Simulation of Heuristics for Automated Guided Vehicle Task Sequencing with Resource Sharing and Dynamic Queues

Abstract

1. Introduction

2. Literature Review

2.1. AGVs in Industry 4.0

2.2. Task Sequencing: Conceptual Clarifications and Evolution

2.3. Application of Discrete-Event Simulation

3. Problem Description

3.1. Motivation and Industrial Context

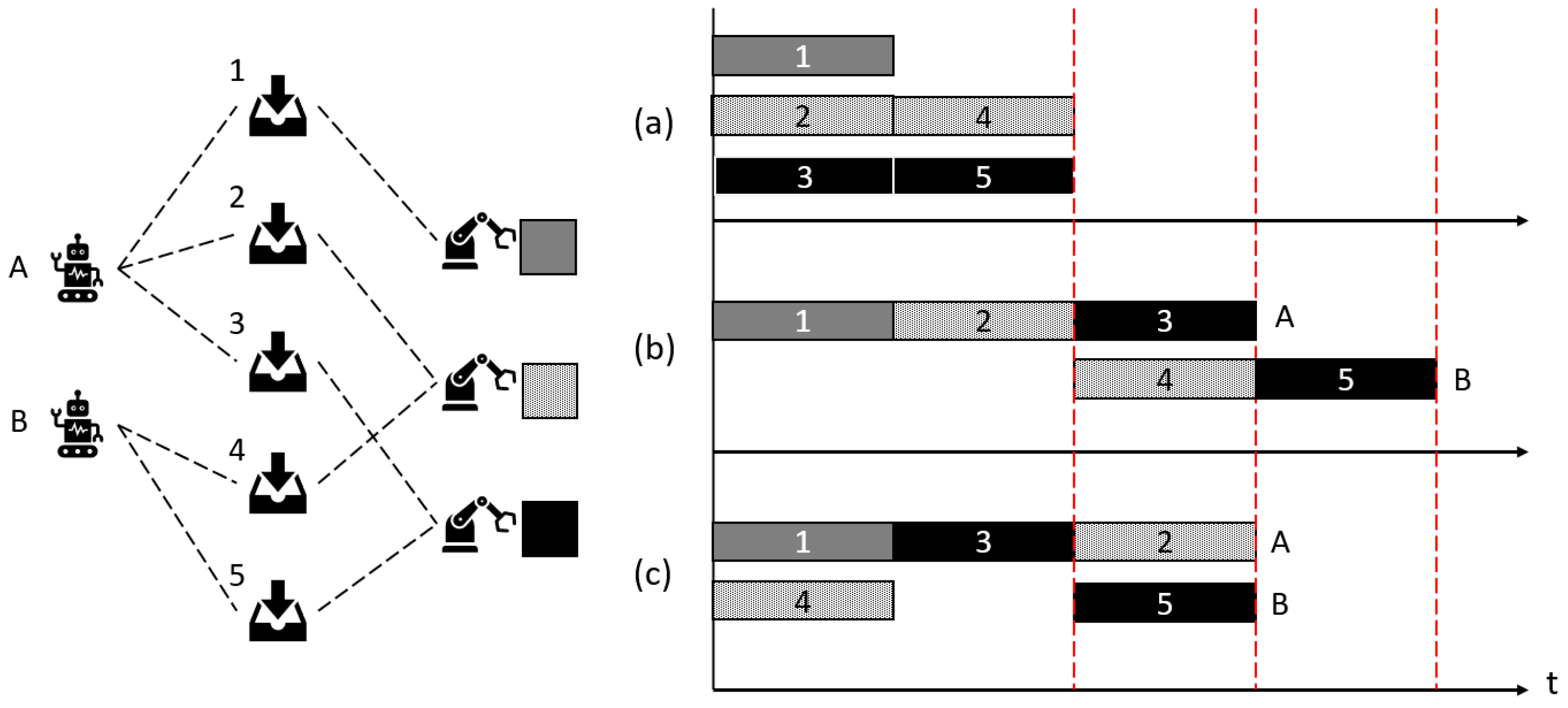

3.2. An Illustrative Numerical Example

