An Adjusted CUSUM-Based Method for Change-Point Detection in Two-Phase Inverse Gaussian Degradation Processes

Abstract

1. Introduction

2. The Model of Inverse Gaussian Process

2.1. The Inverse Gaussian Process

- ;

- has independent increments; i.e., for any , the increments and are independent;

- For any , the degradation increment within the time interval follows an Inverse Gaussian distribution, i.e.,where and are the mean and scale parameters, both greater than 0. and is a monotonically increasing function of time with .

2.2. The Two-Stage Inverse Gaussian Degradation Model

3. Change-Point Detection Method

3.1. Maximum Likelihood Estimation

3.2. The Adjusted CUSUM Statistic

3.3. Likelihood Ratio Statistic

3.4. Modified Information Criterion

4. Numerical Experiments

- Step 1.

- Assume that no change point exists; i.e., under , calculate the corresponding parameter estimates.

- Step 2.

- Generate a new set of samples based on the results from Step 1.

- Step 3.

- Resample B sets of Bootstrap samples with replacements from the samples obtained in Step 2, and calculate the value of the test statistic for each group Bootstrap sample, which is denoted as .

- Step 4.

- Obtain the p-value by the following equation,

4.1. The Probability of Type I Error

4.2. The Power of Change-Point Detection

- (1)

- The Ad-CUSUM method outperforms in most scenarios. Overall, the Ad-CUSUM method offers higher test power compared to LRT and MIC methods, particularly when the time point size is small and the significance level is low. Regardless of whether the time point size is small or large, the test power of the Ad-CUSUM method is nearly 1.000, demonstrating its high sensitivity in detecting changes in the two-stage Inverse Gaussian degradation model. In contrast, the LRT method exhibits relatively lower power, and although the MIC method performs well, it is still slightly inferior to the Ad-CUSUM method in most cases. This may be attributed to the Ad-CUSUM method’s direct consideration of data discrepancies and its monitoring of changes by gradually accumulating data variations, thereby enhancing its sensitivity to changes.

- (2)

- Improvement of test power with increasing time point size. As the time point size n increases, the test powers of the LRT, MIC, and Ad-CUSUM methods all improve. For LRT and MIC, the enhancement in power is relatively significant. However, the Ad-CUSUM method already exhibits high test power (nearly 1.000) with small n.

- (3)

- The effect of the significance level on test power. With the same parameter settings, as the significance level decreases from 0.10 to 0.01, the test power of both methods generally decreases. However, the decrease in power for the Ad-CUSUM method is relatively small, and it still maintains a high test power. This is because, with increasing n, parameter estimation becomes more accurate, thereby enhancing the power of change-point detection.

- (4)

- The relationship between change-point location and test power. For the same sample size and parameter settings, the closer the change point occurs to the middle, the higher the test power tends to be.

- (5)

- The stability of the Ad-CUSUM method. The Ad-CUSUM method demonstrates high stability, particularly under different parameter combinations, where its test power remains stable and close to 1.000, especially at significance levels and , where it performs exceptionally well.

