Luca, A.; Lamanna, G. Composite panel damage classification based on guided waves and machine learning: An experimental approach. Appl. Sci. 2023, 13, 10017. [Google Scholar] [CrossRef]

- Jalali, S.S.; Mahzoon, M.; Mohammadi, H. Identification of damage properties of glass/epoxy laminates using machine learning models. Int. J. Impact Eng. 2023, 177, 104510. [Google Scholar] [CrossRef]

- Dabetwar, S.; Ekwaro-Osire, S.; Dias, J.P. Damage classification of composites based on analysis of Lamb wave signals using machine learning. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B Mech. Eng. 2021, 7, 011002. [Google Scholar] [CrossRef]

- Viotti, I.D.; Gomes, G.F. Delamination identification in sandwich composite structures using machine learning techniques. Comput. Struct. 2023, 280, 106990. [Google Scholar] [CrossRef]

- Lim, D.K.; Mustapha, K.B.; Pagwiwoko, C.P. Delamination detection in composite plates using random forests. Compos. Struct. 2021, 278, 114676. [Google Scholar] [CrossRef]

- Rajeswari, D.; Khalaf, O.I.; Srinivasan, R.; Pushpalatha, M.; Hamam, H. Structural health monitoring of aircraft through prediction of delamination using machine learning. PeerJ Comput. Sci. 2024, 10, e1955. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, L.; Song, R.; Peng, C.; Wu, X.; Wei, J.; Jiang, M.; Sui, Q.; Zhang, L. Damage localization in composite structures based on Lamb wave and modular artificial neural network. Sens. Actuators Phys. 2024, 377, 115644. [Google Scholar] [CrossRef]

- Migot, A.; Saaudi, A.; Giurgiutiu, V. Delamination depth detection in composite plates using the Lamb wave technique based on convolutional neural networks. Sensors 2024, 24, 3118. [Google Scholar] [CrossRef]

- Lee, I.Y.; Jang, J.; Bin Park, Y. Advanced structural health monitoring in carbon fiber-reinforced plastic using real-time self-sensing data and convolutional neural network architectures. Mater. Des. 2022, 224, 111348. [Google Scholar] [CrossRef]

- Rosafalco, L.; Manzoni, A.; Mariani, S.; Corigliano, A. Fully convolutional networks for structural health monitoring through multivariate time series classification. Adv. Model. Simul. Eng. Sci. 2020, 7, 38. [Google Scholar] [CrossRef]

- Parziale, M.; Lomazzi, L.; Rastin, Z.; Giglio, M.; Cadini, F. Unsupervised damage localization in composite plates using Lamb waves and conditional generative adversarial networks. Procedia Struct. Integr. 2024, 52, 551–559. [Google Scholar] [CrossRef]

- Khan, A.; Kim, H.S. Damage assessment of laminated composites using unsupervised autonomous features. J. Thermoplast. Compos. Mater. 2024, 37, 2123–2148. [Google Scholar] [CrossRef]

- Sawant, S.; Sethi, A.; Banerjee, S.; Tallur, S. Unsupervised learning framework for temperature compensated damage identification and localization in ultrasonic guided wave SHM with transfer learning. Ultrasonics 2023, 130, 106931. [Google Scholar] [CrossRef] [PubMed]

- Lomazzi, L.; Junges, R.; Giglio, M.; Cadini, F. Unsupervised data-driven method for damage localization using guided waves. Mech. Syst. Signal Process. 2024, 208, 111038. [Google Scholar] [CrossRef]

- Sattarifar, A.; Nestorović, T. Damage localization and characterization using one-dimensional convolutional neural network and a sparse network of transducers. Eng. Appl. Artif. Intell. 2022, 115, 105273. [Google Scholar] [CrossRef]

- Zong, S.; Wang, S.; Luo, Z.; Wu, X.; Zhang, H.; Ni, Z. Robust damage detection and localization under complex environmental conditions using singular value decomposition-based feature extraction and one-dimensional convolutional neural network. Chin. J. Mech. Eng. 2023, 36, 61. [Google Scholar] [CrossRef]

- Fu, L.; Zhang, L.; Tao, J. An improved deep convolutional neural network with multiscale convolution kernels for fault diagnosis of rolling bearing. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1043, 052021. [Google Scholar] [CrossRef]

- Li, F.; Wang, L.; Wang, D.; Wu, J.; Zhao, H. An adaptive multiscale fully convolutional network for bearing fault diagnosis under noisy environments. Measurement 2023, 216, 112993. [Google Scholar] [CrossRef]

