1. Introduction

With the increasing world-wide demand for renewable energy resources, photovoltaic (PV) systems are gaining much interest. Hence, advances are continuously carried out in the field of their modeling and performance [

1]. A PV system includes a PV power source in the form of series and/or parallel combinations of PV modules forming a PV array with the required voltage and amperage [

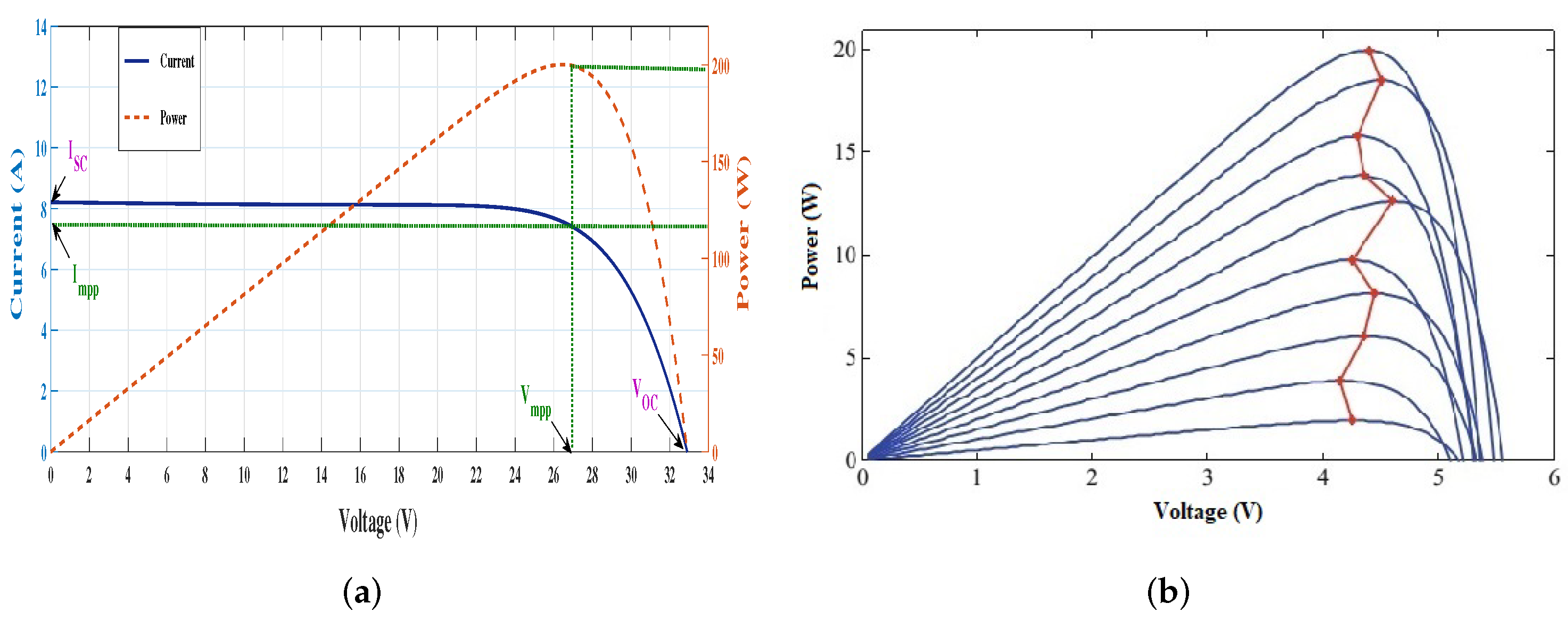

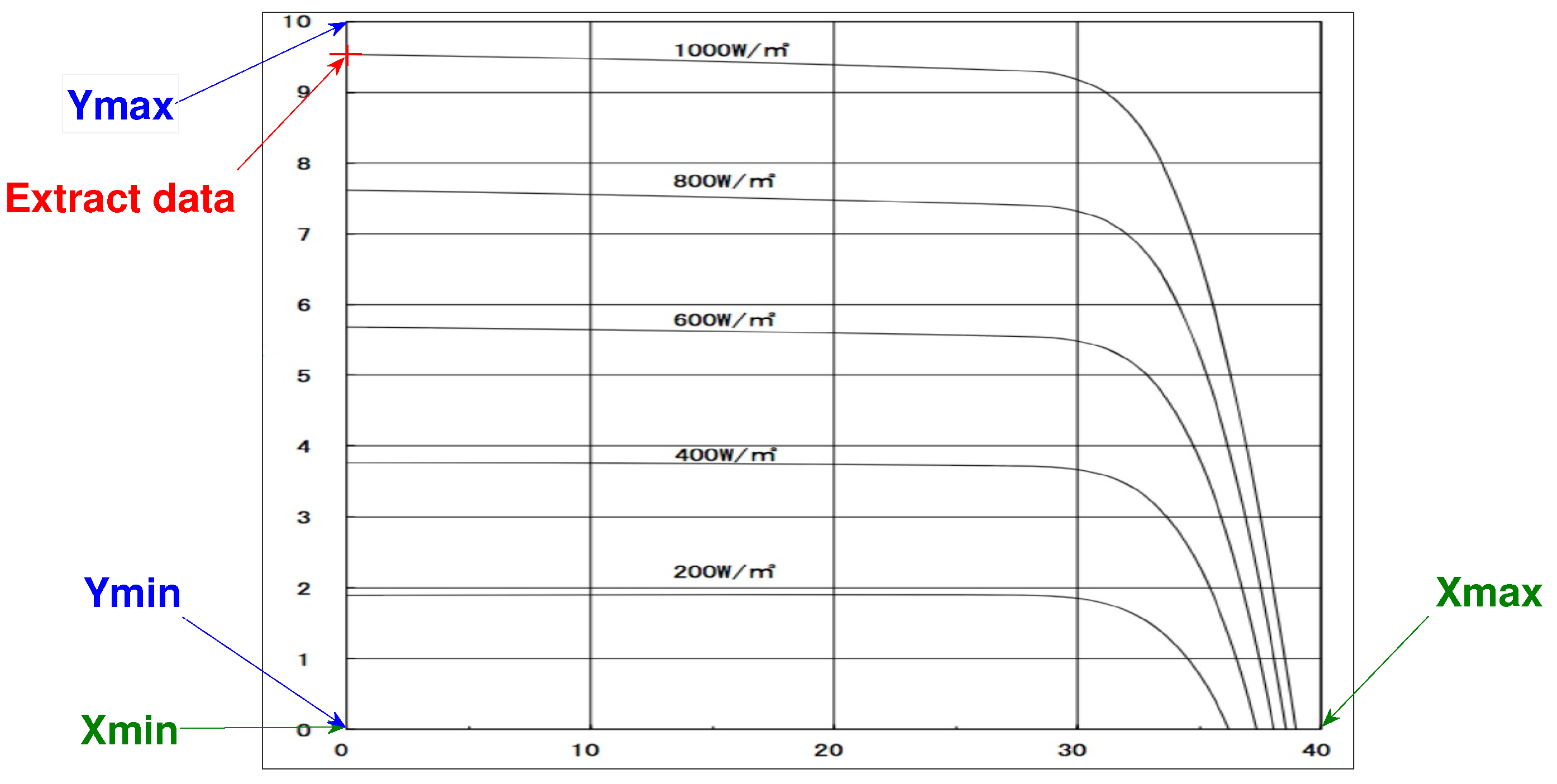

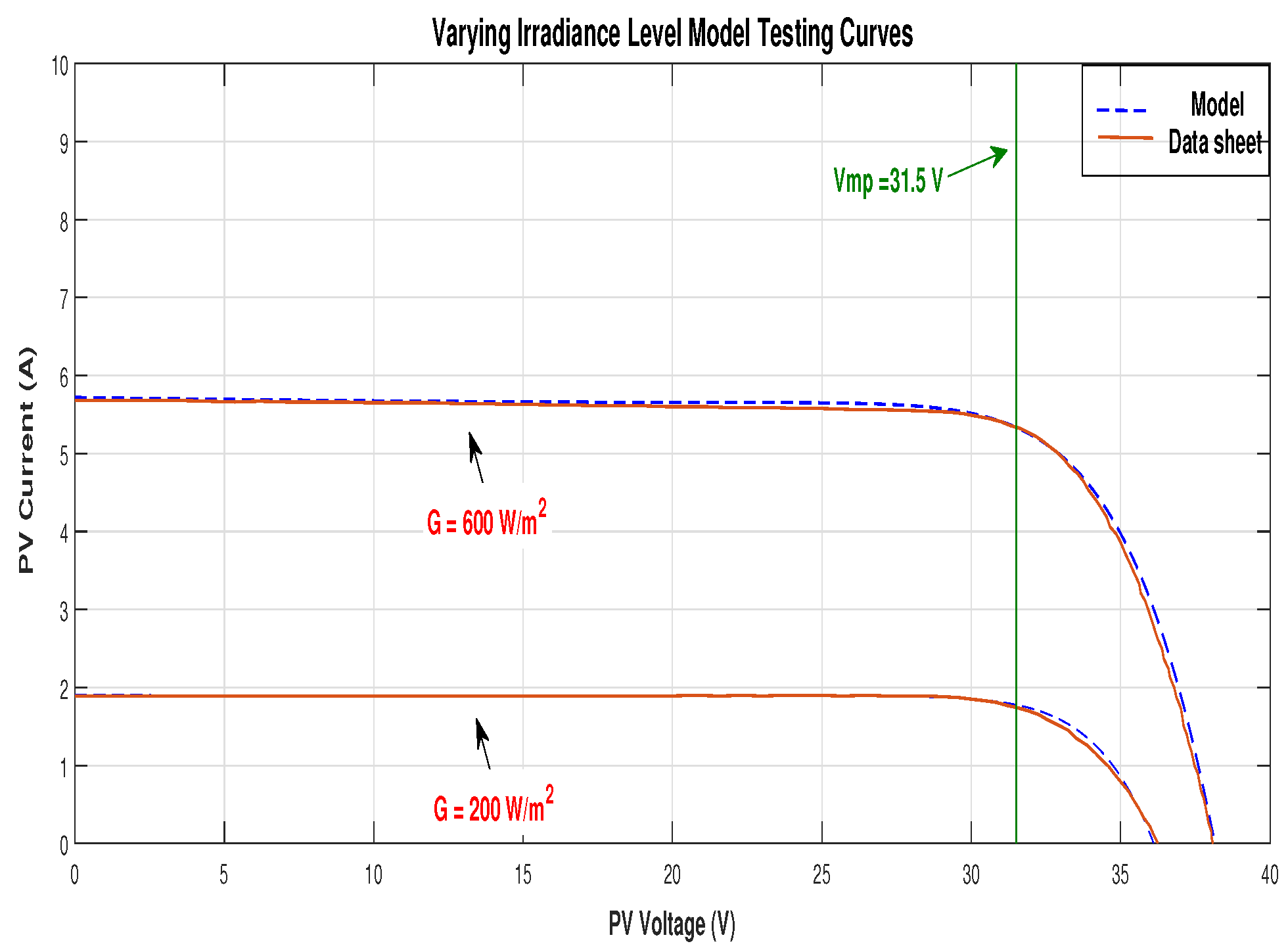

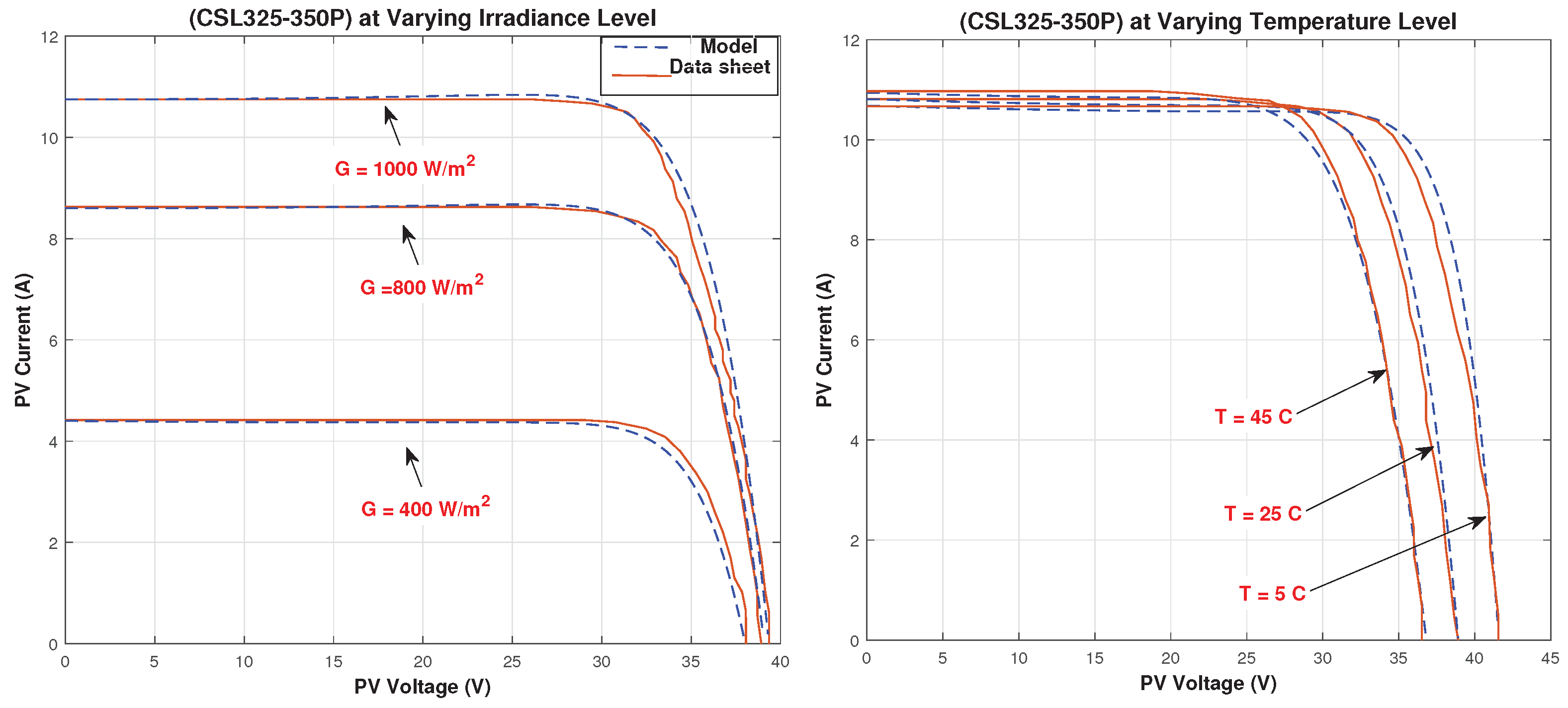

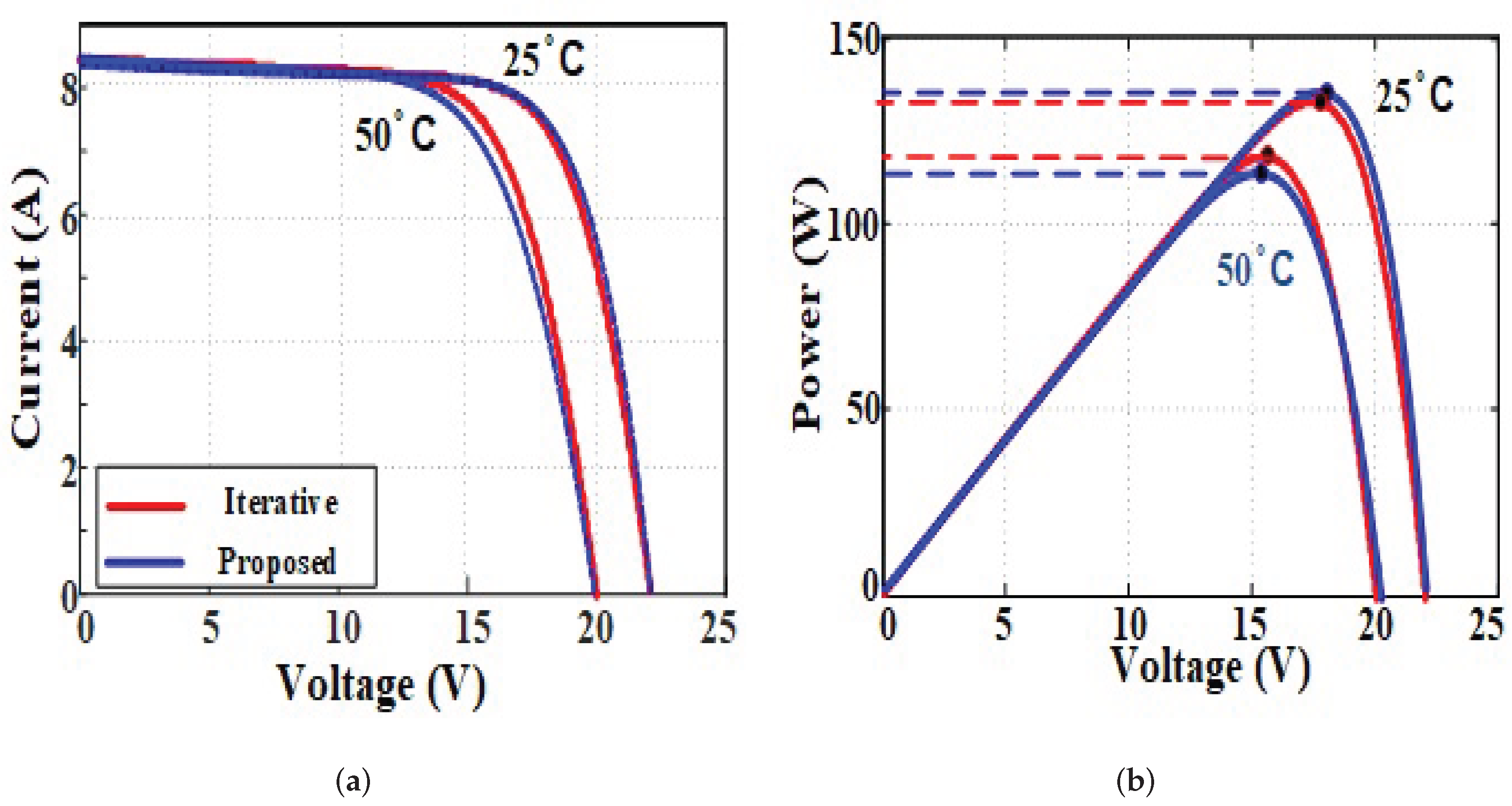

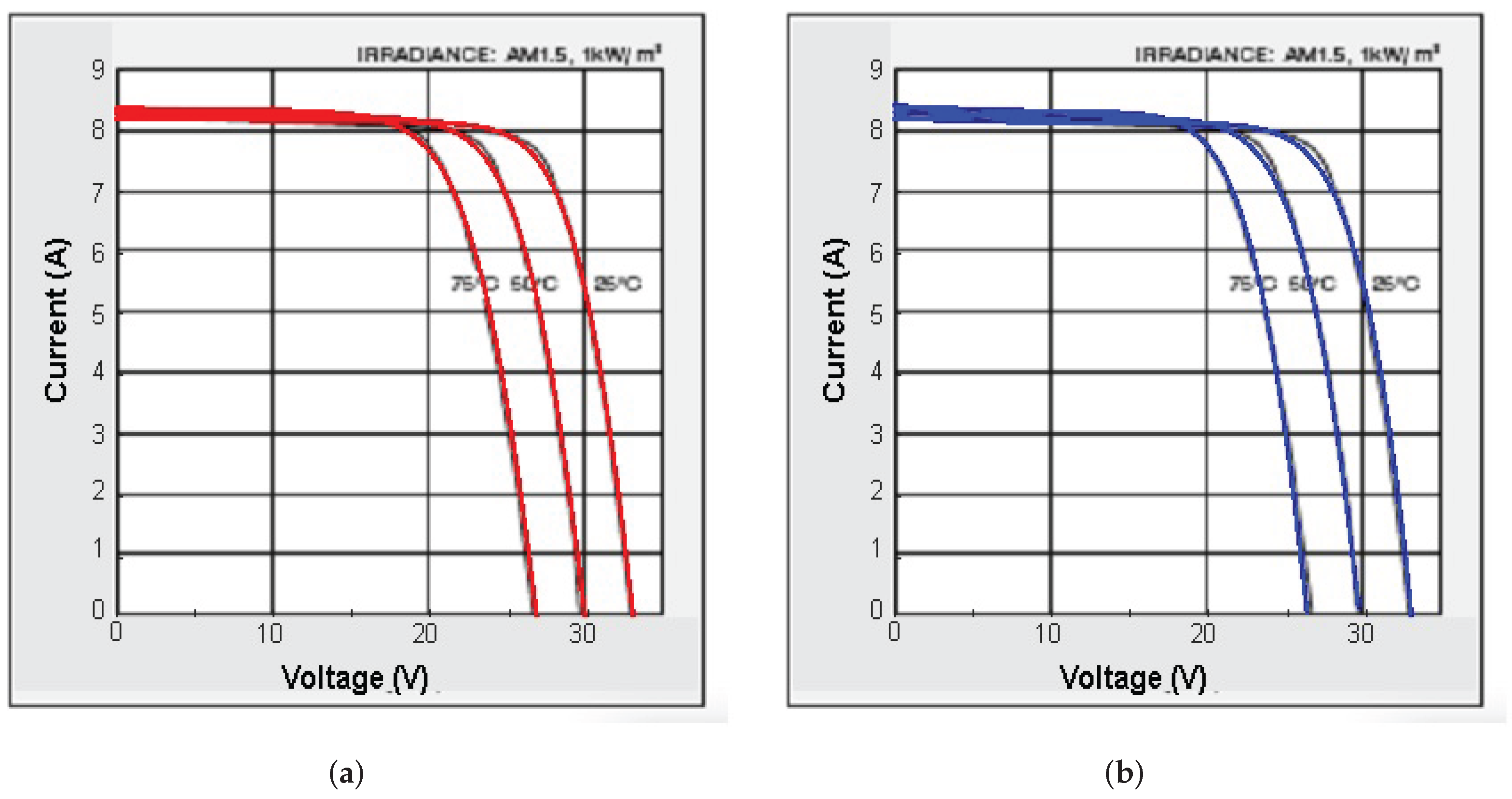

2]. Under uniform environmental conditions, a PV module exerts non-linear electrical characteristic curves, as shown in

Figure 1a, where the PV module gives its maximum possible output power at a certain operating point. This maximum power point (MPP) is irradiance and temperature dependent, as presented in

Figure 1b [

3]. In order to maximize the PV source efficiency under varying environmental conditions, it should be followed by a pulse width modulation (PWM) converter for continuous maximum power point tracking (MPPT) [

4].

For robust control of the entire PV system operation, the PV device should be simulated in the virtual environment [

5]. Thus, a simple, reliable and precise mathematical model of the PV source is mandatory for accurate analysis of its non-linear characteristics under varying conditions. An efficient PV model is useful in the prediction of PV output power, the analysis of PV converter dynamic behavior and the study of MPP tracking algorithms [

6]. PV model accuracy is evaluated by the proximity of the model characteristics to that of the practical device experimental data. Hence, the model should be adjusted using the set of data provided by manufacturers regarding the PV module thermal and electrical characteristics.

