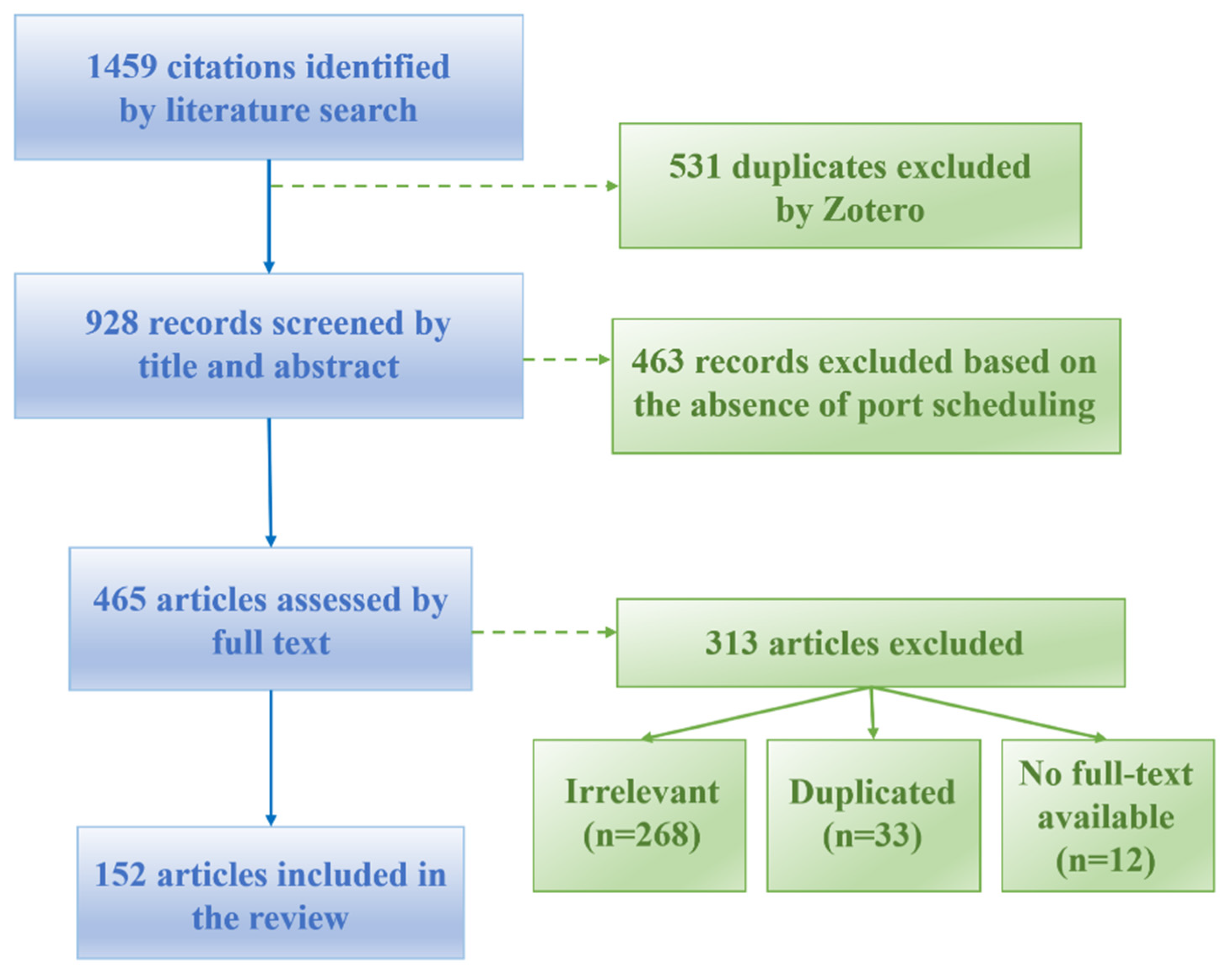

3.2. Components and Workflow of Seaside Operations

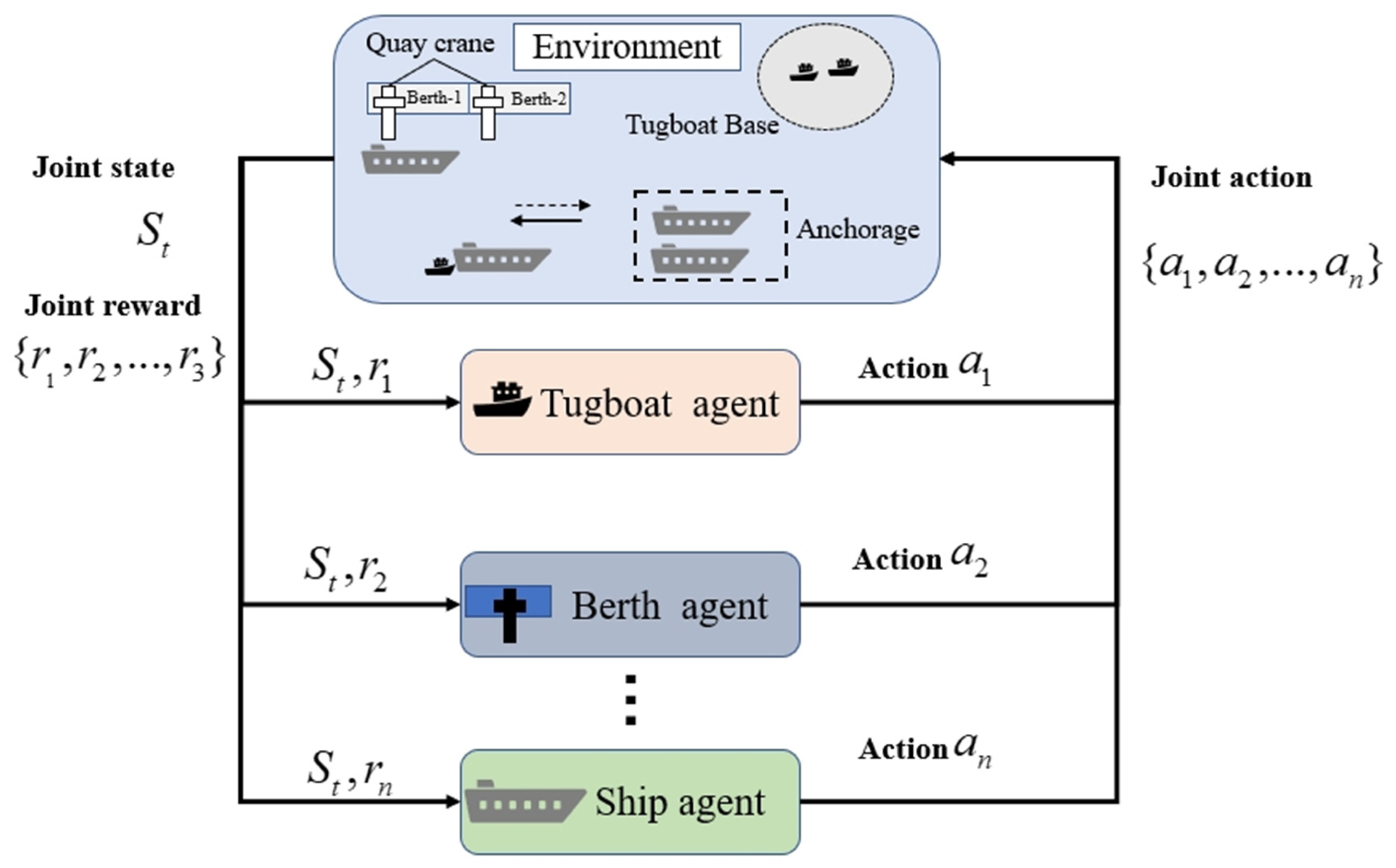

Seaside Operations primarily correspond to the process of vessel inbound and outbound operations, which are typically complex and intricate, involving multiple stages and stakeholders, with the aim of ensuring that vessels complete their entry and departure safely and efficiently. The typical scenario for vessel inbound and outbound operations is illustrated in

Figure 4.

Based on the layouts and vessel inbound and outbound procedures documented for actual ports in the literature—including Tianjin Port [

14,

15,

16], Shanghai Waigaoqiao Port [

17], Tangshan Jingtang Port [

18,

19], Zhoushan Port and Rotterdam Port [

20], Singapore Port [

21,

22], Guangzhou Port [

23], and Bofa Port [

24]—the following general process for vessel entry and departure can be summarized.

First, as a vessel approaches the port, it typically waits at an anchorage area located at a certain distance from the port. The port control center assigns an appropriate berth and arranges tugboats and pilots to assist with berthing, based on real-time data and vessel type. Tugboats are usually on standby at the “tugboat base” before the vessel enters port waters, ensuring they can promptly assist the vessel in safely approaching the berth when needed. In addition, pilots initially wait in the port area; when pilotage services are required, the port dispatches a pilot by pilot boat or helicopter to the anchorage, where the pilot boards the arriving vessel to provide guidance. As the vessel enters port waters, its speed is reduced to ensure safe maneuvering within the narrow channel.

Upon arrival at the designated berth, quay cranes are prepared, including the inspection of handling equipment and personnel. Meanwhile, the quayside operations team readies itself to enable the rapid and smooth loading and unloading of cargo. The handling process typically consists of two main stages: first, discharging, in which appropriate vehicles are arranged for cargo transfer according to cargo type and destination; and second, loading, which ensures that cargo is stowed in the prescribed order and manner to maintain vessel stability and safety.

After cargo operations are completed, the vessel begins the departure process. At this stage, tugboats and pilots are again mobilized to assist the vessel in safely leaving the berth. As the vessel navigates toward the port exit, it follows specific channel guidance to avoid interfering with other vessel traffic.

Finally, once the vessel leaves port waters, the captain continues to maintain contact with the navigation control center to ensure safe passage to the next destination. The entire inbound and outbound operation involves close coordination and cooperation among multiple parties and stages, requiring not only efficient port facilities but also effective information sharing and communication, so as to ensure overall port operational efficiency and safety.