- Liao, Y.; Huang, Y.; Wang, Y.; Wu, M.; Zhang, F.; Qing, X. Complex CFRP damage detection with dual multiscale 1DCNNs and self-selective fusion technique of guided waves. Compos. Struct. 2024, 335, 117993. [Google Scholar] [CrossRef]

- Song, R.; Sun, L.; Gao, Y.; Peng, C.; Wu, X.; Lv, S.; Wei, J.; Jiang, M. Global-local feature cross-fusion network for ultrasonic guided wave-based damage localization in composite structures. Sens. Actuators Phys. 2023, 362, 114659. [Google Scholar] [CrossRef]

- Khurshid, H.; Mohammed, B.S.; Bheel, N.; Cahyadi, W.A.; Mukhtar, H. Study of factors affecting the magnetic sensing capability of shape memory alloys for non-destructive evaluation of cracks in concrete: Using response surface methodology (RSM) and artificial neural network (ANN) approaches. Heliyon 2024, 10, e35772. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, J.; Zhao, J.; Ji, H.; Qiu, J.; Wu, W.; Yang, P. Local wavenumber estimation for small damages based on artificial neural network. NDT E Int. 2023, 138, 102866. [Google Scholar] [CrossRef]

- Santosa, B. Multiclass Classification with cross entropy-support vector machines. Procedia Comput. Sci. 2015, 72, 345–352. [Google Scholar] [CrossRef]

- Nelon, C.M. Detection of delaminations in carbon fiber reinforced polymers embedded with Terfenol-D particles using machine learning. Ph.D. Thesis, Clemson University, Clemson, CA, USA, 2020. [Google Scholar]

- Usmankhujaev, S.; Ibrokhimov, B.; Baydadaev, S.; Kwon, J. Time series classification with inception FCN. Sensors 2021, 22, 157. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Du, J.; Li, S.; Long, Y.; Liang, D.; Liu, Y.; Wang, Y. Multi-scale feature fusion convolutional neural networks for fault diagnosis of electromechanical actuator. Appl. Sci. 2023, 13, 8689. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, C.; Zhang, S. Multiscale convolutional neural networks with attention for plant species recognition. Comput. Intell. Neurosci. 2021, 2021, 5529905. [Google Scholar] [CrossRef]

- Roy, A.M. An efficient multi-scale CNN model with intrinsic feature integration for motor imagery EEG subject classification in brain-machine interfaces. Biomed. Signal Process. Control. 2022, 74, 103496. [Google Scholar] [CrossRef]

- Kim, G.; Park, Y.M.; Yoon, H.J.; Choi, J. A multi-kernel and multi-scale learning based deep ensemble model for predicting recurrence of non-small cell lung cancer. PeerJ Comput. Sci 2023, 9, e1311. [Google Scholar] [CrossRef] [PubMed]

- Azad, M.M.; Raouf, I.; Sohail, M.; Kim, H.S. Structural health monitoring of laminated composites using lightweight transfer learning. Machines 2024, 12, 589. [Google Scholar] [CrossRef]

- Kalimullah, N.M.M.M.; Shelke, A.; Habib, A. A probabilistic framework for source localization in anisotropic composite using transfer learning based multi-fidelity physics informed neural network (mfPINN). Mech. Syst. Signal Process. 2023, 197, 110360. [Google Scholar] [CrossRef]

| Layer | Output Shape | Parameters |

|---|---|---|

| Input layer | (None, 6000, 1) | 0 |

| Conv1 | (None, 6000, 32) | 128 |

| Conv2 | (None, 6000, 64) | 348 |

| Conv3 | (None, 6000, 128) | 1024 |

| Pool1 | (None, 3000, 32) | 0 |

| Pool2 | (None, 3000, 64) | 0 |

| Pool3 | (None, 3000, 128) | 0 |

| Concatenate | (None, 3000, 224) | 0 |

| Conv4 | (None, 3000, 128) | 200,832 |

| Pool4 | (None, 1500, 128) | 0 |

| Flatten | (None, 192,000) | 0 |

| Dense1 | (None, 512) | 98,304,512 |

| Dropout | (None, 512) | 0 |

| Dense2 | (None, 4) | 2052 |

| Total parameters: 98,508,932, Trainable parameters: 98,508,932, Non-trainable parameters: 0 | ||

