A Review of Energy and Sustainability KPI-Based Monitoring and Control Methodologies on WWTPs

Abstract

1. Introduction

2. Materials and Methods

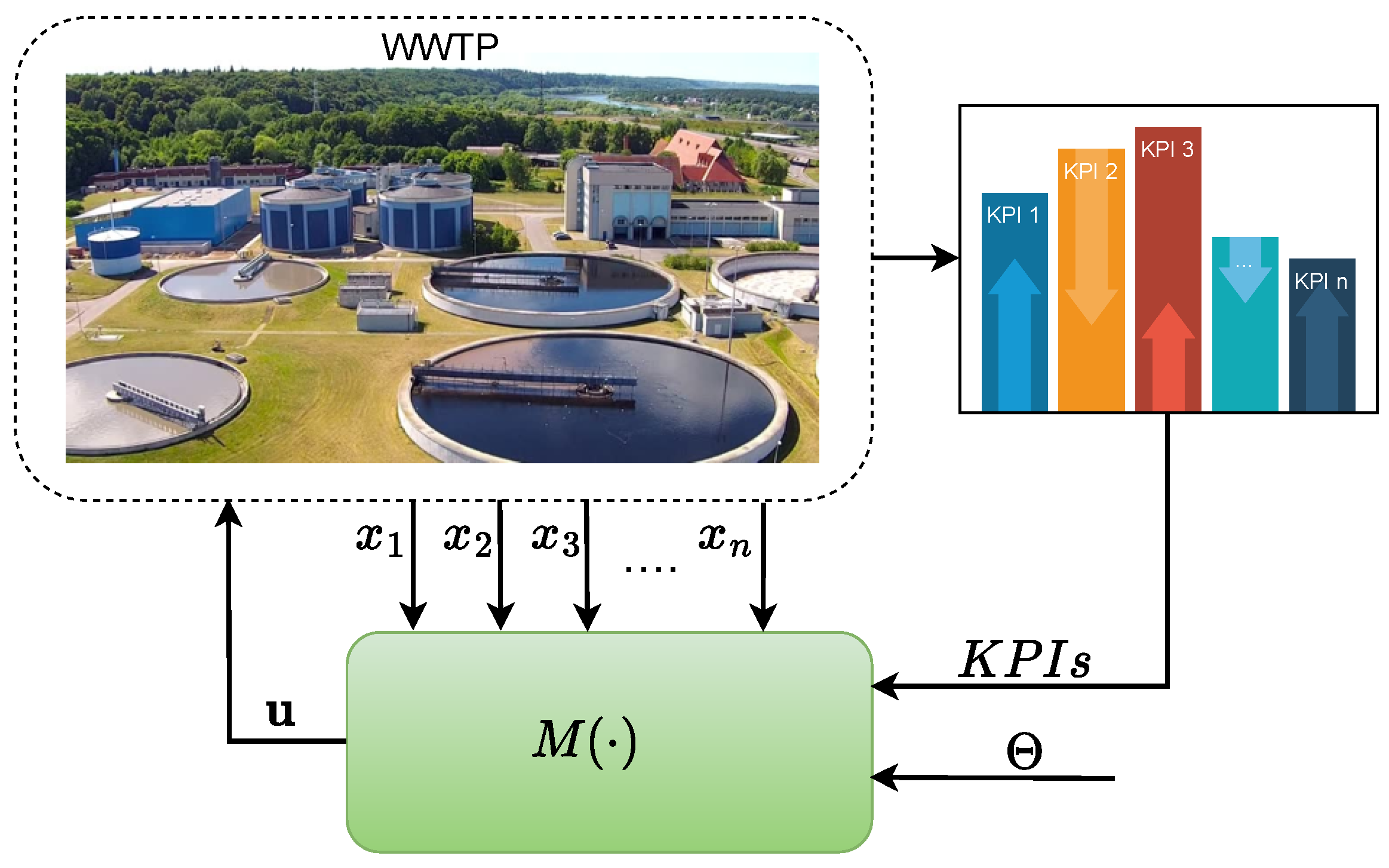

2.1. Problem Formulation

2.2. Literature Review Planning Protocol

- Search questions:

- Which KPIs are used?

- Which KPI-based methods for monitoring, control, or optimization are used?

- How were these KPI-based methods tested and which simulators were used?

- What is the performance of these KPI-based methods?

- Exclusion criteria:

- Monitoring, control, and optimization works whose methodologies are not based on a KPI or any efficiency index;

- Works that have not been tested in real or simulated WWTPs;

- Works dated before the year 2012;

- Quality criterion:

- Works based on KPI or efficiency index tested in real or simulated WWTPs.

- Works that compare its techniques with others.