3.3. Generic Formulation for the Sequencing Problem with Shared Resources

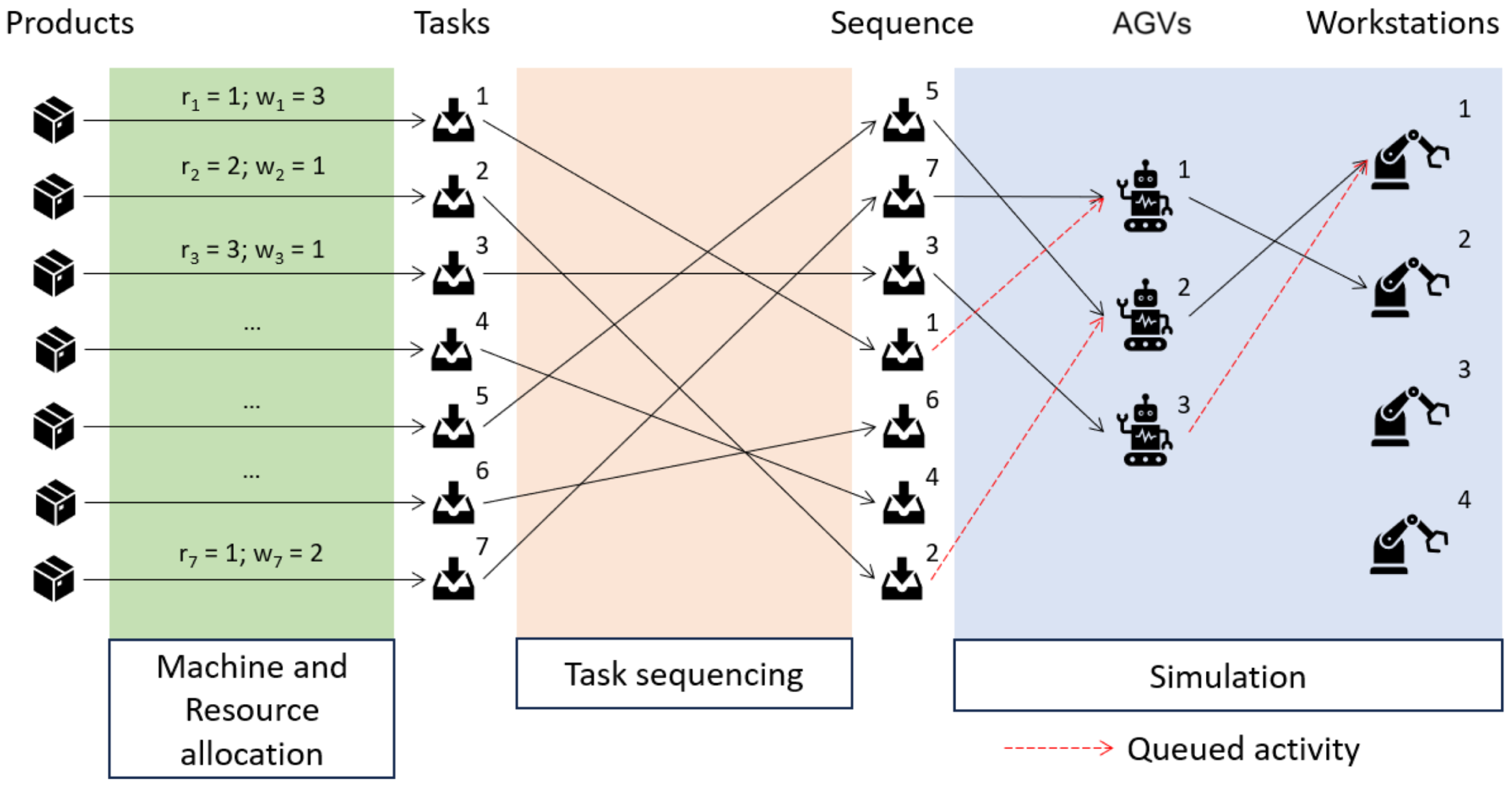

4. Methods and Methodology

4.1. A Two-Step Method for Sequencing Tasks

4.2. Algorithm Combination and the NEH-Based Benchmark

- Most loaded resource first (MLRF): This algorithm sorts AGVs, prioritizing the most loaded AGV first based on either the total processing time the AGV is engaged or the number of times it is required by a task. This study used total processing time for sorting.

