Robust Higher-Order Nonsingular Terminal Sliding Mode Control of Unknown Nonlinear Dynamic Systems

Abstract

1. Introduction

- (1)

- Proposes a comprehensive total robustness MFTSMC framework without using adaptive and/or date-driven online models. The MFTSMC existence theorem is proved with conditions of the monotonicity and the boundness, several corresponding monotonically decreasing controllers are formulated, the singularity origin is eradicated from the model-based TMSMC without extra effort on revising the conventional TSM, the chattering effect is removed or reduced by using Lyapunov negative definite stability embedded in the MFTSMC in conjunction with the other measures, and the other values added on the new approach are analyzed and simulated as well. It is directly extendable to MIMO interconnected nonlinear systems. In addition, a comparative proposition shows the SMC equivalency of the new method and model-based methods in terms of sliding mode manifold and Lyapunov stability.

- (2)

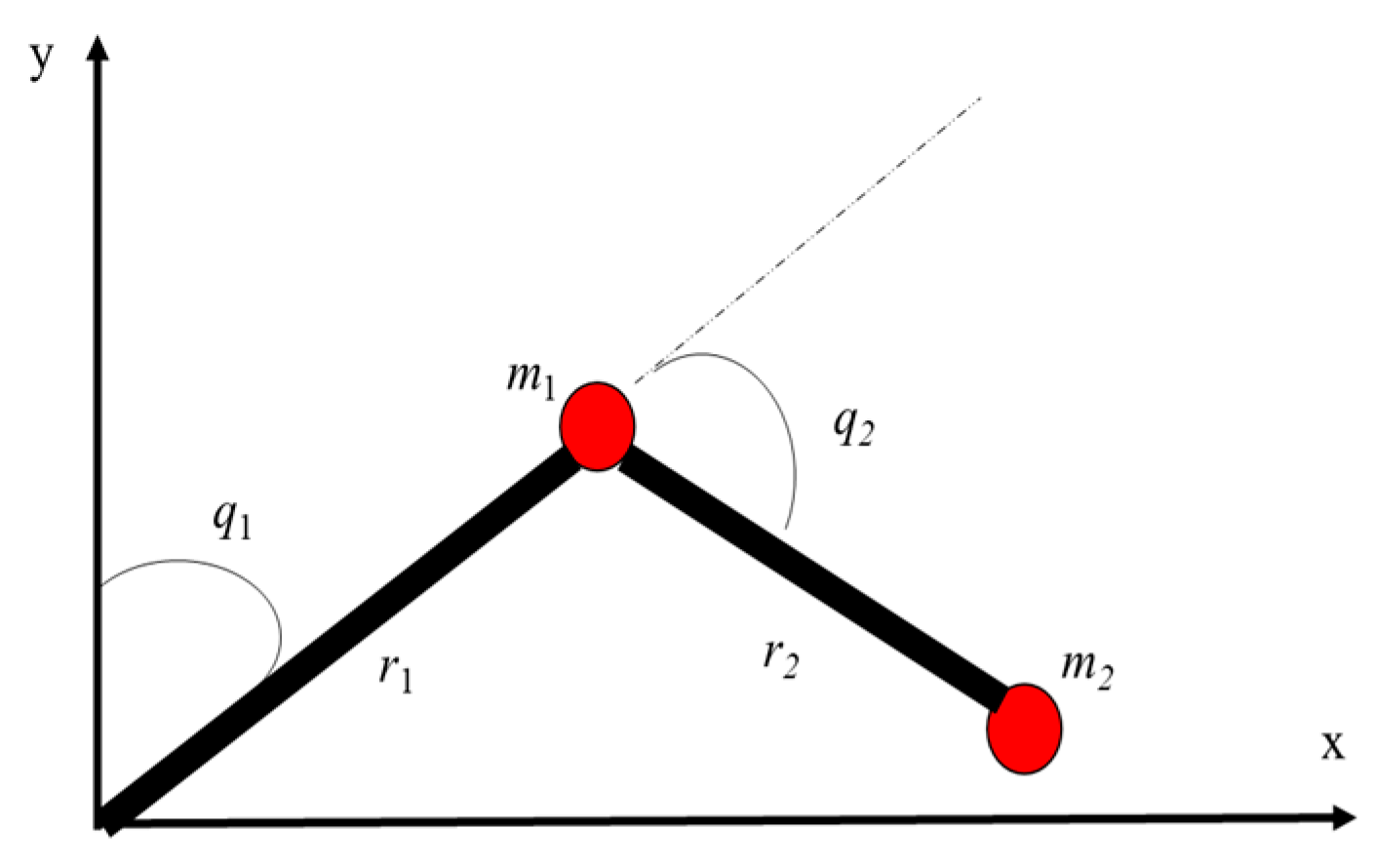

- Regarding the significance to potential applications relating to simplicity and robustness, finite-time convergence, and reliable performance under various conditions, the MFTSMC has the capacity to handle uncertainties and nonlinearities to make it a powerful tool in advanced control systems across a broad range of industries. Simulation demonstrations to some critical challenging examples are conducted and compared with model-based approaches for validation, expansion, and applications. Regarding the practical background, the control of a two-link rigid robotic manipulator with two input and two output (TITO) operational mode, a typical multi-degree interconnected nonlinear dynamics tool, is demonstrated to reflect the widely demanded applications in electrical, mechanical, and process industries to reduce labor and improve applicability and reliability in operation.