However, PV datasheets present a few experimental data that include the nominal open-circuit voltage (

), the nominal short-circuit current (

), the voltage at the MPP (

), the current at the MPP (

), the maximum experimental peak output power (

), the open-circuit voltage/temperature coefficient (

), and the short circuit current/temperature coefficient (

) [

7]. These data are given under the so-called standard test condition (STC) which is defined by irradiation level of 1000 W/m

2, cell temperature of 25 °C, and air mass value of 1.5 [

8]. Some manufacturers may also provide I–V characteristic curves, obtained experimentally under variable operating conditions, to validate and adjust the derived mathematical model. However, obtaining such curves experimentally requires costly and difficult measurements in controlled environmental chambers that should be carried out under certain conditions and according to a number of guidelines [

9].

Many approaches have been developed for PV modules’ modeling and representation as will be illustrated in the following. Equivalent circuit-based PV models, applying the Shockley diode equation for solar cell mathematical representation, have been developed and validated using the experimental data given in manufacturers’ datasheets [

10]. This equation represents the non-linear characteristics of the PV cell, yet it includes several parameters that are not available in commercial manufacturers’ datasheets, hence have to be estimated [

7,

11]. These parameters include the diode ideality factor (

a), diode reverse saturation current (

), the light-generated current (

), and practical PV device series and shunt resistances. The series resistance (

) represents the summation of PV panel structural resistances while the parallel resistance (

) mirrors the

junction leakage current and depends on the PV cell fabrication method. These unknown parameters differ from one panel to another, thus they should be accurately estimated for correct model adjustment of the considered PV device.

Equivalent circuit-based PV models are either based on single-diode equivalent circuits [

12,

13,

14,

15], two-diode circuits [

16,

17,

18,

19], or three-diode circuits [

20,

21]. When more diodes are included in the model, higher accuracy is obtained, though at the cost of more complexity and computational effort as more parameters have to be estimated (i.e., additional ideality factor and reverse saturation current for each added diode) [

22,

23]. For simplicity, most developed PV models are based on the single-diode equivalent circuit, as this model offers a satisfactory compromise between simplicity and accuracy [

11]. Different mathematical procedures for estimating the unknown PV parameters required are elaborated with different levels of implementation complexity, computational time, and accuracy [

24,

25,

26]. These procedures can be analytical, numerical, artificial intelligence-based, evolutionary algorithms-based, or hybrid ones.

Normally, analytical mathematical methods give exact solutions by means of algebraic equations. However, due to PV nonlinearity, it is hard to find out the analytical solution of all unknown parameters. Thus, analytical methods apply approximations or simplified assumptions for some PV parameters resulting in fast and simple solution at the cost of relatively less accuracy [

27,

28]. Generally, the

value is high while that of

is very low, thus some authors neglect the former [

29,

30,

31,

32] while others neglect the latter [

33,

34] or both [

35]. In [

36,

37,

38,

39,

40], an analytical method based on Lambert

W function is introduced for parameters extraction, while in [

41] transcendental equations for solar cell analysis are presented and solved using Special Tran Function Theory (STFT) to increase estimation accuracy.

Numerical methods develop a set of equations which are solved using numerical or iterative algorithms for precise parameters estimation. In [

42], an iterative process is applied where

is slowly incremented and corresponding

and

values are obtained such that the mathematical I–V equation fits specific experimental points on the practical module I–V curve. In [

43], an iterative method to find the actual value of the diode ideality factor is presented. Other methods apply optimization numerical algorithms such as Levenberg–Marquardt Algorithm (LMA), Newton Raphson nonlinear, or least-squares algorithm for best curve fitting [

27,

44]. Although numerical methods outweigh analytical algorithms regarding accuracy, they require long-term time series data, thus consume more time.

Applying artificial intelligence [

45,

46,

47] and evolutionary techniques [

48,

49,

50,

51,

52,

53] for PV parameters extraction can be observed as a fast and accurate solution, yet one which lacks simplicity and requires more computational effort, making it less practical. Hybrid techniques are introduced to compromise between simplicity, accuracy, and computational time. In [

54] a combination between numerical and analytical methods is presented where PV output current expression is determined by Lambert

W function while the PV voltage is computed numerically by the Newton–Raphson method. Lambert

W function along with artificial neural network were employed for determination of PV I–V and PV curves [

55].

Beside the equivalent circuit-based PV modeling techniques, an alternative PV cell mathematical representation based on trigonometrically function (sine and cosine function based model) is presented in [

56,

57]. It depends on observing how PV short-circuit current and open-circuit voltage change versus irradiance and temperature, then translating this observation into a trigonometrically property. However, this trigonometric function includes seven constants whose values have to be obtained through PV experimental characteristics which, in turn, adds to the computational efforts and affects its practicality.

Recently, many approaches have been developed to build PV models based on short-term and long-term PV power forecast using ANN and machine learning techniques [

58,

59,

60,

61,

62]. However, they require complicated implementation, a large number of data samples, and continuous training and fitting results for accurate forecasting. The developed PV modules’ modeling approaches and representation can be summarized and listed as shown below:

PV Modeling Approaches:

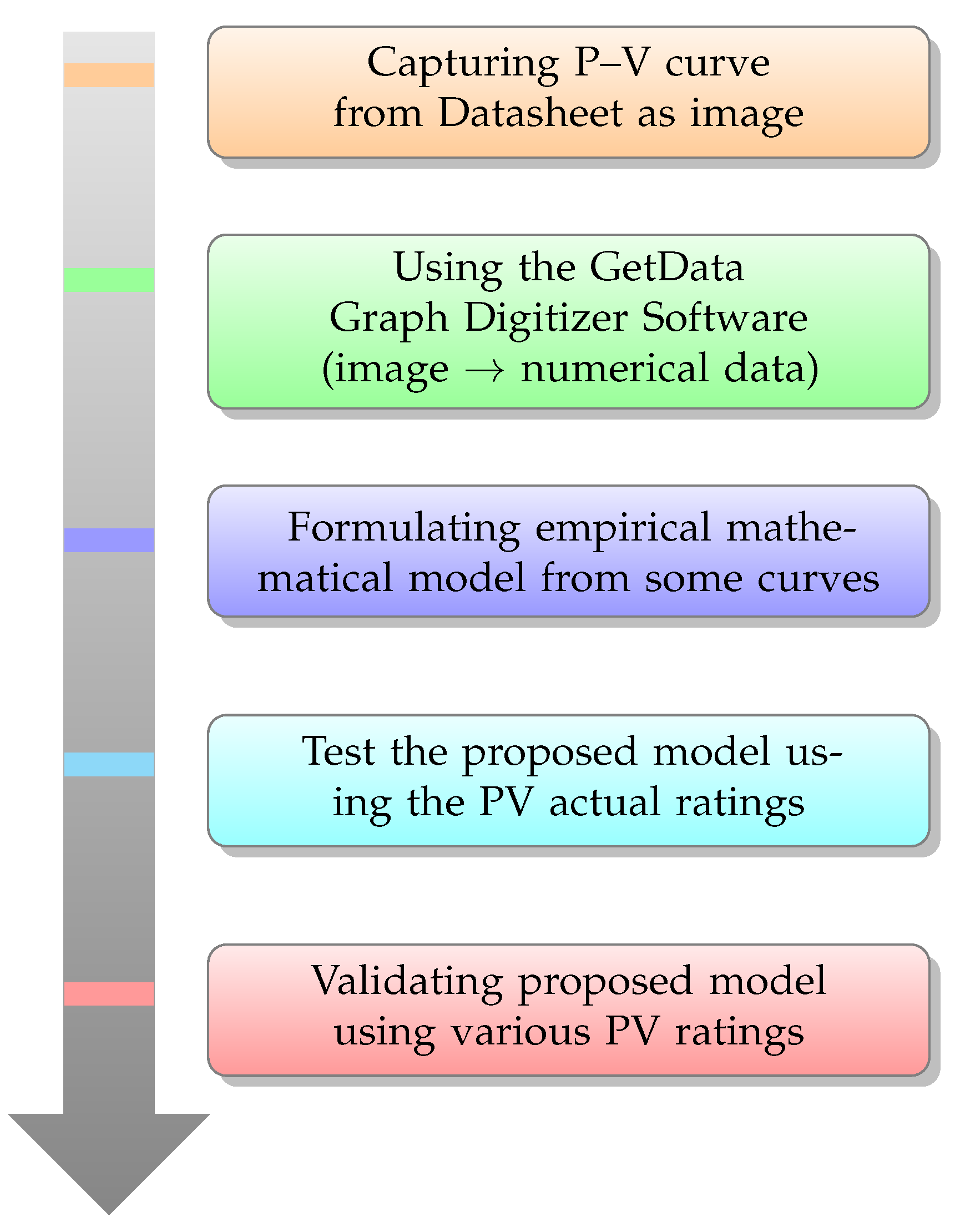

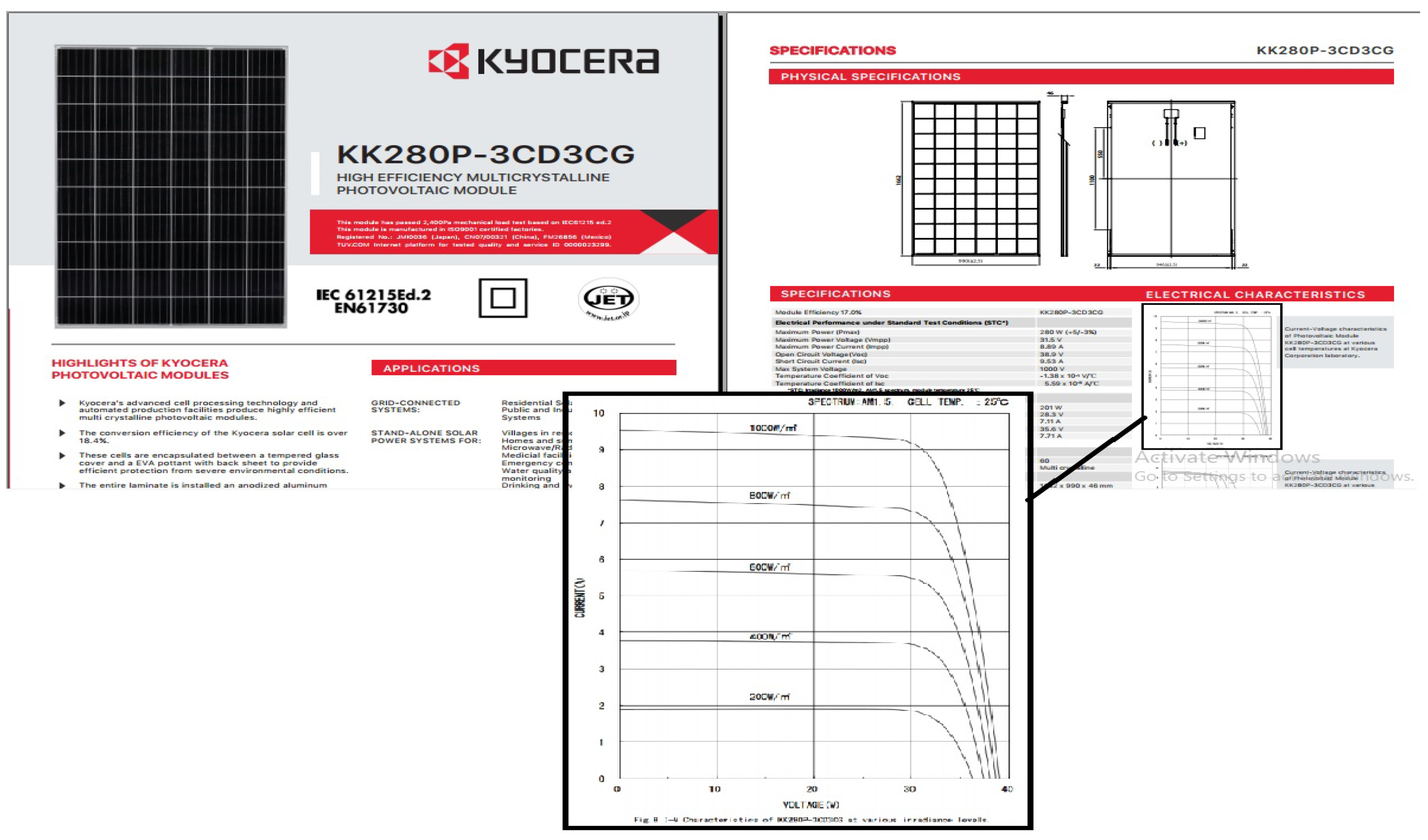

In this paper, a novel generic PV model is presented featuring an empirical mathematical equation based on function representation of captured figures from the datasheet. This model is able to produce characteristic curves for any PV device at any condition based only on four electrical terms found in any practical PV datasheet at standard testing condition (STC). The proposed approach outweighs other models regarding its simplicity and reduced computational time and effort as none of parameters extraction, constants estimation, or PV power forecast are required. Thus, PV experimental curves at different environmental conditions can be emulated easily with the least cost. The proposed model is tested for different practical PV modules at various power ratings, then compared to a conventional PV model based on a single-diode equivalent circuit. The results validated the proposed approach and verified its competitiveness.