- Less loaded resource first (LLRF): Similar to MLRF, LLRF sorts AGVs from lower workload to higher workload.

- Shortest processing time first (SPTF): This algorithm prioritizes tasks with the shortest processing times, sorting workstations from the least to the greatest processing time for tasks.

- Longest processing time first (LPTF): Contrary to SPTF, LPTF sorts workstations in reverse order, from lower to higher processing times.

| Algorithm 1 MLRF/LPTF algorithm. |

Input: Tasks = , Resources = , Machines = Output: Sequence

|

| Algorithm 2 NEH-based algorithm. |

Input: Tasks = , Resources = , Machines = Output: Sequence

|

4.3. Computational Experiment Instances

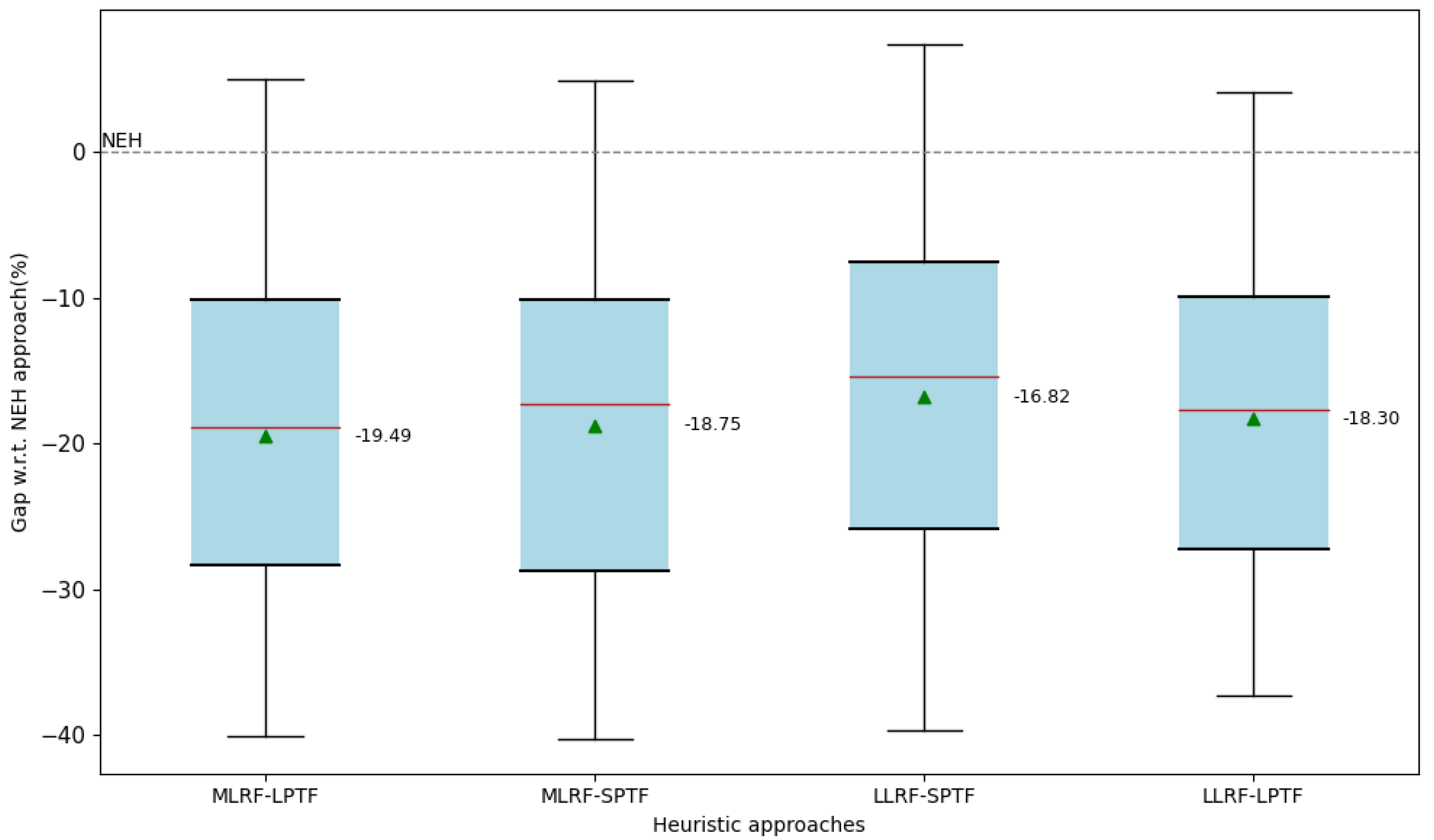

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Klingenberg, C.O.; Borges, M.A.V.; Antunes, J.A.d.V. Industry 4.0: What makes it a revolution? A historical framework to understand the phenomenon. Technol. Soc. 2022, 70, 102009. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Iakovou, E. Sustainable supply chain management in the digitalisation era: The impact of Automated Guided Vehicles. J. Clean. Prod. 2017, 142, 3970–3984. [Google Scholar] [CrossRef]

- Salkin, C.; Oner, M.; Ustundag, A.; Cevikcan, E. A Conceptual Framework for Industry 4.0. In Industry 4.0: Managing The Digital Transformation; Ustundag, A., Cevikcan, E., Eds.; Springer Series in Advanced Manufacturing; Springer International Publishing: Cham, Switzerland, 2018; pp. 3–23. [Google Scholar]

- Vis, I.F.A. Survey of research in the design and control of automated guided vehicle systems. Eur. J. Oper. Res. 2006, 170, 677–709. [Google Scholar] [CrossRef]