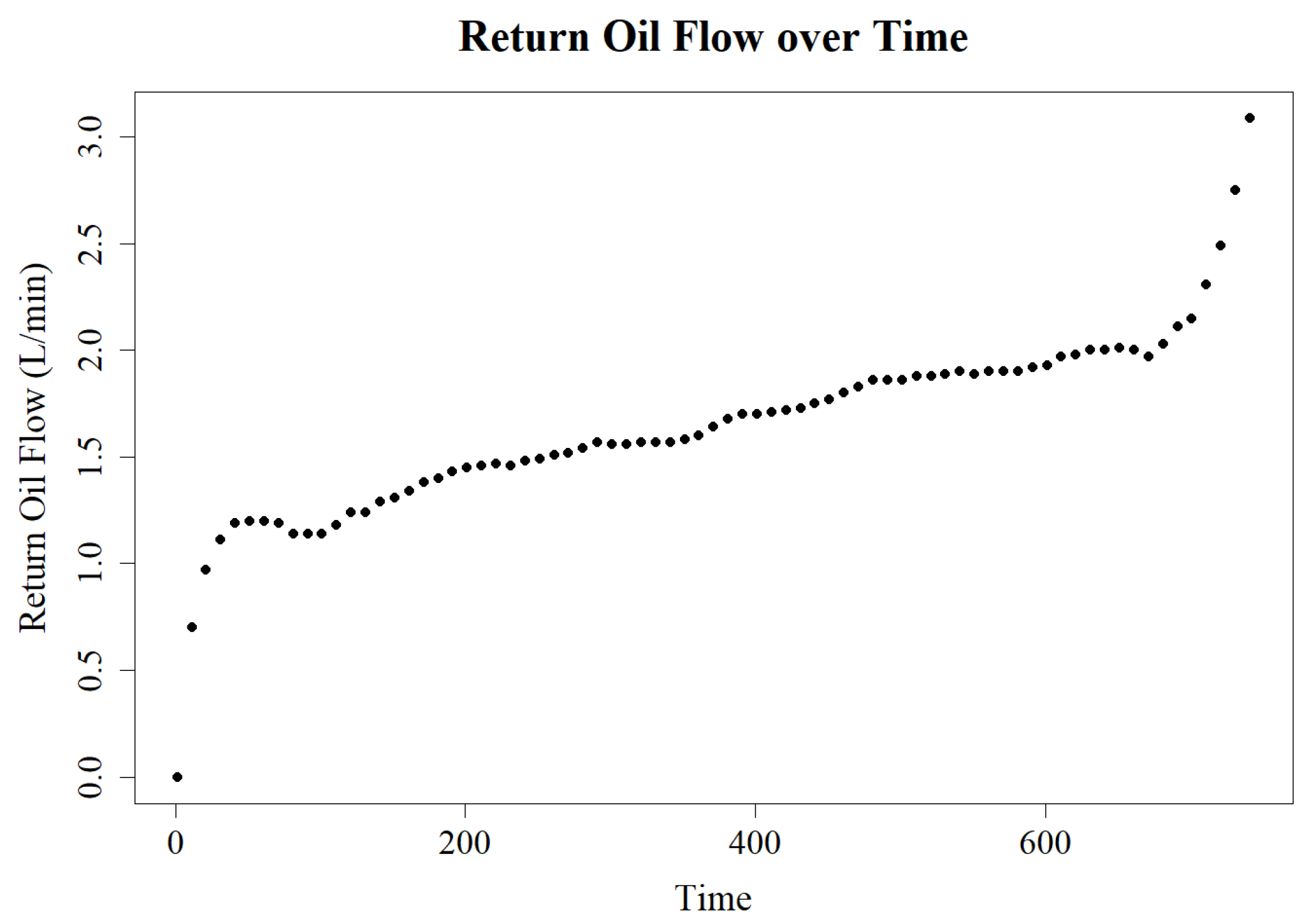

5. Empirical Analysis: Return Oil Flow Data of the Hydraulic Piston Pump

- (I)

- Initial Wear Stage. During the first 80 h of the test, the return oil flow increases sharply, indicating that the pump experiences rapid initial wear, resulting in a rapid performance decline.

- (II)

- Stable Wear Stage. Around 200 h, the return oil flow stabilizes at approximately 2.0 L/min, showing that the wear rate of the pump has stabilized, and its performance remains steady.

- (III)

- Accelerated Degradation Stage. As wear continues to accumulate, the return oil flow begins to gradually rise, indicating that the pump has entered the critical failure period. The wear rate increases sharply, eventually leading to the loss of pump functionality.

- Step 1.