2.3. Search Process

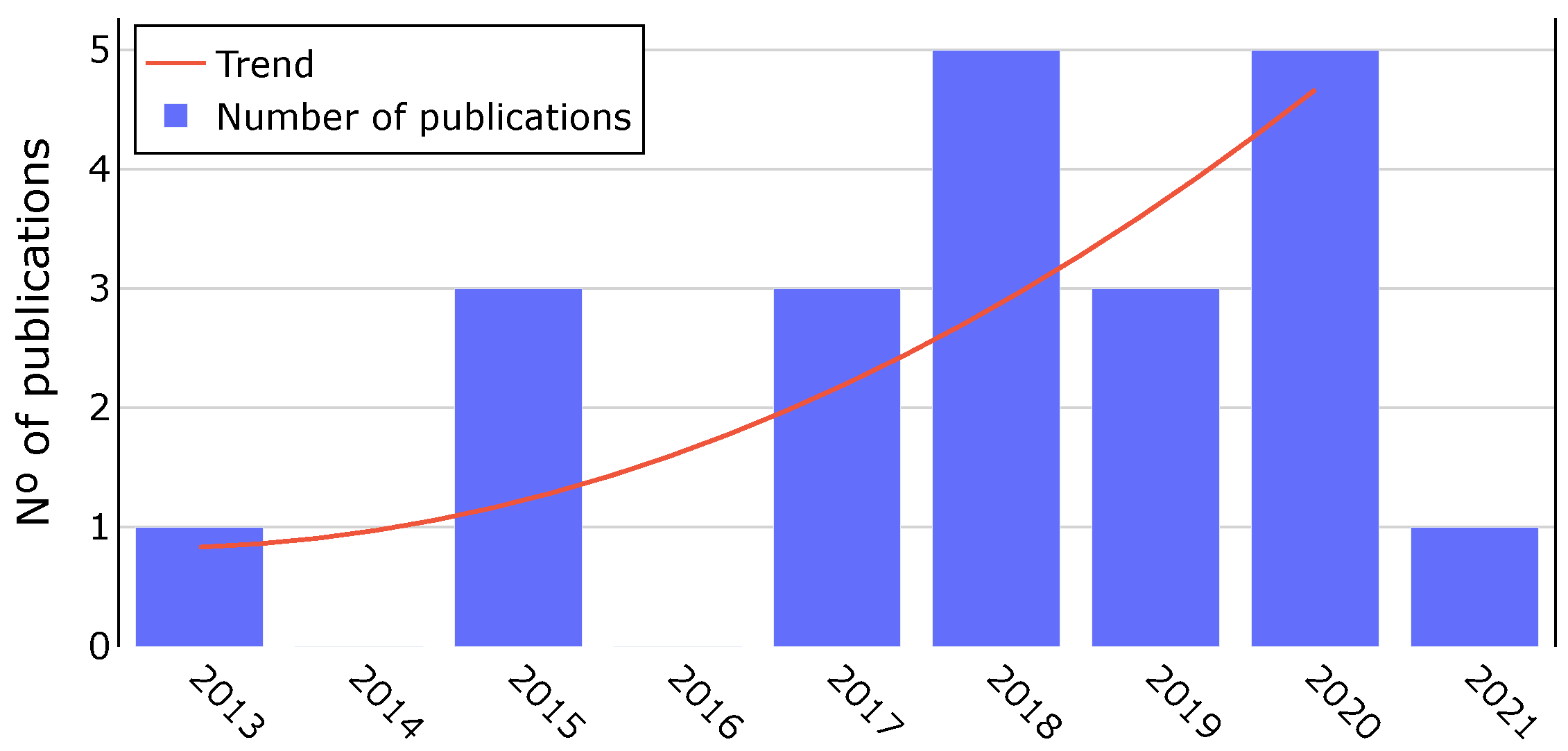

2.4. Publications over the Years

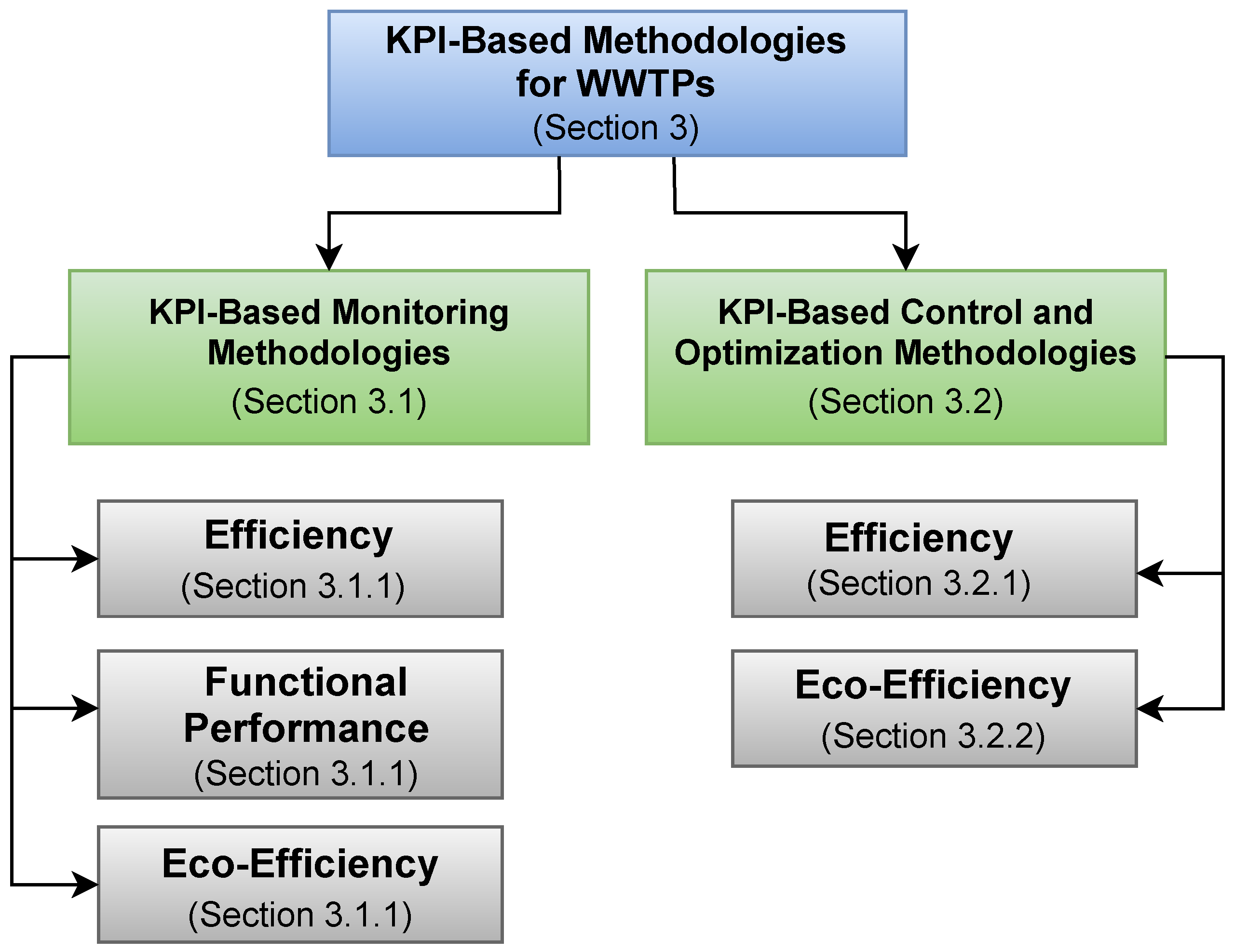

3. Results

3.1. Energy and Sustainability KPI-Based Monitoring

3.1.1. Monitoring of Efficiency

- Daily value of the efficiency of the pump system ();

- Efficiency trend () calculated using a rolling window median for the previous 90 days;

- Fluctuation in the trend ;

- Ageing of the pump ();

- Potential of new failures (Z) that is equal to 0 if the system registers 15 consecutive days with , otherwise .

