Abstract

As the number of alternative machines has increased and their technology has been continuously developed, the machine selection problem has attracted many researchers. This article reviews recent developments in applying multi-criteria decision-making (MCDM) methods for selecting machines in the manufacturing and construction industries. Selected articles are classified according to the application area and the applied MCDM method. By focusing on the last five years, this paper identifies recent trends in developing and using these methods. Results suggest that there has been a noticeable growth in the utilization of MCDM techniques for machine selection problems in both sectors. It is also noted that several decision-support tools and methods have been developed and successfully applied during this period. Accordingly, needs and directions for future research are discussed.

Keywords:

machine selection; Multi-Criteria Decision Making (MCDM); construction equipment; manufacturing; Industry 4.0 MSC:

90B50; 91B06

1. Introduction

Manufacturing and construction industries contribute significantly to many countries’ gross domestic product (GDP). Even though the products in the construction industry generally have a larger scale, construction work can be viewed as a project-like manufacturing business. The borderline between the two sectors disappears when it comes to manufacturing (building) ships and airplanes. When selecting a suitable machine to serve in a manufacturing system or a construction project, the challenges faced by the decision-maker are almost identical. To acquire a competitive advantage for survival in the global business scenario, selecting the most appropriate machine has recently become a vital decision-making problem for many manufacturing and construction firms.

Improper machine selection decisions reduce the return on investments, increase quality and maintenance-related costs, and eventually negatively impact customer satisfaction. Machine selection is a time-consuming process and difficult process, making it necessary for decision-makers to have proper knowledge and experience. Testing the machine selection problem has driven researchers to develop models for helping decision-makers. The rational decision support techniques based on numerical models provide a systematic approach that benefits from the available expertise and, furthermore, give insights that can help the decision-maker analyze the resultant decisions.

Constructing a decision support model for selecting a suitable machine is a challenging task. It involves choosing from a broad range of available alternative technologies in the market. In addition, minimizing the cost of a machine is one of the most desired goals of an industrial or construction firm that is profit oriented. However, making only cost-focused selections can result in incorrect decisions by neglecting many factors that can be as important as cost. These factors can be technical, environmental, logistical, and ergonomic. For these reasons, the decision support models used for machine selection follow a multi-criteria decision-making (MCDM) framework.

A recent literature review by Hamzeh and Xu, 2019 [1], in which they surveyed technology selection publications from 1990 to 2017, concluded that there is an apparent upward trend in the number of publications addressing technology selection decisions in the areas of advanced manufacturing technology and supply chain management. Meanwhile, a recent review by Jato-Espino, 2014 [2] on the applications of MCDM techniques for machine selection in the construction industry revealed that only a few publications had addressed machine selection decisions for construction projects.

This paper reports on publications in the field of machine selection for both manufacturing and construction industries, focusing on recent works from 2017 to 2022. This five-year range is sufficient to provide a reliable assessment of the recent trends in the investigated subject. Based on this assessment, needs and directions for future research are identified.

The remaining sections of this paper are structured as follows. Section 2 identifies the search methodology and the criteria used for including and excluding papers in this review. Section 3 presents the results of the literature review, which includes a list of the used MCDM methods, a classification, and a summary of the contributions of the reviewed papers in the manufacturing field, followed by a summary of the contributions of the reviewed papers in the construction field. In Section 4, different classifications and aspects of the applications of the MCDM methods are discussed. Lastly, in Section 5, conclusions and future research directions are provided.

2. Materials and Methods

This review investigates papers applying MCDM methods to the machine selection problem in manufacturing and construction. A quantitative systematic review approach is followed in this paper. In order to determine relevant publications, an extensive search was carried out using web-based databases and scientific search engines among electronic libraries. The search is conducted on scientific databases, including ScienceDirect, Scopus, and ResearchGate. The search is limited to publications in the English language for scientific research papers in scientific journals, conferences, and theses. All combinations of “machine selection,” “decision making,” “manufacturing,” and “construction” were used in the title, abstract, and keywords over the publication period from 2017 to 2022. The focus was only on published work during that period, while publications that were published online after 30 September 2022 were not included.

Publications that implemented a decision support system that either considered a single criterion or did not apply an MCDM method are excluded from the results. Furthermore, publications that studied the selection of a manufacturing process from different technologies are excluded, as this paper focuses mainly on selecting a set of machines that belong to the same manufacturing technology. Meanwhile, publications that include other selection decisions and machine selection are not excluded. These include selection decisions for the material or material handling equipment. Furthermore, publications that considered the selection of integrated manufacturing systems are not excluded from the review.

3. Results

The conducted search resulted in a total of 37 publications. Nine papers are in the construction field, while the remaining 28 addressed machine selection problems in different manufacturing contexts. Among the found publications are six conference papers and one Ph.D. thesis, while the rest are journal articles.

The surveyed papers have employed different MCDM methods. The following subsections begin by summarizing these methods, and the contributions in both manufacturing and construction fields are summarized afterward.

3.1. Applied MCDM Methods

Diverse MCDM methods have been proposed in the literature to provide an organized procedure that can assist decision-making. These methods are predominantly based on identifying a set of alternative designs or solutions to a given decision problem and constructing relationships between those alternatives and the criteria that direct the decision. Experts’ qualitative and quantitative assessments seek to identify and assess these relationships. The outcome of the MCDM method is a ranking of the alternatives based on an evaluated score, which can be used by the decision-maker for final selection.

The general steps for making machine selection decisions usually consist of the following procedure: (1) Decide on the criteria used to evaluate the machine and select the most critical criteria; (2) Identify alternative machines; (3) Evaluate them with respect to the most critical criteria. Many researchers have applied various approaches to solving different cases of the machine selection problem. Table 1 includes the approaches found in the machine selection literature for the conducted literature review. The reader may refer to [3] for a full description of such methods.

Table 1.

Summary of the MCDM methods applied in the reviewed papers.

Even though the MCDM methods listed in Table 1 follow almost the same procedure described earlier, they differ mainly in the approach used for comparing the criteria and/or alternatives and in developing their interrelationships. Comparisons can be made pairwise such as in AHP, BWM, DEMATEL, ELECTRE, GRA, MACBETH, and PROMETHEE. These pairwise comparisons are then used to rank criteria or alternatives. Other methods depend on ranking alternatives based on a score that can be weighted such as COPRAS, CRITIC, LOWGA, PSI, SAW, SMART, and WASPAS. Other ranking-based methods utilize a measure of how an alternative/criterion is distant from an extreme or an average or marginal alternative/value such as AD, CODAS, EDAS, FDEA, MABAC, MULTIMOORA, PIV, TOPSIS, and VIKOR. Other methods such as Entropy and SWARA are used in conjunction with other MCDM methods for evaluating the weights of the criteria.