This paper is organized as follows:

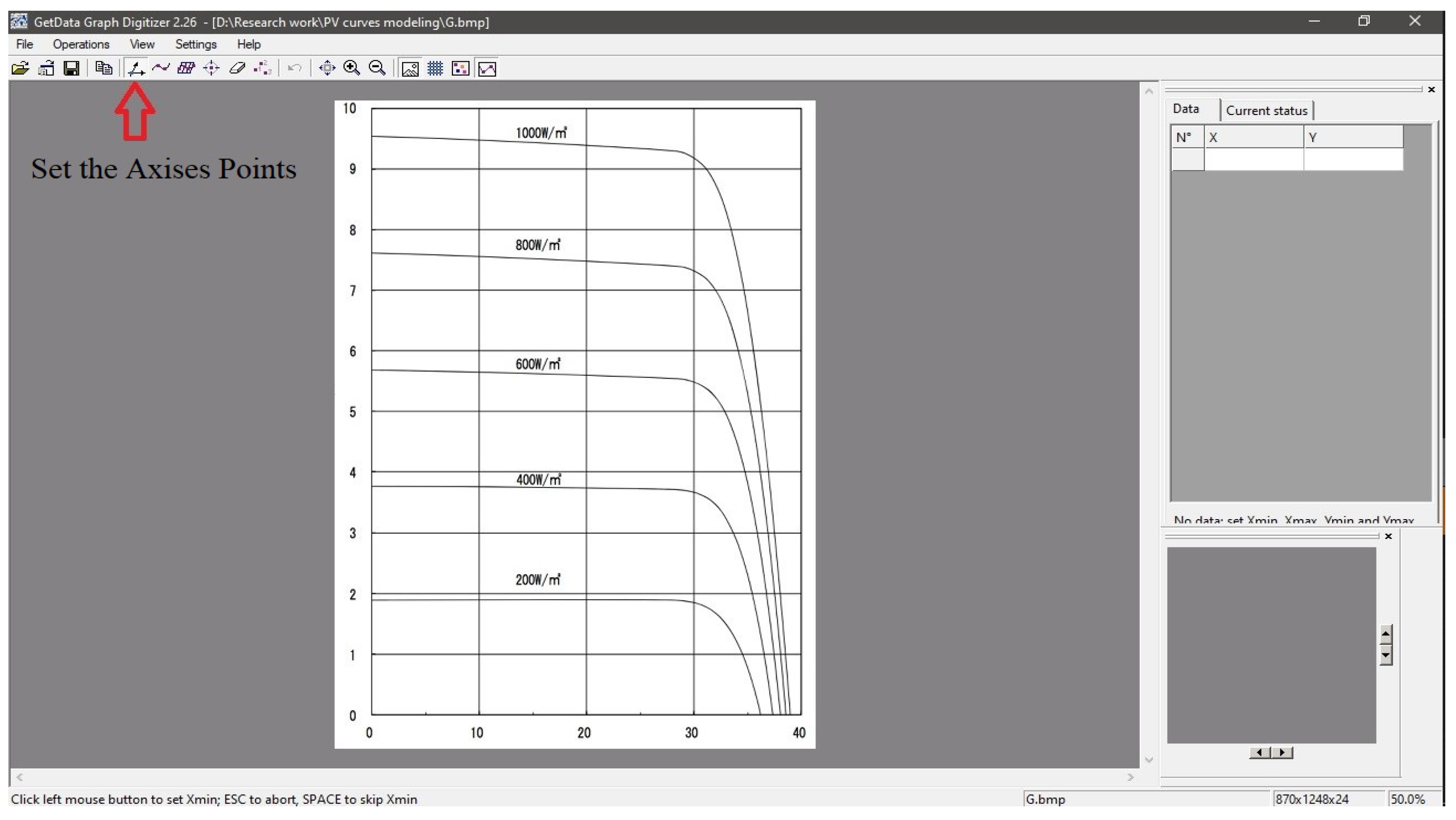

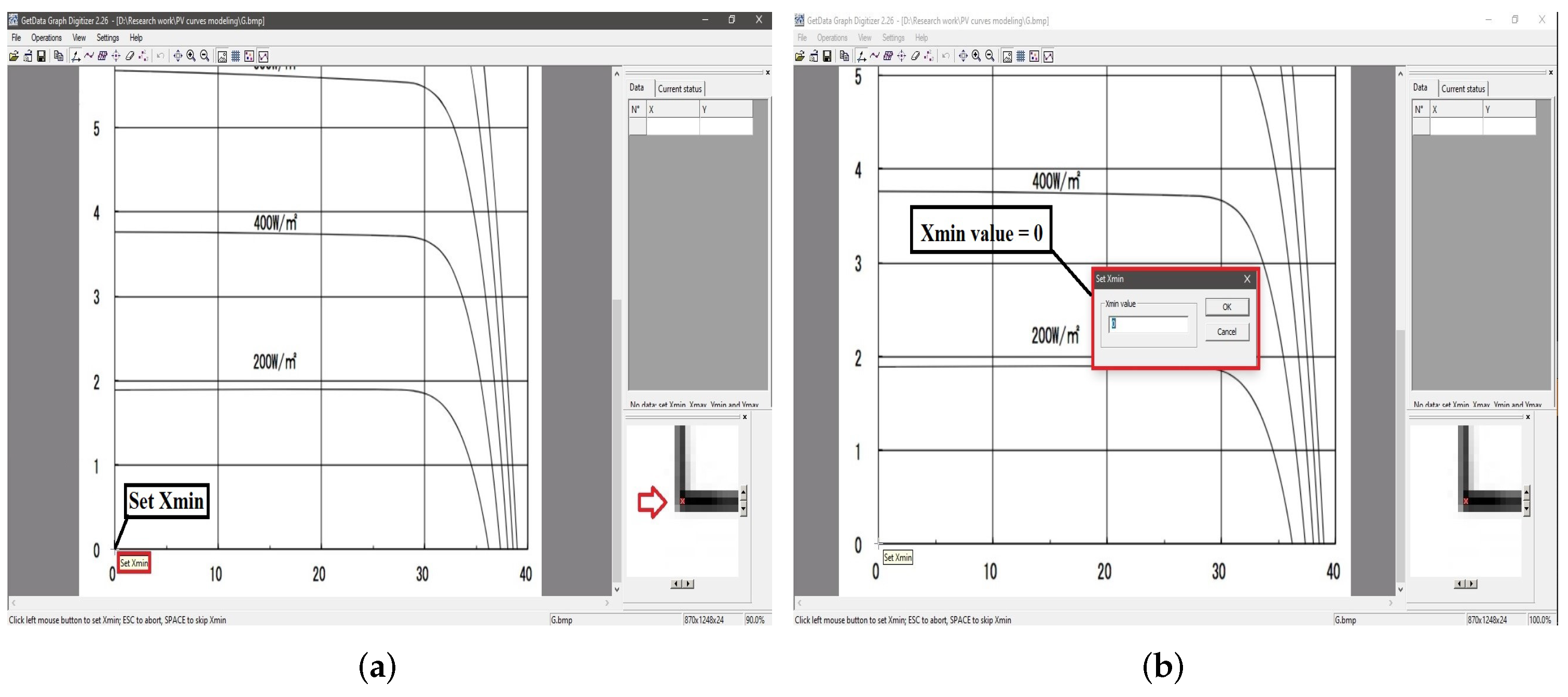

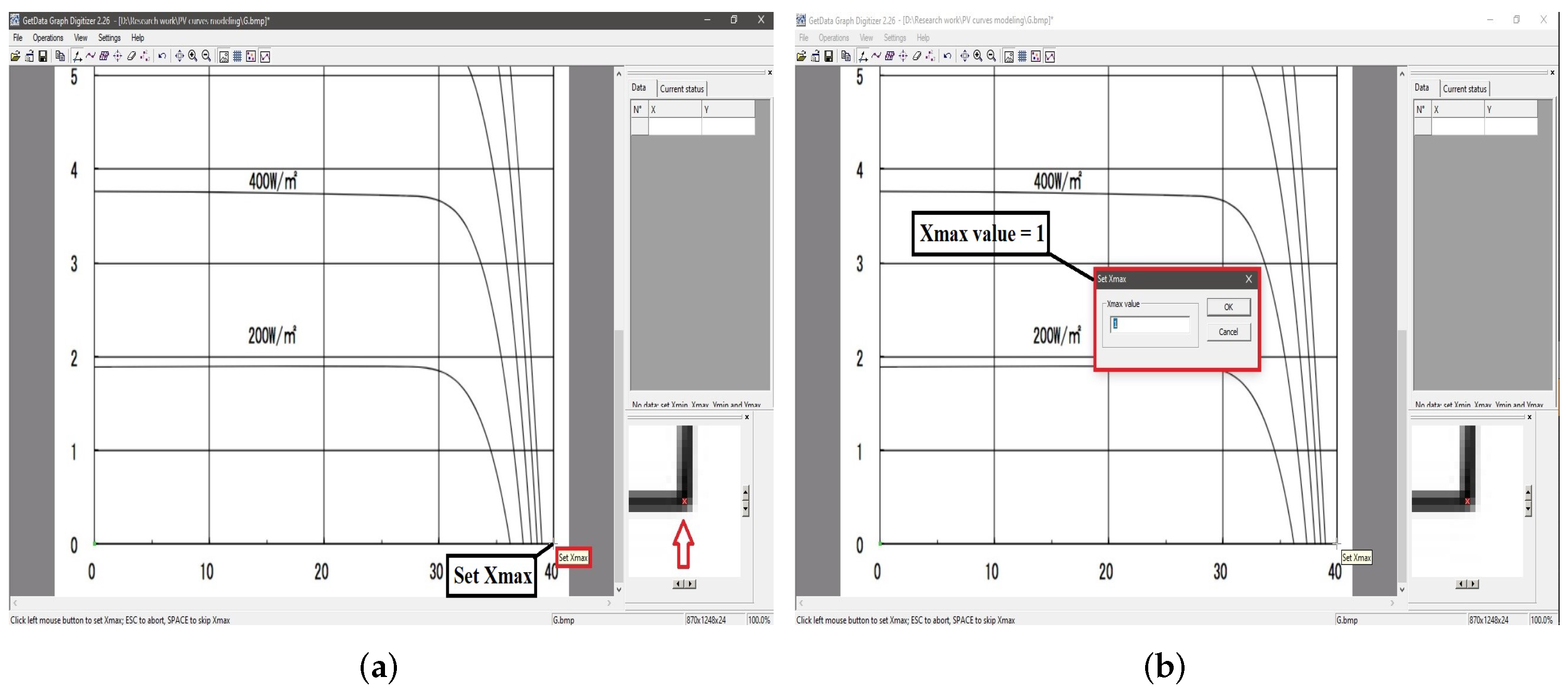

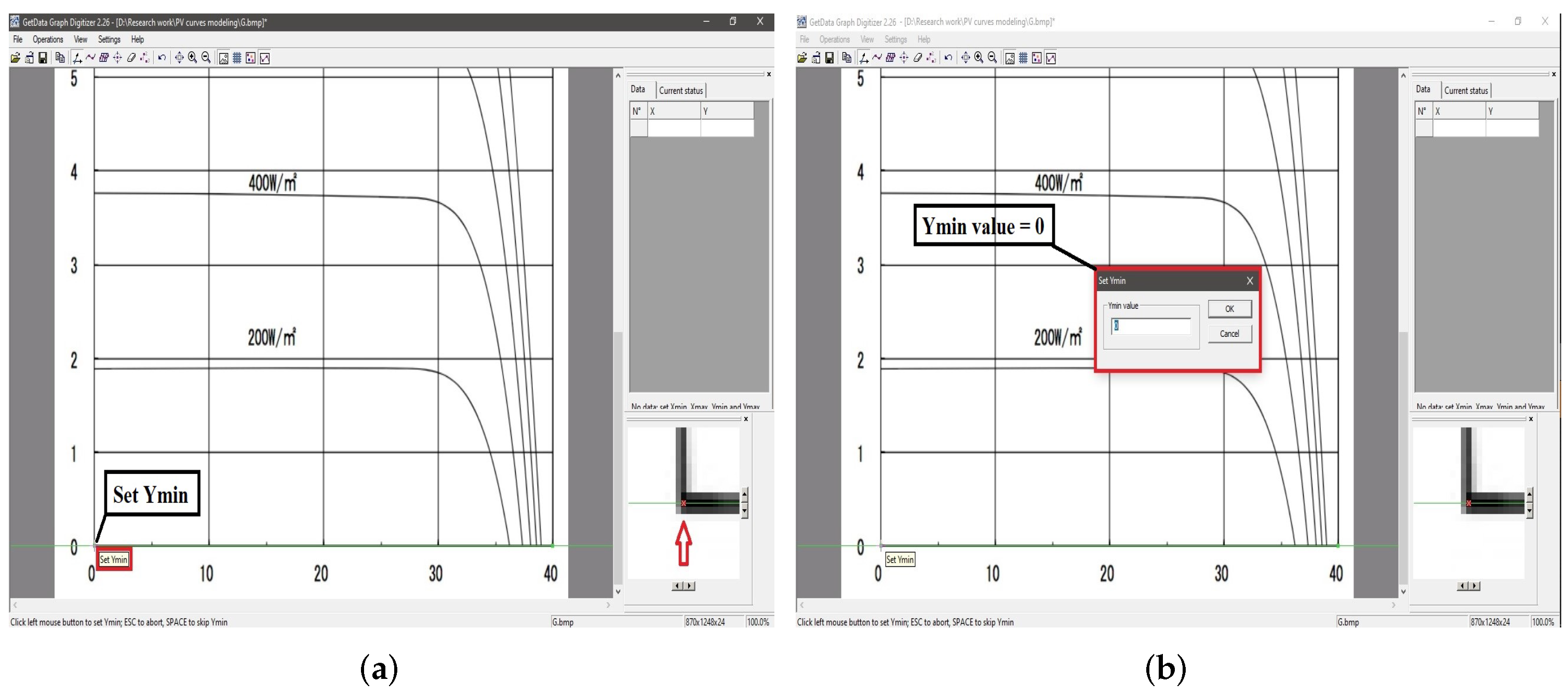

