Bridging Project Management and Supply Chain Management via Optimization Method: Scenarios, Technologies, and Future Opportunities

Abstract

1. Introduction

- Conduct a comprehensive bibliometric synthesis of optimization research in PM and SCM, mapping key themes, methodological applications, and their evolution;

- Identify future research opportunities and practical directions by exploring how optimization methods, along with emerging technologies can advance PM–SCM integration.

- What is the current state of research on optimization in the domains of PM and SCM, and how has it evolved over time?

- How can optimization approaches, in combination with emerging technologies, contribute to systematic PM–SCM integration?

- What research gaps and opportunities remain for future scholarly inquiry and managerial practice?

- Provides the first comprehensive bibliometric mapping of optimization research in PM and SCM, thereby identifying key themes, methodological applications, and their intellectual structure.

- Further clarifies the mechanisms through which optimization and emerging technologies enable integration, advancing both theoretical understanding and managerial practice.

- Identifies research gaps and future directions, providing a roadmap for scholars and practitioners seeking to enhance PM–SCM integration.

2. Background

2.1. Project Management

2.2. Supply Chain Management

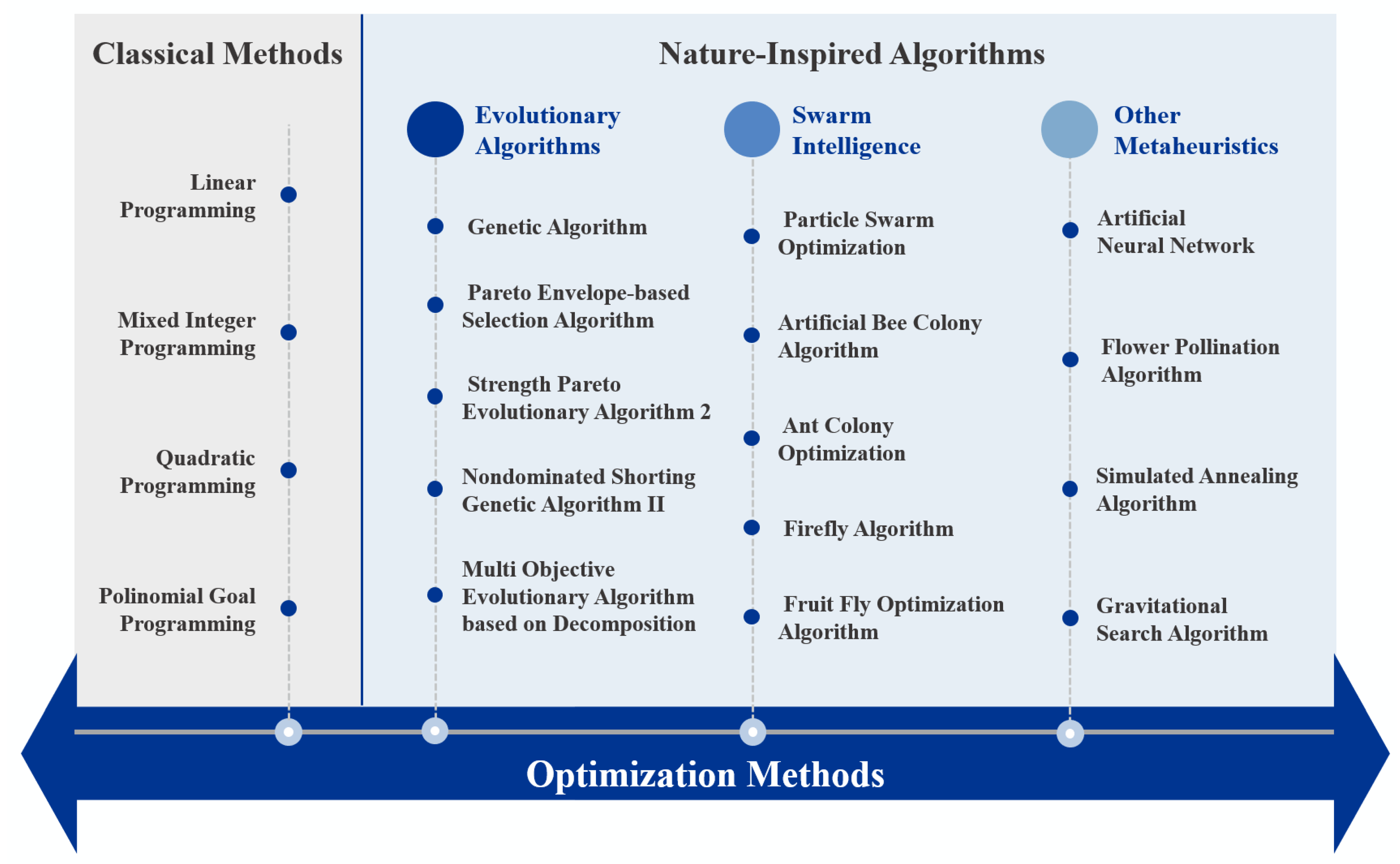

2.3. Optimization Methods

3. Methodology

3.1. Data Sources and Collection

- Collect data for each keyword, including all core and supplementary keywords.

- Conduct preliminary thematic cross-searches using Boolean logic “AND” for all individual keywords. For example: (“Project Management” OR “PM”) AND (“Supply Chain Management” OR “SCM”) AND (“Optimization” OR “Linear Programming” OR “Genetic Algorithm”).

- Combining the aforementioned keyword screening logic with the three-stage combination strategy, the Boolean search logic ultimately determined in this study is: TS = ((“project management” OR “project planning” OR “project scheduling” OR “program management”) AND (“supply chain” OR “logistics” OR “procurement” OR “operations management”) AND (optimization OR “mathematical programming” OR “machine learning” OR “decision support” OR simulation OR modeling OR “artificial intelligence”) AND (integration OR synergy OR coordination OR collaboration OR framework OR scenario* OR application*)).