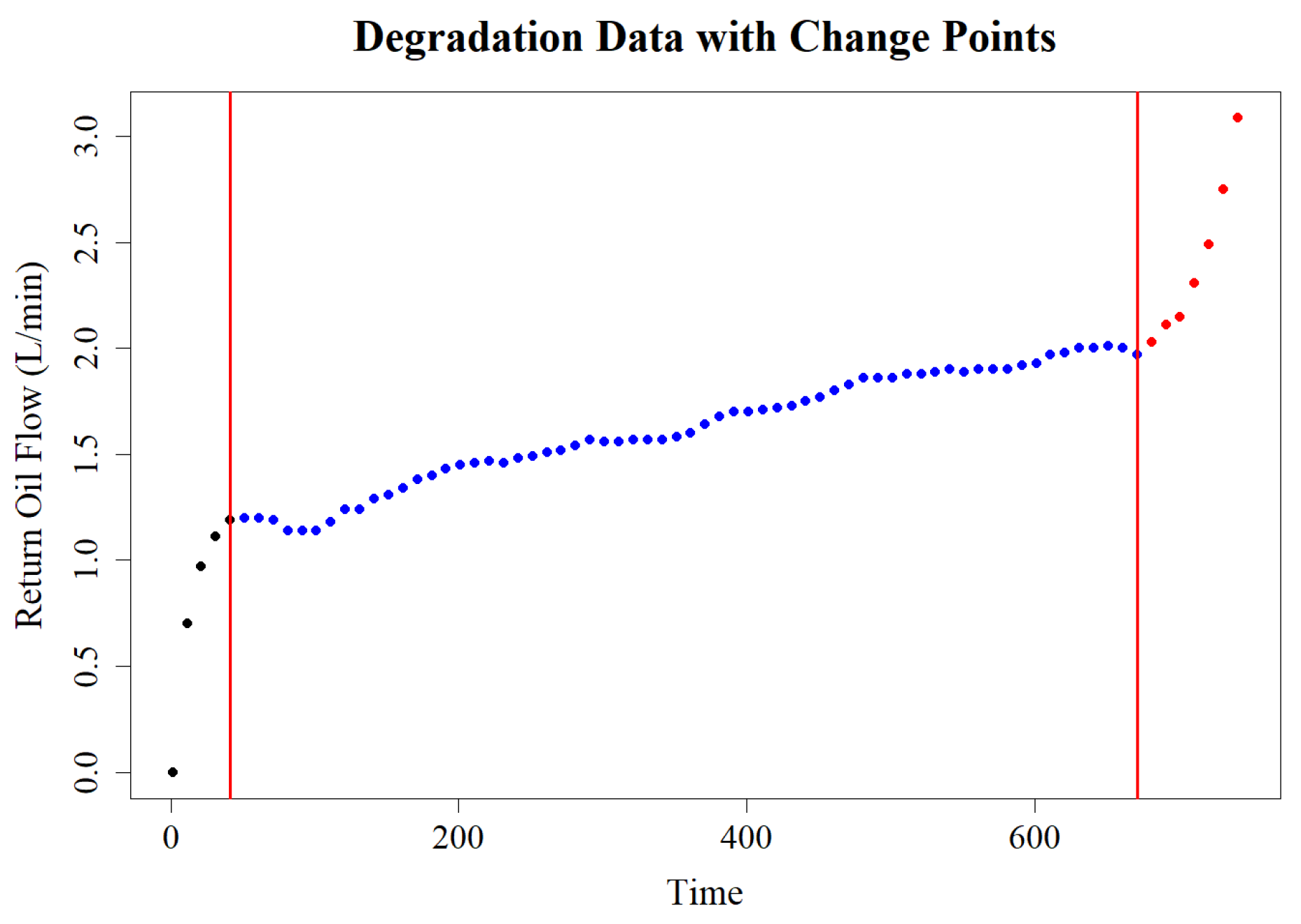

- First, perform change-point detection procedure on the entire return oil flow data sequence from 1 to 75, and calculate the test statistic value of the original data using the adjusted CUSUM statistic, as shown in Figure 2. Here, the Bootstrap method is used, with , yielding a p-value far smaller than 0.05. Therefore, we reject the null hypothesis and conclude that a change point exists. During this process, the first change point is detected at position 5, with a CUSUM statistic value of 11.416 and a p-value of 0.02, indicating that this change point is statistically significant. The occurrence of this change point suggests that the return oil flow undergoes a significant change at 41.25 h, possibly indicating the early stages of degradation in the hydraulic piston pump.