2. Preliminary Information

2.1. Dynamic Plant

2.2. Higher-Order TSM Manifold

2.3. Finite-Time Stability of Homogeneous Systems

3. Model-Free Terminal Sliding Mode Control (MFTSMC)

3.1. Design of MFTSMC Systems

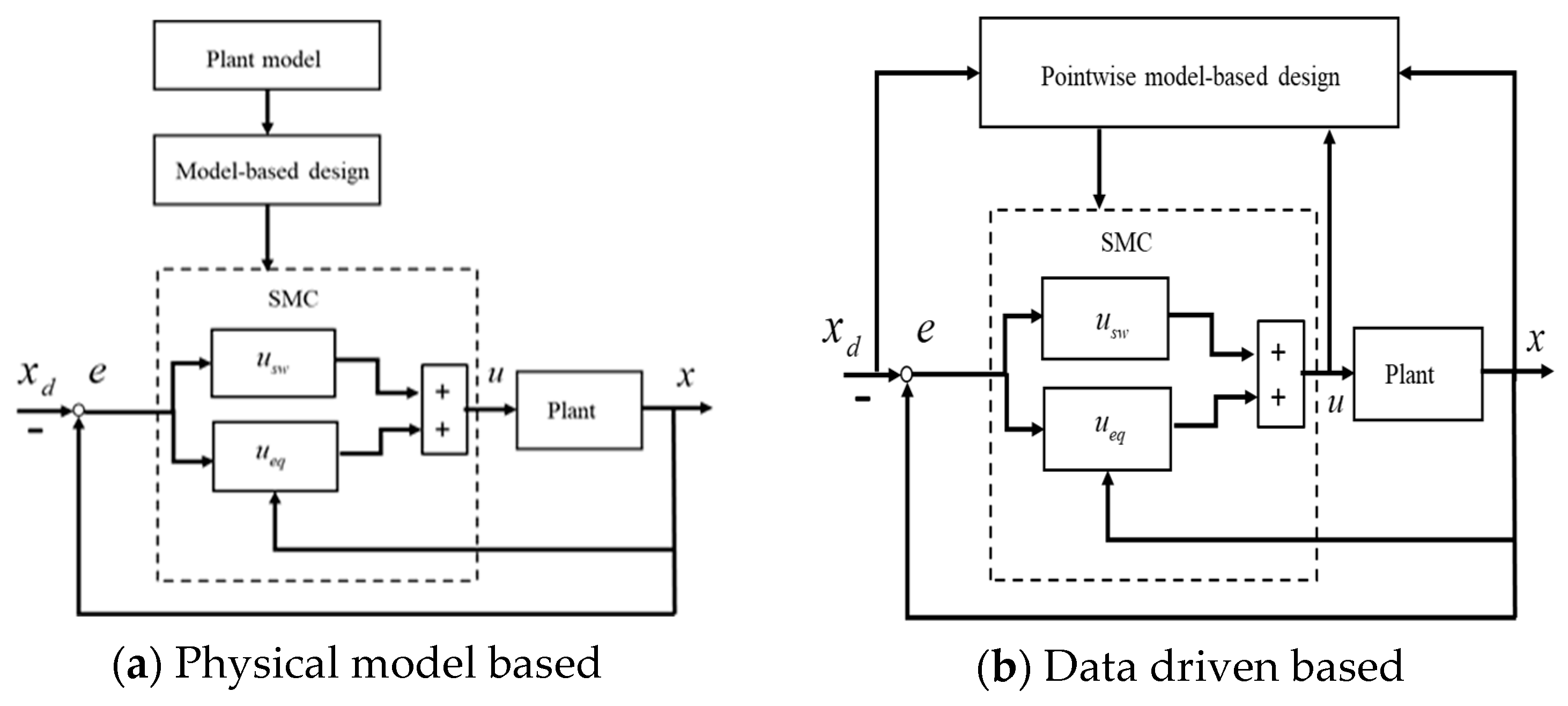

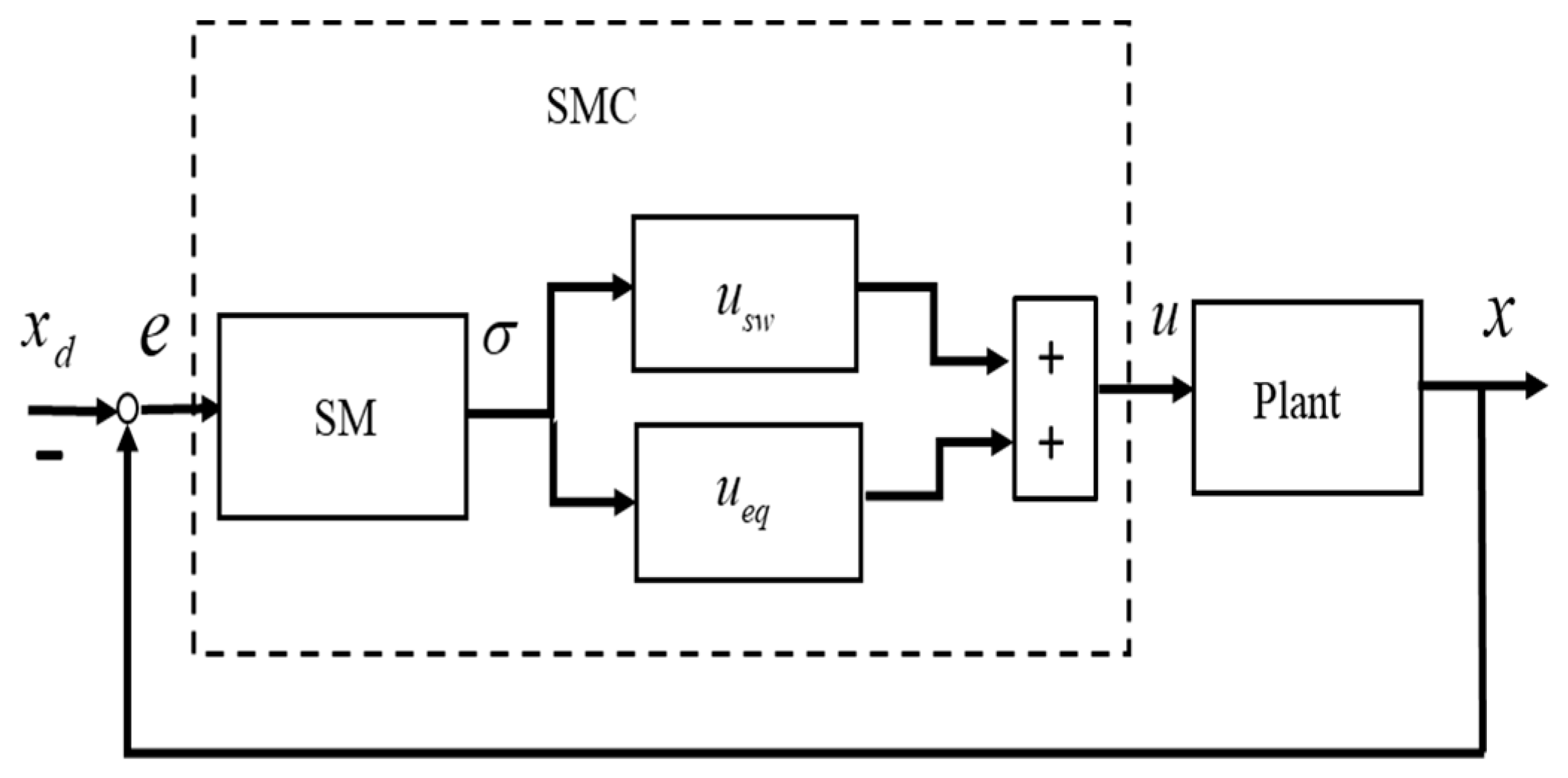

3.2. Model-Free SMC

- (1)

- Without a model, it is difficult to ANALYZE stability, performance bounds, or robustness formally. Yes, it is true. Regarding DESIGN on the other hand, control Lyapunov functions are in data-driven forms, such as the Lyapunov functions formulated from sliding mode, and then determine the controller output by solving the Lyapunov differential inequality in the MFRUC.

- (2)

- Model-free methods are reactive, not predictive. This is an obvious characteristic. This study does not involve predictive control.

- (3)

- Model-free controllers may work “well enough” but rarely achieve optimal control (like minimum energy, fastest response, etc.). They often trade off performance for simplicity and robustness. Yes, this MFTSMC cannot provide global optimization, but at most a trial-and-error local optimization.

- (4)

- Most data-driven model-free approaches (like reinforcement learning or adaptive controllers) requires an initial learning phase or training phase, which may not be safe or feasible in real-time systems. The MFTSMC does not require such an iterative learning routine.

- (5)

