Solving a Multi-Depot Battery Swapping Cabinet Location-Routing Problem with Time Windows via a Heuristic-Enhanced Branch-and-Price Algorithm

Abstract

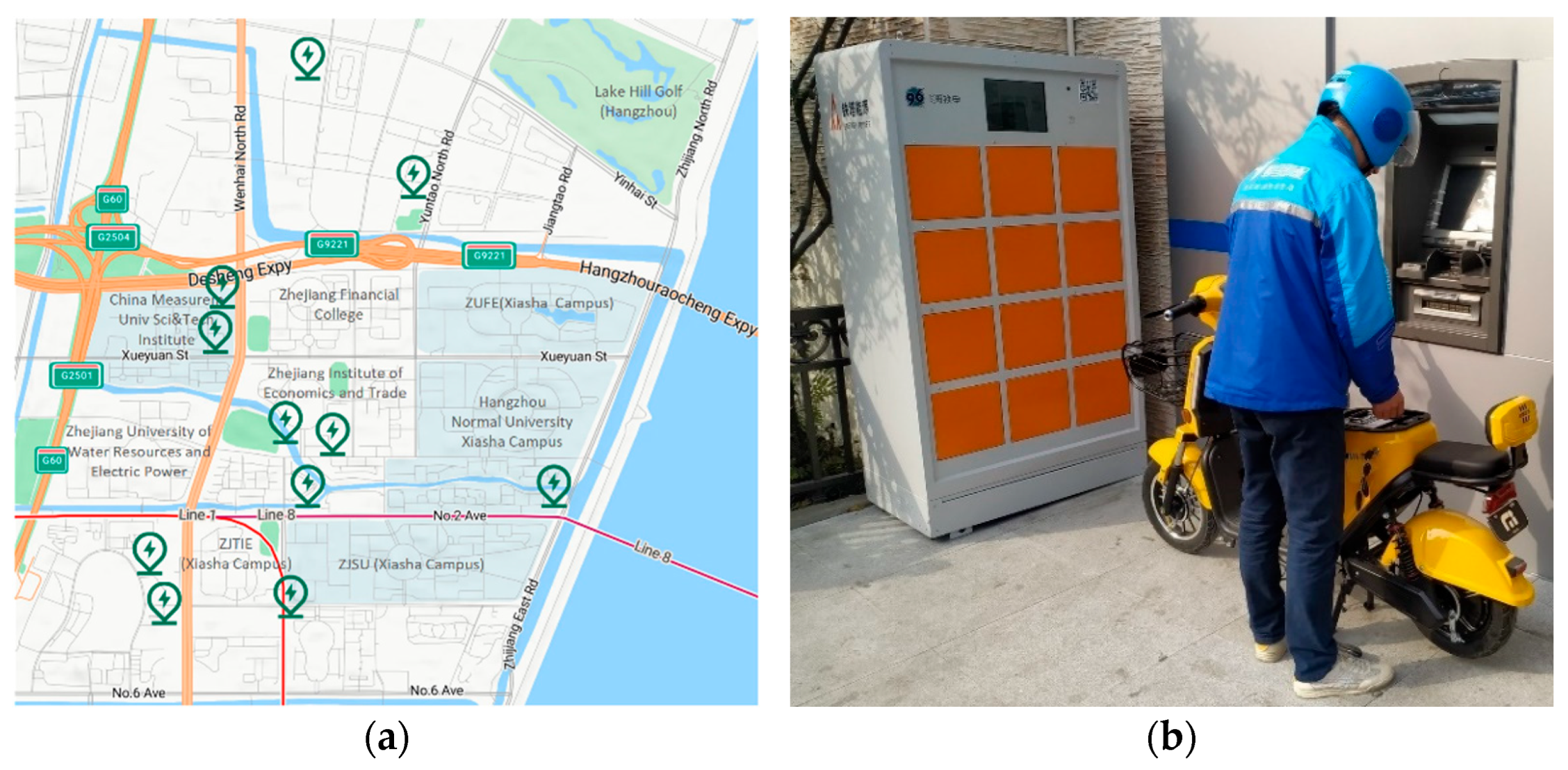

1. Introduction

2. Literature Review

2.1. On-Demand Delivery

2.2. Electric VRP

2.3. Electric LRP

3. Model Formulation

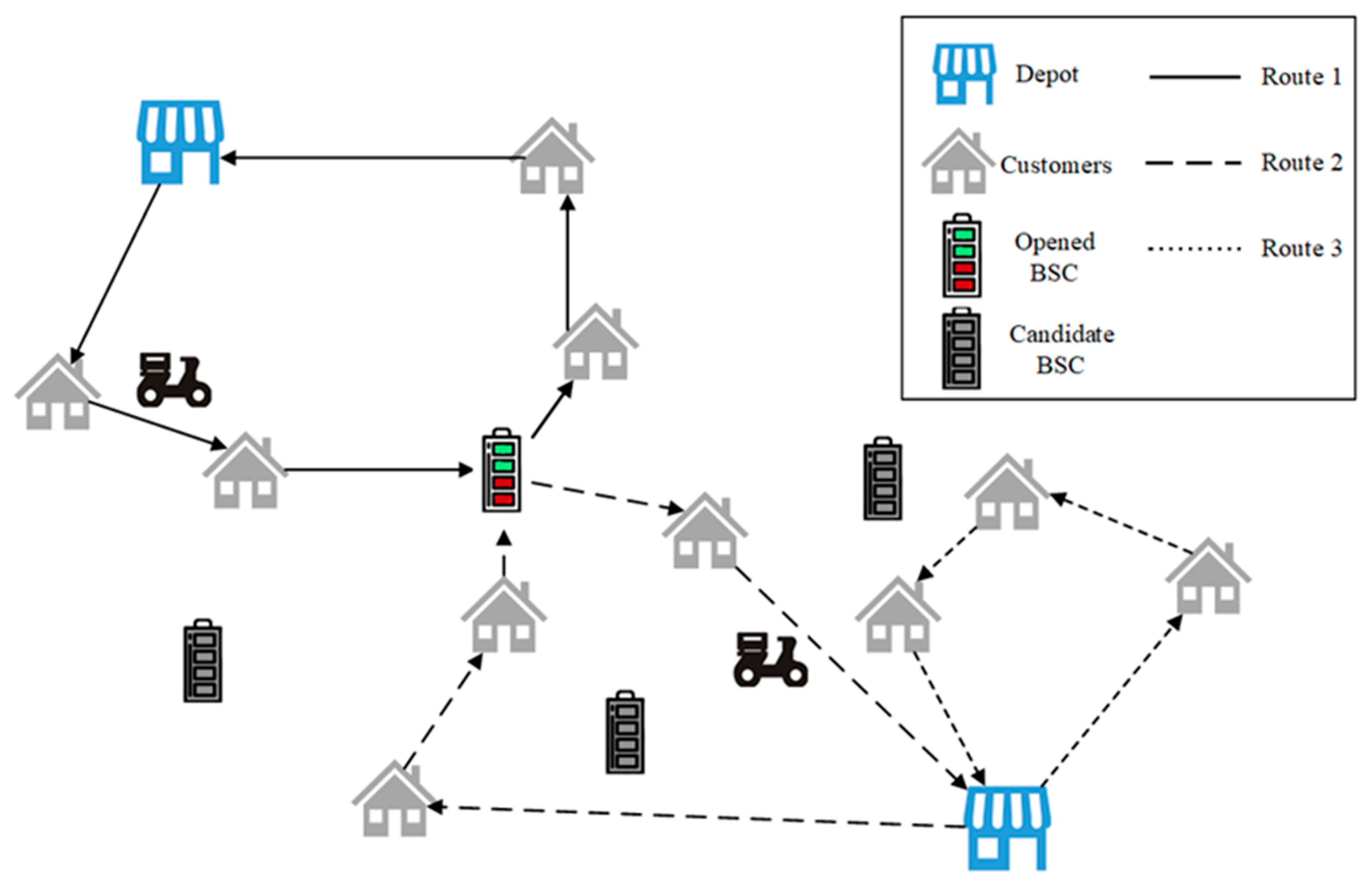

3.1. Problem Description

3.2. Mathematical Model

| Sets | Explanations |

| The set of all customers | |

| The set of all candidate BSCs | |

| The set of all depots | |

| The set of all nodes, as | |

| The set of all arcs, | |

| The set of EDBs assigned to depot | |

| The set of all EDBs, | |

| Parameters | Explanations |