- Step 2.

- After determining the first change-point location, we divide the data into two subsequences and calculate the adjusted CUSUM statistic for each subsequence to further identify potential change points. In the subsequence from 6 to 75, the CUSUM statistic reaches a maximum value of 12.581, and the change point is located at position 68, with a p-value of 0.001, indicating extremely high statistical significance. This change point marks 671.25 h as the second critical moment in the performance degradation of the hydraulic piston pump, likely related to the accumulation of wear or failure in the pump. Repeating the above steps, no further change points are detected.

- Step 3.

- Continuing from Step 2, subsequences are further divided, and the adjusted CUSUM statistic is calculated for each segment. For the subsequence from 5 to 68, the p-value is 0.4620, which is greater than 0.05. No change point is detected, indicating that after this stage, the performance degradation of the pump entered a relatively stable phase.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IG | Inverse Gaussian |

| CUSUM | cumulative sum |

| EM | Expectation–Maximization |

| SIC | Schwartz Information Criterion |

| PDP | plasma display panel |

| IGP | Inverse Gaussian process |

| probability density function | |

| CDF | cumulative distribution function |

| MLE | maximum likelihood estimation |

| LRT | likelihood ratio test |

Appendix A. Deduction Details of Maximum Likelihood Estimation for Inverse Gaussian Process Parameters

References

- Si, X.S.; Wang, W.; Hu, C.H.; Zhou, D.H. Remaining useful life estimation–A review on the statistical data driven approaches. Eur. J. Oper. Res. 2011, 213, 1–14. [Google Scholar] [CrossRef]

- Siegel, D.; Ly, C.; Lee, J. Methodology and framework for predicting helicopter rolling element bearing failure. IEEE Trans. Reliab. 2012, 61, 846–857. [Google Scholar] [CrossRef]

- Zhou, R.R.; Serban, N.; Gebraeel, N. Degradation modeling applied to residual lifetime prediction using functional data analysis. Ann. Appl. Stat. 2011, 5, 1586–1610. [Google Scholar] [CrossRef]

- Verl, A.; Heisel, U.; Walther, M.; Maier, D. Sensorless automated condition monitoring for the control of the predictive maintenance of machine tools. CIRP Ann. 2009, 58, 375–378. [Google Scholar] [CrossRef]

- Ye, Z.S.; Tang, L.C.; Xu, H.Y. A distribution-based systems reliability model under extreme shocks and natural degradation. IEEE Trans. Reliab. 2011, 60, 246–256. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, H.Z.; Li, Y.; Xiao, N.C. An approach to reliability assessment under degradation and shock process. IEEE Trans. Reliab. 2011, 60, 852–863. [Google Scholar] [CrossRef]

- Lawless, J.; Crowder, M. Covariates and random effects in a gamma process model with application to degradation and failure. Lifetime Data Anal. 2004, 10, 213–227. [Google Scholar] [CrossRef]

- Pan, Z.; Balakrishnan, N. Reliability modeling of degradation of products with multiple performance characteristics based on gamma processes. Reliab. Eng. Syst. Saf. 2011, 96, 949–957. [Google Scholar] [CrossRef]

- Van Noortwijk, J.M. A survey of the application of gamma processes in maintenance. Reliab. Eng. Syst. Saf. 2009, 94, 2–21. [Google Scholar] [CrossRef]

- Si, X.S.; Wang, W.; Hu, C.H.; Chen, M.Y.; Zhou, D.H. A Wiener-process-based degradation model with a recursive filter algorithm for remaining useful life estimation. Mech. Syst. Signal Process. 2013, 35, 219–237. [Google Scholar] [CrossRef]

