1. Introduction

Upgrading the value chain is a huge challenge, and it is one of the most critical processes for managers to help their enterprises survive and grow [

1]. In the manufacturing sector, competition is even more fierce among latecomer manufacturers from China, India, and Brazil compared with the past few decades [

2]. As the business environment becomes increasingly competitive, original equipment manufacturers (OEMs) or original design manufacturers (ODMs) have encountered considerable pressure to maintain their low-cost strategy. Companies that rely on OEM or ODM models in developed countries (e.g., Taiwan and Korea) are particularly vulnerable to this low-cost competition. An original brand manufacturer (OBM) can be defined as a company that designs and develops a product and then sells it under its brand name. In general, an OBM has full control over its product’s design, quality, and branding, along with its marketing and sales. Therefore, an OBM typically generates higher profit margins than an OEM. An OEM produces spare parts, semi-finished products, or finished products on the basis of specific materials, specifications, processing procedures, inspection standards, or brand labels by customers, while an ODM can participate in the product design stage. Given the lack of their own brands, achieving higher profit margins in the global value chain is difficult for OEMs and ODMs. To gain higher profit margins in the global value chain, OEMs and ODMs should upgrade their business model to OBMs. Therefore, more advanced, high-quality, and innovative products can solve the aforementioned problems and increase customer satisfaction and loyalty.

Contract manufacturers with many years of design and production experience have advantages and are highly suitable to build their own brands. Some firms have successfully transformed their businesses, but many have failed because they have not adopted the right strategies. As an example of a success story, the largest customer of Giant Bicycles (accounting for 75% of its revenue) transferred to manufacturers in China in 1981 due to high production costs in Taiwan. To overcome this crisis, Giant Bicycles established its own brand and adopted the ODM and OBM models with a global marketing network. It positioned itself as the world’s best brand for designing and manufacturing bicycles. Their transition led to their success as a well-known bicycle brand at present. Other firms that successfully transformed from OEM to OBM include Acer, HTC, Johnson, and Maxxis in Taiwan [

3], Cuckoo, Hankook Chinaware, and Lock & Lock in Korea [

4], and TCL and Lenovo in China [

2]. However, transformation can be a complex and challenging process for contract manufacturers due to poor strategic planning or lack of expertise in design and marketing, particularly for traditional manufacturing [

5].

The objective of the current study is to explore the key factors that help firms remain competitive in the global marketplace and achieve sustainable growth by transforming successfully to the OBM model on the basis of multi-criteria decision-making. Previous studies have focused only on some specific cases or contexts, limiting the generalizability of their findings [

3,

4,

6]. For example, case studies can provide insights into specific situations; however, they cannot offer a comprehensive understanding of the decision-making process or a framework for generalization in an OBM transition. Despite the growing popularity of multiple-criteria decision-making (MCDM) methods in various fields, empirical research that explores the key success criteria for OBM transformation is lacking. Therefore, the current study can contribute to the literature in several ways. First, this work can fill the gap in the existing literature by identifying criteria that affect the success of an OBM transformation on the basis of the Delphi method to achieve a reliable consensus among criteria from experts’ opinions. Second, we present the overall criteria ranking of an OBM transformation that can help firms increase the efficiency of decision-making through a decision-making trial and evaluation laboratory (DEMATEL) with an analytic network process (ANP). In contrast with the traditional MCDM, the integration of DEMATEL–ANP into the Delphi method not only enhances the quality of data but also improves the reliability of the findings. Finally, we illustrate the casual relationships that exhibit the interaction among six key criteria of an OBM transformation. By applying these success factors, companies can improve operational efficiency, increase profits, enhance their competitive position in global value chains, and reduce the risk of failure. The remainder of this paper is organized as follows. Related studies are presented in

Section 2. In

Section 3, we describe the methodology proposed in this study. The results and analysis are presented in

Section 4. Discussions about the theoretical and practical implications are summarized in

Section 5. Then, the conclusion of this study is drawn in

Section 6.