3.1.2. Functional Performance Monitoring

3.1.3. Eco-Efficiency Monitoring

- Energy per population equivalent [kWh/PE];

- Waste sludge production per population equivalent [kg/PE];

- Environmental impacts of chemicals (from LCA method) [mPt/PE];

- COD removed [kg/PE];

- Methane production per population equivalent. [l/PE].

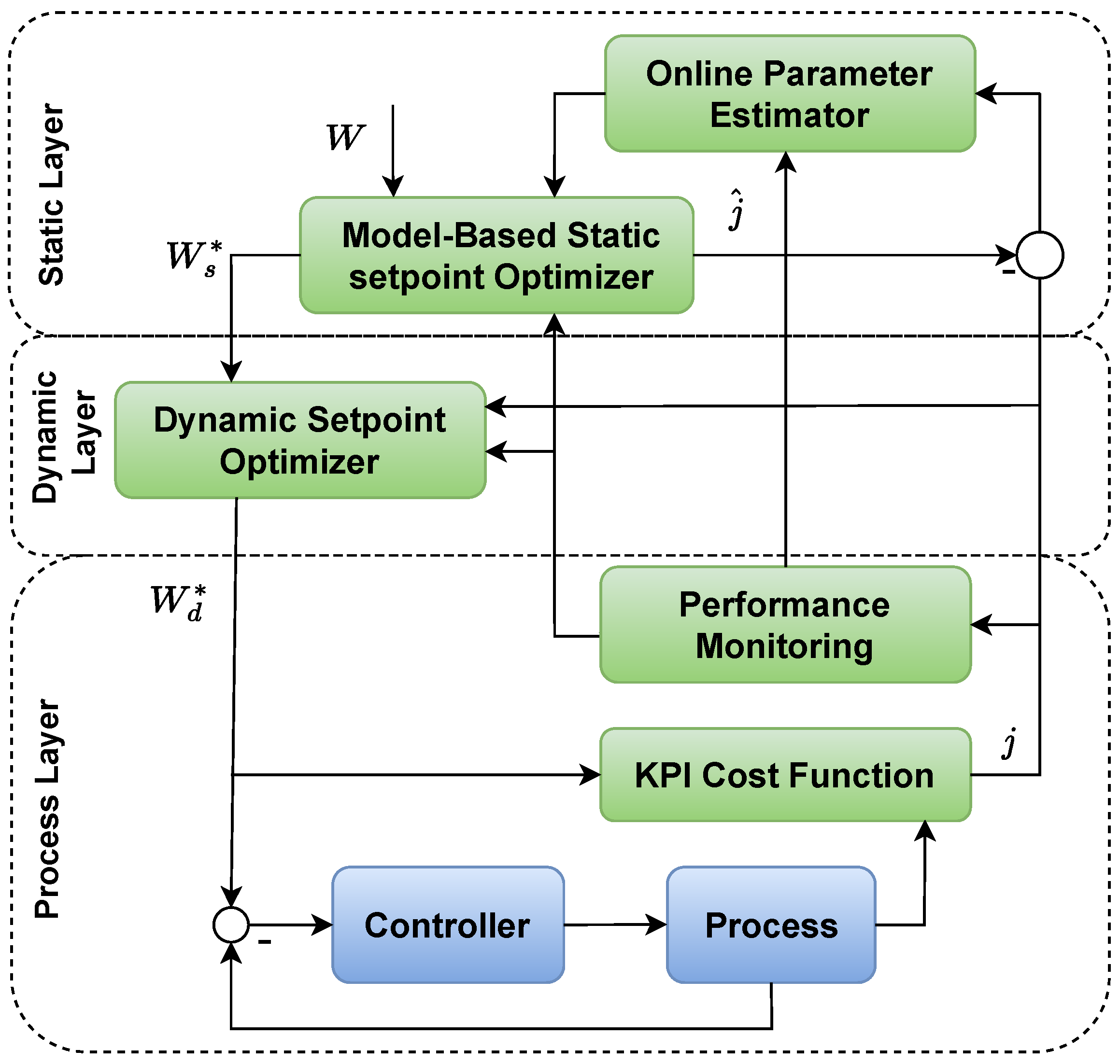

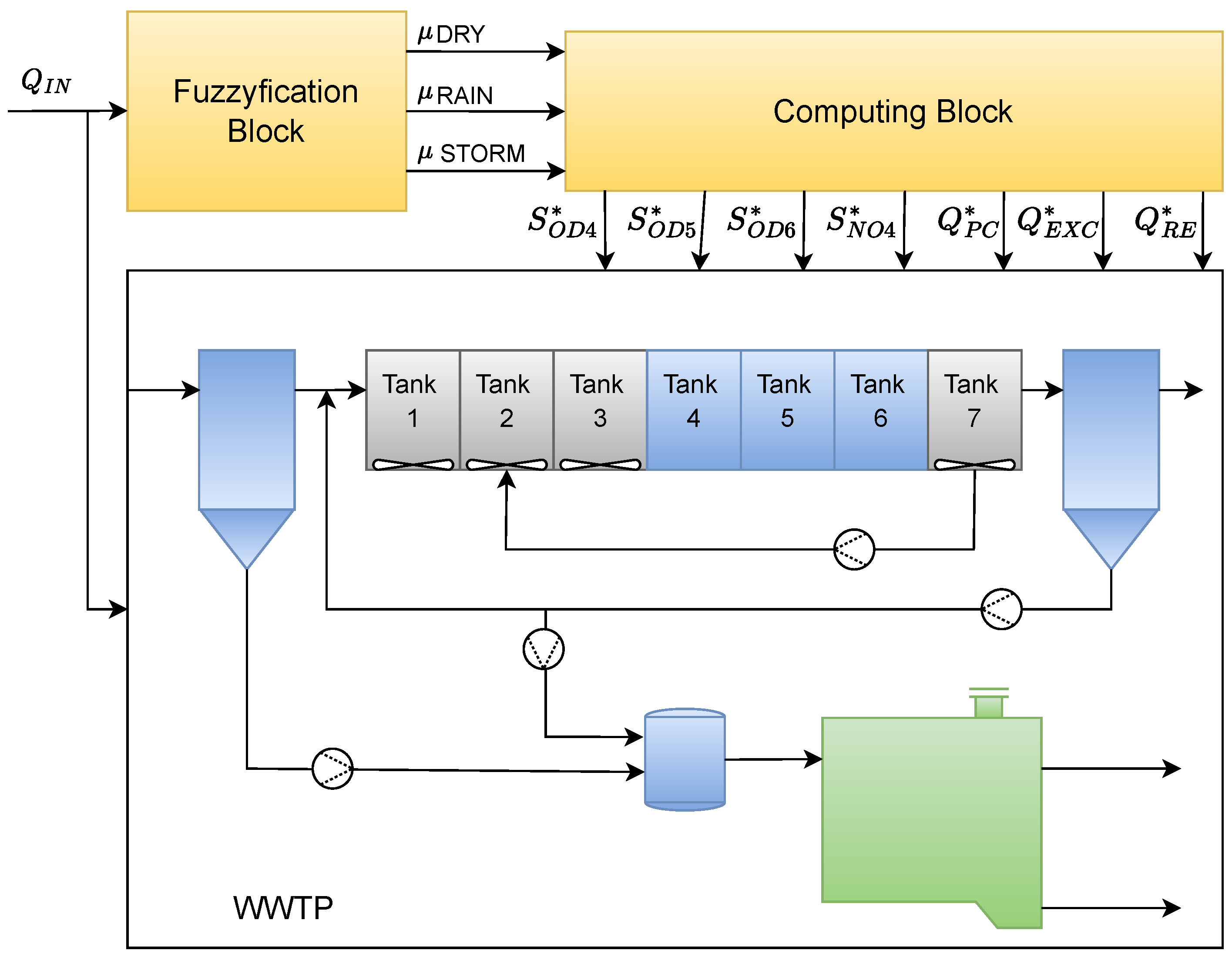

3.2. KPI-Based Control and Optimization Methodologies

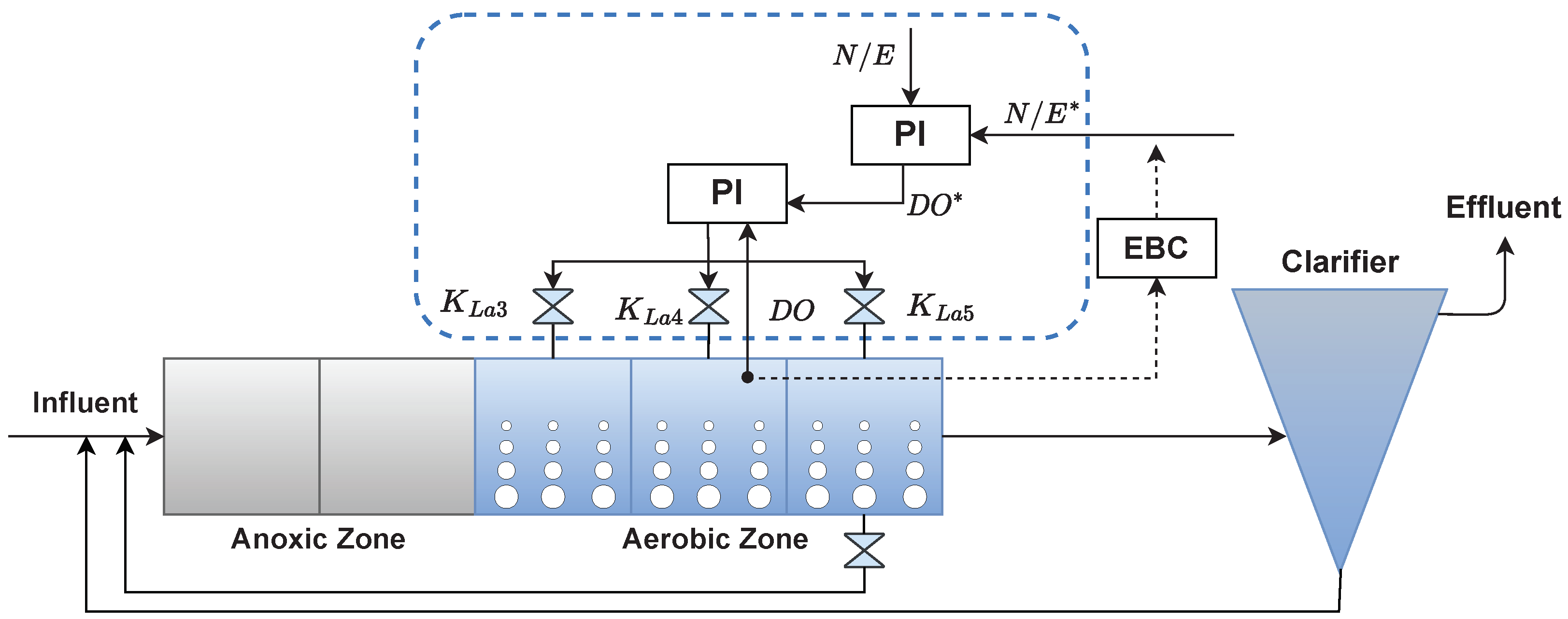

3.2.1. Efficiency Control and Optimization

3.2.2. Eco-Efficiency Optimization

4. Discussion

4.1. KPI-Based Monitoring Methodologies

4.2. KPI-Based Control and Optimization Methodologies

4.3. BSM Simulators

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AE | Aeration Energy |

| ANN | Artificial Neural Network |

| BOD | Biological Oxygen Demand |

| BSM1 | Benchmark Simulation Model No. 1 |

| BSM2 | Benchmark Simulation Model No. 2 |

| COD | Chemical Oxygen Demand |

| DEA | Data Envelopment Analysis |

| DMOPSO | Dynamic Multiobjective Particle Swarm Optimization |

| DO | Dissolved Oxygen |