3.2. Article Screening

3.3. Bibliometric Tools and Techniques

4. Bibliometric Analysis

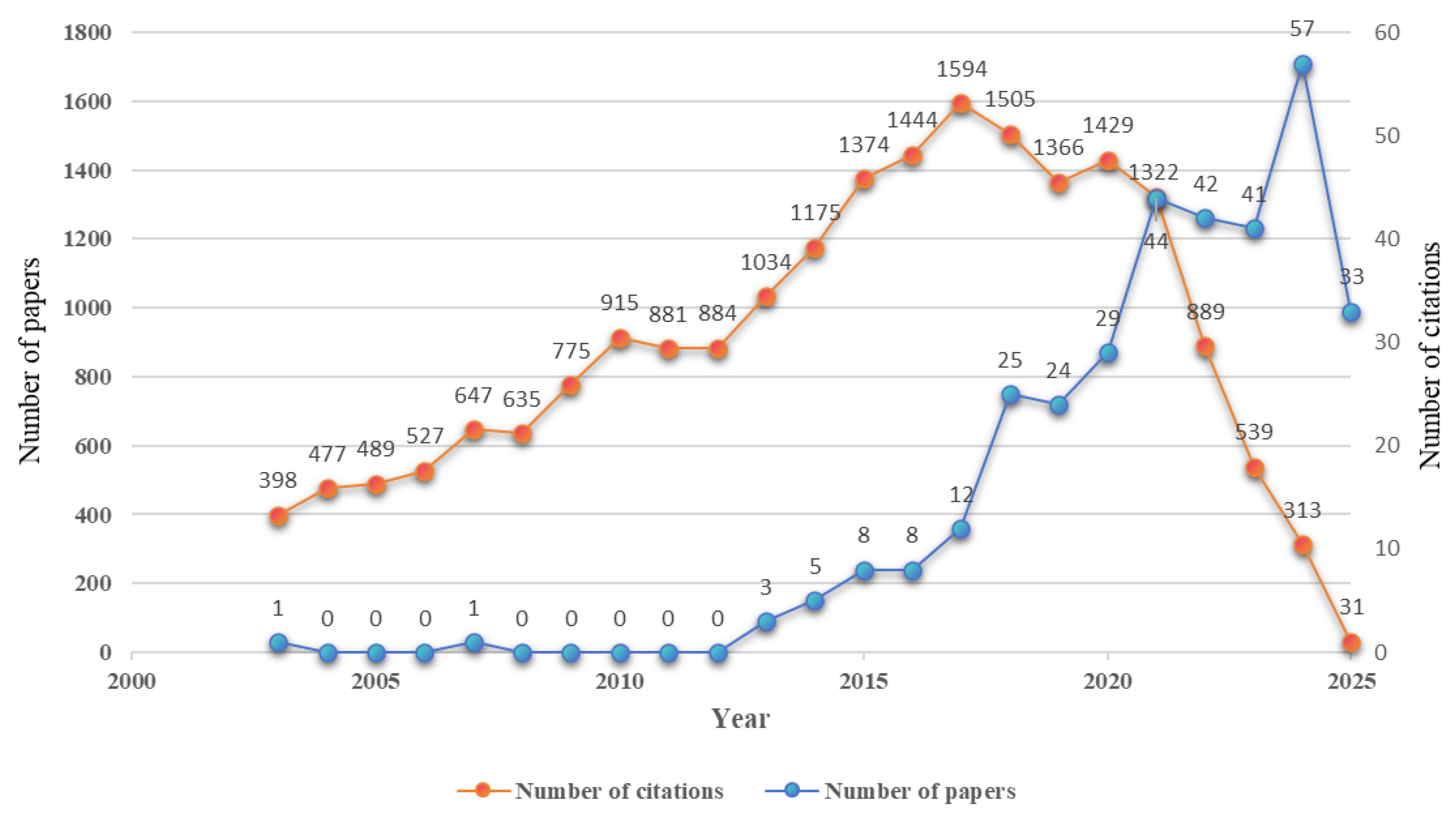

4.1. Analysis of Publication Year

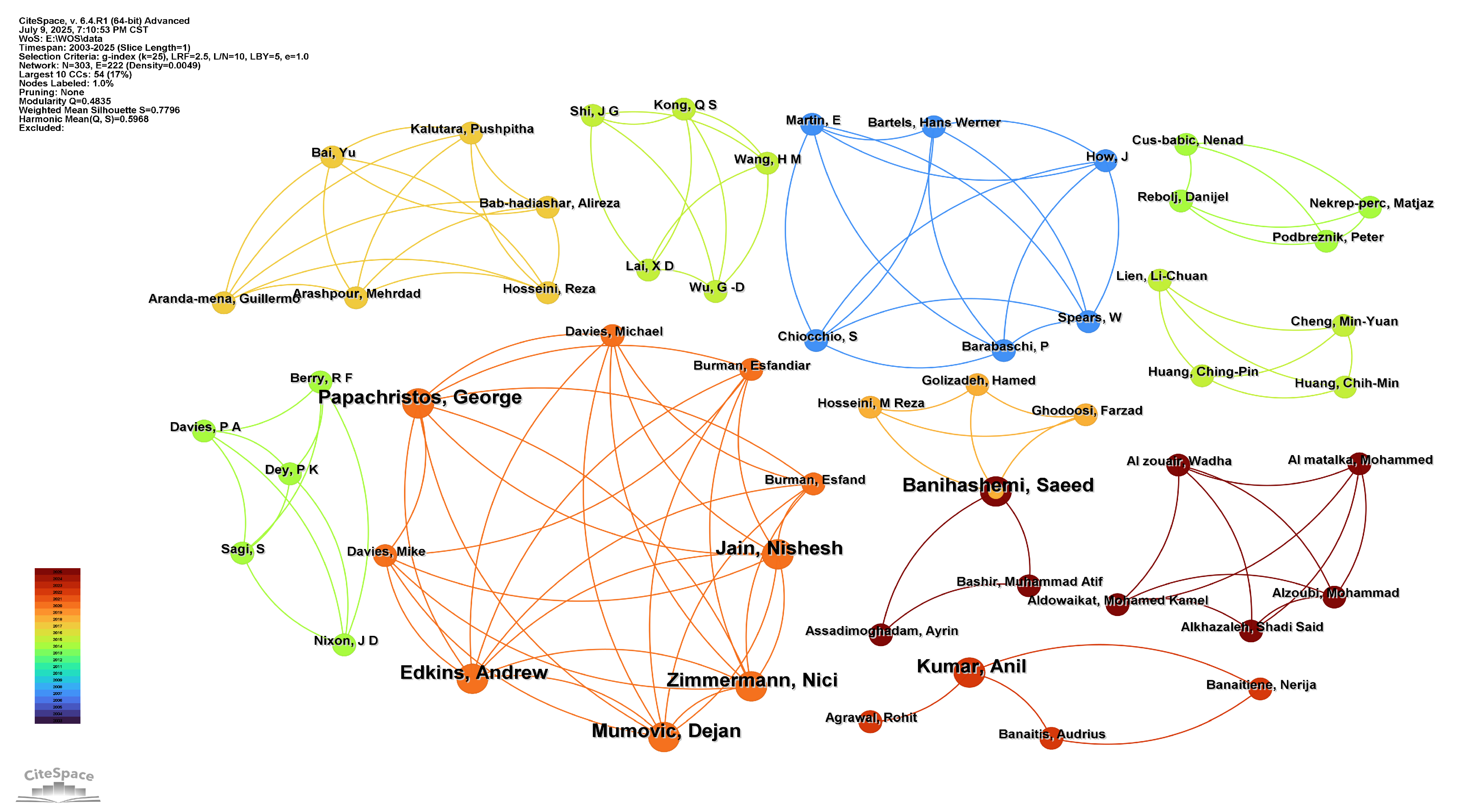

4.2. Analysis of Authors

4.3. Analysis of Countries

4.4. Analysis of Journals

4.5. Analysis of Keywords

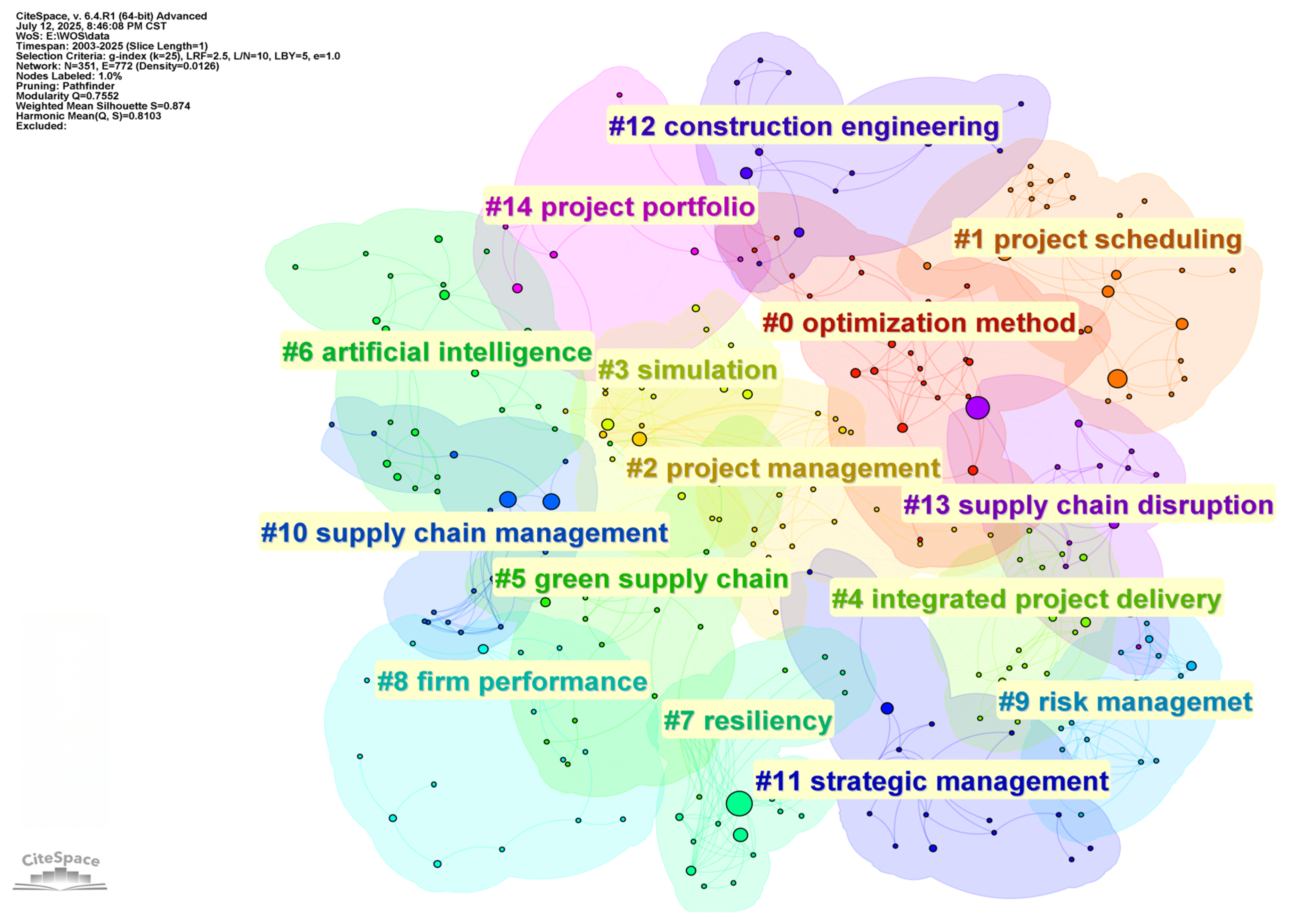

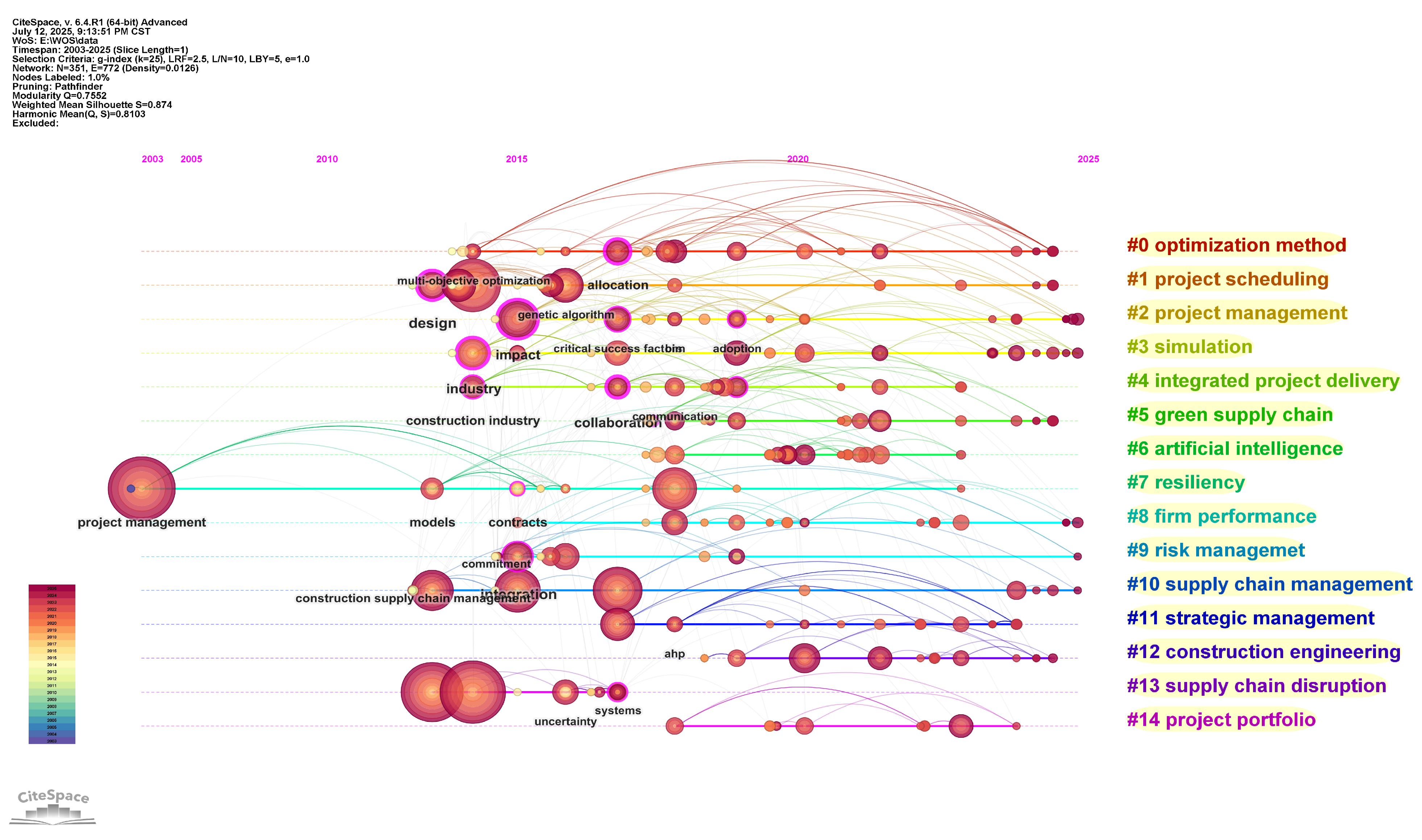

4.5.1. Analysis of Keyword Cluster

4.5.2. Analysis of Keyword Timeline

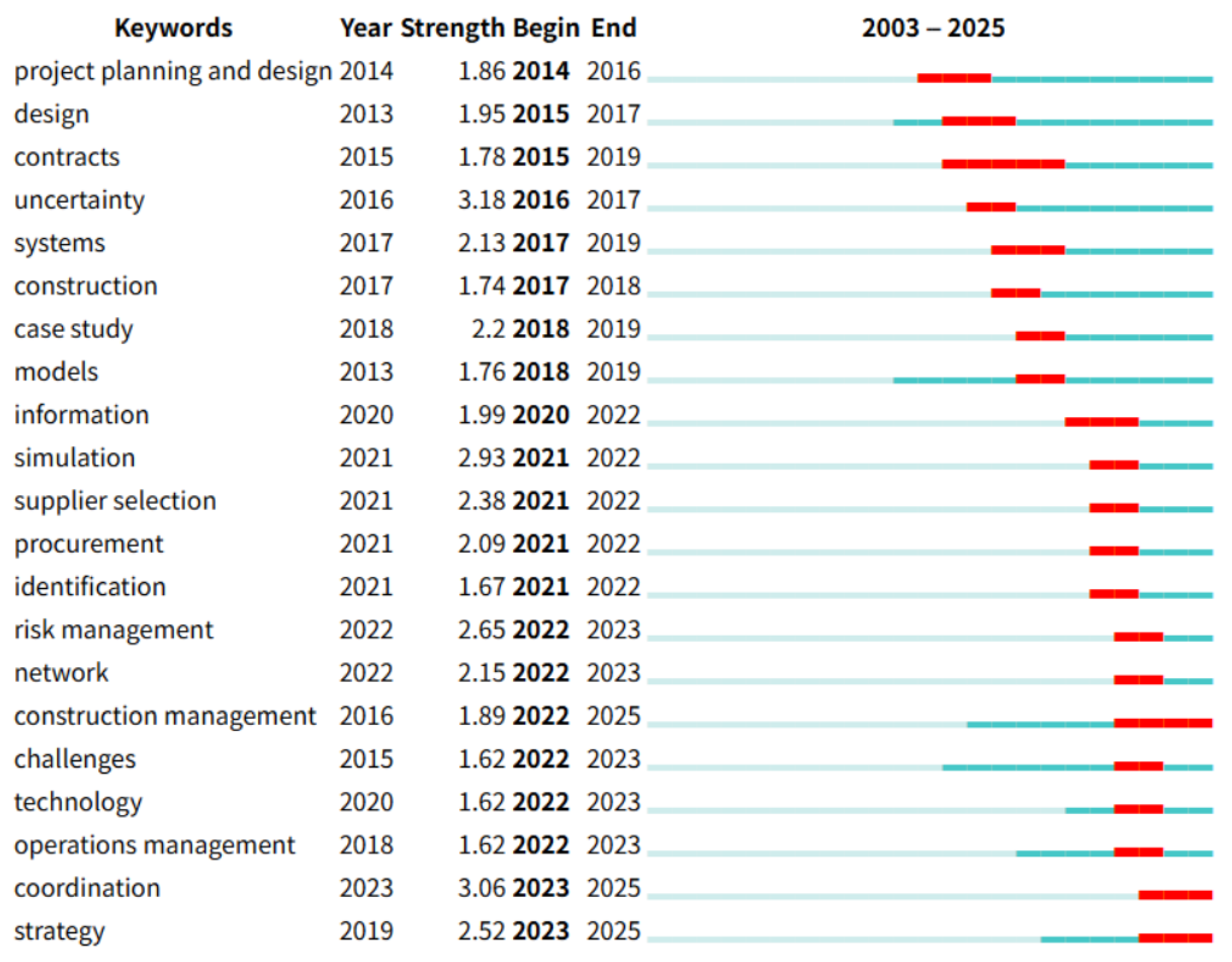

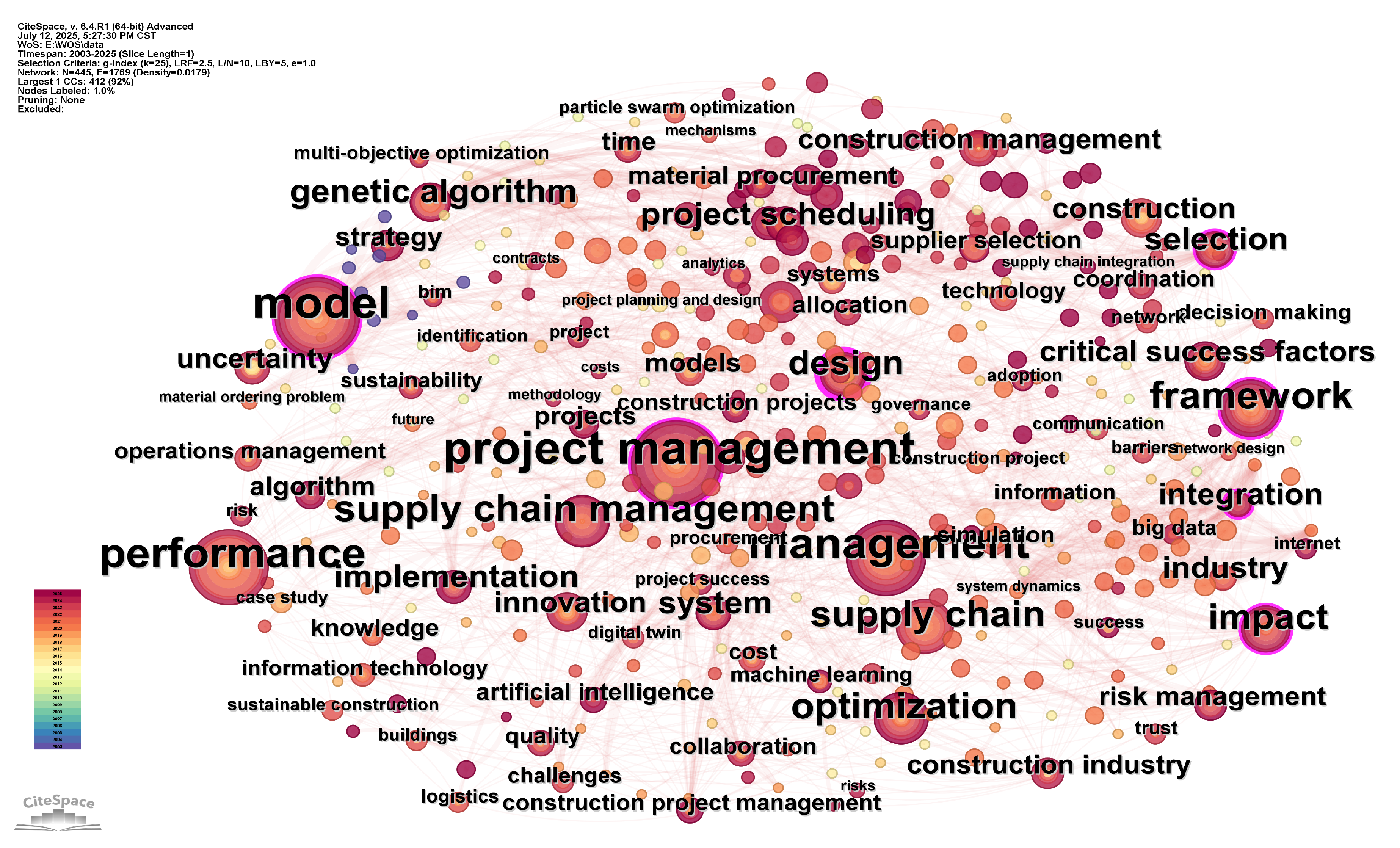

4.5.3. Analysis of Keywords’ Co-Occurrence

4.6. Analysis of Article Citation and Co-Citation

4.6.1. Analysis of Highly Cited Articles

4.6.2. Analysis of Keywords Associated with Citation Impact

5. Application Scenarios of PM-SCM Optimization

5.1. Project Management Within Supply Chain Management

5.2. Supply Chain Management Within Project Management

5.3. Integration of Project Management and Supply Chain Management

6. Optimization Methods and Emerging Technologies for Bridging Project Management and Supply Chain Management

6.1. Mathematical Programming Approaches

6.2. Heuristic and Metaheuristic Optimization

| Algorithm 1. Integrated RCPSP-Inventory MILP |

| Input: Project activities, Resource capacities per period, Demand and supply data, Precedence relationships Output: Optimized activity schedule and inventory levels 1: Initialize activity execution variables as binary 2: Initialize inventory level variables as nonnegative 3: Set objective: 4: For each period : 5: Calculate total resource usage across all activities 6: If : 7: Mark solution as infeasible 8: End for 9: For each item and period : 10: Update inventory: 11: If : 12: Mark solution as infeasible 13: End for 14: For each precedence relationship : 15: If activity starts before activity finishes: 16: Mark solution as infeasible 17: End for 18: Return optimized activity schedule and inventory levels |

| Algorithm 2. Robust Scheduling Optimization |

| Input: Set of tasks with precedence constraints, Uncertainty set for processing times Output: Robust task start and completion times, Worst-case makespan estimate 1: Initialize task start times and completion times 2: Define uncertainty set for processing times 3: For each scenario : 4: Calculate makespan for scenario 5: End for 6: Set objective: minimize 7: For each precedence relationship 8: For each scenario : 9: Ensure 10: End for 11: End for 12: For each task : 13: For each scenario : 14: Calculate 15: End for 16: End for 17: Calculate 18: Return task start times and worst-case makespan |

6.3. Machine Learning and AI-Based Optimization

6.4. Multi-Objective and Robust Optimization

7. Future Opportunities and Challenges

7.1. Research Opportunities

7.2. Practical Implications

7.3. Challenges and Barriers

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PM | Project management |

| SCM | Supply chain management |

| AI | Artificial intelligence |

| PMI | Project management institute |

| CPM | Critical path method |

| WBS | Work breakdown structure |

| LLR | Log-Likelihood Ratio |

| LP | Linear programming |

| NLP | Nonlinear programming |

| MIP | Mixed-integer programming |

| MILP | Mixed-integer linear programming |

| MINLP | Mixed-integer nonlinear programming |

| SCN | Supply chain network |

| PDSC | Project-driven supply chain |

| GA | Genetic algorithms |

| SA | Simulated annealing |

| PSO | Particle swarm optimization |

| ACO | Ant colony optimization |

| TS | Tabu search |

| RL | Reinforcement learning |

| DL | Deep learning |

| MOO | Multi-objective optimization |

Appendix A. Literature Rating Scale and Three Researchers’ Rating Scale