- No insight into system dynamics is the common drawback for model-free control. Hopefully, this study provides a possibility to integrate the model-based qualitative knowledge into its control system interpretation and tuning.

- (6)

- Tuning controller is empirical, relies on trial and error, heuristics, or data-driven optimization. This can be time-consuming, especially in systems with delays, noise, or nonlinearities. Model-free tuning is even more challenging. This study provides a possibility to integrate the model-based qualitative knowledge into its controller tuning, which is demonstrated in the simulation setups.

- (1)

- Proportional and Integral (PI) function

- (2)

- Continuous (non-switching) SMC

4. Property Analysis

4.1. Singularity Analysis

4.2. Mitigation of Fractional Powers—Practical Implementation

- (1)

- Smoothing approximations: Replace the fractional power terms with smooth, bounded approximations (e.g., using a saturation or sigmoid function) in a boundary layer near the origin to prevent singularities or excessive sensitivity to noise [36].

- (2)

- Signal filtering: Apply low-pass filtering to the measured signals before computing the fractional power terms to reduce the impact of high-frequency noise. Care is taken to minimize phase lag and avoid destabilizing the feedback loop [37].

- (3)

- Discretization handling: In digital implementations, the fractional exponents can be regularized near zero to avoid numerical instability (e.g., replacing with [37]).