2. Literature Review

The macroeconomic environment refers to broad economic factors, such as inflation, interest rates, exchange rates, public policies, and politics, which affect the success of a business transition [

1,

2]. The transition from OEM or ODM to OBM requires a significant change in business strategy and is considerably influenced by the macroeconomic environment. Mahmood et al. [

3] demonstrate that political stability is an essential factor in creating an enabling environment for business transformation. Low interest rates, stable inflation, and exchange rates are essential conditions for firms to invest more in research and development (R&D) and build their brand and marketing. Aisen and Veiga [

4] report that political instability exerts a negative effect on macroeconomic performance. As competition increases, firms must innovate and upgrade their business to retain their profits and market share. For example, OEMs and ODMs from Taiwan, Korea, and Japan are losing their competitive advantage to emerging countries, such as China or India, in recent decades [

5]. Firms may experience conflicts of interest between their existing and new business models [

6]. Price hikes and component shortages not only disrupt production but also affect the success of an OBM transition. In particular, if raw materials are unstable, then a company may experience difficulty in producing its product at a price that is competitive in the market. Therefore, a stable supply chain is a major factor in the profitability of an OBM model.

Collis [

7] defines organizational capability as an organization’s ability to use its tangible and intangible resources effectively to achieve its goals. An OBM model requires a strong organizational capability to maintain its innovation and competitiveness in international markets [

8]. An organization must have the innovative capability to differentiate its products and shape the market rather than just be a follower [

9]. Strong innovation capabilities not only allow a company to develop new products quickly and efficiently but also build a strong brand reputation [

10]. Organizations must learn new techniques and knowledge to adapt to business model requirements at each stage. Jerez-Gómez et al. [

11] argue that an organization with a strong learning capability can innovate, develop, and implement effective strategies. In contrast with contract manufacturers, the OBM model requires a company to manage the entire supply chain from sourcing raw materials to delivering finished products to customers. Therefore, effective coordination and integration are essential for an organization to ensure that all necessary activities are performed efficiently and effectively. For example, organizations can reduce double marginalization to improve their revenue and profitability by coordinating closely with their suppliers and retailers. By coordinating with employees and departments, organizations can improve their operational performance to achieve common corporate goals [

12]. Moreover, organizations can quickly adjust their production and delivery schedules to meet the changing needs of customers. An organization’s environmental responsiveness refers to its ability to sense and react quickly to changes in the environment. Moreover, customers’ growing concern about environmental responsibility will create an additional challenge for organizations during an OBM transition [

13]. However, organizations can attract more customers and generate more competitive advantages through their commitment to the environment.

In practice, R&D and technological capabilities are the major drivers of innovation by recombining existing knowledge or generating new knowledge through research [

14]. R&D creates technological progress, while technological competence is required for the effective use of new knowledge. If companies invest in R&D and develop strong technological capability, then they will be in a better position to innovate, improve product quality, reduce costs, and improve customer satisfaction. Tsai-Lin et al. [

15] demonstrate that without cutting-edge R&D, innovation design, and technological capability, companies will experience difficulty in transforming their businesses into the OBM model. If companies can effectively leverage, absorb, and use external technologies, then they can catch up with the latest technologies and create innovation faster from the expertise of other companies or research institutions. External technologies not only allow firms to access cutting-edge research, development tools, and testing capabilities but also help them save time and budget in R&D [

5,

16]. In accordance with Coombs [

17], the mastery of core competencies enables firms to develop a sustainable competitive advantage in long-term growth by leveraging their unique strengths and capabilities [

8]. Moreover, the mastery of core competencies allows firms to make effective decisions with better outcomes on the basis of long-term technological strength.

Marketing capability is well-known as an important factor that contributes to a sustainable competitive advantage and business performance [

18]. A clear market positioning strategy helps companies identify and target the right customers. By focusing on target customers, companies can effectively tailor their marketing strategies to meet customer needs [

19]. Moreover, strong brand awareness can increase sales. Hoyer and Brown [

20] report that brand awareness also influences consumers’ purchase intention. Meanwhile, the success of achieving global sales does not rely heavily on the effectiveness of distribution channels [

21]. Furthermore, effective global logistics and support capabilities not only help firms deliver their products on time and in good condition but also support customers whenever they need them. In accordance with Shokouhyar et al. [

22], after-sales service is an important component of customer satisfaction and loyalty. Several studies have shown that customers are more likely to return if they receive good after-sales service [

23]. Furthermore, after-sales service can be a key differentiator for companies in a competitive market. If customers receive good after-sales service, then they are more likely to recommend the company to others.

