Limit Analysis Theory and Numerical Simulation Study on the Cover Thickness of Tunnel Crown in Soil–Rock Strata

Abstract

1. Introduction

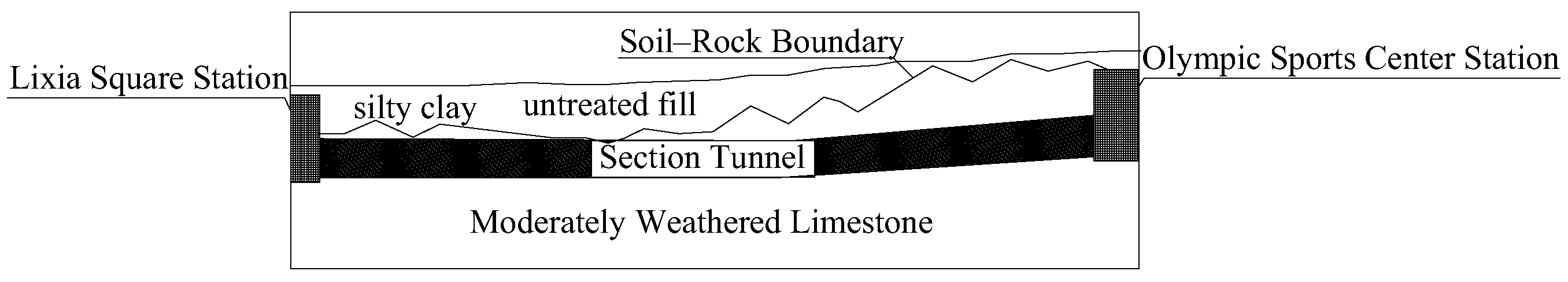

2. Project Overview

3. Numerical Simulation of Tunnel Surrounding Rock Deformation and