Optimal Control Design and Online Controller-Area-Network Bus Data Analysis for a Light Commercial Hybrid Electric Vehicle

Abstract

1. Introduction

1.1. Background

1.2. Model-In-The-Loop Development

1.3. Hardware-In-The-Loop Development

- This paper presents an optimal energy development approach for the reference vehicle of the engineering faculty at the University of Debrecen by performing a time-based simulation in MATLAB/Simulink, unlike the study in [57], which is limited to studying the real transformation of the vehicle from conventional to hybrid.

- The battery charge level might not guarantee optimal performance of the HEV as proposed in [19] using the FLC technique. This paper considers almost every aspect of performance evaluation to ensure the optimal fuel economy of the proposed hybrid car.

- The proposed conventional PID controller in [13,14,15] and [58] might not guarantee optimal fuel economy. The computed fitness function in [59,60] did not achieve more stable systems; therefore, good fuel economy could not be realized. An optimal solution is realized in this paper by computing minimum values of the integral error objective functions. In addition to reducing the computational effort of the analytical approach in ref. [15], PMSM is more efficient than the proposed Brushless Direct Current (BLDC) motor as in [60] for EV application.

- The study in [61] found the power transmission efficiency to be approximately 84%. Moreover, the designed EV is 15% (75–60) more efficient in fuel economy than the traditional car with an ICE. Our research has shown that the designed HEV is 31% (91–60) more efficient than the designed conventional vehicle as in [61]. In this paper, a transmission efficiency of 94% is achieved.