- (4)

- Alternative sliding surfaces: If needed, equivalent sliding surfaces using higher-order error dynamics (e.g., super-twisting-type surfaces or robust integral terms) can be considered, which maintain robustness without relying on fractional powers [38].

4.3. Chattering Suppression

- (1)

- Dealing with stable oscillation by removing negative semi-definite stability condition with negative definite stability in the controller design, and consequently, removing the constant oscillation in the neighbourhood of the origin.

- (2)

- Dealing with switching hard nonlinearity by increasing the sliding mode manifold boundary layer thickness . To reduce the hard nonlinearity, induce a chattering opportunity in the vicinity of the convergent point (normally ). It is noted that properly enlarged thickness does not reduce accuracy, as once on the sliding mode boundary, the error vector converges towards the origin in finite time. The combination of the switching control and equivalent control forms a control law with saturation function [39].

- (3)

- Dealing with fractional power nonlinearity by reducing the relative degree of the systems. Let m be the extra order of the unmodeled dynamics from a given nth order dynamic plant. Thus, a limit cycle/periodic motion may occur in the system with power-fractional SM (PFSM) while the total relative degree of the actuator, plant and sliding surface is above two, because the Nyquist plot of the linear part intersects the negative part of the real axis in this case [19]. To cope with this problem, the proposed approach adopts a mode-free extended state observer ([24,40]) with dynamic order n + m and accordingly increases the dynamic order of the sliding mode manifold to n + m − 1, so that the resultant relative degree is (n + m) − (n + m − 1) = 1.

- (4)

- Avoiding high gain control, in general, the MFTSMC has a relatively large range of gains for achieving almost the same operational performance at the system outputs. Try to use low gain while keeping the similar output performance, and consequently, avoid the limit cycle induced by high gain in the nonlinear dynamic systems.

4.4. Nonlinear Dynamic Inversion (NDI) Though MFTSMC

4.5. Robustness Analysis [42]

4.6. Controller Parameter Tuning

5. Case Studies

- (1)

- selecting three bench tests on nonlinear dynamic plants from the representative numerical models to the real physical plant model;

- (2)

- designing the MFTSMC system to accommodate the performance in robust stability, transient/steady state response, removing singularity, supressing chattering effects;

- (3)

- developing the simulation platform with MATLAB (R2024a)/Simulink and running the simulation tests with robust parameter tuning;

- (4)

- analyzing the MFTSMC performance, as reflected in the generated simulation plots;

- (5)

5.1. Bench Test Plants

5.2. Selection of the Controllers and Parameters

- (1)

- Define the control objectives: stabilization, state response, control input, etc.

- (2)

- Identify the control parameters, as specified with two or three parameters for each controller.

- (3)

- Set up constraints for all the controller parameters’ positive and proposal gains larger than estimated uncertainty bounds.

- (4)

- Start with an initial guess or reasonable solution to test the knowledge and experience of the control systems.

- (5)

- Test the different solutions, as explained in Section 4.5 <Controller parameter tuning>.

- (6)

- Iterate the test procedure to narrow the range or adjust around the promising solutions.

- (7)

- Choose the solution that best meets the control objectives while satisfying all the constraints.