| The distance from node to node | |

| The delivery cost per unit distance | |

| A sufficiently large positive constant | |

| The demand of customer | |

| The maximum loading capacity of EDBs | |

| The maximum driving range of EDBs | |

| The safety level of the remaining power of EDBs | |

| The time window requirement of customer | |

| The battery usage cost | |

| Decision Variables | |

| 1 if EDB travels from node directly to node , 0 otherwise | |

| 1 if candidate BSC is deployed, 0 otherwise | |

| Auxiliary Variables | |

| The remaining loading capacity of EDB leaving from node | |

| The remaining battery power of EDB when it arrives at node | |

| The remaining battery power of EDB when it departs from node | |

| The arrival time of EDB at node | |

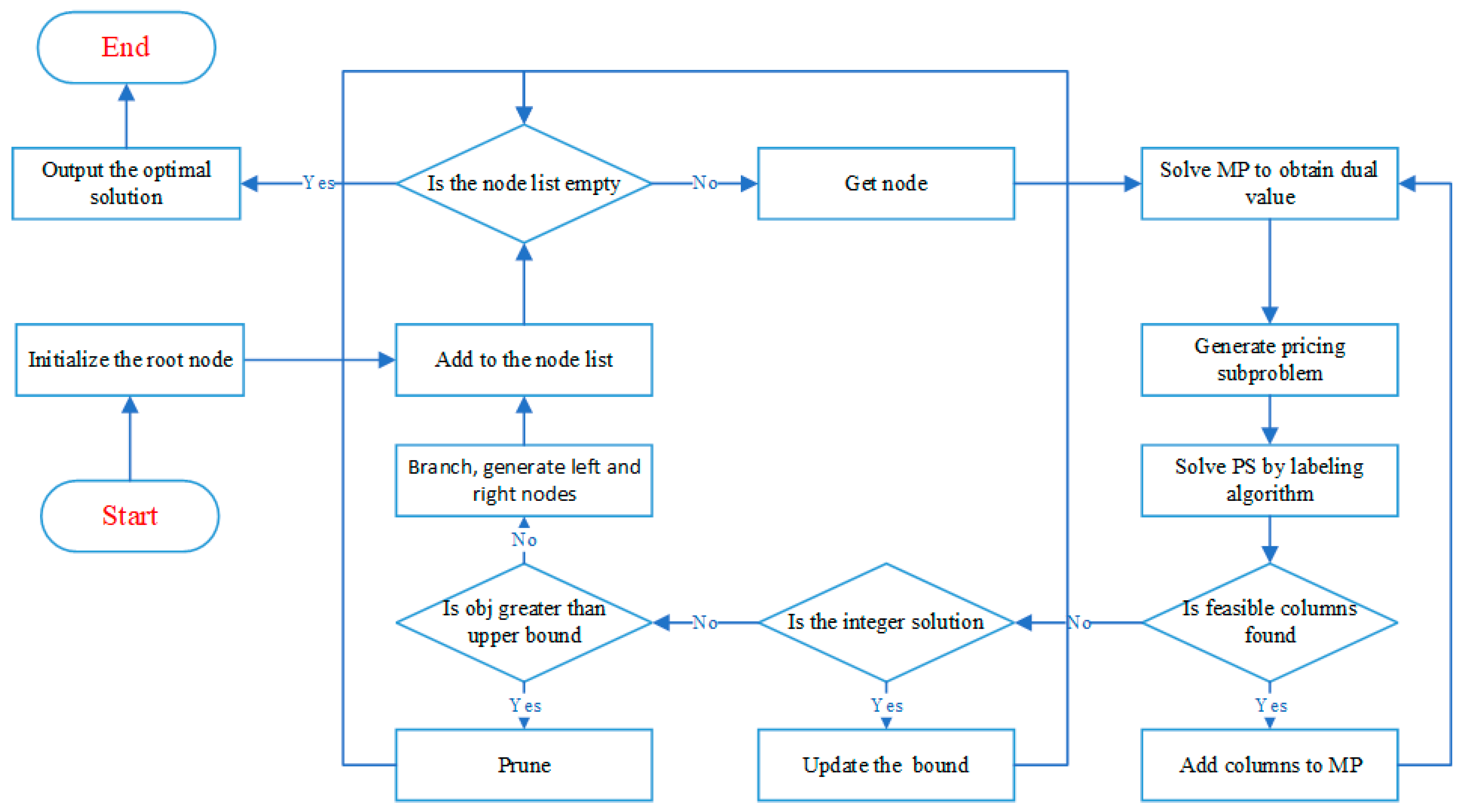

4. Solution Approach

4.1. Model Reformulation

4.1.1. Master Problem

4.1.2. Pricing Subproblem

4.2. Column Generation Procedure

4.3. Labeling Algorithm

4.3.1. Labeling Framework

- : the origin depot from which the delivery route is initiated;

- : the current vertex (i.e., the last visited customer);

- : the set of visited customers;

- : the cumulative customer demand served;

- : the remaining battery level of the EDB after leaving vertex ;

- : the earliest service start time at vertex ;

- : the accumulated reduced cost associated with this delivery route.