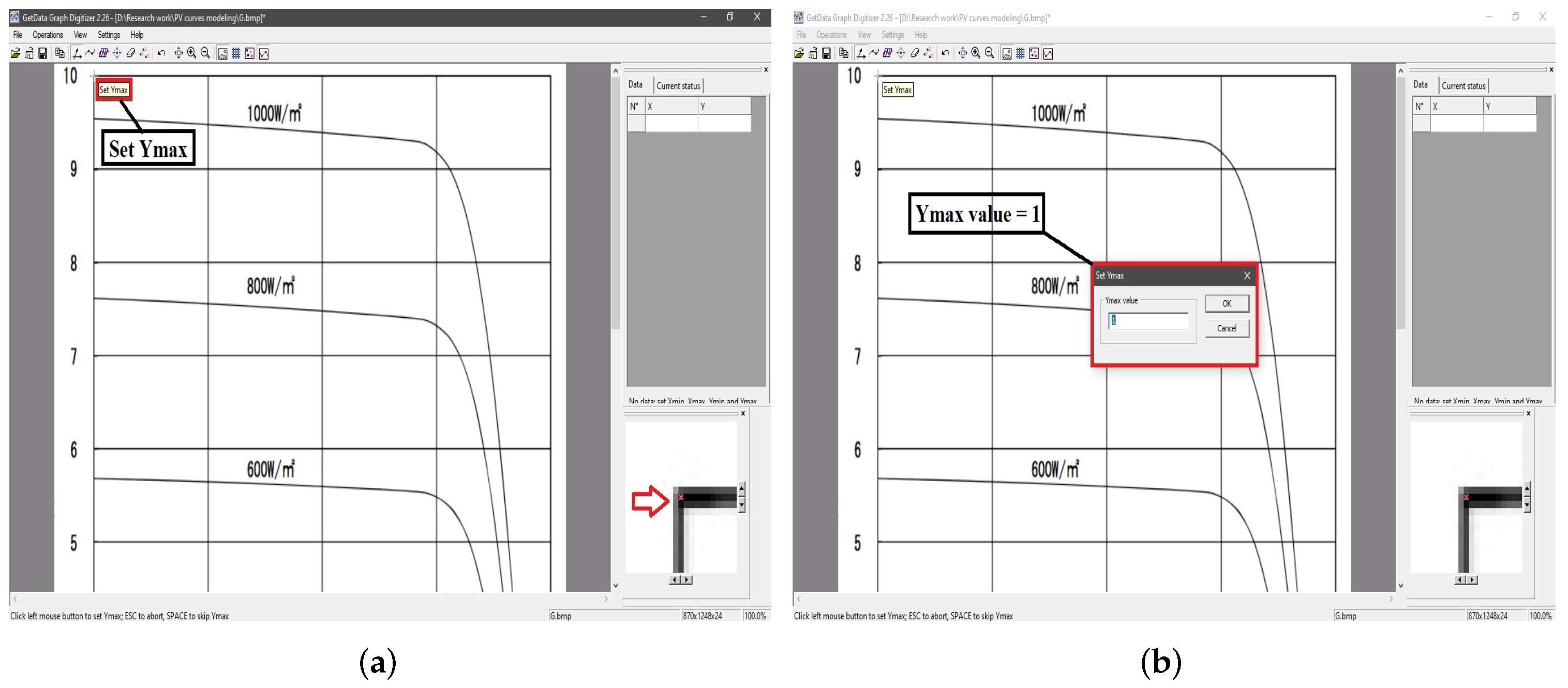

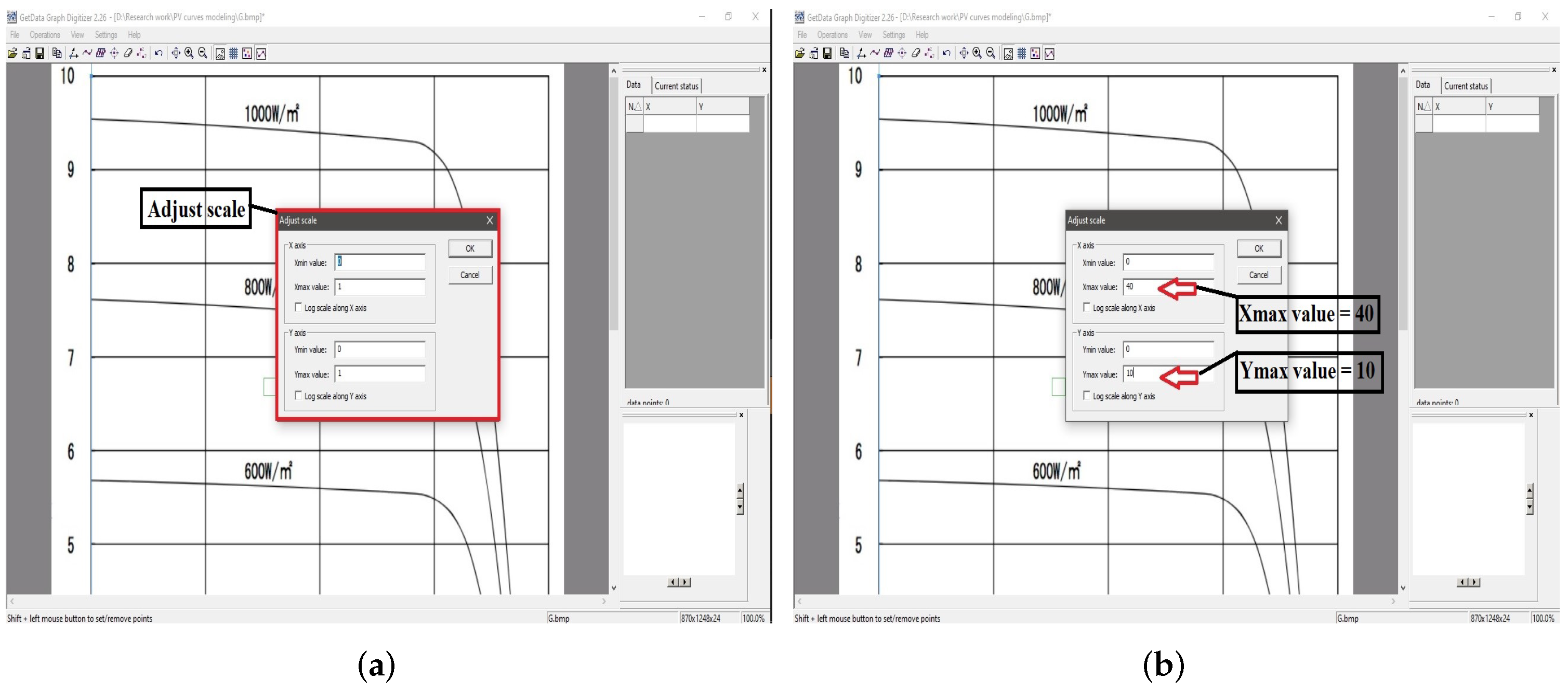

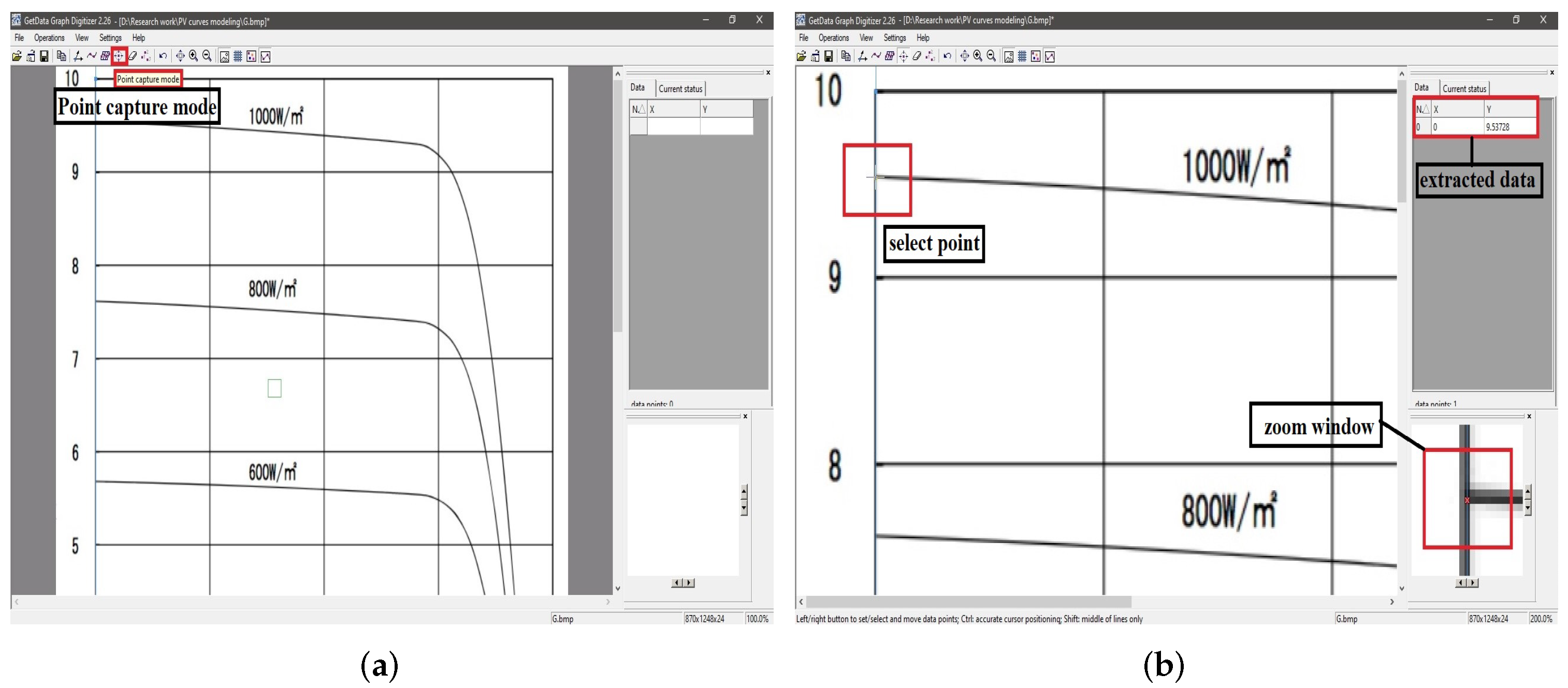

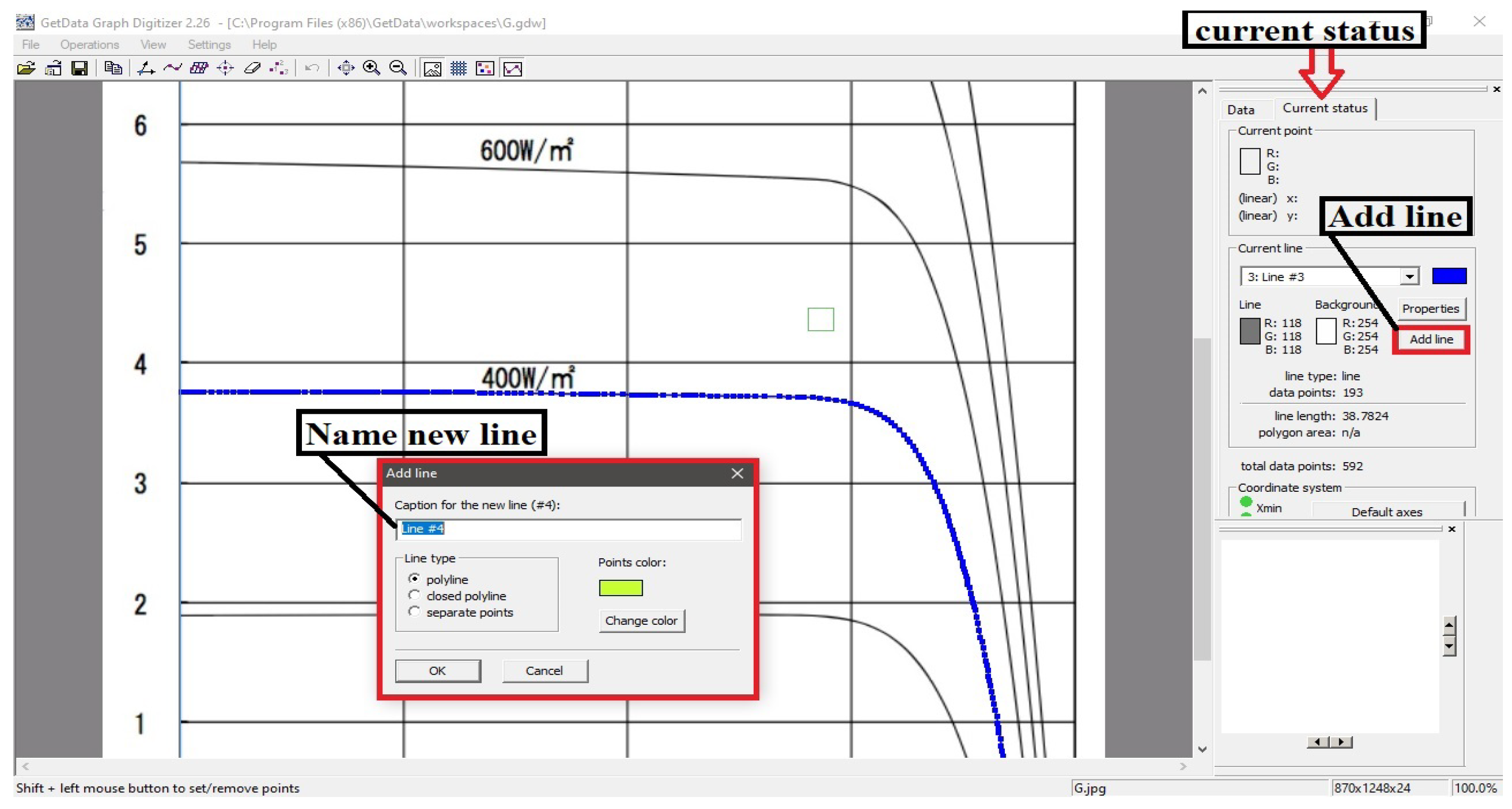