5.3. Discussions on the Simulated System Performance

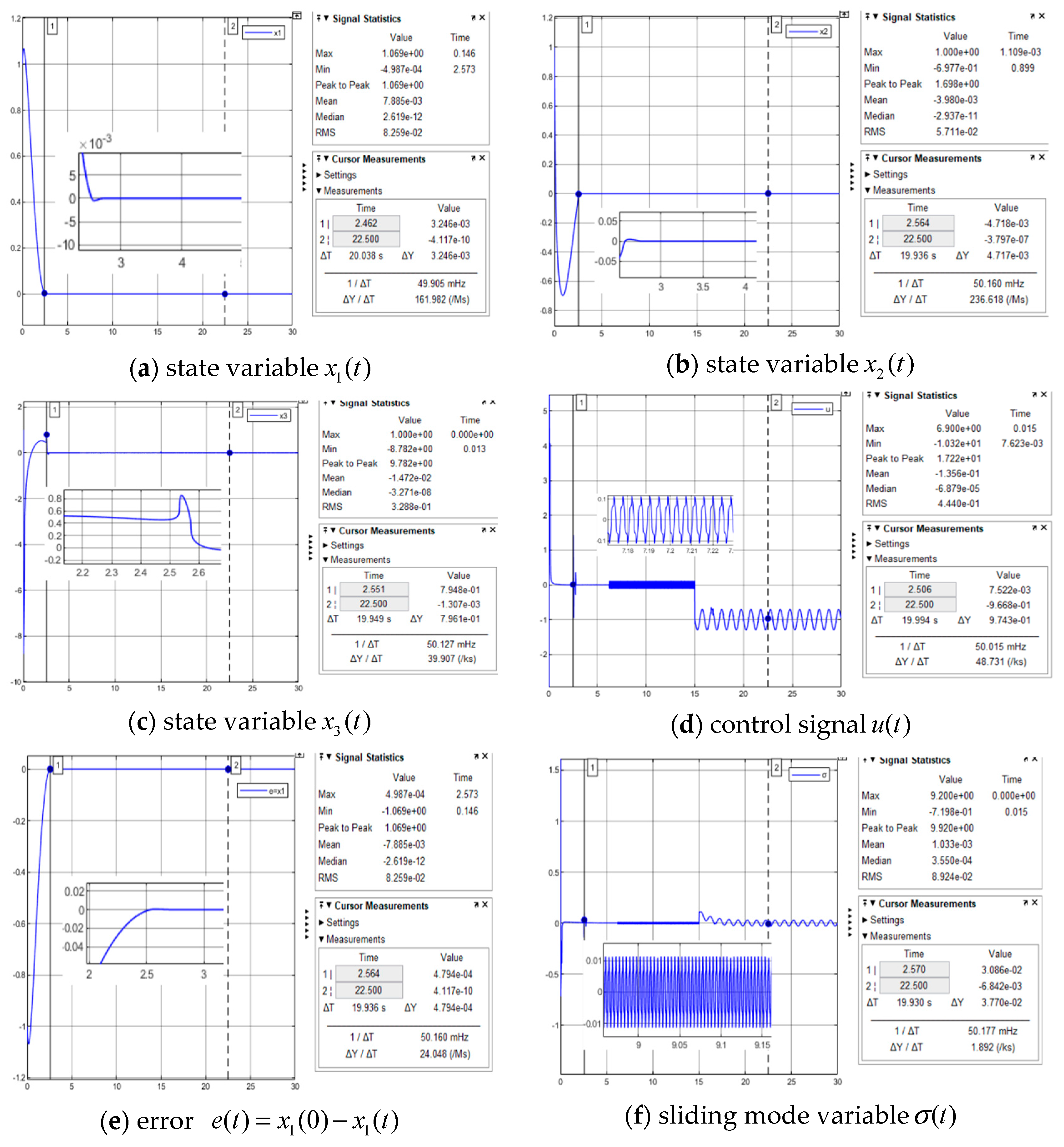

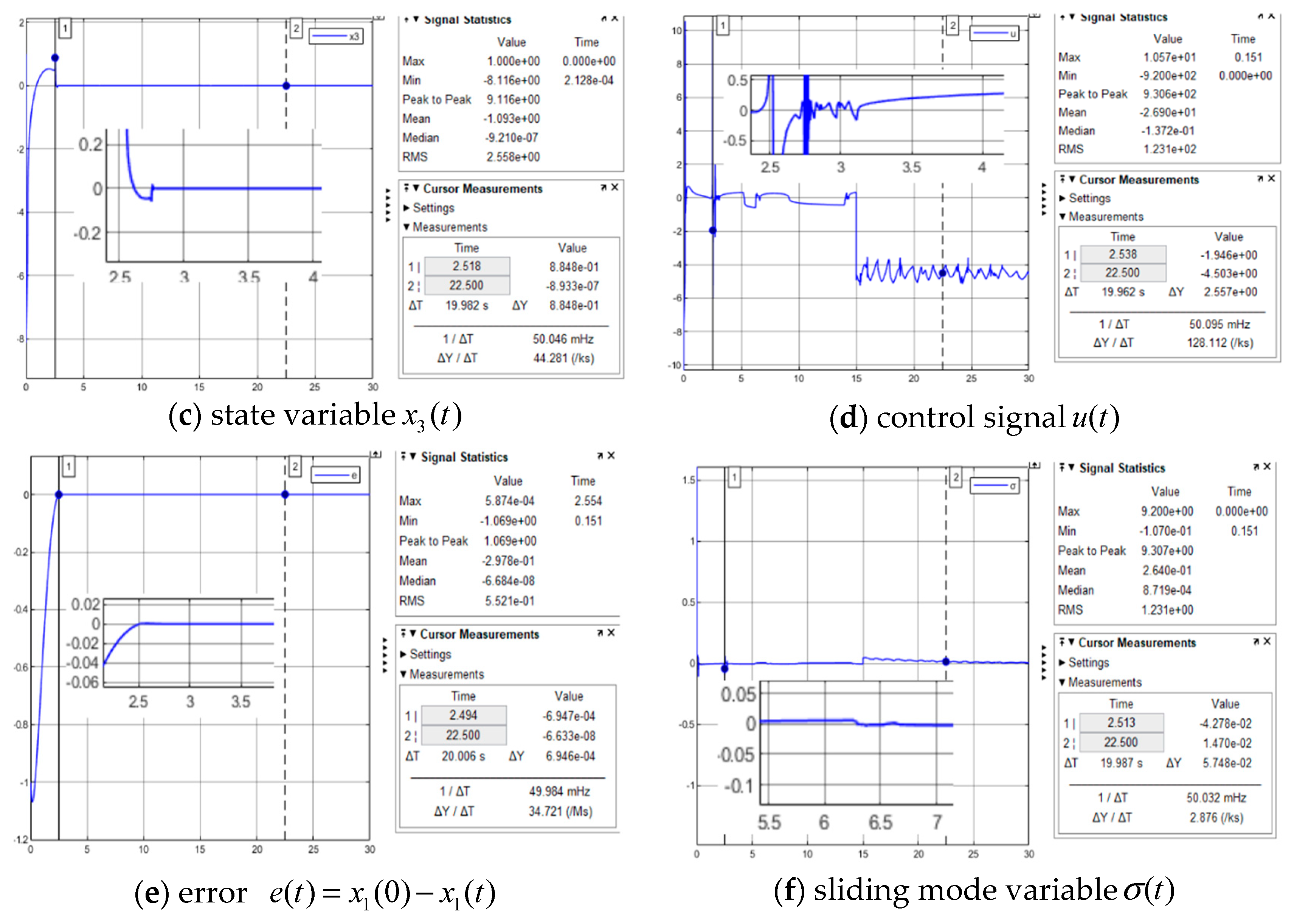

- (1)