- Ruiz, R. Scheduling Heuristics. In Handbook of Heuristics; Martí, R., Pardalos, P.M., Resende, M.G.C., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1197–1220. [Google Scholar]

- Vivaldini, K.C.T.; Rocha, L.F.; Becker, M.; Moreira, A.P. Comprehensive Review of the Dispatching, Scheduling and Routing of AGVs. In Proceedings of the CONTROLO’2014—Proceedings of the 11th Portuguese Conference on Automatic Control, Porto, Portugal, 21–23 July 2014; Moreira, A.P., Matos, A., Veiga, G., Eds.; Lecture Notes in Electrical Engineering. Springer: Cham, Switzerland, 2015; pp. 505–514. [Google Scholar]

- Alatartsev, S.; Stellmacher, S.; Ortmeier, F. Robotic Task Sequencing Problem: A Survey. J. Intell. Robot. Syst. 2015, 80, 279–298. [Google Scholar] [CrossRef]

- Blazewicz, J.; Lenstra, J.K.; Kan, A.H.G.R. Scheduling subject to resource constraints: Classification and complexity. Discret. Appl. Math. 1983, 5, 11–24. [Google Scholar] [CrossRef]

- Pinedo, M.L. Modeling and Solving Scheduling Problems in Practice. In Scheduling: Theory, Algorithms, and Systems; Pinedo, M.L., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 431–458. [Google Scholar]

- Leon, J.F.; Marone, P.; Peyman, M.; Li, Y.; Calvet, L.; Dehghanimohammadabadi, M.; Juan, A.A. A Tutorial on Combining Flexsim with Python for Developing Discrete-Event Simheuristics. In Proceedings of the 2022 Winter Simulation Conference (WSC), Singapore, 11–14 December 2022; pp. 1386–1400. [Google Scholar]

- Fransen, K.; van Eekelen, J. Efficient path planning for automated guided vehicles using A*(Astar) algorithm incorporating turning costs in search heuristic. Int. J. Prod. Res. 2023, 61, 707–725. [Google Scholar] [CrossRef]