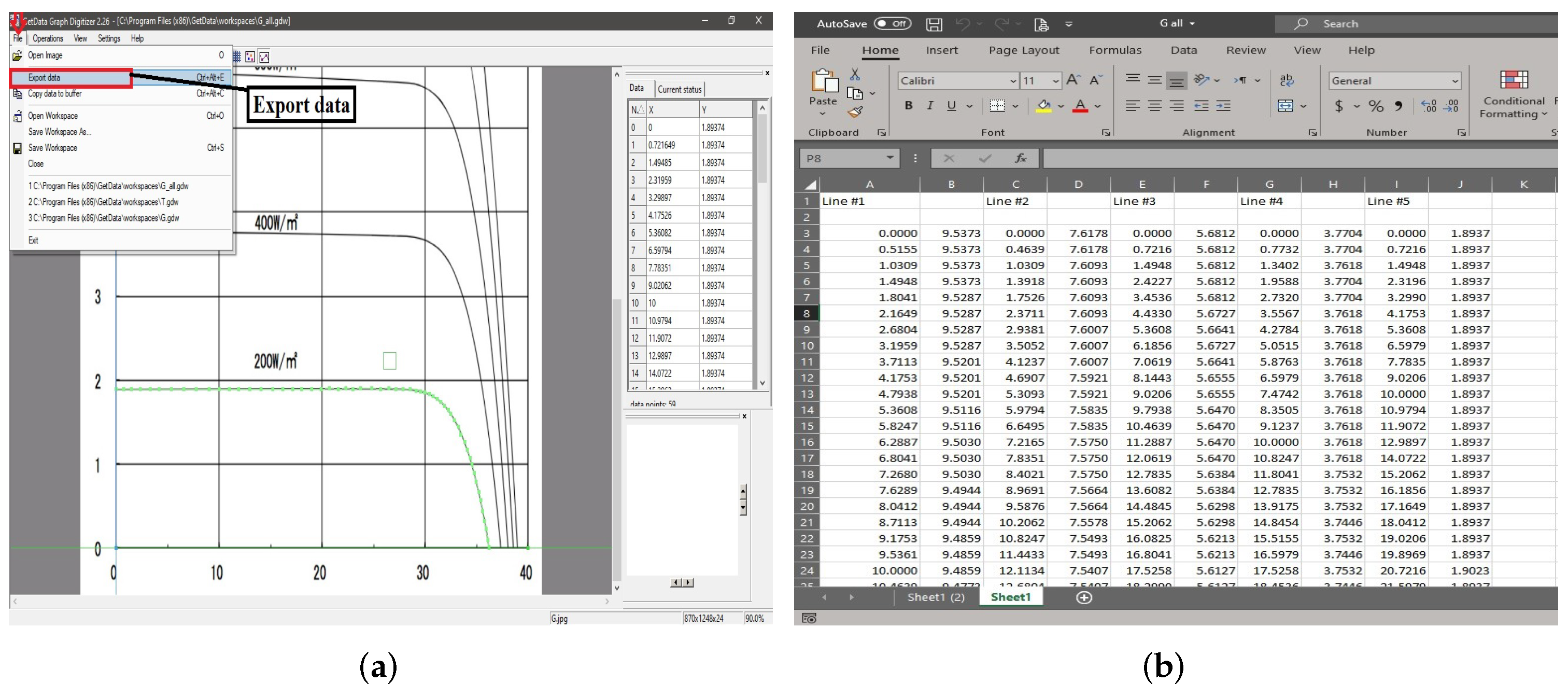

Section 2 illustrates the methodology adopted for developing the proposed empirical mathematical model of the PV based on captured figures from datasheet.

