Model-Free Adaptive Control Based on Pattern Class Variables for a Class of Unknown Non-Affine Nonlinear Discrete-Time Systems

Abstract

1. Introduction

2. Preliminaries

- (1)

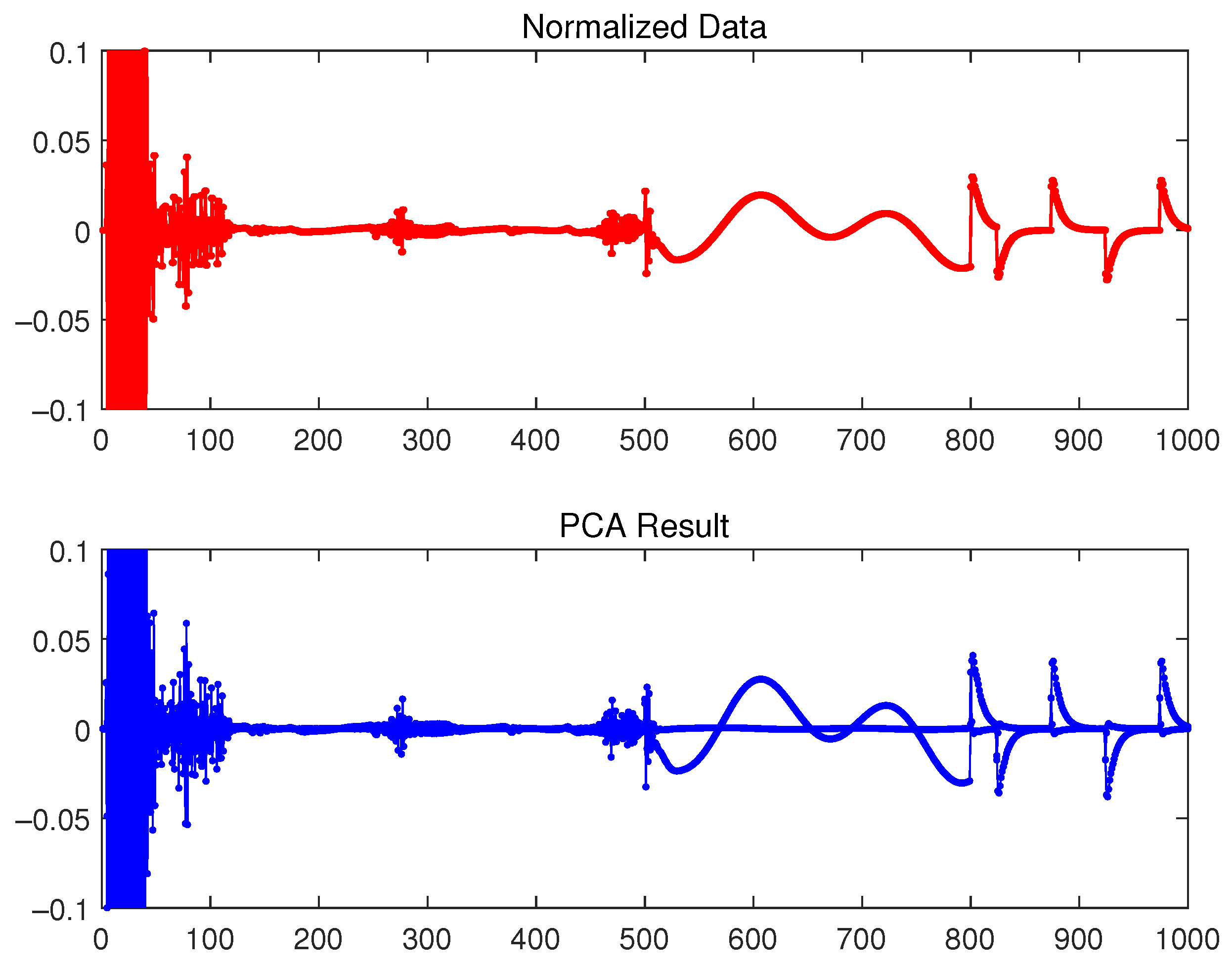

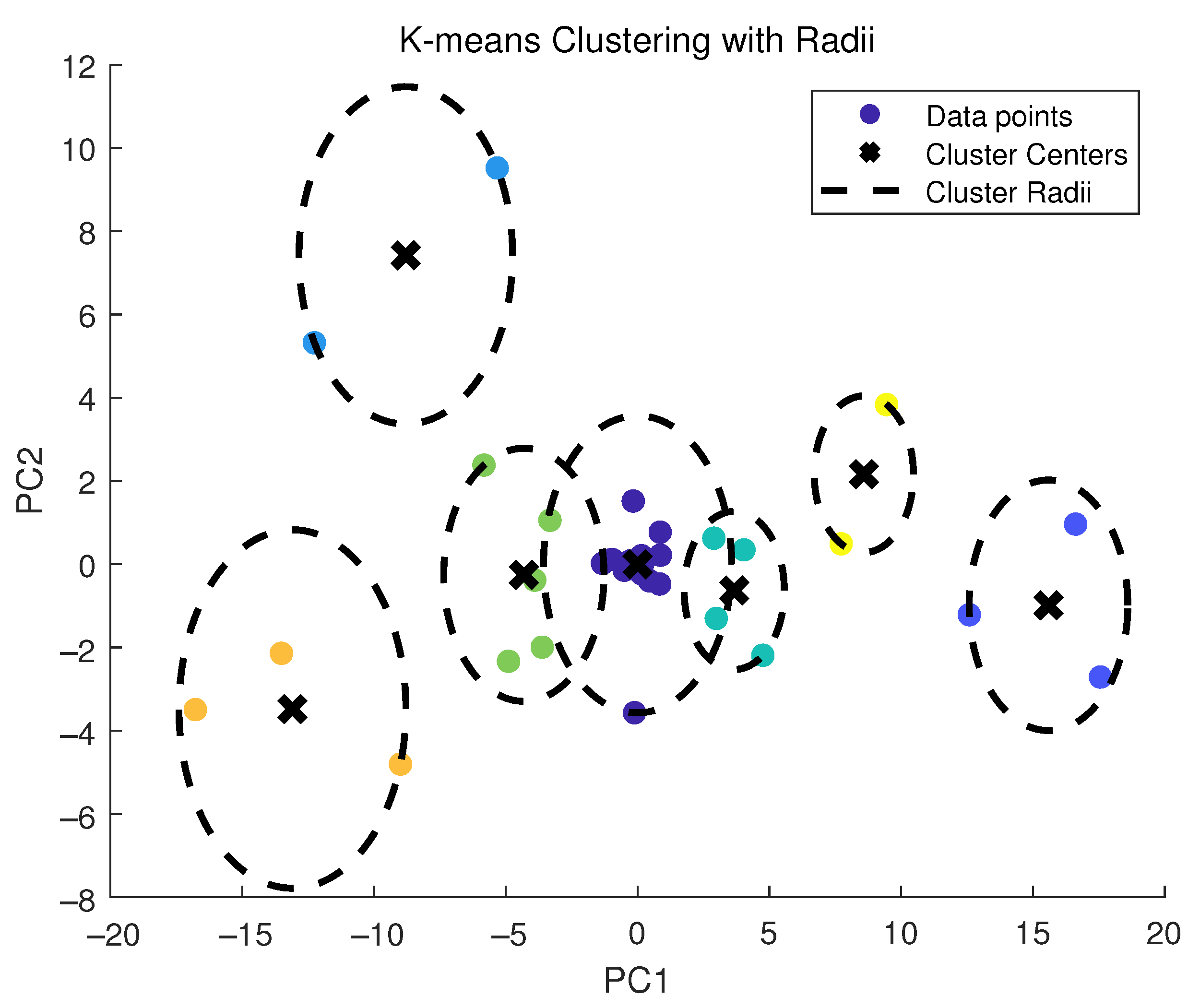

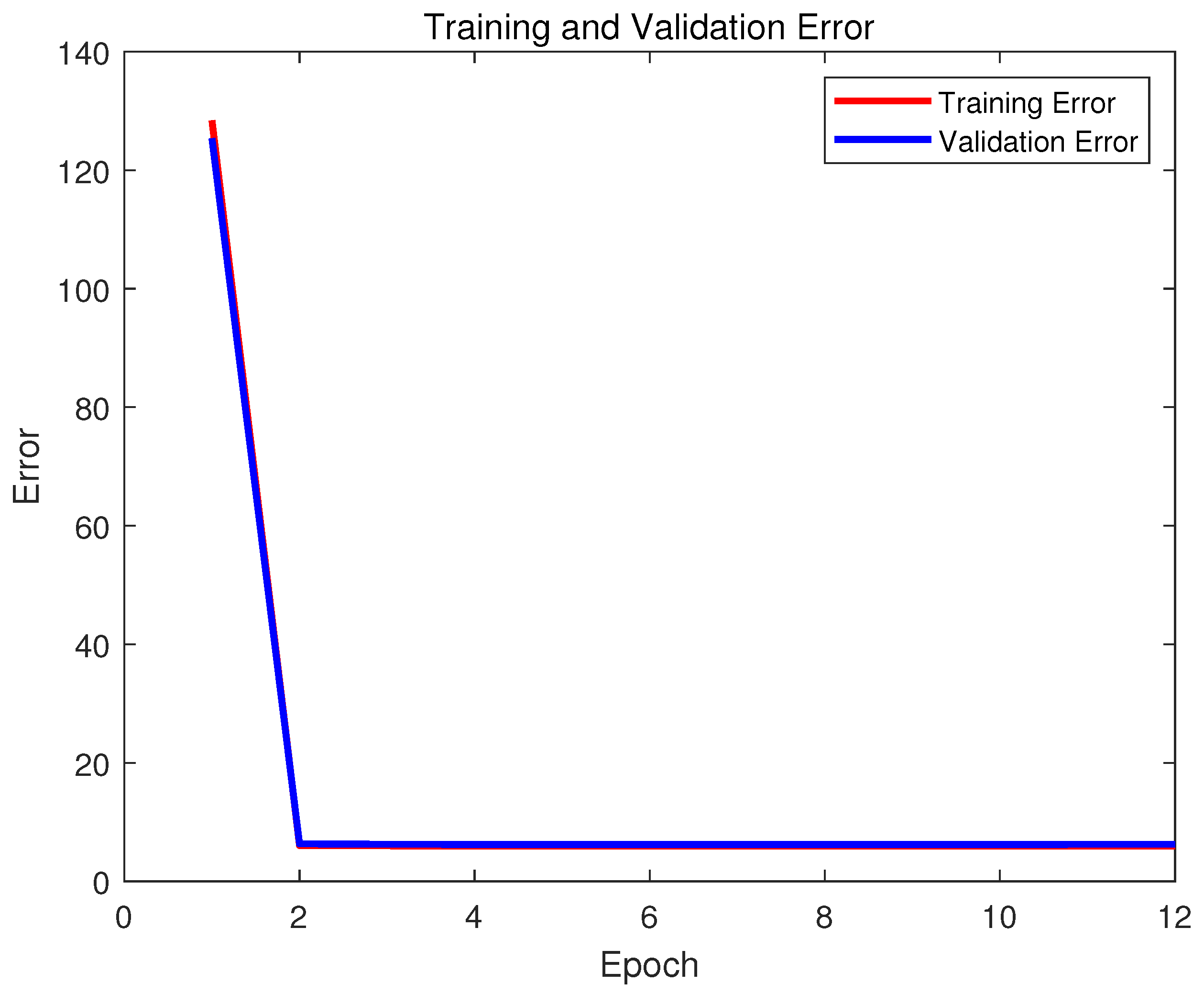

- Pattern moving space. A substantial amount of input and output data are gathered offline. The output data are then standardized, and the features of the output data are extracted using the principal component analysis method, and the appropriate number of principal components is selected for re-dimensioning to create the principal component information set. The K-means algorithm and supervised neural networks are then employed for pattern classes. These pattern classes are subsequently used as scales to construct a pattern moving space.

- (2)

- Define pattern class variable. The pattern variables obtained through feature extraction and classification are defined as pattern class variables. Within this pattern class space, the literature [8] defines variables that describe pattern moving space.

- (3)

- Dynamics description by pattern class variable. Based on the output pattern class variable and the system input time series to establish a model-free adaptive dynamic change relationship, the output time series becomes a time series of metric values of the pattern class variables expressed as . The system model based on the pattern class variable method is as follows:where serves as a classifier for the system pattern samples. Since a pattern class is a collection of pattern samples with the same or similar attributes, it is measured using the class center, S is a metric mapping whose is used to characterize the model of the system dynamics, . is used as a metric in the pattern moving space for the samples of the system model, such that samples with the same output pattern class variable constitute a class of the system model.

3. Problem Formulation and Control Program

3.1. Problem Formulation

3.2. P-FFDL-MFAC Program

4. Performance of Closed-Loop Systems

- (1)

- The system’s tracking error converges asymptotically, and .

- (2)

- If the closed-loop system is stable, the output sequence and the input sequence will be bounded.