- Zhang, Z.; Si, X.; Hu, C.; Lei, Y. Degradation data analysis and remaining useful life estimation: A review on Wiener-process-based methods. Eur. J. Oper. Res. 2018, 271, 775–796. [Google Scholar] [CrossRef]

- Wang, X.; Xu, D. An inverse Gaussian process model for degradation data. Technometrics 2010, 52, 188–197. [Google Scholar] [CrossRef]

- Ye, Z.S.; Chen, N. The inverse Gaussian process as a degradation model. Technometrics 2014, 56, 302–311. [Google Scholar] [CrossRef]

- Peng, W.; Li, Y.; Yang, Y.; Huang, H.Z.; Zuo, M.J. Inverse Gaussian process models for degradation analysis: A Bayesian perspective. Reliab. Eng. Syst. Saf. 2014, 130, 175–189. [Google Scholar] [CrossRef]

- Guan, Q.; Tang, Y.; Xu, A. Reference Bayesian analysis of inverse Gaussian degradation process. Appl. Math. Modell. 2019, 74, 496–511. [Google Scholar] [CrossRef]

- Pan, D.; Liu, J.B.; Cao, J. Remaining useful life estimation using an inverse Gaussian degradation model. Neurocomputing 2016, 185, 64–72. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, Y.; Song, K.; Song, B. Failure analysis of a lock mechanism with multiple dependent components based on two-phase degradation model. Eng. Fail. Anal. 2019, 104, 1076–1093. [Google Scholar] [CrossRef]

- Wang, R.; Zhu, M.; Zhang, X.; Pham, H. Lithium-ion battery remaining useful life prediction using a two-phase degradation model with a dynamic change-point. J. Energy Storage 2023, 59, 106457. [Google Scholar] [CrossRef]

- Duan, F.; Wang, G.; Duan, F.; Wang, G. Reliability modeling of two-phase inverse Gaussian degradation process. In Proceedings of the 2017 Second International Conference on Reliability Systems Engineering (ICRSE), Beijing, China, 10–12 July 2017. [Google Scholar]

- Bae, S.J.; Yuan, T.; Ning, S.; Kuo, W. A Bayesian approach to modeling two-phase degradation using change-point regression. Reliab. Eng. Syst. Saf. 2015, 134, 66–74. [Google Scholar] [CrossRef]

- Duan, F.; Wang, G. Reliability Modeling of Two-Phase Gamma Degradation Process. In Proceedings of the 2017 IEEE International Conference on Software Quality, Reliability and Security Companion (QRS-C), Prague, Czech Republic, 25–29 July 2017. [Google Scholar]

- Liang, Y.; Yan, Z.; Sun, L. Reliability analysis of inverse Gaussian processes with two-stage degenerate paths. Heliyon 2024, 10, e34625. [Google Scholar] [CrossRef] [PubMed]

- Vostrikova, L.Y. Detecting “Disorder” in Multidimensional Random Processes. Soviet. Math. Dokl. 1981, 24, 55–59. [Google Scholar]

- Page, E.S. Continuous inspection schemes. Biometrika 1954, 41, 100–115. [Google Scholar] [CrossRef]

- Chen, J.A.; Gupta,, A.K.B. Parametric Statistical Change-Point Analysis: With Applications to Genetics, Medicine, and Finance, 3rd ed.; Springer Science & Business Media: New York, NY, USA, 2011; pp. 199–204. [Google Scholar]

- Fryzlewicz, P. Wild binary segmentation for multiple change-point detection. Ann. Stat. 2014, 42, 2243–2281. [Google Scholar] [CrossRef]

- Chen, J. Testing for a change-point in linear regression models. Commun. Stat. Theory. Methods. 1998, 27, 2481–2493. [Google Scholar] [CrossRef]

- Niu, Y.S.; Zhang, H. The screening and ranking algorithm to detect DNA copy number variations. Ann. Appl. Stat. 2012, 6, 1306. [Google Scholar] [CrossRef]

