A Derivative-Free Line-Search Algorithm for Simulation-Driven Design Optimization Using Multi-Fidelity Computations

Abstract

:1. Introduction

2. Multi-Fidelity Linesearch-Based Derivative-Free Approach for Nonsmooth Constrained Optimization Algorithm

2.1. Continuous Search

2.2. Projected Continuous Search

| Algorithm 1 MF-CS-DFN |

| Input., , , , , , , for i = 1, …, N such that |

| Let with be the precision levels, such that , |

| Set and |

| fordo ▹ Start the iterations |

| Set |

| for do |

| Compute and by the Continuous Search (, , ; , ) ▹ Call CS |

| if () then |

| Set |

| else |

| Set |

| Set , , |

| if () then |

| Compute and by the Projected Continuous Search ▹ Call PCS |

| if () then |

| else |

| and |

| else |

| Set |

| if ( and ) then |

| ▹ Increase the accuracy |

| Set , for |

| Find such that |

| Algorithm 2 Continuous Search (, , ; , ) |

| Data., |

| Step 1. Compute the largest such that . Set |

| Step 2. If and then set and go to Step 6 |

| Step 3. Compute the largest such that . Set |

| Step 4. If and then set and go to Step 6 |

| Step 5. Set , return and |

| Step 6. Let |

| Step 7. If or return and |

| Step 8. Set and go to Step 6 |

| Algorithm 3 Projected Continuous Search () |

| Data., |

| Step 0. Set |

| Step 1. Ifthen set and go to Step 4 |

| Step 2. Ifthen set and go to Step 4 |

| Step 3. Set , return and |

| Step 4. Let |

| Step 5. Ifreturn |

| Step 8. Set and go to Step 4 |

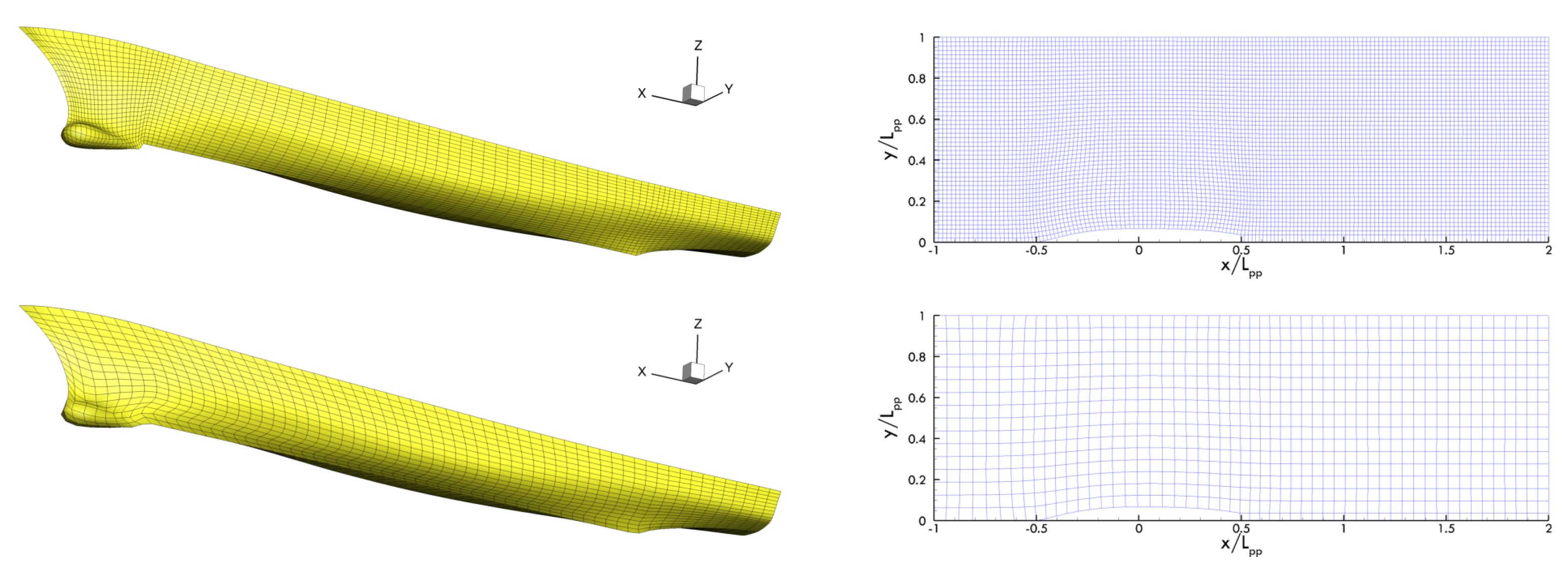

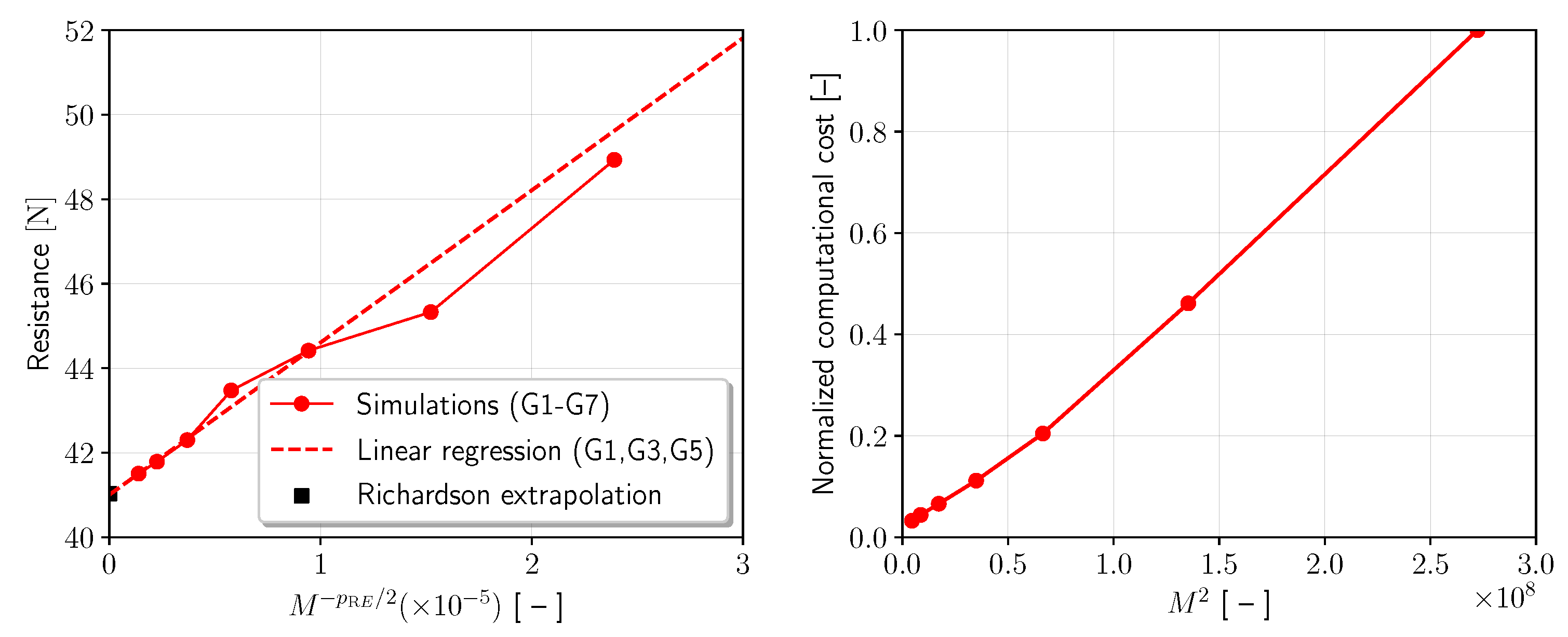

3. SDDO Benchmark Problem

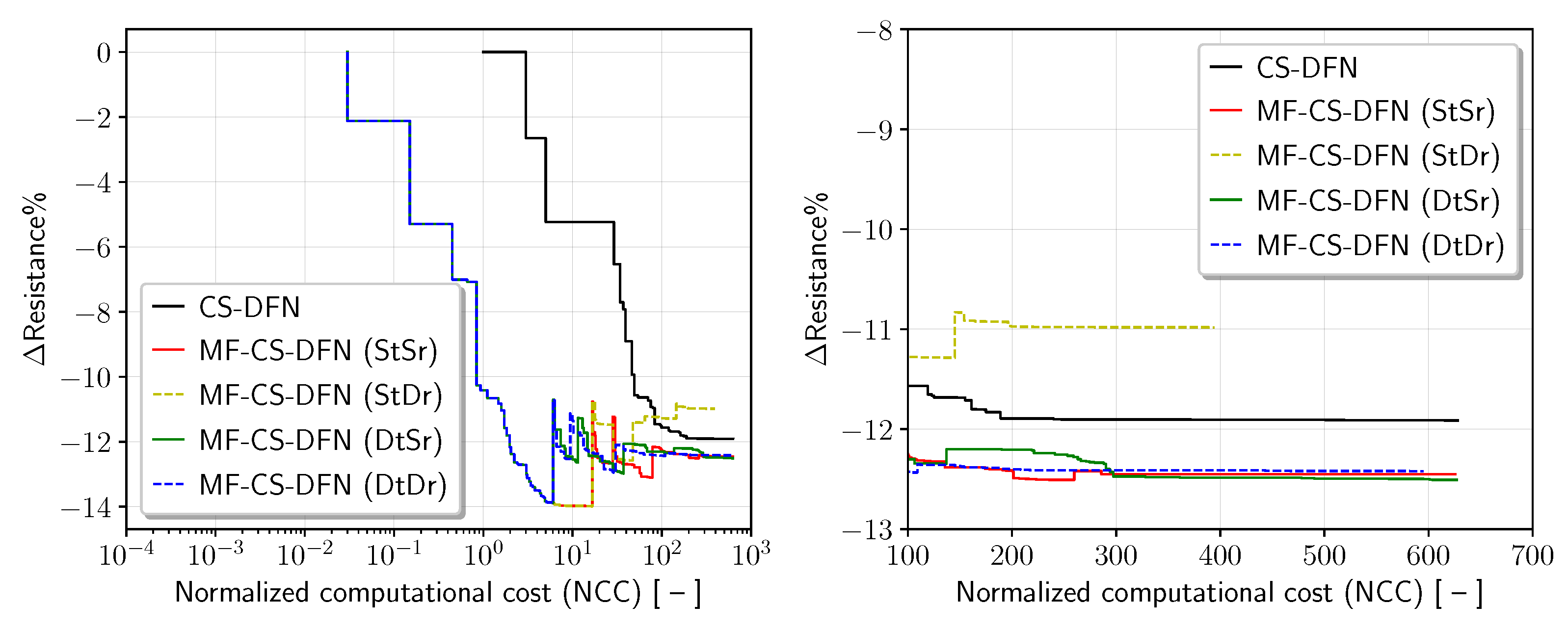

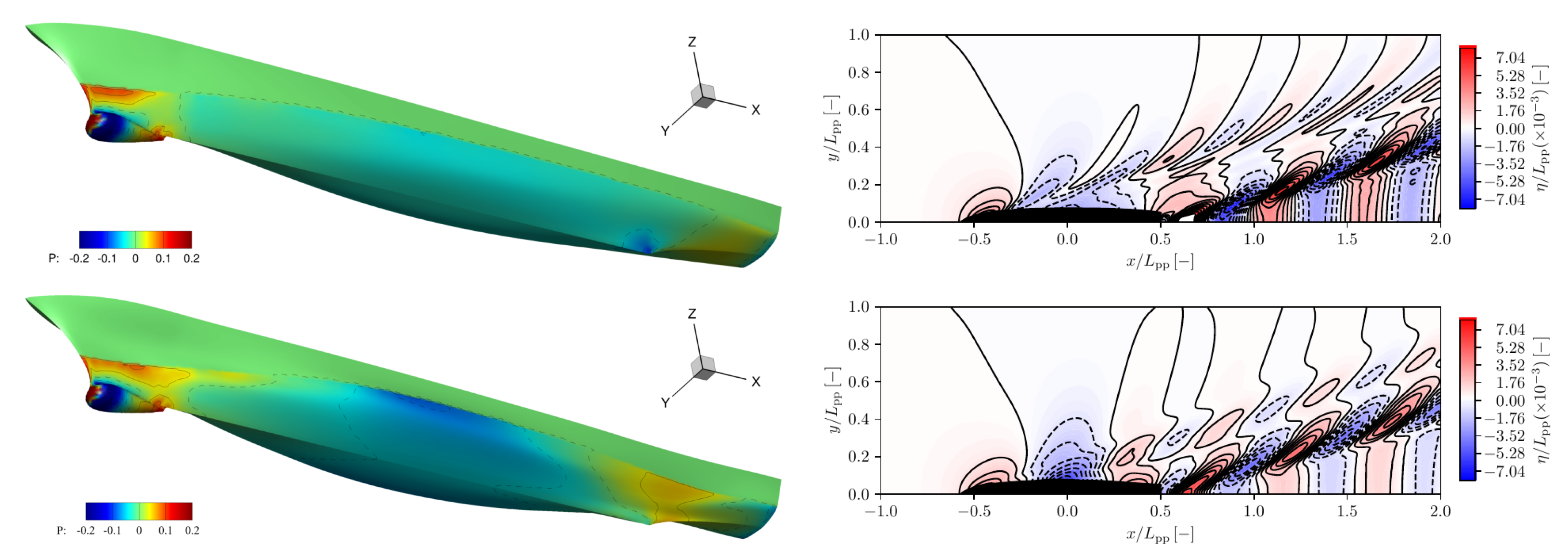

4. Numerical Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Harries, S.; Abt, C. Faster turn-around times for the design and optimization of functional surfaces. Ocean Eng. 2019, 193, 106470. [Google Scholar] [CrossRef]

- Serani, A.; Diez, M.; van Walree, F.; Stern, F. URANS analysis of a free-running destroyer sailing in irregular stern-quartering waves at sea state 7. Ocean Eng. 2021, 237, 109600. [Google Scholar] [CrossRef]

- Serani, A.; Stern, F.; Campana, E.F.; Diez, M. Hull-form stochastic optimization via computational-cost reduction methods. Eng. Comput. 2021, 1–25. [Google Scholar] [CrossRef]