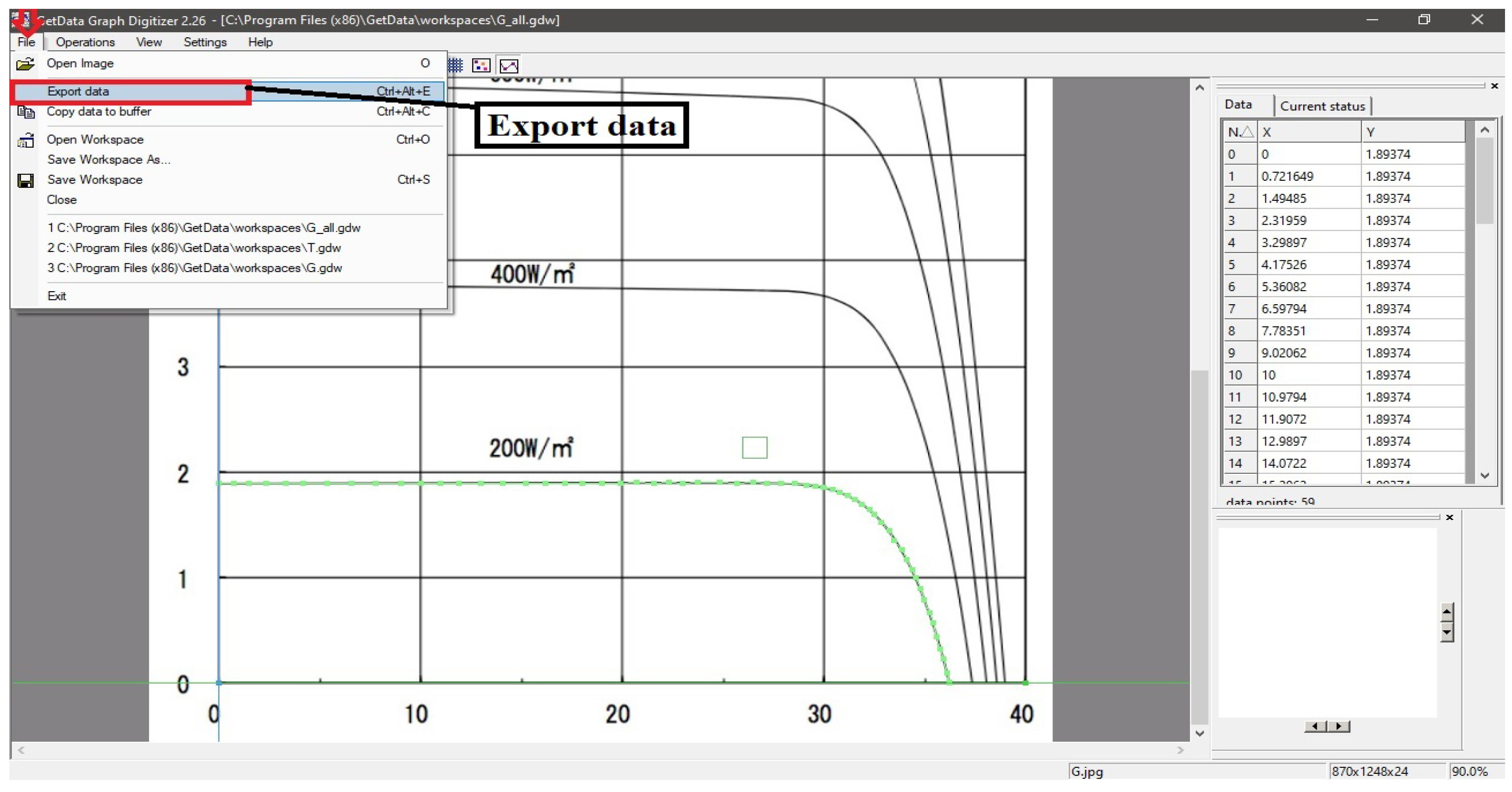

Section 3 includes phase one of the model development of digitizing the captured figures and the data extraction process from the datasheet.

Section 4 demonstrates phase two, which presents the formulation of the model through three cases: (i) varying irradiance at fixed STC temperature level, (ii) varying temperature at fixed STC irradiance level, and (iii) specific irradiance and temperature values differ from STC nominal values.

Section 5 includes the simulation results of the proposed model compared to the extracted data.

Section 6 contains the model validation using various datasheet with different ratings.

Section 7 presents a comparison between the proposed mathematical model and a conventional equivalent circuit based PV model. Finally,

Section 8 presents the discussion and conclusion.

4. Stage Two: The Proposed Empirical Mathematical Model of PV Characteristics Curves

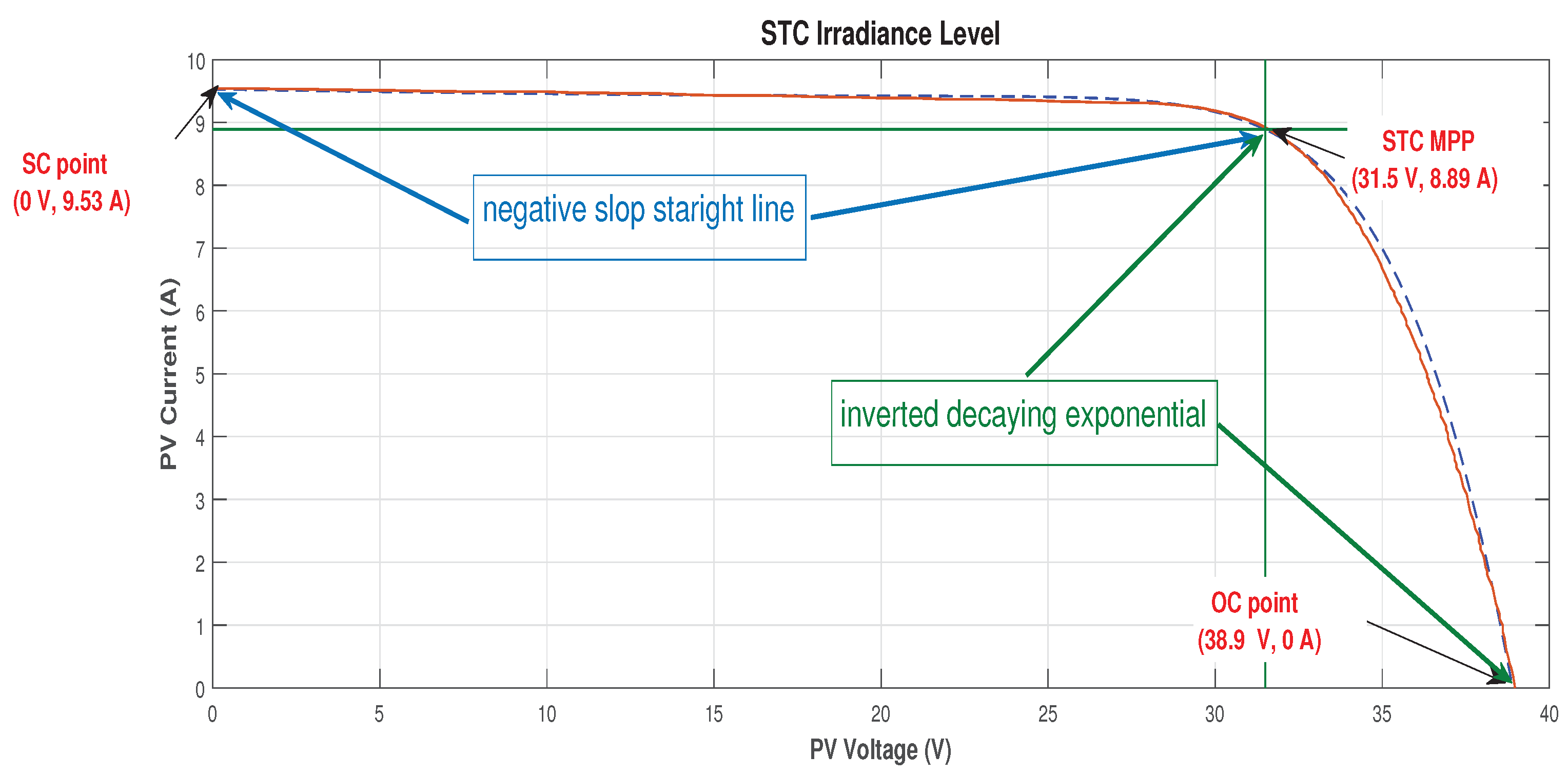

The proposed model is developed based on analyzing the I–V curves in several datasheets. By analyzing the curves we observed that the curve can be represented in the form of combination of two mathematical functions. The first function is negative slop straight line and the second one is inverted decaying exponential function. Varying the values of irradiance and temperature have nearly a scaling effect on the I–V curve shape but with preserving the same form. Therefore, the empirical mathematical model proposed in this paper is developed over two stages. The first one is to resemble the curve features in terms of the STC electrical performance terms. The second stage is to represent the impact of varying levels of irradiance and/or temperature on the curves to generalize the model.

In datasheets, it is common to include the curves of the varying irradiance at fixed temperature and/or varying temperature at fixed irradiance. Some datasheets also include a general case at a certain value of irradiance and temperatures which differ from the STC conditions. Therefore, the proposed model is considered over three cases: (i) varying the irradiance levels at STC temperature value, (ii) varying the temperature values at STC irradiance level, and (iii) general form at any value of irradiance and temperature. Each case of them is represented with separate model.

By investigating the first case of different irradiance level at the STC temperature value ( = 25 °C) the effect of this change on the current and voltage is presented for any value of irradiance relative to the STC one as a scale ratio. However, for the second case, the effect of changing the temperature values at the STC irradiance level ( = 1000 W/m2) is represented in the model with a different ratio of temperature change, producing another form of the model generating the curves at any temperature value at STC irradiance level.

Finally, the general case of producing the curve at any environmental condition different from the STC case is investigated and presented in a general form of the proposed empirical mathematical model after updating the electrical terms used over two passes, one for new irradiance level and STC temperature then for new condition of both new irradiance and temperature required conditions.

The following subsections demonstrate each case of the three models and the used electrical performance terms notations in the models are defined as the following:

| G: | Irradiance Level | : | STC Irradiance Level |

| T: | Temperature Value | : | STC Temperature Value |

| : | Maximum Power Current | : | Maximum Power Voltage |

| : | Short Circuit Current | : | Open Circuit Voltage |

4.1. Case One: I–V Characteristics Empirical Mathematical Model for Varying Irradiance Levels

The varying irradiance level leads to varied values of the current produced by the PV panel with the same curve features mentioned early as a combination of two mathematical functions, (i) negative slop straight line and (ii) inverted decaying exponential function. Therefore, with decreasing the irradiance value the current decreases with a ratio of the irradiance level to STC level. In addition, the value of the open circuit voltage reduces with the exponential reduction in the irradiance amount. The maximum power point voltage value is independent of irradiance level, so it is constant for all its values.

The current for any irradiance value at STC temperature value can be calculated using the shown Equation (

1):

where,

4.2. Case Two: I–V Characteristics Empirical Mathematical Model for Varying Temperature Levels

The same equation previously mentioned in Equation (

1) is used to find the I–V curve at fixed level of irradiance (STC level), and any temperature values, but with updated values of some electrical performance terms. The change in temperature at fixed irradiance level has an effect on the values of the short circuit current, open circuit voltage, and maximum power point voltage, although the maximum power point current is constant for various temperature values.

The current for any temperature value at STC irradiance level can be calculated using the shown Equation (

2):

where,

4.3. Case Three: I–V Characteristics Empirical Mathematical Model for Certain Irradiance and Temperature Values

The current at STC irradiance and temperature values can be produced using either Equation (

1) for the case where

or Equation (

2) at the case of

. However, to generate a curve of PV-panel current output at a certain irradiance and temperature level different from the STC, the same equation is used after updating the model electrical performance terms over two phases, one for updating irradiance to new level, and one updating for the new temperature value, as illustrated below:

Phase one: calculate terms for required irradiance value and at STC temperature

, the following equations are used to find the updated values:

Phase two: based on the values generated from phase one to find the terms for the required environmental condition

, the following equations are used, resulting in the updated values:

After updating the electrical terms for the required irradiance and temperature values the I–V curve is calculated using the following Equation (