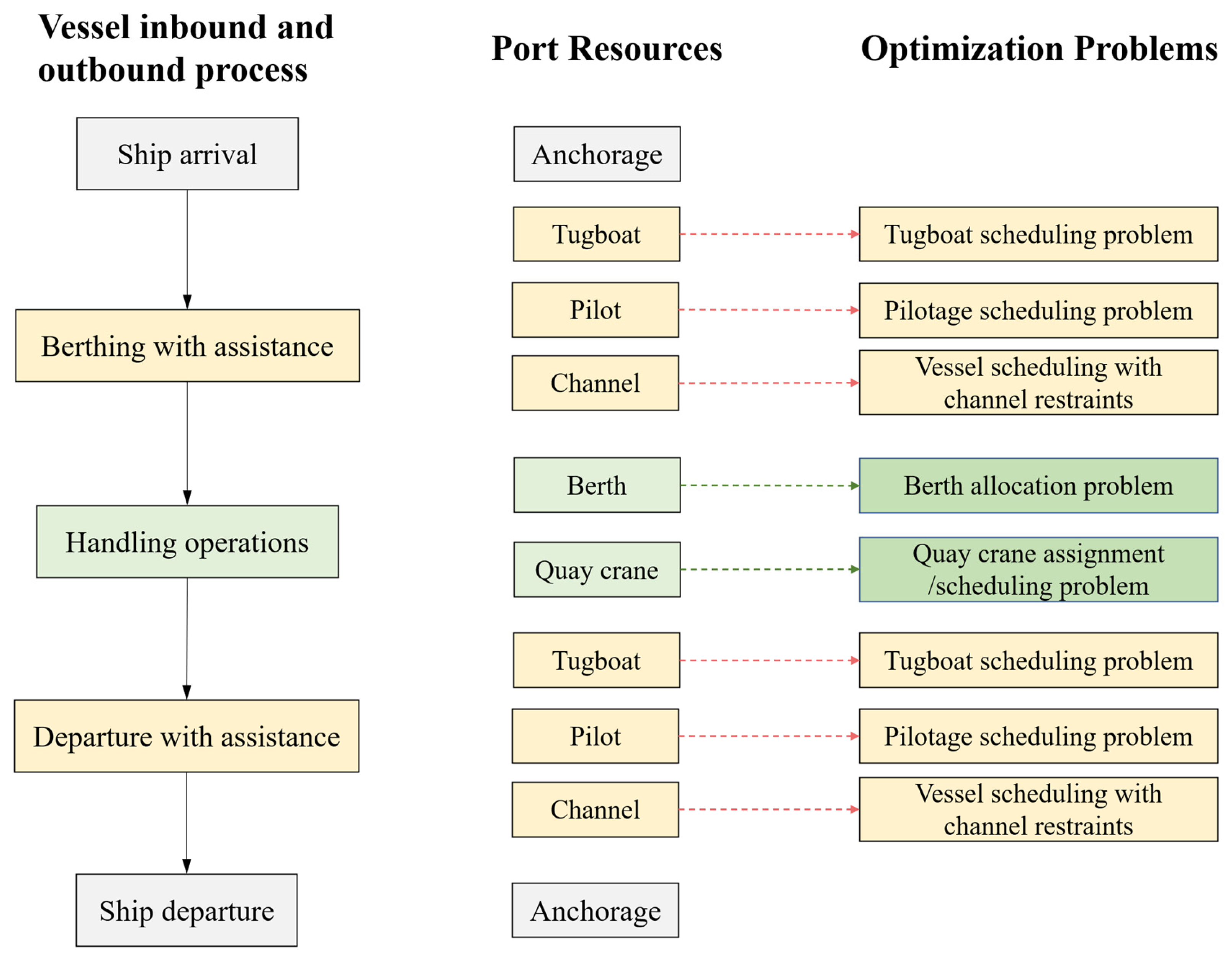

To further clarify the overall structure of port seaside operations,

Figure 5 presents a comprehensive block diagram that maps the entire vessel inbound and outbound process, associated port resources, and corresponding optimization problems. This visualization provides an integrated perspective on the coordination of tugboats, pilots, channels, berths, and quay cranes, alongside the scheduling challenges inherent in each phase.

In summary, this section provides an overview of vessel inbound and outbound operations in seaside port systems, outlining the associated resources and their coordination, and illustrating how these elements relate to corresponding optimization problems.