| EE | Electrical Energy |

| EPI | Energy Performance Indicator |

| EQ | Effluent Quality |

| EQI | Effluent Quality Index |

| FLC | Fuzzy Logic Controller |

| GI | Green Index |

| HRBF | Hierarchical Radial Basis Function |

| KPI | Key Performance Indicator |

| LCA | Life Cycle Assessment |

| LCCA | Life Cycle Cost Analysis |

| MPC | Model Predictive Control |

| NO | Nitric Oxide |

| OCI | Overall Cost Index |

| PE | Pump Energy |

| PI | Proportional–Integral |

| PID | Proportional–Integral–Derivative |

| PLC | Programmable Logic Controller |

| PLI | Pollution Index |

| SCADA | Supervisory Control and Data Acquisition |

| SLR | Systematic Literature Review |

| STOAT | Sewage Treatment Operation and Analysis over Time |

| SVI | Sludge Volume Index |

| TN | Total Nitrogen |

| WQI | Water Quality Index |

| WTEI | Water Treatment Energy Index |

| WWTP | Wastewater Treatment Plant |

References

- Mendes, J.; Maia, R.; Araújo, R.; Souza, F.A.A. Self-Evolving Fuzzy Controller Composed of Univariate Fuzzy Control Rules. Appl. Sci. 2020, 10, 5836. [Google Scholar] [CrossRef]

