1. Introduction

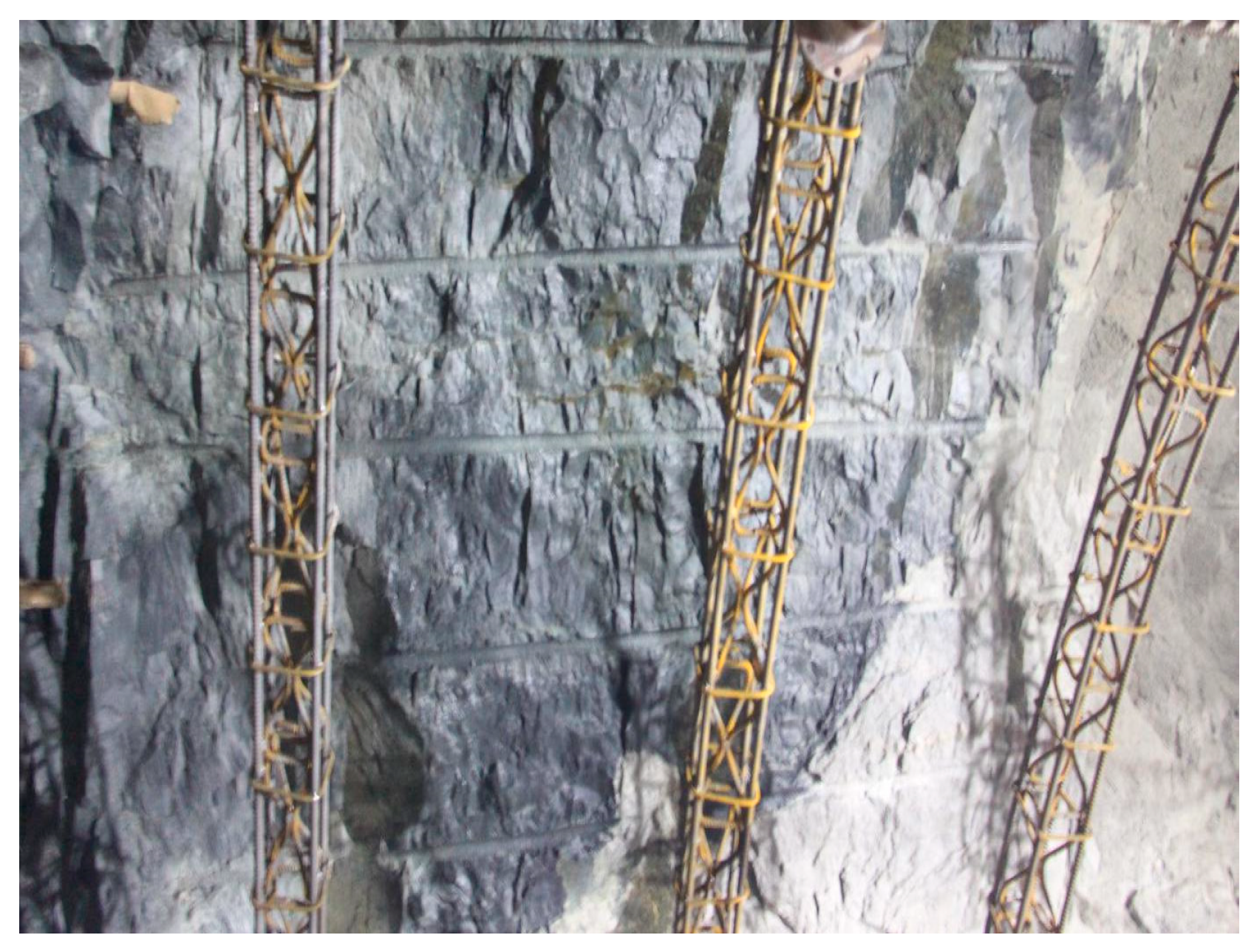

Drilling and blasting method is the main technique for tunnel construction [

1]. With the progress in construction techniques, the SWB technique has been widely accepted in drilling and blasting operations. SWB can effectively control the blasting effect, and hence diminish overbreak and underbreak, keep the tunnel’s rocky wall smooth, and further maintain the stability of surrounding rocks, lessen the supporting workload, reduce the support materials and engineering costs required, and shorten the construction period [

2]. The core issue of SWB lies in the control of overbreak and underbreak [

3]. Mahtab [

4] believes that the combination of traditional blasting methods with simulation technology can assist in the further evaluation of overbreak and underbreak through the tunnel while the tunnel is drilled and blasted forward; the research outcomes can predict the total overbreak and underbreak through the tunnel and further define the confidence interval of the probability of the region where overbreak and underbreak appear. With further development in computer technology, the machine learning method has been widely accepted and used by more and more scholars to predict overbreak and underbreak in surface blasting operations [

5,

6]. Likewise, the theoretical and experimental studies on overbreak and underbreak have also achieved new breakthroughs [

7,

8,

9] and explained macroscopic and microscopic reasons for overbreak and underbreak [

10,

11,

12].

According to research findings, numerous parameters are accountable for the SWB effect, including the physical and mechanical properties of mineral rocks (such as

compressive and tensile strengths,

joint development degree, etc.), blasting design parameters (such as

hole pitch,

array pitch,

blast hole depth,

charge concentration, etc.), and evaluation indexes of blasting effect (such as

average linear overbreak,

average linear underbreak, etc.). Therefore, the selection of influencing factors for SWB is a multilevel, multifactor, multigoal complex decision-making process, with extremely convoluted uncertainty and nonlinear relations between blasting parameters and results [

13,

14]. However, in the current stage, SWB parameters are determined by the mere empirical method or in mere consideration of one or more simple factors; thus, blasting design parameters are extremely subjective and random [

15]. The optimization of SWB parameters is always a challenge under any geological condition with certain control targets (blasting construction targets) [

16].

In practical engineering, especially underground engineering, field test data are typically finite and discrete due to a myriad of limits of the field environment [

17]. A mainstream solution to the global optimization problem with finite and discrete samples in underground engineering is the support vector machine (SVM) [

18,

19] and artificial neural network (ANN) [

20,

21]. The core of SVM is the minimum structural risk such that it has small sample demand and low fitting precision. Therefore, it is more applicable in parameter optimization problems with small numbers of parameters and samples. However, with the continuous development in blasting technology, more and more influencing factors need to be taken into consideration, and higher and higher requirement is raised on the precision of design parameters. Therefore, the minimum empirical risk-based neural network technology has received more attention and is more commonly used [

22,

23].