- D’Agostino, D.; Serani, A.; Diez, M. Design-space assessment and dimensionality reduction: An off-line method for shape reparameterization in simulation-based optimization. Ocean Eng. 2020, 197, 106852. [Google Scholar] [CrossRef]

- D’Agostino, D.; Serani, A.; Campana, E.F.; Diez, M. Nonlinear Methods for Design-Space Dimensionality Reduction in Shape Optimization. In Proceedings of the 3rd International Conference on Machine Learning, Optimization, and Big Data, MOD 2017, Volterra, Italy, 14–17 September 2017. [Google Scholar]

- Alizadeh, R.; Allen, J.K.; Mistree, F. Managing computational complexity using surrogate models: A critical review. Res. Eng. Des. 2020, 31, 275–298. [Google Scholar] [CrossRef]

- Jones, D.R.; Martins, J.R. The DIRECT algorithm: 25 years Later. J. Glob. Optim. 2021, 79, 521–566. [Google Scholar] [CrossRef]

- Beran, P.S.; Bryson, D.E.; Thelen, A.S.; Diez, M.; Serani, A. Comparison of Multi-Fidelity Approaches for Military Vehicle Design. In Proceedings of the 21th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference (MA&O), AVIATION 2020, Denver, CO, USA, 5–9 June 2020. [Google Scholar]