Failure Under Different Overburden Thicknesses

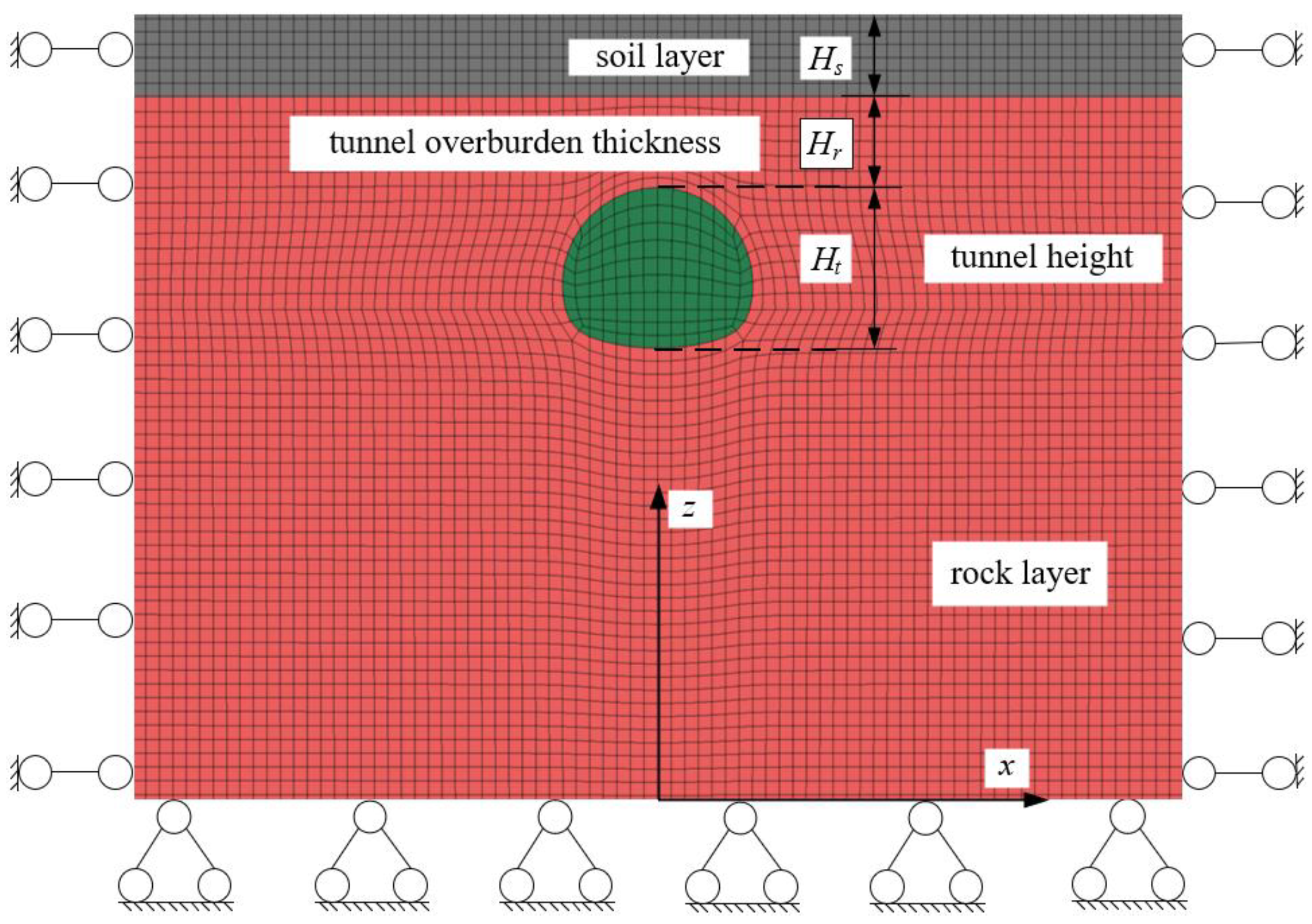

3.1. Model Construction and Solution Design

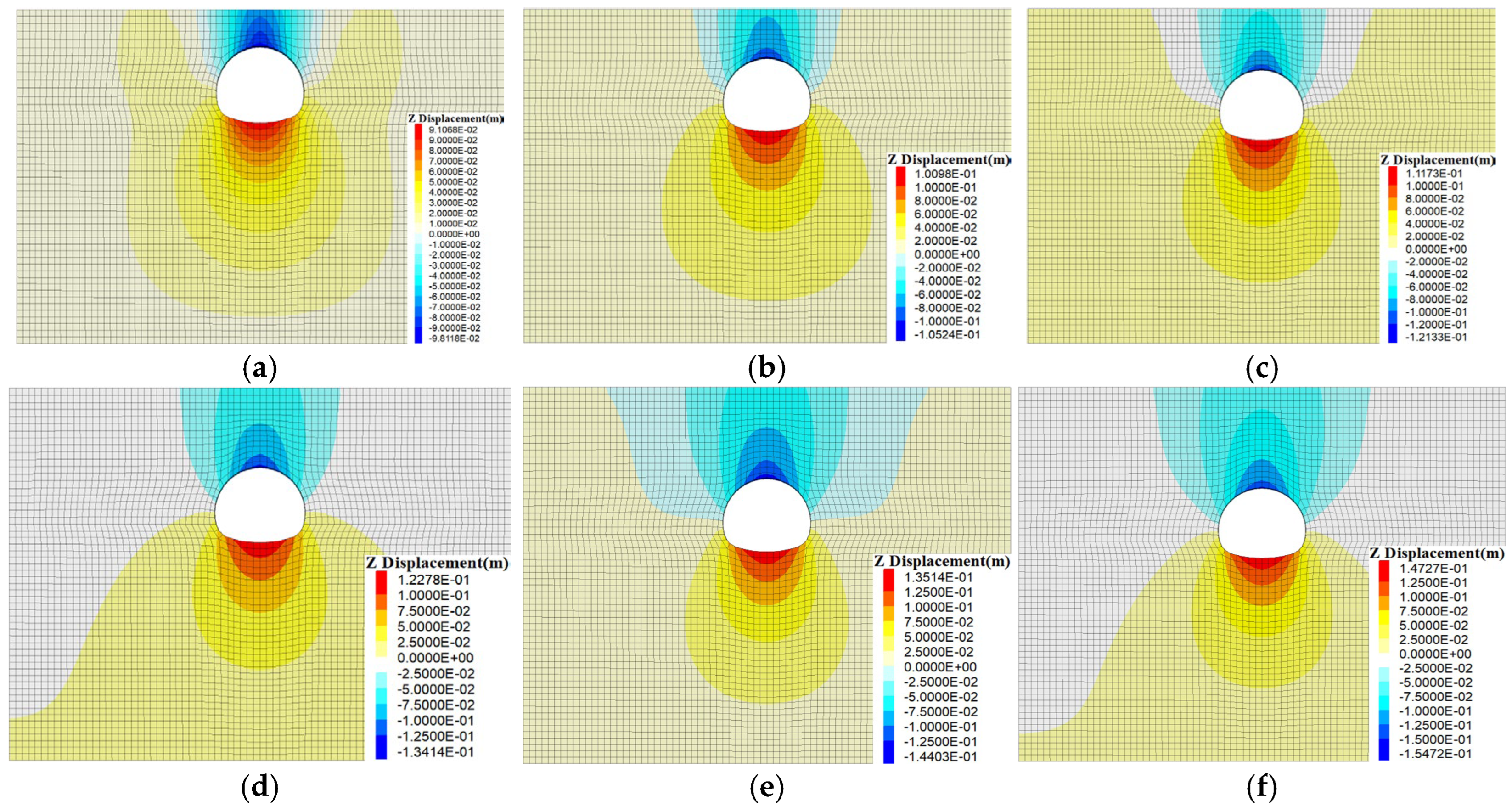

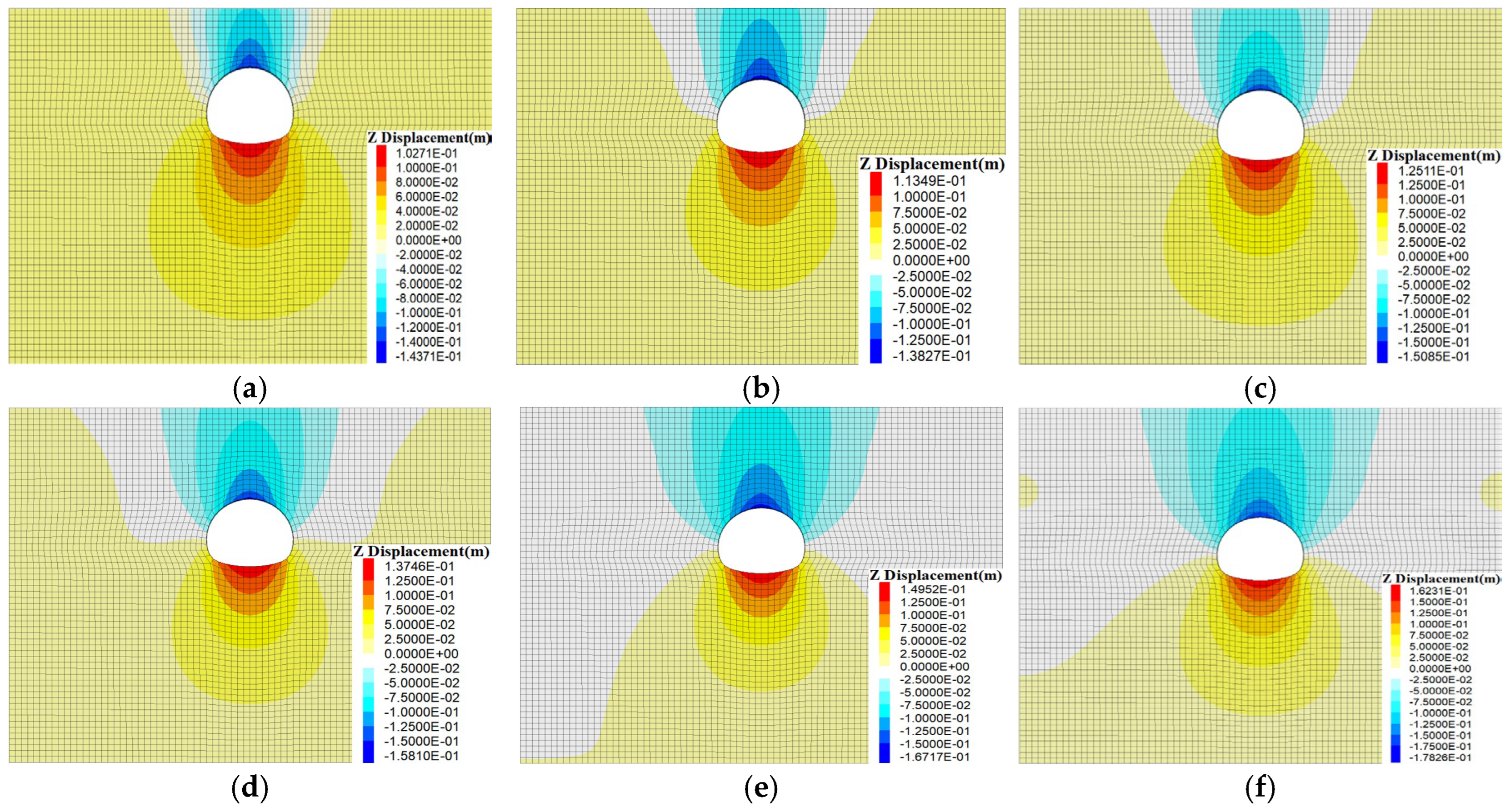

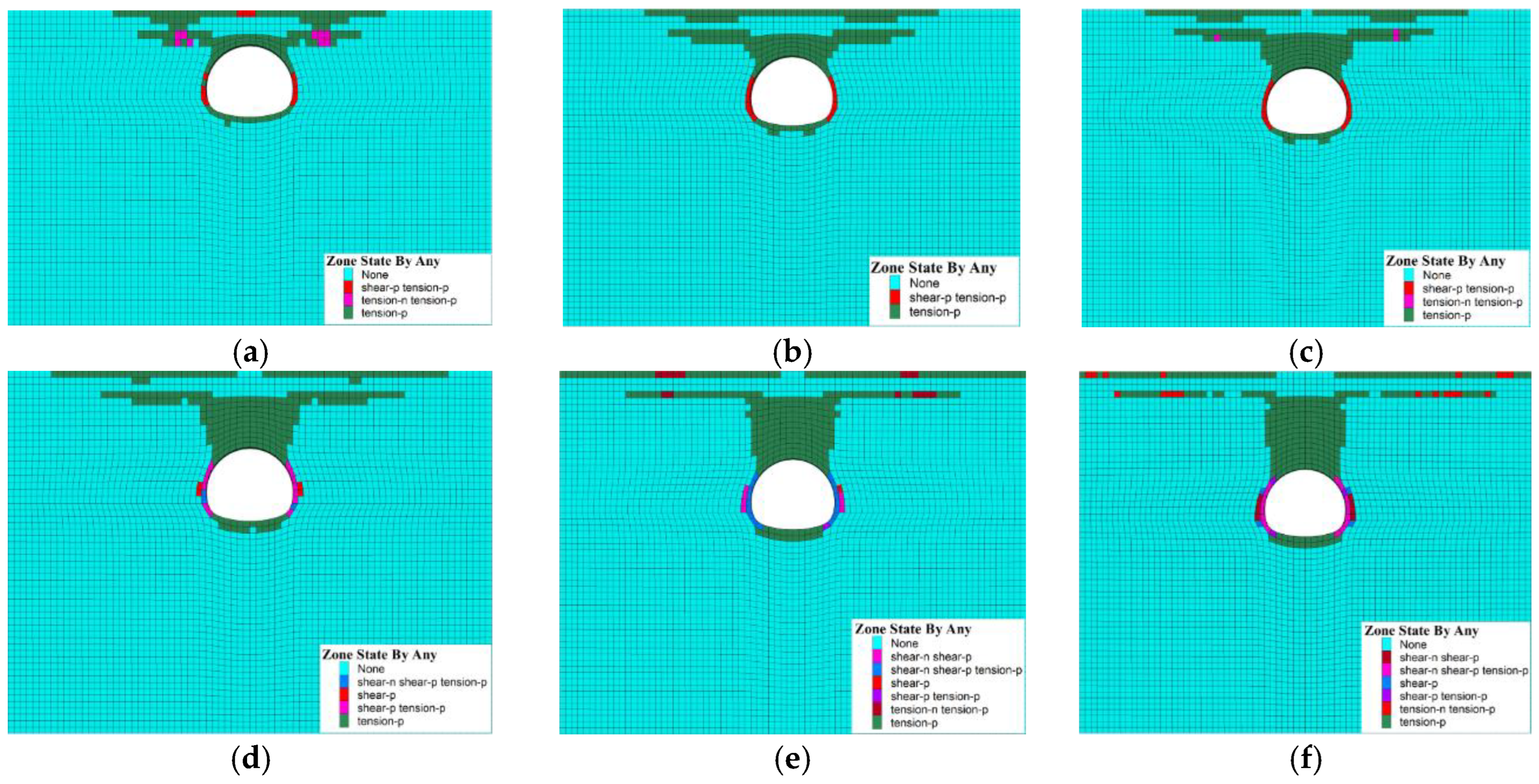