- Mendes, J.; Araújo, R.; Souza, F. Adaptive Fuzzy Identification and Predictive Control for Industrial Processes. Expert Syst. Appl. 2013, 40, 6964–6975. [Google Scholar] [CrossRef]

- Parmenter, D. Key Performance Indicators: Developing, Implementing, and Using Winning KPIs; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Körner, M.F.; Bauer, D.; Keller, R.; Rösch, M.; Schlereth, A.; Simon, P.; Bauernhansl, T.; Fridgen, G.; Reinhart, G. Extending the automation pyramid for industrial demand response. Procedia CIRP 2019, 81, 998–1003. [Google Scholar] [CrossRef]

- Strelnik, E.; Usanova, D.; Khairullin, I. Key performance indicators in corporate finance. Asian Soc. Sci. 2015, 11, 369. [Google Scholar] [CrossRef][Green Version]

- Hřebíček, J.; Misařová, P.; Hyršlová, J. Environmental key performance indicators and corporate reporting. In Proceedings of the International Conference EA-SDI, Prague, The Czech Republic, 23–25 May 2007; pp. 147–155. [Google Scholar]

- Lindberg, C.F.; Tan, S.; Yan, J.; Starfelt, F. Key performance indicators improve industrial performance. Energy Procedia 2015, 75, 1785–1790. [Google Scholar] [CrossRef]

- Belanche, L.A.; Valdés, J.J.; Comas, J.; Roda, I.R.; Poch, M. Towards a model of input–output behaviour of wastewater treatment plants using soft computing techniques. Environ. Model. Softw. 1999, 14, 409–419. [Google Scholar] [CrossRef][Green Version]

- Beraud, B.; Steyer, J.P.; Lemoine, C.; Latrille, E. Optimization of WWTP control by means of multi-objective genetic algorithms and sensitivity analysis. In 18th European Symposium on Computer Aided Process Engineering; Computer Aided Chemical Engineering; Braunschweig, B., Joulia, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; Volume 25, pp. 539–544. [Google Scholar] [CrossRef]

- Dairi, A.; Cheng, T.; Harrou, F.; Sun, Y.; Leiknes, T. Deep learning approach for sustainable WWTP operation: A case study on data-driven influent conditions monitoring. Sustain. Cities Soc. 2019, 50, 101670. [Google Scholar] [CrossRef]

- Salles, R.; Mendes, J.; Araújo, R.; Melo, C.; Moura, P. Prediction of Key Variables in Wastewater Treatment Plants Using Machine Learning Models. In Proceedings of the 2022 IEEE International Joint Conference on Neural Networks (IJCNN 2022), at the 2022 World Congress on Coomputational Intelligence (WCCI 2022), Padua, Italy, 18–23 July 2022; IEEE: Padova, Italy, 2022; pp. 1–9. [Google Scholar] [CrossRef]

- Gernaey, K.V.; Flores-Alsina, X.; Rosen, C.; Benedetti, L.; Jeppsson, U. Dynamic influent pollutant disturbance scenario generation using a phenomenological modelling approach. Environ. Model. Softw. 2011, 26, 1255–1267. [Google Scholar] [CrossRef]

- del Olmo, F.H.; Gaudioso, E.; Duro, N.; Dormido, R. Machine learning weather soft-sensor for advanced control of wastewater treatment plants. Sensors 2019, 19, 3139. [Google Scholar] [CrossRef]

- Salles, R.; Mendes, J.; Antunes, C.H.; Moura, P.; Dias, J. Dynamic Setpoint Optimization Using Metaheuristic Algorithms for Wastewater Treatment Plants. In Proceedings of the 48th Annual Conference of the IEEE Industrial Electronics Society (IECON 2022), Brussels, Belgium, 17–20 October 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Xu, C.M.; Zhang, J.S.; Kong, L.Q.; Jin, X.B.; Kong, J.L.; Bai, Y.T.; Su, T.L.; Ma, H.J.; Chakrabarti, P. Prediction Model of Wastewater Pollutant Indicators Based on Combined Normalized Codec. Mathematics 2022, 10, 4283. [Google Scholar] [CrossRef]

- Wang, D.; Ha, M.; Qiao, J. Data-Driven Iterative Adaptive Critic Control Toward an Urban Wastewater Treatment Plant. IEEE Trans. Ind. Electron. 2021, 68, 7362–7369. [Google Scholar] [CrossRef]

- Rastegar, S.; Araújo, R.; Mendes, J. A New Approach for Online T-S Fuzzy Identification and Model Predictive Control of Nonlinear Systems. J. Vib. Control 2016, 22, 1820–1837. [Google Scholar] [CrossRef]

- Rastegar, S.; Araújo, R.; Mendes, J.; Matias, T.; Emami, A. Self-Adaptive Takagi-Sugeno Model Identification Methodology For Industrial Control Processes. In Proceedings of the 40th Annual Conference of the IEEE Industrial Electronics Society (IECON 2014), Dallas, TX, USA, 29 October–1 November 2014; IEEE: Dallas, TX, USA, 2014; pp. 281–287. [Google Scholar] [CrossRef]

- Sweetapple, C.; Fu, G.; Butler, D. Multi-objective optimisation of wastewater treatment plant control to reduce greenhouse gas emissions. Water Res. 2014, 55, 52–62. [Google Scholar] [CrossRef] [PubMed]

- Mendes, J.; Araújo, R.; Matias, T.; Seco, R.; Belchior, C. Evolutionary Learning of a Fuzzy Controller for Industrial Processes. In Proceedings of the 40th Annual Conference of the IEEE Industrial Electronics Society (IECON 2014), Dallas, TX, USA, 29 October–1 November 2014; IEEE: Dallas, TX, USA, 2014; pp. 139–145. [Google Scholar] [CrossRef]

