A Method for Mathematical Modeling of Hydrodynamic Friction of Plunger Pairs with Consideration of Microgeometry

Abstract

1. Introduction

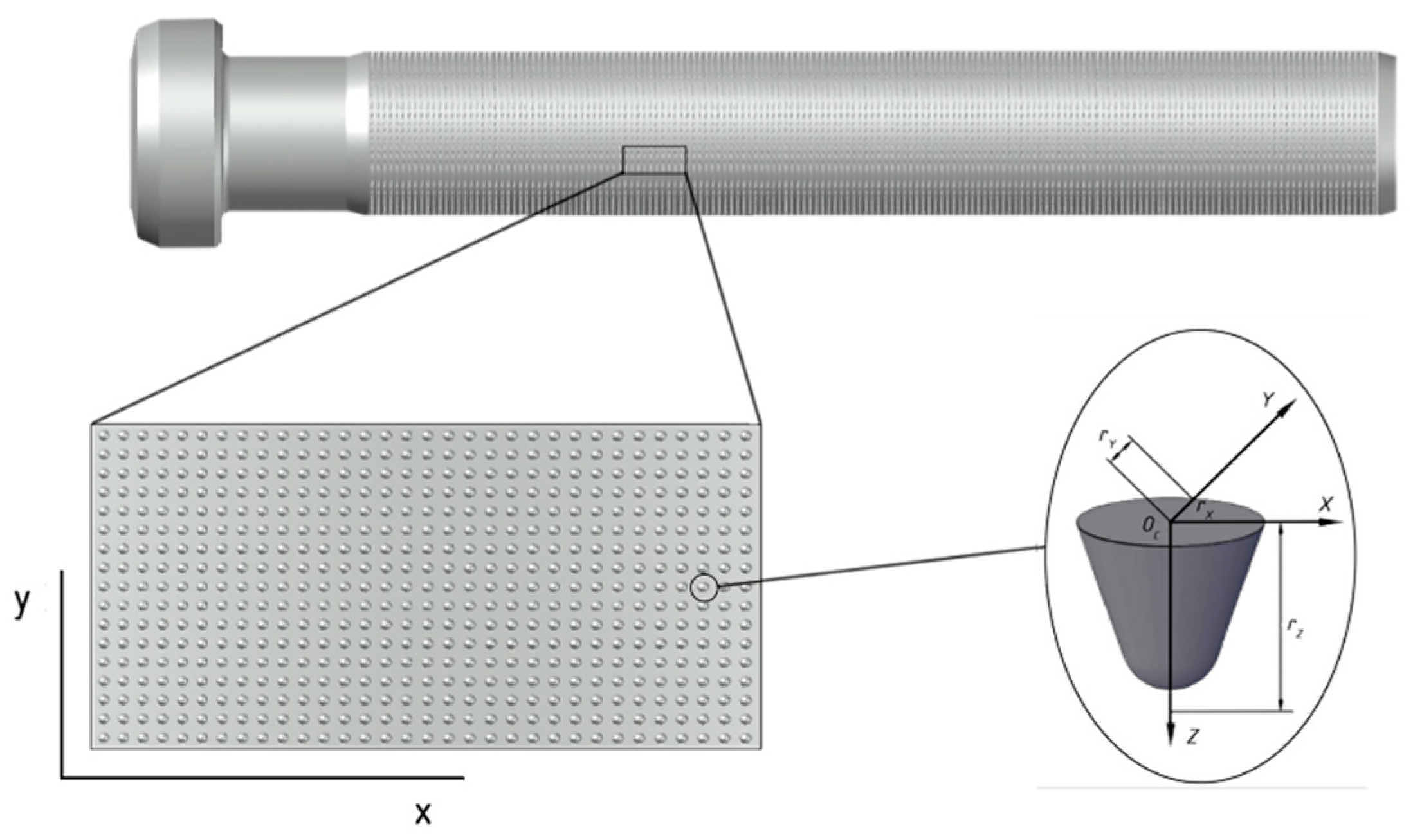

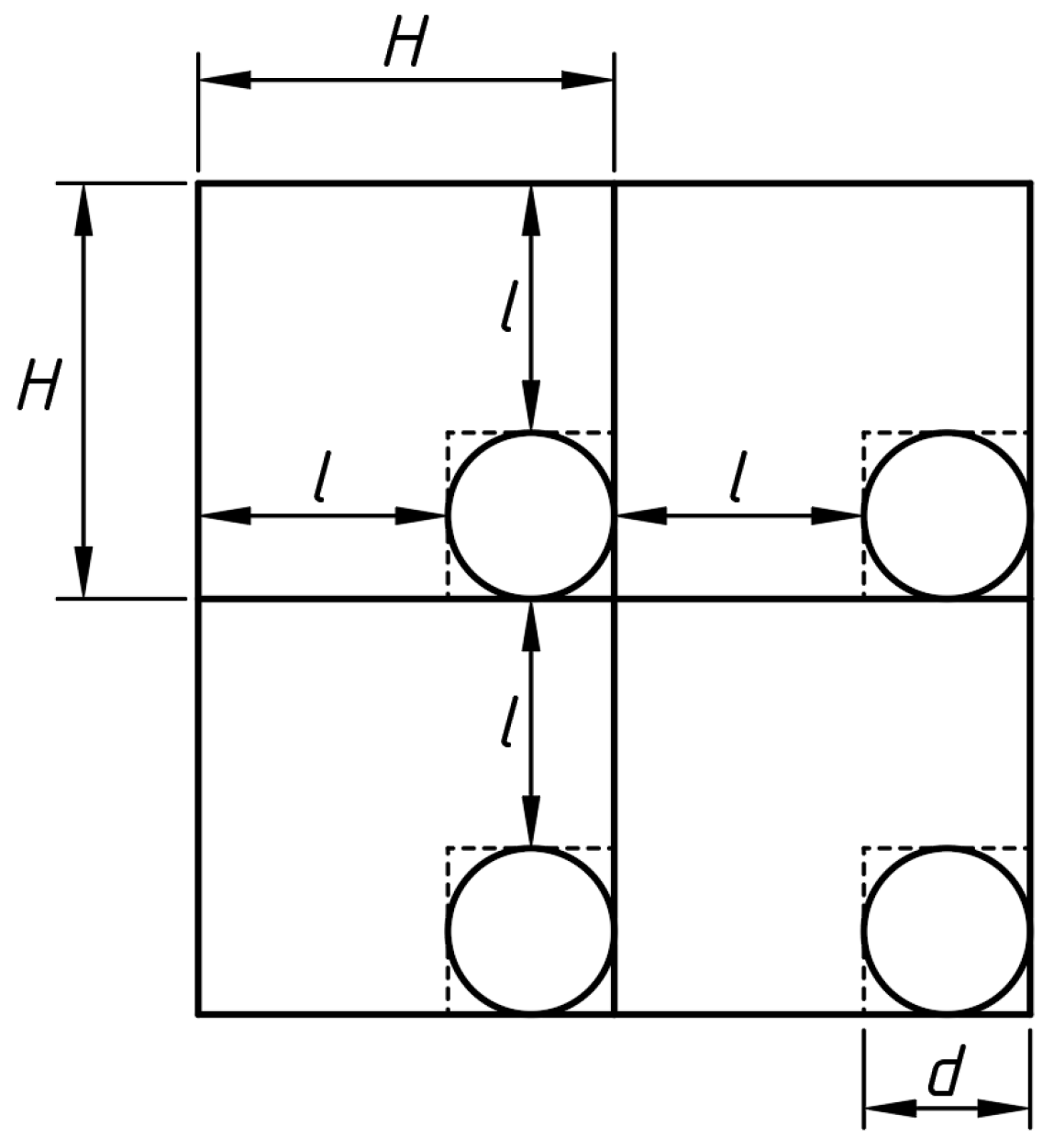

2. Idea: Simple Discrete Model

3. Generalization of the Model

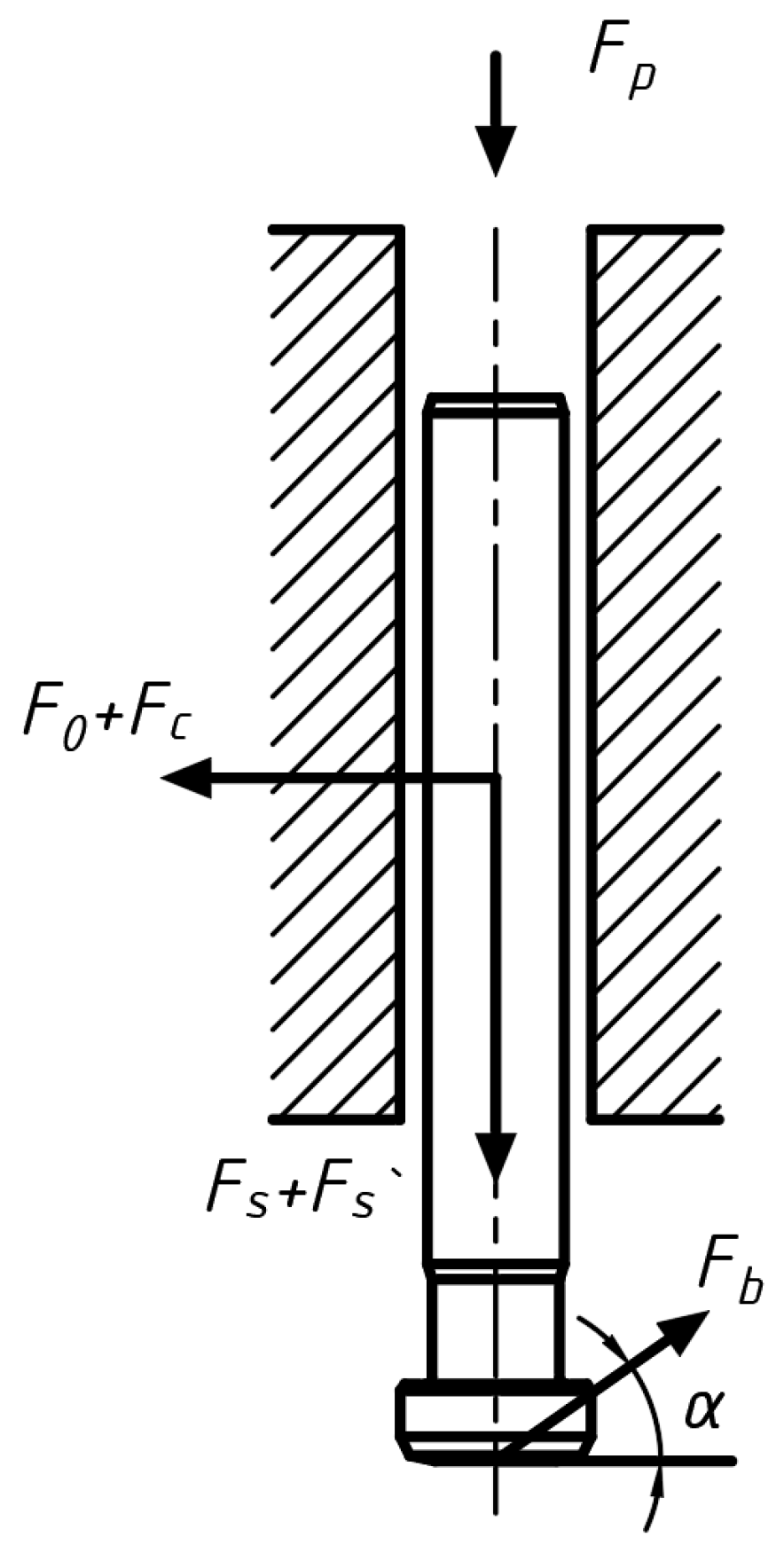

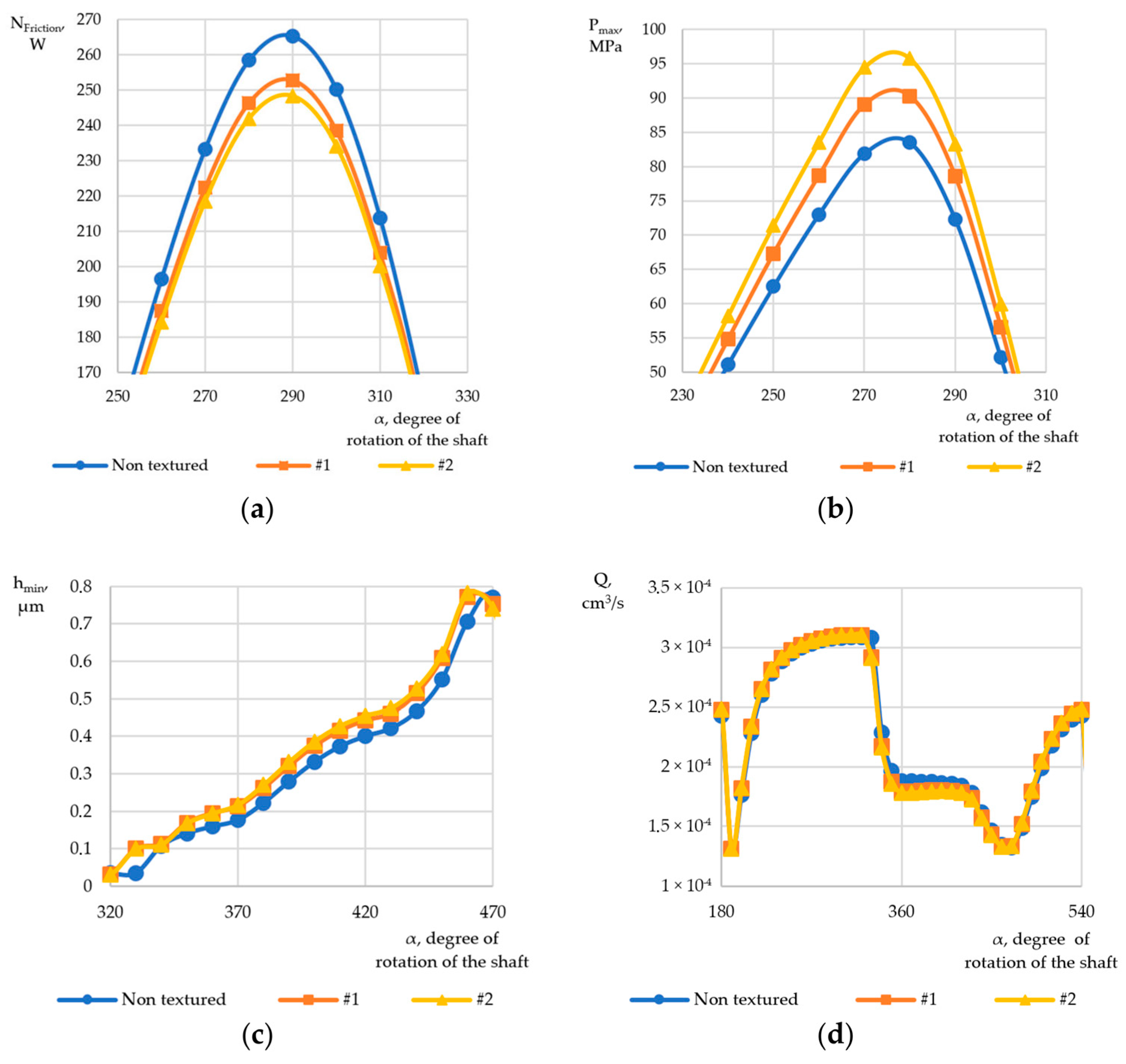

4. The Equation of Motion for a Plunger Pair

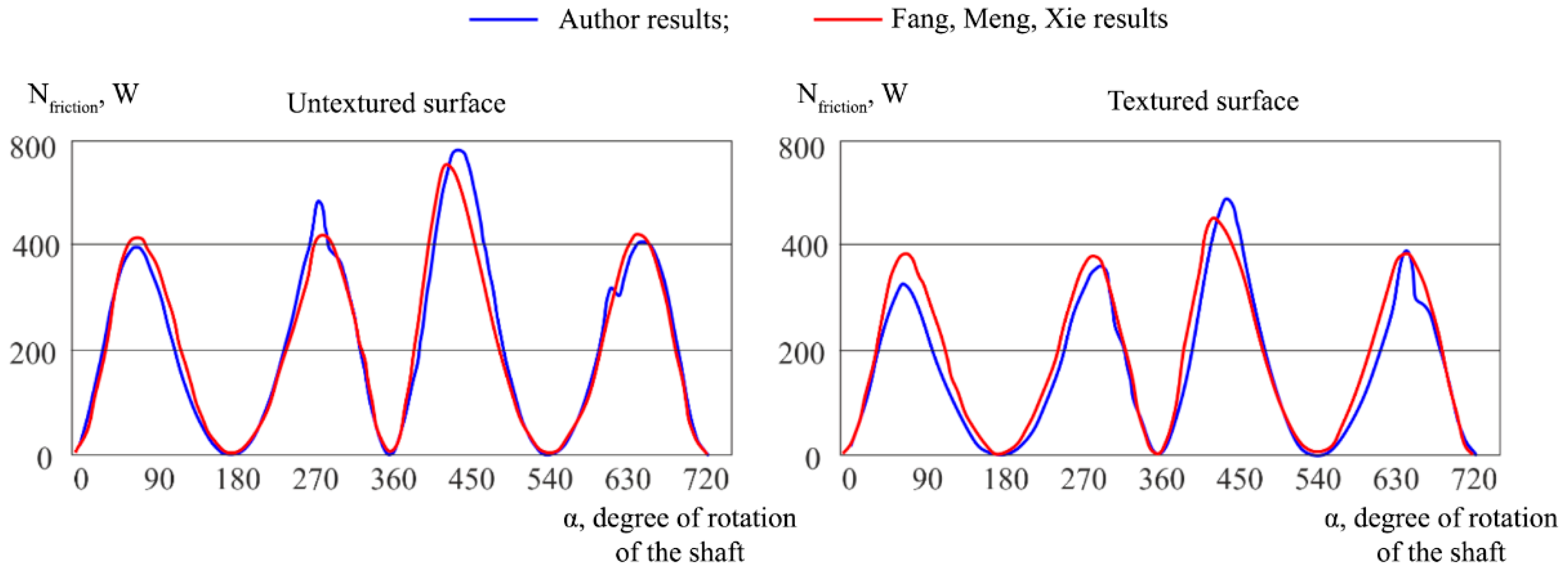