| Evaluation Dimension | Scoring Criteria | Points |

|---|---|---|

| Research Design | Are the research questions clear, are the methods highly applicable, and is the logic sound? | 1–5 |

| Methodological Rigor | Are scientific, transparent, and reproducible research methods used? | 1–5 |

| Data Reliability | Is the data source reliable, is the processing rigorous, and is it verifiable? | 1–5 |

| Validity of Conclusions | Are the conclusions based on data analysis? Do they have practical or theoretical contributions? Are they generalizable? | 1–5 |

| Literature Number | Research Design | Methodological Rigor | Data Reliability | Validity of Conclusions | Total Score | Evaluations |

|---|---|---|---|---|---|---|

| 1 | 4 | 5 | 3 | 4 | 16 | validity |

| 2 | 3 | 4 | 4 | 3 | 14 | not valid |

| 3 | 4 | 4 | 5 | 4 | 17 | validity |

| 4 | 4 | 3 | 4 | 5 | 16 | validity |

| 5 | 4 | 5 | 5 | 3 | 17 | validity |

| 6 | 5 | 4 | 4 | 4 | 17 | validity |

| 7 | 4 | 5 | 5 | 3 | 17 | validity |

| 8 | 3 | 3 | 5 | 4 | 15 | validity |

| 9 | 3 | 5 | 4 | 4 | 16 | validity |

| 10 | 4 | 4 | 5 | 4 | 17 | validity |

| 11 | 5 | 5 | 4 | 4 | 18 | validity |

| 12 | 5 | 5 | 5 | 3 | 18 | validity |

| 13 | 4 | 5 | 3 | 5 | 17 | validity |

| 14 | 4 | 3 | 3 | 5 | 15 | validity |

| 15 | 5 | 3 | 4 | 4 | 16 | validity |

| 16 | 3 | 5 | 4 | 5 | 17 | validity |

| 17 | 5 | 5 | 4 | 5 | 19 | validity |

| 18 | 5 | 3 | 5 | 5 | 18 | validity |

| 19 | 5 | 3 | 4 | 3 | 15 | validity |

| 20 | 5 | 5 | 3 | 3 | 16 | Validity |

| Literature Number | Research Design | Methodological Rigor | Data Reliability | Validity of Conclusions | Total Score | Evaluations |

|---|---|---|---|---|---|---|

| 1 | 3 | 5 | 4 | 4 | 16 | validity |

| 2 | 3 | 4 | 4 | 5 | 16 | validity |

| 3 | 4 | 3 | 5 | 5 | 17 | validity |

| 4 | 4 | 3 | 4 | 4 | 15 | validity |

| 5 | 4 | 5 | 3 | 3 | 15 | validity |

| 6 | 3 | 5 | 5 | 5 | 18 | validity |

| 7 | 5 | 4 | 5 | 5 | 19 | validity |

| 8 | 4 | 5 | 3 | 3 | 15 | validity |

| 9 | 3 | 5 | 4 | 4 | 16 | validity |

| 10 | 4 | 3 | 4 | 4 | 15 | validity |

| 11 | 3 | 3 | 5 | 5 | 16 | validity |

| 12 | 3 | 5 | 3 | 5 | 16 | validity |

| 13 | 3 | 4 | 5 | 3 | 15 | validity |

| 14 | 5 | 3 | 4 | 4 | 16 | validity |

| 15 | 4 | 5 | 3 | 3 | 15 | validity |

| 16 | 3 | 5 | 5 | 5 | 18 | validity |

| 17 | 5 | 4 | 5 | 5 | 19 | validity |

| 18 | 3 | 4 | 5 | 5 | 17 | validity |

| 19 | 3 | 4 | 5 | 5 | 17 | validity |

| 20 | 4 | 5 | 5 | 3 | 17 | validity |

| Literature Number | Research Design | Methodological Rigor | Data Reliability | Validity of Conclusions | Total Score | Evaluations |

|---|---|---|---|---|---|---|

| 1 | 4 | 4 | 4 | 3 | 15 | validity |

| 2 | 3 | 3 | 5 | 4 | 15 | validity |

| 3 | 4 | 5 | 4 | 5 | 18 | validity |

| 4 | 4 | 5 | 4 | 5 | 18 | validity |

| 5 | 4 | 4 | 5 | 4 | 17 | validity |

| 6 | 4 | 4 | 5 | 5 | 18 | validity |

| 7 | 5 | 4 | 5 | 5 | 19 | validity |

| 8 | 5 | 3 | 4 | 4 | 16 | validity |

| 9 | 5 | 5 | 3 | 5 | 18 | validity |

| 10 | 3 | 5 | 4 | 4 | 16 | validity |

| 11 | 4 | 5 | 3 | 4 | 16 | validity |

| 12 | 5 | 4 | 5 | 5 | 19 | validity |

| 13 | 5 | 4 | 3 | 4 | 16 | validity |

| 14 | 5 | 5 | 3 | 3 | 16 | validity |

| 15 | 4 | 3 | 3 | 4 | 14 | not valid |

| 16 | 5 | 5 | 5 | 4 | 19 | validity |

| 17 | 5 | 4 | 5 | 4 | 18 | validity |

| 18 | 3 | 4 | 5 | 4 | 16 | validity |

| 19 | 4 | 4 | 3 | 5 | 16 | validity |

| 20 | 3 | 4 | 4 | 4 | 15 | validity |

Appendix B. Bibliometric Parameter Setting and Execution Process

- Search Database and Time Range:

- Complete Search Strategy:

- Screening Process:

- Identification Stage:

- 2.

- Screening Stage:

- 3.

- Double-blind Screening Stage:

- 4.