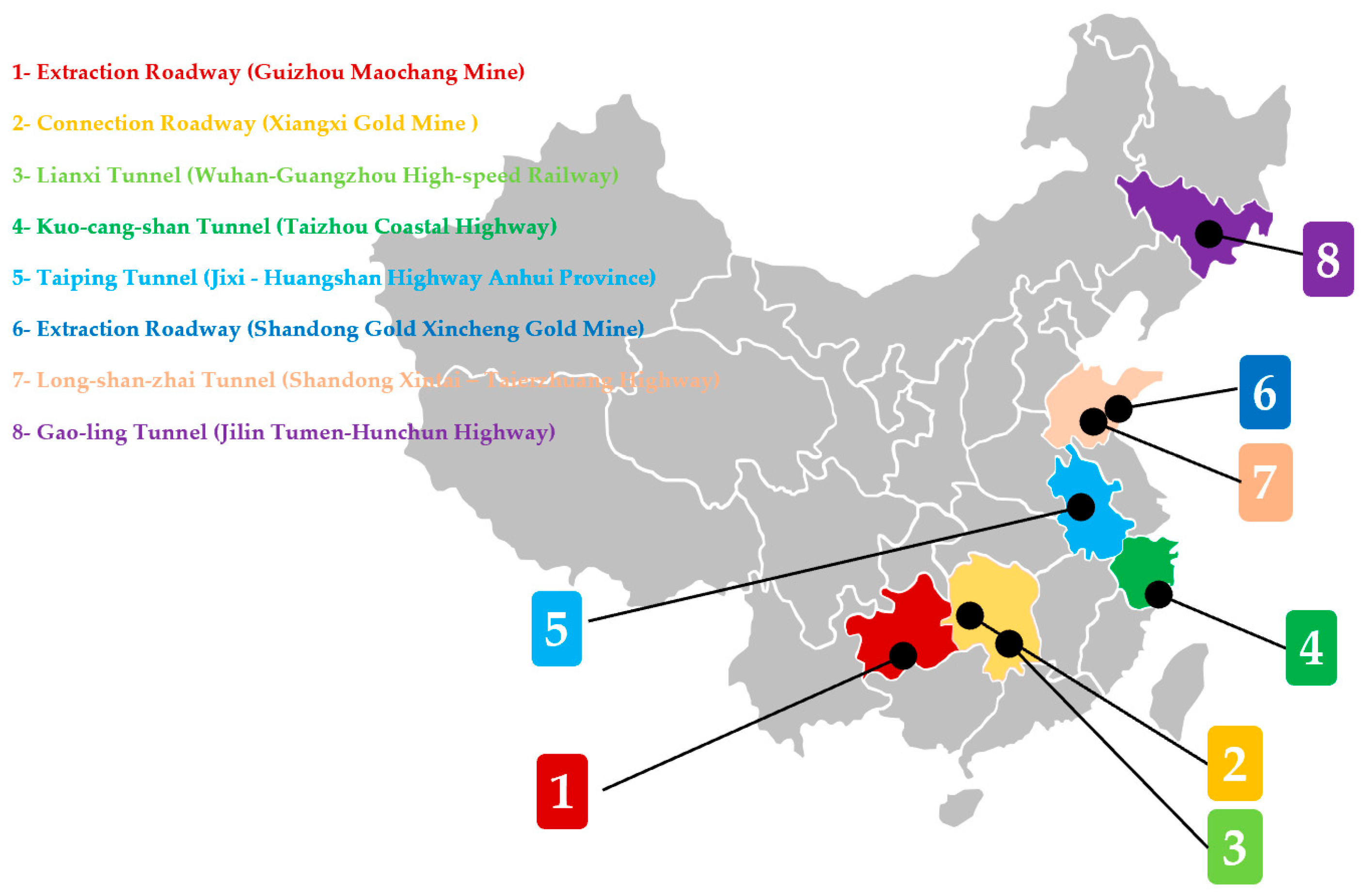

This study proposes an improved neural network algorithm: the GA_BP neural network algorithm, which has optimized the neural network’s initial weights and thresholds, enhanced the fitting precision of BP neural network under small and medium sample sizes, and collected the SWB parameters from other engineering projects under different geological conditions. With the 145 sets of measured data of SWB including the above data as the training samples, and with the 20 sets of field test data in the East Tianshan tunneling project in Xinjiang as the test samples, the nonlinear mapping relation between blasting design parameters and blasting results is obtained through GA_BP neural network fitting. On this base, the blasting effect parameters and parts of the blasting design parameters are controlled as per the practical engineering requirements, and the optimal solutions of blasting design parameters under the control conditions are searched for automatically, so as to achieve the optimization of the design parameters.

In the work of this paper, the coupling algorithm for the GA and BP neural network has been described in

Section 2.

Section 3 introduces the computation flow of the GA_BP neural network algorithm-based SWB parameter optimization model.

Section 4 analyzes, evaluates, and verifies the optimized results in combination with an engineering case.

Section 5 is the conclusion.

2. Methods

The traditional BP neural network is prone to parameter underfitting due to improper selection of initial parameters while training with small and medium samples. To address this problem, the genetic algorithm (GA) is combined with the BP neural network. The preferable weights and thresholds of the initial network are obtained by GA, and thus the fitting precision of the BP neural network is improved [

24,

25,

26,

27].

2.1. Genetic Algorithm (GA)

The implementation of GA includes the following 5 steps: [

28]

- (a)

Population initialization.

Individuals are encoded by the real coding method. Each individual is a real string composed of 4 components: weight of connection between the input layer and the hidden layer, threshold of the hidden layer, weight of connection between the hidden layer and the output layer, and threshold of the output layer. The individuals comprise all weights and thresholds of the neural network. Provided that the network structure is known, a network with a definite mapping structure, number of nodes, weights, and thresholds can be constructed.

- (b)

Fitness function.

According to the initial values of the BP neural network obtained by the individuals, the system output is predicted after training the BP neural network using the training data, and the absolute value of the error and the variance

E between the predicted output and the expected output as individual fitness

F is taken, as calculated by the Equation (1):

where

n is the number of the network’s output nodes;

yi is the expected output of the

ith node of the BP neural network;

oi is the predicted output of the

ith node;

k is the coefficient for normalization; in this paper,

k = 1.

- (c)

Selection operation.

The selection operation in GA is based on the selection strategy of fitness proportion. The selection probability,

pi, of each individual

i is:

where

Fi is the fitness value of individual

i. As it is preferred that fitness be as small as possible, the fitness value shall be inverted prior to individual selection.

k is the coefficient with the same value as Formula (1);

N is the number of individuals in the population.

- (d)

Crossover operation.

As individuals are encoded by real coding, the crossover operation is performed by a real number crossover method. The crossover operation on the

kth chromosome

ak with the

lth chromosome

al at position

j is performed by the following method:

where:

b is a random number within (0, 1).

- (f)

Mutation operation.

The

jth gene of the

ith individual,

aij, is selected to undergo mutation, as operated by the following method:

where

amax is the upper bound to gene

aij;

amin is the lower bound to gene

aij;

;

r2 is a random number;

g is the count up to the current iteration;

Gmax is the maximum evolution count;

r is a random number used to judge the mutation operation within (0, 1), which is automatically generated when selecting

aij.

2.2. BP Neural Network

The BP neural network is a multilayer feedforward neural network that can be regarded as a nonlinear function, whose independent and dependent variables are the network’s input value and predicted value, respectively. When the number of input nodes is n and the number of output nodes is m, the BP neural network expresses the function mapping relation from the n independent variables to the m dependent variables. The BP neural network shall be trained prior to prediction so that it is endowed with associative memory and predictive ability. The training process of BP neural network includes the following 7 steps: [

29]

- (a)

Network initialization.

According to the system’s input and output sequences (X, Y), determine the number of nodes, n, at the network’s input layer, the number of nodes, l, at the hidden layer, the number of nodes, m, at the output layer, initialize the weights wij and wjk of connections between neurons at the input layer, hidden layer, and the output layer, respectively, and the threshold, a, of the hidden layer and the threshold, b, of the output layer, and give the learning rate and the neuron excitation function.

According to the input variable X, weight

wij of connection between the input layer and the hidden layer, and threshold a of the hidden layer, calculate the hidden layer output

H.

where

l is the number of nodes at the hidden layer;

f is the excitation function of the hidden layer, which can be expressed in many ways. Here, the excitation function is selected as:

According to the hidden layer output

H and the weight of connection

wij and threshold b, calculate the predicted output

O of the BP neural network.

According to the network’s predicted output

O and expected output

Y, calculate the network’s predicted error

e.

According to the network’s predicted error

e, update the weights

wij and

wjk of network connections.

where

η is the learning rate.

According to the network’s predicted error

e, update the thresholds

a and

b of network nodes.