3.2. Machine Selection in Manufacturing

Table 2 lists the surveyed papers in manufacturing and their characteristics. The papers are ordered chronologically, and their characteristics in terms of the application field or machine type, the base MCDM method(s) used, the categories of main criteria, and the data evaluation type are listed. The categories of main criteria represent classified criteria subsets. The technical subset includes several machine characteristics, such as size, capacity, electrical power, speed, accuracy, complexity, flexibility, and product quality and durability. The economic subset includes machine procurement, installation, maintenance, and other production and service costs.

Table 2.

Characteristics of surveyed papers in manufacturing.

In Table 2, the base MCDM method has been adopted in the surveyed paper either in its common form or modified by adopting some amendments that suit the specific application. In the column of the base MCDM method(s), if a hybrid method is used (i.e., basically combines two or more MCDM methods), a plus “+” sign is used. If a paper compares between two or more MCDM methods, a cross “×” sign is used. The data evaluation type represents how the numerical data used in evaluating or comparing criteria and alternatives is represented. Crisp data are exact numerical values, while fuzzy data use fuzzy membership functions. In one case, rough data representation is used, which gives a boundary interval with upper and lower bounds in representing the numerical data.

The surveyed papers in the manufacturing field can be classified according to the machine type or application domain into five main categories:

- Additive manufacturing (AM) or three-dimensional (3D) printers: 10 papers;

- Computer-numerically controlled (CNC) machine tools or applications in computer integrated manufacturing (CIM) and flexible manufacturing systems (FMSs): 9 papers;

- Food, pharmaceutical and material processing: 5 papers;

- Machining and other industrial applications: 4 papers;

The following subsections summarize the main contributions of the papers belonging to these categories.

3.2.1. Additive Manufacturing

The problem of selecting an AM machine or a 3D printer has recently attracted many researchers. The AM technology is based on constructing complex parts by transforming a 3D computer model into thin layers of materials to be added on top of each other. As a result, AM produces less wasted material. Other notable benefits of AM include its ability to produce parts with high accuracy, quality, and preferred mechanical properties. The rapid development of 3D printing technology has meant that its machine selection problem is challenging.

In [5], a hybrid fuzzy AHP and PROMETHEE approach was proposed for selecting a proper 3D printer. In that hybrid three-stage approach, after determining the criteria, fuzzy AHP was used to obtain criteria weights. In the third stage, PROMETHEE was used to rank the alternatives. The proposed hybrid MCDM approach was applied in a research and development company planning to replace a traditional machine with a 3D printer. From five alternative 3D printers, the proposed approach successfully selected a machine that serves the technological, economic, and environmental needs of the company. Sensitivity analysis of the results showed minor changes in the alternatives’ final ranks due to changes in the criteria weights. Later, the selection of an AM machine to produce healthcare products was addressed in [28]. A hybrid MCDM approach based on fuzzy AHP and TOPSIS was proposed. A two-step approach was used in which fuzzy AHP was applied first to assess criteria and provide their weights, which were then used within TOPSIS to guide the selection of the 3D printer. A case study was presented for manufacturing heart and jaw pieces of different sizes. It was pointed out that the outcome of the proposed hybrid approach is sensitive to the requirements of the decision-maker and the selected criteria of interest.

Another hybrid MCDM method was proposed in [11], which was based on AHP and TOPSIS. The AHP was used first to help users understand trade-offs and make the right decisions regarding their required printing strategies. This allows for adjusting their design for better performance. Then, TOPSIS was used to rank alternatives and provide suggestions. A case study was presented to illustrate the proposed approach. It was emphasized that rankings of alternatives are significantly different whenever users’ inputs in the first step are not considered.

Taking into consideration the design requirements for the final products while selecting an AM machine is emphasized in [12], where a three-step approach was proposed. In the first step, the functional specifications of the products were extracted by the designer from given computer-aided design models. These specifications generate a set of requirements that govern the selection of the next steps. The machine selection in that paper was combined with material selection in the second and third steps. The second step is a screening phase in which all available materials and machines are examined to generate a short list of valid alternatives based on the generated requirements in the first step. In the last step, AHP was used to rank the alternative materials and machines. An industrial case study was presented, and the results of AHP were compared with the results obtained by SAW for validation. It was shown that both MCDM methods generated similar results, while SAW helped to explore three additional materials.

Another three-step approach for implementing AHP was proposed in [15] for selecting low-cost 3D printers. In the first step, the structure of AHP is defined and used for determining the weights of the criteria. Then, evaluation sample products were manufactured by three alternative 3D printers. The assessment of the sample products was conducted in the third step, in which the AHP structure was complemented. A case study was presented to demonstrate the developed AHP-based approach. The production of sample models to provide assessments based on actual results was also followed in [22], where A hybrid MCDM approach was proposed. That approach is based on the BWM for determining the criteria weights and the PIV for ranking AM machines after the conceptual model fabrication.

Since the technology of the AM machine can affect product characteristics, product designers would benefit from integrating the AM process and machine selection decisions into the design. In [20], an MCDM method based on AHP was proposed to integrate the AM process and machine selection with the product design stage. This integration aims to facilitate the design process by enabling designers to identify the appropriate AM technique and production machine. An industrial case study was presented to prove the validity and benefit of the proposed approach. The considered criteria were primarily technical, including the material availability, strength, dimensional accuracy, and multiple-color printability of the AM process. After identifying the AM processes that suit these criteria, the machine selection was made by comparing the estimated production costs per unit.

The importance of integrating AM material and machine selection was emphasized in [21] as an MCDM framework was proposed. The BWM was used for both decisions in that framework. A case study was presented, which was about the production of a rubber gasket. The benefit of the proposed integrated material and machine framework was affirmed by the customer, who could identify a better material than the original design. In [24], a four-step approach was proposed to guide the selection of AM material, process, and machine. In the fourth step, the AHP is applied, which utilizes criteria defined based on the objectives of the selection decisions for the material, the process, and the machine. These objectives are defined in the preceding three steps based on the design requirements of the part to be produced. A case study was presented for the manufacturing of a gas turbine blade to demonstrate the usefulness of that approach.

Environmental criteria for the AM process selection were first considered in [29], along with other technical, economic, and productivity-related criteria. These criteria represent the long-term sustainability of the AM process and machine, including material/product quality, machine performance, market stability, overall cost, and environmental values. A hybrid SWARA and COPRAS approach was proposed to select an AM process from four alternatives. The proposed approach was claimed to be easy to implement, and decision-makers can extend it to consider more AM processes.

3.2.2. CNC, CIM and FMSs

Computerized manufacturing systems that include CNC machines, CIM framework, and FMSs are the constituents that shaped the third industrial revolution five decades ago. They continue to evolve, serve in modem manufacturing, and are essential elements of the fourth industrial revolution. The machine selection problem in these technologies is a significant challenge due to the wide variety of machines and material handling equipment and their technologies in the market today.