- Final Inclusion Analysis:

- CiteSpace Analysis Parameters:

Appendix C. Sample of Included and Excluded Papers with Reasons

| Literature Number | Author and Year | Decision | Reason |

|---|---|---|---|

| 1 | Du et al., 2023 [133] | Include | The study explicitly integrates PM and SCM, using VBM and JIT optimization methods. The methodology is rigorous, and the conclusions have practical value. |

| 2 | Wicaksana et al., 2022 [185] | Exclude | Focuses solely on SCM risks, without addressing project management or optimization methods. |

| 3 | Forozandeh et al., 2019 [134] | Include | The multi-objective optimization model clearly integrates PM and SCM. The method is innovative and the data is reliable. |

| 4 | Wu et al., 2023 [186] | Exclude | A study on a purely technical optimization algorithm, not combined with practical application in a management scenario. |

Appendix D. Burst Keyword Categories and Cluster Labels Comparison Supplement

| Cluster ID | Size | Silhouette | Label (LSI) | Label (LLR) | Label (MI) |

|---|---|---|---|---|---|

| 0 | 31 | 0.897 | multi-objective optimization; project management; resource constraint; evolutionary computation; main path analysis|greenhouse gases; mathematical models; task analysis; project; sustainable construction management | multi-objective optimization (14.95, 0.001); carbon emissions (11.13, 0.001); constructability (11.13, 0.001); optimization (8.79, 0.005); scheduling (7.44, 0.01) | iot (0.23); planning (0.23); ready-mix-concrete delivery (0.23); integrated design-build (0.23); cluster analysis (0.23) |

| 1 | 26 | 0.944 | project scheduling; primary supplier selection; back-up supplier selection; project networks; shipping modes|project management; simulation; control methodology; framework; disruption | project scheduling (30.89, 0.0001); material procurement (18.37, 0.0001); material ordering (13.76, 0.001); construction project (9.47, 0.005); disruption (5.55, 0.05) | activity crashing (0.42); quantity discount problem in material ordering (0.42); prefabricated prefinished volumetric (0.42); multi-site context (0.42); scenario-based stochastic programs (0.42) |

| 2 | 25 | 0.843 | project management; existing buildings; renovation projects; building information modeling; bim challenges|scope elements; decision making; making trial; interpretive structural modeling; scope management | project management (11.09, 0.001); cost overruns (7.4, 0.01); optimized dismantling (5.53, 0.05); integrated collaboration model (5.53, 0.05); public sector supply chain (5.53, 0.05) | optimized dismantling (0.23); integrated collaboration model (0.23); public sector supply chain (0.23); renovation projects (0.23); automated 3d building reconstruction (0.23) |

| 3 | 23 | 0.783 | project management; cultural dimensions; simulation; heterarchical framework; waste factors|project performance; agile project management; quality performance; lean project management; cost performance | simulation (7.64, 0.01); project management system (5.66, 0.05); quality performance (5.66, 0.05); heterarchical framework (5.66, 0.05); innovation performance (5.66, 0.05) | project management system (0.21); quality performance (0.21); heterarchical framework (0.21); innovation performance (0.21); improvement (0.21) |

| 4 | 22 | 0.845 | project management; integrated project delivery; supply chain integration; relational contracting; systemic innovation|construction industry; supply chain management; construction supply chain; sustainable construction; research questions | integrated project delivery (6.24, 0.05); partnership (6.24, 0.05); erp (6.24, 0.05); sharing economy (6.24, 0.05); it outsourcing (6.24, 0.05) | information technology (0.15); partnership (0.15); erp (0.15); sharing economy (0.15); it outsourcing (0.15) |

| 5 | 22 | 0.812 | project management; green supply chain; project success; project risk management; fuzzy theory|learning capabilities; knowledge management; dynamic capabilities; information systems; focus group | green supply chain (13.5, 0.001); leadership styles (6.73, 0.01); predict cash flow (6.73, 0.01); cfa (6.73, 0.01); material transportation (6.73, 0.01) | leadership styles (0.11); predict cash flow (0.11); cfa (0.11); material transportation (0.11); relationship quality (0.11) |

| 6 | 21 | 0.802 | project management; operations management; open innovation; tertiary study; search schedule|artificial intelligence; sustainable food systems; child nutrition; school food programs; information management | machine learning (18.46, 0.0001); artificial intelligence (15.38, 0.0001); school food programs (6.12, 0.05); project-based data. project management (6.12, 0.05); search schedule (6.12, 0.05) | school food programs (0.16); project-based data. project management (0.16); search schedule (0.16); variation orders (0.16); sustainable food systems (0.16) |

| 7 | 20 | 0.924 | project management; dynamic capabilities; dematel method; environmental strategy; green supply management|supply chain; risk management; project scheduling problem; bi-level multi-objective programming; particle swarm optimization | project management (16.31, 0.0001); supply chain (8.03, 0.005); project scheduling (6.19, 0.05); game theory (4.76, 0.05); resiliency (4.15, 0.05) | resiliency (0.55); fuzzy set (0.55); graph decomposition (0.55); environment (0.55); time-dependent resource availability (0.55) |

| 8 | 20 | 0.743 | firm performance; market orientation; balanced agile project management; strategic agility; innovation diffusion|relational governance; formal governance; collaborative contracting; innovation diffusion; public procurement | firm performance (14.16, 0.001); relational governance (8.73, 0.005); innovation diffusion (7.06, 0.01); concurrent scheduling (7.06, 0.01); strategic agility (7.06, 0.01) | innovation diffusion (0.09); concurrent scheduling (0.09); strategic agility (0.09); capabilities (0.09); public procurement (0.09) |

| 9 | 19 | 0.958 | project management; risk management; decision making; continuous improvement; cost performance|portfolio management; indicators; procurement; success; integration | risk management (7.37, 0.01); indicators (6.36, 0.05); unmanned aerial vehicles (6.36, 0.05); success (6.36, 0.05); construction schedule (6.36, 0.05) | indicators (0.14); unmanned aerial vehicles (0.14); success (0.14); construction schedule (0.14); supply chain projects (0.14) |

| 10 | 19 | 0.908 | supply chain management; operations management; inter-organizational relationships; experiential learning; serious game|project management; risk management; financial performance; supply chain risk; internal logistics | supply chain management (20.71, 0.0001); construction supply chain management (5.65, 0.05); bi-level programming (5.65, 0.05); inventory buffer (4.62, 0.05); construction site (4.62, 0.05) | inventory buffer (0.41); construction site (0.41); inter-organizational relationships (0.41); quarantine level (0.41); information system success model (0.41) |

| 11 | 18 | 0.878 | critical path method; maritime logistics; business process analysis; business process management; resource-constrained project scheduling problem|supply chain management; soft computing; neuro-fuzzy analytic network process; group decision-making; fuzzy judgments | critical path method (13.9, 0.001); strategic management (7.36, 0.01); dynamic critical path (6.93, 0.01); group decision-making (6.93, 0.01); resilience index (6.93, 0.01) | dynamic critical path (0.09); group decision-making (0.09); resilience index (0.09); soft computing (0.09); risk quantification method (0.09) |

| 12 | 16 | 0.827 | project management; quadruple helix; agile mindset; urgent projects; agile project|risk management; subsea gas pipeline; cost overrun; risk analysis; fuzzy Bayesian belief networks | construction engineering (6.45, 0.05); bioethanol (6.45, 0.05); supply chain network design (6.45, 0.05); subsea gas pipeline (6.45, 0.05); fuzzy Bayesian belief networks (6.45, 0.05) | construction engineering (0.13); bioethanol (0.13); supply chain network design (0.13); subsea gas pipeline (0.13); fuzzy Bayesian belief networks (0.13) |

| 13 | 16 | 0.966 | project management; supply chain management; supply chain disruption; smart contracts; construction supply chain | construction supply chain; incentive coordination; sustainable development; robust optimisation; bi-level programming | supply chain disruption (3.79, 0.1); stochastic optimization (3.79, 0.1); multi-criteria decision-making (3.79, 0.1); synergy benefits (3.79, 0.1); whole life cycle (3.79, 0.1) | stochastic optimization (0.69); multi-criteria decision-making (0.69); synergy benefits (0.69); whole life cycle (0.69) |

| 14 | 11 | 0.87 | risk management; operations management; project management; project portfolio; innovation capability|social sustainability; construction project management; conceptual framework; social responsibility; conceptual modeling | project portfolio (13.66, 0.001); program (13.66, 0.001); decision making (9.91, 0.005); risk management (9.48, 0.005); operations management (8.78, 0.005) | procurement procedure (0.1); organizational flexibility (0.1); a systematic literature review (0.1); digitisation (0.1); quality professionals (0.1) |

| Cluster ID | Cluster Name | Size | Mean Year | BurstBegin | Burst | Main Cutting Keywords (After 2020) |

|---|---|---|---|---|---|---|

| 0 | optimization method | 31 | 2020 | 2014 | 2018 | particle swarm optimization, project, megaproject |

| 1 | project scheduling | 26 | 2016 | 2013 | 2014 | search, material ordering, chance-constrained programming |

| 2 | project management | 25 | 2020 | 2015 | 2015 | supply chain integration, benefits, cost overruns |

| 3 | simulation | 23 | 2019 | 2014 | 2014 | barriers, analytics, internet |

| 4 | integrated project delivery | 22 | 2019 | 2014 | 2014 | digital twin, systematic review, data analytics |

| 5 | green supply chain | 21 | 2018 | 2012 | 2016 | carbon neutrality, circular economy, sustainability |

| 6 | artificial intelligence | 20 | 2017 | 2011 | 2017 | machine learning, predictive analytics, artificial intelligence |

| 7 | resiliency | 19 | 2015 | 2003 | 2015 | disruption management, risk assessment, resilience |

| 8 | firm performance | 18 | 2019 | 2010 | 2020 | big data, blockchain, supply chain risk |

| 9 | risk management | 17 | 2018 | 2009 | 2017 | project portfolio, resource allocation, simulation |

| 10 | supply chain management | 16 | 2020 | 2015 | 2022 | agile, stakeholder management, collaboration |

| 11 | strategic management | 15 | 2017 | 2011 | 2016 | hybrid methods, optimization model, scheduling |

| 12 | construction engineering | 14 | 2019 | 2012 | 2021 | sustainability, green supply chain, environmental performance |

| 13 | supply chain disruption | 13 | 2018 | 2014 | 2017 | multi-objective optimization, robustness, uncertainty |

| 14 | project portfolio | 12 | 2016 | 2008 | 2014 | knowledge management, decision support, governance |

References

- Yang, Y.; Li, M.; Yu, C.; Zhong, R.Y. Digital twin-enabled visibility and traceability for building materials in on-site fit-out construction. Autom. Constr. 2024, 166, 105640. [Google Scholar] [CrossRef]

- Colmenar, J.M.; Laguna, M.; Martin-Santamaria, R. Changeover minimization in the production of metal parts for car seats. Comput. Ind. Eng. 2024, 198, 110634. [Google Scholar] [CrossRef]

- Masmoudi, M.; Cheaitou, A.; Babai, M.Z. Home healthcare network design with sustainability and inventory considerations. Int. J. Prod. Res. 2025, 1–28. [Google Scholar] [CrossRef]

- Rohilla, A.; Kundu, T.; Kapoor, R.; Sheu, J.-B. Enhancing retail inventory replenishment amid product life cycle shifts: A system dynamics approach. IEEE Trans. Eng. Manag. 2025, 72, 1939–1953. [Google Scholar] [CrossRef]

- Mariano, S.; Awazu, Y. Managing large-scale projects: Unpacking the role of project memory. Int. J. Proj. Manag. 2024, 42, 102573. [Google Scholar] [CrossRef]

- Yu, R.; Wang, J.; Cheng, T.C.E.; Yu, P. Assessment of new energy industrial clusters: An MCDM approach using DEA and GEMS. Expert Syst. Appl. 2024, 252 Pt A, 124231. [Google Scholar] [CrossRef]

- Li, Y.L.; Xiang, P.C.; Chan, P.W.; Zhang, J.W. Examining owners’ and contractors’ motivations to participate in collaborative risk management of mega infrastructure projects. Int. J. Proj. Manag. 2024, 42, 102614. [Google Scholar] [CrossRef]

- Bai, L.; Zhang, L.; Zhang, L.; Shao, K.; Luo, X. Unlocking the potential of project portfolio: Value-oriented interactive risk management. Humanit. Soc. Sci. Commun. 2025, 12, 1012. [Google Scholar] [CrossRef]

- Oliver, R.K.; Webber, M.D. Supply-chain management: Logistics catches up with strategy. In The Roots of Logistics; Springer: Berlin/Heidelberg, Germany, 2012; pp. 183–194. [Google Scholar]

- Peng, Y.; Chen, X.; Wang, X. Enhancing supply chain flows through blockchain: A comprehensive literature review. Int. J. Prod. Res. 2023, 61, 4503–4524. [Google Scholar] [CrossRef]

- Alves, G.A.; Tavares, R.; Amorim, P.; Camargo, V.C.B. A systematic review of mathematical programming models and solution approaches for the textile supply chain. Comput. Ind. Eng. 2025, 202, 110937. [Google Scholar] [CrossRef]

- Jin, L.; Zhai, X.; Wang, K.; Zhang, K.; Wu, D.; Nazir, A.; Jiang, J.; Liao, W.-H. Big data, machine learning, and digital twin assisted additive manufacturing: A review. Mater. Des. 2024, 244, 113086. [Google Scholar] [CrossRef]

- Shriharsha Pai, J.B.; Hungund, S.S. Enhancing decision-making in construction projects: The mediating role of adaptability and response strategy in supply chain and coordination dynamics. Results Eng. 2025, 27, 106193. [Google Scholar] [CrossRef]

- Kerzner, H. Project Management: A Systems Approach to Planning, Scheduling, and Controlling; John Wiley & Sons: Hoboken, NJ, USA, 2025. [Google Scholar]

- Bai, L.; Qu, X.; Liu, J.; Han, X. Analysis of Factors Influencing Project Portfolio Benefits with Synergy Considerations. Eng. Constr. Archit. Manag. 2023, 30, 2691–2715. [Google Scholar] [CrossRef]

- Collyer, S.; Warren, C.M.J. Project management approaches for dynamic environments. Int. J. Proj. Manag. 2009, 27, 355–364. [Google Scholar] [CrossRef]

- Sánchez, M.G.; Lalla-Ruiz, E.; Gil, A.F.; Castro, C.; Voss, S. Resource-constrained multi-project scheduling problem: A survey. Eur. J. Oper. Res. 2023, 309, 958–976. [Google Scholar] [CrossRef]