2.3. GA_BP Neural Network

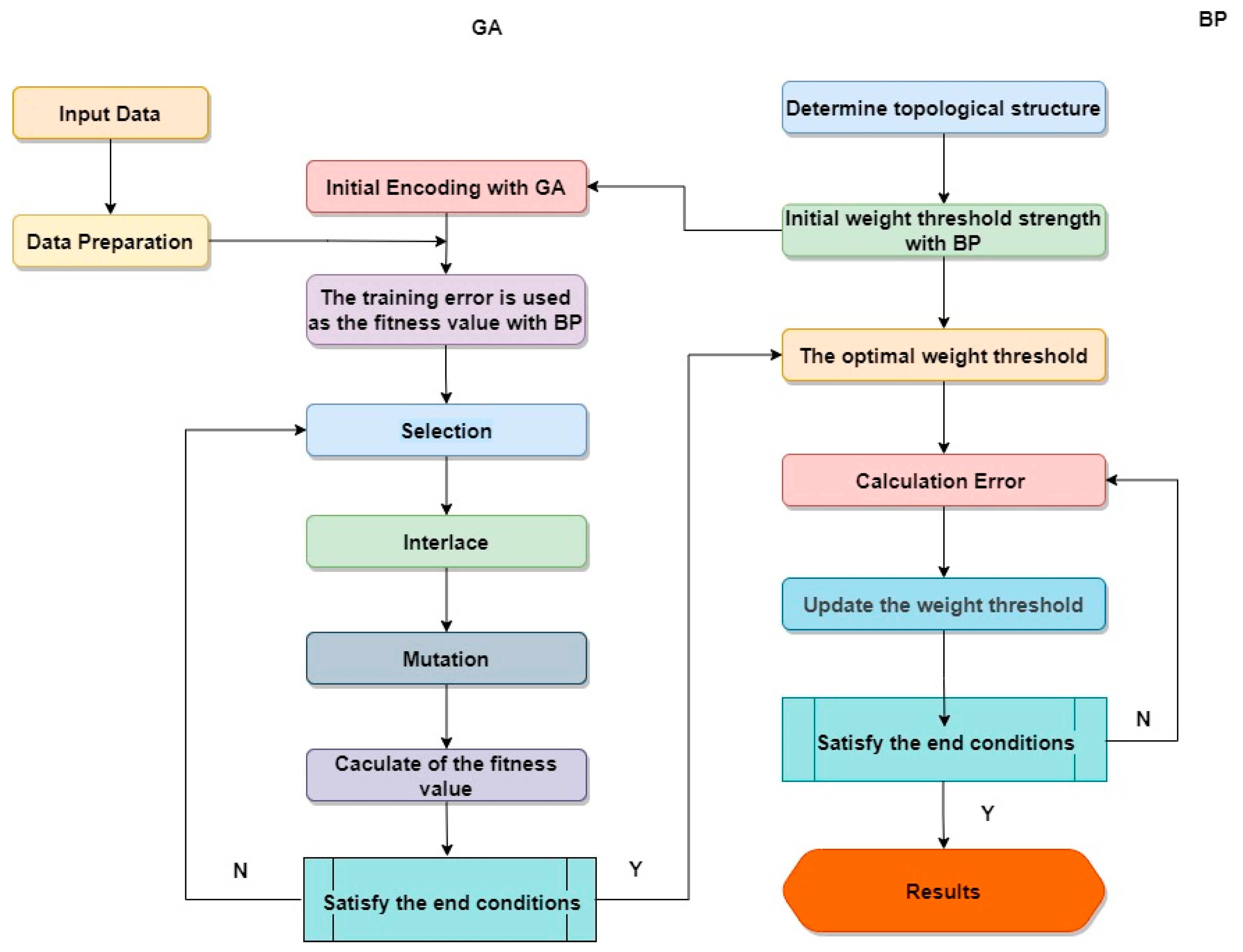

The parameter fitting calculation of the GA_BP neural network falls into two components: the BP neural network and GA optimization. The calculation flowchart is shown in

Figure 1.

Where the BP neural network is composed of two parts: One is the part of the BP neural network structure determination, namely to determine the results of the BP neural network, and thereby the length of GA individuals, according to the number of input and output parameters of the fitting function; the other is the part of the BP neural network parameter fitting, which is responsible for fitting the neural network’s input and output parameters, determining the nonlinear relations between parameters, and predicting the function output after network training. The GA optimization component uses the weights and thresholds of the genetic optimization algorithm of the BP neural network. Each individual in the population comprises all weights and thresholds of a network. Individuals’ fitness is calculated via the fitness function, in order for the genetic algorithm to find the individual with the optimal fitness value through selection, crossover, and mutation operations, and thus to optimize the initial weights and thresholds of the BP neural network. The concrete procedure of GA_BP neural network goes as follows:

(a) Determine the input and output parameters of GA_BP neural network; (b) initialize the weights and thresholds between the initial parameters of the BP neural network; (c) optimize the above weights and thresholds by GA and select the optimal ones; (d) fit the input and output parameters of GA_BP neural network; (e) error test as to whether the requirement is met, if yes end the calculation, or else return to Step (c).

3. Optimization Model

3.1. Parameter Optimization

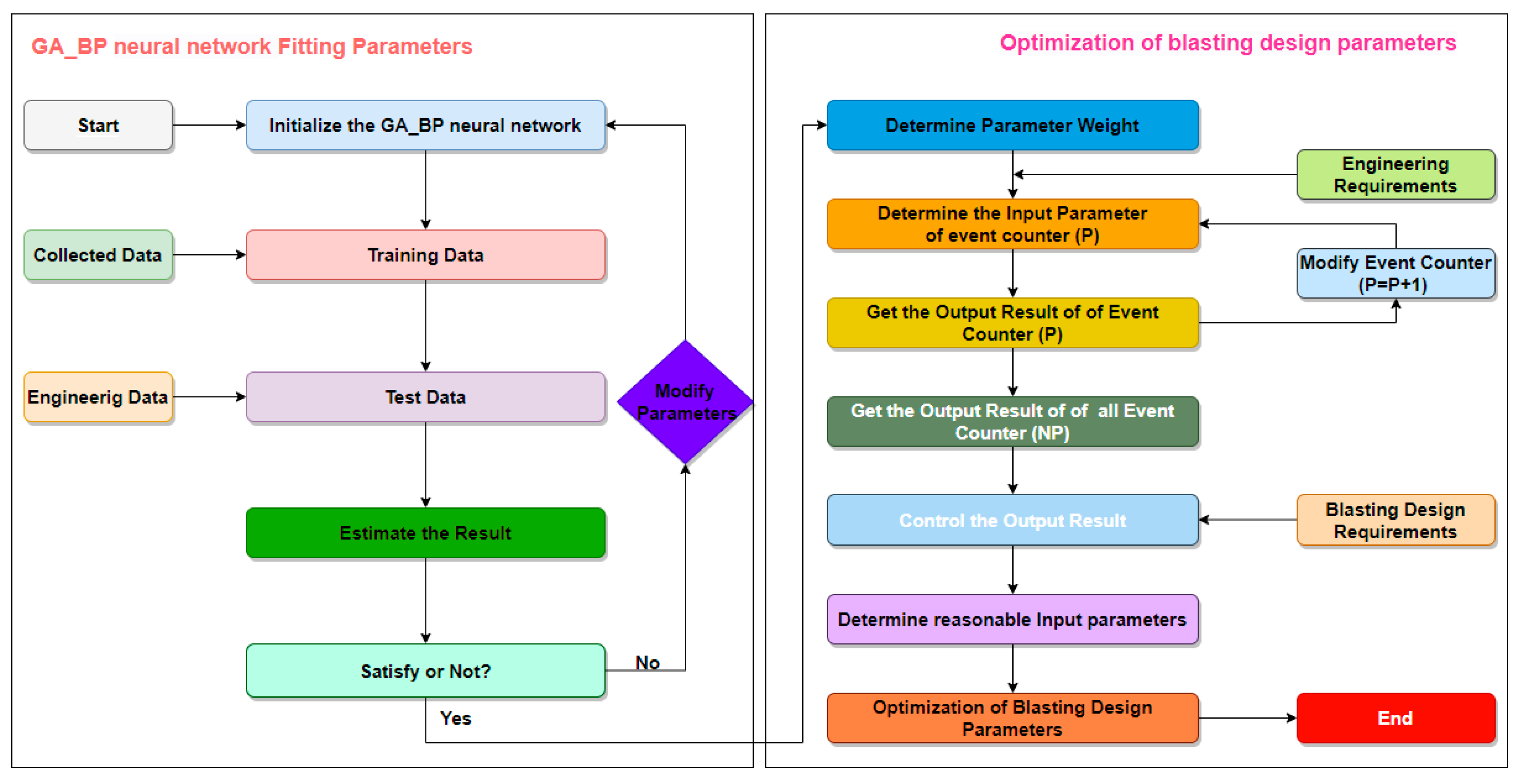

The calculation for the SWB parameter optimization is to determine the nonlinear relations between input parameters and output parameters by fitting all these parameters via the GA_BP neural network, and to implement the prediction of the output results under the condition of input parameters; next, through the control of the output results, it automates the optimization model to search for the optimal solutions among the input parameters. The calculation process falls into two parts: One is the fitting of GA_BP neural network parameters, and the other is the calculation for parameter optimization. The concrete calculation model is shown in

Figure 2.