- ;

- ;

- ;

- ;

- ;

- ;

- ;

- (1)

- Initialization: Generate root labels for all depots and set , .

- (2)

- Label selection: While , select a label for expansion.

- (3)

- Label extension: For each unvisited customer , extend label to if resource constraints are satisfied. Add feasible to .

- (4)

- Dominance check: Apply dominance rules to prune inferior labels with the same depot and end node.

- (5)

- Completion check: If corresponds to a complete and feasible route with negative reduced cost, add the corresponding path to .

- (6)

- Path selection: Select the most cost-effective path from for inclusion in the RMP.

4.3.2. Exact Labeling Algorithm

- (non-redundant customer coverage);

- (non-increasing cumulative demand);

- (non-decreasing residual power);

- (non-delayed arrival);

- (non-increasing reduced cost).

4.3.3. Heuristic Labeling Strategies

4.3.4. Adaptive Selection Mechanism

4.4. Branching Rules

- Left child node: Impose . All columns (paths) in the current RMP that include arc are removed. In the pricing subproblem, arc is eliminated from the graph , without changing the subproblem formulation structure.

- Right child node: Impose . All columns that do not include arc but pass through either vertex or vertex are removed from the RMP. In the pricing subproblem, a path is required to traverse arc . To enforce this, all arcs with and with are removed from the graph , ensuring that any feasible path visiting vertex must subsequently visit vertex . Depending on the position of arc in the path, three cases are distinguished to implement the above logic.

- as the starting node: remove paths not containing but passing through ; in the graph, delete all arcs for .

- as the terminal node: remove paths not containing but passing through ; in the graph, delete all arcs for .

- as intermediate nodes: remove all arcs , and , to ensure the traversal of arc .

| Step | Description |

| 1. Initialization | Construct an initial pool of feasible paths and formulate the root node RMP. |

| 2. Search tree management | Create a depth-first search tree and insert the root node. |

| 3. Node selection | Select an unexplored node from the tree. Retrieve its associated RMP and arc removal constraints. |

| 4. Solve the RMP | Apply column generation to solve the RMP, yielding LP solution . |

| 5. Check integrality | If is integer feasible, compare its objective value with the incumbent upper bound and update if better; otherwise, prune the node. If is fractional, proceed to next step. |

| 6. Branch | If the objective value is less than the current upper bound, identify arc with usage closest to 0.5, and generate two child nodes as described above. Otherwise, prune the node. |

| 7. Termination | Repeat Steps 3–6 until the search tree is empty. |

| 8. Output | Return the best integer solution identified during the search. |

5. Computational Experiments

5.1. Instance Generation and Parameter Settings

5.2. Performance on Small-Scale Instances

5.3. Performance on Medium-Scale Instances

5.4. Performance on Large-Scale Instances

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, J.; Liu, X.; Liu, T.; Li, N.; Martinez-Sykora, A. The electric vehicle routing problem with synchronized mobile partial recharging and non-strict waiting strategy. Ann. Oper. Res. 2024. [Google Scholar] [CrossRef]

- Aghalari, A.; Salamah, D.; Kabli, M.; Marufuzzaman, M. A two-stage stochastic location–routing problem for electric vehicles fast charging. Comput. Oper. Res. 2023, 158, 106286. [Google Scholar] [CrossRef]

- Allen, J.; Piecyk, M.; Cherrett, T.; Juhari, M.N.; McLeod, F.; Piotrowska, M.; Bates, O.; Bektas, T.; Cheliotis, K.; Friday, A. Understanding the transport and CO2 impacts of on-demand meal deliveries: A London case study. Cities 2021, 108, 102973. [Google Scholar] [CrossRef]

- Schnieder, M.; Hinde, C.; West, A.; Health, P. Emission Estimation of On-Demand Meal Delivery Services Using a Macroscopic Simulation. Int. J. Environ. Res. Public Health 2022, 19, 11667. [Google Scholar] [CrossRef]