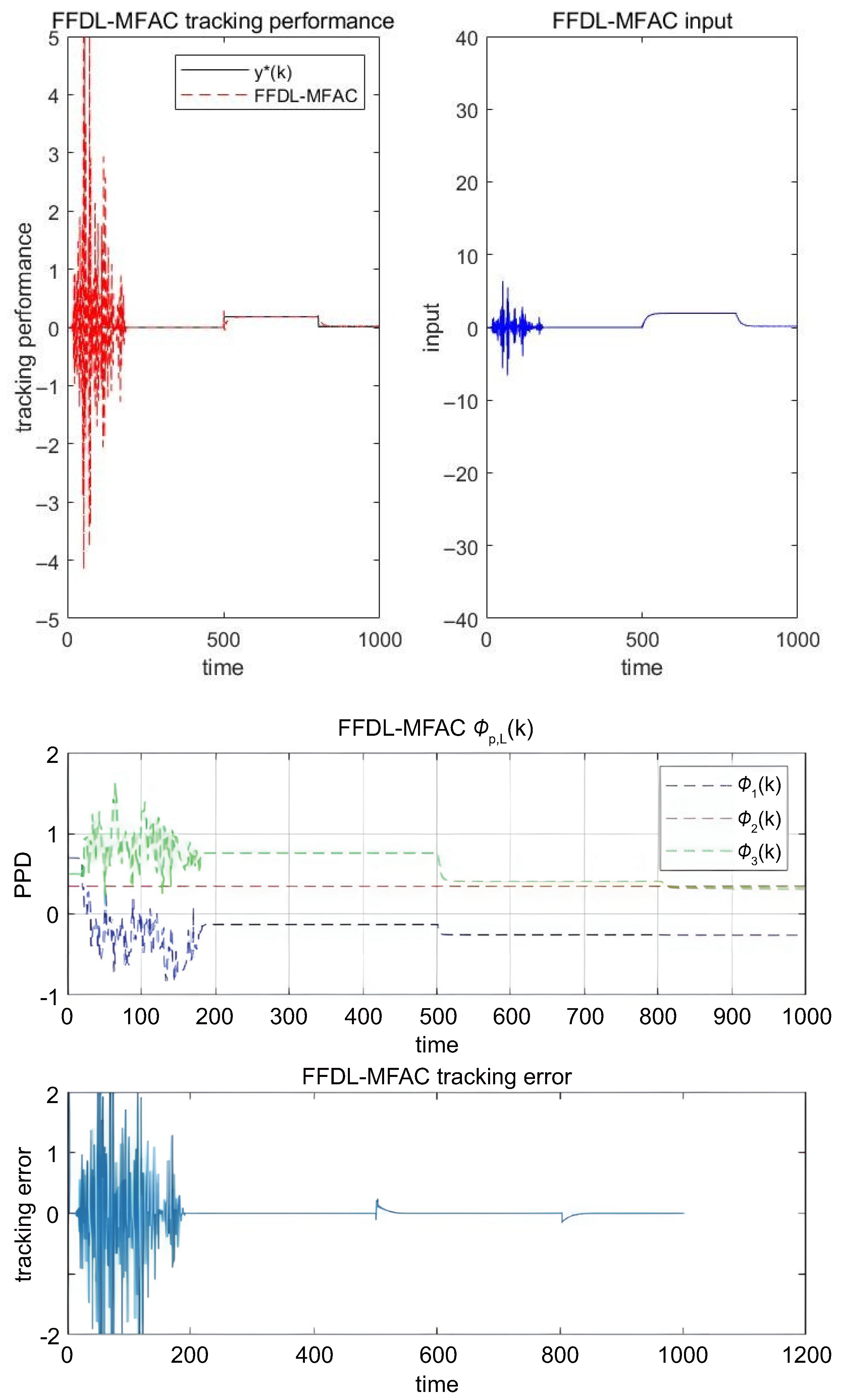

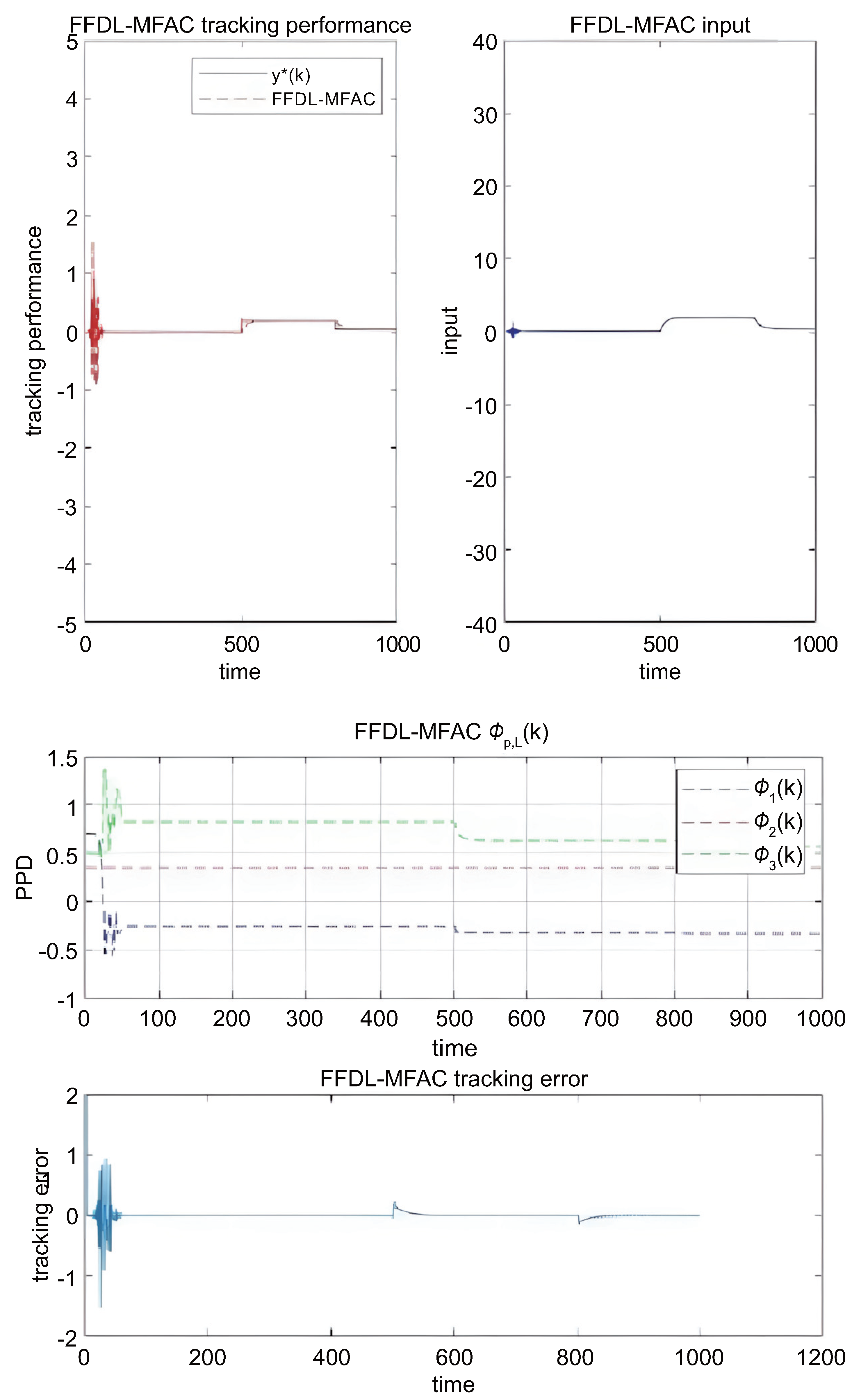

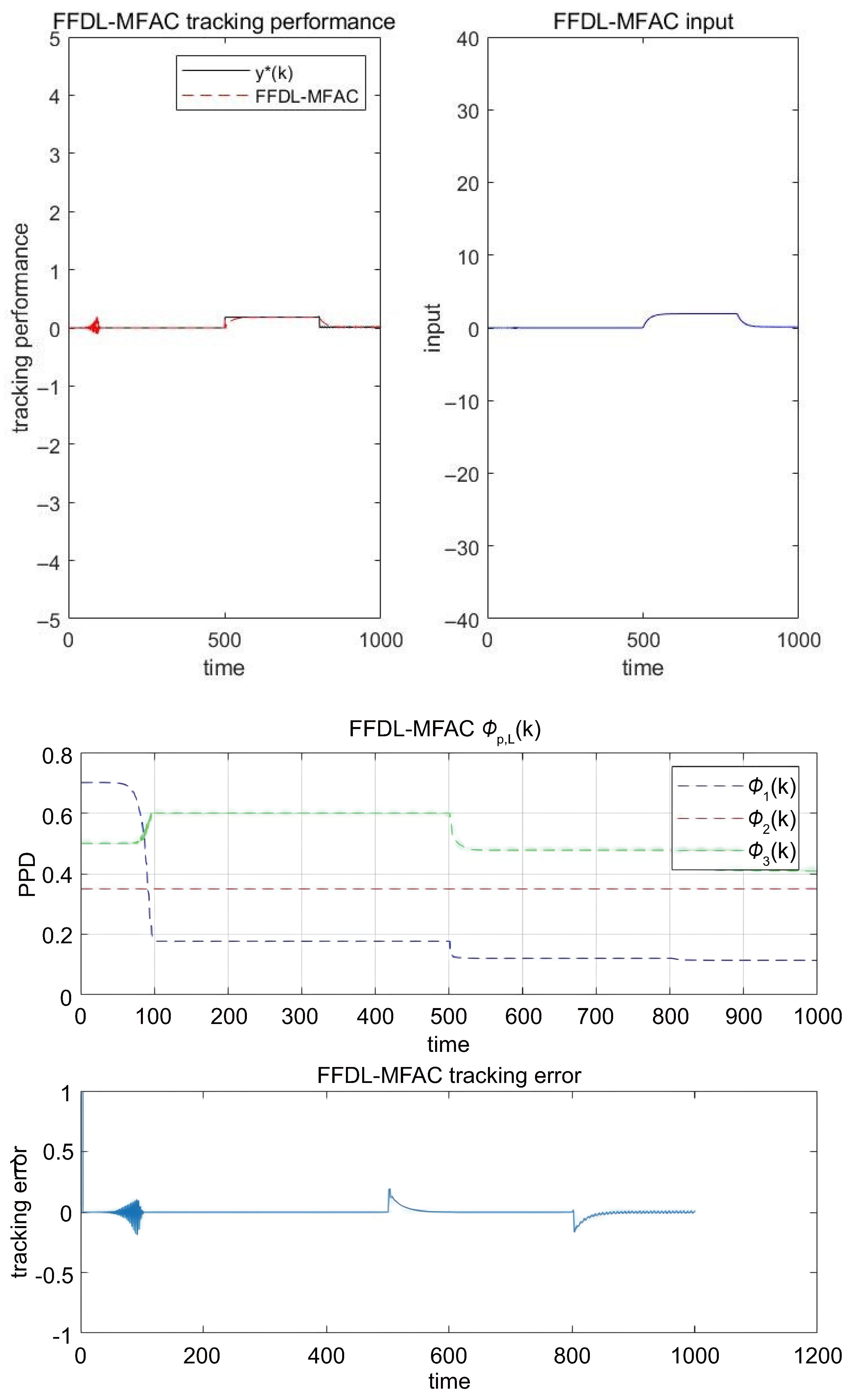

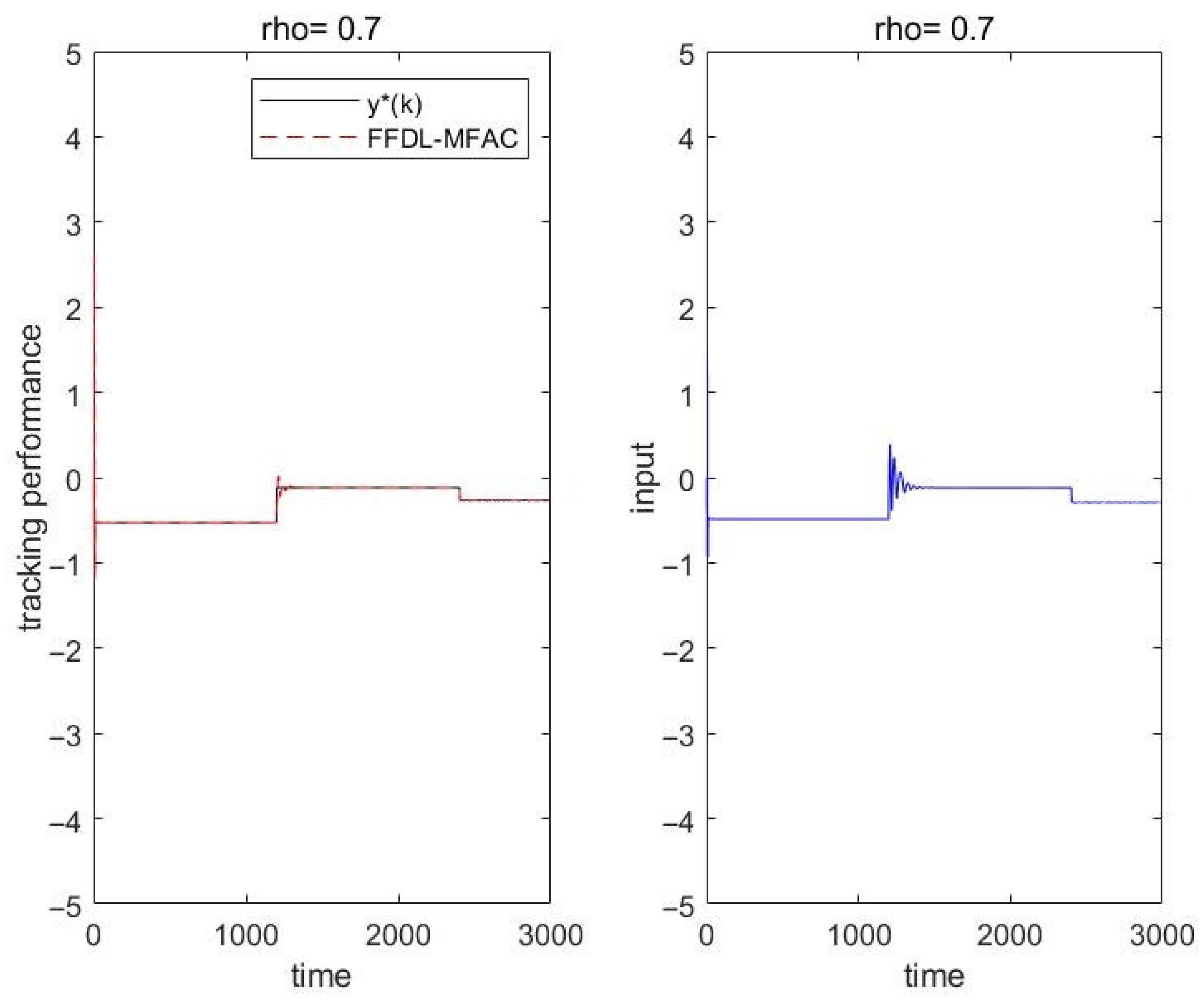

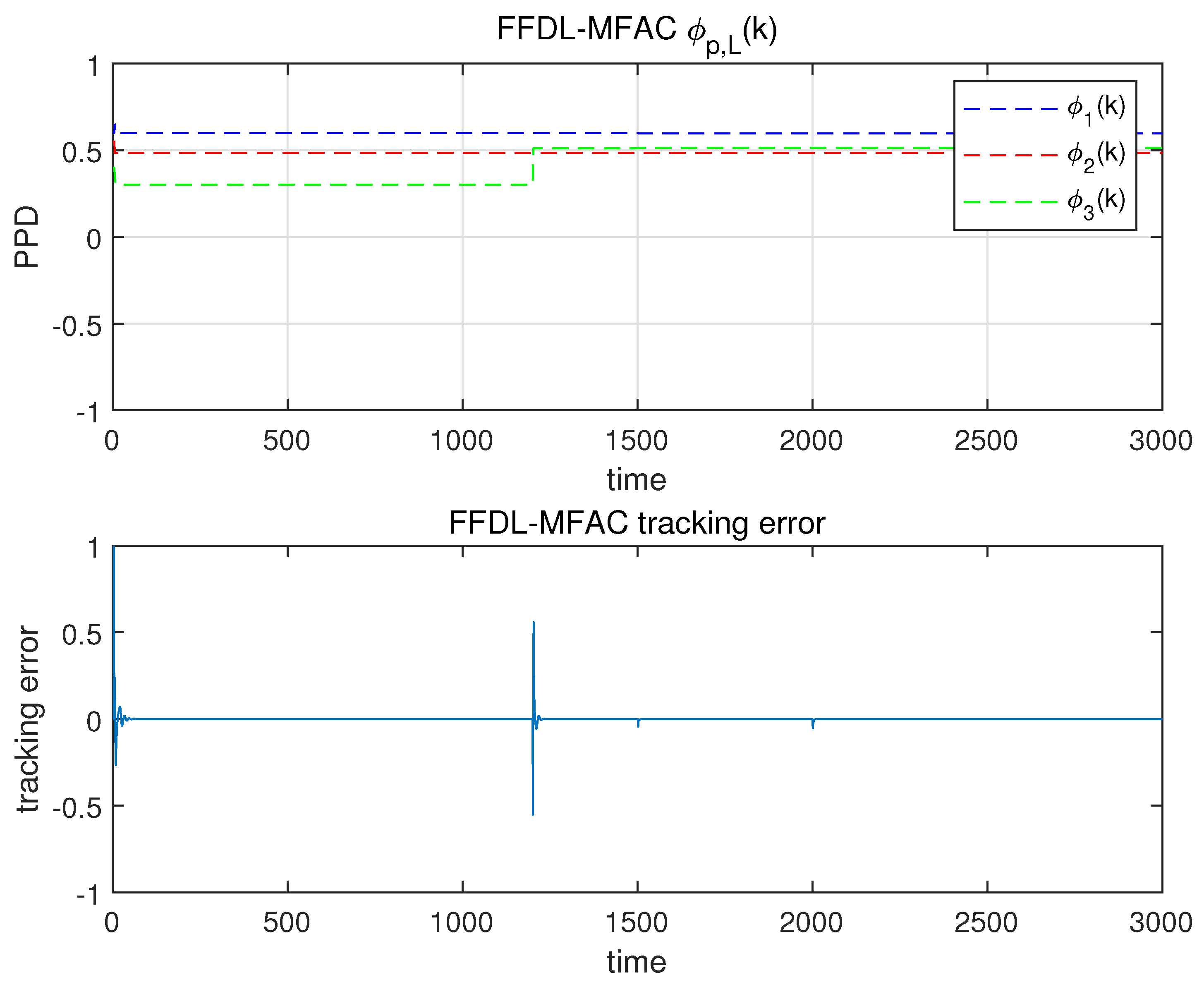

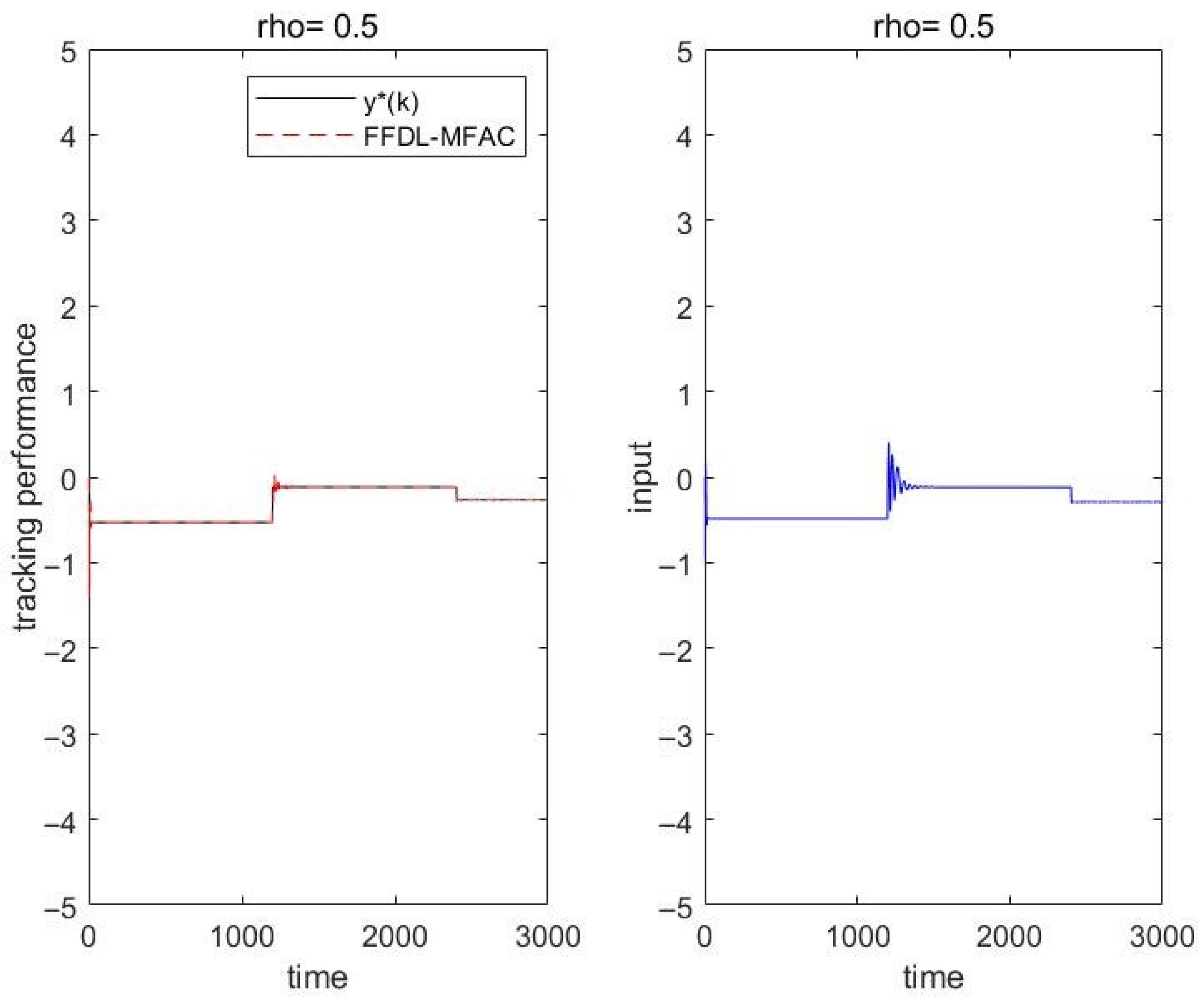

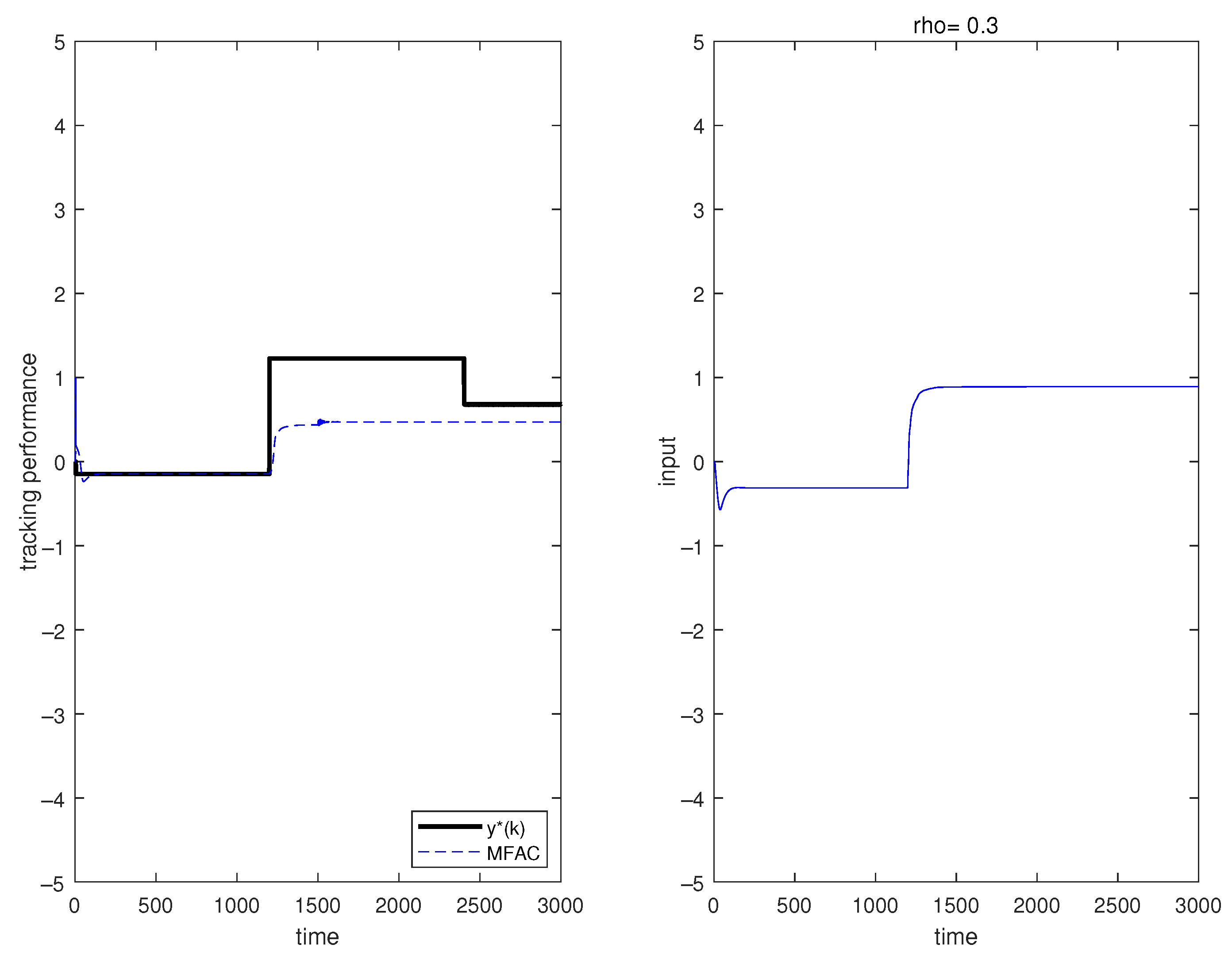

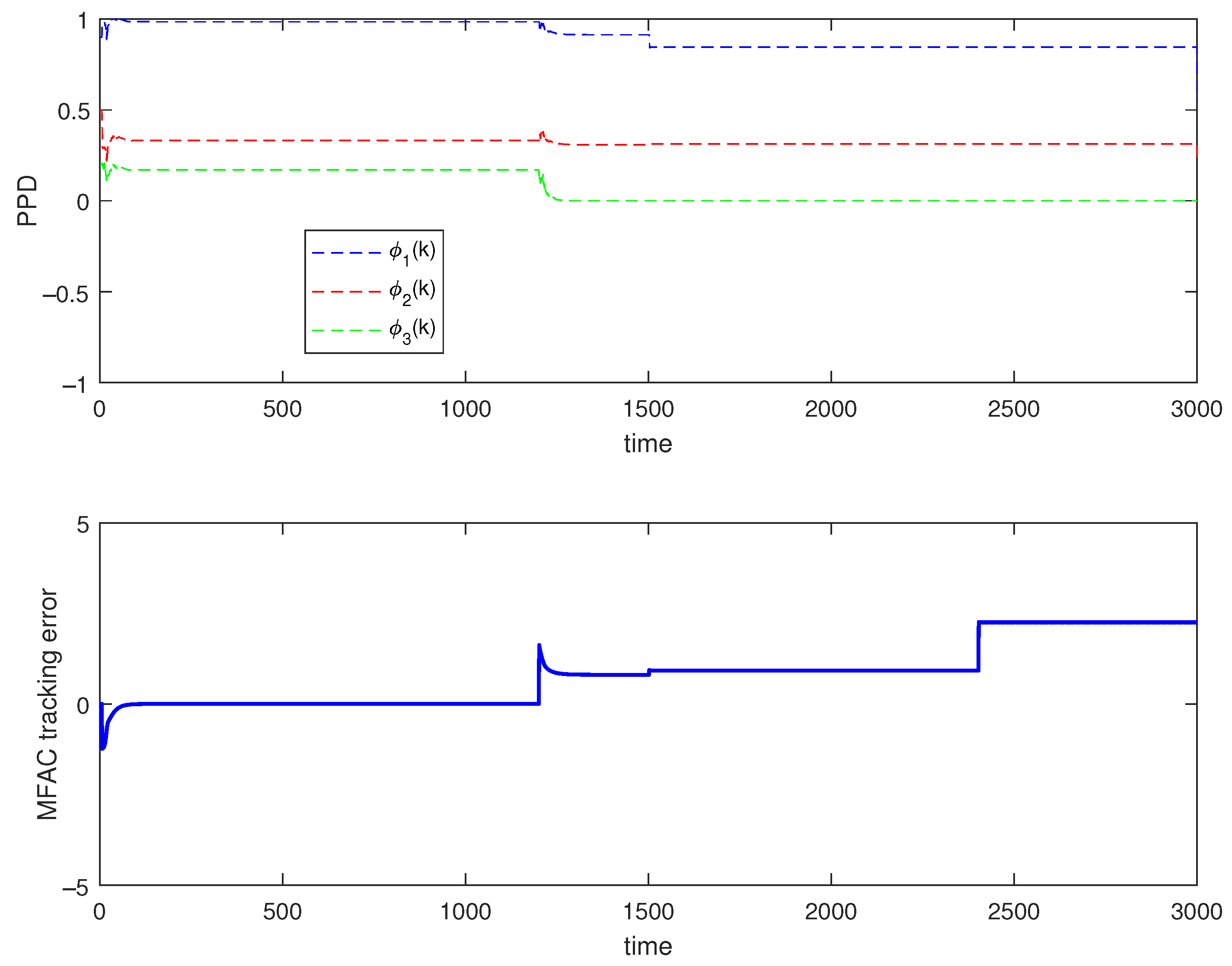

5. Simulation Example

5.1. Numerical Example

5.2. Actual Example

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sklansky, J. Learning systems for automatic control. IEEE Trans. Autom. Control 1996, 11, 6–19. [Google Scholar] [CrossRef]

- Yin, S.; Gao, H.; Kaynak, O. Data-driven control and process monitoring for industrial applications—Part I. IEEE Trans. Ind. Electron. 2014, 61, 6356–6359. [Google Scholar] [CrossRef]

- Xu, Z. A pattern recognition approach to model a class of complex systems. J. Comput. Inf. Syst. 2011, 7, 4636–4643. [Google Scholar]

- Qu, S.D. Pattern recognition approach to intelligent automation for complex industrial processes. J. Univ. Sci. Technol. Beijing 1998, 20, 385–389. [Google Scholar] [CrossRef]