The selection of a CNC machine is an important problem that caught the attention of many researchers. The problem of selecting a 5-axis CNC machine was addressed in [8,14]. In [8], a 4-step approach utilizing both AHP and PROMETHEE was proposed. In the first step, data and experts’ recommendations are gathered, which were then used in the second step to construct the AHP structure, which was used to assign criteria weights. In the third step, PROMETHEE was used to rank alternatives. In the last step, benefit/cost analysis and sensitivity analysis were used to guide the final selection. Later, in [14], an approach based on fuzzy AHP was proposed to help reduce the risks associated with selecting a 5-axis CNC machine. The risks under consideration are related to the performance of the manufacturing system in which the new machine will be included, which can deteriorate due to improper machine selection. These risks affect costs, productivity, and quality. In that research, the criteria used in the evaluation were classified into two groups. The first group includes four technical measures that can be quantified and measured using crips values. The second group includes qualitative measures for which fuzzy representations are used. Industrial case studies were presented in [8,14] to demonstrate the proposed approaches. In [26], the problem of selecting a CNC lathe was considered. A fuzzy TOPSIS approach was proposed. A case study was presented for institute research purposes. It was emphasized that fuzzy representations help represent uncertain judgments.

Since the CNC machine tool selection problem is an important traditional MCDM problem, it has been used as a benchmark for assessing MCDM methods and experimenting with newly suggested approaches. A flexible group decision-making method based on LOWGA was proposed in [23]. That approach was applied to the CNC machine tool selection problem to demonstrate its benefits. It utilizes a hesitant fuzzy linguistic term set (HFLTS) to treat certain, uncertain, and incomplete information in the information accumulation procedure of the LOWGA approach. Although the focus of that research was not on the issues related to the CNC machine tool selection problem, it provided an effective tool that can be used in situations with hesitant or incomplete information from experts. In [27], different MCDM methods were compared, including WASPAS, EDAS, CODAS, and VIKOR. For the four MCDM methods, AHP was applied to obtain criteria weights. All methods were also compared with TOPSIS and modified TOPSIS methods traditionally used in the literature. Spearman’s rank correlation method was used to compare the final rankings of CNC machines that are generated using the compared MCDM methods. It was concluded that WASPS, VIKOR, and TOPSIS give similar results, whereas EDAS and modified TOPSIS have similar results.

In [30], a multi-expert, multi-MCDM approach was proposed for the problem of selecting a CNC machine. Three different hybrid MCDM methods were independently applied by three different experts simultaneously. In the three hybrid methods, the BWM was used to determine the criteria weights. Using a case study of seven alternative CNC machines, four main, and thirteen sub-criteria, the MCDM methods GRA, COPRAS, and MULTIMOORA were used for providing rankings of the alternatives. In that research, it was recommended that working on the same MCDM problem using different experts, each utilizing a different MCDM method, would result in more reliable outcomes that can be analyzed and compared as opposed to a single method and a single expert’s opinion, which results in making poor decisions for the machine-selection problem.

In modern CIM systems, industrial robots serve in applications, including material handling and manufacturing. The use of industrial robots in manufacturing is not confined to traditional welding applications but has been extended recently to manufacturing operations requiring continuous movement of the tooltip. In [6], the problem of selecting an industrial robot used in milling processes was addressed. The AHP was used to solve that problem. The technical criteria considered were load capacity, reach, position accuracy, and power consumption. Furthermore, the availability of maintenance service in the location where the robot is used was considered one of the crucial criteria. Another important criterion is the dexterity of the robot arm which has different definitions in the literature. It is related to the ability of the robot arm to change the tool tip’s orientation and position effectively. An industrial case study was presented to demonstrate the application of the proposed AHP structure.

Other papers investigated the CNC machine selection problem within an integrated FMS or a flexible manufacturing cell (FMC). In such applications, either a set of CNC machines and a robot are selected from alternatives such that they form a complete FMC as in [7], or a complete FMS is selected from among alternative FMSs as in [16]. The PSI method was introduced in [7] for selecting two CNC milling machines, one CNC lathe, and one robot for material handling. That problem was used to validate the results of the proposed PSI with a previously developed MCDM method. Later, an extension of CODAS was proposed in [16] that included interval-based assessments for criteria and alternatives. The results of the proposed approach were compared with interval-valued TOPSIS and interval-valued EDAS. A previously published case study in which a tractor manufacturer wanted to select an FMS from among four alternative FMSs was presented and used in the comparison. It was shown that the interval-valued CODAS method gave the same ranking as interval-valued TOPSIS and EDAS. It was concluded that interval-valued MCDM methods are more convenient for this type of MCDM problem.

3.2.3. Food, Pharmaceutical and Material Processing

Food, pharmaceutical, and material processing industries are a production system characterized by large quantities of material to be processed in a unit of time and require accordingly continuous flow. For these production systems, the output rate is significantly higher than the AM and CIM systems, while on the other hand, the product variety is minimal. As a result of these fundamental differences, the machine selection problem in these systems has completely different requirements and characteristics.

The machine selection problem in the raw material processing industry appeared mainly in the selection of the separation machines category. In [10], the problem of selecting a biomass separation machine was addressed. The importance of bio-separation stems from its wide range of industrial applications in food, beverage, wastewater treatment, and chemical and fuel production, to name a few. A 3-step approach was proposed in [10], where the first step is providing information about the gathered process requirements and alternative machines identified. In the second step, the criteria used in assessing the alternatives are defined, and AHP was applied in the last step to rank the alternatives. An example is presented to demonstrate the proposed approach. It was noted that AHP is well-suited for that application.

The problem of selecting a floatation machine was addressed in [13]. Due to the crucial role that floatation machines play in separating mineral concentrations or solid and waste materials in several industries, selecting a suitable floatation machine is a crucial decision-making problem. Two MCDM approaches based on TOPSIS and VIKOR were examined in [13]. A case study in which five floatation machines are studied is presented. Results showed a slight difference in the final rankings between the two methods. Further analysis might be needed if such conflicts exist. Another separation process that was addressed is in the cotton ginnery industry. An MCDM method based on MACBETH was proposed in [17]. An industrial case study was presented in which the focus was to identify the most important criteria to be used in selecting the cotton gin machine. Four qualitative criteria were identified, and MACBETH was used to rank them and select the top criterion related to minimizing the risk of injury.

Two papers are found to deal with the machine selection problem in the food industries. In [4], the problem of selecting a homogenizer for yogurt production was addressed. A hybrid approach based on Entropy and SAW was proposed. Twelve criteria were considered, where Entropy is used to develop their weights. An industrial case study was presented to select a machine from among three alternatives. Concerning technical criterial, all three alternatives were similar, but service and maintenance-related criteria were the most effective. In [9], a hybrid approach based on fuzzy SMART and fuzzy AD was proposed for the tea dryer selection problem. The hybrid in that study was composed of three phases. In the first phase, experts’ opinions were gathered to identify essential criteria and to narrow down alternatives. In the second phase, fuzzy SMART was used to assess the criteria, and in the last phase, weighted fuzzy AD was used to calculate the weighted information contents of the alternative and finally, to select one criterion.