- Giselle Fernández-Godino, M.; Park, C.; Kim, N.H.; Haftka, R.T. Issues in deciding whether to use multifidelity surrogates. AIAA J. 2019, 57, 2039–2054. [Google Scholar] [CrossRef]

- Giselle Fernández-Godino, M.; Park, C.; Kim, N.H.; Haftka, R.T. Review of multi-fidelity models. arXiv 2016, arXiv:1609.07196. [Google Scholar]

- Vanilla, T.T.; Benoit, A.; Benoit, P. Hydro-elastic response of composite hydrofoil with FSI. Ocean Eng. 2021, 221, 108230. [Google Scholar] [CrossRef]

- Anselma, P.; Niutta, C.B.; Mainini, L.; Belingardi, G. Multidisciplinary design optimization for hybrid electric vehicles: Component sizing and multi-fidelity frontal crashworthiness. Struct. Multidiscip. Optim. 2020, 62, 2149–2166. [Google Scholar] [CrossRef]

- Biehler, J.; Gee, M.W.; Wall, W.A. Towards efficient uncertainty quantification in complex and large-scale biomechanical problems based on a Bayesian multi-fidelity scheme. Biomech. Model. Mechanobiol. 2015, 14, 489–513. [Google Scholar] [CrossRef] [PubMed]