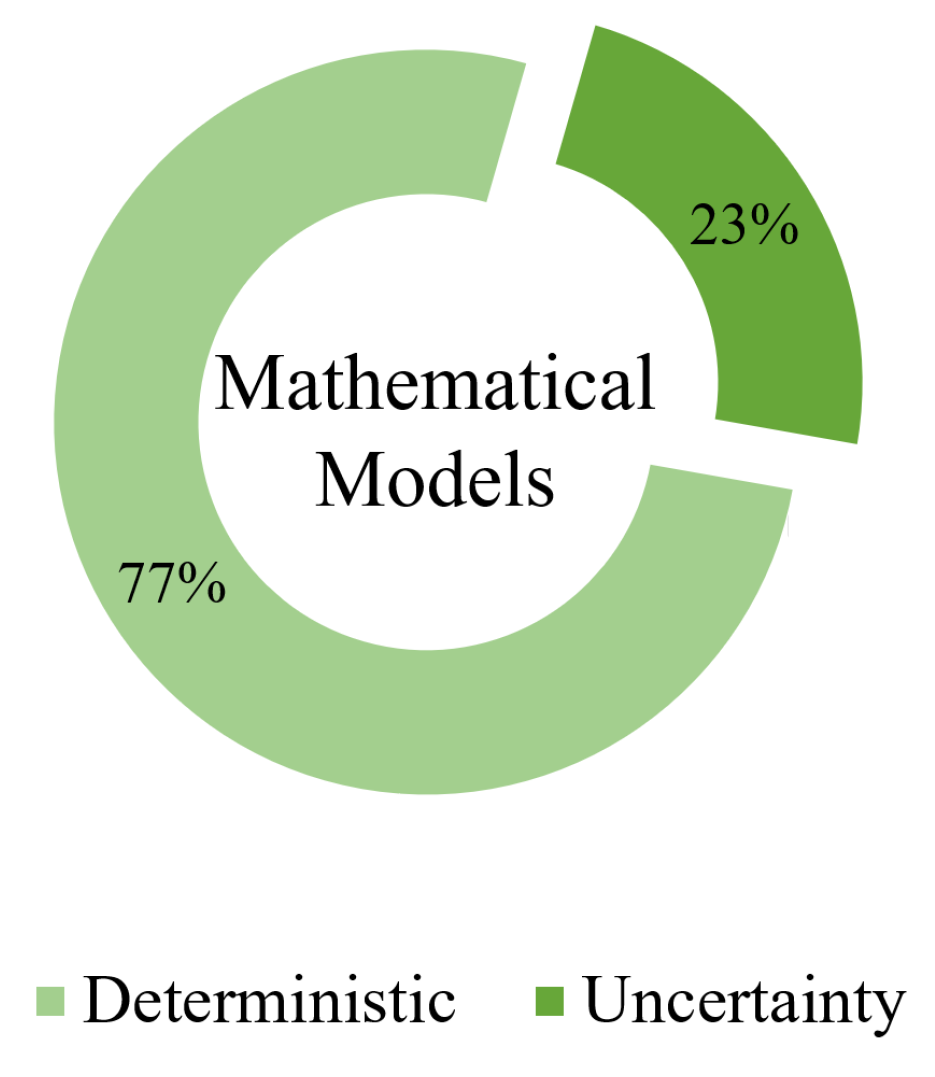

3.3. Mathematical Formulations for Main Problems in Seaside Port Operations

As discussed in the previous section, the seaside port operation system comprises a series of interrelated processes with corresponding optimization problems, each characterized by limited resources, strict time constraints, and complex interdependencies. To effectively address these challenges, it is essential to construct mathematical formulations that clearly define decision variables, objectives, and operational constraints, thereby enabling systematic analysis and optimization through appropriate solution methods.

In the following, mathematical models for the main optimization problems in the seaside port operation system are presented, providing a formal basis for performance evaluation and the design of effective scheduling algorithms.

(1) Berth allocation problem

The berth allocation problem (BAP) is one of the most fundamental and extensively studied issues in port seaside operations. It focuses on determining the optimal assignment of vessels to specific berthing positions and time intervals along the quay, with the objective of improving berth utilization and minimizing vessel turnaround time. BAP directly affects downstream operations such as quay crane scheduling and yard logistics, and is subject to constraints including berth length, vessel draft requirements, and arrival–departure time windows. Depending on the spatial and temporal representation of berths, BAP can be categorized into discrete, continuous, and hybrid forms, each reflecting different levels of operational flexibility and complexity. In practical applications, BAP models may also incorporate tidal restrictions, channel accessibility, and environmental objectives, making it a critical decision-making problem in integrated port scheduling.

A typical BAP model was proposed by Imai et al. [

25], which extended the static BAP to the Dynamic BAP (DBAP) and has made a significant contribution to subsequent BAP research. In this problem setting, it is assumed that berths are discrete and that each berth can serve only one vessel at a time, without considering other operational constraints. Suppose that a port has

berths (set

),

n vessels awaiting berthing (set

), and a set

representing the service order of vessels. Let the arrival time of vessel

be

, the handling time of vessel

at berth

be

, and

represent the time when berth

becomes idle for berth allocation planning. The decision variable is a binary variable

, which equals 1 if vessel

is serviced as the

th vessel at berth

, and 0 otherwise. Based on the above parameters, a static BAP mathematical model can be formulated as follows:

The objective function (1) of this model aims to minimize the total service time and waiting time of all vessels. Constraint (2) ensures that each vessel is served at exactly one berth, and constraint (3) guarantees that at most one vessel can be served at the same berth at any given time. In the static BAP described above, it is assumed that all vessels arrive before the start of the planning horizon, i.e.,

. However, according to the analysis of Imai et al. [

25], vessels may arrive after the beginning of the planning horizon. Therefore, the corresponding DBAP model was proposed.