- Norman, E.S.; Brotherton, S.A.; Fried, R.T. Work Breakdown Structures: The Foundation for Project Management Excellence; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Aghajani, M.; Ruge, G.; Jugdev, K. An integrative review of project portfolio management literature: Thematic findings on sustainability mindset, assessment, and integration. Proj. Manag. J. 2023, 54, 629–650. [Google Scholar] [CrossRef]

- Highsmith, J.; Cockburn, A. Agile software development: The business of innovation. Computer 2001, 34, 120–127. [Google Scholar] [CrossRef]

- Bai, L.; Liu, X.; An, M. A New Project Portfolio Strategic Objective Promoting Model Considering Existing Resource Synergies in the Enterprises. Int. J. Inf. Technol. Decis. Mak. 2025, 198. [Google Scholar] [CrossRef]

- Wu, K.; de Soto, B.G.; Zhang, F. Spatio-temporal planning for tower cranes in construction projects with simulated annealing. Autom. Constr. 2020, 111, 103060. [Google Scholar] [CrossRef]

- Khelifa, B.; Laouar, M.R. A holonic intelligent decision support system for urban project planning by ant colony optimization algorithm. Appl. Soft Comput. 2020, 96, 106621. [Google Scholar] [CrossRef]

- Turner, J.R. Towards a theory of project management: The nature of the project governance and project management. Int. J. Proj. Manag. 2006, 24, 93–95. [Google Scholar] [CrossRef]

- Bai, L.; Wang, C.; Sun, Y.; Xie, X.; Tang, T.; Xie, Q. Project portfolio network risk propagation modelling: A risk perception per-spective. IEEE Trans. Eng. Manag. 2024, 71, 14608–14620. [Google Scholar] [CrossRef]

- Nolan, R.L. Ubiquitous IT: The case of the Boeing 787 and implications for strategic IT research. J. Strateg. Inf. Syst. 2012, 21, 91–102. [Google Scholar] [CrossRef]

- Edalatpour, M.A.; Al-E-Hashem, S.M.J.M.; Ghasemi, S. Harmonizing Project Management and Supply Chain for Sustainable Construction: A Comprehensive Mathematical Model and Case Study. Sustain. Futures 2025, 10, 100805. [Google Scholar] [CrossRef]

- Cooper, M.C.; Ellram, L.M. Characteristics of supply chain management and the implications for purchasing and logistics strategy. Int. J. Logist. Manag. 1993, 4, 13–24. [Google Scholar] [CrossRef]

- Al-Mudimigh, A.S.; Zairi, M.; Ahmed, A.M.M. Extending the concept of supply chain: The effective management of value chains. Int. J. Prod. Econ. 2004, 87, 309–320. [Google Scholar] [CrossRef]

- Schuler, R.S.; Jackson, S.E. Linking competitive strategies with human resource management practices. Acad. Manag. Perspect. 1987, 1, 207–219. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning & Operation; Gabler: Lübeck, Germany, 2007. [Google Scholar]

- Power, D. Supply chain management integration and implementation: A literature review. Supply Chain. Manag. Int. J. 2005, 10, 252–263. [Google Scholar] [CrossRef]

- Patrucco, A.; Ciccullo, F.; Pero, M. Industry 4.0 and supply chain process re-engineering: A coproduction study of materials management in construction. Bus. Process Manag. J. 2020, 26, 1093–1119. [Google Scholar] [CrossRef]

- Lai, K.H.; Ngai, E.W.T.; Cheng, T.C.E. An empirical study of supply chain performance in transport logistics. Int. J. Prod. Econ. 2004, 87, 321–331. [Google Scholar] [CrossRef]

- Hutchins, M.J.; Sutherland, J.W. An exploration of measures of social sustainability and their application to supply chain decisions. J. Clean. Prod. 2008, 16, 1688–1698. [Google Scholar] [CrossRef]

- Vega, P.N.; Castresana, U.L. Sustainability in Project Risk Management Methodologies through the AHP-TOPSIS method applied to Logistics and Supply Chain Management. Environ. Sustain. Indic. 2025, 26, 100719. [Google Scholar] [CrossRef]

- Sandberg, E.; Oghazi, P.; Chirumalla, K.; Patel, P.C. Interactive research framework in logistics and supply chain management: Bridging the academic research and practitioner gap. Technol. Forecast. Soc. Change 2022, 178, 121563. [Google Scholar] [CrossRef]

- Hartel, D.H. Project Management in Logistics and Supply Chain Management; Springer Fachmedien: Wiesbaden, Germany, 2022. [Google Scholar]

- Wang, J.; Liwen, Z.; Song, L.; Liang, C.; Bai, L. Analysis of power battery technology R&D strategies under the supply chain competitive environment in post-subsidy era. Technol. Forecast. Soc. Change 2025, 215, 124080. [Google Scholar] [CrossRef]

- Mandal, P.K. A review of classical methods and Nature-Inspired Algorithms (NIAs) for optimization problems. Results Control Optim. 2023, 13, 100315. [Google Scholar] [CrossRef]

- Ponsich, A.; Jaimes, A.L.; Coello, C.A.C. A survey on multiobjective evolutionary algorithms for the solution of the portfolio optimization problem and other finance and economics applications. IEEE Trans. Evol. Comput. 2012, 17, 321–344. [Google Scholar] [CrossRef]

- Calafiore, G.C.; El Ghaoui, L. Optimization Models; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Fathollahi-Fard, A.M.; Wong, K.Y.; Aljuaid, M. An efficient adaptive large neighborhood search algorithm based on heuristics and reformulations for the generalized quadratic assignment problem. Eng. Appl. Artif. Intell. 2023, 126, 106802. [Google Scholar] [CrossRef]

- Bertsimas, D.; Tsitsiklis, J.N. Introduction to Linear Optimization; Athena Scientific: Belmont, MA, USA, 1997. [Google Scholar]

- Yang, X.S. Nature-Inspired Optimization Algorithms; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Williamson, D.P.; Shmoys, D.B. The Design of Approximation Algorithms; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Gomes, C.P.; Williams, R. Approximation algorithms. In Search Methodologies: Introductory Tutorials in Optimization and Decision Support Techniques; Springer: New York, NY, USA, 2005; pp. 557–585. [Google Scholar]

- Salem, A.H.; Azzam, S.M.; Emam, O.E.; Abohany, A.A. Advancing cybersecurity: A comprehensive review of AI-driven detection techniques. J. Big Data 2024, 11, 105. [Google Scholar] [CrossRef]

- Osaba, E.; Villar-Rodriguez, E.; Del Ser, J.; Nebro, A.J.; Molina, D.; LaTorre, A.; Suganthan, P.N.; Coello, C.A.C.; Herrera, F. A tutorial on the design, experimentation and application of metaheuristic algorithms to real-world optimization problems. Swarm Evol. Comput. 2021, 64, 100888. [Google Scholar] [CrossRef]

- Luenberger, D.G.; Ye, Y. Linear and Nonlinear Programming; Addison-Wesley: Reading, MA, USA, 1984. [Google Scholar]

- Gad, A.G. Particle swarm optimization algorithm and its applications: A systematic review. Arch. Comput. Methods Eng. 2022, 29, 2531–2561. [Google Scholar] [CrossRef]

- Chen, H.; Cao, Y.; Liu, Y.; Qin, Y.; Xia, L. Enhancing the durability of concrete in severely cold regions: Mix proportion optimization based on machine learning. Constr. Build. Mater. 2023, 371, 130644. [Google Scholar] [CrossRef]

- Zhang, M.; Yu, S.R.; Chung, K.S.; Chen, M.; Yuan, Z. Time-optimal path planning and tracking based on nonlinear model predictive control and its application on automatic berthing. Ocean Eng. 2023, 286 Pt 1, 115228. [Google Scholar] [CrossRef]

- Kale, A.; Upadhyay, A.; Anbanandam, R. A hierarchical facility location-allocation model for sustainable Municipal Solid Waste Management in urban cities. Socio-Econ. Plan. Sci. 2025, 101, 102259. [Google Scholar] [CrossRef]

- Bang, I.; Kim, B.I.; Park, J.; Kim, G. Integrated cutting stock and multi-period inventory optimization considering raw material–product eligibility for steel-pipe manufacturers. Appl. Math. Model. 2025, 142, 115953. [Google Scholar] [CrossRef]

- Ding, Y.; Pei, Z.; Cao, C. When two chains meet: Optimizing the design of blockchain-enabled supply chain networks. Expert Syst. Appl. 2025, 261, 125481. [Google Scholar] [CrossRef]

- Enayati, S.; Özaltın, O.Y. Supplier selection under disruption risk with hybrid procurement. Comput. Oper. Res. 2024, 165, 106593. [Google Scholar] [CrossRef]

- Zou, X.; Zhang, L.; Zhang, Q. Time-cost optimization in repetitive project scheduling with limited resources. Eng. Constr. Archit. Manag. 2022, 29, 669–701. [Google Scholar] [CrossRef]

- Taghaddos, M.; Mousaei, A.; Taghaddos, H.; Hermann, U.; Mohamed, Y.; Abourizk, S. Optimized variable resource allocation framework for scheduling of fast-track industrial construction projects. Autom. Constr. 2024, 158, 105208. [Google Scholar] [CrossRef]

- Cao, R.; Li, S.; Ji, Y.; Zhang, Z.; Xu, H.; Zhang, M.; Li, M.; Li, H. Task assignment of multiple agricultural machinery cooperation based on improved ant colony algorithm. Comput. Electron. Agric. 2021, 182, 105993. [Google Scholar] [CrossRef]

- Shen, Z.; Li, X. An extended model of dynamic project portfolio selection problem considering synergies between projects. Comput. Ind. Eng. 2023, 179, 109175. [Google Scholar] [CrossRef]

- Ezugwu, A.E.; Ikotun, A.M.; Oyelade, O.O.; Abualigah, L.; Agushaka, J.O.; Eke, C.I.; Akinyelu, A.A. A comprehensive survey of clustering algorithms: State-of-the-art machine learning applications, taxonomy, challenges, and future research prospects. Eng. Appl. Artif. Intell. 2022, 110, 104743. [Google Scholar] [CrossRef]

- Roberts, T.; Keddie, S.H.; Rattanavong, S.; Gomez, S.R.; Bradley, J.; Keogh, R.H.; Bärenbold, O.; Falconer, J.; Mens, P.F.; Hopkins, H.; et al. Accuracy of the direct agglutination test for diagnosis of visceral leishmaniasis: A systematic review and meta-analysis. BMC Infect. Dis. 2023, 23, 782. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.L.; O’Leary, T.J. Relative sensitivity of anterior nares and nasopharyngeal swabs for initial detec-tion of SARS-CoV-2 in ambulatory patients: Rapid review and meta-analysis. PLoS ONE 2021, 16, e0254559. [Google Scholar] [CrossRef] [PubMed]

- Abdzadeh, B.; Noori, S.; Ghannadpour, S.F. Simultaneous scheduling of multiple construction projects considering supplier selection and material transportation routing. Autom. Constr. 2022, 140, 104336. [Google Scholar] [CrossRef]

- RezaHoseini, A.; Noori, S.; Ghannadpour, S.F. Integrated scheduling of suppliers and multi-project activities for green construction supply chains under uncertainty. Autom. Constr. 2021, 122, 103485. [Google Scholar] [CrossRef]

- Badkoubeh, M.; Ghannadpour, S.F. Designing a construction supply chain model using backup supplier aiming at optimizing resiliency against disruption. J. Civ. Eng. Manag. 2024, 30, 614–631. [Google Scholar] [CrossRef]

- Abdzadeh, B.; Noori, S.; Ghannadpour, S.F. A comprehensive mathematical model for quality integration in a project supply chain with concentrating on material flow and transportation. Adv. Eng. Inform. 2023, 57, 102034. [Google Scholar] [CrossRef]

- Mohammadnazari, Z.; Ghannadpour, S.F. Sustainable construction supply chain management with the spotlight of inventory optimization under uncertainty. Environ. Dev. Sustain. 2021, 23, 10937–10972. [Google Scholar] [CrossRef]

- Lee, H.; Noh, C.; Kim, S.; Kim, H.; Kim, J. Neutral model-based interfacing of 3D design to support collaborative project management in the process plant industry. J. Comput. Des. Eng. 2021, 8, 824–835. [Google Scholar] [CrossRef]

- Kim, S.; Chang, S.; Castro-Lacouture, D. Dynamic modeling for analyzing impacts of skilled labor shortage on construction project management. J. Manag. Eng. 2020, 36, 04019035. [Google Scholar] [CrossRef]

- Kim, S.; Park, J.; Chung, W.; Lee, H.; Yoon, J. Techno-economic analysis for design and management of international green hydrogen supply chain under uncertainty: An integrated temporal planning approach. Energy Convers. Manag. 2024, 301, 118010. [Google Scholar] [CrossRef]