- Pratissoli, F.; Battilani, N.; Fantuzzi, C.; Sabattini, L. Hierarchical and Flexible Traffic Management of Multi-AGV Systems Applied to Industrial Environments. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an China, 30 May–5 June 2021; pp. 10009–10015. [Google Scholar]

- Vlachos, I.; Pascazzi, R.M.; Ntotis, M.; Spanaki, K.; Despoudi, S.; Repoussis, P. Smart and flexible manufacturing systems using Autonomous Guided Vehicles (AGVs) and the Internet of Things (IoT). Int. J. Prod. Res. 2022, 1–22. [Google Scholar] [CrossRef]

- Reis, W.P.N.d.; Couto, G.E.; Junior, O.M. Automated guided vehicles position control: A systematic literature review. J. Intell. Manuf. 2023, 34, 1483–1545. [Google Scholar] [CrossRef]

- Oyekanlu, E.A.; Smith, A.C.; Thomas, W.P.; Mulroy, G.; Hitesh, D.; Ramsey, M.; Kuhn, D.J.; Mcghinnis, J.D.; Buonavita, S.C.; Looper, N.A.; et al. A Review of Recent Advances in Automated Guided Vehicle Technologies: Integration Challenges and Research Areas for 5G-Based Smart Manufacturing Applications. IEEE Access 2020, 8, 202312–202353. [Google Scholar] [CrossRef]

- Kim, K.H.; Bae, J.W. A Look-Ahead Dispatching Method for Automated Guided Vehicles in Automated Port Container Terminals. Transp. Sci. 2004, 38, 224–234. [Google Scholar] [CrossRef]

- Li, G.; Li, X.; Gao, L.; Zeng, B. Tasks assigning and sequencing of multiple AGVs based on an improved harmony search algorithm. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 4533–4546. [Google Scholar] [CrossRef]

- Zou, W.Q.; Pan, Q.K.; Meng, T.; Gao, L.; Wang, Y.L. An effective discrete artificial bee colony algorithm for multi-AGVs dispatching problem in a matrix manufacturing workshop. Expert Syst. Appl. 2020, 161, 113675. [Google Scholar] [CrossRef]

- Hari, S.K.K.; Nayak, A.; Rathinam, S. An Approximation Algorithm for a Task Allocation, Sequencing and Scheduling Problem Involving a Human-Robot Team. IEEE Robot. Autom. Lett. 2020, 5, 2146–2153. [Google Scholar] [CrossRef]

- Dike, S.H. Project scheduling with resource constraints. IEEE Trans. Eng. Manag. 1964, EM-11, 155–157. [Google Scholar] [CrossRef]

- Ding, H.; Zhuang, C.; Liu, J. Extensions of the resource-constrained project scheduling problem. Autom. Constr. 2023, 153, 104958. [Google Scholar] [CrossRef]

- Van Eynde, R.; Vanhoucke, M. Resource-constrained multi-project scheduling: Benchmark datasets and decoupled scheduling. J. Sched. 2020, 23, 301–325. [Google Scholar] [CrossRef]

- Hartman, S.; Briskorn, D. A survey of variants and extensions of the resource-constrained project scheduling problem. Oper. Res. Manag. Sci. 2011, 51, 67. [Google Scholar]

- van der Beek, T.; Souravlias, D.; van Essen, J.; Pruyn, J.; Aardal, K. Hybrid differential evolution algorithm for the resource constrained project scheduling problem with a flexible project structure and consumption and production of resources. Eur. J. Oper. Res. 2023, 313, 92–111. [Google Scholar] [CrossRef]

- Maimon, O. The robot task-sequencing planning problem. IEEE Trans. Robot. Autom. 1990, 6, 760–765. [Google Scholar] [CrossRef]

- Suárez-Ruiz, F.; Lembono, T.S.; Pham, Q.C. Robotsp—A fast solution to the robotic task sequencing problem. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 1611–1616. [Google Scholar]

- Li, D.; Wang, Q.; Zou, W.; Su, H.; Wang, X.; Xu, X. An Efficient Approach for Solving Robotic Task Sequencing Problems Considering Spatial Constraint. In Proceedings of the 2022 IEEE 18th International Conference on Automation Science and Engineering (CASE), Mexico City, Mexico, 20–24 August 2022; pp. 60–66. [Google Scholar]