- Tu, W.; Zhao, T.; Zhou, B.; Jiang, J.; Xia, J.; Li, Q. OCD: Online crowdsourced delivery for on-demand food. IEEE Internet Things J. 2019, 7, 6842–6854. [Google Scholar] [CrossRef]

- Simoni, M.D.; Winkenbach, M. Crowdsourced on-demand food delivery: An order batching and assignment algorithm. Transp. Res. Part C Emerg. Technol. 2023, 149, 104055. [Google Scholar] [CrossRef]

- Liu, D.; Yan, P.; Pu, Z.; Wang, Y.; Kaisar, E.I. Hybrid artificial immune algorithm for optimizing a Van-Robot E-grocery delivery system. Transp. Res. Part E Logist. Transp. Rev. 2021, 154, 102466. [Google Scholar] [CrossRef]

- Huang, H.; Hu, C.; Zhu, J.; Wu, M.; Malekian, R. Stochastic task scheduling in UAV-based intelligent on-demand meal delivery system. IEEE Trans. Intell. Transp. Syst. 2021, 23, 13040–13054. [Google Scholar] [CrossRef]

- Liu, Y. An optimization-driven dynamic vehicle routing algorithm for on-demand meal delivery using drones. Comput. Oper. Res. 2019, 111, 1–20. [Google Scholar] [CrossRef]

- Chen, M.; Hu, M. Courier Dispatch in On-Demand Delivery. Manage. Sci. 2024, 70, 3789–3807. [Google Scholar] [CrossRef]

- Schneider, M.; Stenger, A.; Goeke, D. The Electric Vehicle-Routing Problem with Time Windows and Recharging Stations. Transp. Sci. 2014, 48, 500–520. [Google Scholar] [CrossRef]

- Felipe, Á.; Ortuño, M.T.; Righini, G.; Tirado, G. A heuristic approach for the green vehicle routing problem with multiple technologies and partial recharges. Transp. Res. Part E Logist. Transp. Rev. 2014, 71, 111–128. [Google Scholar] [CrossRef]

- Keskin, M.; Çatay, B. Partial recharge strategies for the electric vehicle routing problem with time windows. Transp. Res. Part C Emerg. Technol. 2016, 65, 111–127. [Google Scholar] [CrossRef]

- Montoya, A.; Guéret, C.; Mendoza, J.E.; Villegas, J.G. The electric vehicle routing problem with nonlinear charging function. Transp. Res. Part B Methodol. 2017, 103, 87–110. [Google Scholar] [CrossRef]

- Basso, R.; Kulcsár, B.; Egardt, B.; Lindroth, P.; Sanchez-Diaz, I. Energy consumption estimation integrated into the Electric Vehicle Routing Problem. Transp. Res. Part D Transp. Environ. 2019, 69, 141–167. [Google Scholar] [CrossRef]

- Pelletier, S.; Jabali, O.; Laporte, G. The electric vehicle routing problem with energy consumption uncertainty. Transp. Res. Part B Methodol. 2019, 126, 225–255. [Google Scholar] [CrossRef]

- Keskin, M.; Çatay, B.; Laporte, G. A simulation-based heuristic for the electric vehicle routing problem with time windows and stochastic waiting times at recharging stations. Comput. Oper. Res. 2021, 125, 105060. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, T.; Fang, C.; Yang, S. A novel collaborative electric vehicle routing problem with multiple prioritized time windows and time-dependent hybrid recharging. Expert Syst. Appl. 2024, 244, 122990. [Google Scholar] [CrossRef]

- Hiermann, G.; Puchinger, J.; Ropke, S.; Hartl, R.F. The Electric Fleet Size and Mix Vehicle Routing Problem with Time Windows and Recharging Stations. Eur. J. Oper. Res. 2016, 252, 995–1018. [Google Scholar] [CrossRef]

- Zhang, S.; Gajpal, Y.; Appadoo, S.S.; Abdulkader, M.M.S. Electric vehicle routing problem with recharging stations for minimizing energy consumption. Int. J. Prod. Econ. 2018, 203, 404–413. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, J.; Sun, Y.; Fan, J.; Wang, Z.; Wang, H. Collaborative multidepot electric vehicle routing problem with time windows and shared charging stations. Expert Syst. Appl. 2023, 219, 119654. [Google Scholar] [CrossRef]

- Souza, A.L.S.; Papini, M.; Penna, P.H.V.; Souza, M.J.F. A flexible variable neighbourhood search algorithm for different variants of the Electric Vehicle Routing Problem. Comput. Oper. Res. 2024, 168, 106713. [Google Scholar] [CrossRef]