- Bakhshi, J.; Golzad, H.; Martek, I.; Hosseini, M.R.; Papadonikolaki, E. Unveiling the complexity code: Navigating BIM-enabled projects with a project management complexity index. Eng. Constr. Archit. Manag. 2024; ahead of print. [Google Scholar] [CrossRef]

- Fathalizadeh, A.; Hosseini, M.R.; Silvius, A.J.G.; Martek, I.; Banihashemi, S. Barriers impeding sustainable project management: A Social Network Analysis of the Iranian construction sector. J. Clean. Prod. 2021, 318, 128405. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Banihashemi, S.; Martek, I.; Golizadeh, H.; Ghodoosi, F. Sustainable delivery of megaprojects in Iran: Integrated model of contextual factors. J. Manag. Eng. 2018, 34, 05017011. [Google Scholar] [CrossRef]

- Habibi, F.; Chakrabortty, R.K.; Servranckx, T.; Abbasi, A.; Vanhoucke, M. Project portfolio selection and scheduling problem under material supply uncertainty. Oper. Manag. Res. 2025, 18, 226–256. [Google Scholar] [CrossRef]

- Habibi, F.; Chakrabortty, R.K.; Abbasi, A. Maximizing projects’ profitability, environmental score, and quality: A multi-project scheduling and material ordering problem. Environ. Sci. Pollut. Res. 2023, 30, 59925–59962. [Google Scholar] [CrossRef] [PubMed]

- Asadujjaman, M.; Rahman, H.F.; Chakrabortty, R.K.; Ryan, M.J. Supply chain integrated resource-constrained multi-project scheduling problem. Comput. Ind. Eng. 2024, 194, 110380. [Google Scholar] [CrossRef]

- Asadujjaman, M.; Rahman, H.F.; Chakrabortty, R.K.; Ryan, M.J. Resource constrained project scheduling and material ordering problem with discounted cash flows. Comput. Ind. Eng. 2021, 158, 107427. [Google Scholar] [CrossRef]

- Li, Y.; Sun, T.; Han, R.; Zhang, X.Y. Influence of contractual and relational governance on green supply chain management practices and sustainability performance in the construction industry. Eng. Constr. Archit. Manag. 2025; ahead of print. [Google Scholar] [CrossRef]

- Li, Y.; Lin, M.; Shen, H.; Zhang, L. Hedging against demand ambiguity in new product development: A two-stage distributionally robust approach. Ann. Oper. Res. 2025, 348, 1001–1035. [Google Scholar] [CrossRef]

- Fan, Z.; Liu, Y.; Li, Y. Research on Collaborative Mechanisms of Railway EPC Project Design and Construction from the Perspective of Social Network Analysis. Systems 2023, 11, 443. [Google Scholar] [CrossRef]

- Bai, L.; Li, Y.; Du, Q.; Xu, Y. A Fuzzy Comprehensive Evaluation Model for Sustainability Risk Evaluation of PPP Projects. Sustainability 2017, 9, 1890. [Google Scholar] [CrossRef]

- Zhang, Q.; Tang, W.; Liu, J.; Duffiel, C.F.; Hui, F.K.P.; Zhang, L.; Zhang, X. Improving Design Performance by Alliance between Contractors and Designers in International Hydropower EPC Projects from the Perspective of Chinese Construction Companies. Sustainability 2018, 10, 1171. [Google Scholar] [CrossRef]

- Yang, J.; Yuan, H.; Zhang, L. Influence factors on general contractor capability in the context of transforming China. Adv. Civ. Eng. 2020, 1, 8874579. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, H.H.; Zhao, D.; Han, Y.L.; Chen, J.Y. Understanding innovation diffusion and adoption strategies in megaproject networks through a fuzzy system dynamic model. Front. Eng. Manag. 2021, 8, 32–47. [Google Scholar] [CrossRef]

- Guo, S.; Xiong, H.; Chen, J.; Hu, K. Using Bibliometrics and Grounded Theory in Investigating Factors Influencing Profit Distribution in Integrated Project Delivery Projects. Buildings 2024, 14, 1418. [Google Scholar] [CrossRef]

- Meng, Q.; Chen, J.; Qian, K. The complexity and simulation of revenue sharing negotiation based on construction stakeholders. Complexity 2018, 1, 5698170. [Google Scholar] [CrossRef]

- Dhawan, K.; Tookey, J.E.; GhaffarianHoseini, A.; GhaffarianHoseini, A. Greening construction transport as a sustainability enabler for New Zealand: A research framework. Front. Built Environ. 2022, 8, 871958. [Google Scholar] [CrossRef]

- Omrany, H.; Al-Obaidi, K.M.; Husain, A.; Ghaffarianhoseini, A. Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions. Sustainability 2023, 15, 10908. [Google Scholar] [CrossRef]

- Nwadigo, O.B.; Naismith, N.; GhaffarianHoseini, A.; GhaffarianHoseini, A.; Tookey, J. Construction project planning and scheduling as a dynamic system: A content analysis of the current status, technologies and forward action. Smart Sustain. Built Environ. 2022, 11, 972–995. [Google Scholar] [CrossRef]

- Habibi, F.; Barzinpour, F.; Sadjadi, S.J. A mathematical model for project scheduling and material ordering problem with sustainability considerations: A case study in Iran. Comput. Ind. Eng. 2019, 128, 690–710. [Google Scholar] [CrossRef]

- Dorfeshan, Y.; Jolai, F.; Mousavi, S.M. A multi-criteria decision-making model for analyzing a project-driven supply chain under interval type-2 fuzzy sets. Appl. Soft Comput. 2023, 148, 110902. [Google Scholar] [CrossRef]

- Dorfeshan, Y.; Jolai, F.; Mousavi, S.M. A new risk quantification method in project-driven supply chain by MABACODAS method under interval type-2 fuzzy environment with a case study. Eng. Appl. Artif. Intell. 2023, 119, 105729. [Google Scholar] [CrossRef]

- Salari, A.S.; Mahmoudi, H.; Aghsami, S.Y.M. Off-Site Construction Three-Echelon Supply Chain Management with Stochastic Constraints: A Modelling Approach. Buildings 2022, 12, 119. [Google Scholar] [CrossRef]

- Papachristos, G.; Jain, N.; Burman, E.; Zimmermann, N.; Wu, X.Y.; Liu, P.; Mumovic, D.; Lin, B.R.; Davies, M.; Edkins, A. Low carbon building performance in the construction industry: A multi-method approach of system dynamics and building performance modelling. Constr. Manag. Econ. 2020, 38, 856–876. [Google Scholar] [CrossRef]

- Cataldo, I.; Banaitis, A.; Samadhiya, A.; Banaitienė, N.; Kumar, A.; Luthra, S. Sustainable supply chain management in construction: An exploratory review for future research. J. Civ. Eng. Manag. 2022, 28, 536–553. [Google Scholar] [CrossRef]

- Prasad, A.; Kumar, A.; Chatnani, N.N. Carbon neutrality with sustainable supply chain project management framework for affordable access to natural gas in India. Pacific Bus. Rev. Int. 2023, 15. [Google Scholar]

- Tabrizi, B.H. Integrated planning of project scheduling and material procurement considering the environmental impacts. Comput. Ind. Eng. 2018, 120, 103–115. [Google Scholar] [CrossRef]

- Tabrizi, B.H.; Ghaderi, S.F. A robust bi-objective model for concurrent planning of project scheduling and material procurement. Comput. Ind. Eng. 2016, 98, 11–29. [Google Scholar] [CrossRef]

- Tabrizi, B.H.; Ghaderi, S.F. Simultaneous planning of the project scheduling and material procurement problem under the presence of multiple suppliers. Eng. Optim. 2016, 48, 1474–1490. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Zuo, J.; Rameezdeen, R. Ways to improve the project management efficiency in a centralized public procurement system: A structural equation modeling approach. Eng. Constr. Archit. Manag. 2020, 27, 168–185. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Cao, T.T.; Wang, Y. The mediation role of leadership styles in integrated project collaboration: An emotional intelligence perspective. Int. J. Project Manag. 2018, 36, 317–330. [Google Scholar] [CrossRef]

- Wang, Y.; Kwak, Y.H.; Cui, Q. The power (lessness) of flexibility in public–private partnerships: Two capital projects from the national capital region. Proj. Manag. J. 2024, 55, 650–667. [Google Scholar] [CrossRef]

- Naz, F.; Kumar, A.; Majumdar, A.; Agrawal, R. Is artificial intelligence an enabler of supply chain resiliency post COVID-19? An exploratory state-of-the-art review for future research. Oper. Manag. Res. 2022, 15, 378–398. [Google Scholar] [CrossRef]

- Patoghi, A.; Mousavi, S.M. A new approach for material ordering and multi-mode resource constraint project scheduling problem in a multi-site context under interval-valued fuzzy uncertainty. Technol. Forecast. Soc. Change 2021, 173, 121137. [Google Scholar] [CrossRef]

- Han, Y.H.; Fang, X. Systematic review of adopting blockchain in supply chain management: Bibliometric analysis and theme discussion. Int. J. Prod. Res. 2024, 62, 991–1016. [Google Scholar] [CrossRef]

- Lai, X.; Shui, H.; Ding, D.; Ni, J. Data-driven dynamic bottleneck detection in complex manufacturing systems. J. Manuf. Syst. 2021, 60, 662–675. [Google Scholar] [CrossRef]

- Hu, X.; Cui, N.; Demeulemeester, E.; Bie, L. Incorporation of activity sensitivity measures into buffer management to manage project schedule risk. Eur. J. Oper. Res. 2016, 249, 717–727. [Google Scholar] [CrossRef]

- Bao, T.; Liu, Y.; Yang, Z.; Wu, S.; Yan, Z. Evaluating sustainable service quality in higher education from a multi-stakeholder perspective: An inte-grated fuzzy group decision-making method. Socio-Econ. Plan. Sci. 2024, 92, 101849. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Cubric, M. Drivers, barriers and social considerations for AI adoption in business and management: A tertiary study. Technol. Soc. 2020, 62, 101257. [Google Scholar] [CrossRef]

- Teizer, J. Status quo and open challenges in vision-based sensing and tracking of temporary resources on infrastructure construction sites. Adv. Eng. Inf. 2015, 29, 225–238. [Google Scholar] [CrossRef]

- Yadav, D.; Kumari, R.; Kumar, N.; Sarkar, B. Reduction of waste and carbon emission through the selection of items with cross-price elasticity of demand to form a sustainable supply chain with preservation technology. J. Clean. Prod. 2021, 297, 126298. [Google Scholar] [CrossRef]

- Fonseca, J.D.; Camargo, M.; Commenge, J.M.; Iván, D.; Gil, L.F. Trends in design of distributed energy systems using hydrogen as energy vector: A systematic literature review. Int. J. Hydrogen Energy 2019, 44, 9486–9504. [Google Scholar] [CrossRef]

- Brinkhoff, A.; Özer, Ö.; Sargut, G. All you need is trust? An examination of inter-organizational supply chain projects. Prod Oper Manag. 2015, 24, 181–200. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital Twin for Supply Chain Coordination in Modular Construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Behera, P.; Mohanty, R.P.; Prakash, A. Understanding construction supply chain management. Prod. Plan. Control 2015, 26, 1332–1350. [Google Scholar] [CrossRef]

- Sabini, L.; Muzio, D.; Alderman, N. 25 years of ‘sustainable projects’: What we know and what the literature says. Int. J. Project Manag. 2019, 37, 820–838. [Google Scholar] [CrossRef]

- Akhbari, M. Integration of multi-mode resource-constrained project scheduling under bonus-penalty policies with material ordering under quantity discount scheme for minimizing project cost. Sci. Iran. 2022, 29, 427–446. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, N.F. Project scheduling and material ordering problem with storage space constraints. Autom. Constr. 2021, 129, 103796. [Google Scholar] [CrossRef]

- Rzepecki, L. Optimization of inventory costs management in the construction enterprise. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 032046. [Google Scholar] [CrossRef]

- Pérez-Fortes, M.; Laínez-Aguirre, J.M.; Arranz-Piera, P.; Velo, E.; Puigjaner, L. Design of regional and sustainable bio-based networks for electricity generation using a multi-objective MILP approach. Energy 2012, 44, 79–95. [Google Scholar] [CrossRef]

- Chen, Z.; Hammad, A.W.; Alyami, M. Building construction supply chain resilience under supply and demand uncertainties. Autom. Constr. 2024, 158, 105190. [Google Scholar] [CrossRef]

- Sánchez-Bautista, A.D.F.; Santibañez-Aguilar, J.E.; Fuentes-Cortés, L.F.; Flores-Tlacuahuac, A.; Ponce-Ortega, J.M. A multistakeholder approach for the optimal planning of sustainable energy systems. ACS Sustain. Chem. Eng. 2018, 6, 9451–9460. [Google Scholar] [CrossRef]

- Mahmood, S.; Iqbal, A.; El-kenawy, E.S.M.; Eid, M.M.; Alhussan, A.A.; Khafaga, D.S. The impact of green technology innovation, pro-environmental be-havior and eco-design on green new product success: Examine the moderating role of green corporate image. Environ. Res. Commun. 2025, 7, 015028. [Google Scholar] [CrossRef]