- The plots in Figure 5 show off the achieved stabilization of the unstable dynamic plant. The states with transient response and steady errors are achieved from the design objectives. The tracking errors first reach TSM at about , and then the state vector converges to at about = 2.5 s.

- (2)

- Regarding the controller tuning for Figure 5, initially set to establish the system, and fine-tune to , while the plots are almost the same within the tested domain of . In case of low gain (not enough strength to keep the control monotonicity), such as gains with , the simulation is stopped by numerical errors.

- (3)

- There is no singularity problem observed in the operational range, as the MFTSMC is designed without involving the negative derivative of the TSM .

- (4)

- Three measures are embedded in the MFTSMC to reduce the chattering effect at the controller output: (a) using the negative definite Lyapunov stability condition rather than model-based negative semi-definite Lyapunov stability condition ; (b) accommodating the system relative degree, where the plant dynamic order is known in the simulation to imply that there is no missed unmodelled dynamic order, and the system relative degree is 3(plant)-2(TSM) = 1 < 3; (c) maintaining the sliding mode boundary thickness , which does not need to be increased.

- (5)

- Robustness has been tested in (a) the controller parameter () tuning, as in the Lyapunov differential inequality used in the controller design , where there exists a domain satisfying the inequality, for example, (), (b) plant dynamic variations (), and (c) external disturbance rejection, where the same performance is kept as shown in Figure 6. The whole system uncertainty is unknown but bounded. The controller parameter tuning covers the choice to supress the uncertainties to stratify the Lyapunov differential inequality and avoid the chattering effect. The concept of the total robustness controller tuning against plant uncertainties is well demonstrated with the computational experiments. The MFTSMC has much stronger robustness compared with those model-based approaches [5]. This is because of the model-based TSMC using the nominal model. Determining the equivalent control involves the percentage of the uncertainty with ( and are the absolute values of uncertainty and nominal model, respectively), and MFTSMC involves uncertainty in control.

- (6)

- For rejection of external disturbance added at the control input, refer to plant (17). The external disturbance in the simulation is considered in the form of , entered at the control input at , which is the same as that used [5] in attenuating the external disturbance effectively and maintaining the same performance at the state outputs. Figure 6 shows the simulation outcomes.

- (7)

- (1)

- The same tuning process/observations/discussions are not repeated as those described in the first plant simulation studies. This demonstrates that the MFTMSC is applicable to the nonlinear non-affine system as well.

- (2)

- For dealing with chattering, the same measures (a) and (b) are kept as with the first system control; (c) enlarge the sliding mode boundary thickness starting from , which has been tested in the range of having chattering with the amplitude . It is noted that the state vector output is the same in all the tested cases no matter whether chattering appeared or not at the controller output.

- (3)

- The MFTSMC robustness has been tested again in (a) the controller parameter () tuning and (2) plant dynamic variations (), in which the same performance is kept as shown in Figure 7.

- (4)

- Rejection of external disturbance that is the same as used with the first control system, added at the control input. The same satisfactory performance is observed as with those in the first control system. Due to the length of the study, the plots are not shown in the draft.

- (5)

- While applying the controller with the second plant for both plants, the fact that the same performance was achieved gives further insight that the MFTSMC can be conveniently expanded for switching control, while the whole system switches from plant 1 to plant 2, and vice versa.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shtessel, Y.; Edwards, C.; Fridman, L.; Levant, A. Sliding Mode Control and Observation; Birkhauser: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Slotine, J.J.E.; Li, W. Applied Nonlinear Control; Prentice Hall: Hoboken, NJ, USA, 1991. [Google Scholar]

- Bandyopadhyay, B.; Deepak, F.; Kim, K.S. Sliding Mode Control Using Novel Sliding Surfaces; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Yu, X.; Feng, Y.; Man, Z. Terminal sliding mode control-An overview. IEEE Open J. Ind. Electron. Soc. 2021, 2, 36–52. [Google Scholar] [CrossRef]

- Yang, J.; Yu, X.; Zhang, L.; Li, S. A Lyapunov-based approach for recursive continuous higher order nonsingular terminal sliding-mode control. IEEE Trans. Autom. Control 2021, 66, 4424–4431. [Google Scholar] [CrossRef]

- Yan, X.; Spurgeon, S.K.; Edwards, C. Variable Structure Control of Complex Systems; Communications and Control Engineering; Springer: London, UK, 2017. [Google Scholar]

- Nasiri, M.; Mobayen, S.; Arzani, A. PID-type terminal sliding mode control for permanent magnet synchronous generator-based enhanced wind energy conversion systems. CSEE J. Power Energy Syst. 2022, 8, 993–1003. [Google Scholar] [CrossRef]