- Zou, C.; Liu, Y.; Qin, P.; Wang, Z. Empirical likelihood ratio test for the change-point problem. Stat. Probab. Lett. 2007, 77, 374–382. [Google Scholar] [CrossRef]

- Akaike, H. Information theory and an extension of the maximum likelihood principle. In Proceedings of the 2nd International Symposium on Information Theory, Tsahkadsor, Armenia, 2–8 September 1971. [Google Scholar]

- Schwartz, G. Estimating the Dimension of a Model. Ann. Stat. 1978, 6, 31–38. [Google Scholar] [CrossRef]

- Chen, J.; Gupta, A.K.; Pan, J. Information criterion and problem for regular models. Sankhya 2006, 68, 252–282. [Google Scholar]

- Qiao, J.; Cai, X.; Zhang, M. Modified Information Criterion for Testing Changes in the Inverse Gaussian Degradation Process. Mathematics 2025, 13, 663. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, S.; Liao, H.; Zhang, C. Engineering-driven performance degradation analysis of hydraulic piston pump based on the inverse Gaussian process. Qual. Reliab. Eng. Int. 2019, 35, 2278–2296. [Google Scholar] [CrossRef]

| n | Method | |||||

|---|---|---|---|---|---|---|

| (1, 1.3) | (1.5, 1.5) | (1.5, 2) | (1.2, 1.7) | (1.4, 2.7) | ||

| 60 | LRT | 0.051 | 0.049 | 0.055 | 0.051 | 0.059 |

| MIC | 0.051 | 0.046 | 0.043 | 0.058 | 0.060 | |

| Ad-CUSUM | 0.048 | 0.043 | 0.039 | 0.046 | 0.039 | |

| 70 | LRT | 0.051 | 0.050 | 0.045 | 0.047 | 0.053 |

| MIC | 0.041 | 0.049 | 0.057 | 0.048 | 0.058 | |

| Ad-CUSUM | 0.059 | 0.046 | 0.053 | 0.054 | 0.064 | |

| 80 | LRT | 0.054 | 0.061 | 0.063 | 0.058 | 0.041 |

| MIC | 0.051 | 0.049 | 0.052 | 0.053 | 0.048 | |

| Ad-CUSUM | 0.063 | 0.060 | 0.054 | 0.041 | 0.049 | |

| 90 | LRT | 0.049 | 0.040 | 0.050 | 0.045 | 0.049 |

| MIC | 0.043 | 0.051 | 0.042 | 0.058 | 0.052 | |

| Ad-CUSUM | 0.062 | 0.054 | 0.065 | 0.049 | 0.051 | |

| 100 | LRT | 0.063 | 0.063 | 0.054 | 0.052 | 0.061 |

| MIC | 0.062 | 0.044 | 0.071 | 0.051 | 0.048 | |

| Ad-CUSUM | 0.052 | 0.061 | 0.059 | 0.048 | 0.055 | |

| n | k | Method | |||||

|---|---|---|---|---|---|---|---|

| (1, 1.3) | (1.5, 1.5) | (1.5, 2) | (1.2, 1.7) | (1.4, 2.7) | |||

| 60 | 15 | LRT | 0.557 | 0.916 | 0.979 | 0.853 | 0.992 |

| MIC | 0.608 | 0.935 | 0.984 | 0.888 | 0.998 | ||

| Ad-CUSUM | 1.000 | 0.992 | 1.000 | 1.000 | 1.000 | ||

| 30 | LRT | 0.750 | 0.984 | 0.998 | 0.961 | 1.000 | |

| MIC | 0.830 | 0.992 | 0.999 | 0.981 | 1.000 | ||

| Ad-CUSUM | 0.996 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 45 | LRT | 0.591 | 0.929 | 0.965 | 0.855 | 0.982 | |