3.2.4. Machining and Other Industrial Applications

The selection of machine tools for traditional machining applications is an important problem as it can broadly impact the performance of the production system. In [19], the selection of a milling machine was addressed. A hybrid approach was proposed, which utilizes fuzzy DEMATEL for determining subjective weights of the criteria, Entropy for determining objective weights of the criteria, and a variant of VIKOR to determine the ranks of the alternatives. An industrial case study was presented with five decision-makers, four alternative milling machines, and six criteria. Sensitivity analysis on changes in criteria weights on the selected machine was conducted. It was concluded that the proposed hybrid approach is robust and effective.

Non-traditional machining refers to manufacturing processes in which material removal is conducted using modern techniques that avoid cutting tools which have direct contact with the working material. Nowadays, these modern techniques are very common and are necessary to create complex products’ shape features and utilize hard and brittle materials. Different non-traditional machining technologies utilize mechanical, thermal, and chemical processes. Accordingly, the machine selection problem for non-traditional machining applications has attracted researchers’ interest. In [18], an approach based on MABAC was proposed. The weights of the criteria representing technical machining characteristics were determined based on rough information entropy theory, in which numerical data are represented using rough sets. This claims to help avoid subjectivity in the selection of alternatives. MABAC was used to rank the non-traditional machining alternatives.

Industrial robots are used for material handling and in handling and moving tooltips that can perform manufacturing operations. Industrial robots have different sizes and movement capabilities that make their selection problem a challenge. In [25], the problem of selecting an industrial robot for welding processes was addressed. A hybrid approach based on Entropy and TOPSIS was proposed. Entropy was used first in the criteria selection and weighting stage, while TOPSIS was used in the alternatives’ ranking. An industrial case study considered five objective technical criteria and eight alternative robots. It was noted that TOPSIS is a simple MCDM approach that can produce accurate results.

Printed circuit board (PCB) manufacturing is crucial in the high-tech world. PCB manufacturing has recently faced many challenges that threaten its profitability due to rising wages. This forced manufacturers to adopt new technologies that reduced reliance on skilled labor. As a result, the machine selection problem in that industry regained focus from researchers to provide MCDM methods that guide decision-makers effectively. In [31], an approach based on the Delphi technique, which is used to compile opinions from separate experts, and AHP was proposed. The 12 criteria considered were technical, economic, and warranty related. AHP was used to provide the weights of the criteria.

3.3. Machine Selection in Construction

Table 3 lists the surveyed papers in the construction field and their characteristics. Papers are listed in a chronological order, and the presented data are similar to that in Table 2.

Table 3.

Characteristics of surveyed papers in construction.

Excavation or earthmoving machinery represents most of the surveyed papers in the literature of machine selection in construction. In [32], the problem of selecting an excavation machine was addressed. Two MCDM approaches were investigated. The first approach was based on AHP, while the second was based on PROMETHEE. AHP was used to rank the alternatives determined by the decision maker. The calculations were conducted using the Expert Choice software. In the PROMETHEE method, qualitative and quantitative data were used to evaluate four alternatives obtained from the manufacturers and experienced operators. Criteria were assessed with respect to the preference functions and parameters obtained from the decision-makers. Computations showed that AHP and PROMETHEE resulted in the same ranking of the alternative machines.

In [33], two different MCDM methods were investigated using a fuzzy data representation: TOPSIS and VIKOR. To select a hydraulic excavator for open pit mines, it was noted that the modern generation of hydraulic excavators is equipped with computerized engine management systems that challenge their selection problem. Since the assessments of the hydraulic excavators are generally based on subjective measures by their operators, fuzzy representations were found to be suitable for that application. A case study was presented to demonstrate the effectiveness of the proposed MCDM approaches. Five alternative hydraulic excavators were examined for 16 technical criteria and one economic. It was concluded that both fuzzy TOPSIS and fuzzy VIKOR resulted in the same top-ranked alternative.

Environmental factors in construction work are of utmost importance, especially for excavation operations. Such factors are generally assessed using subjective measures, which need non-crisp representations. Accordingly, an MCDM method was introduced in [34] for the problem of evaluating construction equipment. A hybrid fuzzy SWARA, CRITIC, and EDAS approach was proposed. The subjective criteria weights were determined using fuzzy SWARA, while the objective criteria weights were determined using fuzzy CRITIC. Both were combined, and the fuzzy EDAS method was used to rank the alternatives. A case study was presented for the selection of two new excavators. Alongside technical criteria, environmental and socio-economic criteria were considered. Five different alternative excavators were considered. Sensitivity analysis results demonstrated the stability and validity of the proposed hybrid approach.

A case study of selecting earthmoving equipment for construction projects was presented in [35]. Sustainability aspects were considered, including life cycle cost, performance, system capability, operational convenience, environmental impact, and social benefits. Based on those aspects, 38 sub-criteria were identified and used within an AHP approach to guide the selection. A sensitivity analysis was conducted to study the effect of changing assessment values under several scenarios. Results proved the stability of the AHP approach.

When selecting a deep excavation support system (DESS), environmental impact was an important criterion to be considered in [40], along with technical, economic, and safety criteria. A hybrid MCDM approach based on AHP and fuzzy TOPSIS was proposed to deal with uncertainties associated with the selection decision. Three different DESSs were considered in a case study to demonstrate the effectiveness of the proposed approach. After identifying 14 sub-criteria, AHP was used to estimate their weights. In the third stage, fuzzy TOPSIS was used to rank the alternatives. Sensitivity analysis was conducted by changing the criteria weights and comparing the final ranking of the alternatives. It was shown that the proposed approach is robust against such changes.

AHP with a crisp representation of assessment data was used in [36,37]. Both applications are related to different types of excavation projects. The first application was used to select a tunnel boring machine for a railway project, while the second was concerned with selecting an erection machine for a turbine. Both publications represent direct, straightforward implementations of the AHP approach.

In [38], a hybrid MCDM approach with six steps was proposed for selecting construction equipment. In the first step, assessment criteria were determined using information from the literature along with on-site visits. This was followed by subjective evaluations of the criteria determined using two-dimension uncertain linguistic variables (2DULVs) for non-crisp data and real numbers for crisp ones. In the third step, social network analysis (SNA) was proposed to determine weights for experts performing evaluations and assessments. SNA is used in sociology to develop social structures by utilizing tools from graph theory. First, a network was constructed in which nodes represented individuals and arcs represented their relationships. The weights of individuals can be determined by analyzing clusters of nodes and their relationships. In the fourth step, assessments of criteria and weights of experts were aggregated to generate criteria weights as real numbers. This was followed by applying AHP and Entropy to generate the sub-criteria weights. Finally, in the last step, EDAS was used to rank the alternatives. A case study for selecting loaders in a construction project was presented. It was concluded that the proposed framework can generate more reliable results than other MCDM methods.

The problem of selecting a truck mixer drum (TMD) for construction firms was addressed in [39]. In the proposed approach, expert users of TMDs were surveyed to determine their qualitative assessments of the criteria. Those qualitative assessments are represented by fuzzy numbers combined with crisp technical characteristics provided by the suppliers of the TMDs. Then the selection procedure, which utilizes FDEA, was applied. A case study was presented in which three alternative TMDs were considered. Seven different criteria were considered, which were classified into technical, economic, and maintenance-related groups. Examining four different scenarios of applying FDEA under different evaluation conditions resulted in the same best-ranked alternative.