5. Results of Modeling

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Knauder, C.; Allmaier, H.; Sander, D.E.; Salhofer, S.; Reich, F.M.; Sams, T. Analysis of the journal bearing friction losses in a heavy-duty diesel engine. Lubricants 2015, 3, 142–154. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Nylund, N.O.; Mäkelä, K.; Erdemir, A. Global energy consumption due to friction in trucks and buses. Tribol. Int. 2014, 78, 94–114. [Google Scholar] [CrossRef]

- Brazhenko, V.N.; Mochalin, E.V.; Jian-Cheng, C. Mechanical Admixture Influence in the Working Fluid on Wear and Jamming of Spool Pairs from Aircraft Hydraulic Drives. J. Frict. Wear 2020, 41, 526–530. [Google Scholar] [CrossRef]

- Brazhenko, V. The Influence of Contaminated Hydraulic Fluid on the Relative Volume Flow Rate and the Wear of Rubbing Parts of the Aviation Plunger Pump. Aviation 2019, 23, 43–47. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Ai, C.; Ge, Y.; Li, Z.; Zhu, Y.; Hao, M. A new test method for simulating wear failure of hydraulic pump slipper pair under high-speed and high-pressure conditions. Front. Energy Res. 2023, 10, 1096633. [Google Scholar] [CrossRef]

- Zhang, Q.; Fu, Y.; Yuan, Z.; Song, Z. Multi-medium running induced piston pump erosion. Sci. Technol. Rev. 2012, 30, 44–48. [Google Scholar]

- Teoh, Y.H.; How, H.G.; Masjuki, H.H.; Nguyen, H.-T.; Kalam, M.A.; Alabdulkarem, A. Investigation on particulate emissions and combustion characteristics of a common-rail diesel engine fuelled with Moringa oleifera biodiesel-diesel blends. Renew. Energy 2019, 136, 521–534. [Google Scholar] [CrossRef]

- Huang, J.L.; Xu, H.; Sun, S.Y.; Wang, D. Influence of fuel injection system’s optimization on performance of diesel engine and its injection parameter reoptimization. J. Dalian Marit. Univ. 2017, 43, 2–108. [Google Scholar]