- Jiang, Y.; Hu, W.; Gu, W.; Yu, Y.; Xu, M. A multi-mode hybrid electric vehicle routing problem with time windows. Transp. Res. Part E Logist. Transp. Rev. 2025, 195, 103976. [Google Scholar] [CrossRef]

- Chang, X.H.; Liu, X.M.; Hou, L.W.; Qi, J.H. Quantized Fuzzy Feedback Control for Electric Vehicle Lateral Dynamics. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 2331–2341. [Google Scholar] [CrossRef]

- Picotti, E.; Bruschetta, M.; Mion, E.; Beghi, A. A Nonlinear Model-Predictive Contouring Controller for Shared Control Driving Assistance in High-Performance Scenarios. IEEE Trans. Syst. Man Cybern. Syst. 2023, 53, 204–215. [Google Scholar] [CrossRef]

- Yang, J.; Sun, H. Battery swap station location-routing problem with capacitated electric vehicles. Comput. Oper. Res. 2015, 55, 217–232. [Google Scholar] [CrossRef]

- Hof, J.; Schneider, M.; Goeke, D. Solving the battery swap station location-routing problem with capacitated electric vehicles using an AVNS algorithm for vehicle-routing problems with intermediate stops. Transp. Res. Part B Methodol. 2017, 97, 102–112. [Google Scholar] [CrossRef]

- Chen, Y.; Li, D.; Zhang, Z.; Wahab, M.I.M.; Jiang, Y. Solving the battery swap station location-routing problem with a mixed fleet of electric and conventional vehicles using a heuristic branch-and-price algorithm with an adaptive selection scheme. Expert Syst. Appl. 2021, 186, 115683. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, J.; Huang, Z.; Huang, W. Simultaneous charging station location-routing problem for electric vehicles: Effect of nonlinear partial charging and battery degradation. Energy 2022, 250, 12374. [Google Scholar] [CrossRef]

- Schiffer, M.; Walther, G. The electric location routing problem with time windows and partial recharging. Eur. J. Oper. Res. 2017, 260, 995–1013. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, M.; Zhang, W. A novel location-routing problem in electric vehicle transportation with stochastic demands. J. Clean. Prod. 2019, 221, 567–581. [Google Scholar] [CrossRef]

- Çalık, H.; Oulamara, A.; Prodhon, C.; Salhi, S. The electric location-routing problem with heterogeneous fleet: Formulation and Benders decomposition approach. Comput. Oper. Res. 2021, 131, 105251. [Google Scholar] [CrossRef]

- Wang, M.; Miao, L.; Zhang, C. A branch-and-price algorithm for a green location routing problem with multi-type charging infrastructure. Transp. Res. Part E Logist. Transp. Rev. 2021, 156, 102529. [Google Scholar] [CrossRef]

- Aghalari, A.; Salamah, D.E.; Marino, C.; Marufuzzaman, M. Electric vehicles fast charger location-routing problem under ambient temperature. Ann. Oper. Res. 2023, 324, 721–759. [Google Scholar] [CrossRef]

- Toro, E.M.; Franco, J.F.; Echeverri, M.G.; Guimarães, F.G. A multi-objective model for the green capacitated location-routing problem considering environmental impact. Comput. Ind. Eng. 2017, 110, 114–125. [Google Scholar] [CrossRef]

- Bezerra, S.N.; Souza, M.J.F.; de Souza, S.R.J.C.; Research, O. A variable neighborhood search-based algorithm with adaptive local search for the Vehicle Routing Problem with Time Windows and multi-depots aiming for vehicle fleet reduction. Comput. Oper. Res. 2023, 149, 106016. [Google Scholar] [CrossRef]

- Desrosiers, J.; Soumis, F.; Desrochers, M.J.N. Routing with time windows by column generation. Networks 1984, 14, 545–565. [Google Scholar] [CrossRef]