4. Discussion

Based on the reviewed recent papers, it is evident that the machine selection problem for manufacturing and construction industries continues to challenge researchers and practitioners. There is growing interest in developing state-of-the-art decision-support tools that utilize MCDM methods to help decision-makers make rational decisions. However, there are evident differences in the development of such tools in terms of the utilized MCDM methods, their hybridizations, the use of different data representation forms (crisp, fuzzy, and others), as well as the general structure followed to collect and compile experts’ assessments.

In this section, the classification, and statistics of the utilized MCDM methods are provided first. Then, an analysis of the data representation methods and their respective applications is discussed. Finally, an analysis of the problem-solving elements used in the application of the MCDM methods of the surveyed papers is provided.

4.1. Classification and Statistics of Used MCDM Methods

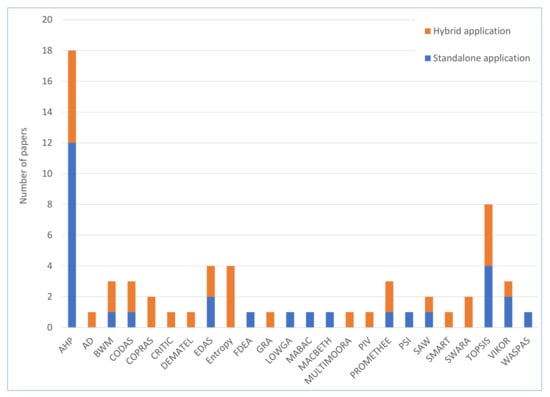

The vast body of MCDM literature includes a plethora of methods that can be used. This explains the diversity of the methods used in the machine selection problem, as 24 different methods have been counted for the reviewed papers. Either an MCDM method is used as a standalone approach for the entire problem of evaluating the criteria and the alternatives, or hybrid techniques that combine two or more methods are used. Figure 1 represents the number of papers that used the 24 methods as standalone and hybrid applications.

Figure 1.

The number of papers found applying each MCDM method.

Figure 1 shows that AHP is the most used MCDM method, either as standalone or hybridized. This can be attributed to its simple implementation and stable results which have been reported in the literature for various MCDM problems. AHP was hybridized three times with TOPSIS, two times with PROMETHEE, and one time with both Entropy and EDAS. All of these hybridized versions of AHP were used at the first stage to provide weights for the criteria or the sub-criteria.

The second most used MCDM method is TOPSIS. For the four papers in which TOPSIS was utilized as a standalone approach, a comparison was conducted for its results with other methods in three cases. The compared methods include VIKOR (two times) and CODAS and EDAS in one paper. Comparing TOPSIS and these methods is plausible since they follow a comparative ranking approach that compares each alternative or criterion with extreme best/worst or average candidates. As indicated earlier, TOPSIS was hybridized with AHP three times. It was also hybridized with Entropy only one time.

As shown in Figure 1, other than AHP and TOPSIS, the list of MCDM methods that were used, standalone and hybridized, include BWM, CODAS, EDAS, PROMETHEE, SAW, and VIKOR. This is an indication of the flexibility and expandability of these methods. On the other hand, some methods are used only standalone. The list of such methods includes FDEA, LOWGA, MABAC, MACBETH, PSI, and WASPAS. All these methods appeared only in one paper. Except for MACBETH and PSI, standalone methods can be attributed to using fuzzy, hesitant, or rough data representation because of the uncertainty in the numerical data, which may have tempted researchers to investigate the applicability of these MCDM methods since they are developed to deal with such data.

Other MCDM methods that appeared only as hybrid approaches in the reviewed papers include AD, COPRAS, CRITIC, DEMATEL, Entropy, GRA, MULTIMOORA, PIV, SMART, and SWARA. Entropy appeared four times, followed by COPRAS and SWARA, which appeared two times each. As indicated in Section 3.1, both Entropy and SWARA are not designed to provide a standalone comparison of the criteria and the alternatives. Therefore, they must be hybridized with other MCDM methods. By definition, Entropy is used for evaluating alternatives based on a set of pre-selected criteria based on measuring uncertainty in that evaluation. Therefore, another MCDM method is needed to provide weights for the pre-selected criteria. On the other hand, SWARA develops comparative weights for the criteria based on stepwise rankings; therefore, another MCDM method is needed to provide rankings for the alternatives. Meanwhile, other hybridized MCDM methods may not have such restrictions.

4.2. Analysis of Data Representation Forms

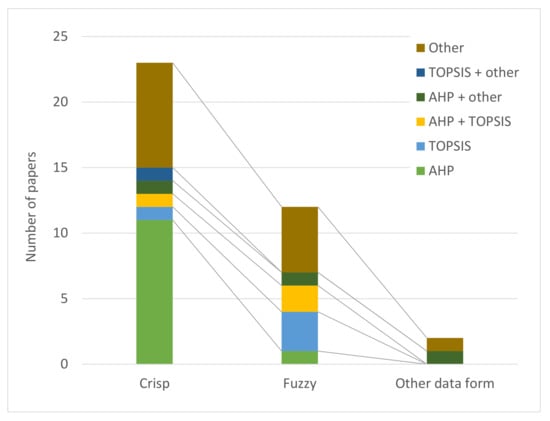

In the literature on applying MCDM methods, experts’ assessments and comparisons made for the criteria and the alternatives can be objective or subjective. For objective measures, crisp numerical forms are easily used, while for subjective measures, a conversion is needed to numerical values that can be used within the MCDM method. In many MCDM methods, such as AHP, subjective comparisons are inherently conducted using a predefined numerical scale representing different assessment levels for the experts. However, in situations where incomplete or hesitant information is present, using fuzzy representations of data becomes viable. Other data representation forms alongside fuzzy sets have been used in the literature on applying MCDM methods to the machine selection problem, such as rough sets and two-dimensional uncertain linguistic variables (2DULVs). Figure 2 represents the distribution of the number of reviewed papers with respect to the different data representation forms with the distribution of the main MCDM methods used.

Figure 2.

Distribution of data representation forms in the reviewed papers.

As shown in Figure 2, the number of papers that utilized the crisp data form in the recent machine selection literature is almost double the number of papers that utilized the fuzzy form. Only a minor fraction considered other data forms, including one paper utilizing rough sets along with MABAC and one paper utilizing 2DULVs with a hybrid approach that combines AHP, Entropy, and EDAS. It is important to note here that linguistic variables have recently received more attention due to their ability to mitigate information loss [41]. The 2DULV belongs to this category which may be a trend in future research for the machine selection problem.

It is also evident from Figure 2 that all the implementations of AHP as a standalone MCDM method use crisp data form except only in one paper. This can be attributed to the assessment structure adopted in AHP, which allows for subjective comparisons. The opposite case can be noticed for TOPSIS, as most of the papers implementing it prefer to use a fuzzy data form.