In this model, a set

is introduced to represent vessels arriving after the start of berth planning (i.e.,

), which is a subset of the vessel set

. In addition, a set

is defined to represent the service sequence prior to the

, which is a subset of

. Furthermore, an additional decision variable

is introduced, representing the idle time of berth

between the departure of the

th vessel and the arrival of the

th vessel when vessel

is serviced as the

th vessel at berth

. Based on the above notation, the mathematical formulation of the DBAP can be expressed as follows:

subject to constraints (2)–(4) and

The objective function (5) still aims to minimize the total handling time and waiting time of all vessels. The additional constraint (6) ensures that all vessels must begin service only after their arrival. This mathematical model represented a significant breakthrough in the early research on the BAP, and many subsequent studies [

26,

27] have built upon it for further improvements and extensions. Overall, this mathematical model captures the dynamic nature of vessel arrivals and berth availability, providing a more realistic framework for berth allocation in practical port operations.

Building on the above, the BAP has become one of the most extensively studied problems in seaside port operations, giving rise to a diverse range of mathematical formulations. These include discrete, continuous, and hybrid spatial representations, as well as deterministic, stochastic, and robust optimization frameworks, each tailored to different operational contexts and uncertainty conditions. A detailed and comparative overview of these formulations can be found in the review [

6,

10].

(2) BACAP

Following berth allocation, the efficient assignment and scheduling of quay cranes (QC) is critical to minimizing vessel turnaround time and maximizing berth productivity. The Quay Crane Assignment/Scheduling Problem (QCAP/QCSP) determines not only how many cranes should be assigned to each vessel but also the sequence and timing of their operations, subject to operational constraints such as non-crossing rules, safety margins, and interference avoidance between adjacent cranes. As a core component of seaside operations, this problem is inherently interdependent with berth allocation decisions and has been extensively studied through various mathematical formulations, ranging from deterministic mixed-integer programming models to stochastic and robust optimization frameworks. The following presents a representative mathematical model for the QC assignment and scheduling problem.

Kim and Park [

28] developed an MIP model for the QCSP focusing on a single vessel, with the objective of minimizing the weighted sum of the makespan and the total completion time of QC. The primary aim of this model is to determine the sequence in which multiple quay cranes perform loading and unloading operations according to the vessel’s stowage plan, while considering constraints such as crane availability, precedence relationships between tasks, the non-crossing rule between cranes, and restrictions on tasks that cannot be executed simultaneously. This work laid the foundation for subsequent studies on quay crane scheduling and remains a benchmark for modeling operational constraints in port seaside resource management. Furthermore, different mathematical modeling frameworks for the QCSP have been summarized and discussed in detail in the review [

5], providing a comprehensive overview of the problem’s diverse formulations.

In practice, berth allocation and quay crane scheduling are highly interdependent, and optimizing them separately may lead to suboptimal overall performance. This has given rise to the berth and quay crane assignment problem (BACAP), an integrated scheduling problem that jointly determines berth positions, vessel berthing times, and quay crane allocations. With the growing complexity of port operations and the increasing emphasis on resource coordination, BACAP has become a research hotspot, attracting significant attention for its potential to improve vessel turnaround times and enhance overall terminal productivity. Building on the BAP framework [

25], Imai et al. [

29] proposed a widely cited mathematical model for BACAP, which extends berth allocation to simultaneously determine optimal quay crane assignments under realistic operational constraints.

The model minimizes the total service time of all vessels while considering the required number of cranes per vessel, crane availability constraints, and detailed crane movement restrictions. By coupling berth allocation with quay crane assignment, this formulation captures the interdependence between the two resources more effectively than separate optimization, making it a key reference for coordinated scheduling in seaside port operations.

In the BACAP model, the berth set , vessel set , and service order set defined in the previous BAP model are retained, along with the parameters , , , and the decision variable . Building on this foundation, the following additional parameters and variables are introduced: denotes a sufficiently large constant; represents the number of cranes required by vessel ; denotes the number of cranes initially assigned to berth in the planning horizon; and is the total number of available quay cranes. In addition to , new decision variables and are defined to represent, respectively, the start time and finish time of serving vessel at berth as the th vessel.

For QC movement–related parameters, three additional decision variables are introduced:

denotes the number of cranes at berth

immediately after serving the

th vessel, including cranes transferred from neighboring berths;

represents the number of cranes transferred from berth

after serving its

th vessel to berth

(the next to

) after serving its

th vessel; and

indicates the number of cranes allocated to berth

for the

th vessel, including those in an idle state. In addition, three auxiliary variables—

,

, and

—are introduced to describe the temporal relationships in quay crane transfers between adjacent berths, ensuring the model can accurately distinguish between different crane movement scenarios; the detailed definitions of these variables can be found in [

29]. The BACAP model is formulated as follows:

subject to constraints (2)–(4) and

The objective function (8) is the minimization of the total service time.