- Saridis, G.N. Application of pattern recognition method to control systems. IEEE Trans. Autom. Control 1981, 26, 638–645. [Google Scholar] [CrossRef]

- Zhu, Q.; Onori, S.; Prucka, R. Pattern recognition technique based active set QP strategy applied to MPC for a driving cycle test. IEEE Am. Control Conf. 2015, 7, 4935–4940. [Google Scholar] [CrossRef]

- Yu, B.; Zhang, X.; Wu, L.; Chen, X. A novel postprocessing method for robust myoelectric pattern-recognition control through movement pattern transition detection. IEEE Trans. Hum.-Mach. Syst. 2020, 50, 32–41. [Google Scholar] [CrossRef]

- Xu, Z. Pattern Recognition Method of Intelligent Automation and Its Implementation in Engineering. Doctoral Dissertation, University of Science and Technology Beijing, Beijing, China, 2001. [Google Scholar]

- Wang, M.; Xu, Z.; Guo, L. Stability and stabilization for a class of complex production processes via LMIs. Optim. Control Appl. Methods 2019, 40, 460–478. [Google Scholar] [CrossRef]

- Sun, C.; Xu, Z.; Guo, L. Multi-dimensional moving pattern prediction based on multi-dimensional interval T-S fuzzy model. J. Control Decis. 2016, 31, 1569–1576. [Google Scholar]

- Hai, P.P.; Xia, C. Global robust optimal sliding mode control for uncertain affine nonlinear systems. J. Syst. Eng. Electron. 2009, 20, 838–843. [Google Scholar]

- Yu, S.; Guo, G.; Ma, Z. Global fast terminal sliding mode control for robotic manipulators. Int. J. Model. Identif. Control 2006, 1, 72–79. [Google Scholar] [CrossRef]

- Skruch, P. A terminal sliding mode control of disturbed nonlinear second-order dynamical systems. J. Comput. Nonlinear Dyn. 2016, 11, 054501. [Google Scholar] [CrossRef]

- Tayebi-Haghighi, S.; Piltan, F.; Kim, J.M. Robust composite high-order super-twisting sliding mode control of robot manipulators. Robotics 2018, 7, 13. [Google Scholar] [CrossRef]

- Guo, L.; Xu, Z.; Wang, Y. Dynamic modeling and optimal control for complex systems with statistical trajectory. Discret. Dyn. Nat. Soc. 2015, 2015, 245685. [Google Scholar] [CrossRef]