The concrete steps of calculation for the SWB parameter optimization go as follows:

Initialize the GA_BP neural network and determine the optimal neural network parameters;

Fit the input parameters and output parameters of SWB among the training samples of the GA_BP neural network;

After fitting the parameters of the GA_BP neural network, conduct an error analysis into the GA_BP neural network using the test samples. If the requirement is met, go to the next step, else return to the first step and modify the basic parameters of the neural network;

When the fitting results meet the requirement of test error, the nonlinear relations between the input and output parameters are reflected, and thus the prediction of results is implemented;

According to the purpose of practical engineering and the parameter design requirement (input parameter control), determine the calculation parameters when the event counter P = 1;

Try figuring out the SWB calculation results under the feasible condition when the event counter P = 1, using the nonlinear relations reflected in the GA_BP neural network.

After going through the case when the event counter P = 1, determine the calculation parameters when the event counter P = 2, and return to the previous step for calculation until covering all event counters for P = P + 1;

Control the calculation results and thus automatically search for the optimal values of them under this trial condition, so as to derive the optimal design parameters by inversion and implement the optimization of SWB design parameters.

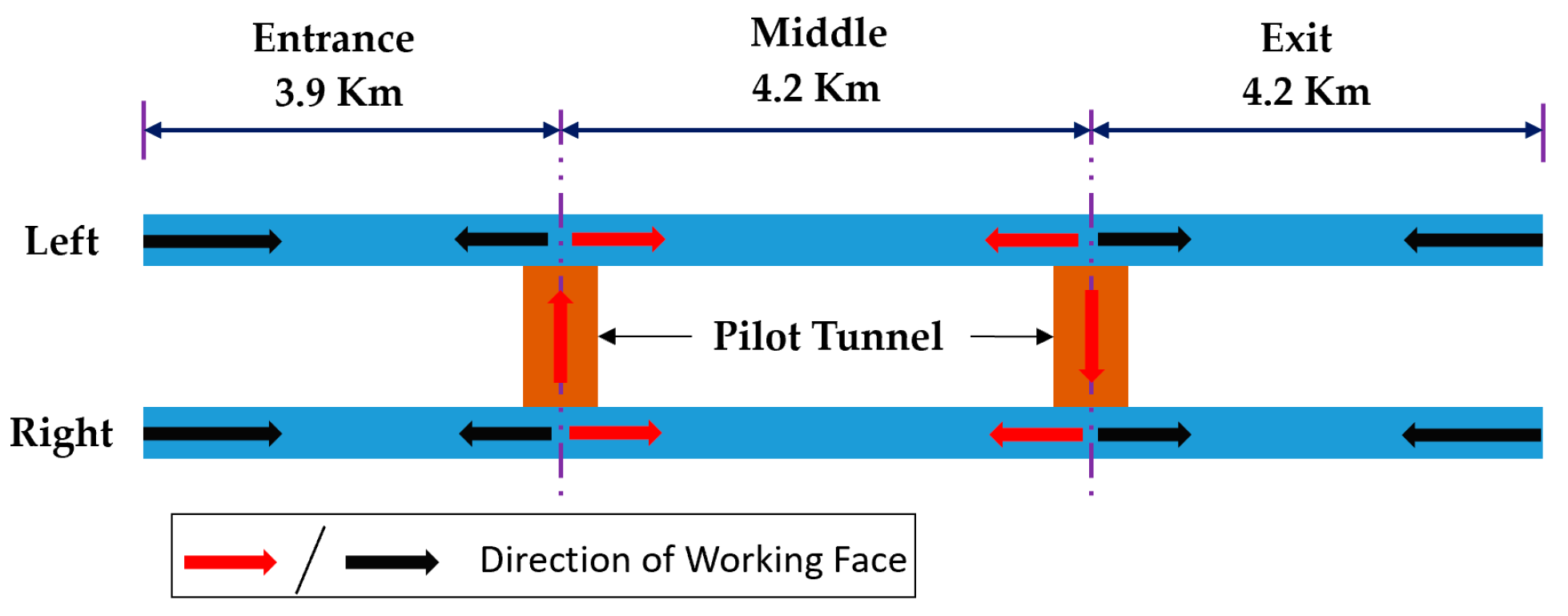

3.2. Parameters

In practical tunneling, SWB involves numerous data. Taking the parameters into consideration of the calculation model for SWB parameter optimization is bound to the problems of data redundancy and computational complexity. Therefore, it is necessary to screen the important parameters in SWB and perform the corresponding simplification of the concrete fitting parameters. In general, the SWB effect is subject mainly to geological conditions and blasting parameters. Accordingly, the selected parameters should include factors in three aspects: geological conditions, blasting design parameters, and blasting result parameters. Considering the practical engineering application, and for the convenience of the uniform measurement of test data, the SWB parameters are simplified with overall consideration of the blasting design standard and scholars’ research outcomes [

8,

30,

31].