- Jonsson, I.M.; Leifsson, L.; Koziel, S.; Tesfahunegn, Y.A.; Bekasiewicz, A. Shape optimization of trawl-doors using variable-fidelity models and space mapping. Procedia Comput. Sci. 2015, 51, 905–913. [Google Scholar] [CrossRef] [Green Version]

- Koziel, S.; Tesfahunegn, Y.; Amrit, A.; Leifsson, L.T. Rapid multi-objective aerodynamic design using co-kriging and space mapping. In Proceedings of the 57th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, San Diego, CA, USA, 4–8 January 2016; p. 0418. [Google Scholar]

- Song, Y.; Cheng, Q.S.; Koziel, S. Multi-fidelity local surrogate model for computationally efficient microwave component design optimization. Sensors 2019, 19, 3023. [Google Scholar] [CrossRef] [Green Version]

- Leotardi, C.; Serani, A.; Iemma, U.; Campana, E.F.; Diez, M. A variable-accuracy metamodel-based architecture for global MDO under uncertainty. Struct. Multidiscip. Optim. 2016, 54, 573–593. [Google Scholar] [CrossRef]

- Volpi, S.; Diez, M.; Stern, F. Multidisciplinary design optimization of a 3D composite hydrofoil via variable accuracy architecture. In Proceedings of the 2018 Multidisciplinary Analysis and Optimization Conference, Atlanta, GA, USA, 25–29 June 2018; p. 4173. [Google Scholar]

- Branke, J.; Asafuddoula, M.; Bhattacharjee, K.S.; Ray, T. Efficient use of partially converged simulations in evolutionary optimization. IEEE Trans. Evol. Comput. 2016, 21, 52–64. [Google Scholar] [CrossRef] [Green Version]

- Palar, P.S.; Zuhal, L.R.; Shimoyama, K.; Tsuchiya, T. Global sensitivity analysis via multi-fidelity polynomial chaos expansion. Reliab. Eng. Syst. Saf. 2018, 170, 175–190. [Google Scholar] [CrossRef] [Green Version]

- Zou, Z.; Liu, J.; Zhang, W.; Wang, P. Shroud leakage flow models and a multi-dimensional coupling CFD (computational fluid dynamics) method for shrouded turbines. Energy 2016, 103, 410–429. [Google Scholar] [CrossRef]

- Le Gratiet, L.; Cannamela, C.; Iooss, B. A Bayesian approach for global sensitivity analysis of (multifidelity) computer codes. SIAM/ASA J. Uncertain. Quantif. 2014, 2, 336–363. [Google Scholar] [CrossRef]

- Kuya, Y.; Takeda, K.; Zhang, X.; Forrester, A.I. Multifidelity surrogate modeling of experimental and computational aerodynamic data sets. AIAA J. 2011, 49, 289–298. [Google Scholar] [CrossRef]

- Choi, W.; Radhakrishnan, K.; Kim, N.H.; Park, J.S. Multi-Fidelity Surrogate Models for Predicting Averaged Heat Transfer Coefficients on Endwall of Turbine Blades. Energies 2021, 14, 482. [Google Scholar] [CrossRef]

- Peherstorfer, B.; Willcox, K.; Gunzburger, M. Survey of multifidelity methods in uncertainty propagation, inference, and optimization. Siam Rev. 2018, 60, 550–591. [Google Scholar] [CrossRef]

- Rumpfkeil, M.P.; Beran, P.S. Multi-Fidelity, Gradient-enhanced, and Locally Optimized Sparse Polynomial Chaos and Kriging Surrogate Models Applied to Benchmark Problems. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 0677. [Google Scholar]

- Coppedè, A.; Gaggero, S.; Vernengo, G.; Villa, D. Hydrodynamic shape optimization by high fidelity CFD solver and Gaussian process based response surface method. Appl. Ocean Res. 2019, 90, 101841. [Google Scholar] [CrossRef]

- Nuñez, L.; Regis, R.G.; Varela, K. Accelerated random search for constrained global optimization assisted by radial basis function surrogates. J. Comput. Appl. Math. 2018, 340, 276–295. [Google Scholar] [CrossRef]

- Han, Z.H.; Görtz, S.; Zimmermann, R. Improving variable-fidelity surrogate modeling via gradient-enhanced kriging and a generalized hybrid bridge function. Aerosp. Sci. Technol. 2013, 25, 177–189. [Google Scholar] [CrossRef]