- AlRushood, M.A.; Rahbar, F.; Selim, S.Z.; Dweiri, F. Accelerating use of drones and robotics in post-pandemic project supply chain. Drones 2023, 7, 313. [Google Scholar] [CrossRef]

- Kayikci, Y.; Demir, S.; Mangla, S.K.; Subramanian, N.; Koc, B. Data-driven optimal dynamic pricing strategy for reducing perishable food waste at retailers. J. Clean. Prod. 2022, 344, 131068. [Google Scholar] [CrossRef]

- Liu, R.; Vakharia, V. Optimizing supply chain management through BO-CNN-LSTM for demand forecasting and inventory management. J. Organ. End User Comput. (JOEUC) 2024, 36, 1–25. [Google Scholar] [CrossRef]

- Gao, N.; Sun, W. A Mathematical Model Based on Supply Chain Optimization for International Petrochemical Engineering Projects. China Pet. Process. Petrochem. Technol. 2015, 17, 91–100. [Google Scholar]

- Mirghaderi, S.D.; Modiri, M. Application of meta-heuristic algorithm for multi-objective optimization of sustainable supply chain uncertainty. Sādhanā 2021, 46, 52. [Google Scholar] [CrossRef]

- Feng, C.; Hu, S.; Ma, Y.; Li, Z. A project scheduling game equilibrium problem based on dynamic resource supply. Appl. Sci. 2022, 12, 9062. [Google Scholar] [CrossRef]

- Du, J.; Xue, Y.; Sugumaran, V.; Hu, M.; Dong, P. Improved biogeography-based optimization algorithm for lean production scheduling of prefabricated components. Eng. Constr. Archit. Manag. 2023, 30, 1601–1635. [Google Scholar] [CrossRef]

- Forozandeh, M.; Teimoury, E.; Makui, A. A mathematical formulation of time-cost and reliability optimization for supply chain management in research-development projects. Rairo-Oper. Res. 2019, 53, 1385–1406. [Google Scholar] [CrossRef]

- Yuan, Y.S.; Ye, S.D.; Lin, L.; Gen, M.S. Multi-objective multi-mode resource-constrained project scheduling with fuzzy activity durations in prefabricated building construction. Comput. Ind. Eng. 2021, 158, 107316. [Google Scholar] [CrossRef]

- Gholizadeh-Tayyar, S.; Dupont, L.; Lamothe, J.; Falcon, M. Modeling a generalized resource constrained multi project scheduling problem integrated with a forward-backward supply chain planning. IFAC-PapersOnLine 2016, 49, 1283–1288. [Google Scholar] [CrossRef]

- Gholizadeh-Tayyar, S.; Okongwu, U.; Lamothe, J. A heuristic-based genetic algorithm for scheduling of multiple projects subjected to resource constraints and environmental responsibility commitments. Process Integr. Optim. Sustain. 2021, 5, 361–382. [Google Scholar] [CrossRef]

- Lai, X.D.; Wu, G.D.; Shi, J.G.; Wang, H.M.; Kong, Q.S. Project value-adding optimization of project-based supply chain under dynamic reputation incentives. Int. J. Simul. Model. 2015, 14, 121–133. [Google Scholar] [CrossRef] [PubMed]

- Koutsokosta, A.; Katsavounis, S. A dynamic multi-period, mixed-integer linear programming model for cost minimization of a three-echelon, multi-site and multi-product construction supply chain. Logistics 2020, 4, 19. [Google Scholar] [CrossRef]

- Chen, W.; Lei, L.; Wang, Z.; Teng, M.; Liu, J. Coordinating supplier selection and project scheduling in resource-constrained construction supply chains. Int. J. Prod. Res. 2018, 56, 6512–6526. [Google Scholar] [CrossRef]

- Ehrgott, M.; Kksalan, M.; Kadziński, M.; Deb, K. Fifty years of multi-objective optimization and decision-making: From mathematical programming to evolutionary computation. Eur. J. Oper. Res. 2025. [Google Scholar] [CrossRef]

- Wu, J.; Zhu, Q.; An, Q.; Chu, J.; Ji, X. Resource allocation based on context-dependent data envelopment analysis and a multi-objective linear programming approach. Comput. Ind. Eng. 2016, 101, 81–90. [Google Scholar] [CrossRef]

- Sik, A.Y.H. Transportation problem: A special case for linear programming problems in mining engineering. Int. J. Min. Sci. Technol. 2012, 22, 371–377. [Google Scholar] [CrossRef]

- Paras, A.H.; Gacuan, E.G.R.; Halim, E.; Redi, A.A.N.P.; German, J.D. Optimizing Project Scheduling Using Linear Programming Approach: A Case Study of Heating Ventilation & Air Conditioning Mechanical Installation. Procedia Comput. Sci. 2024, 234, 683–690. [Google Scholar] [CrossRef]

- Keyser, E.D.; Rowe, T.; Giacomella, L.; Jasinski, D.; Mathijs, E.; Vranken, L. Combining life-cycle assessment and linear programming to optimize social fertilizer costs. J. Environ. Manag. 2024, 369, 12. [Google Scholar] [CrossRef] [PubMed]

- Ferone, D.; Gruler, A.; Festa, P.; Gruler, A.; Juan, A.A. Combining simulation with a GRASP metaheuristic for solving the permutation flow-shop problem with stochastic processing times. In Proceedings of the 2016 Winter Simulation Conference (WSC), Washington, DC, USA, 11–14 December 2016; IEEE: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Jiuping, X.U.; Wei, P. Production-distribution planning of construction supply chain management under fuzzy random environment for large-scale construction projects. J. Ind. Manag. Optim. 2013, 9, 31–56. [Google Scholar] [CrossRef]

- Elloumi, S.; Loukil, T.; Fortemps, P. Reactive heuristics for disrupted multi-mode resource-constrained project scheduling problem. Expert Syst. Appl. 2021, 167, 114156. [Google Scholar] [CrossRef]

- Kheiri, A. Heuristic sequence selection for inventory routing problem. Transp. Sci. 2020, 54, 302–312. [Google Scholar] [CrossRef]

- Ng, C.Y.; Lam, S.S.; Samuel, C.P.M. Logistic sequencing for improving environmental performance using ant colony optimization. Environ. Impact Assess. Rev. 2019, 77, 182–190. [Google Scholar] [CrossRef]

- Valls, V.; Quintanilla, S.; Ballestín, F. Resource-constrained project scheduling: A critical activity reordering heuristic. European J. Oper. Res. 2003, 149, 282–301. [Google Scholar] [CrossRef]

- Pan, Q.K.; Gao, L.; Wang, L.; Liang, J.; Li, X. Effective heuristics and metaheuristics to minimize total flowtime for the distributed permutation flowshop problem. Expert Syst. Appl. 2019, 124, 309–324. [Google Scholar] [CrossRef]

- Aytug, H.; Lawley, M.A.; McKay, K.N.; Mohan, S.; Uzsoy, R. Executing production schedules in the face of uncertainties: A review and some future directions. Eur. J. Oper. Res. 2005, 161, 86–110. [Google Scholar] [CrossRef]

- Altiparmak, F.; Gen, M.; Lin, L.; Paksoy, T. A genetic algorithm approach for multi-objective optimization of supply chain networks. Comput. Ind. Eng. 2006, 51, 196–215. [Google Scholar] [CrossRef]

- Bai, L.; Qu, X.; Wang, X.; Zhang, L.; Yang, J. Project portfolio selection with relationship considerations: A random walk with restart based on influencing factors. Comput. Ind. Eng. 2024, 198, 110718. [Google Scholar] [CrossRef]

- Grillo, H.; Peidro, D.; Alemany, M.M.E.; Mula, J. Application of particle swarm optimisation with backward calculation to solve a fuzzy multi-objective supply chain master planning model. Int. J. Bio-Inspired Comput. 2015, 7, 157–169. [Google Scholar] [CrossRef]

- Tang, L.; Jing, K.; He, J. An improved ant colony optimisation algorithm for three-tier supply chain scheduling based on networked manufacturing. Int. J. Prod. Res. 2013, 51, 3945–3962. [Google Scholar] [CrossRef]

- Dou, R.L.; Liu, X.; Hou, Y.C.; Wei, Y. Mitigating closed-loop supply chain risk through assessment of production cost, disruption cost, and reliability. Int. J. Prod. Econ. 2024, 270, 109934. [Google Scholar] [CrossRef]

- Luo, L.Z.; Jin, X.; Shen, G.Q.; Wang, Y.; Liang, X.; Li, X.; Li, C. Supply chain management for prefabricated building projects in Hong Kong. J. Manag. Eng. 2020, 36, 05020001. [Google Scholar] [CrossRef]

- Wei, Z.C.; Alam, T.; Al Sulaie, S.; Bouye, M.; Deebani, W.; Song, M. An efficient IoT-based perspective view of food traceability supply chain using optimized classifier algorithm. Inf. Process. Manag. 2023, 60, 103275. [Google Scholar] [CrossRef]

- Tang, G.H.; Zeng, H. Collaborative management and control of blockchain in cloud computing environment. J. Intell. Fuzzy Syst. 2021, 40, 5963–5973. [Google Scholar] [CrossRef]

- Feng, J.; Phillips, R.V.; Malenica, I.; Bishara, A.; Hubbard, A.E.; Celi, L.A.; Pirracchio, R. Clinical artificial intelligence quality improvement: Towards continual monitoring and updating of AI algorithms in healthcare. npj Digit. Med. 2022, 5, 121. [Google Scholar] [CrossRef]

- Yang, J.K.; Ng, S.T. Prospects for digital twin technology in the building modular construction and operation phases: A game theory-based analysis. J. Clean. Prod. 2024, 470, 143344. [Google Scholar] [CrossRef]

- Wang, X.; Lu, S.; Qian, X.; Hu, C.; Liu, X. Dynamic scheduling of decentralized high-end equipment R&D projects via deep reinforcement learning. Comput. Ind. Eng. 2024, 190, 110018. [Google Scholar] [CrossRef]

- Soleymani, M.; Bonyani, M.; Wang, C. Simulation of autonomous resource allocation through deep reinforcement learning-based portfolio-project integration. Autom. Constr. 2024, 162, 105381. [Google Scholar] [CrossRef]

- Kotecha, N.; del Rio Chanona, A. Leveraging graph neural networks and multi-agent reinforcement learning for inventory control in supply chains. Comput. Chem. Eng. 2025, 199, 109111. [Google Scholar] [CrossRef]

- Zou, H.; Yi, L.; Zhang, T.; Yu, C.; Huang, J. Deep Reinforcement Learning-Based Optimisation of Reverse Logistics Transport in Closed-Loop Supply Chain. Proc. Inst. Civ. Eng. Transp. 2025. [Google Scholar] [CrossRef]

- Abushaega, M.M.; Moshebah, O.Y.; Hamzi, A.; Alghamdi, S.Y. Multi-objective sustainability optimization in modern supply chain networks: A hybrid approach with federated learning and graph neural networks. Alex. Eng. J. 2025, 115, 585–602. [Google Scholar] [CrossRef]

- Long, L.N.B.; You, S.S.; Cuong, T.N.; Kim, H.S. Optimizing quay crane scheduling using deep reinforcement learning with hybrid metaheuristic algorithm. Eng. Appl. Artif. Intell. 2025, 143, 110021. [Google Scholar] [CrossRef]

- Bai, L.; Xie, X.; Sun, Y.; Qu, X.; Han, X. Assessing project criticality in project portfolio: A vulnerability modeling approach. Eng. Constr. Archit. Manag. 2025, 32, 2890–2919. [Google Scholar] [CrossRef]

- Luo, J.; Vanhoucke, M.; Coelho, J. Automated Design of Priority Rules for Resource-Constrained Project Scheduling Problem Using Surrogate-Assisted Genetic Programming. Swarm Evol. Comput. 2023, 81, 101339. [Google Scholar] [CrossRef]

- Guo, W.; Vanhoucke, M.; Coelho, J.; Luo, J. Automatic detection of the best performing priority rule for the resource-constrained project scheduling problem. Expert Syst. Appl. 2021, 167, 114116. [Google Scholar] [CrossRef]

- Gaudenzi, B.; Qazi, A. Assessing project risks from a supply chain quality management (SCQM) perspective. Int. J. Qual. Reliab. Manag. 2021, 38, 908–931. [Google Scholar] [CrossRef]

- Li, F.F.; Xu, Z. A multi-agent system for distributed multi-project scheduling with two-stage decomposition. PLoS ONE 2018, 13, 0205445. [Google Scholar] [CrossRef]

- Fu, F.; Xing, W. An agent-based approach for project-driven supply chain problem under information asymmetry and decentralized decision-making. Comput. Ind. Eng. 2021, 158, 107410. [Google Scholar] [CrossRef]

- Tian, Y.T.; Song, S.X.; Zhou, D.; Yang, R.R.; Wei, C. Toward sustainable joint optimisation for product family and supply chain configuration with smart contracting consideration. J. Eng. Des. 2023, 34, 1013–1045. [Google Scholar] [CrossRef]