4.3. Analysis of Problem-Solving Elements

Solving the machine selection problem in manufacturing and construction using MCDM techniques is a project that involves several steps and requires careful planning and allocation of dedicated resources. By investigating the different approaches used in the reviewed papers, it can be concluded that the main tasks that a decision maker would take in this project include the following:

- Define the requirements of the new machine to be procured;

- Define the requirements of the experts who will be consulted to provide assessments for the criteria and the alternatives;

- Choose a pool of experts to be consulted;

- Experts define the criteria to be considered based on the stated requirements of the new machine;

- Identify a large set of all possible alternative machines;

- Experts screen the identified set of alternative machines and select a small set of alternatives to be considered in the study;

- Choose a MCDM method to be applied;

- Apply the steps of the chosen MCDM method. In this application, experts are consulted to provide the required evaluations and assessments through a series of meetings or via questionnaires. The application of any MCDM method generally involves the following major steps:

- a.

- Evaluate the relative weights of the defined criteria;

- b.

- Assess alternative machines based on the defined criteria;

- c.

- Combine the results of the previous two steps to rank the alternative machines.

- Conduct sensitivity analysis to study the effect of changes in the applied MCDM method on the final ranking of the machines;

- Choose a machine based on the final raking of the alternatives.

The reviewed papers have differences in the elements of their implementations of the above steps. Of the 37 reviewed papers, 12 were found to have a direct, simple application of the MCDM methods represented by the last three steps of the above list. Out of those 12 papers, 4 were found to focus on the comparison of two or more MCDM methods ([13,16,32,33]); in comparison, the remaining 8 papers presented an investigation of the direct implementation of one MCDM method. The remaining 25 papers considered different variants of the preceding steps from 1 to 7.

Only 14 papers reported the number of experts involved in the problem-solving process, despite the experts’ vital role. In those 14 papers, the number of experts ranged from 3 to 16, with a mean of approximately 5 and a mode of 3. Despite their essential role, few papers discussed the criteria for choosing the experts, such as their qualifications, years of experience, and current positions.

The criteria used in the reviewed papers are found to be predominantly technical and economic. Technical criteria vary depending on the application in which the machine is used. Common technical criteria include machine size, power consumption, accuracy, speed, and capacity. Economic criteria consider different elements of cost, including the machine procurement cost, service, and maintenance cost, and operating costs. As illustrated in Table 2, other frequently used manufacturing-related criteria include productivity, maintainability, and environmental impact. Meanwhile, in construction, as shown in Table 3, other frequently used criteria include environmental, ease of use, and safety.

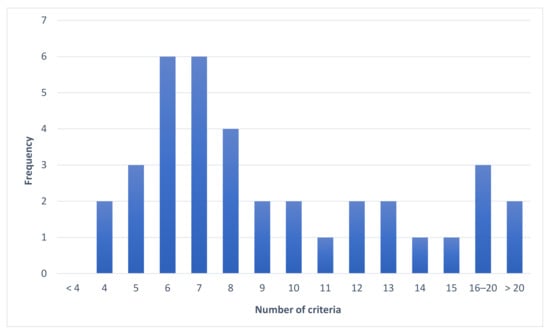

The number of criteria in the reviewed papers ranged from 4 to 38. Figure 3 presents the frequency histogram for the distribution of the number of criteria. Statistics show that the average number of criteria is 10, while the modes are 6 and 7. In a few cases, the number of criteria exceeded 20, which is not recommended in an MCDM study since there will be difficulties in the assessments and a negative impact on the sensitivity of the MCDM method. Usually, when the number of criteria is ten or more, they are categorized into three or four major criteria to simplify the assessments and comparisons.

Figure 3.

Distribution of the number of criteria in the reviewed papers.

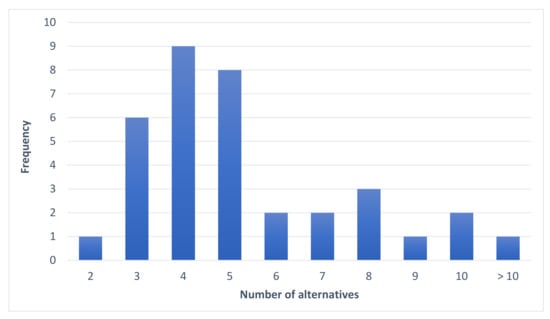

The number of alternatives in the reviewed papers ranged from 2 to 17, with a mode of 4 and median of 5. Figure 4 presents the frequency histogram of the number of alternatives. In two papers, [17,31], no specific alternatives were presented. The focus in these two papers was on developing an MCDM methodology to assess the criteria used and provide their weights to decision makers in two different industries.

Figure 4.

Distribution of the number of alternatives in the reviewed papers.

As shown in Figure 4, the number of alternatives in the reviewed papers ranges from 3 to 5 in two-thirds of the cases. This is the most convenient range for the involved MCDM assessments and comparisons. As with the number of criteria, increasing the number of alternatives will negatively impact the sensitivity and increase the assessment effort. This highlights the importance of initial screening for the criteria and the alternatives in the problem-solving process.

5. Conclusions and Future Research

Selecting a new machine to be added to a manufacturing system or a construction project is a critical decision-making problem that can broadly impact business success. Because the number of alternative machine tools is increasing and manufacturing technology is developing continuously, the machine selection problem has recently attracted many researchers. This study provided an in-depth evaluation of MCDM studies in manufacturing and construction conducted over the last five years.

It was stated that applying the MCDM methods for the machine selection problem is a project that needs proper planning. The decision-maker taking responsibility in that endeavor needs to start by looking for answers to the following questions:

- Which MCDM method to use? Is a standalone method sufficient, or is there a need for a hybrid method?

- What data representation form (crisp, fuzzy, …) suits the specific application?

- What is the appropriate number of experts to consult? Moreover, what are their levels and experiences?

- What are the assessment criteria as related to the specific application? Furthermore, what is their classification?

- What are the alternative machines to be included in the study?

Based on the reviewed papers, analyses were provided for the number of times each MCDM method was used, either standalone or hybridized, the data representation forms, and the different elements related to the structure of the application of the MCDM methods. The statistics reported in Section 4 can provide a guide to start with when planning for such a project in future research.

It was found that the AHP method was the MCDM method used most frequently for the machine selection problem as it appeared in 48.65% of the reviewed papers, either as a standalone approach or hybridized with other MCDM methods. This is followed by TOPSIS, which appeared in 21.62% of the reviewed papers. However, based on the reviewed papers, there is no specific preference as to which MCDM method to use, nor is there any reported superiority of one method over the others. In fact, seven papers have reported comparisons between two or three different MCDM methods, and none of them claimed the superiority of one method over the others. They reported the similarity of the final rankings of the alternatives between the compared methods in most cases. The popularity of AHP and TOPSIS in the machine selection problem suggests that they suit that specific application or are more accessible to implement than the other methods. However, a hybrid MCDM method is a good choice since it provides more flexibility in the application and benefits from the strengths of the combined methods.