Constraints (2)–(4) and (9)–(13) correspond to the BAP-related constraints and are therefore not repeated here. Constraint (14) ensures that each vessel is allocated a sufficient number of quay cranes to perform loading and unloading operations. Constraint sets (15)–(20) define the flow conservation rules governing crane movements, while constraints (21)–(28) specify flow conservation for crane transfers between two specific adjacent berths. Constraint (29) ensures that if vessel

is served at a berth other than berth

, then no crane flow associated with vessel

is generated at berth

. Constraint (30) links the initial number of cranes at each berth to the number of cranes assigned to the first vessel served at that berth. Equation (31) guarantees that all available quay cranes are allocated across all berths. Constraints (32) and (33) describe, for a given berth, the relationship between crane movements, a hypothetical crane-move node, and the number of cranes located at the berth immediately before the node. Equalities (34) ensure that, at any stage of the planning horizon, the total number of quay cranes distributed among all berths equals the total number available in the system. Finally, constraints (35)–(41) define the domains and admissible ranges of the decision variables. For further details and a complete description of the model, readers are referred to [

29].

In summary, the BACAP model integrates berth allocation and quay crane assignment within a single optimization framework, capturing the spatial and temporal interdependencies between the two resources. This type of mathematical modeling framework for BACAP/BACASP has been well summarized and discussed in several review studies [

8,

9], reflecting the richness and diversity of research in this area. By combining vessel scheduling decisions with detailed crane allocation and movement constraints, the model provides a realistic and comprehensive representation of seaside port operations, offering a solid foundation for developing coordinated scheduling strategies that can significantly improve terminal efficiency.

(3) Tugboat scheduling problem

The tugboat scheduling problem is a critical component of seaside port operations, involving the allocation and scheduling of tugboats to assist vessels during berthing and unberthing maneuvers. Tugboats are essential for guiding vessels safely through harbor channels, positioning them at berths, and ensuring efficient departure procedures, particularly for large container ships and tankers that have limited maneuverability. The problem typically aims to minimize vessel waiting times, tugboat idle times, or total operational costs, while satisfying constraints related to tugboat availability, travel times between locations, required tug capacity for different vessel sizes, and service time windows. Due to the dynamic nature of vessel arrivals, varying tugboat assignments, and the tight coordination required with other port resources, the tugboat scheduling problem is inherently complex and has been widely studied using mathematical optimization and heuristic approaches.

A mathematical model for tugboat scheduling is presented in [

30], designed to capture the key operational characteristics of tug allocation in port operations. In this model, it is assumed that the port operates with

tugboats (set

) and

vessels awaiting towage services (set

), with the set of service sequences denoted by

and indexed by

. To simplify the problem description, a First-Come-First-Served (FCFS) rule is applied, meaning that vessels are towed in the order of their arrival. The matching rules between tugboat availability, horsepower, and vessel length, as well as the corresponding operation durations, are assumed to be predefined. The parameter

denotes the arrival time of vessel

,

represents the towage operation time for vessel

,

indicates the start time of vessel

for the

th job, and

represents its completion time. Tugboat

has a horsepower

, while vessel

requires a minimum horsepower

. The decision variable

is defined to be 1 if tugboat

is assigned to vessel

, and 0 otherwise. Based on the above definitions, the mathematical model can be formulated as follows:

The objective function (42) minimizes the maximum completion time of all the vessels. Constraints (43) and (44) specify that the number and horsepower of tugboats assigned to each vessel must satisfy the assignment rules. Equality (45) calculates the completion time of vessel for the th job as the sum of its start time and operation time. Equality (46) states that the start time of a vessel’s operation depends on the later of its arrival time and the completion time of its preceding task. Through these formulations, the mathematical model provides a concise yet effective representation of the key characteristics of the tugboat scheduling problem, capturing both resource matching requirements and temporal dependencies in service operations.

In summary, the presented mathematical model offers a straightforward yet representative framework for describing the tugboat scheduling problem, effectively capturing its core operational constraints and timing relationships. Subsequent studies have extended this modeling approach to incorporate additional practical considerations; for example, Kang et al. [

31] account for the uncertainty in vessel arrival and tugging process time, further enhancing the applicability of tugboat scheduling models in dynamic port environments.

(4) Other problems

In addition to the BAP, BACAP, and tugboat scheduling problems discussed above, the seaside port operation system also involves several scheduling and optimization problems that have only recently begun to attract research attention. Examples include the vessel scheduling problem with channel restrictions and the pilotage scheduling problem, both of which were also mentioned in the inbound and outbound operation process described in the previous section. These problems, while less extensively studied than the classical models, play a critical role in ensuring safe, efficient, and coordinated port operations. In this subsection, we briefly introduce the main characteristics and core constraints of these two problems.