- Zhao, J.; Fu, Y.; Ma, J.; Fu, J.; Chao, Q.; Wang, Y. Review of cylinder block/valve plate interface in axial piston pumps: Theoretical models, experimental investigations, and optimal design. Chin. J. Aeronaut. 2021, 34, 1–134. [Google Scholar] [CrossRef]

- Segu, D.Z.; Hwang, P. Effectiveness of multishape laser surface texturing in the reduction of friction under lubrication regime. Ind. Lubr. Tribol. 2016, 68, 116–124. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, X.; Zhu, J.; Gao, Y.; Wang, H.; Zhao, X.; Teng, Q.; Ren, Y.; Zhu, G. On the lubrication characteristics of piston ring under different engine operation conditions. Ind. Lubr. Tribol. 2019, 72, 101–108. [Google Scholar] [CrossRef]

- Cavallo, M.; Frattini, E.; Palmieri, F. Fuel Influence on Single-Piston Common Rail Pump Performance; SAE Technical Paper 2021; N° 2021-24-0063; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Chen, L.; Ren, L.Q.; Zhao, Y.; Zhou, H. The wear-resistance of 3Cr2W8V steel with cave pit non-smooth processed by laser. J. Bionic Eng. 2008, 5, 34–39. [Google Scholar] [CrossRef]

- Lee, Y.H.; Schuh, J.K.; Ewoldt, R.H.; Allison, J.T. Simultaneous design of non-Newtonian lubricant and surface texture using surrogate-based multiobjective optimization. Struct. Multidiscip. Optim. 2019, 60, 99–116. [Google Scholar] [CrossRef]

- Singh, A.; Patel, D.S.; Ramkumar, J.; Balani, K. Single step laser surface texturing for enhancing contact angle and tribological properties. Int. J. Adv. Manuf. Technol. 2019, 100, 1253–1267. [Google Scholar] [CrossRef]

- Fukagai, S.; Le, M.; Lewis, R. Tribological aspects to optimize traction coefficient during running-in period using surface texture. Wear 2019, 424, 223–232. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Kovalchenkova, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G. A laser surface textured hydrostatic mechanical seal. Tribol. Trans. 2002, 45, 430–434. [Google Scholar] [CrossRef]

- Etsion, I.; Kligerman, Y.; Halperin, G. Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 1999, 42, 511–516. [Google Scholar] [CrossRef]

- Yin, B.; Zhou, H.; Xu, B.; Hekun, J. The influence of roughness distribution characteristic on the lubrication performance of textured cylinder liners. Ind. Lubr. Tribol. 2019, 71, 483–493. [Google Scholar] [CrossRef]

- Gavrilov, K.; Rozhdestvenskii, Y.; Umurzakov, I. The Construction of Models of Rough Surfaces’ Interaction: Markov’s Approach. Mathematics 2022, 10, 3607. [Google Scholar] [CrossRef]

- Jia, H.; Zhou, Z.; Yin, B.; Zhou, H.; Xu, B. Effect of compound texture on lubrication and sealing performance of plunger pump. Lubr. Sci. 2020, 33, 43–59. [Google Scholar] [CrossRef]

- Jia, H.; Zhou, Z.; Yin, B.; Zhou, H.; Xu, B. Influence of microdimple on lubrication performance of textured plunger pump. Ind. Lubr. Tribol. 2021, 73, 4–571. [Google Scholar] [CrossRef]

- Sinong, X.; Xiuqing, H.; Yinfei, Y.; Liang, L.; Ning, H.; Hanlong, L. Feasible fabrication of a wear-resistant hydrophobic surface. Appl. Surf. Sci. 2019, 463, 923–930. [Google Scholar]

- Puzanov, A.; Simakov, A.; Kosorukova, O.; Kotov, V. Perspectives using synthetic corundum in hydraulic drives. J. Phys. Conf. Ser. 2021, 1925, 012021. [Google Scholar] [CrossRef]

- Prokopyev, V.N.; Gavrilov, K.V. Optimization of parameters of lightly loaded sliding bearings. Probl. Mech. Eng. Mach. Reliab. 2007, 5, 79–86. (In Russian) [Google Scholar]