- Ryan, D.M.; Foster, B.A. An integer programming approach to scheduling. In Computer Scheduling of Public Transport: Urban Passenger Vehicle and Crew Scheduling; Brans, W., Ed.; Elsevier: Amsterdam, The Netherlands, 1981; pp. 269–280. [Google Scholar]

| References | Problem Features | Algorithm | ||||

|---|---|---|---|---|---|---|

| Charging Station | Swapping Station | Location | Multi Depots | Time Window | ||

| Schneider, Stenger [11] | √ | √ | Heuristic | |||

| Hiermann, Puchinger [19] | √ | Heuristic | ||||

| Wang, Miao [33] | √ | √ | √ | √ | Exact | |

| Keskin, Çatay [17] | √ | √ | Heuristic | |||

| Toro, Franco [35] | √ | √ | Heuristic | |||

| Bezerra, Souza [36] | √ | √ | Heuristic | |||

| Yang and Sun [26] | √ | √ | Heuristic | |||

| Hof, Schneider [27] | √ | √ | Heuristic | |||

| Schiffer and Walther [30] | √ | √ | √ | Heuristic | ||

| Chen, Li [28] | √ | √ | √ | Heuristic | ||

| Çalık, Oulamara [32] | √ | √ | Exact | |||

| Zhang, Chen [31] | √ | √ | Heuristic | |||

| Guo, Zhang [29] | √ | √ | Heuristic | |||

| This research | √ | √ | √ | √ | Exact | |

| Num | Description | Method | Performance | |||||

|---|---|---|---|---|---|---|---|---|

| Optimal | Feasible | Avg Gap (%) | Avg Time (s) | |||||

| 3 | 5 | 2 | 2 | Gurobi | 3/3 | 3/3 | 0.00 | 0.20 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 0.09 | ||||

| 3 | 5 | 3 | 2 | Gurobi | 3/3 | 3/3 | 0.00 | 0.33 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 0.26 | ||||

| 3 | 6 | 3 | 2 | Gurobi | 3/3 | 3/3 | 0.00 | 0.66 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 0.23 | ||||

| 3 | 8 | 3 | 2 | Gurobi | 3/3 | 3/3 | 0.00 | 2.22 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 1.18 | ||||

| 3 | 10 | 3 | 2 | Gurobi | 3/3 | 3/3 | 0.00 | 44.27 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 9.79 | ||||

| 3 | 10 | 4 | 2 | Gurobi | 3/3 | 3/3 | 0.00 | 74.42 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 22.44 | ||||

| 3 | 12 | 4 | 2 | Gurobi | 3/3 | 3/3 | 0.00 | 191.16 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 22.92 | ||||

| 3 | 12 | 5 | 2 | Gurobi | 3/3 | 3/3 | 0.00 | 242.63 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 36.23 | ||||

| 3 | 15 | 4 | 2 | Gurobi | 1/3 | 3/3 | 12.33 | 1341.79 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 74.35 | ||||

| 3 | 15 | 5 | 2 | Gurobi | 1/3 | 3/3 | 15.32 | 1413.16 |

| IBP-HL | 3/3 | 3/3 | 0.00 | 78.18 | ||||

| Description | Instance | IBP-HL | B&P | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (s) | (s) | (s) | |||||||||