Manufacturing capability is defined as a fundamental proficiency that allows firms to achieve production goals [

24]. To transform successfully into the OBM model, the manufacturing capability of companies should have the ability to design efficient processes, supply chain management, quality control, and lean manufacturing [

25]. Previous studies have shown that smart manufacturing practices can help firms effectively control operations in manufacturing, increase flexibility, improve quality, and enhance productivity [

26]. In particular, the implementation of effective quality control helps firms ensure that products meet customer specifications and expectations, helping increase the satisfaction of existing customers and helping attract new customers. Lewis [

27] suggests that lean manufacturing is the essential approach that can push the continuous improvement of manufacturing processes by eliminating waste and increasing efficiency.

MCDM is widely used to solve highly complex and uncertain decision-making problems in many areas that traditional methods cannot solve. DEMATEL was developed in the 1970s for evaluating interdependent relationships among factors; it has gained popularity in recent years [

28,

29]. In general, DEMATEL is a mathematical computational method that aims to explore the cause–effect relationship among criteria. In addition, the analytic hierarchy process (AHP) cannot solve interdependency between criteria. ANP is a nonlinear structure that has been proposed to analyze criteria priorities and their complex relationships [

30]. ANP exhibits the advantage of analyzing complex and interdependent decision-making situations, such as resource allocation, technology selection, or strategic planning [

31]. Other MCDM methods and variants, such as the technique for order of preference by similarity to ideal solution (TOPSIS), VIKOR, gray theory, AHP, ANP, and DEMATEL or fuzzy MCDM, have also been developed to solve different problems, with each method having its own characteristics for finding the best solutions [

32,

33,

34]. However, TOPSIS does not consider the correlation between criteria in evaluating Euclidean distance, while VIKOR is challenging to apply when dealing with conflicting scenarios of real-world problems. If the decision-making process is ambiguous, gray theory methods can be used to test the interaction analysis. To deal with uncertain data or unclear judgment, fuzzy MCDM is a useful technique [

35]. Nevertheless, fuzzy MCDM can only generate an approximate solution [

32].

To increase the reliability and accuracy of the results, prior studies have developed many variants and combinations of the DEMATEL method, such as DEMATEL with ANP, hierarchical DEMATEL, and fuzzy DEMATEL. OBM transformation is a complex problem with many criteria that may be related to one another directly or indirectly. In the current study, a hybrid DEMATEL-based ANP approach is used to explore complicated causal relationships by providing a comprehensive analysis of a decision-making problem [

36]. The hybrid DEMATEL–ANP method exhibits advantages in handling complex interactions between criteria and alternatives, and, thus, it also helps decision makers visualize the relationships between criteria, making the decision-making process more transparent and easier to understand [

37]. In this regard, the DEMATEL–ANP method is well-suited for identifying the key success factors over other popular methods in the current study. Furthermore, DEMATEL–ANP is combined with the Delphi method to obtain consistent and reliable opinions from experts.

5. Discussions

In contrast with the traditional Delphi method, all the experts in this study completed the survey in person, with a clear explanation of each question and specific instructions on the methodology to avoid misleading information, achieving a reliable consensus within a short period of time. Moreover, we encouraged the experts to make comments and suggestions instead of simply filling the survey to enhance the quality of the study. By conducting the survey in person, we mitigated some of the disadvantages of the traditional Delphi method, such as limited open discussion or commitment in multiple rounds. In addition, the combination of the Delphi method, DEMATEL, and ANP to identify key criteria of an OBM transformation can benefit from qualitative and quantitative approaches to enhance the accuracy of the findings and reduce uncertainties compared with other hybrid MCDM methods. As a complex problem, this integration can identify the ranking and illustrate the cause-and-effect relationships among criteria to help decision makers easily understand the factors that affect an OBM transformation.

Upgrading to OBM can be a significant step for a company, and it poses many risks and challenges. One of the major challenges is managing the transition to a business-to-consumer (B2C) business model. Firms must shift their focus to meet the needs and preferences of end consumers, and such a shift requires a different mindset, skills, and approach to business. In addition, firms should develop their brand image, establish marketing channels, and invest in R&D to innovate their product to become more than just manufacturing. In addition, the OBM market is highly competitive and success has no guarantee. Any failure in a product launch or a lack of market demand can lead to financial loss or even bankruptcy. Moreover, firms may not have the expertise required to set up and manage distribution networks. This scenario can lead to inefficient and delayed deliveries and increased costs. In this section, we summarize the theoretical and practical implications of the six key factors that affect the success of an OBM transformation.