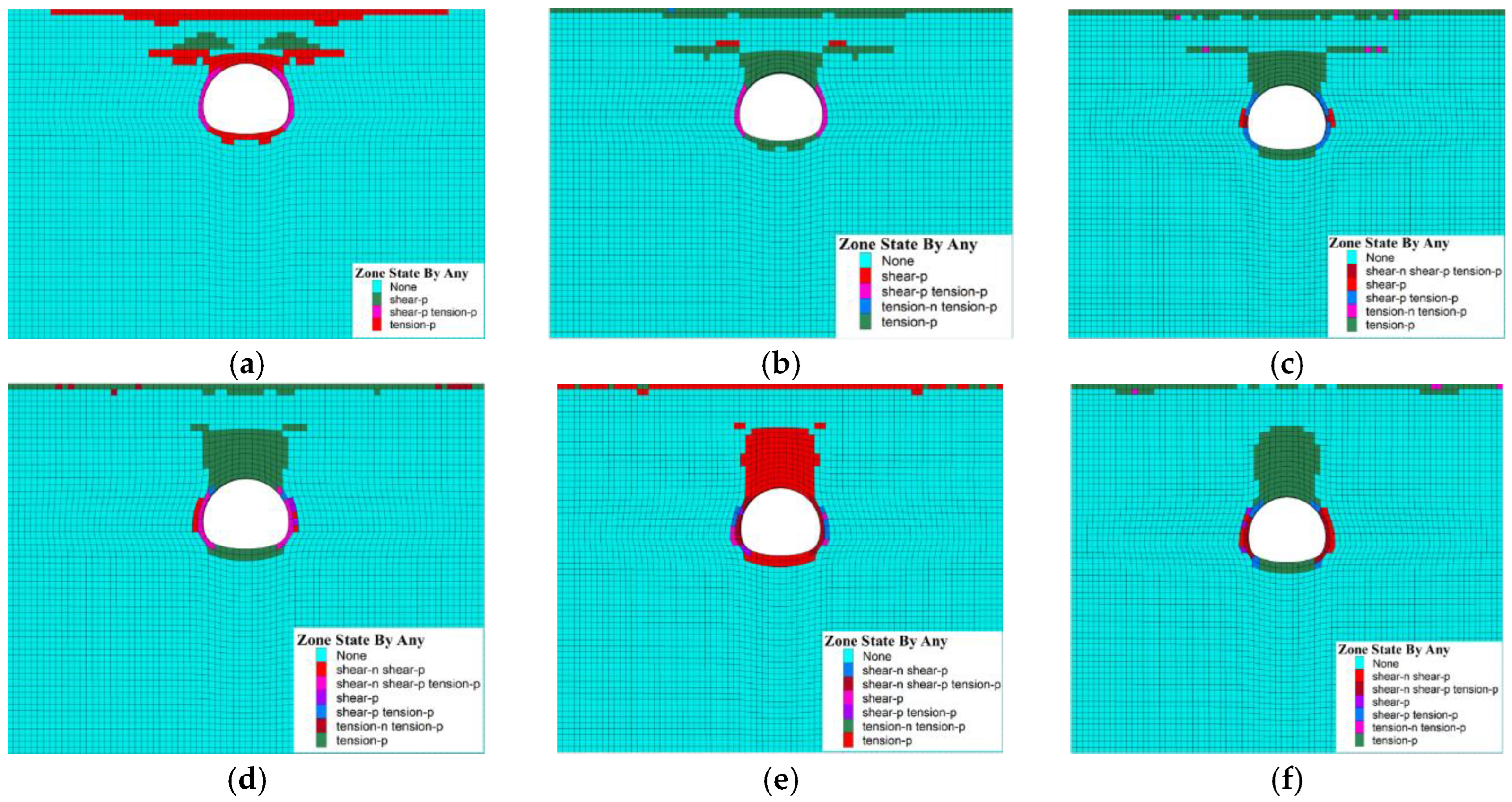

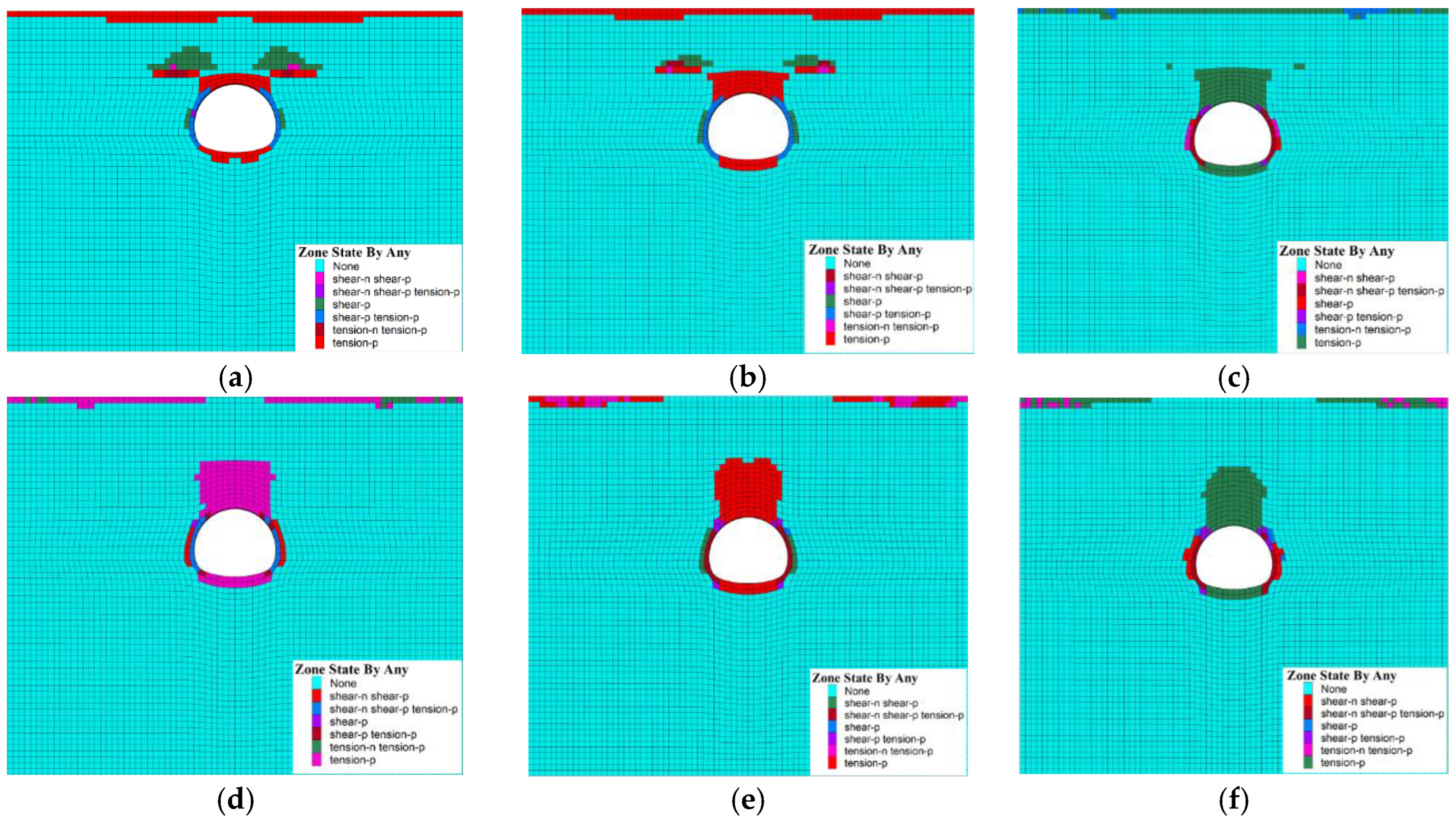

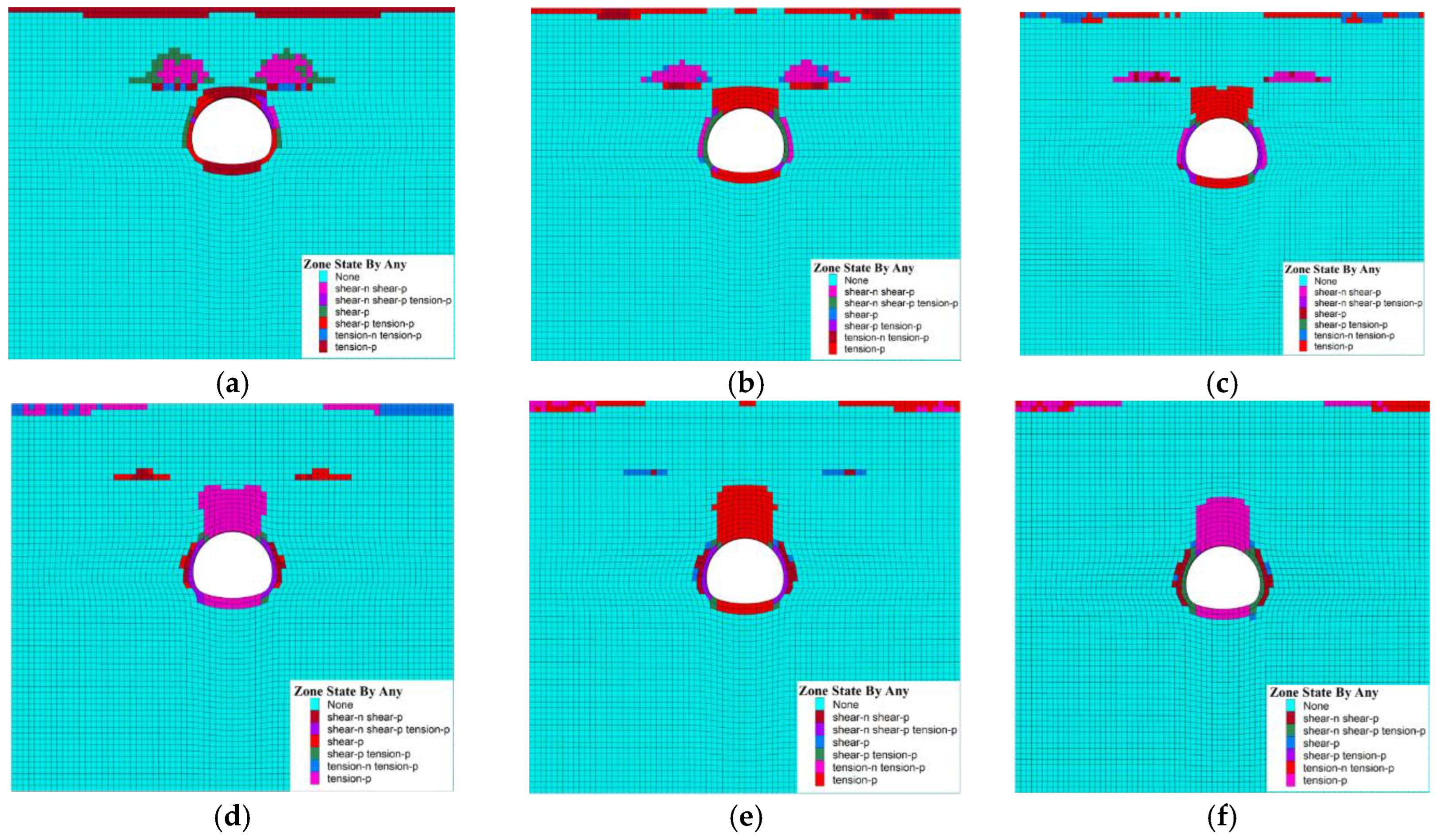

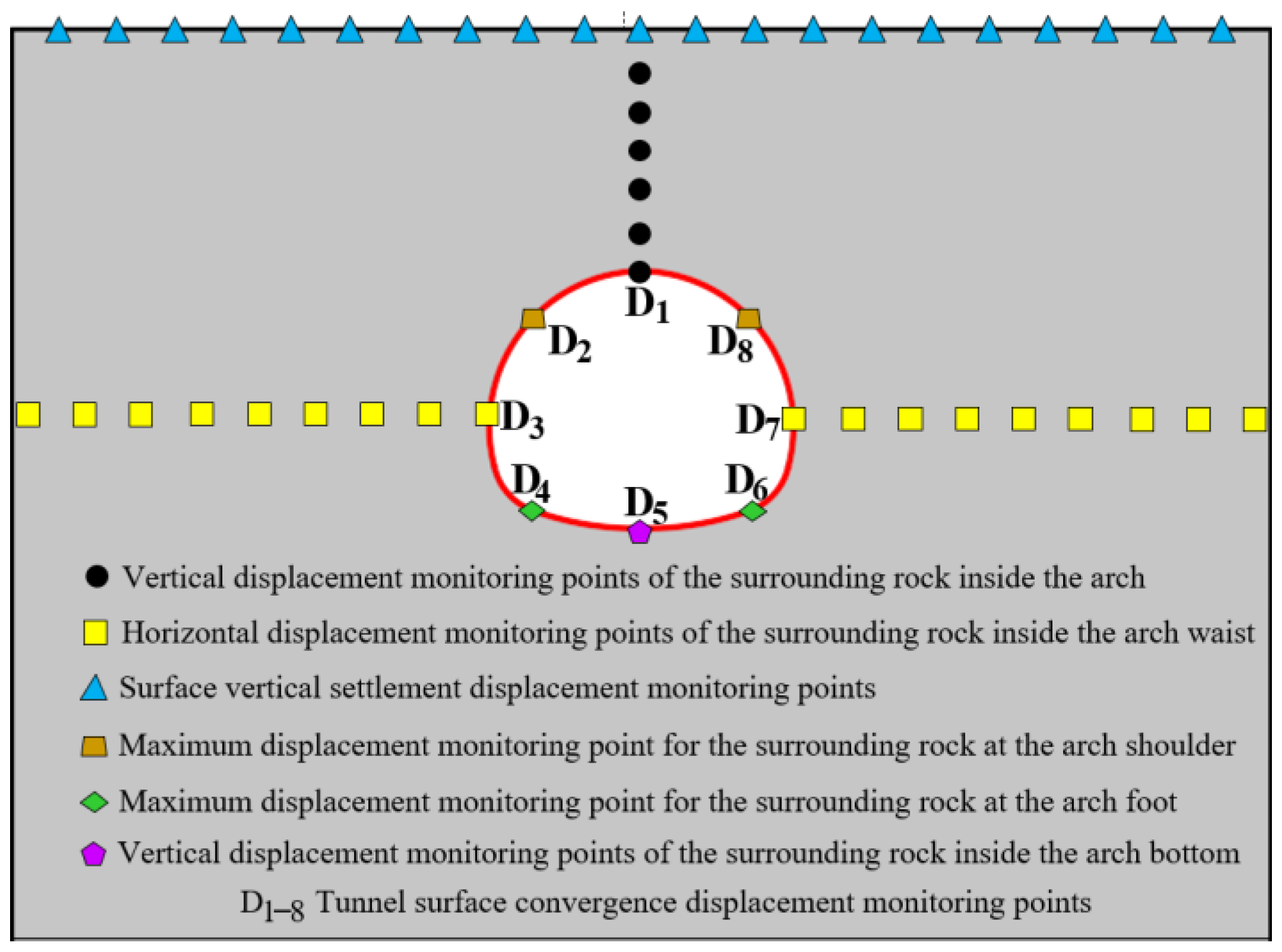

3.2. Comparison and Analysis of Numerical Simulation Results

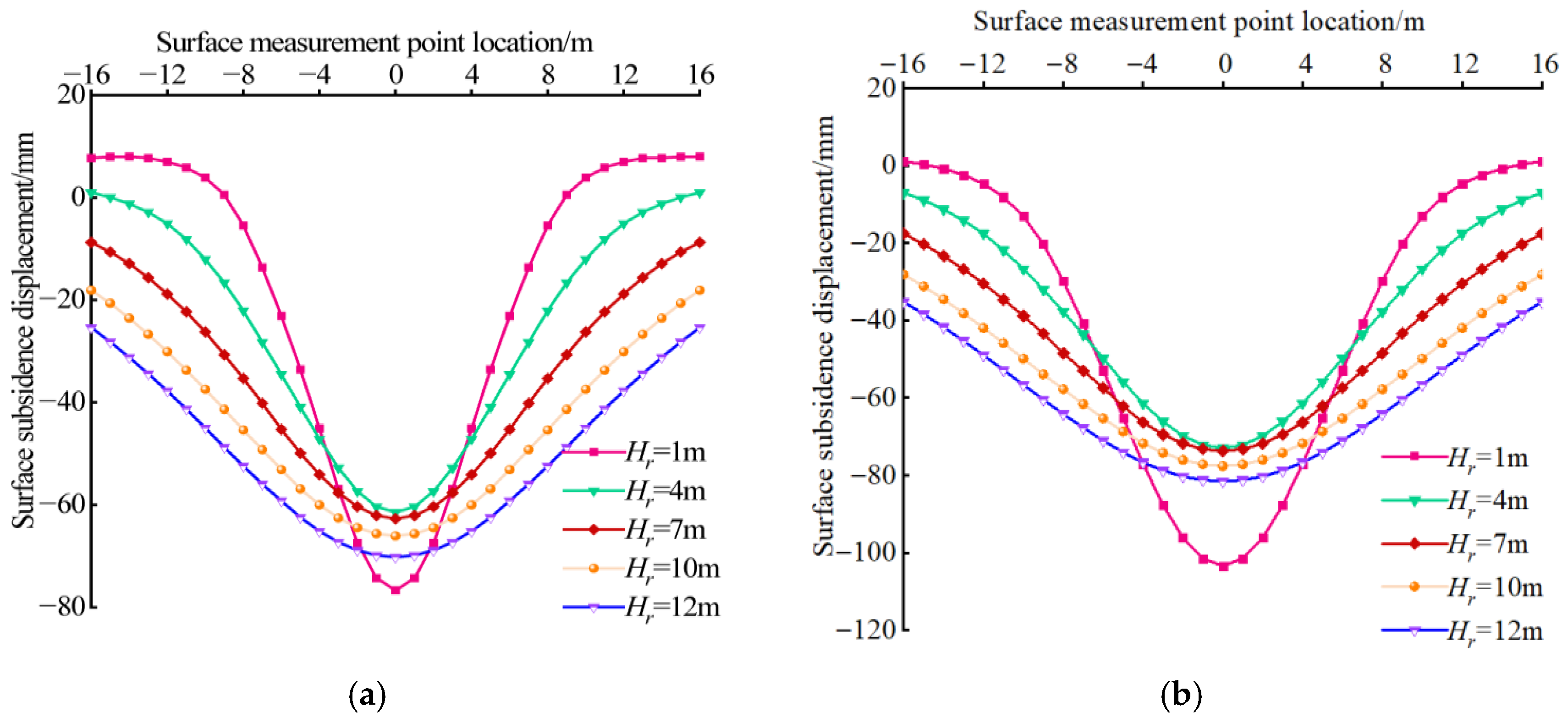

- (1)