2. System Description and Design

2.1. HEV Configuration

2.2. Vehicle Dynamics Description

2.3. Tire Dynamics Description

2.4. ICE Modeling

2.5. Motor Modeling

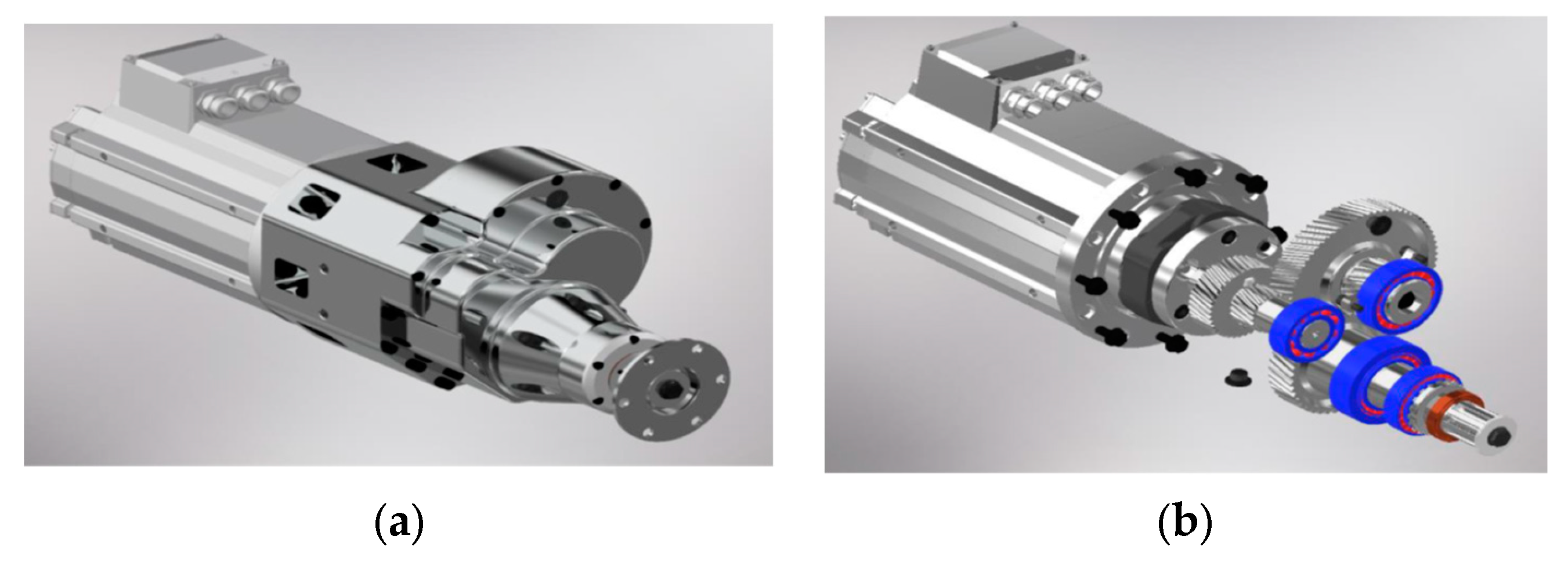

2.6. Gearbox Design for the Electric Mode

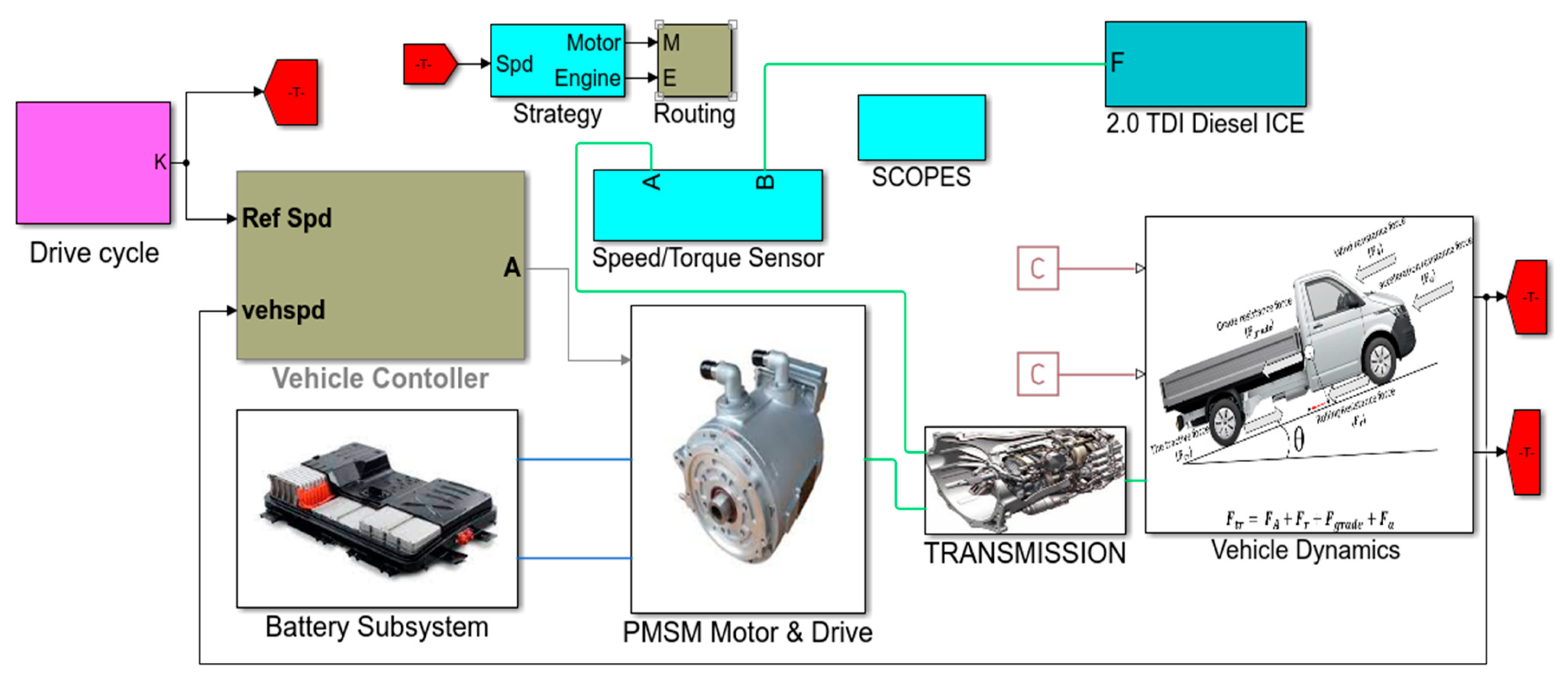

2.7. MATLAB Simulation

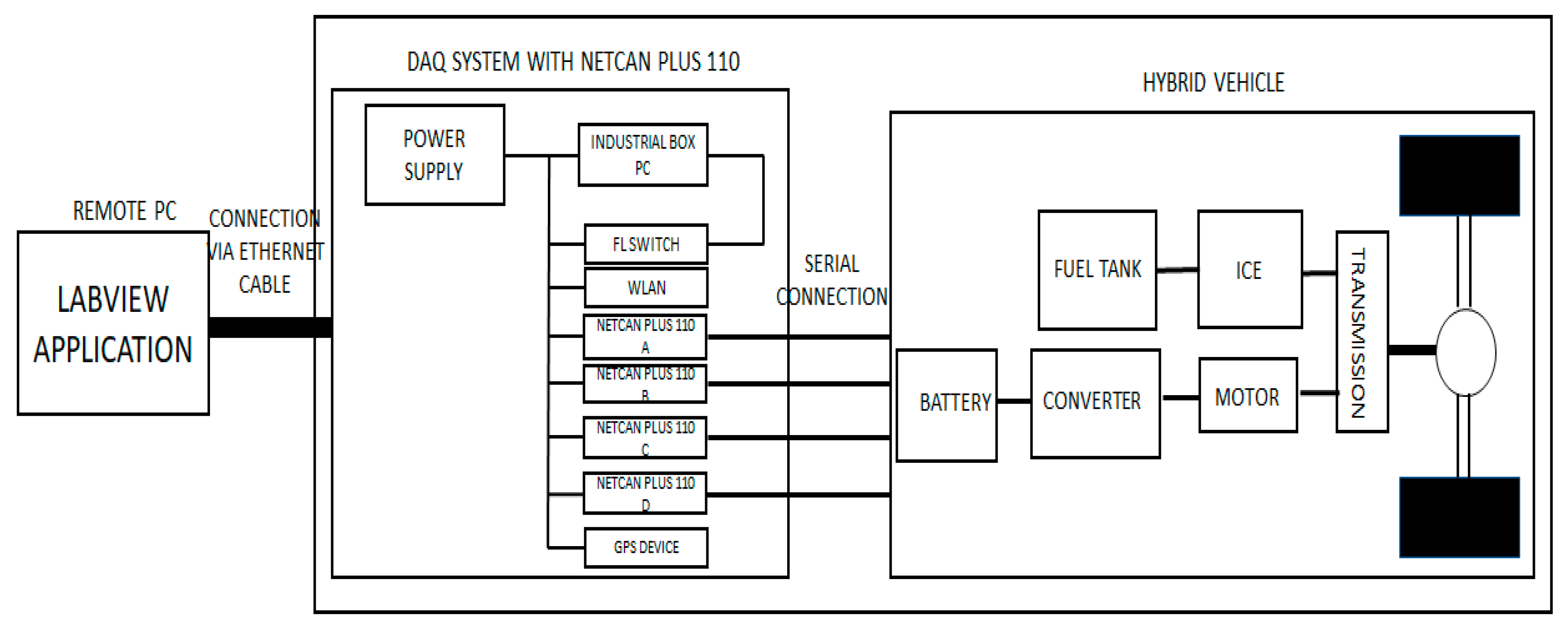

2.8. Experimental Set-Up

3. Simulation and Experimental Results

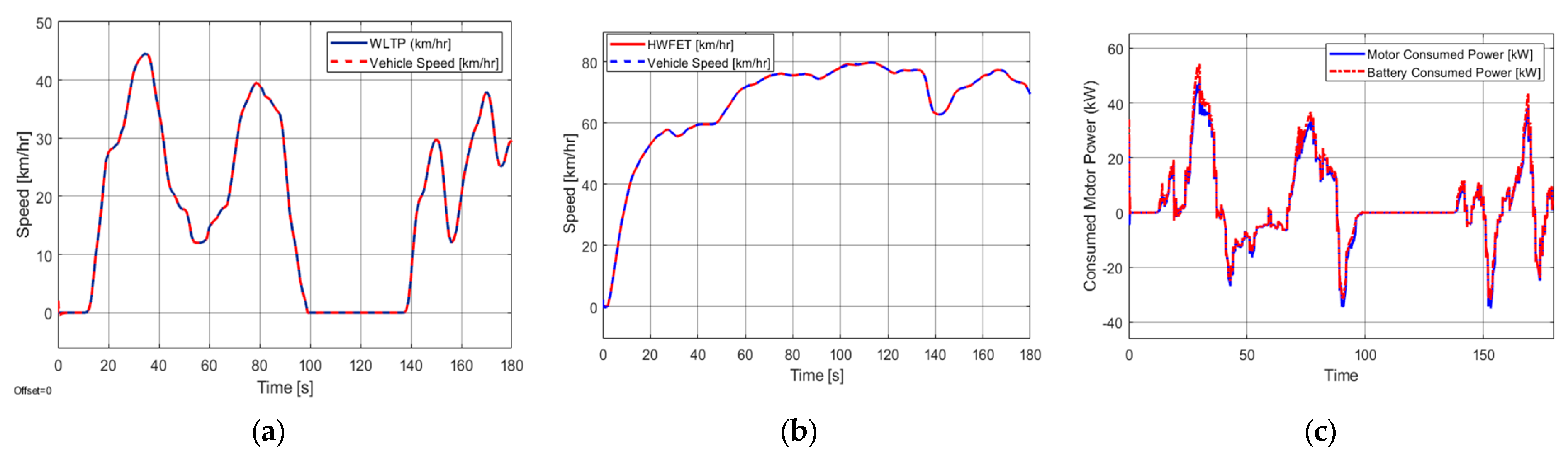

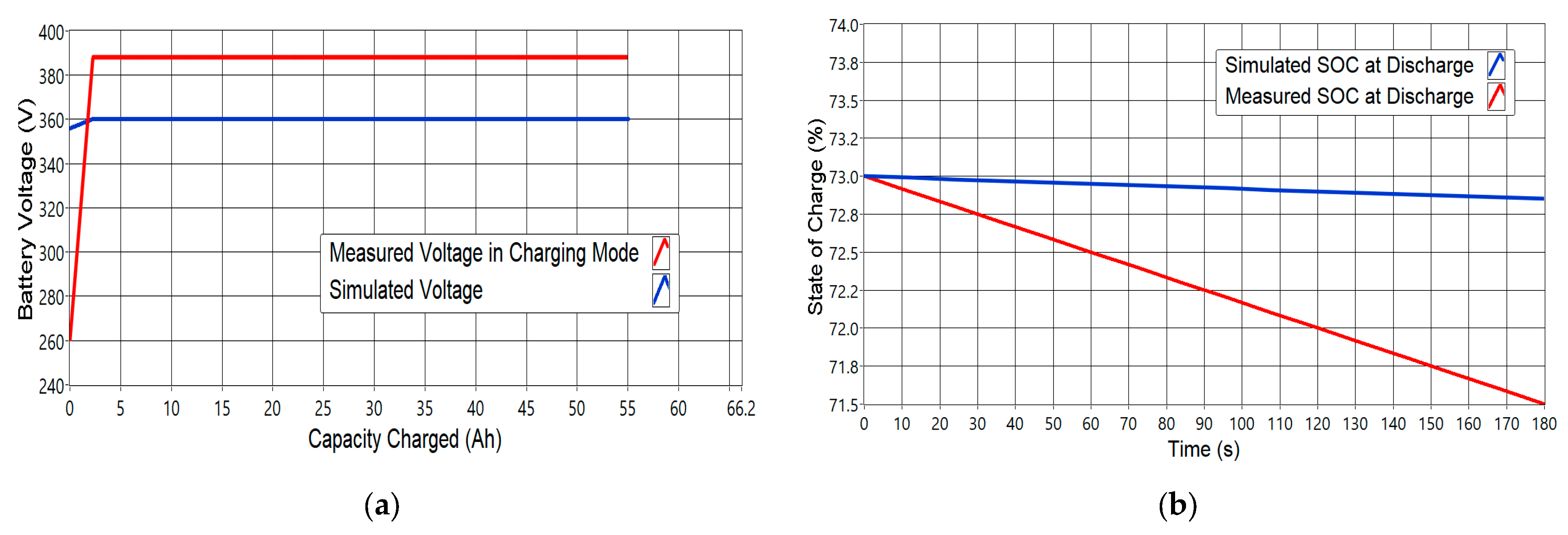

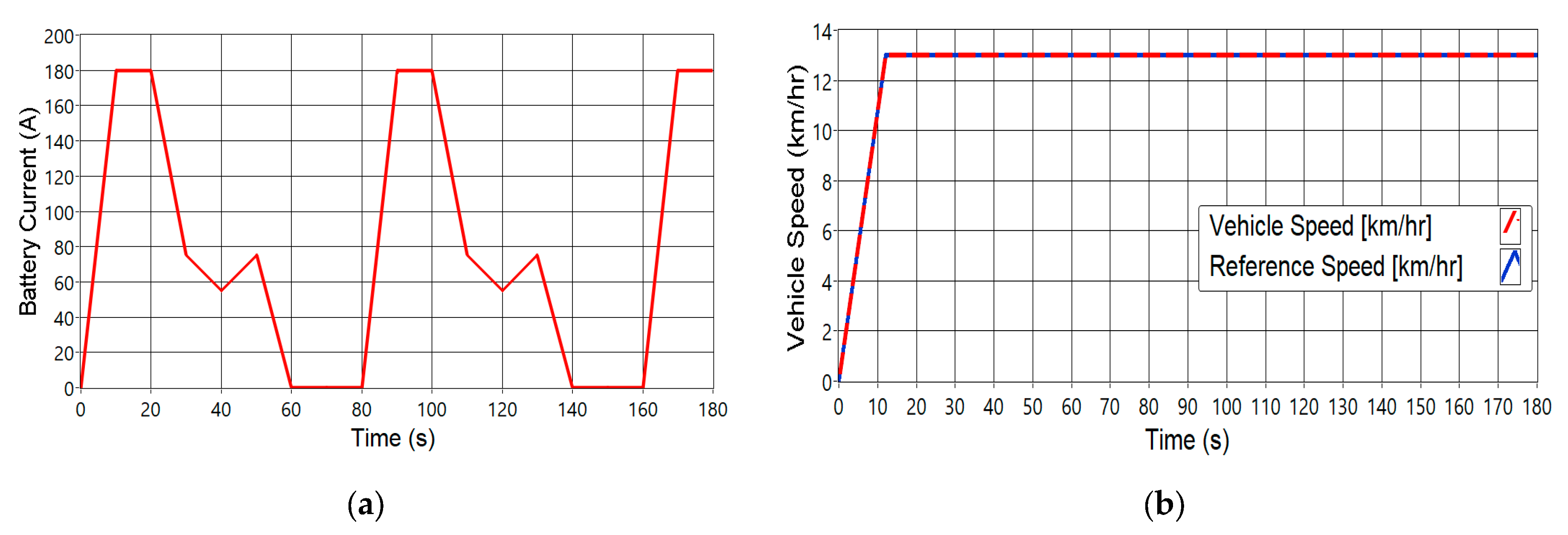

3.1. Simulation Results

3.2. Experimental Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al Khoury, J.; Nader, W.B. Design and simulation of turbogenerators for series hybrid electric vehicles. Energy Convers. Manag. 2021, 236, 114078. [Google Scholar] [CrossRef]