- Chen, C.H.; Chou, F.I.; Chou, J.H. Optimization of robotic task sequencing problems by crowding evolutionary algorithms. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 6870–6885. [Google Scholar] [CrossRef]

- Li, H.; Liu, S.Y.; Huang, Y.W.; Chen, Y.Q.; Fu, Z.H. An Efficient 2-opt Operator for the Robotic Task Sequencing Problem. In Proceedings of the 2019 IEEE International Conference on Real-time Computing and Robotics (RCAR), Irkutsk, Russia, 4–9 August 2019; pp. 124–129. [Google Scholar]

- Martin, X.A.; Hatami, S.; Calvet, L.; Peyman, M.; Juan, A.A. Dynamic Reactive Assignment of Tasks in Real-Time Automated Guided Vehicle Environments with Potential Interruptions. Appl. Sci. 2023, 13, 3708. [Google Scholar] [CrossRef]

- Korsah, G.A.; Stentz, A.; Dias, M.B. A comprehensive taxonomy for multi-robot task allocation. Int. J. Robot. Res. 2013, 32, 1495–1512. [Google Scholar] [CrossRef]

- Khamis, A.; Hussein, A.; Elmogy, A. Multi-robot task allocation: A review of the state-of-the-art. In Cooperative Robots and Sensor Networks 2015; Springer: Cham, Switzerland, 2015; pp. 31–51. [Google Scholar]

- Alshaboti, M.; Baroudi, U. Multi-robot task allocation system: Fuzzy auction-based and adaptive multi-threshold approaches. SN Comput. Sci. 2021, 2, 1–11. [Google Scholar] [CrossRef]

- Chakraa, H.; Guérin, F.; Leclercq, E.; Lefebvre, D. Optimization techniques for Multi-Robot Task Allocation problems: Review on the state-of-the-art. Robot. Auton. Syst. 2023, 168, 104492. [Google Scholar] [CrossRef]

- Leon, J.F.; Li, Y.; Peyman, M.; Calvet, L.; Juan, A.A. A Discrete-Event Simheuristic for Solving a Realistic Storage Location Assignment Problem. Mathematics 2023, 11, 1577. [Google Scholar] [CrossRef]

- López, J.; Zalama, E.; Gómez-García-Bermejo, J. A simulation and control framework for AGV based transport systems. Simul. Model. Pract. Theory 2022, 116, 102430. [Google Scholar] [CrossRef]

- Inoue, K. Discrete-Event Simulation for Autonomous Guided Vehicle. IFAC Proc. Vol. 2001, 34, 87–92. [Google Scholar] [CrossRef]

- bin Md Fauadi, M.H.F.; Li, W.L.; Murata, T.; Prabuwono, A.S. Vehicle requirement analysis of an AGV system using discrete-event simulation and data envelopment analysis. In Proceedings of the 2012 8th International Conference on Computing Technology and Information Management (NCM and ICNIT), Seoul, Republic of Korea, 24–26 April 2012; Volume 2, pp. 819–823. [Google Scholar]

- Kühn, M.; Schmidt, T.; Völker, M. Simulation-Based Optimization Approach for Efficient Generation of Sequencing Heuristics for Solving the Stochastic Resource-Constrained Scheduling Problem. In Proceedings of the Simulation in Produktion und Logistik; Kassel University Press: Kassel, Germany, 2019; pp. 403–412. [Google Scholar]

- Azimi, P.; Sholekar, S. A simulation optimization approach for the multi-objective multi-mode resource constraint project scheduling problem. Int. J. Ind. Eng. Prod. Res 2021, 32, 37–45. [Google Scholar]

- Kesen, S.E.; Baykoç, O.F. Simulation of automated guided vehicle (AGV) systems based on just-in-time (JIT) philosophy in a job-shop environment. Simul. Model. Pract. Theory 2007, 15, 272–284. [Google Scholar] [CrossRef]