- Man, Z.; Yu, X. Terminal sliding mode control of MIMO linear systems. IEEE Trans. Circuits Syst. I Regul. Pap. 1997, 44, 1065–1070. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, X.; Man, Z. Terminal sliding mode control design for uncertain dynamic systems. Syst. Control Lett. 1998, 34, 281–288. [Google Scholar] [CrossRef]

- Feng, Y.; Yu, X.; Man, Z. Non-singular terminal sliding mode control of rigid manipulators. Automatica 2002, 38, 2159–2167. [Google Scholar] [CrossRef]

- Feng, Y.; Yu, X.; Han, F. On nonsingular terminal sliding-mode control of nonlinear systems. Automatica 2013, 49, 1715–1722. [Google Scholar] [CrossRef]

- Hou, Z.; Xiong, S. On model-free adaptive control and its stability analysis. IEEE Trans. Autom. Control 2019, 64, 4555–4569. [Google Scholar] [CrossRef]

- Castellanos-Cárdenas, D.; Posada, N.L.; Orozco-Duque, A.; Sepúlveda-Cano, L.M.; Castrillón, F.; Camacho, O.E.; Vásquez, R.E. A review on data-driven model-free sliding mode control. Algorithms 2024, 17, 543. [Google Scholar] [CrossRef]

- Mahalle, M.; Ramezani, A.; Moarefianpour, A. Adaptive terminal sliding mode active fault-tolerant control for a class of uncertain nonlinear systems with application of aircraft wing model with actuator faults. Int. J. Syst. Sci. 2024, 55, 1259–1269. [Google Scholar] [CrossRef]

- Wang, L.; Chai, T.; Zhai, L. Neural-network-based terminal sliding-mode control of robotic manipulators including actuator dynamics. IEEE Trans. Ind. Electron. 2009, 56, 3296–3304. [Google Scholar] [CrossRef]

- Chu, Y.; Hou, S.; Fei, J. Continuous terminal sliding mode control using novel fuzzy neural network for active power filter. Control Eng. Pract. 2021, 109, 104735. [Google Scholar] [CrossRef]

- Zhu, X.; Deng, Y.; Zheng, X.; Zheng, Q.; Liang, B.; Liu, Y. Online reinforcement-learning-based adaptive terminal sliding mode control for disturbed bicycle robots on a curved pavement. Electronics 2022, 11, 3495. [Google Scholar] [CrossRef]

- Lee, H.; Utkin, V.I. Chattering suppression methods in sliding mode control systems. Annu. Rev. Control 2007, 31, 179–188. [Google Scholar] [CrossRef]

- Boiko, I.; Fridman, L. Analysis of chattering in continuous sliding-mode controllers. IEEE Trans. Autom. Control 2005, 50, 1442–1446. [Google Scholar] [CrossRef]

- Seshagiri, S.; Khalil, H.K. On introducing integral action in sliding mode control. In Proceedings of the 41st IEEE Conference on Decision and Control, Las Vegas, NV, USA, 10–13 December 2002; pp. 1473–1478. [Google Scholar] [CrossRef]

- Pan, Y.; Yang, C.; Pan, L.; Yu, H. Integral Sliding Mode Control: Performance, Modification, and Improvement. IEEE Trans. Ind. Inf. 2018, 14, 3087–3096. [Google Scholar] [CrossRef]

- Yu, S.; Yu, X.; Shirinzadeh, B.; Man, Z. Continuous finite-time control for robotic manipulators with terminal sliding mode. Automatica 2005, 41, 1957–1964. [Google Scholar] [CrossRef]

- Pérez-Ventura, U.; Mendoza-Avila, J.; Fridman, L. Design of a proportional integral derivative-like continuous sliding mode controller. Int. J. Robust. Nonlinear Control 2021, 31, 3439–3454. [Google Scholar] [CrossRef]

- Carvalho, A.D.; Pereira, B.S.; Angélico, B.A.; Laganá, A.A.M.; Justo, J.F. Model-free control applied to a direct injection system: Experimental validation. Fuel 2024, 358 Pt A, 130071. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, W.; Li, S.; Chen, Q.; Na, J.; Ding, H. U-control-a universal platform for control system design with inversion/cancellation of nonlinearity, dynamic and coupling through model-based to model-free procedures. Int. J. Syst. Sci. 2025, 56, 484–501. [Google Scholar] [CrossRef]

- Gambhire, S.J.; Kishore, D.R.; Londhe, P.S.; Pawar, S.N. Review of sliding mode based control techniques for control system applications. Int. J. Dyn. Control 2021, 9, 363–378. [Google Scholar] [CrossRef]

- Yu, S.; Wu, H.; Kang, S.; Ma, J.; Xie, M.; Dai, L. Model-free robust motion control for biological optical microscopy using time-delay estimation with an adaptive RBFNN compensator. ISA Trans. 2024, 149, 365–372. [Google Scholar] [CrossRef] [PubMed]

- Hou, Z.; Yu, X.; Lu, P. Terminal sliding mode control for quadrotors with chattering reduction and disturbances estimator: Theory and application. J. Intell. Robot. Syst. 2022, 105, 71. [Google Scholar] [CrossRef]