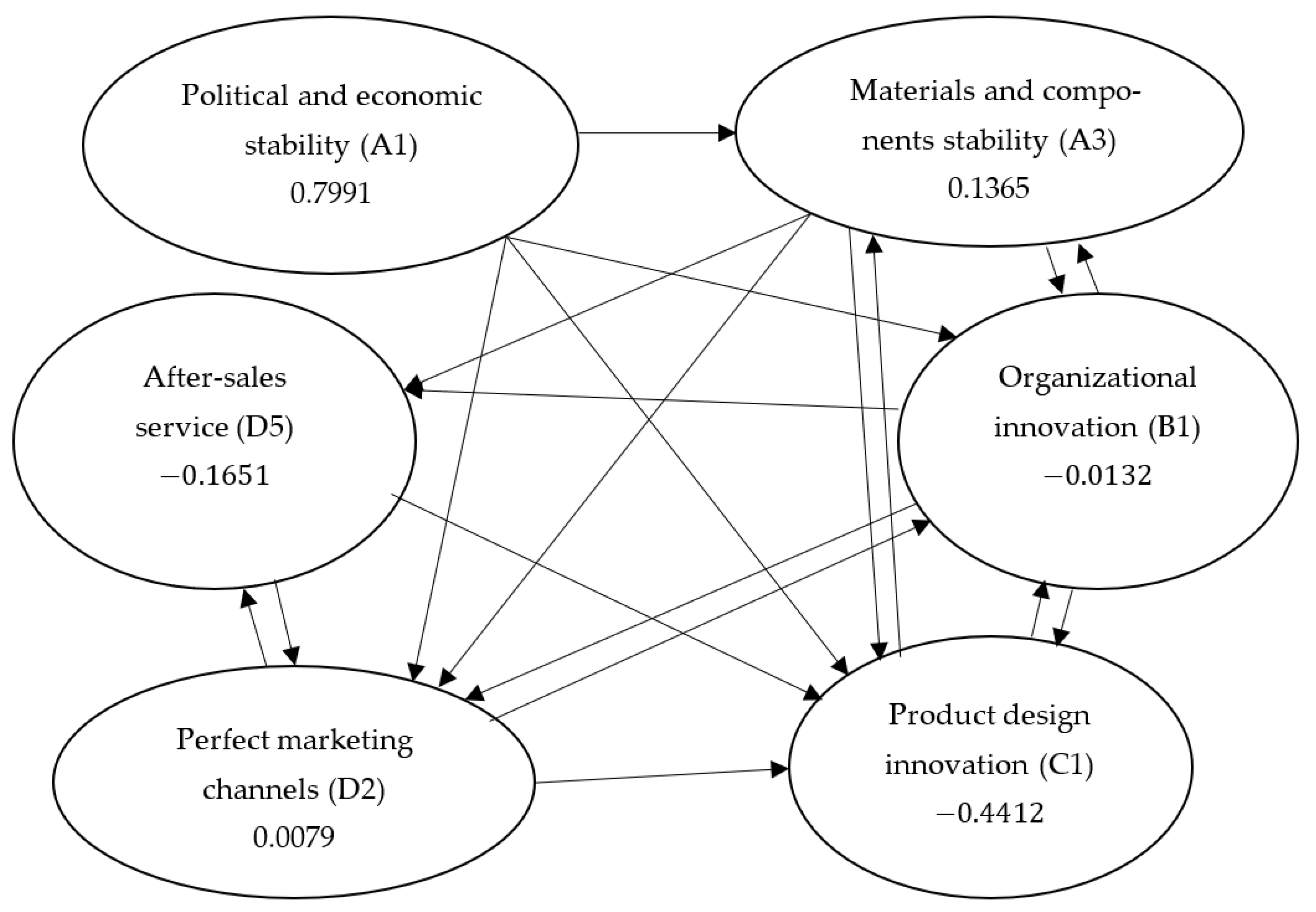

Political and economic stability (A1): In accordance with the results above, political and economic stability was constructed as a cause factor with a positive value (0.7991). In addition, the degree of importance between the dimensions was 5.8023. That is, political and economic stability may not be the most important factor in the success of an OBM transformation; however, it highly influences other factors. In a politically stable environment, manufacturers are more likely to experience a predictable regulatory environment, which can help them plan and execute their transformation strategies with greater confidence. For example, consistent policies and regulations with low inflation and stable interest rates can support businesses investing in R&D and innovation in the long run. By contrast, high inflation and volatile interest rates can make planning and budgeting for their transformation initiatives difficult for firms. In addition, economic instability can lead to a decrease in the demand for goods and services. Such a decrease can affect revenue and limit resources for their transformation effort.

Material and component stability (A3): Material and component stability was categorized as a cause factor with a positive value (0.1365). Moreover, the importance value of material and component stability was 6.7003. That is, material and component stability is more important than political and economic stability. Similar to political and economic stability, material and component stability can influence other factors. In an environment with stable materials and components, businesses can acquire more confidence in their ability to deliver products and services that meet the quality standards expected by their customers. This condition can be critical for businesses that are undergoing a transformation effort, because it can provide a foundation of stability upon which they can build their new business models and processes. Meanwhile, unreliable or inconsistent materials and components can lead to long lead time, quality issues, and increased production costs. These challenges can affect the effort to innovate and adopt new technologies, and, consequently, the success of a business transformation.

Organizational innovation (B1): The organizational innovation factor was described as an effect rather than a cause factor with a negative value () and its degree of importance was 6.7948. This condition denotes that the organizational innovation factor is more affected than its influences in OBM transition. Furthermore, it is more important than political and economic stability, material and component stability, perfect marketing channels, and after-sales service. Organizational innovation is essential for any firms, particularly those undergoing a transformation process, because it enables them to develop new products, services, and business models that can better meet customer needs. Organizations that are able to innovate are more likely to be successful in transforming their business, given that they are better equipped to identify and capitalize on new opportunities. By contrast, firms that are slow to innovate may find transforming and adapting to changing market conditions difficult.