- Chen, J.C.; Chen, T.L.; Teng, Y.C. Meta-model based simulation optimization for automated guided vehicle system under different charging mechanisms. Simul. Model. Pract. Theory 2021, 106, 102208. [Google Scholar] [CrossRef]

- Viana, J.; Brailsford, S.C.; Harindra, V.; Harper, P.R. Combining discrete-event simulation and system dynamics in a healthcare setting: A composite model for Chlamydia infection. Eur. J. Oper. Res. 2014, 237, 196–206. [Google Scholar] [CrossRef]

- Mensah, P.; Merkuryev, Y.; Longo, F. Using ICT in Developing a Resilient Supply Chain Strategy. Procedia Comput. Sci. 2015, 43, 101–108. [Google Scholar] [CrossRef]

- Wales, J.; Marinov, M. Analysis of delays and delay mitigation on a metropolitan rail network using event based simulation. Simul. Model. Pract. Theory 2015, 52, 52–77. [Google Scholar] [CrossRef]

- Nawaz, M.; Enscore, E.E., Jr.; Ham, I. A heuristic algorithm for the m-machine, n-job flow-shop sequencing problem. Omega 1983, 11, 91–95. [Google Scholar] [CrossRef]

- Hatami, S.; Calvet, L.; Fernández-Viagas, V.; Framinan, J.M.; Juan, A.A. A simheuristic algorithm to set up starting times in the stochastic parallel flowshop problem. Simul. Model. Pract. Theory 2018, 86, 55–71. [Google Scholar] [CrossRef]

- Dominguez, O.; Juan, A.A.; Faulin, J. A biased-randomized algorithm for the two-dimensional vehicle routing problem with and without item rotations. Int. Trans. Oper. Res. 2014, 21, 375–398. [Google Scholar] [CrossRef]

| Instance | Workstations | AGVs | Tasks | Type |

|---|---|---|---|---|

| 5 | 3 | 100 | LVPT/LVTA | |

| 5 | 3 | 100 | HVPT/LVTA | |

| 5 | 3 | 100 | LVPT/HVTA | |

| 5 | 3 | 100 | HVPT/HVTA | |

| 5 | 3 | 200 | LVPT/LVTA | |

| 5 | 3 | 200 | HVPT/LVTA | |

| 5 | 3 | 200 | LVPT/HVTA | |

| 5 | 3 | 200 | HVPT/HVTA | |

| 10 | 5 | 300 | LVPT/LVTA | |

| 10 | 5 | 300 | HVPT/LVTA | |

| 10 | 5 | 300 | LVPT/HVTA | |

| 10 | 5 | 300 | HVPT/HVTA | |

| 10 | 5 | 600 | LVPT/LVTA | |

| 10 | 5 | 600 | HVPT/LVTA | |

| 10 | 5 | 600 | LVPT/HVTA | |

| 10 | 5 | 600 | HVPT/HVTA | |

| 20 | 10 | 1200 | LVPT/LVTA | |

| 20 | 10 | 1200 | HVPT/LVTA | |

| 20 | 10 | 1200 | LVPT/HVTA | |

| 20 | 10 | 1200 | HVPT/HVTA |

| Instance | NEH | MLRF/LPTF | Gap (%) | MLRF/SPTF | Gap (%) | LLRF/SPTF | Gap (%) | LLRF/LPTF | Gap (%) |

|---|---|---|---|---|---|---|---|---|---|

| 6594 | 5248 | −20.41% | 5377 | −18.46% | 5480 | −16.89% | 5310 | −19.47% | |

| 6838 | 5674 | −17.02% | 6061 | −11.36% | 6414 | −6.20% | 5536 | −19.04% | |

| 8644 | 8125 | −6.00% | 8115 | −6.12% | 8568 | −0.88% | 8277 | −4.25% | |

| 8688 | 9121 | 4.98% | 9115 | 4.91% | 9333 | 7.42% | 9043 | 4.09% | |

| Average: | 7691 | 7042 | −9.61% | 7167 | −7.76% | 7448.75 | −4.14% | 7041.50 | −9.67% |

| 13,818 | 9752 | −29.43% | 10,090 | −26.98% | 10,405 | −24.70% | 9946 | −28.02% | |