- Mabboux, J.; Pommier-Budinger, V.; Delbecq, S.; Bordeneuve-Guibe, J. Co-design of a multirotor UAV with robust control considering handling qualities and motor failure. Aerosp. Sci. Technol. 2024, 144, 108778. [Google Scholar] [CrossRef]

- Bhat, S.P.; Bernstein, D.S. Finite-time stability of homogeneous systems. In Proceedings of the 1997 American Control Conference (Cat. No. 97CH36041), Albuquerque, NM, USA, 6 June 1997; pp. 2513–2514. [Google Scholar] [CrossRef]

- Bhat, S.P.; Bernstein, D.S. Geometric homogeneity with applications to finite-time stability. Math. Control Signals Syst. 2005, 17, 101–127. [Google Scholar] [CrossRef]

- Karagiannopoulos, S.; Aristidou, P.; Hug, G.; Botterud, A. Decentralized control in active distribution grids via supervised and reinforcement learning. Energy AI 2024, 16, 100342. [Google Scholar] [CrossRef]

- Guo, B.; Zhao, Z. On the convergence of an extended state observer for nonlinear systems with uncertainty. Syst. Control Lett. 2011, 60, 420–430. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, R.; Zhang, J. Model-free robust decoupling control of nonlinear nonaffine dynamic systems. Int. J. Syst. Sci. 2023, 54, 2590–2607. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Y.; Song, Y. Unifying fixed time and prescribed time control for strict-feedback nonlinear systems. IEEE/CAA J. Autom. Sin. 2025, 12, 347–355. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, L.; Xu, Y.; Cao, X. Practical tracking control of robot manipulators with continuous fractional-order nonsingular terminal sliding mode. IEEE Trans. Ind. Electron. 2016, 63, 6194–6204. [Google Scholar] [CrossRef]

- Lahiri, A.; Rawat, T.K. Noise analysis of single stage fractional-order low-pass filter using stochastic and fractional Calculus. ECTI Trans. Electr. Eng. Electron. Commun. 2009, 7, 47–54. [Google Scholar] [CrossRef]

- Liu, W.; Ye, H.; Yang, X. Super-Twisting Sliding Mode Control for the Trajectory Tracking of Underactuated USVs with Disturbances. J. Mar. Sci. Eng. 2023, 11, 636. [Google Scholar] [CrossRef]

- Zhu, Q. Model-free sliding mode enhanced proportional, integral, and derivative (SMPID) control. Axioms 2023, 12, 721. [Google Scholar] [CrossRef]

- Yang, I.; Lee, D.; Han, D. Designing a robust nonlinear dynamic inversion controller for spacecraft formation flying. Math. Probl. Eng. 2014, 2014, 471352. [Google Scholar] [CrossRef]

- Eslami, M. Sensitivity reduction and robustness. In Theory of Sensitivity in Dynamic Systems; Springer: Berlin/Heidelberg, Germany, 1994. [Google Scholar]

- Zhu, Q.; Na, J.; Zhang, W.; Chen, Q. Total Model-Free Robust Control of Non-Affine Nonlinear Systems with Discontinuous Inputs. Processes 2025, 13, 1315. [Google Scholar] [CrossRef]

- Iqbal, K. Introduction to Control Systems; University of Ottawa: Ottawa, ON, Canada, 2021. [Google Scholar] [CrossRef]

- Chen, B.M.; Lee, T.H.; Peng, K.; Venkataramanan, V. Composite nonlinear feedback control for linear systems with input saturation: Theory and an application. IEEE Trans. Autom. Control 2003, 48, 427–439. [Google Scholar] [CrossRef]

- Rawat, D.; Gupta, M.K.; Sharma, A. Intelligent control of robotic manipulators: A comprehensive review. Spat. Inf. Res. 2023, 31, 345–357. [Google Scholar] [CrossRef]

| TSM (8) | Parameters |

| Controller (10) | Parameters |

| TSM (8) | Parameters |

| Controller (10) | The parameters |

| TMC (8) | Parameters |

| Controller (11) | Parameters |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Zhang, J.; Liu, Z.; Yu, S. Robust Higher-Order Nonsingular Terminal Sliding Mode Control of Unknown Nonlinear Dynamic Systems. Mathematics 2025, 13, 1559. https://doi.org/10.3390/math13101559

Zhu Q, Zhang J, Liu Z, Yu S. Robust Higher-Order Nonsingular Terminal Sliding Mode Control of Unknown Nonlinear Dynamic Systems. Mathematics. 2025; 13(10):1559. https://doi.org/10.3390/math13101559

Chicago/Turabian StyleZhu, Quanmin, Jianhua Zhang, Zhen Liu, and Shuanghe Yu. 2025. "Robust Higher-Order Nonsingular Terminal Sliding Mode Control of Unknown Nonlinear Dynamic Systems" Mathematics 13, no. 10: 1559. https://doi.org/10.3390/math13101559

APA StyleZhu, Q., Zhang, J., Liu, Z., & Yu, S. (2025). Robust Higher-Order Nonsingular Terminal Sliding Mode Control of Unknown Nonlinear Dynamic Systems. Mathematics, 13(10), 1559. https://doi.org/10.3390/math13101559