Regarding the data representation forms, it was noticed that the number of papers utilizing a crisp representation is almost double those utilizing a fuzzy representation. This can be attributed to the fact that the decisions in machine selection are influenced mainly by technical and economic criteria for which crisp assessments are readily available in most cases. For instance, it is elementary to compare two machines based on their capacity, dimensions, power consumption, and speed. The purchase price and operating costs can similarly be acquired and used in the comparisons. Most surveyed papers found it straightforward to utilize such criteria in the comparisons. Whenever some technical criteria do not have crisp values or when other non-crisp criteria are adopted, such as those related to sustainability, maintainability, productivity, and similar items, fuzzy representations are employed mainly by researchers.

Only two papers follow different paths. In the first paper [18], rough data representation is used to model engineers’ assessments for technical criteria that do not have crisp values. These are related to their subjective performance assessments for alternative machines. Such assessments are only based on the engineers’ technical experience. This interesting case encourages future research in which rough data representation can be used to apply MCDM methods for the machine selection problem. The second case [38] utilized 2DULVs to represent subjective experts’ linguistic evaluations of alternative loaders. Along with crisp technical criteria that were represented using real numbers, that study considered subjective environmental, safety, convenience, and socio-economic criteria for which the 2DULVs are used. It was recommended that the application of 2DULVs that include both the linguistic evaluations on alternatives and the reliability degree of the given evaluation results could better represent subjective fuzzy evaluation information, thus rendering more reasonable and persuasive results. This is another important aspect that needs to be considered in future research.

Regarding the elements of the problem-solving structure in the reviewed papers, it was noticed that the number of experts participating in the inherent assessments, comparisons, and evaluations ranged from 3 to 16, with a mean of approximately five and a mode of 3. The distribution of the number of criteria defined in the reviewed papers revealed that the average number of criteria is 10, while the modes are 6 and 7. Meanwhile, the number of alternative machines ranged from 2 to 17, with a mode of 4 and a median of 5. These statistics can provide general guidelines for future research addressing the machine selection problem. Depending on the specific application and situation, larger numbers of experts, criteria, and alternatives are expected whenever the machine selection decision greatly impacts the business’s success. Another important aspect in that regard is the selection of the method by which experts’ judgments are acquired. This may be completed either individually or in groups. In that regard, the influence or weight of each expert on the assessments made can have a large effect on the result. An attempt is made in [38] to study that effect using social network analysis (SNA), which was employed to determine weights for experts performing evaluations and assessments. Similar methodologies are expected to be a trend in future research.

Author Contributions

Conceptualization, T.F.A., A.M.H. and L.S.Y.; methodology, T.F.A. and A.M.H.; formal analysis, A.M.H.; investigation, A.M.H.; data curation, A.M.H. and T.F.A.; writing—original draft preparation, A.M.H.; writing—review and editing, T.F.A.; supervision, T.F.A. and L.S.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hamzeh, R.; Xu, X. Technology Selection Methods and Applications in Manufacturing: A Review from 1990 to 2017. Comput. Ind. Eng. 2019, 138, 106123. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Castillo-Lopez, E.; Rodriguez-Hernandez, J.; Canteras-Jordana, J.C. A Review of Application of Multi-Criteria Decision Making Methods in Construction. Autom. Constr. 2014, 45, 151–162. [Google Scholar] [CrossRef]

- Figueira, J.R.; Ehrgott, M.; Greco, S. Multiple Analysis Criteria Decision:State of the Art Surveys, 2nd ed.; Springer Science+Business Media LLC: New York, NY, USA, 2016; ISBN 9781493930937. [Google Scholar]

- Özdağoğlu, A.; Yakut, E.; Bahar, S. Machine Selection in a Dairy Product Company with Entropy and SAW Methods Integration. Dokuz Eylul Univ. Iktis. Idari Bilim. Derg. 2017, 32, 343–361. [Google Scholar] [CrossRef]

- Çetĩnkaya, C.; Kabak, M.; Özceylan, E. 3D Printer Selection by Using Fuzzy Analytic Hierarchy Process and PROMETHEE. Bilişim Teknol. Derg. 2017, 10, 371–380. [Google Scholar] [CrossRef]

- Breaz, R.E.; Bologa, O.; Racz, S.G. Selecting Industrial Robots for Milling Applications Using AHP. Procedia Comput. Sci. 2017, 122, 346–353. [Google Scholar] [CrossRef]

- Jian, S.; Ying, S. Preference Selection Index Method for Machine Selection in a Flexible Manufacturing Cell. In Proceedings of the MATEC Web of Conferences, Chengdu, China, 16–17 December 2017; Volume 139, pp. 4–7. [Google Scholar]

- Wiriyapirom, M. Multi-Criteria Decision Making for Selecting a 5-Axis Machine Tool; Asian Institute of Technology: Amphoe Khlong Luang, Thailand, 2017. [Google Scholar]

- Çakır, S. An Integrated Approach to Machine Selection Problem Using Fuzzy SMART-Fuzzy Weighted Axiomatic Design. J. Intell. Manuf. 2018, 29, 1433–1445. [Google Scholar] [CrossRef]

- Hutahaean, J.; Cilliers, J.; Brito-Parada, P.R. A Multicriteria Decision Framework for the Selection of Biomass Separation Equipment. Chem. Eng. Technol. 2018, 41, 2346–2357. [Google Scholar] [CrossRef]

- Wang, Y.; Zhong, R.Y.; Xu, X. A Decision Support System for Additive Manufacturing Process Selection Using a Hybrid Multiple Criteria Decision-Making Method. Rapid Prototyp. J. 2018, 24, 1544–1553. [Google Scholar] [CrossRef]

- Uz Zaman, U.K.; Rivette, M.; Siadat, A.; Mousavi, S.M. Integrated Product-Process Design: Material and Manufacturing Process Selection for Additive Manufacturing Using Multi-Criteria Decision Making. Robot. Comput. Integr. Manuf. 2018, 51, 169–180. [Google Scholar] [CrossRef]

- Štirbanović, Z.; Stanujkić, D.; Miljanović, I.; Milanović, D. Application of MCDM Methods for Flotation Machine Selection. Miner. Eng. 2019, 137, 140–146. [Google Scholar] [CrossRef]

- Cioca, L.I.; Breaz, R.E.; Racz, S.G. Reducing the Risks during the Purchase of Five-Axis CNC Machining Centers Using AHP Method and Fuzzy Systems. Sustain. 2019, 11, 315. [Google Scholar] [CrossRef]

- Justino Netto, J.M.; Ragoni, I.G.; Frezzatto Santos, L.E.; Silveira, Z.C. Selecting Low-Cost 3D Printers Using the AHP Method: A Case Study. SN Appl. Sci. 2019, 1, 335. [Google Scholar] [CrossRef]

- Mathew, M.; Thomas, J. Interval Valued Multi Criteria Decision Making Methods for the Selection of Flexible Manufacturing System. Int. J. Data Netw. Sci. 2019, 3, 349–358. [Google Scholar] [CrossRef]