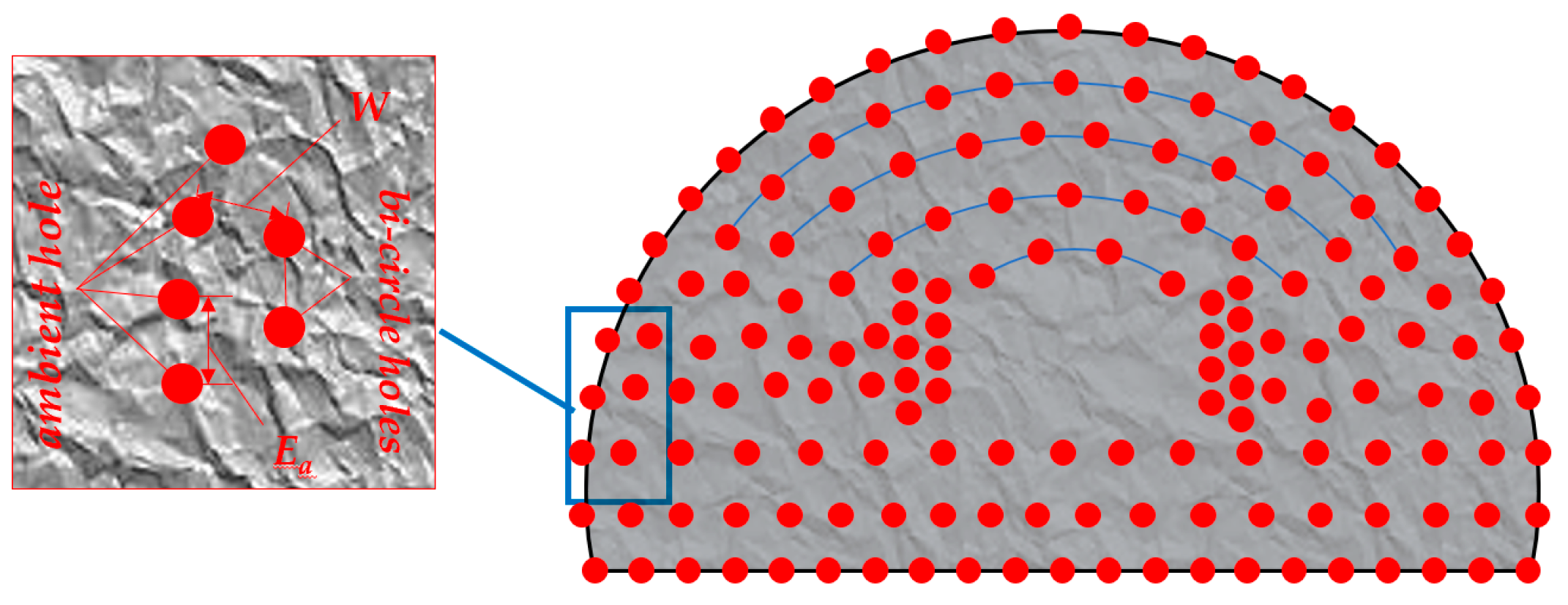

Figure 3 is a schematic diagram of the SWB design parameters.

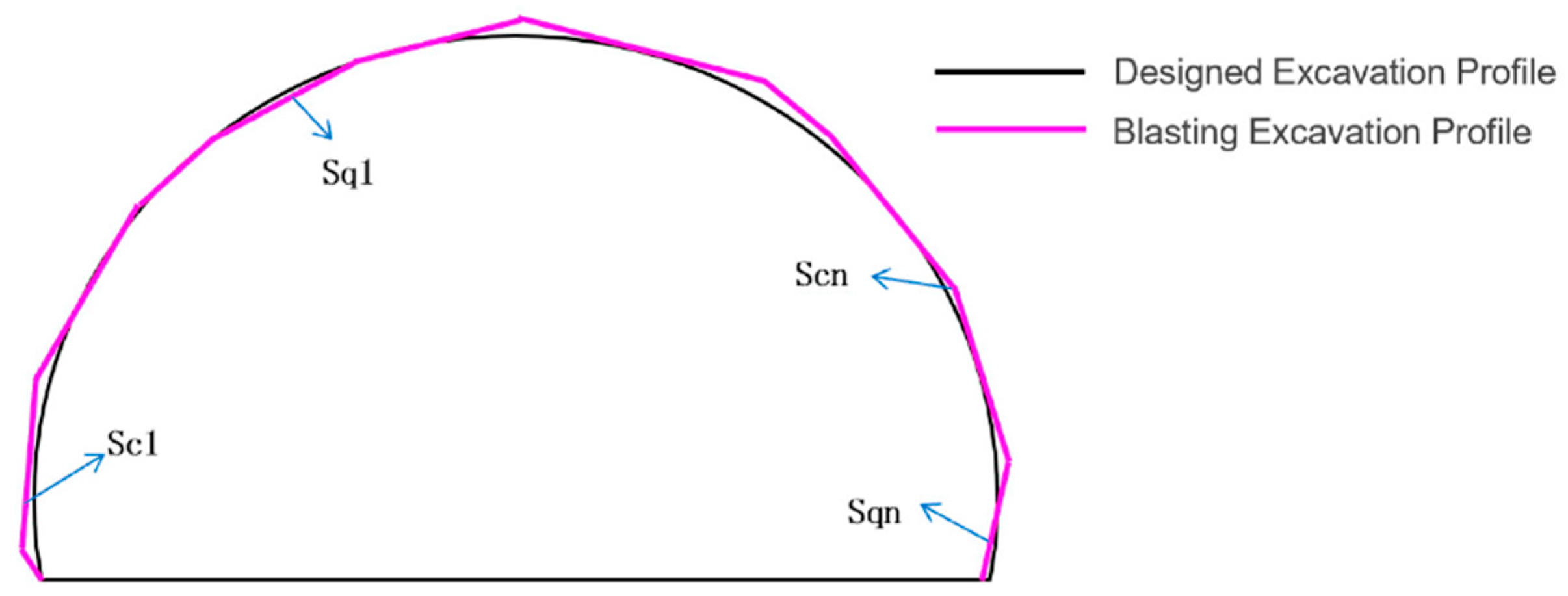

Figure 4 is a schematic diagram for the calculation of average linear overbreak and underbreak.

Average overbreak and underbreak are calculated by the formulae:

for

average linear overbreak, and:

for

average linear underbreak, where

Ic and

Iq correspond, respectively, to the arclength corresponding to each overbreak area and underbreak area.

For optimization calculation, the input parameters are the ones that affect the blasting results, whereas the output parameters are the blasting results. Moreover, in practical engineering, due to the influences of geological conditions, boring equipment, and tunneling purpose, the parameters already have fixed values or designed values and cannot or need not be optimized further. Therefore, the core purpose of SWB parameter optimization is to search for the optimal solutions of spacing between lines of least resistance W, auxiliary hole pitch Eb, and ambient hole pitch Ea, under the condition of controlling the average linear overbreak and average linear underbreak.

3.3. Determination of GA_BP Neural Network Topology and Basic Parameters

Through the above description, the number of input parameters of the GA_BP neural network can be determined to be 11, whereas the number of output parameters is 2. The neural network adopts a three-layer topological structure. The excitation function is selected as a sigmoid function.

Generally, the number of nodes in the hidden layer is calculated by the following empirical formulas [

29]:

where

n is the number of input layer nodes,

l is the number of hidden layer nodes,

m is the number of output layer nodes, and

a is a constant between 0 and 10.

In this paper, the number of nodes in the input layer is

n = 11 and the number of nodes in the output layer is

m = 2. Therefore, according to the above formula, it is considered that the value range of

l is between 4 and 20.