- Hernández-Sancho, F.; Molinos-Senante, M.; Sala-Garrido, R. Energy efficiency in Spanish wastewater treatment plants: A non-radial DEA approach. Sci. Total. Environ. 2011, 409, 2693–2699. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, X.; Zeng, S. Measuring and explaining eco-efficiencies of wastewater treatment plants in China: An uncertainty analysis perspective. Water Res. 2017, 112, 195–207. [Google Scholar] [CrossRef]

- Alizadeh, S.; Zafari-Koloukhi, H.; Rostami, F.; Rouhbakhsh, M.; Avami, A. The eco-efficiency assessment of wastewater treatment plants in the city of Mashhad using emergy and life cycle analyses. J. Clean. Prod. 2020, 249, 119327. [Google Scholar] [CrossRef]

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Amores, M.J.; Termes-Rifé, M.; Marín-Navarro, D.; Moreira, M.T.; Feijoo, G. Benchmarking wastewater treatment plants under an eco-efficiency perspective. Sci. Total. Environ. 2016, 566–567, 468–479. [Google Scholar] [CrossRef]

- Chen, X.; Al, R.; Behera, C.R.; Sin, G. Process Synthesis, Design, and Control of Wastewater Treatment Plants. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–14. [Google Scholar] [CrossRef]

- Sanchez, A.; Katebi, M. Predictive control of dissolved oxygen in an activatedsludge wastewater treatment plant. In Proceedings of the 2003 European Control Conference (ECC), Cambridge, UK, 1–4 September 2003; pp. 2424–2429. [Google Scholar] [CrossRef]

- Grochowski, M.; Rutkowski, T.A. Supervised model predictive control of wastewater treatment plant. In Proceedings of the 2016 21st International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 29 August–1 September 2016; pp. 613–618. [Google Scholar] [CrossRef]

- Alex, J.; Tschepetzki, R.; Jumar, U. Predictive control of nitrogen removal in WWTPs using parsimonious models. IFAC Proc. Vol. 2002, 35, 405–410. [Google Scholar] [CrossRef]

- Steffens, M.A.; Lant, P. Multivariable control of nutrient-removing activated sludge systems. Water Res. 1999, 33, 2864–2878. [Google Scholar] [CrossRef]

- SotomayoR, O.A.; Park, S.W.; Garcia, C. MPC control of a predenitrification plant using linear subspace models. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2002; Volume 10, pp. 553–558. [Google Scholar] [CrossRef]

- Charef, A.; Ghauch, A.; Martin-Bouyer, M. An adaptive and predictive control strategy for an activated sludge process. Bioprocess Eng. 2000, 23, 529–534. [Google Scholar] [CrossRef]

- Pisa, I.; Morell, A.; Vicario, J.L.; Vilanova, R. Denoising Autoencoders and LSTM-Based Artificial Neural Networks Data Processing for Its Application to Internal Model Control in Industrial Environments—The Wastewater Treatment Plant Control Case. Sensors 2020, 20, 3743. [Google Scholar] [CrossRef]

- Yu, R.F.; Chen, H.W.; Cheng, W.P.; Shen, Y.C. Dynamic control of disinfection for wastewater reuse applying ORP/pH monitoring and artificial neural networks. Resour. Conserv. Recycl. 2008, 52, 1015–1021. [Google Scholar] [CrossRef]

- Lee, C. Fuzzy logic in control systems: Fuzzy logic controller. I. IEEE Trans. Syst. Man Cybern. 1990, 20, 404–418. [Google Scholar] [CrossRef]

- Pedrycz, W. Fuzzy Control and Fuzzy Systems; Research Studies Press Ltd.: Somerset, UK, 1993. [Google Scholar]

- Hájek, P. Metamathematics of Fuzzy Logic; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 4. [Google Scholar] [CrossRef]

- Mendes, J.; Araújo, R.; Matias, T.; Seco, R.; Belchior, C. Automatic Extraction of the Fuzzy Control System by a Hierarchical Genetic Algorithm. Eng. Appl. Artif. Intell. 2014, 29, 70–78. [Google Scholar] [CrossRef]

- Zawadzki, A.; Piotrowski, R. Nonlinear fuzzy control of the dissolved oxygen in activated sludge processes. In Proceedings of the 2012 IEEE 17th International Conference on Emerging Technologies Factory Automation (ETFA 2012), Krakow, Poland, 17–21 September 2012; pp. 1–7. [Google Scholar] [CrossRef]

- Fiter, M.; Güell, D.; Comas, J.; Colprim, J.; Poch, M.; Rodríguez-Roda, I. Energy saving in a wastewater treatment process: An application of fuzzy logic control. Environ. Technol. 2005, 26, 1263–1270. [Google Scholar] [CrossRef]

- Bongards, M. Improving the efficiency of a wastewater treatment plant by fuzzy control and neural networks. Water Sci. Technol. 2001, 43, 189–196. [Google Scholar] [CrossRef] [PubMed]

- Kalker, T.; Goor, C.V.; Roeleveld, P.; Ruland, M.; Babuška, R. Fuzzy control of aeration in an activated sludge wastewater treatment plant: Design, simulation and evaluation. Water Sci. Technol. 1999, 39, 71–78. [Google Scholar] [CrossRef]

- Boiocchi, R.; Gernaey, K.V.; Sin, G. A novel fuzzy-logic control strategy minimizing N2O emissions. Water Res. 2017, 123, 479–494. [Google Scholar] [CrossRef]

- Kitchenham, B. Procedures for performing systematic reviews. Keele UK Keele Univ. 2004, 33, 1–26. [Google Scholar]

- Sabia, G.; Luigi, P.; Avolio, F.; Caporossi, E. Energy saving in wastewater treatment plants: A methodology based on common key performance indicators for the evaluation of plant energy performance, classification and benchmarking. Energy Convers. Manag. 2020, 220, 113067. [Google Scholar] [CrossRef]

- Longo, S.; Mauricio-Iglesias, M.; Soares, A.; Campo, P.; Fatone, F.; Eusebi, A.L.; Akkersdijk, E.; Stefani, L.; Hospido, A. ENERWATER–A standard method for assessing and improving the energy efficiency of wastewater treatment plants. Appl. Energy 2019, 242, 897–910. [Google Scholar] [CrossRef]