- Schmid, M.; Vögele, U.; Endisch, C. A novel matrix-vector-based framework for modeling and simulation of electric vehicle battery packs. J. Energy Storage 2020, 32, 101736. [Google Scholar] [CrossRef]

- Maaruf, M.; Khalid, M. Global sliding-mode control with fractional-order terms for the robust optimal operation of a hybrid renewable microgrid with battery energy storage. Electronics 2022, 11, 88. [Google Scholar] [CrossRef]

- Maaruf, M.; Khalid, M. Hybrid Solar/PEM Fuel Cell/and Water Electrolyzer Energy System for All-Electric Ship. In Proceedings of the 2022 IEEE Kansas Power and Energy Conference (KPEC), Manhattan, KS, USA, 25–26 April 2022; pp. 1–5. [Google Scholar] [CrossRef]

- He, H.; Luo, J.; Peng, J.; Wu, J. Parameter Matching and Simulation Analysis of Electromechanical Coupling Device for Hybrid Electric Vehicle. Energy Procedia 2017, 105, 2329–2334. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Poursamad, A.; Ghalichi, B. Application of genetic algorithm for optimization of control strategy in parallel hybrid electric vehicles. J. Frankl. Inst. 2006, 343, 420–435. [Google Scholar] [CrossRef]

- Gozukucuk, M.A.; Akdogan, T.; Hussain, W.; Tasooji, T.K.; Sahin, M.; Celik, M.; Ugurdag, H.F. Design and simulation of an optimal energy management strategy for plug-in electric vehicles. In Proceedings of the 2018 6th International Conference on Control Engineering and Information Technology, CEIT 2018, Istanbul, Turkey, 25–27 October 2018; pp. 25–27. [Google Scholar] [CrossRef]

- Van Mierlo, J.; Maggettto, G. Views on hybrid drivetrain power management strategies. In Proceedings of the EVS-17, Montreal, QC, Canada, 15–18 October 2000; Available online: http://etecnts1.vub.ac.be/etec/ (accessed on 13 February 2022).