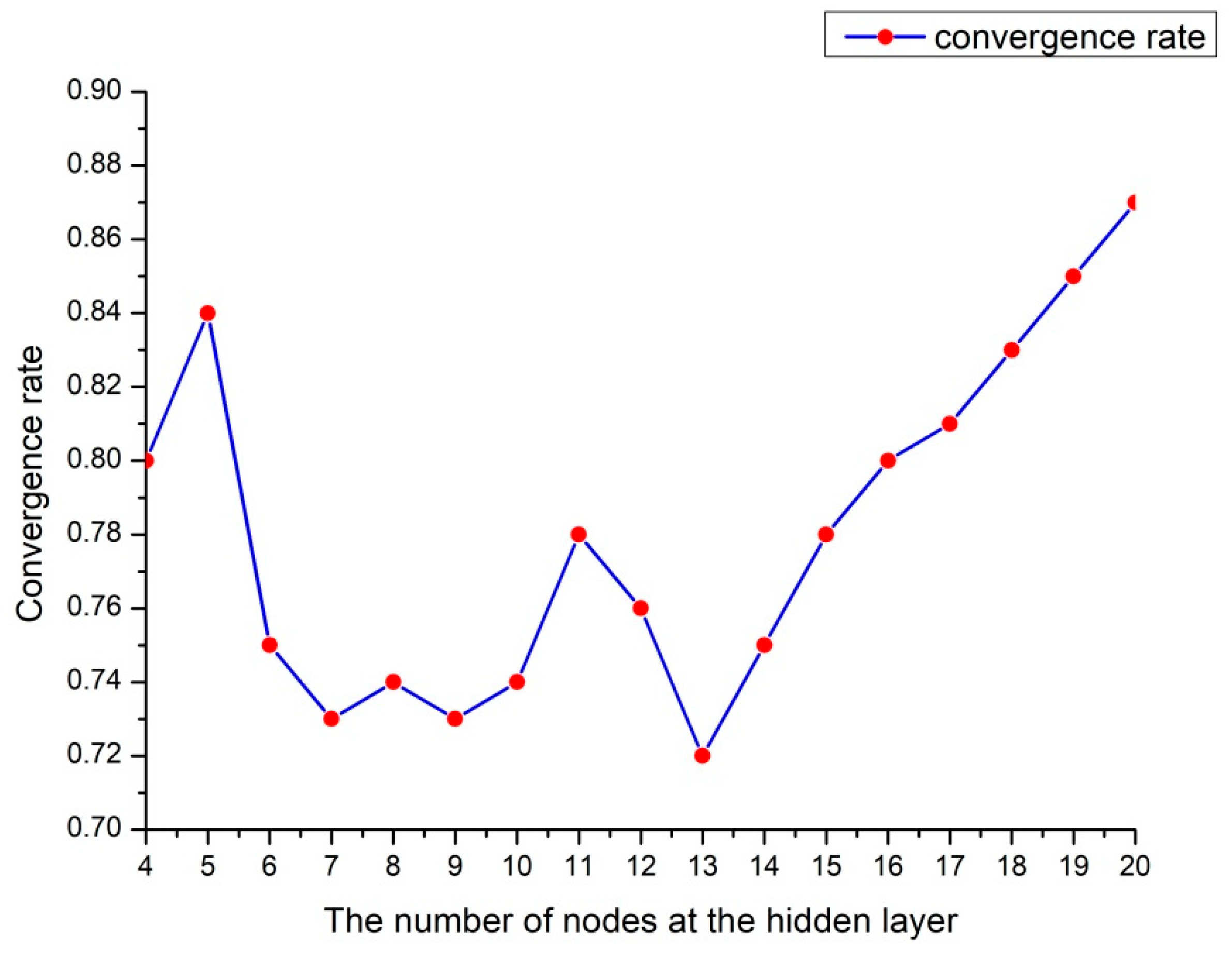

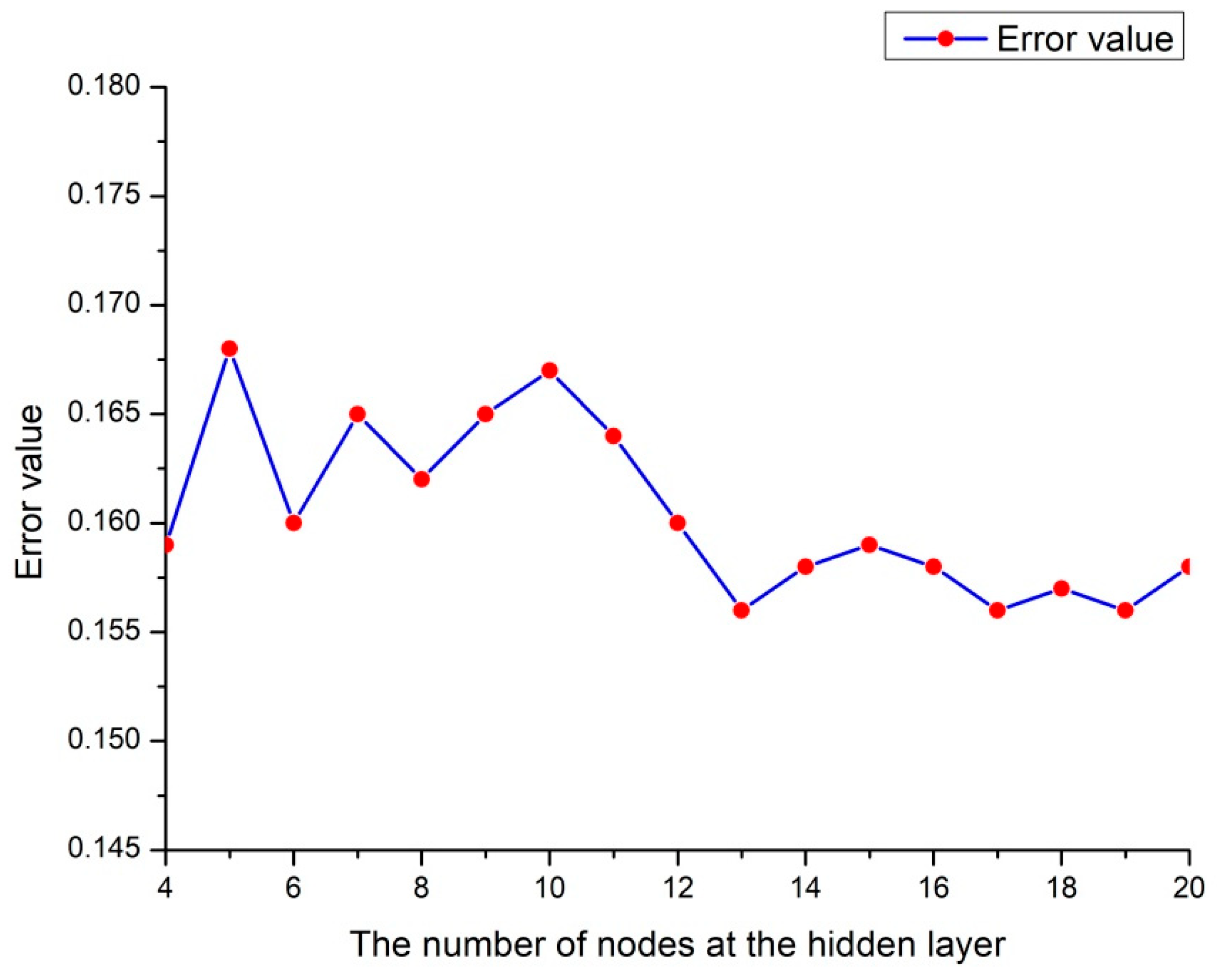

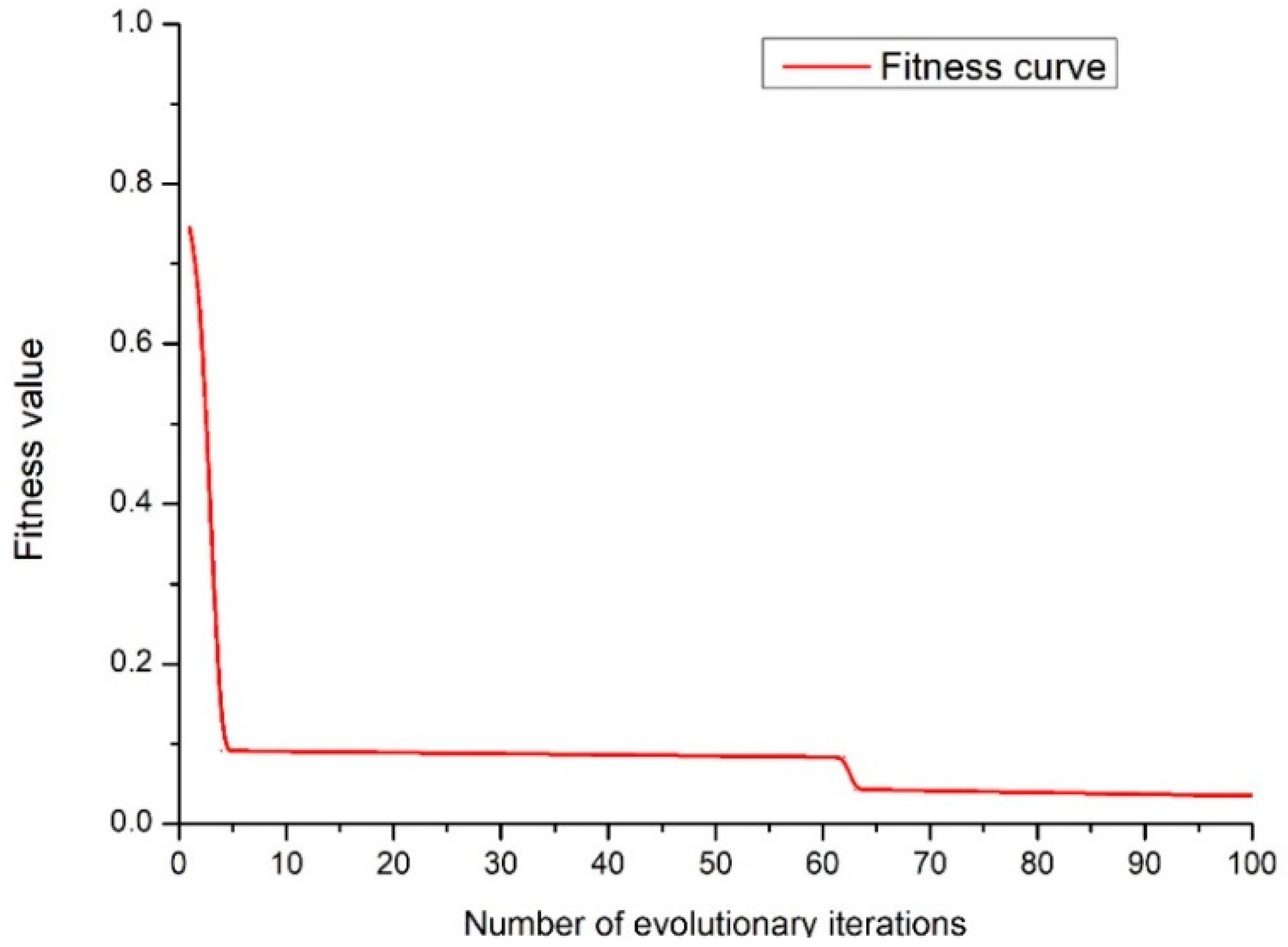

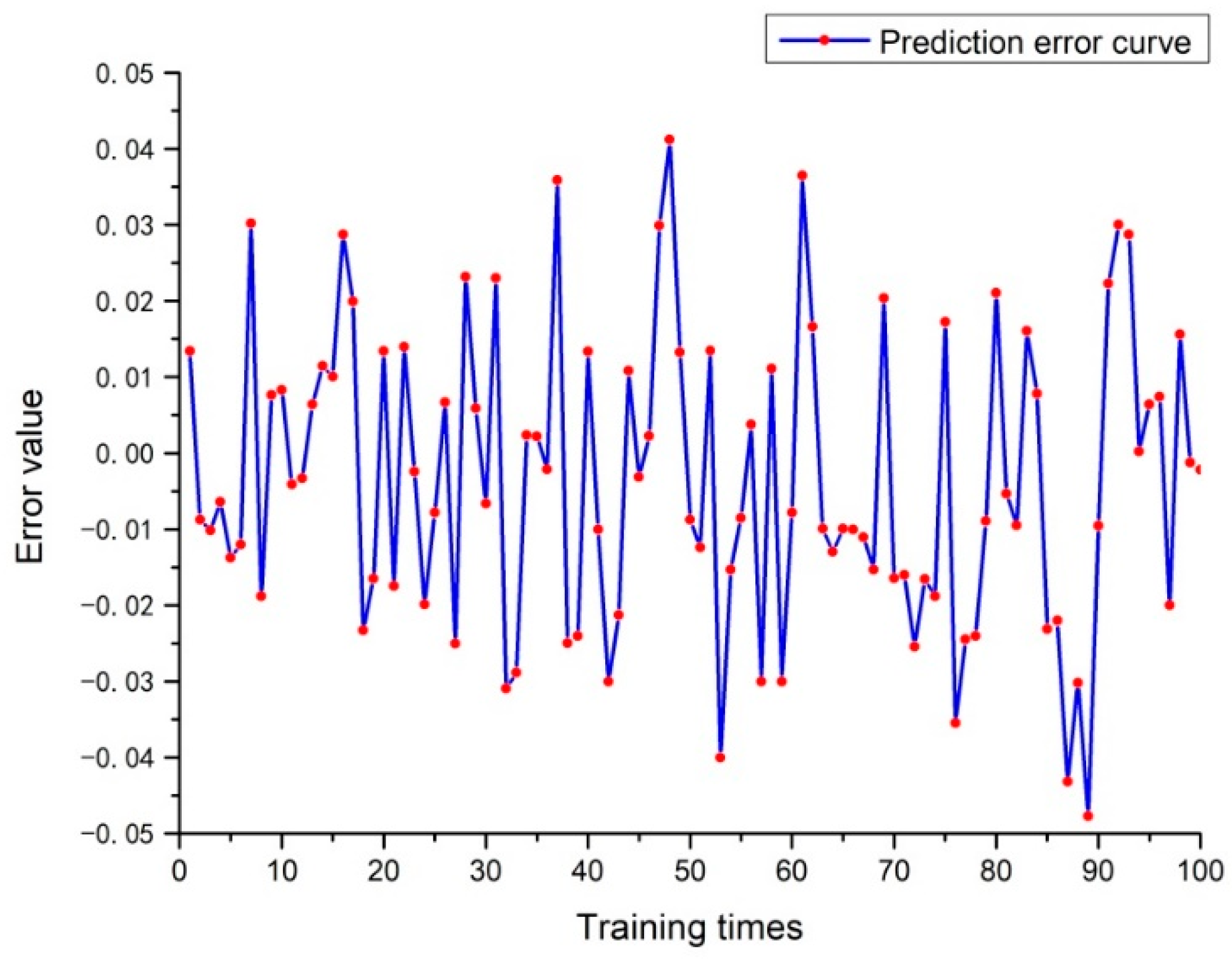

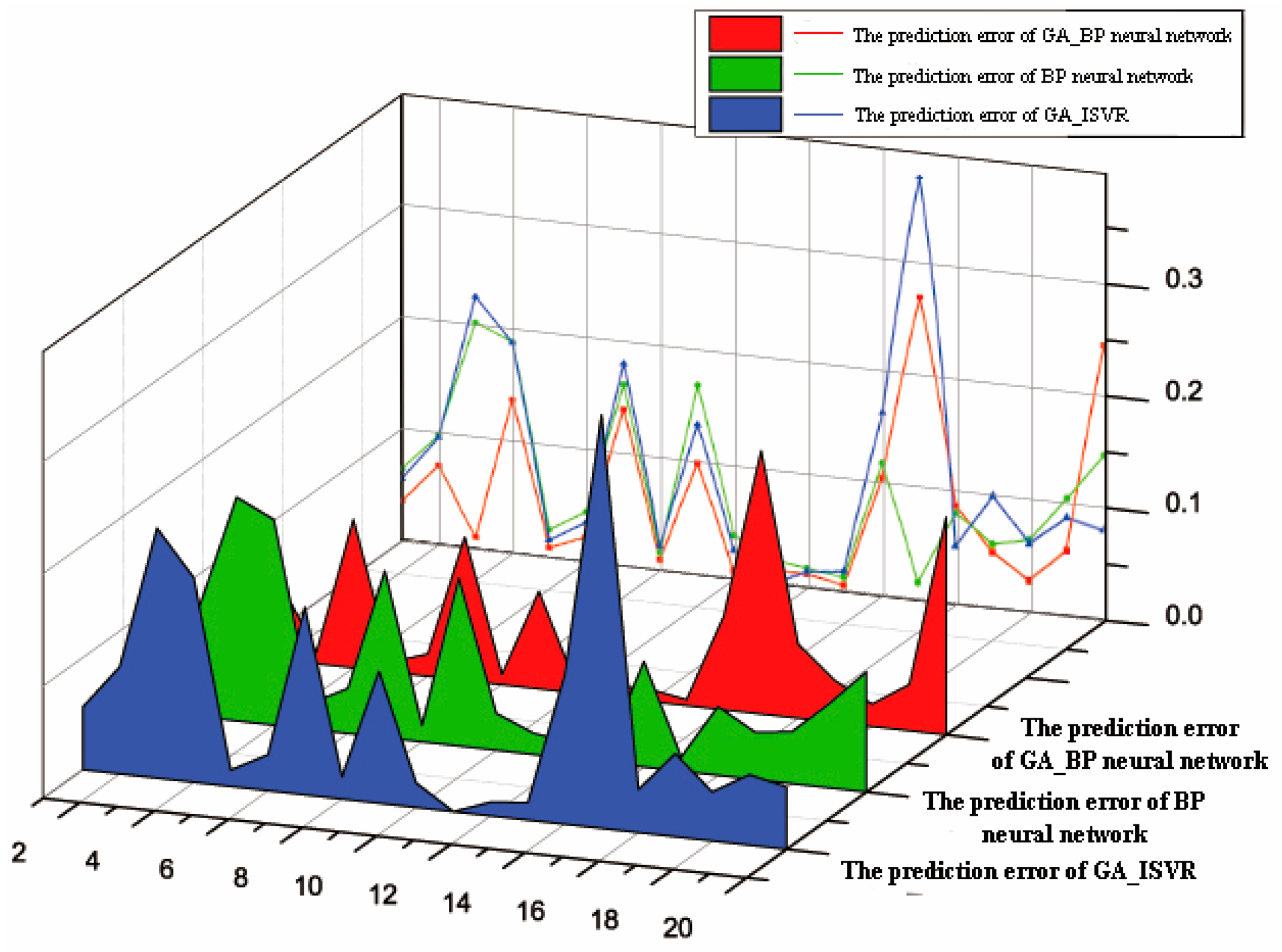

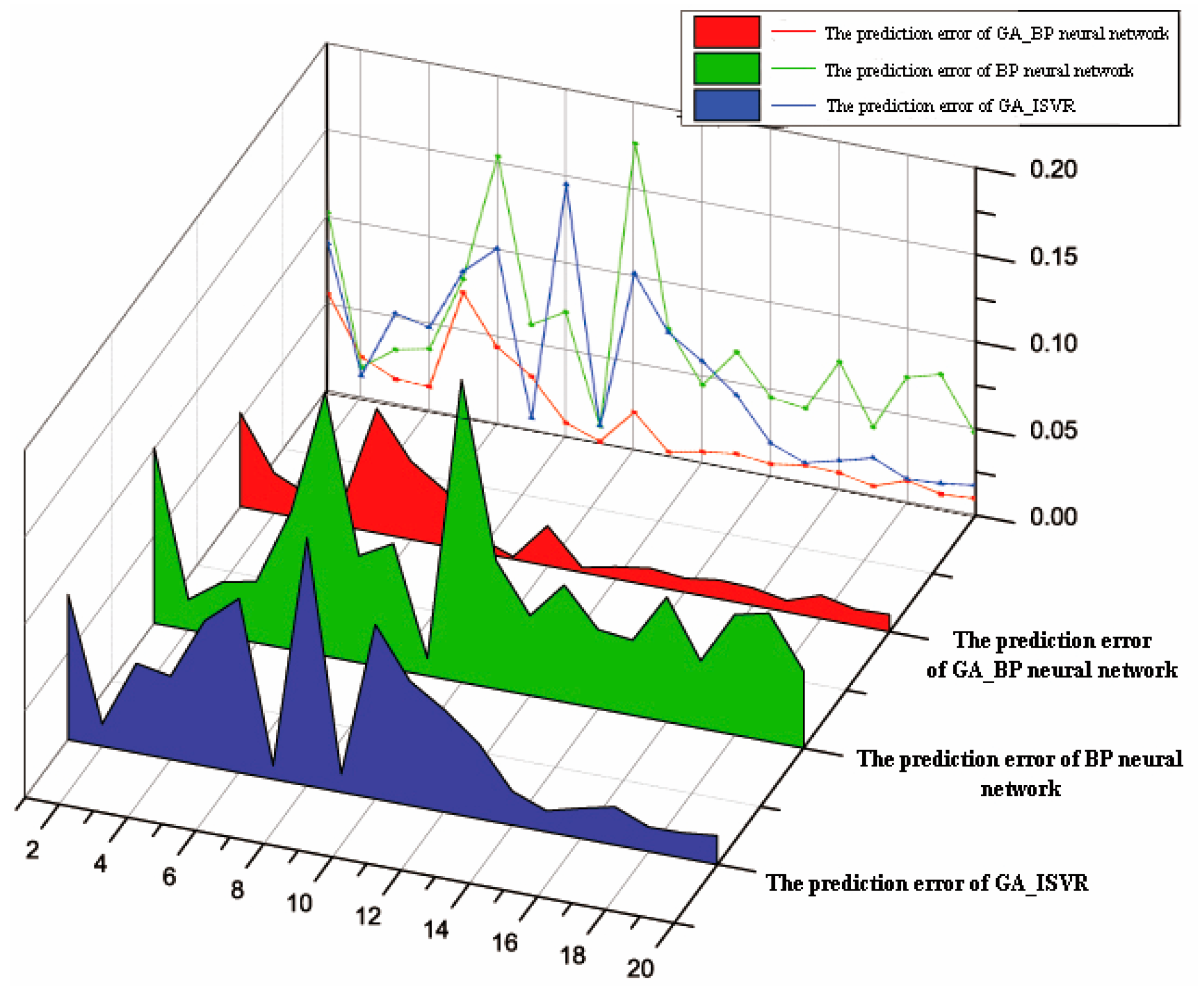

Figure 5 and

Figure 6 show the convergence speed during sample training and the error rate after sample fitting under different hidden layer nodes during trial calculation. Considering the results of

Figure 1 and

Figure 2, it is most reasonable to set the number of nodes of the hidden layer as

l = 13.

Relevant references [

32,

33], are selected to determine the network’s initial basic parameters: The number of nodes at the hidden layer of GA_BP neural network is 13, with 11 × 13 + 2 × 13 = 169 weights and 13 + 2 = 15 thresholds; individual encoding length in GA is 169 + 15 = 184, population size is 20, evolution count is 100, crossover probability is 0.94, and mutation probability is 0.2. The final GA_BP neural network topology is shown in

Figure 7.

3.4. Control Targets of SWB Parameter Optimization