- Piltan, F.; TayebiHaghighi, S.; Sulaiman, N.B. Comparative study between ARX and ARMAX system identification. J. Int. J. Intell. Syst. Appl. 2017, 9, 25–34. [Google Scholar] [CrossRef]

- Kon, J.; Yamashita, Y.; Tanaka, T.; Tashiro, A.; Daiguji, M. Practical application of model identification based on ARX models with transfer functions. Control Eng. Pract. 2013, 21, 195–203. [Google Scholar] [CrossRef]

- Mobayen, S.; Tchier, F. A novel robust adaptive second-order sliding mode tracking control technique for uncertain dynamical systems with matched and unmatched disturbances. Int. Control Autom. Sust. 2017, 15, 1097–1106. [Google Scholar] [CrossRef]

- Yeh, Y.L. A Robust Noise-Free Linear Control Design for Robot Manipulator with Uncertain System Parameters. J. Actuators 2021, 10, 121. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, K.S. Iterative learning control applied to batch processes: An overview. J. Control Eng. Pract. 2007, 15, 1306–1318. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, H.; Liu, Y. Neural-network-based control scheme for a class of nonlinear systems with actuator faults via data-driven reinforcement learning method. J. Neurocomput. 2017, 239, 1–8. [Google Scholar] [CrossRef]

- Ahn, H.; Chen, Y.; Moore, K. Iterative learning control: Brief survey and categorization. IEEE Trans. Syst. Man. Cybern. Part C Appl. Rev. 2007, 37, 1099–1121. [Google Scholar] [CrossRef]

- Pierallini, M.; Angelini, F.; Mengacci, R. Iterative learning control for compliant underactuated arms. IEEE Trans. Syst. Man Cybern. Syst. 2023, 53, 3810–3822. [Google Scholar] [CrossRef]

- Zhou, M.; Li, T.; Zhang, C. Sliding mode iterative learning control with iteration-dependent parameter learning mechanism for nonlinear systems and its application. IEEE Trans. Autom. Sci. Eng. 2023, 21, 7052–7063. [Google Scholar] [CrossRef]

- Xu, Z.; Wu, J.; Guo, L. Modeling and optimal control based on moving pattern. In Proceedings of the 32nd Chinese Control Conference, Xi’an, China, 26–28 July 2013; pp. 7894–7899. Available online: https://ieeexplore.ieee.org/document/6640830 (accessed on 1 March 2024).