| MIC | 0.631 | 0.944 | 0.976 | 0.880 | 0.991 | ||

| Ad-CUSUM | 0.829 | 1.000 | 1.000 | 0.954 | 1.000 | ||

| 80 | 20 | LRT | 0.727 | 0.985 | 0.998 | 0.954 | 1.000 |

| MIC | 0.769 | 0.990 | 0.998 | 0.964 | 1.000 | ||

| Ad-CUSUM | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 40 | LRT | 0.875 | 0.997 | 0.999 | 0.992 | 1.000 | |

| MIC | 0.923 | 0.998 | 1.000 | 0.995 | 1.000 | ||

| Ad-CUSUM | 0.998 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 60 | LRT | 0.800 | 0.992 | 0.997 | 0.964 | 1.000 | |

| MIC | 0.816 | 0.993 | 0.998 | 0.973 | 1.000 | ||

| Ad-CUSUM | 0.915 | 1.000 | 1.000 | 0.991 | 1.000 | ||

| 100 | 25 | LRT | 0.834 | 0.997 | 1.000 | 0.986 | 1.000 |

| MIC | 0.868 | 0.999 | 1.000 | 0.991 | 1.000 | ||

| Ad-CUSUM | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 50 | LRT | 0.949 | 1.000 | 1.000 | 0.999 | 1.000 | |

| MIC | 0.973 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| Ad-CUSUM | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 75 | LRT | 0.855 | 0.996 | 1.000 | 0.991 | 1.000 | |

| MIC | 0.887 | 0.997 | 1.000 | 0.990 | 1.000 | ||

| Ad-CUSUM | 0.959 | 0.999 | 1.000 | 0.995 | 1.000 | ||

| n | k | Method | |||||

|---|---|---|---|---|---|---|---|

| (1, 1.3) | (1.5, 1.5) | (1.5, 2) | (1.2, 1.7) | (1.4, 2.7) | |||

| 60 | 15 | LRT | 0.454 | 0.858 | 0.942 | 0.770 | 0.983 |

| MIC | 0.503 | 0.890 | 0.966 | 0.926 | 0.989 | ||

| Ad-CUSUM | 0.999 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 30 | LRT | 0.653 | 0.970 | 0.992 | 0.925 | 0.997 | |

| MIC | 0.747 | 0.987 | 0.999 | 0.958 | 1.000 | ||

| Ad-CUSUM | 0.994 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 45 | LRT | 0.507 | 0.904 | 0.946 | 0.787 | 0.967 | |

| MIC | 0.541 | 0.914 | 0.955 | 0.816 | 0.973 | ||

| Ad-CUSUM | 0.775 | 0.987 | 0.996 | 0.938 | 0.998 | ||

| 80 | 20 | LRT | 0.595 | 0.960 | 0.992 | 0.902 | 0.998 |

| MIC | 0.629 | 0.975 | 0.995 | 0.921 | 0.998 | ||

| Ad-CUSUM | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 40 | LRT | 0.807 | 0.994 | 0.998 | 0.979 | 1.000 | |

| MIC | 0.850 | 0.996 | 0.998 | 0.989 | 1.000 | ||

| Ad-CUSUM | 0.998 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 60 | LRT | 0.706 | 0.978 | 0.994 | 0.930 | 0.997 | |

| MIC | 0.723 | 0.984 | 0.995 | 0.939 | 0.999 | ||

| Ad-CUSUM | 0.853 | 0.997 | 1.000 | 0.982 | 1.000 | ||

| 100 | 25 | LRT | 0.705 | 0.993 | 1.000 | 0.960 | 1.000 |

| MIC | 0.752 | 0.995 | 1.000 | 0.974 | 1.000 | ||

| Ad-CUSUM | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 50 | LRT | 0.895 | 1.000 | 1.000 | 0.993 | 1.000 | |

| MIC | 0.937 | 1.000 | 1.000 | 0.999 | 1.000 | ||

| Ad-CUSUM | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 75 | LRT | 0.774 | 0.994 | 0.998 | 0.971 | 1.000 | |