- Bryson, D.E.; Rumpfkeil, M.P. All-at-once approach to multifidelity polynomial chaos expansion surrogate modeling. Aerosp. Sci. Technol. 2017, 79, 121–136. [Google Scholar] [CrossRef]

- Liu, H.; Ong, Y.S.; Cai, J. A survey of adaptive sampling for global metamodeling in support of simulation-based complex engineering design. Struct. Multidiscip. Optim. 2018, 57, 393–416. [Google Scholar] [CrossRef]

- Grassi, F.; Manganini, G.; Garraffa, M.; Mainini, L. Resource Aware Multifidelity Active Learning for Efficient Optimization. In Proceedings of the AIAA Scitech 2021 Forum, Nashville, TN, USA, 11–15 January 2021; p. 0894. [Google Scholar]

- Di Fiore, F.; Maggiore, P.; Mainini, L. Multifidelity domain-aware learning for the design of re-entry vehicles. Struct. Multidiscip. Optim. 2021, 64, 3017–3035. [Google Scholar] [CrossRef]

- Alexandrov, N.M.; Dennis, J.; Lewis, R.M.; Torczon, V. A trust-region framework for managing the use of approximation models in optimization. Struct. Optim. 1998, 15, 16–23. [Google Scholar] [CrossRef]

- March, A.; Willcox, K. Provably convergent multifidelity optimization algorithm not requiring high-fidelity derivatives. AIAA J. 2012, 50, 1079–1089. [Google Scholar] [CrossRef] [Green Version]

- Bryson, D.E.; Rumpfkeil, M.P. Multifidelity quasi-newton method for design optimization. AIAA J. 2018, 56, 4074–4086. [Google Scholar] [CrossRef]

- Bryson, D.E.; Rumpfkeil, M.P. Aerostructural Design Optimization Using a Multifidelity Quasi-Newton Method. J. Aircr. 2019, 56, 2019–2031. [Google Scholar] [CrossRef]

- Koziel, S. Computationally efficient multi-fidelity multi-grid design optimization of microwave structures. ACES J.-Appl. Comput. Electromagn. Soc. 2010, 25, 578. [Google Scholar]

- Koziel, S. Multi-fidelity multi-grid design optimization of planar microwave structures with Sonnet. Int. Rev. Prog. Appl. Comput. Electromagn. 2010, 4, 26–29. [Google Scholar]

- Fasano, G.; Liuzzi, G.; Lucidi, S.; Rinaldi, F. A linesearch-based derivative-free approach for nonsmooth constrained optimization. SIAM J. Optim. 2014, 24, 959–992. [Google Scholar] [CrossRef] [Green Version]

- Bassanini, P.; Bulgarelli, U.; Campana, E.F.; Lalli, F. The wave resistance problem in a boundary integral formulation. Surv. Math. Ind. 1994, 4, 151–194. [Google Scholar]

- Lucidi, S.; Sciandrone, M. A Derivative-Free Algorithm for Bound Constrained Optimization. Comput. Optim. Appl. 2002, 21, 119–142. [Google Scholar] [CrossRef]

- Liuzzi, G.; Lucidi, S.; Rinaldi, F. Derivative-free methods for bound constrained mixed-integer optimization. Comput. Optim. Appl. 2012, 53, 505–526. [Google Scholar] [CrossRef] [Green Version]

- Irvine, M., Jr.; Longo, J.; Stern, F. Pitch and Heave Tests and Uncertainty Assessment for a Surface Combatant in Regular Head Waves. J. Ship Res. 2008, 52, 146–163. [Google Scholar] [CrossRef]

- Larsson, L.; Stern, F.; Visonneau, M.; Hirata, N.; Hino, T.; Kim, J. Proceedings, Tokyo 2015 Workshop on CFD in Ship Hydrodynamics. In Proceedings of the Tokyo CFD Workshop, Tokyo, Japan, 2–4 December 2015. [Google Scholar]

- Grigoropoulos, G.; Campana, E.; Diez, M.; Serani, A.; Goren, O.; Sariöz, K.; Danişman, D.; Visonneau, M.; Queutey, P.; Abdel-Maksoud, M.; et al. Mission-based hull-form and propeller optimization of a transom stern destroyer for best performance in the sea environment. In Proceedings of the VII International Conference on Computational Methods in Marine Engineering MARINE 2017, Nantes, France, 15–17 May 2017. [Google Scholar]