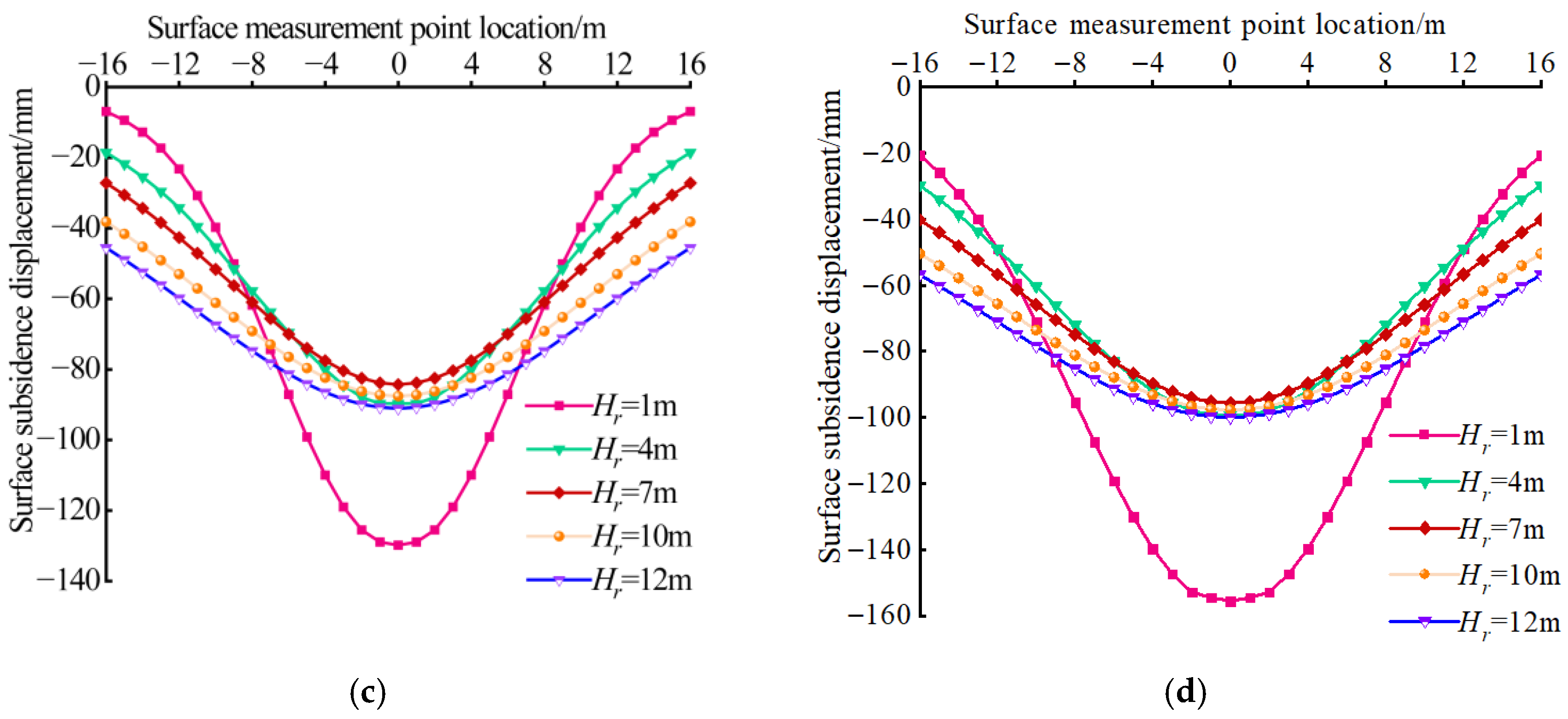

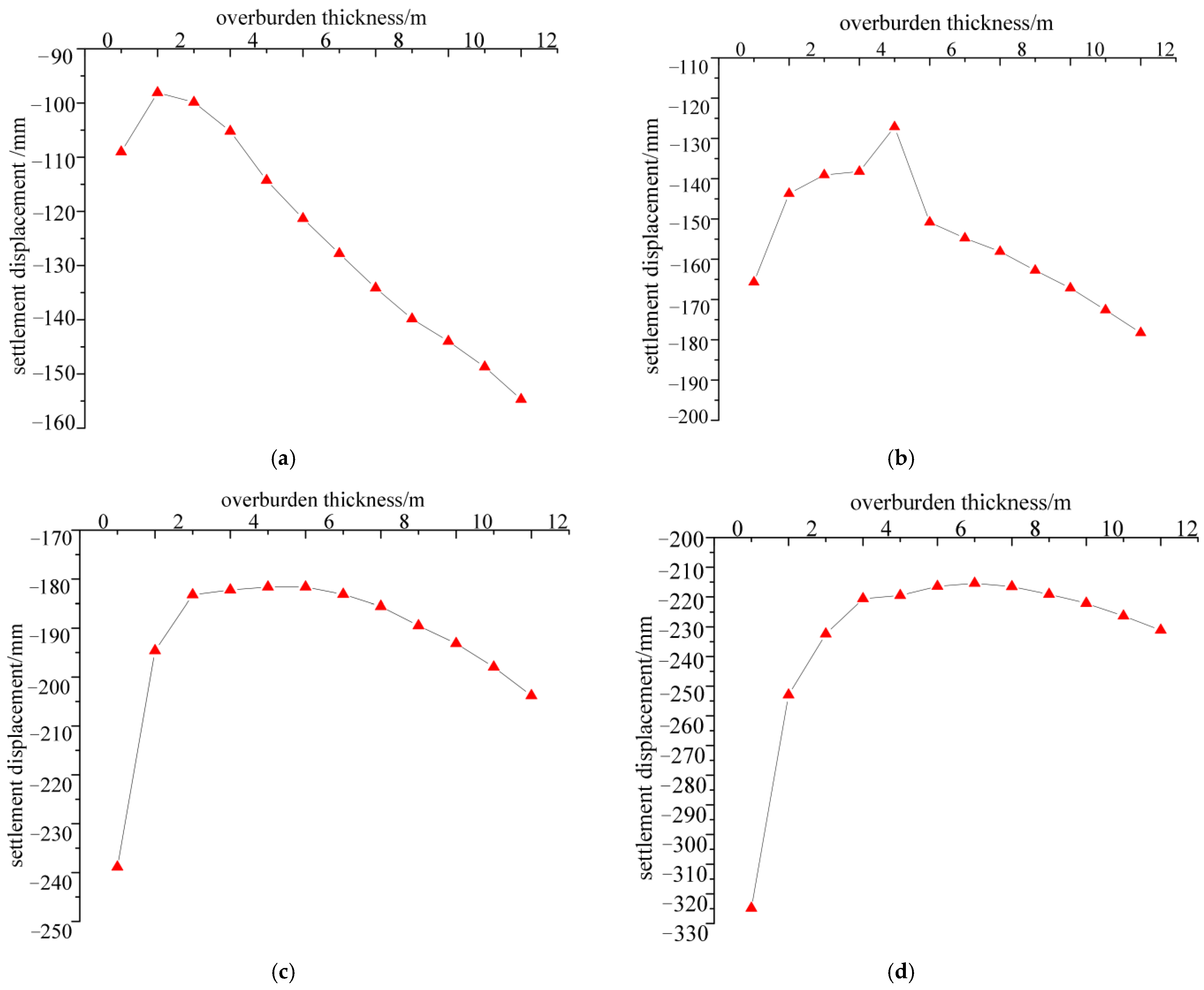

- Vertical settlement displacement on the surface

- (2)