- Molinos-Senante, M.; Hernandez-Sancho, F.; Sala-Garrido, R. Benchmarking in wastewater treatment plants: A tool to save operational costs. Clean Technol. Environ. Policy 2014, 16, 149–161. [Google Scholar] [CrossRef]

- Reyment, R.A.; Jvreskog, K. Applied Factor Analysis in the Natural Sciences; Cambridge University Press: Cambridge, UK, 1996. [Google Scholar] [CrossRef]

- Fraia, S.D.; Massarotti, N.; Vanoli, L. A novel energy assessment of urban wastewater treatment plants. Energy Convers. Manag. 2018, 163, 304–313. [Google Scholar] [CrossRef]

- Mauricio-Iglesias, M.; Longo, S.; Hospido, A. Designing a robust index for WWTP energy efficiency: The ENERWATER water treatment energy index. Sci. Total. Environ. 2020, 713, 136642. [Google Scholar] [CrossRef] [PubMed]

- Torregrossa, D.; Hansen, J.; Hernández-Sancho, F.; Cornelissen, A.; Schutz, G.; Leopold, U. A data-driven methodology to support pump performance analysis and energy efficiency optimization in Waste Water Treatment Plants. Appl. Energy 2017, 208, 1430–1440. [Google Scholar] [CrossRef]

- Krueger, M.; Luo, H.; Ding, S.X.; Dominic, S.; Yin, S. Data-driven approach of KPI monitoring and prediction with application to wastewater treatment process. IFAC-PapersOnLine 2015, 48, 627–632. [Google Scholar] [CrossRef]

- Jeppsson, U.; Pons, M.N.; Nopens, I.; Alex, J.; Copp, J.; Gernaey, K.; Rosén, C.; Steyer, J.P.; Vanrolleghem, P. Benchmark simulation model no 2: General protocol and exploratory case studies. Water Sci. Technol. 2007, 56, 67–78. [Google Scholar] [CrossRef]

- Ju, H.; Yin, S.; Gao, H.; Kaynak, O. A data-based KPI prediction approach for wastewater treatment processes. In Proceedings of the 2015 International Conference on Man and Machine Interfacing (MAMI), Bhubaneswar, India, 17–19 December 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Li, Z.; Zou, Z.; Wang, L. Analysis and forecasting of the energy consumption in wastewater treatment plant. Math. Probl. Eng. 2019, 2019, 8690898. [Google Scholar] [CrossRef]

- Han, H.; Qiao, J. Hierarchical Neural Network Modeling Approach to Predict Sludge Volume Index of Wastewater Treatment Process. IEEE Trans. Control. Syst. Technol. 2013, 21, 2423–2431. [Google Scholar] [CrossRef]

- Gómez, T.; Gémar, G.; Molinos-Senante, M.; Sala-Garrido, R.; Caballero, R. Measuring the eco-efficiency of wastewater treatment plants under data uncertainty. J. Environ. Manag. 2018, 226, 484–492. [Google Scholar] [CrossRef]

- Torregrossa, D.; Marvuglia, A.; Leopold, U. A novel methodology based on LCA+ DEA to detect eco-efficiency shifts in wastewater treatment plants. Ecol. Indic. 2018, 94, 7–15. [Google Scholar] [CrossRef]

- Mustapha, M.A.; Manan, Z.A.; Alwi, S.R.W. A new quantitative overall environmental performance indicator for a wastewater treatment plant. J. Clean. Prod. 2017, 167, 815–823. [Google Scholar] [CrossRef]

- Dominic, S.; Shardt, Y.A.; Ding, S.X.; Luo, H. An adaptive, advanced control strategy for KPI-based optimization of industrial processes. IEEE Trans. Ind. Electron. 2015, 63, 3252–3260. [Google Scholar] [CrossRef]

- Nelles, O. Nonlinear System Identification: From Classical Approaches to Neural Networks, Fuzzy Models, and Gaussian Processes; Springer Nature: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Han, H.G.; Liu, Z.; Lu, W.; Hou, Y.; Qiao, J.F. Dynamic MOPSO-based optimal control for wastewater treatment process. IEEE Trans. Cybern. 2019, 51, 2518–2528. [Google Scholar] [CrossRef] [PubMed]

- Silvana, R.; Pastora, V.; Ramón, V.; Mario, F. Optimal control of wastewater treatment plants using economic-oriented model predictive dynamic strategies. Appl. Sci. 2017, 7, 813. [Google Scholar] [CrossRef]

- Caraman, S.; Luca, L.; Vasiliev, I.; Barbu, M. Optimal-Setpoint-Based Control Strategy of a Wastewater Treatment Process. Processes 2020, 8, 1203. [Google Scholar] [CrossRef]

- Pereira, J.; Mendes, J.; Júnior, J.S.S.; Viegas, C.; Paulo, J.R. A Review of Genetic Algorithm Approaches for Wildfire Spread Prediction Calibration. Mathematics 2022, 10, 300. [Google Scholar] [CrossRef]

- Revollar, S.; Vilanova, R.; Francisco, M.; Vega, P. PI Dissolved Oxygen control in wastewater treatment plants for plantwide nitrogen removal efficiency. IFAC-PapersOnLine 2018, 51, 450–455. [Google Scholar] [CrossRef]

- Revollar, S.; Vega, P.; Francisco, M.; Vilanova, R. A hierachical Plant wide operation in wastewater treatment plants: Overall efficiency index control and event-based reference management. In Proceedings of the 2018 22nd International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 10–12 October 2018; pp. 201–206. [Google Scholar]

- Revollar, S.; Vilanova, R.; Vega, P.; Francisco, M.; Meneses, M. Wastewater treatment plant operation: Simple control schemes with a holistic perspective. Sustainability 2020, 12, 768. [Google Scholar] [CrossRef]

- Oulebsir, R.; Lefkir, A.; Safri, A.; Bermad, A. Optimization of the energy consumption in activated sludge process using deep learning selective modeling. Biomass Bioenergy 2020, 132, 105420. [Google Scholar] [CrossRef]

- Chen, K.; Wang, H.; Valverde-Pérez, B.; Zhai, S.; Vezzaro, L.; Wang, A. Optimal control towards sustainable wastewater treatment plants based on multi-agent reinforcement learning. Chemosphere 2021, 279, 130498. [Google Scholar] [CrossRef] [PubMed]

- Pereira, S.F. Modelling of a wastewater treatment plant using GPS-X. Ph.D. Thesis, Faculdade de Ciências e Tecnologia, Departamento de Química, Universidade NOVA de Lisboa, Lisbon, Portugal, 2014. [Google Scholar]

- Henze, M.; Jr, C.L.G.; Gujer, W.; Marais, G.; Matsuo, T. Activated Sludge Model No. 1. IAWQ Scientific and Technical Report No. 1 IAWQ; IAWPRC: London, UK, 1987. [Google Scholar]

- Henze, M.; Gujer, W.; Mino, T.; Matsuo, T.; Wentzel, M.; Marais, G. Activated sludge model No. 2 (ASM2). IWA Scientific and Technical Report No. 3, IAWQ: London 1995.