Product design innovation (C1): Among the six key factors, the product design innovation factor had the lowest difference between column and row (−0.4412). By contrast, its degree of importance between dimensions had the highest value (7.0150) compared with the five other factors. That is, the product design innovation factor is the most important factor; however, it tends to be affected by other factors. Product design innovation refers to the ability of a firm’s R&D department to create new and innovative products that meet the growing needs and preferences of current and future customers. In addition, innovation in product design can help businesses differentiate themselves from their competitors. Firms can also build a strong brand identity by creating unique and innovative products. However, innovation in product design also requires significant resources and investment. Businesses must be willing to invest in research and development and take risks on new product designs.

Perfect marketing channels (D2): From the results above, the perfect marketing channels factor was constructed as a cause factor with a positive value (0.0079). Moreover, its degree of importance between dimensions was 6.3900. That is, the perfect marketing channels factor tends to influence rather than be affected by other factors. In addition, it is also more important than the political and economic stability factor. Perfect marketing channels enable firms to reach and satisfy their target customers. For example, firms can build brand loyalty and create a stronger connection with their customers by engaging effectively with their customers through the right marketing channels. However, leveraging effective marketing channels requires significant knowledge and expertise. Businesses must be able to understand their target customers and identify the right marketing channels to reach them effectively. To be successful in their transformation effort, businesses must be able to identify the right marketing channels in each market and condition while also carefully managing costs and resources.

After-sales service (D5): Similar to organizational innovation and product design innovation, after-sales service was an effect factor with a negative value (−0.1651), while its value of importance between dimensions was 6.5466. This condition indicates that after-sales service is more affected by other factors. In addition, after-sales service is more important than political and economic stability and perfect marketing channels. Effective after-sales service enables firms to build stronger relationships with their customers and enhance customer satisfaction. Firms that can provide high-quality after-sales service are more likely to succeed in building customer loyalty and expanding market share. By contrast, firms that are unable to provide effective after-sales service may struggle to transform and adapt to customer needs. They may be more likely to experience negative word-of-mouth and customer churn, which can make achieving their transformation goals difficult.