The vessel scheduling problem under channel restrictions is critical for ports with narrow channels, where limited navigational capacity can lead to vessel congestion and delays if not properly managed. In Zhang et al. [

32], the case of a one-way channel is considered, and a mathematical model is proposed to minimize the total waiting time of vessels by jointly determining their entry and exit times while ensuring navigational safety. The model incorporates vessel time windows, channel transit times, and safety separation constraints for both same-direction and opposite-direction traffic, as well as berth availability, vessel speed and length, and berth position dependencies. This coordinated channel–berth scheduling framework ensures conflict-free vessel movements and adherence to port navigation rules. Building on this problem setting, subsequent studies have extended the one-way channel assumption to two-way channels, compound channel systems, and other more complex restricted channels [

33,

34,

35,

36,

37].

Pilots, as another essential resource alongside tugboats in assisting vessel entry and departure, have only recently begun to attract research attention in the context of seaside port operations, and their scheduling is often studied in conjunction with other resources. Wu et al. [

38] formulated the pilotage planning problem in seaports as an MIP model that jointly determines vessel scheduling through the channel, pilot shift assignments, and pilot routing. The model incorporates constraints on channel capacity for inbound and outbound traffic, vessel service time windows, pilot working time regulations, and travel times between pilots’ locations and vessels, ensuring feasible and efficient pilotage schedules that meet both navigational and labor requirements.

In summary, all the optimization problems discussed in this paper revolve around the core scheduling challenges illustrated in the diagram, which comprehensively represent the port seaside operation system. Specifically, the research scope of this study—focusing on berth allocation, quay crane scheduling, tugboat scheduling, pilot assignment, and channel-constrained vessel scheduling—aligns with the corresponding stages and resources mapped in the process. This structured overview provides a consistent foundation for the subsequent analysis and classification of optimization methods within the port seaside operations context.

3.4. Optimization Objectives and Performance Indicators of Port Seaside Operation Systems

In port seaside operation systems, optimization metrics are crucial for enhancing overall port efficiency. These metrics not only determine operational costs and resource utilization but also directly impact service quality and the achievement of environmental objectives. The following section discusses several key optimization metrics and illustrates how ports can achieve optimization through intelligent scheduling systems and advanced technologies.

(1) Time

Vessel turnaround time plays a vital role in port seaside operation systems. Prolonged turnaround times can lead to port congestion, delay subsequent vessel operations, and negatively affect overall logistics efficiency. To optimize this metric, ports employ intelligent scheduling systems to arrange vessel entry and departure sequences and adjust tugboat deployment in real time, ensuring that vessels can complete each operational stage swiftly and safely. In addition, efficient quay crane operations are essential for minimizing vessel berth time, while real-time monitoring and data analysis further support optimal resource allocation and high operational efficiency.

Based on a review and classification of the retrieved literature, time-related performance indicators in this study are divided into four categories: completion time, waiting time, delay/deviation time, and total turnaround time. Each type of objective emphasizes different aspects, as summarized in

Table 1.

Minimizing completion time targets reducing the overall duration of port operations, commonly expressed as makespan or maximum completion time, thereby enhancing operational efficiency and resource utilization. For example, Tasoglu and Yildiz [

39] focused on minimizing vessel departure times in integrated berth and quay crane scheduling. Liu et al. [

16] addressed the expected weighted completion time considering uncertainties in vessel arrivals and handling times. Additional studies also emphasized completion time reduction across berth allocation, quay crane, and tugboat scheduling problems, highlighting its critical role in port efficiency [

19,

28,

30,

40,

41,

42,

43].

Minimizing vessel waiting/delay time addresses the idle or delayed periods experienced by vessels or equipment due to resource conflicts or scheduling uncertainties, such as waiting for berths, quay cranes, or tugboats. Abou Kasm et al. [

44] optimized the maximum vessel waiting time involving pilotage and tugboat operations, while Lv et al. [

45] addressed weighted average vessel waiting time within dynamic berth allocation scenarios. Other studies further explored specific delays, including mooring, unberthing, and deballasting delays, underscoring their significant impact on operational efficiency and resource utilization [

46,

47].

Minimizing total vessel turnaround time concerns the entire duration of a vessel’s stay at port from arrival until departure, typically encompassing waiting, service, and operational delays. Li et al. [

54] considered uncertainties in quay crane maintenance activities to effectively reduce vessel dwell time. Liang et al. [

55] optimized total operational, waiting, and delay durations through dynamic quay crane scheduling. Additional research concentrated on minimizing vessel service time, further demonstrating the importance of reducing overall turnaround time for improved port throughput and resource efficiency [

56,

57].

(2) Cost

Operating cost is another core metric in port seaside operation systems. Excessive operational costs not only increase the financial burden on ports but may also undermine their market competitiveness, particularly in an unstable global economic environment. To reduce operating costs, ports optimize operational processes through intelligent scheduling systems to maximize resource utilization and avoid equipment and labor idleness or overuse. In addition, optimizing vessel entry and departure routes and introducing automated, energy-efficient equipment—such as electric tugboats and automated quay cranes—not only reduces energy consumption but also improves operational efficiency, thereby lowering operating costs and enhancing overall port competitiveness.

Based on a review of the literature related to cost metrics, optimization indicators in this category can generally be classified into four groups: resource utilization cost, waiting/delay/deviation cost, energy and emission cost, and comprehensive operating cost, as summarized in

Table 2.