- Henze, M.; Gujer, W.; Mino, T.; Matsuo, T.; Marais, G.V.R.; Marais, G.; Van Loosdrecht, M.C. Activated sludge model No.2D, ASM2D. Water Sci. Technol. 1999, 39, 165–182. [Google Scholar] [CrossRef]

- Gujer, W.; Henze, M.; Mino, T.; van Loosdrecht, M. Activated sludge model No. 3. Water Sci. Technol. 1999, 39, 183–193. [Google Scholar] [CrossRef]

- van Veldhuizen, H.; van Loosdrecht, M.; Heijnen, J. Modelling biological phosphorus and nitrogen removal in a full scale activated sludge process. Water Res. 1999, 33, 3459–3468. [Google Scholar] [CrossRef]

- Alex, J.; Benedetti, L.; Copp, J.; Gernaey, K.; Jeppsson, U.; Nopens, I.; Pons, M.; Rieger, L.; Rosen, C.; Steyer, J.; et al. Benchmark simulation model no. 1 (BSM1). In Report by the IWA Taskgroup on Benchmarking of Control Strategies for WWTPs; Department of Industrial Electrical Engineering and Automation, Lund University: Lund, Sweden, 2008; pp. 19–20. [Google Scholar]

- Revollar, S.; Meneses, M.; Vilanova, R.; Vega, P.; Francisco, M. Eco-Efficiency Assessment of Control Actions in Wastewater Treatment Plants. Water 2021, 13, 612. [Google Scholar] [CrossRef]

- Jeppsson, U.; Rosen, C.; Alex, J.; Copp, J.; Gernaey, K.; Pons, M.N.; Vanrolleghem, P. Towards a benchmark simulation model for plant-wide control strategy performance evaluation of WWTPs. Water Sci. Technol. 2006, 53, 287–295. [Google Scholar] [CrossRef]

- Gernaey, K.V.; Jeppsson, U. Benchmarking of Control Strategies for Wastewater Treatment Plants; IWA publishing: London, UK, 2014. [Google Scholar]

| Reference | KPI Type | KPI(s) | Plant |

|---|---|---|---|

| [51] | Operational | in the effluent. | BSM |

| [53] | Operational | in the effluent | BSM |

| [54] | Operational | Energy consumption obtained from and performance indicators. | BSM |

| [50] | Energy | Efficiency based on fuzzy rules and the daily value of 5 KPIs. | Real WWTP |

| [55] | Operational | obtained | |

| [45,49] | Energy | WTEI (12) | Real WWTP |

| [44] | Energy | Global Energetic Index (GEI) (2) | Real WWTP |

| [48] | Energy | Energy Performance Indicators: , , and | Real WWTP |

| [57] | Eco | Through DEA and LCA. Outputs: , | STOAT simulator |

| [56] | Eco | Eco-efficiency obtained by DEA from resources consumed (costs), desirable outputs (TSS and COD) and undesirable output (indirect green-house gases) | Real WWTP |

| [58] | Eco | (14) | SuperPro Designer 8.5 |

| Reference | KPI Type | KPI(s) | Plant |

|---|---|---|---|

| [62] | Energy | Model Predictive Control that takes into account the economic performance index (energies and costs), (15) | BSM |

| [61] | Energy | Objective functions based on , and that are models based on regression kernel functions | BSM/Real |

| [59] | Energy | OCI | BSM |

| [68] | Eco Energy | KPIs, (18) to (25), to select data that respect to: environmental requirements, Global Treatment Yield () and Standardizes (); and to optimized energy consumption, , Global Abatement () and | Real |

| [65,66,67] | Eco Energy | Index, ration between the amount of nitrogenated compounds eliminated and the energy consumed | BSM |

| [63] | Eco Energy | OCI, EQI and the percentage of times that the pollutant levels exceed the legal limits | SIMBA/Benchmark Simulation Model No. 2 (BSM2) Real |

| [69] | Eco Energy | LCCA (based on costs with energy () and chemical () products, costs of transporting () and disposing () the sludge, biogas production (), and miscellaneous () costs) and LCA (based on energy consumption, eutrophication potential and greenhouse gas emission) | GPS-X |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Matos, B.; Salles, R.; Mendes, J.; Gouveia, J.R.; Baptista, A.J.; Moura, P. A Review of Energy and Sustainability KPI-Based Monitoring and Control Methodologies on WWTPs. Mathematics 2023, 11, 173. https://doi.org/10.3390/math11010173

de Matos B, Salles R, Mendes J, Gouveia JR, Baptista AJ, Moura P. A Review of Energy and Sustainability KPI-Based Monitoring and Control Methodologies on WWTPs. Mathematics. 2023; 11(1):173. https://doi.org/10.3390/math11010173

Chicago/Turabian Stylede Matos, Bárbara, Rodrigo Salles, Jérôme Mendes, Joana R. Gouveia, António J. Baptista, and Pedro Moura. 2023. "A Review of Energy and Sustainability KPI-Based Monitoring and Control Methodologies on WWTPs" Mathematics 11, no. 1: 173. https://doi.org/10.3390/math11010173

APA Stylede Matos, B., Salles, R., Mendes, J., Gouveia, J. R., Baptista, A. J., & Moura, P. (2023). A Review of Energy and Sustainability KPI-Based Monitoring and Control Methodologies on WWTPs. Mathematics, 11(1), 173. https://doi.org/10.3390/math11010173