- Dawson, C.W. A practical computer method for solving ship-wave problems. In Proceedings of the 2nd International Conference on Numerical Ship Hydrodynamics, Berkeley, CA, USA, 19–21 September 1977; pp. 30–38. [Google Scholar]

- Schlichting, H.; Gersten, K. Boundary-Layer Theory; Springer: Berlin, Germany, 2000. [Google Scholar]

- Serani, A.; Campana, E.F.; Diez, M.; Stern, F. Towards Augmented Design-Space Exploration via Combined Geometry and Physics Based Karhunen-Loève Expansion. In Proceedings of the AIAA-AVIATION 2017 Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Xing, T.; Stern, F. Factors of safety for Richardson extrapolation. J. Fluids Eng. 2010, 132, 061403. [Google Scholar] [CrossRef] [Green Version]

| Quantity | Symbol | Unit | Value |

|---|---|---|---|

| Displacement | ∇ | m3 | 0.549 |

| Length between perpendiculars | m | 5.720 | |

| Beam | B | m | 0.760 |

| Draft | T | m | 0.248 |

| Water density | kg/m3 | 998.5 | |

| Kinematic viscosity | m2/s | 1.09 × 106 | |

| Gravity acceleration | g | m/s2 | 9.803 |

| Froude number | Fr | – | 0.280 |

| Grid | Hull Nodes | Free-Surface Nodes | Total Nodes (M) | Resistance [N] | Grid Error (%) | NCC |

|---|---|---|---|---|---|---|

| G1 | 16.5k | 41.5 | 1.16 | 1.00 | ||

| G2 | 11.6k | 41.8 | 1.85 | 0.46 | ||

| G3 | 8.2k | 42.3 | 3.10 | 0.20 | ||

| G4 | 5.7k | 43.5 | 5.97 | 0.11 | ||

| G5 | 4.2k | 44.4 | 8.26 | 0.07 | ||

| G6 | 2.9k | 45.3 | 10.5 | 0.04 | ||

| G7 | 2.1k | 48.9 | 19.3 | 0.03 |

| Reinitialization | |||

|---|---|---|---|

| Static, 1 | Dynamic, | ||

| Threshold | Static, 10 × 10−3 | StSr | StDr |

| Dynamic, | DtSr | DtDr | |

| Grid | Optimized [N] | Optimized % | Optimized % | Gain of MF-CS-DFN% | Cumulative NCC [-] |

|---|---|---|---|---|---|

| G7 | 42.1 | −13.9 | −11.5 | 6.57 | 6.18 |

| G6 | 39.6 | −12.6 | −11.6 | 6.77 | 11.7 |

| G5 | 38.9 | −12.4 | −11.2 | 6.27 | 20.5 |

| G4 | 37.8 | −13.0 | −12.1 | 4.79 | 37.9 |

| G3 | 37.1 | −12.2 | −12.2 | 1.74 | 69.5 |

| G2 | 36.6 | −12.3 | −12.2 | 0.59 | 140 |

| G1 | 36.3 | −12.5 | −12.5 | 0.67 | 628 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pellegrini, R.; Serani, A.; Liuzzi, G.; Rinaldi, F.; Lucidi, S.; Diez, M. A Derivative-Free Line-Search Algorithm for Simulation-Driven Design Optimization Using Multi-Fidelity Computations. Mathematics 2022, 10, 481. https://doi.org/10.3390/math10030481

Pellegrini R, Serani A, Liuzzi G, Rinaldi F, Lucidi S, Diez M. A Derivative-Free Line-Search Algorithm for Simulation-Driven Design Optimization Using Multi-Fidelity Computations. Mathematics. 2022; 10(3):481. https://doi.org/10.3390/math10030481

Chicago/Turabian StylePellegrini, Riccardo, Andrea Serani, Giampaolo Liuzzi, Francesco Rinaldi, Stefano Lucidi, and Matteo Diez. 2022. "A Derivative-Free Line-Search Algorithm for Simulation-Driven Design Optimization Using Multi-Fidelity Computations" Mathematics 10, no. 3: 481. https://doi.org/10.3390/math10030481

APA StylePellegrini, R., Serani, A., Liuzzi, G., Rinaldi, F., Lucidi, S., & Diez, M. (2022). A Derivative-Free Line-Search Algorithm for Simulation-Driven Design Optimization Using Multi-Fidelity Computations. Mathematics, 10(3), 481. https://doi.org/10.3390/math10030481