| 14,761 | 11,016 | −25.37% | 11,509 | −22.03% | 11,895 | −19.42% | 11,350 | −23.11% | |

| 16,896 | 14,528 | −14.02% | 14,623 | −13.45% | 15,048 | −10.94% | 14,921 | −11.69% | |

| 17,236 | 15,986 | −7.25% | 16,410 | −4.79% | 16,607 | −3.65% | 16,402 | −4.84% | |

| Average: | 15,677.75 | 12,820.50 | −19.02% | 13,158 | −16.81% | 13,488.75 | −14.68% | 13,154.75 | −16.91% |

| 14,966 | 11,249 | −24.84% | 10,613 | −29.09% | 11,866 | −20.71% | 10,918 | −27.05% | |

| 14,719 | 11,393 | −22.60% | 11,786 | −19.93% | 12,243 | −16.82% | 12,226 | −16.94% | |

| 24,557 | 22,198 | −9.61% | 22,438 | −8.63% | 22,589 | −8.01% | 22,453 | −8.57% | |

| 23,817 | 21,690 | −8.93% | 21,828 | −8.35% | 22,546 | −5.34% | 21,905 | −8.03% | |

| Average: | 19,514.75 | 16,632.50 | −16.49% | 16,666.25 | −16.50% | 17,311 | −12.72% | 16,875.50 | −15.15% |

| 36,203 | 23,095 | −36.21% | 22,665 | −37.39% | 22,094 | −38.97% | 24,633 | −31.96% | |

| 36,759 | 26,424 | −28.12% | 25,766 | −29.91% | 25,414 | −30.86% | 26,826 | −27.02% | |

| 53,791 | 47,427 | −11.83% | 47,565 | −11.57% | 47,684 | −11.35% | 47,628 | −11.46% | |

| 54,801 | 49,184 | −10.25% | 48,980 | −10.62% | 49,037 | −10.52% | 49,149 | −10.31% | |

| Average: | 45,388.50 | 36,532.50 | −21.60% | 36,244 | −22.37% | 36,057.25 | −22.93% | 37,059 | −20.19% |

| 52,242 | 31,338 | −40.01% | 31,198 | −40.28% | 31503 | −39.70% | 32,768 | −37.28% | |

| 54,533 | 38,646 | −29.13% | 38,945 | −28.58% | 37,442 | −31.34% | 37,821 | −30.65% | |

| 75,115 | 45,027 | −40.06% | 45,039 | −40.04% | 47,707 | −36.49% | 47,524 | −36.73% | |

| 78,231 | 54,280 | −30.62% | 55,022 | −29.67% | 55,259 | −29.36% | 54,306 | −30.58% | |

| Average: | 65,030.25 | 42,322.75 | −34.95% | 42,551 | −34.64% | 42,977.75 | −34.22% | 43,104.75 | −33.81% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leon, J.F.; Peyman, M.; Martin, X.A.; Juan, A.A. Simulation of Heuristics for Automated Guided Vehicle Task Sequencing with Resource Sharing and Dynamic Queues. Mathematics 2024, 12, 271. https://doi.org/10.3390/math12020271

Leon JF, Peyman M, Martin XA, Juan AA. Simulation of Heuristics for Automated Guided Vehicle Task Sequencing with Resource Sharing and Dynamic Queues. Mathematics. 2024; 12(2):271. https://doi.org/10.3390/math12020271

Chicago/Turabian StyleLeon, Jonas F., Mohammad Peyman, Xabier A. Martin, and Angel A. Juan. 2024. "Simulation of Heuristics for Automated Guided Vehicle Task Sequencing with Resource Sharing and Dynamic Queues" Mathematics 12, no. 2: 271. https://doi.org/10.3390/math12020271

APA StyleLeon, J. F., Peyman, M., Martin, X. A., & Juan, A. A. (2024). Simulation of Heuristics for Automated Guided Vehicle Task Sequencing with Resource Sharing and Dynamic Queues. Mathematics, 12(2), 271. https://doi.org/10.3390/math12020271