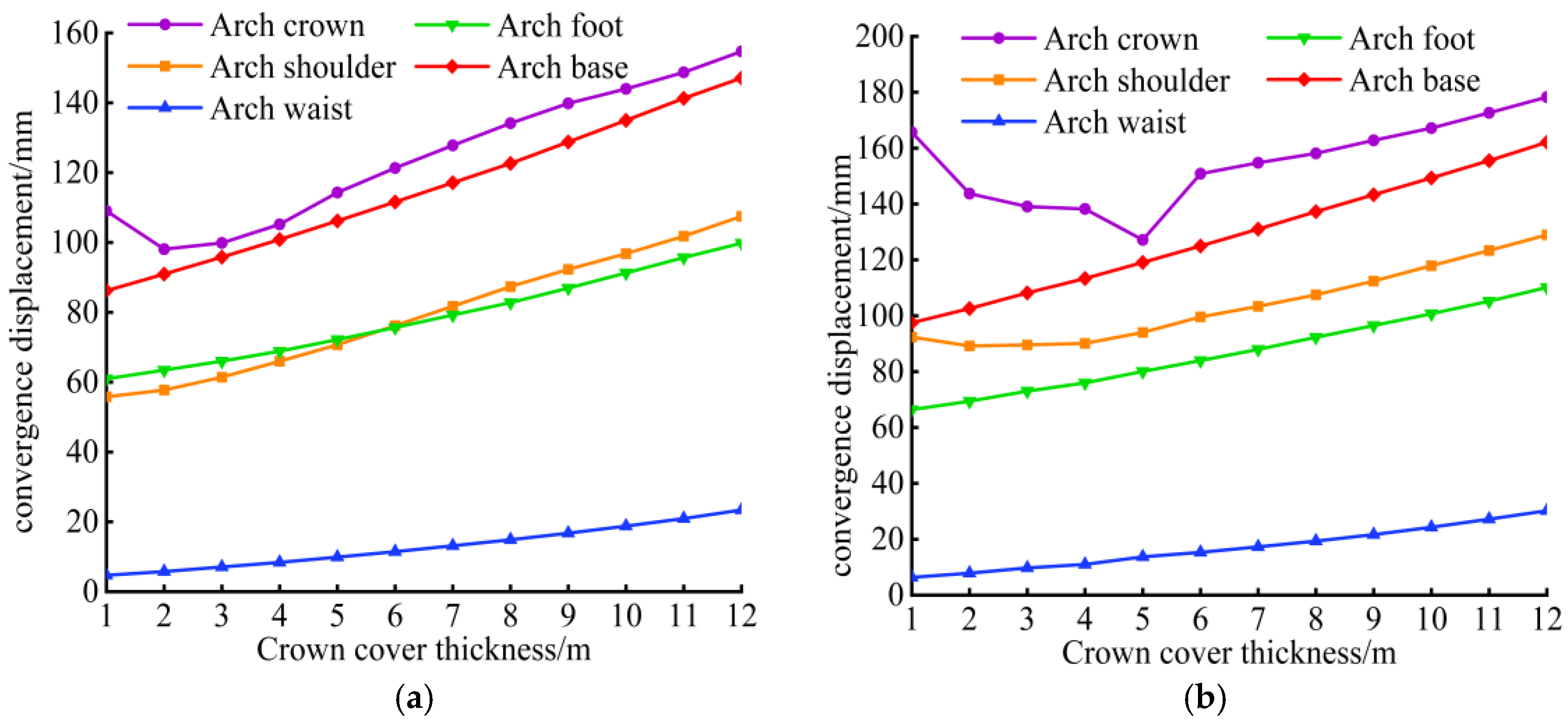

- Convergence Displacement of Tunnel Surrounding Surface

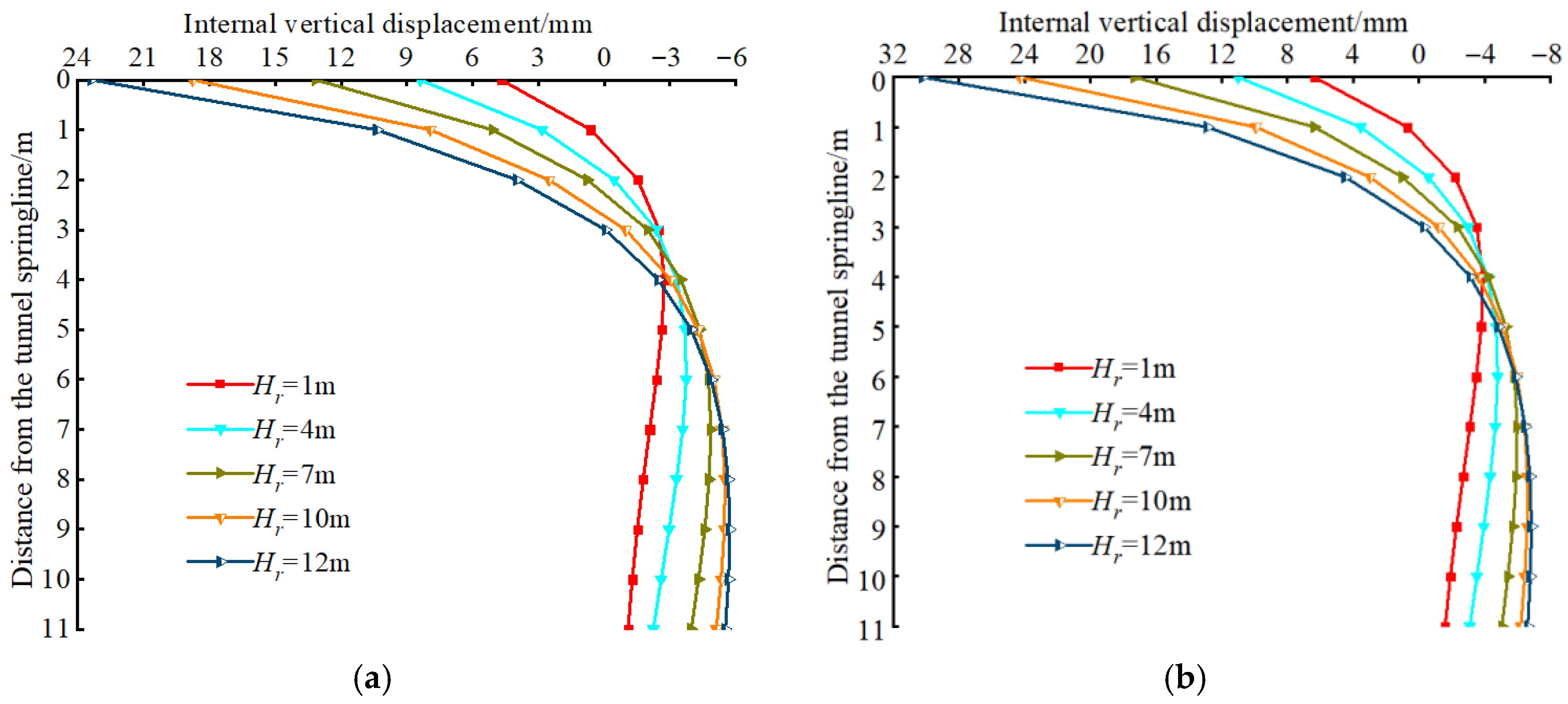

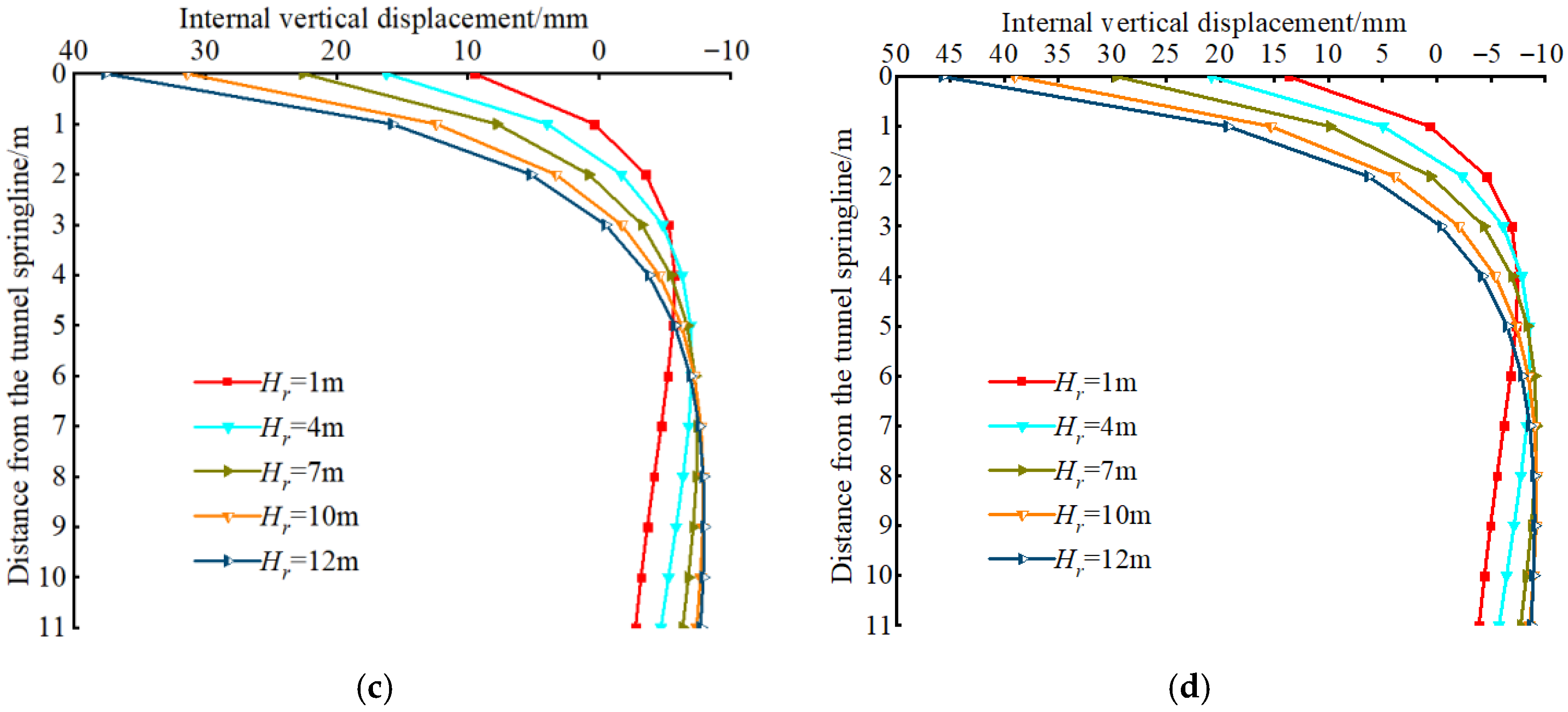

- (3)