- Bu, X.H.; Hou, Z.S.; Zhang, H.W. Data driven multiagent systems consensus tracking using model free adaptive control. IEEE Trans. Neural Netw. Learn. Syst. 2018, 29, 1514–1524. [Google Scholar] [CrossRef]

- Li, X.Q.; Xu, Z.G.; Lu, Y.L.; Cui, J.R.; Zhang, L.X. Modified Model Free Adaptive Control for a Class of Nonlinear Systems with Multi-threshold Quantized Observations. Int. J. Control. Autom. Syst. 2021, 19, 3285–3296. [Google Scholar] [CrossRef]

- Xu, Z.; Wu, J. Data-driven pattern moving and generalized predictive control. In Proceedings of the 2012 lEEE Interational Conference on Systems, Man and Cybernetics, Seoul, Republic of Korea, 14–17 October 2012. [Google Scholar] [CrossRef]

- Hou, Z.S.; Xiong, S.S. On model-free adaptive control and its stability analysis. IEEE Trans. Autom. Control 2019, 11, 4555–4569. [Google Scholar] [CrossRef]

- Hou, Z.S.; Jin, S.T. Model Free Adaptive Control: Theory and Applications; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar] [CrossRef]

- Li, X.Q.; Xu, Z. Pattern-Moving-Based Partial Form Dynamic Linearization Model Free Adaptive Control for a Class of Nonlinear Systems. J. Actuators 2021, 10, 223. [Google Scholar] [CrossRef]

- Basohbat Novinzadeh, A.; Heydari, M.; Yaseri, M. Model-Free Adaptive Controller Design for Nonlinear system of an Air Vehicle pitch channel. Modares Mech. Eng. 2018, 17, 161–171. [Google Scholar]

- Gao, H.; Ma, G.; Lv, Y. Forecasting-based data-driven model-free adaptive sliding mode attitude control of combined spacecraft. J. Aerosp. Sci. Technol. 2019, 86, 364–374. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, Y.; Xie, X.; Zhang, H. Resilient model-free adaptive control for cyber-physical systems against jamming attack. J. Neurocomput. 2020, 413, 422–430. [Google Scholar] [CrossRef]

- Yongjun, D.; Jianhong, W.; Jinlong, Z.; Xi, L. Design of quadcopter attitude controller based on data-driven model-free adaptive sliding mode control. Int. J. Dyn. Control 2024, 12, 1404–1414. [Google Scholar] [CrossRef]

- Ren, C.; Jiang, H.; Li, C.; Sun, W.; Ma, S. Koopman-operator-based robust data-driven control for wheeled mobile robots. IEEE/ASME Trans. Mech. 2022, 28, 461–472. [Google Scholar] [CrossRef]

- Bu, X.; Dai, X.; Hou, R. Data-driven iterative learning trajectory-tracking control for wheeled mobile robot under constraint of velocity saturation. IET Cyber-Syst. Robot. 2023, 5, e12091. [Google Scholar] [CrossRef]

- Hou, R.; Cui, L.; Bu, X.; Yang, J. Distributed formation control for multiple non-holonomic wheeled mobile robots with velocity constraint by using improved data-driven iterative learning. Appl. Math. Comput. 2021, 395, 125829. [Google Scholar] [CrossRef]

- Huang, J.; Chen, H.; Shen, C. Event-Triggered Model-Free Adaptive Control for Wheeled Mobile Robot with Time Delay and External Disturbance Based On Discrete-Time Extended State Observer. J. Dyn. Syst. Meas. Control 2024, 146, 021005. [Google Scholar] [CrossRef]

- Tutsoy, O.; Barkana, D.E. Model free adaptive control of the under-actuated robot manipulator with the chaotic dynamics. J. ISA Trans. 2021, 118, 106–115. [Google Scholar] [CrossRef] [PubMed]

- Earl, R.; Nicholson, J. The Concise Oxford Dictionary of Mathematics, 6th ed.; Oxford University Press: Oxford, UK, 2021. [Google Scholar] [CrossRef]

| Class No. | Class Center | Class Radius |

|---|---|---|

| 1 | (−0.0180, −0.0073) | 2.9853 |

| 2 | (7.3567, 6.2062) | 5.5453 |

| 3 | (−13.0390, −0.8266) | 1.5866 |

| 4 | (0.1367, 1.2690) | 1.1211 |

| 5 | (10.9540, −2.9166) | 2.4866 |

| 6 | (−7.1804, 1.8080) | 2.8153 |

| 7 | (3.6094, −0.2141) | 2.5436 |

| Class No. | Class Center | Class Radius |

|---|---|---|

| 1 | (−0.5017, −0.5580) | 0.4961 |

| 2 | (0.1857, 0.6282) | 0.4600 |

| 3 | (1.8278, −0.4929) | 0.4331 |

| 4 | (−2.9019, −0.7778) | 0.6773 |

| 5 | (−1.7517, 0.1289) | 0.4487 |

| 6 | ( 0.6954, −0.4751) | 0.4388 |

| 7 | (1.4996, 0.5842) | 0.5166 |

| 8 | (−0.8493, 0.4924) | 0.3953 |

| 9 | (3.0346, 0.2092) | 0.6028 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Huyan, M. Model-Free Adaptive Control Based on Pattern Class Variables for a Class of Unknown Non-Affine Nonlinear Discrete-Time Systems. Mathematics 2025, 13, 2717. https://doi.org/10.3390/math13172717

Wu J, Huyan M. Model-Free Adaptive Control Based on Pattern Class Variables for a Class of Unknown Non-Affine Nonlinear Discrete-Time Systems. Mathematics. 2025; 13(17):2717. https://doi.org/10.3390/math13172717

Chicago/Turabian StyleWu, Jinxia, and Mengnan Huyan. 2025. "Model-Free Adaptive Control Based on Pattern Class Variables for a Class of Unknown Non-Affine Nonlinear Discrete-Time Systems" Mathematics 13, no. 17: 2717. https://doi.org/10.3390/math13172717

APA StyleWu, J., & Huyan, M. (2025). Model-Free Adaptive Control Based on Pattern Class Variables for a Class of Unknown Non-Affine Nonlinear Discrete-Time Systems. Mathematics, 13(17), 2717. https://doi.org/10.3390/math13172717