- Kim, T.Y.; Lee, S.H. Combustion and Emission Characteristics of Wood Pyrolysis Oil-Butanol Blended Fuels in a Di Diesel Engine. Int. J. 2012, 13, 293–300. [Google Scholar] [CrossRef]

- Dlugosch, O.; Brandt, T.; Neumann, D. Combining analytics and simulation methods to assess the impact of shared, autonomous electric vehicles on sustainable urban mobility. Inf. Manag. 2020, 59, 103285. [Google Scholar] [CrossRef]

- Keskin, M.; Çatay, B.; Laporte, G. A simulation-based heuristic for the electric vehicle routing problem with time windows and stochastic waiting times at recharging stations. Comput. Oper. Res. 2021, 125, 105060. [Google Scholar] [CrossRef]

- Marmaras, C.; Xydas, E.; Cipcigan, L. Simulation of electric vehicle driver behaviour in road transport and electric power networks. Transp. Res. Part C Emerg. Technol. 2017, 80, 239–256. [Google Scholar] [CrossRef]

- Haitao, Y.; Yulan, Z.; Zunnian, L.; Kui, H. LQR-based power train control method design for fuel cell hybrid vehicle. Math. Probl. Eng. 2013, 2013, 968203. [Google Scholar] [CrossRef]

- Ahmed, A.; Yelamali, P.; Udayakumar, R. Modelling and simulation of hybrid technology in vehicles. Energy Rep. 2020, 6, 589–594. [Google Scholar] [CrossRef]

- Katrašnik, T. Analytical method to evaluate fuel consumption of hybrid electric vehicles at balanced energy content of the electric storage devices. Appl. Energy 2010, 87, 3330–3339. [Google Scholar] [CrossRef]

- Precup, R.-E.; Preitl, S.; Korondi, P. Fuzzy Controllers With Maximum Sensitivity for Servosystems. IEEE Trans. Ind. Electron. 2007, 54, 1298–1310. [Google Scholar] [CrossRef]

- Miranda, M.H.R.; Silva, F.L.; Lourenço, M.A.M.; Eckert, J.J.; Silva, L.C.A. Electric vehicle powertrain and fuzzy controller optimization using a planar dynamics simulation based on a real-world driving cycle. Energy 2022, 238, 121979. [Google Scholar] [CrossRef]

- Schouten, N.J.; Salman, M.A.; Kheir, N.A. Energy management strategies for parallel hybrid vehicles using fuzzy logic. Control Eng. Pract. 2003, 11, 171–177. [Google Scholar] [CrossRef]

- Saju, C.; Michael, P.A.; Jarin, T. Modeling and control of a hybrid electric vehicle to optimize system performance for fuel efficiency. Sustain. Energy Technol. Assess. 2022, 52, 102087. [Google Scholar] [CrossRef]

- Eckert, J.J.; da Silva, S.F.; de Menezes Lourenço, M.A.; Corrêa, F.C.; Silva, L.C.A.; Dedini, F.G. Energy management and gear shifting control for a hybridized vehicle to minimize gas emissions, energy consumption and battery aging. Energy Convers. Manag. 2021, 240, 114222. [Google Scholar] [CrossRef]

- Hasan, S.K. Fuzzy Logic Controller for Parallel Plug-in Hybrid Vehicle; University of Wisconsin Milwaukee: Milwaukee, WI, USA, 2012. [Google Scholar]

- Schouten, N.J.; Salman, M.A.; Kheir, N.A. Fuzzy logic control for parallel hybrid vehicles. IEEE Trans. Control Syst. Technol. 2002, 10, 460–468. [Google Scholar] [CrossRef]

- Halima, N.B.; Hadj, N.B.; Chaieb, M.; Neji, R. Energy Management of Parallel Hybrid Electric Vehicle Based on Fuzzy Logic Control Strategies. J. Circuits Syst. Comput. 2023, 32, 2350007. [Google Scholar] [CrossRef]

- Xu, E.; Wei, F.; Lin, C.; Meng, Y.; Zhu, J.; Liu, X. Model predictive control-based energy management strategy with vehicle speed prediction for hybrid electric vehicles. AIP Adv. 2022, 12, 075019. [Google Scholar] [CrossRef]

- Gaya, M.S.; Muhammad, A.; Abdulkadir, R.A.; Salim, S.N.S.; Madugu, I.S.; Tijjani, A.; Yusuf, L.A.; Umar, I.D.; Khairi, M.T.M. Enhanced pid vs. model predictive control applied to bldc motor. IOP Conf. Ser. Mater. Sci. Eng. 2018, 303, 012017. [Google Scholar] [CrossRef]

- Vu, T.M.; Moezzi, R.; Cyrus, J.; Hlava, J.; Petru, M. Parallel hybrid electric vehicle modelling and model predictive control. Appl. Sci. 2021, 11, 10668. [Google Scholar] [CrossRef]

- Zhou, Q.; Du, C. A quantitative analysis of model predictive control as energy management strategy for hybrid electric vehicles: A review. Energy Rep. 2021, 7, 6733–6755. [Google Scholar] [CrossRef]

- Hu, X.L.X.; Zhang, X.; Tang, X. Model predictive control of hybrid electric vehicles for fuel economy, emission reductions, and inter-vehicle safety in car-following scenarios, Energy. Energy 2020, 196, 117101. [Google Scholar] [CrossRef]

- Millo, F.; Rolando, L.; Tresca, L.; Pulvirenti, L. Development of a neural network-based energy management system for a plug-in hybrid electric vehicle. Transp. Eng. 2023, 11, 100156. [Google Scholar] [CrossRef]

- Chen, Z.; Mi, C.C.; Xu, J.; Gong, X.; You, C. Energy Management for a Power-Split Plug-in Hybrid Electric Vehicle Based on Dynamic Programming and Neural Networks. IEEE Trans. Veh. Technol. 2013, 63, 1567–1580. [Google Scholar] [CrossRef]

- Cipek, M.; Pavković, D.; Petrić, J.Š. A control-oriented simulation model of a power-split hybrid electric vehicle. Appl. Energy 2013, 101, 121–133. [Google Scholar] [CrossRef]