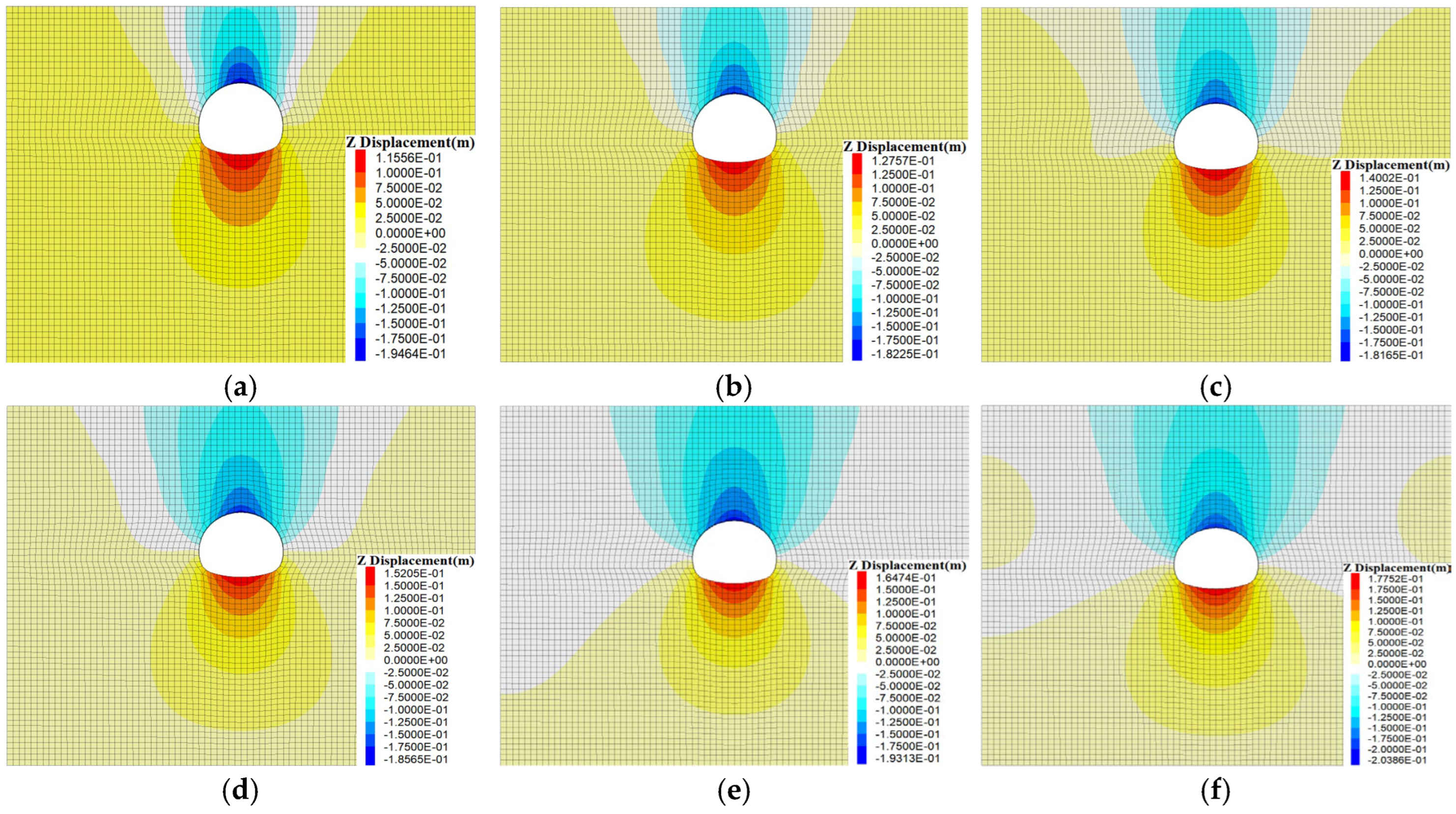

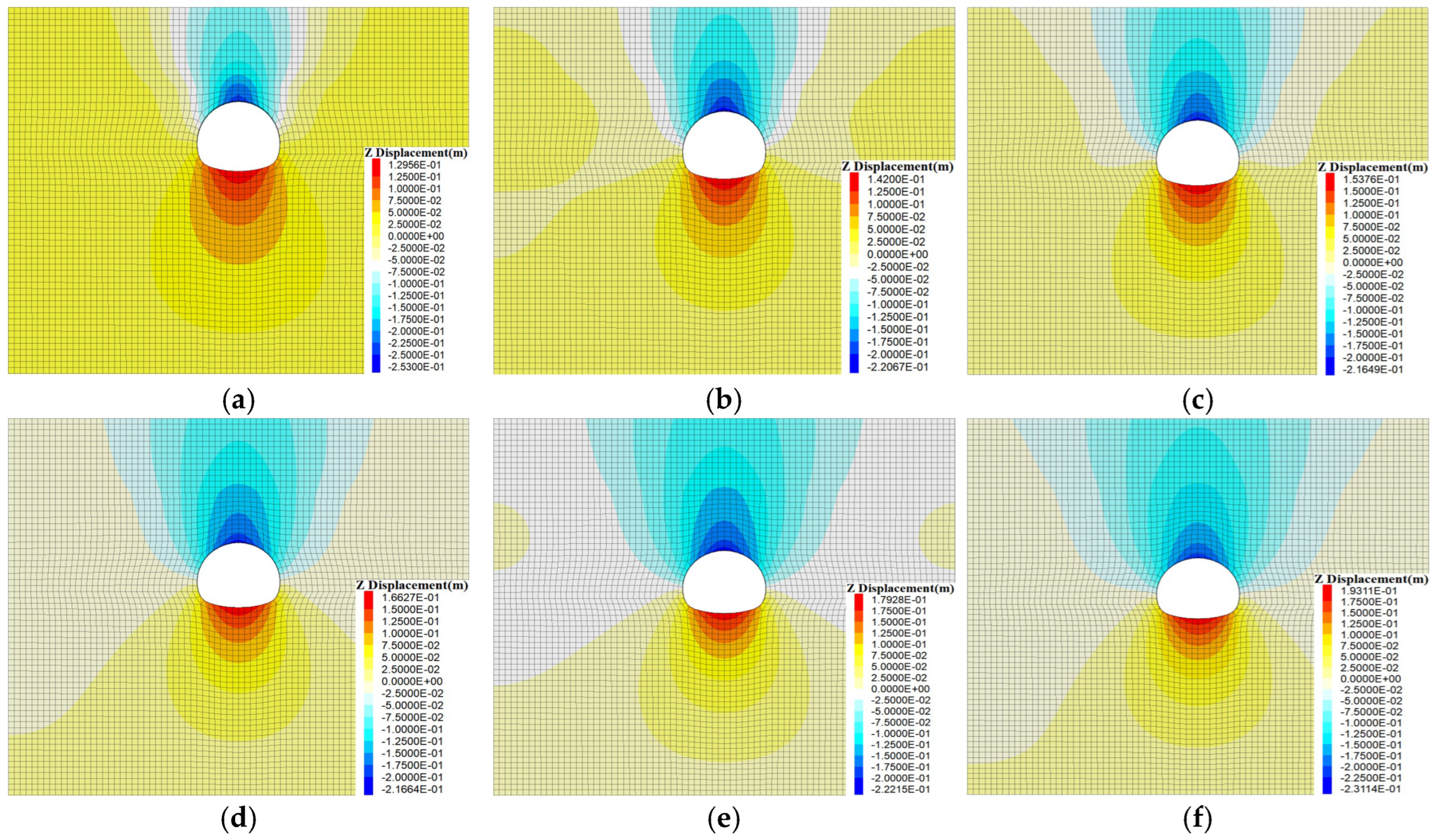

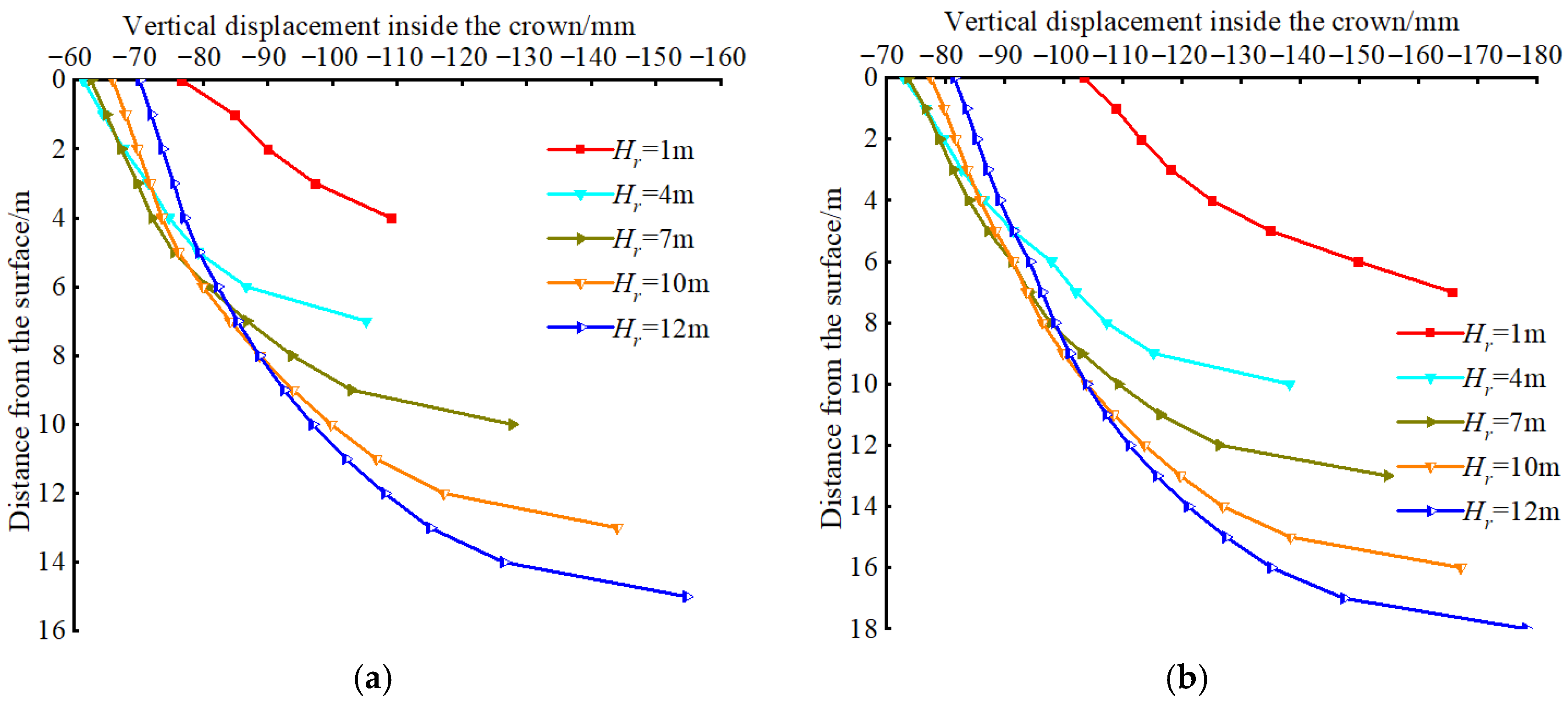

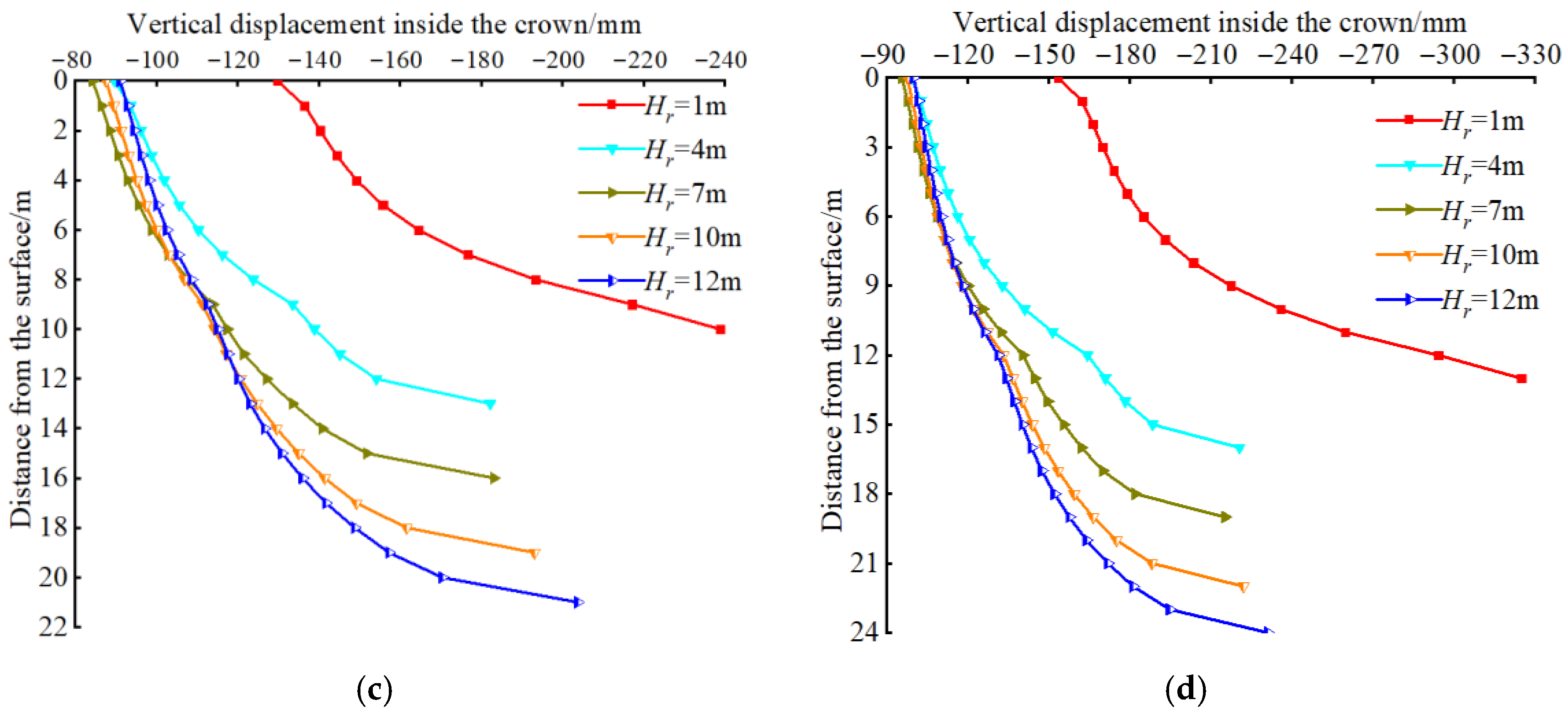

- Vertical Displacement of the Roof Surrounding Rock

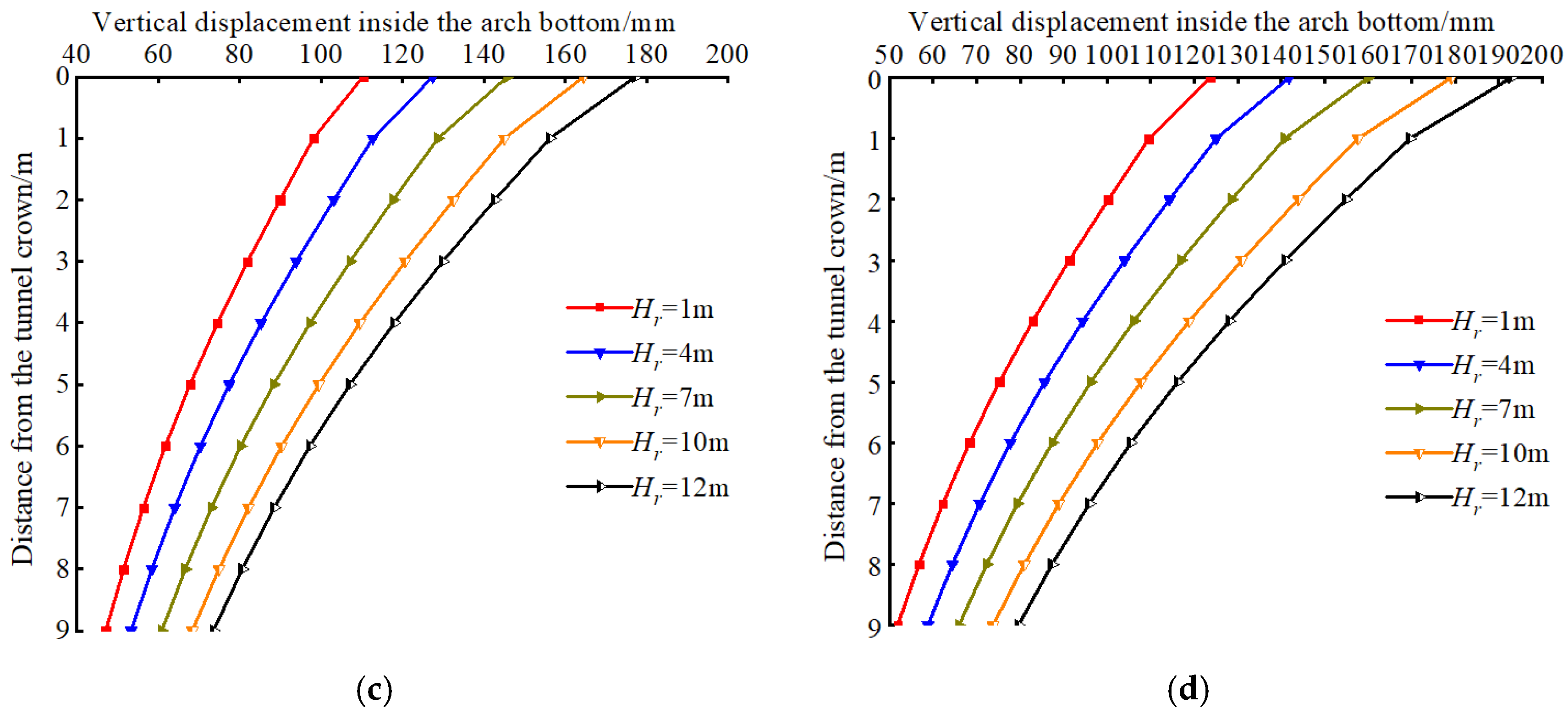

- (4)

- Vertical Displacement of the Surrounding Rock at the Tunnel Bottom

- (5)

- Horizontal Displacement of the Arch Waist Surrounding Rock

4. Upper Limit Analysis of Critical Overburden Thickness of the Crown in Soil–Rock Strata