| MIC | 0.804 | 0.994 | 0.999 | 0.981 | 1.000 | ||

| Ad-CUSUM | 0.917 | 0.998 | 1.000 | 0.988 | 1.000 | ||

| n | k | Method | |||||

|---|---|---|---|---|---|---|---|

| (1, 1.3) | (1.5, 1.5) | (1.5, 2) | (1.2, 1.7) | (1.4, 2.7) | |||

| 60 | 15 | LRT | 0.235 | 0.671 | 0.847 | 0.562 | 0.928 |

| MIC | 0.541 | 0.732 | 0.884 | 0.629 | 0.955 | ||

| Ad-CUSUM | 0.999 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 30 | LRT | 0.426 | 0.892 | 0.962 | 0.797 | 0.988 | |

| MIC | 0.531 | 0.942 | 0.985 | 0.877 | 0.955 | ||

| Ad-CUSUM | 0.979 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 45 | LRT | 0.287 | 0.770 | 0.858 | 0.579 | 0.908 | |

| MIC | 0.344 | 0.797 | 0.890 | 0.654 | 0.920 | ||

| Ad-CUSUM | 0.586 | 0.946 | 0.967 | 0.846 | 0.965 | ||

| 80 | 20 | LRT | 0.341 | 0.843 | 0.960 | 0.738 | 0.989 |

| MIC | 0.421 | 0.898 | 0.976 | 0.807 | 0.995 | ||

| Ad-CUSUM | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 40 | LRT | 0.581 | 0.966 | 0.993 | 0.910 | 0.997 | |

| MIC | 0.703 | 0.990 | 0.997 | 0.961 | 1.000 | ||

| Ad-CUSUM | 0.994 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 60 | LRT | 0.488 | 0.921 | 0.975 | 0.830 | 0.988 | |

| MIC | 0.566 | 0.944 | 0.985 | 0.867 | 0.994 | ||

| Ad-CUSUM | 0.712 | 0.988 | 0.996 | 0.936 | 0.995 | ||

| 100 | 25 | LRT | 0.468 | 0.946 | 0.992 | 0.888 | 0.998 |

| MIC | 0.497 | 0.954 | 0.994 | 0.899 | 0.998 | ||

| Ad-CUSUM | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 50 | LRT | 0.752 | 0.997 | 1.000 | 0.975 | 1.000 | |

| MIC | 0.807 | 0.999 | 1.000 | 0.984 | 1.000 | ||

| Ad-CUSUM | 0.995 | 1.000 | 1.000 | 1.000 | 1.000 | ||

| 75 | LRT | 0.594 | 0.981 | 0.996 | 0.912 | 0.999 | |

| MIC | 0.611 | 0.984 | 0.996 | 0.925 | 0.999 | ||

| Ad-CUSUM | 0.786 | 0.991 | 0.998 | 0.964 | 0.999 | ||

| Model | logLik | AIC | BIC |

|---|---|---|---|

| Inverse Gaussian | 105.708 | −207.415 | −203.006 |

| Wiener | 57.115 | −110.230 | −105.821 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Fu, T.; Li, Q. An Adjusted CUSUM-Based Method for Change-Point Detection in Two-Phase Inverse Gaussian Degradation Processes. Mathematics 2025, 13, 3167. https://doi.org/10.3390/math13193167

Li M, Fu T, Li Q. An Adjusted CUSUM-Based Method for Change-Point Detection in Two-Phase Inverse Gaussian Degradation Processes. Mathematics. 2025; 13(19):3167. https://doi.org/10.3390/math13193167

Chicago/Turabian StyleLi, Mei, Tian Fu, and Qian Li. 2025. "An Adjusted CUSUM-Based Method for Change-Point Detection in Two-Phase Inverse Gaussian Degradation Processes" Mathematics 13, no. 19: 3167. https://doi.org/10.3390/math13193167

APA StyleLi, M., Fu, T., & Li, Q. (2025). An Adjusted CUSUM-Based Method for Change-Point Detection in Two-Phase Inverse Gaussian Degradation Processes. Mathematics, 13(19), 3167. https://doi.org/10.3390/math13193167