- Gavrilov, K.V.; Izzatulloev, M.A.; Gritsenko, P.S.; Tsveshko, I.R. Influence of lubrication source location on hydro-mechanical characteristics of lightly loaded bearings in thermal engines. Vestnik of South Ural State University. Ser. Mech. Eng. 2019, 19, 3–21. (In Russian) [Google Scholar]

- Fang, C.; Meng, X.; Xie, Y. A piston tribodynamic model with deterministic consideration of skirt surface grooves. Tribol. Int. 2017, 110, 232–251. [Google Scholar] [CrossRef]

| Diameter of Plunger, mm | Mass of Plunger, grams | Length of Working Part of Plunger, mm | Eccentricity, mm | Rotational Speed of Shaft, RPM | Average Velocity of Plunger, m/s |

|---|---|---|---|---|---|

| 11.0 | 56.0 | 55.60 | 3.5 | 3300 | 0.77 |

| Density, kg/m3 | Thermal Capacity, joule/K·kg | Coefficient of Thermal Conduction, W/m·K | Coefficient of Dynamic Viscosity, Pa·s |

|---|---|---|---|

| 730 | 2090 | 0.149 | 0.0024 |

| № | Varied Parameters | Quality Criteria (Hydrodynamic Characteristics) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| X1, m | X2, m | d, m | ry, m | D, % | , μm | , MPa | N*, W | Q*, cm3/s | |

| 1 | 0.1533 × 10−1 | 0.4378 × 10−1 | 1.19 × 10−5 | 4.76 × 10−6 | 37.5599 | 3.01 × 10−2 | 102.651 | 113.384 | 2.20 × 10−4 |

| 2 | 0.1583 × 10−1 | 0.4444 × 10−1 | 1.22 × 10−5 | 4.89 × 10−6 | 38.8817 | 2.98 × 10−2 | 105.045 | 112.774 | 2.21 × 10−4 |

| 3 | 0.1375 × 10−1 | 0.4166 × 10−1 | 1.08 × 10−5 | 4.33 × 10−6 | 33.3326 | 3.08 × 10−2 | 96.340 | 114.463 | 2.19 × 10−4 |

| 4 | 0.1535 × 10−1 | 0.4380 × 10−1 | 1.19 × 10−5 | 4.76 × 10−6 | 37.6066 | 3.01 × 10−2 | 102.724 | 113.369 | 2.20 × 10−4 |

| 5 | 0.1370 × 10−1 | 0.4161 × 10−1 | 1.08 × 10−5 | 4.32 × 10−6 | 33.2203 | 3.09 × 10−2 | 96.306 | 115.307 | 2.18 × 10−4 |

| 6 | 0.1361 × 10−1 | 0.4148 × 10−1 | 1.07 × 10−5 | 4.30 × 10−6 | 32.9657 | 3.09 × 10−2 | 95.989 | 115.406 | 2.18 × 10−4 |

| 7 | Plunger pair without microgeometry | 3.31 × 10−2 | 85.603 | 121.908 | 2.17 × 10−4 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavrilov, K.; Rozhdestvenskii, Y.; Umurzakov, I. A Method for Mathematical Modeling of Hydrodynamic Friction of Plunger Pairs with Consideration of Microgeometry. Mathematics 2023, 11, 2637. https://doi.org/10.3390/math11122637

Gavrilov K, Rozhdestvenskii Y, Umurzakov I. A Method for Mathematical Modeling of Hydrodynamic Friction of Plunger Pairs with Consideration of Microgeometry. Mathematics. 2023; 11(12):2637. https://doi.org/10.3390/math11122637

Chicago/Turabian StyleGavrilov, Konstantin, Yuriy Rozhdestvenskii, and Ildar Umurzakov. 2023. "A Method for Mathematical Modeling of Hydrodynamic Friction of Plunger Pairs with Consideration of Microgeometry" Mathematics 11, no. 12: 2637. https://doi.org/10.3390/math11122637

APA StyleGavrilov, K., Rozhdestvenskii, Y., & Umurzakov, I. (2023). A Method for Mathematical Modeling of Hydrodynamic Friction of Plunger Pairs with Consideration of Microgeometry. Mathematics, 11(12), 2637. https://doi.org/10.3390/math11122637