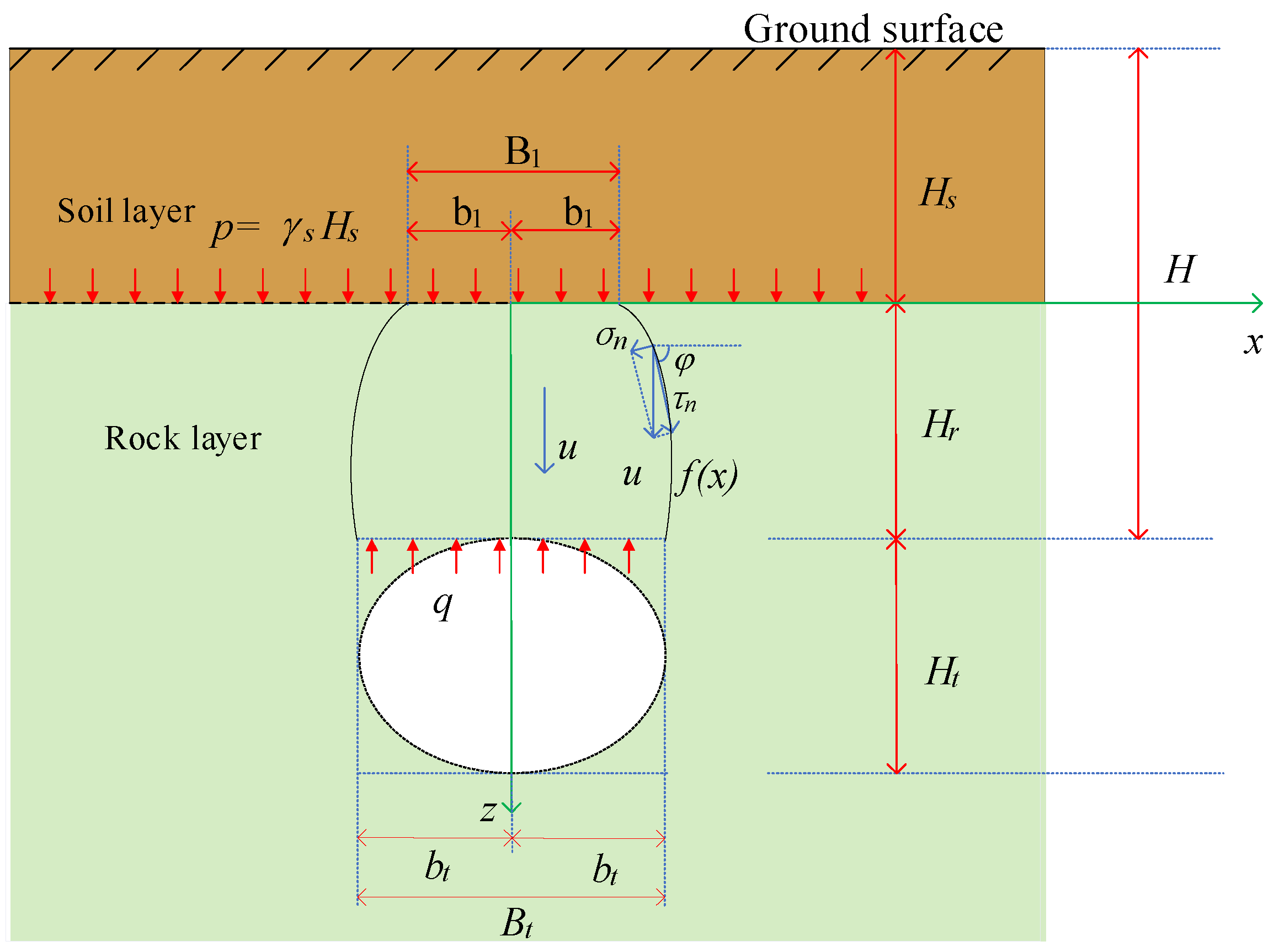

4.1. Tunnel Crown Failure Mechanism in Soil–Rock Strata

4.2. Internal Energy Dissipation Rate

4.3. External Power

4.4. Determination of Critical Overburden Thickness

5. Comparison and Verification with Example Analysis

5.1. Comparison with Numerical Simulation Results

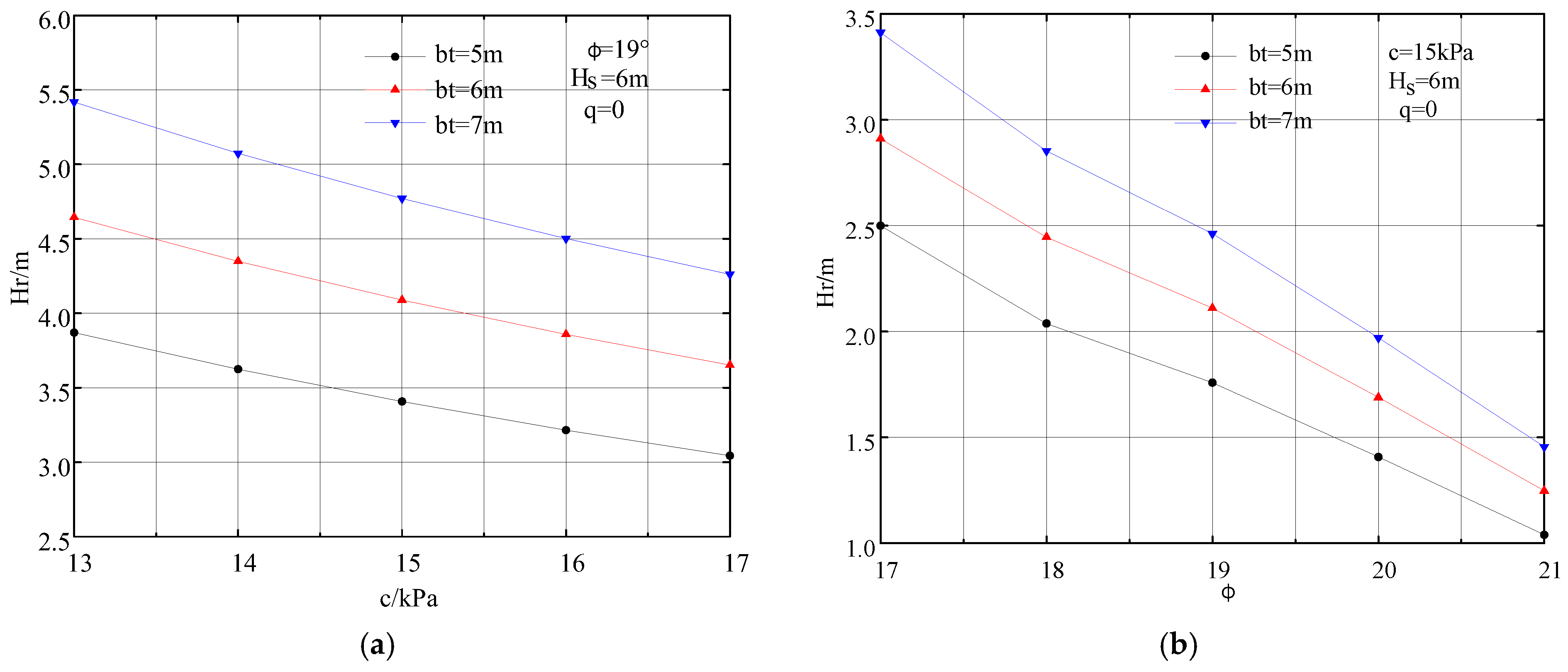

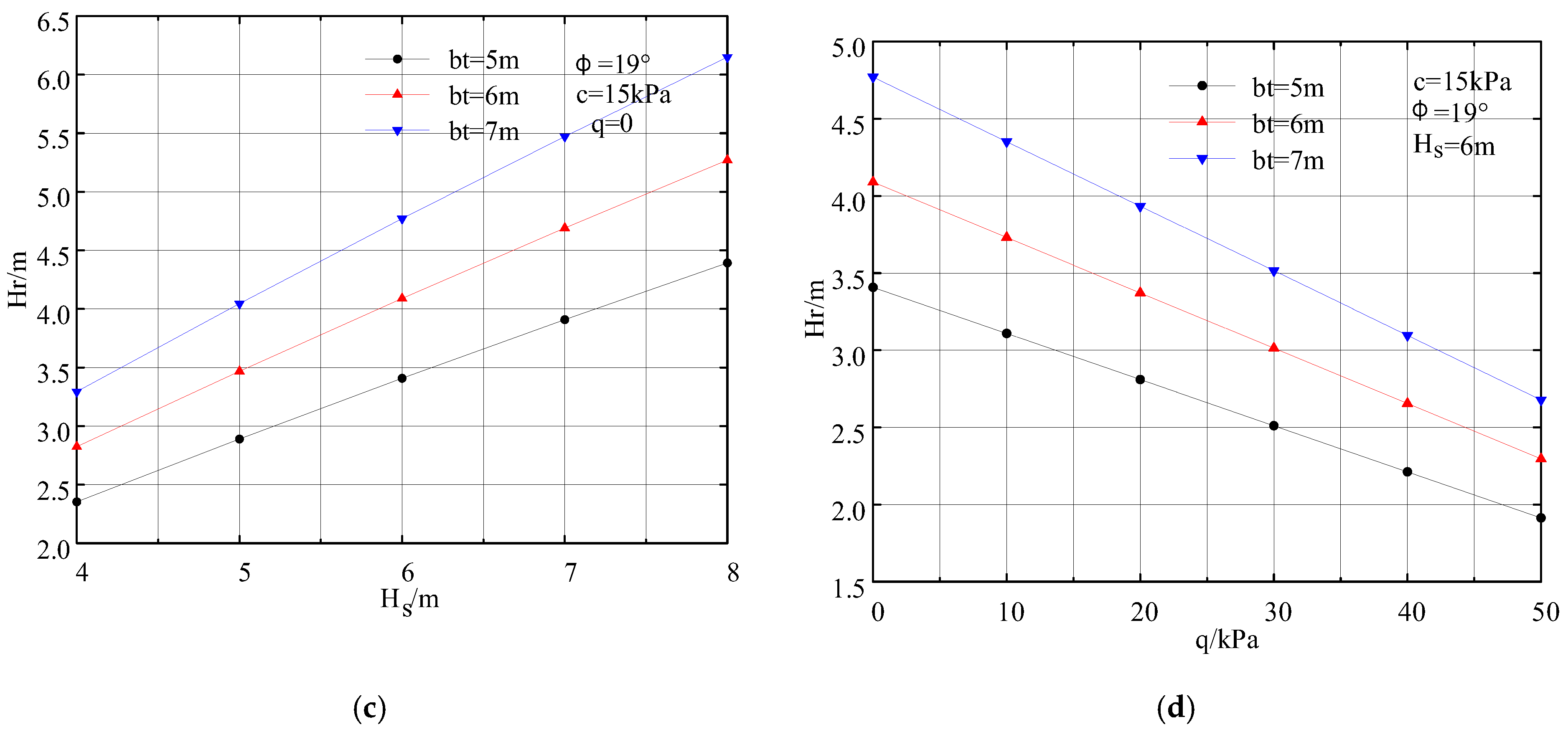

5.2. Influence of Different Parameters on the Critical Overburden Thickness

6. Conclusions

- (1)