The purpose of parameter optimization is to search for the optimal results. SWB involves numerous parameters, and, without a unique evaluation index of the blasting results, the evaluation is a multitask and multipurpose problem. At the current stage, the multitask and multipurpose optimization using neural network is implemented mainly by two methods: One is to figure out the multiple goals into mutually independent target solutions by the method of Pareto solutions, and the other is to turn the multiple goals into single goals by some calculation model. Combining the practical engineering, the two target parameters, the average linear overbreak and average linear underbreak, are difficult to become mutually independent target solutions. Therefore, the latter approach can be more effective. Moreover, the optimal solutions for the results of SWB typically need to meet two requirements: One is that the tunnel profile shall be as smooth as possible; the other is that the contour line of the practically blasted tunnel shall be as designed as possible. Therefore, reflected in the calculation model for optimization, the control targets of the output parameters are:

6. Conclusions

The combination of genetic algorithm and the BP neural network can improve the generalization degree and calculation accuracy of the prediction model, so as to solve the problem of insufficient accuracy caused by insufficient data quantity. Based on this, in this work, a new algorithm based on the GA_BP neural network is proposed, which is applied to the prediction and optimization of the tunnel SWB parameters. By training the input data (geological conditions and SWB parameters) and output data (overbreak/underbreak), the algorithm model builds the nonlinear relationship and realizes the prediction of the SWB effect. Moreover, based on the control of the prediction, the optimization of the design parameters of the SWB is realized.

In addition, through the analysis of the optimization of tunnel SWB parameters, it is believed that the “Eb (auxiliary hole pitch)” has the greatest impact on overbreak and underbreak. Therefore, this index should be given priority when determining parameters.

The application results demonstrate that the algorithm model is effective and feasible to predict and optimize the parameters of SWB, and the results can meet the requirements of practical engineering.