- Alegre, S.; Míguez, J.V.; Carpio, J. Modelling of electric and parallel-hybrid electric vehicle using Matlab/Simulink environment and planning of charging stations through a geographic information system and genetic algorithms. Renew. Sustain. Energy Rev. 2017, 74, 1020–1027. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Hu, M.; Yang, Z.; Fu, C. Longitudinal–vertical comprehensive control for four-wheel drive pure electric vehicle considering energy recovery and ride comfort. Energy 2021, 236, 121417. [Google Scholar] [CrossRef]

- Mackanic, D.; Marquez, E.D.; Dennington, J.; McClean, J.; Wheeler, K.; Nelson, D. Development of a Software-in-the-Loop Model for a Parallel Plug-in Hybrid Electric Vehicle. SAE Tech. Pap. 2016. [Google Scholar] [CrossRef]

- Bartolini, C.; Lipari, G.; Almeida, L. Using Priority Inheritance techniques to override the size limit of CAN messages. IFAC Proc. Vol. 2007, 7, 127–134. [Google Scholar] [CrossRef]

- Tindell, K.W.; Hansson, H.; Wellings, A.J. Analyzing real-time communications: Controller area network (CAN). In Proceedings of the 1994 Proceedings Real-Time Systems Symposium, San Juan, PR, USA, 7–9 December 1994; pp. 259–263. [Google Scholar] [CrossRef]

- De Andrade, R.; Hodel, K.N.; Justo, J.F.; Laganá, A.M.; Santos, M.M.; Gu, Z. Analytical and Experimental Performance Evaluations of CAN-FD Bus. IEEE Access 2018, 6, 21287–21295. [Google Scholar] [CrossRef]

- Ruta, M.; Scioscia, F.; Gramegna, F.; Di Sciascio, E. A mobile knowledge-based system for on-board diagnostics and car driving assistance. In Proceedings of the UBICOMM 2010—4th International Conference on Mobile Ubiquitous Computing, Systems, Services and Technologies, Florence, Italy, 25–30 October 2010; pp. 91–96. [Google Scholar]

- Moniaga, J.V.; Manalu, S.R.; Hadipurnawan, D.A.; Sahidi, F. Diagnostics vehicle’s condition using obd-ii and raspberry pi technology: Study literature. J. Phys. Conf. Ser. 2018, 978, 012011. [Google Scholar] [CrossRef]

- Kushiro, N.; Oniduka, Y.; Sakurai, Y. Initial Practice of Telematics-Based Prognostics for Commercial Vehicles: Analysis Tool for Building Faults Progress Model for Trucks on Telematics Data. Procedia Comput. Sci. 2017, 112, 2155–2164. [Google Scholar] [CrossRef]

- Yadav, A.; Bose, G.; Bhange, R.; Kapoor, K.; Iyengar, N.C.S.N.; Caytiles, R.D. Security, vulnerability and protection of vehicular on-board diagnostics. Int. J. Secur. Appl. 2016, 10, 405–422. [Google Scholar] [CrossRef]

- Gilman, E.; Keskinarkaus, A.; Tamminen, S.; Pirttikangas, S.; Röning, J.; Riekki, J. Personalized assistance for fuel-efficient driving. Transp. Res. Part C Emerg. Technol. 2015, 58, 681–705. [Google Scholar] [CrossRef]

- Rajput, P.; Parekh, R. On-Board Diagnostics based remote emission test for Light Motor Vehicles. In Proceedings of the CONECCT 2020–6th IEEE International Conference on Electronics, Computing and Communication Technologies, Online, 2–4 July 2020. [Google Scholar] [CrossRef]

- Malekian, R.; Moloisane, N.R.; Nair, L.; Maharaj, B.T.; Chude-Okonkwo, U.A.K. Design and Implementation of a Wireless OBD II Fleet Management System. IEEE Sens. J. 2017, 17, 1154–1164. [Google Scholar] [CrossRef]

- D’Agostino, M.; Naddeo, M.; Rizzo, G. Development and validation of a model to detect active gear via OBD data for a Through-The-Road Hybrid Electric Vehicle. IFAC Proc. Vol. 2014, 19, 6618–6623. [Google Scholar] [CrossRef]

- Pan, J.S.; Snasel, V.; Corchado, E.S.; Abraham, A.; Wang, S.L. Preface. Adv. Intell. Syst. Comput. 2014, 297, 2014. [Google Scholar] [CrossRef]

- Kim, H.S.; Jang, S.J.; Jang, J.W. A study on development of engine fault diagnostic system. Math. Probl. Eng. 2015, 2015, 271374. [Google Scholar] [CrossRef]

- Rimpas, D.; Papadakis, A.; Samarakou, M. OBD-II sensor diagnostics for monitoring vehicle operation and consumption. Energy Rep. 2020, 6, 55–63. [Google Scholar] [CrossRef]

- Fonseca, H.; Ferreira, C.; Fernandes, T. New Methodologies To Measure in Real Time Fuel Consumption of Internal Combustion Engines. In Proceedings of the 15th International Conference on Experimental Mechanics, Porto, Portugal, 22–27 July 2012; pp. 1–8. [Google Scholar]

- Balcı, Ö.; Karagöz, Y.; Gezer, O.; Kale, S.; Köten, H.; Pusat, S.; Yüksek, L. Numerical and experimental investigation of fuel consumption and CO2 emission performance for a parallel hybrid vehicle. Alex. Eng. J. 2021, 60, 3649–3667. [Google Scholar] [CrossRef]

- Sik, D.; Balogh, T.; Ekler, P.; Lengyel, L. Comparing OBD and CAN Sampling on the go with the SensorHUB Framework. Procedia Eng. 2016, 168, 39–42. [Google Scholar] [CrossRef]