- A comparative study of tunnel excavation numerical simulations with different overlying soil layer thickness was conducted, based on a typical urban subway tunnel project in soil–rock strata. A total of 4 soil layer thickness conditions were considered, and 48 design schemes were developed. The study revealed the deformation and failure characteristics of tunnel excavation surrounding rock and surface settlement patterns under different roof overlying rock thicknesses. The tunnel arch crown area was identified as the key region for deformation and failure. As the overburden thickness increased, the corresponding surface settlement showed a trend of decreasing first and then increasing. An optimal overburden thickness range was identified for subway tunnels in soil–rock strata.

- (2)

- A mechanical analysis model for the failure of the tunnel arch rock layer in soil–rock composite strata was constructed based on the upper bound approach of plastic limit analysis. The internal energy dissipation rate and external work of the tunnel arch crown surrounding rock collapse were calculated. The theoretical prediction formula for the critical overburden thickness of the crown and the rock mass failure surface was derived. The influence of different soil layer thicknesses, rock mass strength parameters, and tunnel design parameters on the critical overburden thickness was analyzed. As the rock mass cohesion (c), internal friction angle (), and support force (q) increased, the critical overburden thickness gradually decreased. However, as the soil layer thickness increased, the corresponding critical overburden thickness of the crown gradually increased.

- (3)

- A comparison and validation were conducted between the numerical simulation results and the theoretical method results in this study. The optimal overburden thickness ranges for the four upper soil layer thicknesses obtained from the numerical simulation were 1–3 m, 4–6 m, 5–7 m, and 6–8 m, while the theoretical critical overburden thicknesses were 2.26 m, 4.29 m, 6.12 m, and 7.71 m. These values were within the range of the numerical simulation results and were quite close to each other, thereby confirming the validity of the theoretical method presented in this study.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qi, H.; Zhou, Z.-P.; Yuan, J.-F.; Li, N.; Zhou, J.-J. Accident pattern recognition in subway construction for the provision of customized safety measures. Tunn. Undergr. Space Technol. 2023, 137, 105157. [Google Scholar] [CrossRef]

- Lin, D.; Nelson, J.D.; Cui, J.-Q. Exploring influencing factors on metro development in China from urban and economic perspectives. Tunn. Undergr. Space Technol. 2021, 112, 103877. [Google Scholar] [CrossRef]

- Li, Q.-M.; Song, L.-L.; List, G.F.; Deng, Y.-L.; Zhou, Z.-P.; Liu, P. A new approach to understand metro operation safety by exploring metro operation hazard network (MOHN). Saf. Sci. 2017, 93, 50–61. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, P.-P.; Liu, Q.-S.; Sun, C.-Y.; Yang, Y.-T.; He, G.-C.; He, C.-C. Equivalent Nodal Intensity-Based Contact Model for 3D Finite–Discrete Element Method in Rock Fracturing Analysis. Rock Mech. Rock Eng. 2025, 58, 6059–6086. [Google Scholar] [CrossRef]

- Liu, P.; Wang, H.-T.; Liu, Q.-S.; Li, X.-J.; Dong, Y.-X.; Xie, X.-Q. FDEM numerical study on the large deformation mechanism of layered rock mass tunnel under excavation-unloading disturbance. Tunn. Undergr. Space Technol. 2025, 159, 106497. [Google Scholar] [CrossRef]

- Niu, H.-T.; Shao, S.-J.; Zou, X. Study on failure characteristics of surrounding rock of benching excavation in loess overburden soil-rock contact zone. Earth Sci. Inform. 2022, 15, 1879–1887. [Google Scholar]

- Luo, W.-P.; Yuan, D.-J.; Jin, D.-L.; Lu, P. Prediction and analysis of slurry pressure at the shield cut in composite strata based on random forest. Tumu Gongcheng Xuebao/China Civ. Eng. J. 2020, 53, 43–49. [Google Scholar]

- Zhang, S.-L.; Gao, J.-L.; Liu, C.; Li, P.-F.; Yang, Z.-F.; Lu, X. Model test on the collapse mechanism of subway tunnels in the soil-sand-rock composite strata. Eng. Fail. Anal. 2024, 162, 108356. [Google Scholar] [CrossRef]

- Yang, S.-Q.; Tao, Y.; Xu, P.; Chen, M. Large-scale model experiment and numerical simulation on convergence deformation of tunnel excavating in composite strata. Tunn. Undergr. Space Technol. 2019, 94, 103133. [Google Scholar] [CrossRef]

- Huang, F.; Zhu, H.-H.; Xu, Q.-W.; Cai, Y.-C.; Zhuang, X.-Y. The effect of weak interlayer on the failure pattern of rock mass around tunnel–Scaled model tests and numerical analysis. Tunn. Undergr. Space Technol. 2013, 35, 207–218. [Google Scholar] [CrossRef]

- Xu, S.-S.; Lei, H.; Li, C.; Liu, H.-Q.; Lai, J.-X.; Liu, T. Model test on mechanical characteristics of shallow tunnel excavation failure in gully topography. Eng. Fail. Anal. 2021, 119, 104978. [Google Scholar] [CrossRef]

- Shi, L.; Zhou, H.; Song, M.; Lu, J.-J.; Liu, Z.-J. Geomechanical model test for analysis of surrounding rock behaviours in composite strata. J. Rock Mech. Geotech. Eng. 2021, 13, 774–786. [Google Scholar] [CrossRef]

- Chakeri, H.; Hasanpour, R.; Hindistan, M.A.; Ünver, B. Analysis of interaction between tunnels in soft ground by 3D numerical modeling. Bull. Eng. Geol. Environ. 2011, 70, 439–448. [Google Scholar] [CrossRef]

- Huang, F.; Wu, C.-Z.; Jang, B.-A.; Hong, Y.; Guo, N.; Guo, W. Instability mechanism of shallow tunnel in soft rock subjected to surcharge loads. Tunn. Undergr. Space Technol. 2020, 99, 103350. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, J.-L.; Wang, Z.-Z.; Liu, C. Model Test on the Collapse Evolution Law of Tunnel Excavation in Composite Strata with a Cavity. Buildings 2024, 14, 932. [Google Scholar] [CrossRef]

- Zhang, X.; Fu, D.; Zhou, X.-S.; Han, Y.-Y. Characterization of Mechanical Behavior of Ultra-Small Clearance Tunnel Construction in Upper Soil and Lower Rock Composite Strata. Buildings 2023, 13, 559. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, J.; Wang, Y.-G.; Wang, Y.-F. Mechanical behaviors of surrounding rock and supporting structure of shallow-buried unsymmetrical pressure tunnel crossing soil–rock interface. Front. Earth Sci. 2023, 10, 1113430. [Google Scholar] [CrossRef]

- Li, J.; Liu, A.-Y.; Xing, H. Study on Ground Settlement Patterns and Prediction Methods in Super-Large-Diameter Shield Tunnels Constructed in Composite Strata. Appl. Sci. 2023, 13, 10820. [Google Scholar] [CrossRef]

- Liang, J.-Y.; Cui, J.; Lu, Y.; Li, Y.-D.; Shan, Y. Limit analysis of shallow tunnels collapse problem with optimized solution. Appl. Mathmat. Model. 2022, 109, 98–116. [Google Scholar] [CrossRef]

- Yang, X.-L.; Yin, J.-H. Linear Mohr–Coulomb strength parameters from the non-linear Hoek–Brown rock masses. Int. J. Non-Linear Mech. 2006, 41, 1000–1005. [Google Scholar] [CrossRef]

- Sheorey, P.R.; Biswas, A.K.; Choubey, V.D. An empirical failure criterion for rocks and jointed rock masses. Eng. Geol. 1989, 26, 141–159. [Google Scholar] [CrossRef]

- Balmer, G. A general analysis solution for Mohr’s envelope. Proc. ASTM 1952, 52, 1260–1271. [Google Scholar]

- Lee, Y.-K.; Pietruszczak, S. Analytical representation of Mohr failure envelope approximating the generalized Hoek-Brown failure criterion. Int. J. Rock Mech. Min. Sci. 2017, 100, 90–99. [Google Scholar] [CrossRef]

| Layer Names | Density (g/cm3) | Young’s Modulus (MPa) | Poisson’s Ratio | Friction (°) | Cohesion (kPa) |

|---|---|---|---|---|---|

| Silty Clay | 1.9 | 6.8 | 0.45 | 19 | 21 |

| Weathered Limestone | 2.3 | 40 | 0.33 | 35 | 150 |

| Overburden Thickness | Optimal Overburden Thickness Range in Numerical Simulations | Critical Overburden Thickness Calculated by Theoretical Methods |

|---|---|---|

| 3 m | 1–3 m | 2.26 m |

| 6 m | 4–6 m | 4.29 m |

| 9 m | 5–7 m | 6.12 m |

| 12 m | 6–8 m | 7.71 m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, F.; Wang, Q.; Wang, H.; Yuan, Y.; Hao, Z.; Liu, P.; Liu, R. Limit Analysis Theory and Numerical Simulation Study on the Cover Thickness of Tunnel Crown in Soil–Rock Strata. Mathematics 2025, 13, 3293. https://doi.org/10.3390/math13203293

Ji F, Wang Q, Wang H, Yuan Y, Hao Z, Liu P, Liu R. Limit Analysis Theory and Numerical Simulation Study on the Cover Thickness of Tunnel Crown in Soil–Rock Strata. Mathematics. 2025; 13(20):3293. https://doi.org/10.3390/math13203293

Chicago/Turabian StyleJi, Fang, Qinshan Wang, Hongtao Wang, Yaotao Yuan, Zhenxiang Hao, Ping Liu, and Rongli Liu. 2025. "Limit Analysis Theory and Numerical Simulation Study on the Cover Thickness of Tunnel Crown in Soil–Rock Strata" Mathematics 13, no. 20: 3293. https://doi.org/10.3390/math13203293

APA StyleJi, F., Wang, Q., Wang, H., Yuan, Y., Hao, Z., Liu, P., & Liu, R. (2025). Limit Analysis Theory and Numerical Simulation Study on the Cover Thickness of Tunnel Crown in Soil–Rock Strata. Mathematics, 13(20), 3293. https://doi.org/10.3390/math13203293