Resource utilization cost primarily aims to minimize the operational costs associated with tugboat, quay crane, or pilot deployment during port activities. For example, Wei et al. [

21] focused on minimizing the tugboat operation cost through optimized scheduling. Building on this, subsequent studies have further incorporated both sailing costs and fixed costs of tugboats into the optimization objective, thus providing a more comprehensive evaluation of tugboat assignment expenses [

22,

76]. In addition, Xiao et al. [

77] addressed minimization of total pilot service cost, including mobilization, fixed, and delay-related penalties.

Waiting/delay/deviation cost reflects economic losses from vessel waiting times and schedule deviations, emphasizing scheduling timeliness and robustness. In the context of BACAP, previous studies have minimized total costs comprising berth section deviation, late berthing, and late departure for each vessel [

78,

79,

80]. Kolley et al. [

81] addressed penalty costs from potential waiting time, spatial deviation, and non-robust or postponed assignments using a robust optimization model with vessel-specific priorities. Xie et al. [

82] considered the weighted sum of deviations from expected berthing locations and times, optimizing both spatial and temporal assignments.

Energy and emission cost has also received attention in the recent literature. For example, Mao et al. [

87] investigated berth allocation in a port multi-energy system, where the energy supply costs include the power generation unit’s fuel cost, start-up cost, and the cost of procuring electricity from the bulk power grid. Tang et al. [

88] decompose terminal energy into operating, transport, and standby parts and show that layout-driven coordination cuts consumption. Iris & Lam [

90] integrate PV-battery storage with time-of-use pricing and load shifting for further savings. Chargui et al. [

91] embed robust optimization in berth–QC scheduling, hedging against uncertain arrival and processing times while tracking spot electricity prices, proving that simultaneous operational flexibility and price awareness can still shrink energy-emission expenditure.

Comprehensive operating cost encompasses multiple cost types, including equipment operation, vessel waiting and delay, and energy-related expenses, providing a holistic perspective more aligned with actual port operations. For instance, Wang et al. [

92] minimized total costs involving vessel waiting, delay penalties, position deviation, and quay crane operation by jointly optimizing berth and crane allocation. Venturini et al. [

93] considered idle time, operating, delay, and fuel costs for multi-port berth allocation, also optimizing vessel speed. He et al. [

94] included quay crane operator performance and wage costs, while Yang et al. [

95] focused on the integrated optimization of berths, tugboats, and quay cranes, considering costs related to in-port time, extra truck distance, tugboat use, and crane handling. Chargui et al. [

91] further incorporated energy consumption costs and the potential revenue from vessels arriving ahead of schedule.

(3) Other

In addition to time- and cost-related metrics, optimization research in port seaside operation systems increasingly emphasizes energy consumption, resource utilization, service level, and indicators specific to quay crane operations, as summarized in

Table 3.

With growing emphasis on global green development, optimizing energy consumption has become a crucial research direction. By integrating energy-efficient equipment and refining operational processes, ports can significantly lower energy use and environmental impact. The adoption of electric tugboats and automation technology has been shown to reduce the consumption associated with traditional fuel-driven equipment. Intelligent scheduling further optimizes vessel routing and operations, minimizing sailing and waiting times to enhance overall energy efficiency and support sustainability goals. Recent studies have addressed energy consumption in multi-resource scheduling scenarios [

88], green tugboat operations [

23], and overall port fuel consumption [

105], collectively advancing energy conservation and emission reduction within port environments.

Resource utilization rate serves as a key indicator for evaluating the efficiency of equipment deployment, with implications for capacity enhancement, cost reduction, and scheduling flexibility. For example, Lassoued and Elloumi [

106] investigated the joint berth and quay crane assignment problem and proposed a two-level model aimed at maximizing the number of available quay cranes to improve utilization rates.

Service level indicators, which assess punctuality, reliability, and customer satisfaction, are increasingly integrated into multi-objective port scheduling models. Notably, Xiang et al. [

107] introduced a robust optimization framework that jointly minimizes total berth allocation cost and maximizes customer satisfaction under uncertainty. Similarly, Xu et al. [

108] considered customer service improvements by targeting reductions in vessel delay and increases in buffer times to strengthen the robustness of berth planning.

Quay crane operation metrics, such as minimizing travel distance [

109] and crane movements [

110,

111], are also frequently optimized, as they directly affect the efficiency and energy usage of cargo handling processes. Improvements in these areas not only reduce unnecessary movements and operational time but also decrease equipment wear and energy consumption. Further, Zhang and Kim [

112] advanced dual-cycle operation strategies for quay crane assignment, aiming to maximize dual-cycle operations and thus minimize the number of operational cycles required.

In summary, these diverse optimization metrics are highly interrelated. Coordinated optimization across these areas not only boosts operational efficiency and cost-effectiveness but also strengthens port competitiveness and sustainability. The continued adoption of intelligent scheduling and automation technologies promises further gains in cost reduction, resource efficiency, service quality, and environmental performance.