- Li, H.; Saldivar-Carranza, E.; Mathew, J.K.; Kim, W.; Desai, J.; Wells, T.; Bullock, D.M. Extraction of Vehicle CAN Bus Data for Roadway Condition Monitoring; Purdue University: West Lafayette, IN, USA, 2020. [Google Scholar] [CrossRef]

- Mattetti, M.; Maraldi, M.; Lenzini, N.; Fiorati, S.; Sereni, E.; Molari, G. Outlining the mission profile of agricultural tractors through CAN-BUS data analytics. Comput. Electron. Agric. 2021, 184, 106078. [Google Scholar] [CrossRef]

- Mocera, F. A Model-Based Design Approach for a Parallel Hybrid Electric Tractor Energy Management Strategy Using Hardware in the Loop Technique. Vehicles 2021, 3, 1–19. [Google Scholar] [CrossRef]

- Szalay, Z.; Kánya, Z.; Lengyel, L.; Ekler, P.; Ujj, T.; Balogh, T.; Charaf, H. ICT in road vehicles—Reliable vehicle sensor information from OBD versus CAN. In Proceedings of the 2015 International Conference on Models and Technologies for Intelligent Transportation Systems, MT-ITS 2015, Budapest, Hungary, 3–5 June 2015; pp. 469–476. [Google Scholar] [CrossRef]

- Aguilar-Alvarez, P.; Valencia-Palomo, G.; López-Estrada, F.-R.; Zepeda-Hernández, J.Á.; López-Pérez, M.-D.-J.; Santos-Ruiz, I.; García-Ramos, O.-Y. Instrumentation and Dynamic Characterization of a Commercial Electric Vehicle for Rural Public Transport. IEEE Access 2023, 11, 12639–12647. [Google Scholar] [CrossRef]

- Bodzás, S.; Tiba, Z.; Ailer, P.; Husi, G. Redesign of a Volkswagen Crafter vehicle to a hybrid vehicle having e-motor and diesel engine. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1237, 012008. [Google Scholar] [CrossRef]

- Minh, V.T.; Moezzi, R.; Cyrus, J.; Hlava, J. Optimal Fuel Consumption Modelling, Simulation, and Analysis for Hybrid Electric Vehicles. Appl. Syst. Innov. 2022, 5, 36. [Google Scholar] [CrossRef]

- Babangida, A.; Szemes, P.T. Electric Vehicle Modelling and Simulation of a Light Commercial Vehicle Using PMSM Propulsion. Hung. J. Ind. Chem. 2021, 49, 37–46. [Google Scholar] [CrossRef]

- Babangida, A.; Szemes, P.T. Energy Consumption Simulation and Economic Benefit Analysis for a Light Duty Urban Commercial Electric Vehicle. In Proceedings of the IEEE 20th International Power Electronics and Motion Control Conference (PEMC), Brasov, Romania, 25–28 September 2022; pp. 667–672. [Google Scholar] [CrossRef]

- Du, G.; Member, S.; Cao, W.; Member, S.; Hu, S. Assessment of an Electric Vehicle Powertrain Model Based on Real-World Driving and Charging Cycles. IEEE Trans. Veh. Technol. 2018, 68, 1178–1187. [Google Scholar] [CrossRef]

- Pappalardo, C.M.; Lombardi, N.; Dašić, P.V.; Guida, D. Design and development of a virtual model of an electric vehicle of category L7. IOP Conf. Ser. Mater. Sci. Eng. 2019, 568, 012114. [Google Scholar] [CrossRef]

- Saleem, A.; Iqbal, A. Calculation Along with Factors Affecting the Total Tractive Power and Energy Demand. In Proceedings of the 3rd International Conference on Computing, Mathematics and Engineering Technologies: Idea to Innovation for Building the Knowledge Economy, iCoMET 2020, Sukkur, Pakistan, 29–30 January 2020. [Google Scholar]

- Pacejka, H.B. Tire and Vehicle Dynamics; Elsevier Scinence: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Norbakyah, J.S.; Daniel, H.W.C.; Atiq, W.H.; Daud, M.Z.; Salisa, A.R. Modeling, simulation and model optimization of internal combustion engine for PHERB powertrain. J. Teknol. 2017, 79, 161–173. [Google Scholar] [CrossRef][Green Version]

- Han, W. Simulation Model Development of Electric Motor and Controller; Chalmers University of Technology: Goteborg, Sweden, 2017; pp. 1–73. [Google Scholar]

- Virani, V.P.; Arya, S.; Baria, J. Modelling and Control of PMSM Drive by Field Oriented Control For HEV. SSRN Electron. J. 2019, 1–11. [Google Scholar] [CrossRef]

- Espina, J.; Arias, A.; Balcells, J.; Ortega, C. Speed anti-windup PI strategies review for field oriented control of permanent magnet synchronous machines. In Proceedings of the CPE 2009—6th International Conference-Workshop—Compatability and Power Electronics, Badajoz, Spain, 20–22 May 2009; pp. 279–285. [Google Scholar] [CrossRef]

- Zarour, L.; Chenni, R.; Borni, A.; Bouzid, A. Improvement of synchronous and asynchronous motor drive systems supplied by photovoltaic arrays with frequency control. J. Electr. Eng. 2008, 59, 169–177. [Google Scholar]

- Ito, I. Battery Electric Vehiclle Model in Simscape. Available online: https://githumb.com/mathworks/Simscape-Battery-Electric-VehicleModel/releases/tag/1.0.0 (accessed on 1 January 2021).