- Özdağoğlu, A.; Yilmaz, K.; Keleş, M.K. Evaluation of Machine Selection Criteria with MACBETH Method in a Ginnery Factory. Süleyman Demirel Üniversitesi Sos. Bilim. Enstitüsü Derg. 2020, 37, 26–37. [Google Scholar]

- Chakraborty, S.; Dandge, S.S.; Agarwal, S. Non-Traditional Machining Processes Selection and Evaluation: A Rough Multi-Attributive Border Approximation Area Comparison Approach. Comput. Ind. Eng. 2020, 139, 106201. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.; Fan, L.; Li, Q.; Chen, X. A Novel Hybrid MCDM Model for Machine Tool Selection Using Fuzzy DEMATEL, Entropy Weighting and Later Defuzzification VIKOR. Appl. Soft Comput. J. 2020, 91, 106207. [Google Scholar] [CrossRef]

- Liu, W.; Zhu, Z.; Ye, S. A Decision-Making Methodology Integrated in Product Design for Additive Manufacturing Process Selection. Rapid Prototyp. J. 2020, 26, 895–909. [Google Scholar] [CrossRef]

- Palanisamy, M.; Pugalendhi, A.; Ranganathan, R. Selection of Suitable Additive Manufacturing Machine and Materials through Best–Worst Method (BWM). Int. J. Adv. Manuf. Technol. 2020, 107, 2345–2362. [Google Scholar] [CrossRef]

- Raigar, J.; Sharma, V.S.; Srivastava, S.; Chand, R.; Singh, J. A Decision Support System for the Selection of an Additive Manufacturing Process Using a New Hybrid MCDM Technique. Sadhana—Acad. Proc. Eng. Sci. 2020, 45, 101. [Google Scholar] [CrossRef]

- Wen, T.C.; Lai, H.H.; Chang, K.H. A New Flexible Method for Solving Multi-Expert Multi-Criterion Decision-Making Problems. Appl. Sci. 2020, 10, 4582. [Google Scholar] [CrossRef]

- Bikas, H.; Porevopoulos, N.; Stavropoulos, P. A Decision Support Method for Knowledge-Based Additive Manufacturing Process Selection. Procedia CIRP 2021, 104, 1650–1655. [Google Scholar] [CrossRef]

- Chodha, V.; Dubey, R.; Kumar, R.; Singh, S.; Kaur, S. Selection of Industrial Arc Welding Robot with TOPSIS and Entropy MCDM Techniques. Mater. Today Proc. 2021, 50, 709–715. [Google Scholar] [CrossRef]

- Lata, S.; Sachdeva, A.K.; Paswan, M.K. Selection of Machine Tool by Using FUZZY TOPSIS Method. AIP Conf. Proc. 2021, 2341, 020015. [Google Scholar]

- Naik, P.A.; Patil, S.; Raut, D.N. Assessment of CNC Machine Tools Using MCDM Techniques. J. Xi’an Univ. Archit. Technol. 2021, XIII, 572–583. [Google Scholar]

- Ransikarbum, K.; Khamhong, P. Integrated Fuzzy Analytic Hierarchy Process and Technique for Order of Preference by Similarity to Ideal Solution for Additive Manufacturing Printer Selection. J. Mater. Eng. Perform. 2021, 30, 6481–6492. [Google Scholar] [CrossRef]

- Chandra, M.; Shahab, F.; KEK, V.; Rajak, S. Selection for Additive Manufacturing Using Hybrid MCDM Technique Considering Sustainable Concepts. Rapid Prototyp. J. 2022, 28, 1297–1311. [Google Scholar] [CrossRef]

- Sahin, Y.; Aydemir, E. A Comprehensive Solution Approach for CNC Machine Tool Selection Problem. Inform. 2022, 33, 81–108. [Google Scholar] [CrossRef]

- Yu, V.F.; Kao, H.C. Equipment Procurement for Printed Circuit Boards, Using the Analytic Hierarchy Process. J. King Saud Univ.-Eng. Sci. 2022; in press. [Google Scholar] [CrossRef]

- Temiz, I.; Calis, G. Selection of Construction Equipment by Using Multi-Criteria Decision Making Methods. Procedia Eng. 2017, 196, 286–293. [Google Scholar] [CrossRef]

- Alpay, S.; Iphar, M. Equipment Selection Based on Two Different Fuzzy Multi Criteria Decision Making Methods: Fuzzy TOPSIS and Fuzzy VIKOR. Open Geosci. 2018, 10, 661–677. [Google Scholar] [CrossRef]

- Keshavarz Ghorabaee, M.; Amiri, M.; Zavadskas, E.K.; Antucheviciene, J. A New Hybrid Fuzzy MCDM Approach for Evaluation of Construction Equipment with Sustainability Considerations. Arch. Civ. Mech. Eng. 2018, 18, 32–49. [Google Scholar] [CrossRef]

- Waris, M.; Panigrahi, S.; Mengal, A.; Soomro, M.I.; Mirjat, N.H.; Ullah, M.; Azlan, Z.S.; Khan, A. An Application of Analytic Hierarchy Process (Ahp) for Sustainable Procurement of Construction Equipment: Multicriteria-Based Decision Framework for Malaysia. Math. Probl. Eng. 2019, 2019, 6391431. [Google Scholar] [CrossRef]

- Deme, D. Tunnel Boring Machine Selection in Railway Project. J. Adv. Eng. Technol. 2020, 7, 4. [Google Scholar] [CrossRef]

- Thakur, K.G.; Keprate, A. Use of Analytical Hierarchy Process in Selecting the Optimum Equipment for Execution at a Construction Project. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 14–17 December 2020; pp. 1022–1026. [Google Scholar] [CrossRef]

- Zhang, F.; Ju, Y.; Santibanez Gonzalez, E.D.R.; Wang, A. SNA-Based Multi-Criteria Evaluation of Multiple Construction Equipment: A Case Study of Loaders Selection. Adv. Eng. Informatics 2020, 44, 101056. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Arslan, V.; Uygun, O.; Demir, I.H. Construction Equipment Selection through Scenario-Based FDEA: Truck-Mixer Drums. KSCE J. Civ. Eng. 2021, 25, 2794–2808. [Google Scholar] [CrossRef]

- Issa, U.; Saeed, F.; Miky, Y.; Alqurashi, M.; Osman, E. Hybrid AHP-Fuzzy TOPSIS Approach for Selecting Deep Excavation Support System. Buildings 2022, 12, 295. [Google Scholar] [CrossRef]

- Wang, W.; Tian, G.; Zhang, T.; Jabarullah, N.H.; Li, F.; Fathollahi-Fard, A.M.; Wang, D.; Li, Z. Scheme Selection of Design for Disassembly (DFD) Based on Sustainability: A Novel Hybrid of Interval 2-Tuple Linguistic Intuitionistic Fuzzy Numbers and Regret Theory. J. Clean. Prod. 2021, 281, 124724. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).