- Chu, X.C.; Han, X.F.; Zhang, M.R.; Li, M.Q. Improving decomposition-based MOEAs for combinatorial optimisation by intensifying corner weights. Swarm Evol. Comput. 2024, 91, 101722. [Google Scholar] [CrossRef]

- Köbis, E. On Robust Optimization Relations Between Scalar Robust Optimization and Unconstrained Multicriteria Optimization. J. Optim. Theory Appl. 2015, 167, 969–984. [Google Scholar] [CrossRef]

- Hsu, P.Y.; Aurisicchio, M.; Angeloudis, P. Risk-averse supply chain for modular construction projects. Autom. Constr. 2019, 106, 102898. [Google Scholar] [CrossRef]

- Bruni, M.E.; Hazir, O. A risk-averse distributionally robust project scheduling model to address. Eur. J. Oper. Res. 2024, 318, 398–407. [Google Scholar] [CrossRef]

- Chen, Z.X.; Hammad, A.W.A.; Waller, S.T.; Haddad, A.N. Modelling supplier selection and material purchasing for the construction supply chain in a fuzzy scenario-based environment. Autom. Constr. 2023, 150, 104847. [Google Scholar] [CrossRef]

- Hajiagha, S.H.R.; Mahdiraji, H.A.; Behnam, M.; Nekoughadirli, B.; Joshi, R. A scenario-based robust time-cost tradeoff model to handle the effect of COVID-19 on supply chains project management. Oper. Manag. Res. 2022, 15, 357–377. [Google Scholar] [CrossRef]

- Du, W.Y.; Fan, Y.B.; Liu, X.J.; Park, S.C.; Tang, X.W. A game-based production operation model for water resource management: An analysis of the South-to-North Water Transfer Project in China. J. Clean. Prod. 2019, 228, 1482–1493. [Google Scholar] [CrossRef]

- Lukas, E.; Welling, A. Timing and eco(nomic) efficiency of climate-friendly investments in supply chains. Eur. J. Oper. Res. 2014, 233, 448–457. [Google Scholar] [CrossRef]

- Wicaksana, A.; Ho, W.; Talluri, S.; Dolgui, A. A decade of progress in supply chain risk management: Risk typology, emerging topics, and research collaborators. Int. J. Prod. Res. 2022, 60, 7155–7177. [Google Scholar] [CrossRef]

- Wu, T.Y.; Shao, A.; Pan, J.S. CTOA: Toward a chaotic-based tumbleweed optimization algorithm. Mathematics 2023, 11, 2339. [Google Scholar] [CrossRef]

| Key Theme | Optimization Method Category | Typical Representative Studies | Core Application Scenario |

|---|---|---|---|

| PM Project Scheduling | Classical Optimization | CPM-based scheduling [18]; Linear Programming (LP) for time–cost trade-off [58]; | Balancing project timeline constraints and resource utilization to avoid delays. |

| PM Resource Allocation | Modern Heuristic Optimization | Genetic Algorithms (GAs) for multi-project resource sharing [59]; Particle swarm optimization (PSO) for human resource assignment [60]; | Allocating limited time, manpower, and equipment across concurrent projects. |

| SCM Supplier Collaboration | Multi-Objective Optimization | Mixed-integer programming (MIP) for supplier selection [57]; Pareto-based algorithms for multi-tier supply chain coordination [56]; | Optimizing supplier selection, order quantity, and delivery schedules to reduce costs. |

| SCM Inventory Optimization | Deterministic/Uncertainty Optimization | LP for static inventory level setting [56]; Stochastic programming for inventory under demand volatility [36]; | Maintaining optimal inventory levels to balance holding costs and stockout risks. |

| PM-SCM Risk Mitigation | Hybrid Optimization | Simulated annealing (SA) for integrated project–supply risk scheduling [24]; Ant colony optimization (ACO) for risk-driven resource reallocation [25]; | Coordinating project task adjustments and supply chain responses to mitigate disruptions. |

| PM-SCM Sustainability | Multi-Objective/Technology-Enabled Optimization | AI-integrated GAs for green project–supply network design [8]; Digital twin-assisted optimization for carbon footprint reduction [62]. | Aligning project execution with supply chain sustainability goals. |

| Year Range | Initial Hits | After Screening | Final Inclusion |

|---|---|---|---|

| 2003–2010 | 89 | 51 | 43 |

| 2011–2015 | 128 | 85 | 79 |

| 2016–2020 | 160 | 123 | 119 |

| 2020–2025 | 112 | 94 | 86 |

| Total | 489 | 353 | 327 |

| Gold Standard: “Relevant” (Total 302) | Gold Standard: “Irrelevant” | |

|---|---|---|

| Retrieved by Search Strategy (Total 327) | True Positives (TP) = 295 | False Positives (FP) = 32 |

| Not Retrieved by Search Strategy | False Negatives (FN) = 7 | True Negatives (TN) (This value is not considered in this study) |

| Authors | Number of Articles | Number of Citations | Average Citations |

|---|---|---|---|

| Ghannadpour SF [65,66,67,68,69] | 5 | 108 | 22 |

| Chakrabortty RK [76,77,78,79] | 4 | 35 | 9 |

| Li Y [80,81,82,83] | 4 | 34 | 9 |

| Zhang L [81,84,85] | 4 | 104 | 26 |

| Chen [86,87,88] | 3 | 62 | 21 |

| Ghaffa-anhoseini A [89,90,91] | 3 | 71 | 24 |

| Habibi F [76,77,92] | 3 | 65 | 22 |

| Hosseini MR [73,74,75] | 3 | 123 | 41 |

| Jolai F [93,94,95] | 3 | 58 | 19 |

| Kim S [70,71,72] | 3 | 144 | 48 |

| Kumar A [96,97,98] | 3 | 106 | 35 |

| Martek I [73,74,75] | 3 | 123 | 41 |

| Noori S [65,66,68] | 3 | 86 | 29 |

| Tabrizi BH [99,100,101] | 3 | 110 | 37 |

| Wang Y [102,103,104] | 3 | 99 | 33 |

| Country | Number of Articles | Number of Citations | Average Citations |

|---|---|---|---|

| China | 82 | 1212 | 15 |

| USA | 52 | 772 | 15 |

| Iran | 35 | 573 | 16 |

| England | 31 | 733 | 24 |

| Australia | 30 | 419 | 14 |

| India | 24 | 342 | 14 |

| Germany | 14 | 409 | 29 |

| Canada | 13 | 74 | 6 |

| France | 12 | 278 | 23 |

| Korea | 11 | 258 | 23 |

| Journals | Number of Articles | Number of Citations | Average Citations | Impact Factor |

|---|---|---|---|---|

| Engineering Construction and Architectural Management | 15 | 102 | 7 | 3.6 |

| Sustainability | 15 | 119 | 8 | 3.9 |

| Computers and Industrial Engineering | 13 | 107 | 8 | 6.7 |

| Journal of Construction Engineering and Management | 13 | 131 | 10 | 4.1 |

| Automation in Construction | 9 | 144 | 16 | 9.6 |

| International Journal of Managing Projects in Business | 9 | 50 | 6 | 2.3 |

| Applied Sciences-Basel | 8 | 26 | 3 | 2.5 |

| Engineering Management Journal | 8 | 3 | 0 | 1.9 |

| International Journal of Project Management | 7 | 161 | 23 | 7.4 |

| Journal of Cleaner Production | 7 | 129 | 18 | 9.7 |

| Buildings | 6 | 41 | 7 | 2.7 |

| Built Environment Project and Asset Management | 6 | 22 | 4 | 1.9 |

| Journal of Management in Engineering | 6 | 110 | 18 | 5.3 |

| Project Management Journal | 6 | 76 | 13 | 5.1 |

| Journal of Civil Engineering and Management | 5 | 49 | 10 | 3.7 |

| IEEE ACCESS | 4 | 29 | 7 | 3.4 |

| IEEE transactions on engineering management | 4 | 53 | 13 | 4.6 |

| Management science | 4 | 72 | 18 | 5.4 |

| Operations Management Research | 4 | 36 | 9 | 6.9 |

| Production Planning and Control | 4 | 64 | 16 | 6.1 |

| Cluster ID | Size | Silhouette Value | Mean Year | Cluster Name |

|---|---|---|---|---|

| 0 | 31 | 0.897 | 2019 | optimization method |

| 1 | 26 | 0.944 | 2016 | project scheduling |

| 2 | 25 | 0.843 | 2019 | project management |

| 3 | 23 | 0.783 | 2019 | simulation |

| 4 | 22 | 0.845 | 2018 | integrated project delivery |

| 5 | 22 | 0.812 | 2020 | green supply chain |

| 6 | 21 | 0.802 | 2020 | artificial intelligence |

| 7 | 20 | 0.924 | 2013 | resiliency |

| 8 | 20 | 0.743 | 2020 | firm performance |

| 9 | 19 | 0.958 | 2016 | risk management |

| 10 | 19 | 0.908 | 2016 | supply chain management |

| 11 | 18 | 0.878 | 2021 | strategic management |

| 12 | 16 | 0.827 | 2021 | construction engineering |

| 13 | 16 | 0.966 | 2016 | supply chain disruption |

| 14 | 11 | 0.87 | 2021 | project portfolio |

| Document | Title | Citations | Per Year | Normalized TC |

|---|---|---|---|---|

| Hwang, Bon-Gang et al., 2018 [111] | ‘Key constraints and mitigation strategies for prefabricated prefinished volumetric construction’ | 208 | 26.00 | 5.48 |

| Cubric, Marija, 2020 [112] | ‘Drivers, barriers and social considerations for AI adoption in business and management: A tertiary study’ | 173 | 28.83 | 6.10 |

| Teizer, Jochen, 2015 [113] | ‘Status quo and open challenges in vision-based sensing and tracking of temporary resources on infrastructure construction sites’ | 144 | 13.09 | 2.66 |

| Yadav, Dharmendra et al., 2021 [114] | ‘Reduction of waste and carbon emission through the selection of items with cross-price elasticity of demand to form a sustainable supply chain with preservation technology’ | 141 | 28.20 | 4.89 |

| Fonseca, Juan D et al., 2019 [115] | ‘Trends in design of distributed energy systems using hydrogen as energy vector: A systematic literature review’ | 131 | 18.71 | 3.58 |

| Brinkhoff, Andreas et al., 2015 [116] | ‘All You Need Is Trust? An Examination of Inter-organizational Supply Chain Projects’ | 123 | 11.18 | 2.27 |

| Lee, Dongmin et al., 2021 [117] | ‘Digital Twin for Supply Chain Coordination in Modular Construction’ | 122 | 24.40 | 4.23 |

| Behera, Panchanan et al., 2015 [118] | ‘Understanding Construction Supply Chain Management’ | 115 | 10.45 | 2.12 |

| Kim, Sungjin et al., 2020 [71] | ‘Dynamic Modeling for Analyzing Impacts of Skilled Labor Shortage on Construction Project Management’ | 113 | 18.83 | 3.99 |

| Sabini, Luca et al., 2019 [119] | ‘25 years of ‘sustainable projects’. What we know and what the literature says’ | 112 | 16.00 | 3.06 |

| Dimension | Project-Driven Supply Chain (PDSC) | Project-Based Supply Chain (PBSC) |

|---|---|---|

| Core Objective | Complete specific projects efficiently and at a low cost. | Through outstanding project management skills, I have successfully won and delivered multiple complex projects. |

| Organizational Form | Temporary and task-oriented organizations. | Permanent and capability-oriented organization. |

| Nature of Demand | Unique, one-time, and highly uncertain, driven by project-specific specifications and milestone schedules. | Repetitive or semi-repetitive across multiple projects, aiming for standardization and process improvement. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Zhao, W.; Fang, M.; Yuan, K.; Cheng, S.; Jia, W.; Bai, L. Bridging Project Management and Supply Chain Management via Optimization Method: Scenarios, Technologies, and Future Opportunities. Mathematics 2025, 13, 3490. https://doi.org/10.3390/math13213490

Zhang L, Zhao W, Fang M, Yuan K, Cheng S, Jia W, Bai L. Bridging Project Management and Supply Chain Management via Optimization Method: Scenarios, Technologies, and Future Opportunities. Mathematics. 2025; 13(21):3490. https://doi.org/10.3390/math13213490

Chicago/Turabian StyleZhang, Liwen, Wanyang Zhao, Mingjuan Fang, Keke Yuan, Sijie Cheng, Wenjia Jia, and Libiao Bai. 2025. "Bridging Project Management and Supply Chain Management via Optimization Method: Scenarios, Technologies, and Future Opportunities" Mathematics 13, no. 21: 3490. https://doi.org/10.3390/math13213490

APA StyleZhang, L., Zhao, W., Fang, M., Yuan, K., Cheng, S., Jia, W., & Bai, L. (2025). Bridging Project Management and Supply Chain Management via Optimization Method: Scenarios, Technologies, and Future Opportunities. Mathematics, 13(21), 3490. https://doi.org/10.3390/math13213490