| 20 | 5 | 2 | R101 | 464.14 | 464.14 | 2.10 | 1 | 464.14 | 2.72 | 253 | 3.13 |

| R102 | 451.51 | 451.51 | 19.44 | 1 | 451.51 | 19.47 | 559 | 25.00 | |||

| R201 | 401.76 | 401.76 | 26.27 | 1 | 401.76 | 26.34 | 1047 | 26.35 | |||

| R205 | 350.67 | 350.67 | 69.15 | 1 | 350.67 | 69.26 | 1062 | 82.35 | |||

| C101 | 152.29 | 152.29 | 205.64 | 1 | 152.29 | 205.77 | 2205 | 504.81 | |||

| C205 | 232.86 | 249.62 | 5020.15 | 2 | - | 7200 * | 2475 | 7200 * | |||

| RC105 | 344.53 | 344.53 | 265.08 | 1 | 344.53 | 265.15 | 1202 | 450.18 | |||

| RC206 | 283.22 | 283.22 | 712.98 | 1 | 283.22 | 713.11 | 2387 | 1689.54 | |||

| Average | 790.10 | 1062.73 | 1252.00 | ||||||||

| 25 | 5 | 2 | R102 | 648.01 | 648.01 | 210.90 | 1 | 648.01 | 210.96 | 1119 | 288.45 |

| R105 | 577.62 | 589.31 | 28.33 | 13 | 584.20 | 171.07 | 1091 | 318.77 | |||

| R109 | 498.44 | 504.76 | 150.59 | 11 | 504.76 | 950.70 | 2485 | 1566.21 | |||

| R210 | 402.67 | 410.85 | 7200 * | 1 | - | 7200 * | 2489 | 7200 * | |||

| C105 | 168.63 | 168.63 | 261.60 | 1 | 168.63 | 261.78 | 3202 | 302.77 | |||

| C201 | 280.37 | 281.94 | 7200 * | 1 | - | 7200 * | 3779 | 7200 * | |||

| RC106 | 323.28 | 329.38 | 1022.27 | 5 | 327.90 | 2240.21 | 2047 | 2891.91 | |||

| RC107 | 278.40 | 278.40 | 1069.89 | 1 | - | 1070.57 | 4688 | 1660.93 | |||

| Average | 2142.95 | 2413.16 | 2678.63 | ||||||||

| 30 | 5 | 2 | R101 | 610.06 | 611.41 | 35.74 | 3 | 611.41 | 49.35 | 890 | 76.96 |

| R105 | 665.28 | 676.65 | 94.45 | 15 | 672.77 | 700.93 | 2181 | 810.86 | |||

| R201 | 606.66 | 627.12 | 7200 * | 1 | - | 7200 * | 5738 | 7200 * | |||

| R211 | 422.64 | 505.94 | 7200 * | 1 | - | 7200 * | 6621 | 7200 * | |||

| C105 | 182.99 | 182.99 | 1057.96 | 1 | 182.99 | 1058.25 | 5323 | 1796.03 | |||

| C107 | 192.15 | 192.15 | 5058.05 | 1 | 192.15 | 5058.42 | 5727 | 5752.94 | |||

| RC101 | 495.24 | 604.90 | 141.38 | 11 | 571.46 | 336.35 | 1613 | 2612.45 | |||

| RC206 | 399.05 | 399.05 | 7200 * | 1 | - | 7200 * | 5887 | 7200 * | |||

| Average | 3498.45 | 3600.41 | 4081.16 | ||||||||

| Description | Instance | IBP-HL Algorithm | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (s) | (s) | |||||||||

| 40 | 8 | 2 | R101 | 835.98 | 838.86 | 41.13 | 11 | 838.86 | 298.69 | 1413 |

| R102 | 748.17 | 751.92 | 1451.88 | 3 | 749.97 | 3593.64 | 2721 | |||

| C101 | 317.95 | 317.95 | 808.22 | 1 | 317.95 | 808.64 | 7945 | |||

| C105 | 226.77 | 226.77 | 11,657.13 | 1 | 226.77 | 11,657.62 | 9126 | |||

| RC105 | 1086.97 | 1086.97 | 570.52 | 1 | 1086.97 | 570.52 | 3932 | |||

| Average | 2905.78 | 3385.82 | ||||||||

| 50 | 10 | 3 | R101 | 939.50 | 944.90 | 570.73 | 7 | 942.24 | 2529.57 | 2735 |

| R102 | 852.39 | 857.70 | 18,000 * | 1 | - | 18,000 * | 4014 | |||

| C101 | 309.84 | 309.84 | 18,000 * | 1 | - | 18,000 * | 11,675 | |||

| C105 | 311.06 | 311.06 | 18,000 * | 1 | - | 18,000 * | 16,135 | |||

| RC105 | 767.14 | 767.14 | 18,000 * | 1 | - | 18,000 * | 7154 | |||

| Average | 14,514.15 | 14,905.91 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zheng, H.; Zhang, S. Solving a Multi-Depot Battery Swapping Cabinet Location-Routing Problem with Time Windows via a Heuristic-Enhanced Branch-and-Price Algorithm. Mathematics 2025, 13, 3243. https://doi.org/10.3390/math13203243

Chen Y, Zheng H, Zhang S. Solving a Multi-Depot Battery Swapping Cabinet Location-Routing Problem with Time Windows via a Heuristic-Enhanced Branch-and-Price Algorithm. Mathematics. 2025; 13(20):3243. https://doi.org/10.3390/math13203243

Chicago/Turabian StyleChen, Yongtong, Haojie Zheng, and Shuzhu Zhang. 2025. "Solving a Multi-Depot Battery Swapping Cabinet Location-Routing Problem with Time Windows via a Heuristic-Enhanced Branch-and-Price Algorithm" Mathematics 13, no. 20: 3243. https://doi.org/10.3390/math13203243

APA StyleChen, Y., Zheng, H., & Zhang, S. (2025). Solving a Multi-Depot Battery Swapping Cabinet Location-Routing Problem with Time Windows via a Heuristic-Enhanced Branch-and-Price Algorithm. Mathematics, 13(20), 3243. https://doi.org/10.3390/math13203243