- Khaled, N. Hybrid Electric Vehicle (HEV) Model for a Passenger Car. 2022. Available online: https://www.mathworks.com/matlabcentral/fileexchange/75226-hybrid-electric-vehicle-hev-model-for-a-passenger-car (accessed on 10 December 2022).

- Simscape Powertrain Spark Ignition Model. Available online: https://github.com/maybachy1121/Simscape-Powertrain-SI-Model/find/master (accessed on 10 December 2022).

- Tan, W.; Marquez, H.J.; Chen, T. Performance assessment of PID controllers. Control Intell. Syst. 2004, 32, 158–166. [Google Scholar] [CrossRef]

| Surface | B | C | D | E |

|---|---|---|---|---|

| Ice | 4 | 2 | 0.1 | 1 |

| Snow | 5 | 2 | 0.3 | 1 |

| Wet tarmac | 12 | 2.3 | 0.82 | 1 |

| Dry tarmac | 10 | 1.9 | 1 | 0.97 |

| Parameters | Values |

|---|---|

| Stator resistance (R) | 0.07 Ohm |

| d-axis Inductance () | 0.0013 H |

| q-axis Inductance () | 0.0039 H |

| Rotor Flux (Vs) | 0.1447 Weber |

| Pole Pairs | 4 |

| Sample time (T) | 2 × 10−6 s |

| Parameters | Specifications |

|---|---|

| Peak/Rated Power | 82.3/53.5 kW |

| Peak/Rated Torque | 173/78.6 Nm |

| Peak/Rated RPM | 8000/6500 rpm |

| Time Constant | 0.02 s |

| Series Resistance | 0 |

| Rotor Inertia | 3.90 × 10−4 kg/m2 |

| Rotor Damping | 1 × 10−5 Nm/(rad/s) |

| Diameters, d (mm) | Axial Module, m (mm) | Number of Teeth, z | Gear Ratio, i |

|---|---|---|---|

| d1 | 2.25 | 26 | 1.54 |

| d2 | 2.25 | 40 | |

| d3 | 2.5 | 20 | 3.4 |

| d4 | 2.5 | 68 | |

| d5 | 3 | 18 | 2.33 |

| d6 | 3 | 42 | |

| i = 12.22 |

| Vehicle Controller | Speed Ref. | Performance Indices | Energy Economy (kWh/100 km) | ||||

|---|---|---|---|---|---|---|---|

| IAE | ISE | ITAE | ITSE | ||||

| 1500 | 2000 | WLTP | 0.0887 | 0.8553 | 0.0037 | 22.07 | |

| 2000 | 2000 | WLTP | 0.0780 | 0.7670 | 0.0029 | 22.08 | |

| 2000 | 1500 | WLTP | 0.0574 | 0.5669 | 0.0016 | 22.07 | |

| 1000 | 600 | WLTP | 0.0029 | 0.0368 | 22.09 | ||

| 2000 | 700 | WLTP | 0.0918 | 0.0403 | 22.09 | ||

| Vehicle Controller | Speed Ref. | Performance Indices | Energy Economy (kWh/100 km) | ||||

|---|---|---|---|---|---|---|---|

| 𝐾𝑝 | 𝐾𝑖 | IAE | ISE | ITAE | ITSE | ||

| 700 | 800 | WLTP | 0.3753 | 0.0071 | 3.6593 | 0.0670 | 22.75 |

| 700 | 600 | WLTP | 0.4243 | 0.0090 | 4.1354 | 0.0856 | 22.76 |

| 600 | 500 | WLTP | 0.4907 | 0.0121 | 4.7829 | 0.1145 | 22.77 |

| 1000 | 800 | WLTP | 0.3106 | 0.0048 | 3.0381 | 0.0462 | 22.74 |

| 2000 | 1000 | WLTP | 0.1387 | 1.3739 | 0.0094 | 22.73 | |

| Drive Cycle (km/h) | L/100 km | km/L | MPG | TFU (L) | ||

|---|---|---|---|---|---|---|

| 1500 | 2000 | WLTP | 2.769 | 36.11 | 84.95 | 0.02476 |

| 2000 | 2000 | WLTP | 2.769 | 36.12 | 84.95 | 0.02476 |

| 2000 | 1500 | WLTP | 2.769 | 36.11 | 84.93 | 0.02476 |

| 1000 | 600 | WLTP | 2.774 | 36.05 | 84.79 | 0.0248 |

| 2000 | 700 | WLTP | 2.769 | 36.11 | 84.94 | 0.02476 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babangida, A.; Light Odazie, C.M.; Szemes, P.T. Optimal Control Design and Online Controller-Area-Network Bus Data Analysis for a Light Commercial Hybrid Electric Vehicle. Mathematics 2023, 11, 3436. https://doi.org/10.3390/math11153436

Babangida A, Light Odazie CM, Szemes PT. Optimal Control Design and Online Controller-Area-Network Bus Data Analysis for a Light Commercial Hybrid Electric Vehicle. Mathematics. 2023; 11(15):3436. https://doi.org/10.3390/math11153436

Chicago/Turabian StyleBabangida, Aminu, Chiedozie Maduakolam Light Odazie, and Péter Tamás Szemes. 2023. "Optimal Control Design and Online Controller-Area-Network Bus Data Analysis for a Light Commercial Hybrid Electric Vehicle" Mathematics 11, no. 15: 3436. https://doi.org/10.3390/math11153436

APA StyleBabangida, A., Light Odazie, C. M., & Szemes, P. T. (2023). Optimal Control Design and Online Controller-Area-Network Bus Data Analysis for a Light Commercial Hybrid Electric Vehicle. Mathematics, 11(15), 3436. https://doi.org/10.3390/math11153436