| Health State | Classifier | Evaluation Metrics | |||

|---|---|---|---|---|---|

| Accuracy | Precision | Recall | F1-Score | ||

| D1 | SVM | 0.50 | 0.55 | 0.50 | 0.53 |

| ANN | 0.82 | 0.90 | 0.82 | 0.86 | |

| FCN | 0.92 | 0.90 | 0.92 | 0.91 | |

| MS-1D-CNN | 0.94 | 0.90 | 0.94 | 0.92 | |

| D2 | SVM | 0.72 | 0.49 | 0.72 | 0.58 |

| ANN | 0.85 | 0.82 | 0.85 | 0.84 | |

| FCN | 0.89 | 0.88 | 0.92 | 0.91 | |

| MS-1D-CNN | 0.89 | 0.93 | 0.94 | 0.94 | |

| D3 | SVM | 0.68 | 0.88 | 0.68 | 0.77 |

| ANN | 0.90 | 0.87 | 0.90 | 0.88 | |

| FCN | 0.91 | 0.90 | 0.93 | 0.92 | |

| MS-1D-CNN | 0.94 | 0.93 | 0.94 | 0.94 | |

| H | SVM | 0.74 | 1.00 | 0.74 | 0.85 |

| ANN | 0.99 | 0.97 | 0.99 | 0.98 | |

| FCN | 0.93 | 1.00 | 0.93 | 0.96 | |

| MS-1D-CNN | 0.97 | 1.00 | 0.97 | 0.99 | |

| Model | |||

|---|---|---|---|

| SVM | 15.80 | 519.74 | 0.87 |

| ANN | 12.34 | 324.77 | 0.90 |

| FCN | 13.75 | 400.10 | 0.91 |

| MS-1D-CNN | 10.57 | 306.29 | 0.93 |

| Actual Location (mm) | Predicted Location for D1 (mm) | Estimated Error (mm) | Predicted Location for D2 (mm) | Estimated Error (mm) | Predicted Location for D3 (mm) | Estimated Error (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 67 | 83 | 72.66 | 79.42 | 6.70 | 66.97 | 88.86 | 5.86 | 64.8 | 84.03 | 2.43 |

| 67 | 154 | 84.55 | 143.09 | 20.66 | 66.62 | 157.5 | 3.52 | 66.63 | 149.93 | 4.09 |

| 67 | 226 | 66.45 | 213.68 | 12.33 | 73.19 | 200.5 | 26.24 | 65.31 | 225.35 | 1.81 |

| 157 | 83 | 149.99 | 80.33 | 7.50 | 152.1 | 91.84 | 10.11 | 155.83 | 78.13 | 5.01 |

| 157 | 154 | 132.67 | 133.34 | 31.92 | 146.3 | 141.92 | 16.14 | 166.72 | 148.51 | 11.16 |

| 157 | 226 | 162.25 | 228.81 | 5.95 | 158.78 | 237.52 | 11.66 | 152.03 | 221.21 | 6.90 |

| 247 | 83 | 239.27 | 89.37 | 10.02 | 221.35 | 77.54 | 26.22 | 241.16 | 88.63 | 8.11 |

| 247 | 154 | 222.23 | 158.24 | 25.13 | 242.07 | 141.33 | 13.60 | 248.67 | 157.72 | 4.08 |

| 247 | 226 | 241.19 | 216.12 | 11.46 | 230.7 | 221.17 | 17.00 | 248.96 | 224.17 | 2.68 |

| Average error (mm) | 14.63 | Average error (mm) | 14.48 | Average error (mm) | 5.14 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munyaneza, O.; Sohn, J.W. Multiscale 1D-CNN for Damage Severity Classification and Localization Based on Lamb Wave in Laminated Composites. Mathematics 2025, 13, 398. https://doi.org/10.3390/math13030398

Munyaneza O, Sohn JW. Multiscale 1D-CNN for Damage Severity Classification and Localization Based on Lamb Wave in Laminated Composites. Mathematics. 2025; 13(3):398. https://doi.org/10.3390/math13030398

Chicago/Turabian StyleMunyaneza, Olivier, and Jung Woo Sohn. 2025. "Multiscale 1D-CNN for Damage Severity Classification and Localization Based on Lamb Wave in Laminated Composites" Mathematics 13, no. 3: 398. https://doi.org/10.3390/math13030398

APA StyleMunyaneza, O., & Sohn, J. W. (2025). Multiscale 1D-CNN for Damage Severity Classification and Localization Based on Lamb Wave in Laminated Composites. Mathematics, 13(3), 398. https://doi.org/10.3390/math13030398