3):

where,

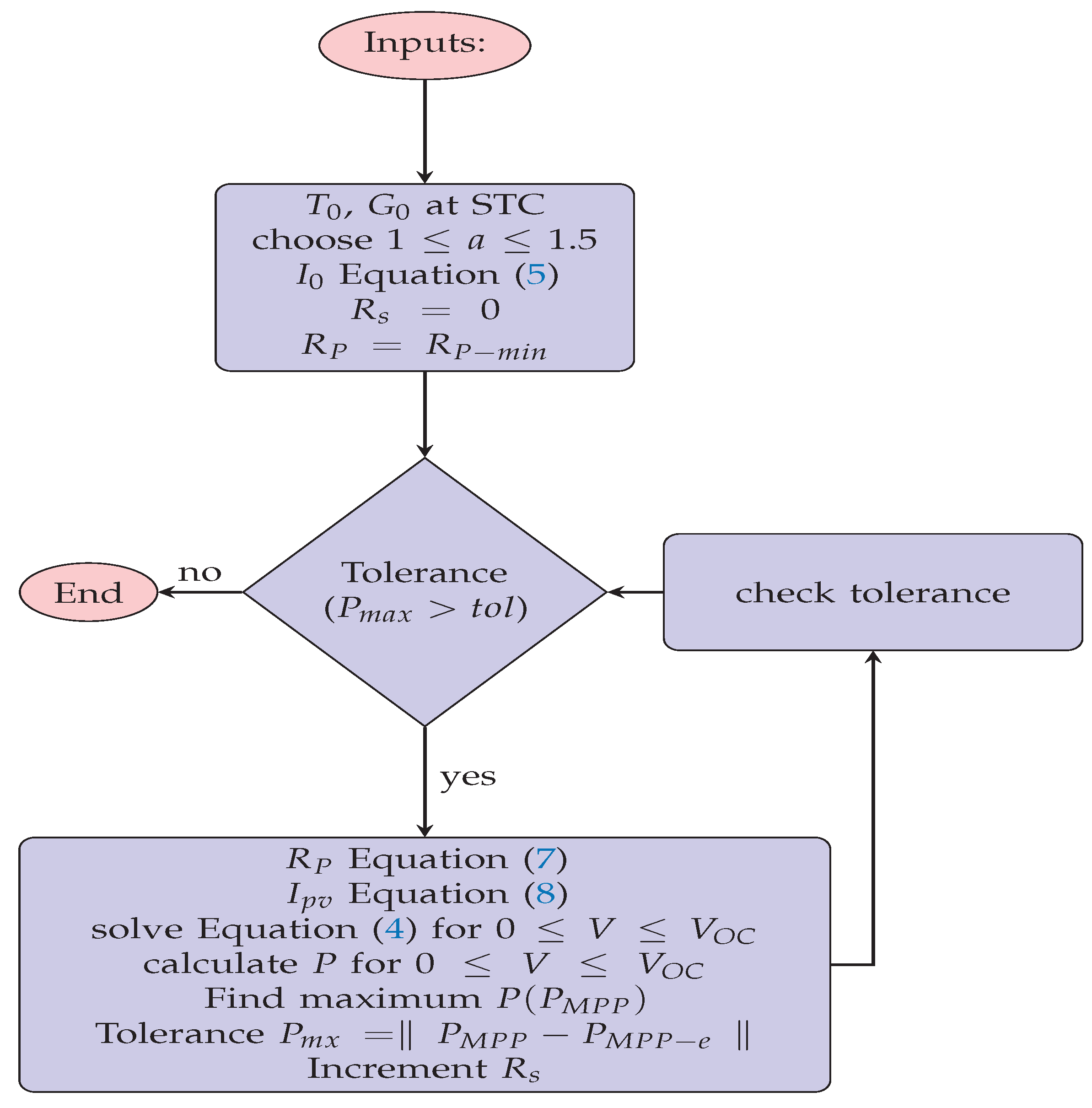

7. Comparison of the Proposed Model with a Single Diode Equivalent-Circuit Based Model

In this section, a comparison between the proposed empirical mathematical PV model and conventional model is presented in order to verify the proposed model. The conventional model is an equivalent circuit-based iterative approach and it is derived for single diode equivalent circuit with the I–V equation given by Equation (

4):

where,

which is equal to

, is the PV thermal voltage with

PV cells connected in series,

q is the electron charge (

C),

K is the Boltzmann constant (

J/°K),

T (in °K) is the temperature of the

p −

n junction.

Unlike the proposed approach, which only requires four electrical terms (

,

and

) obtained from PV datasheet, the iterative model requires seven electrical terms (

,

,

,

,

and

) as well as an iterative parameters extraction procedure. The latter puts a random estimation for the ideality factor

, uses an analytical equation to compute

, and finally applies a numerical iterative method to compute

then

and

. The curves fitting steps can be summarized as follows [

7];

The iterative method flowchart applied for finding

and

is shown in

Figure 23. Both models are validated using the ratings of

-

[

68] module PV with datasheet parameters shown in

Table 5.

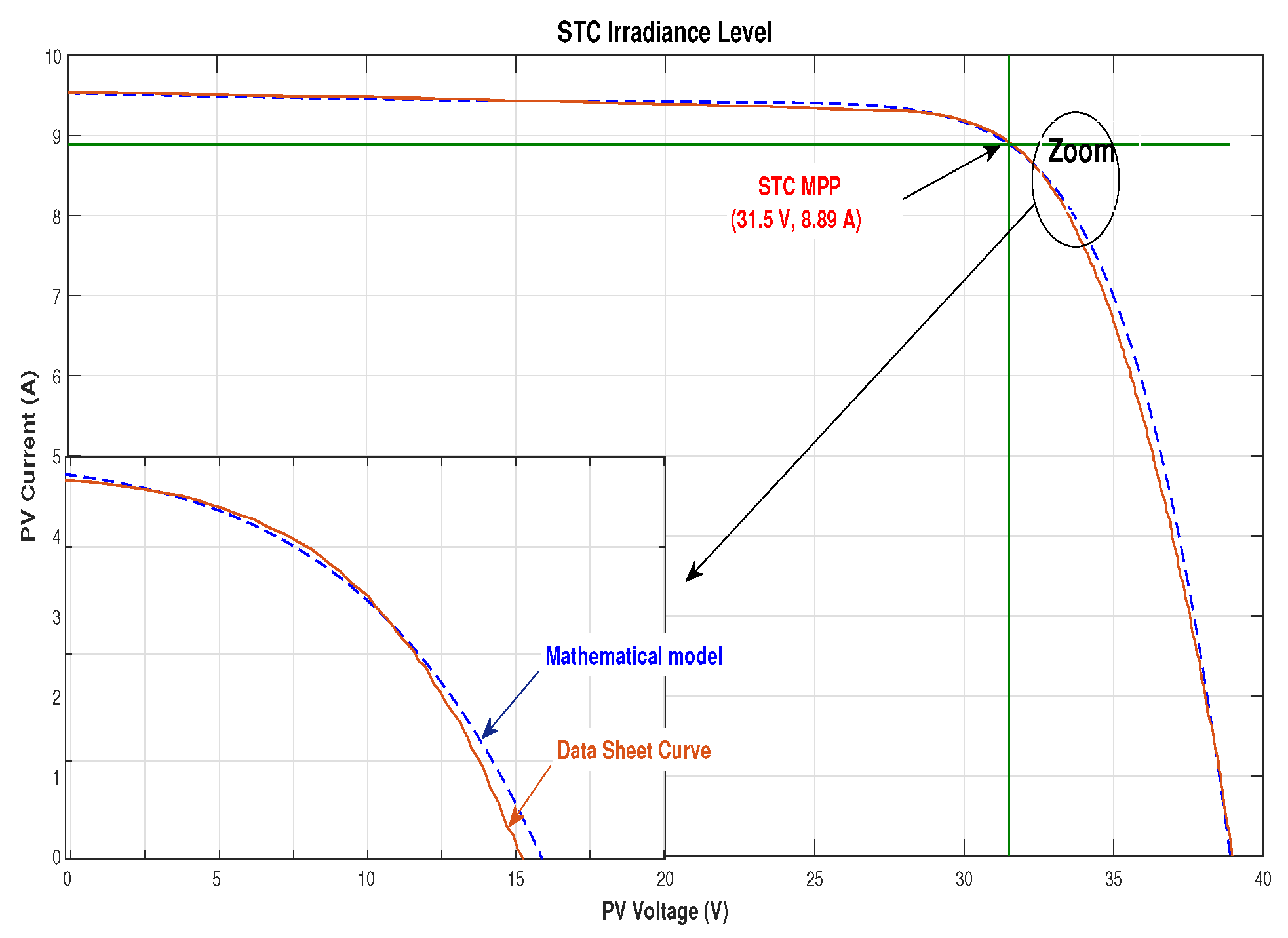

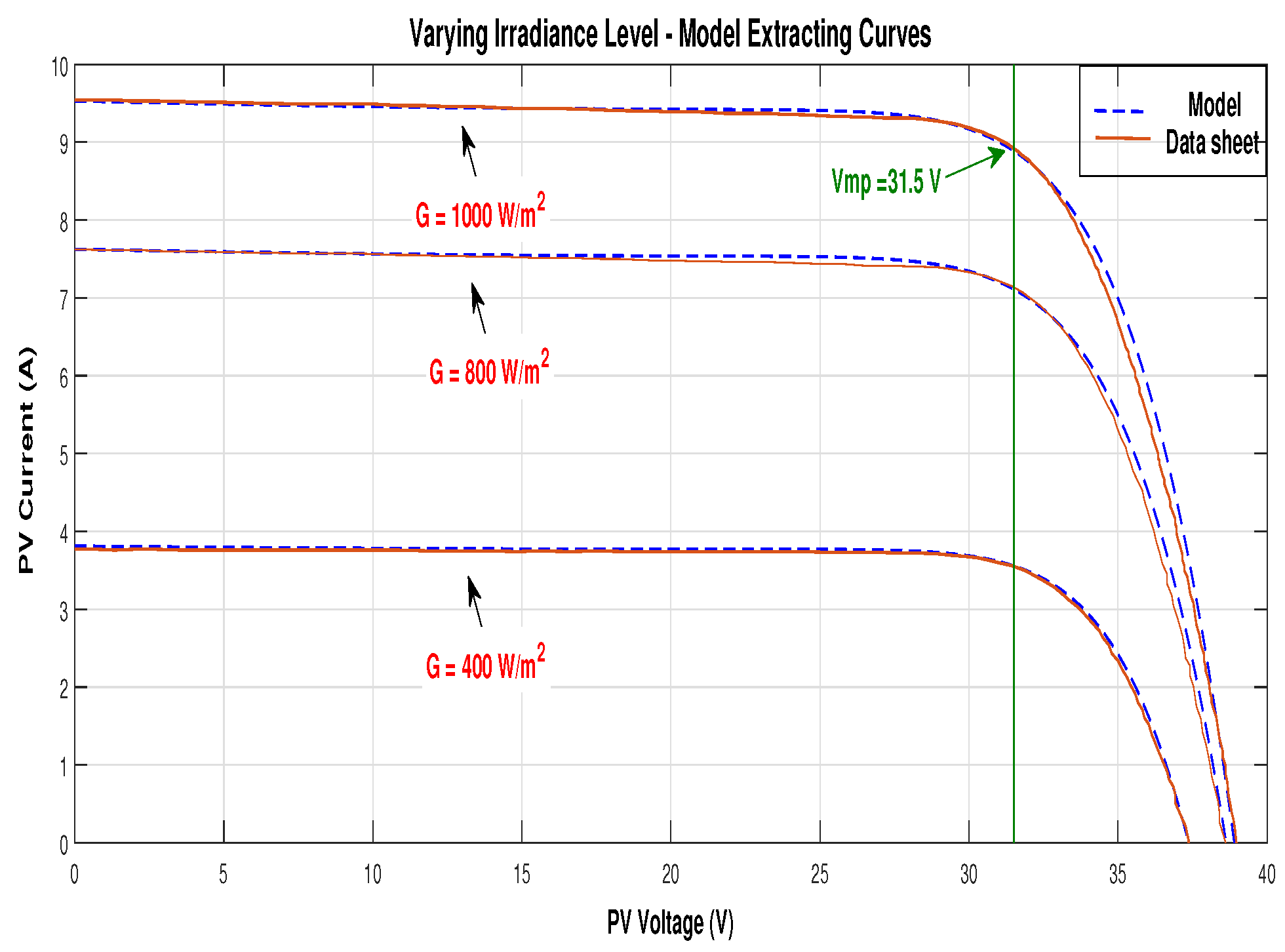

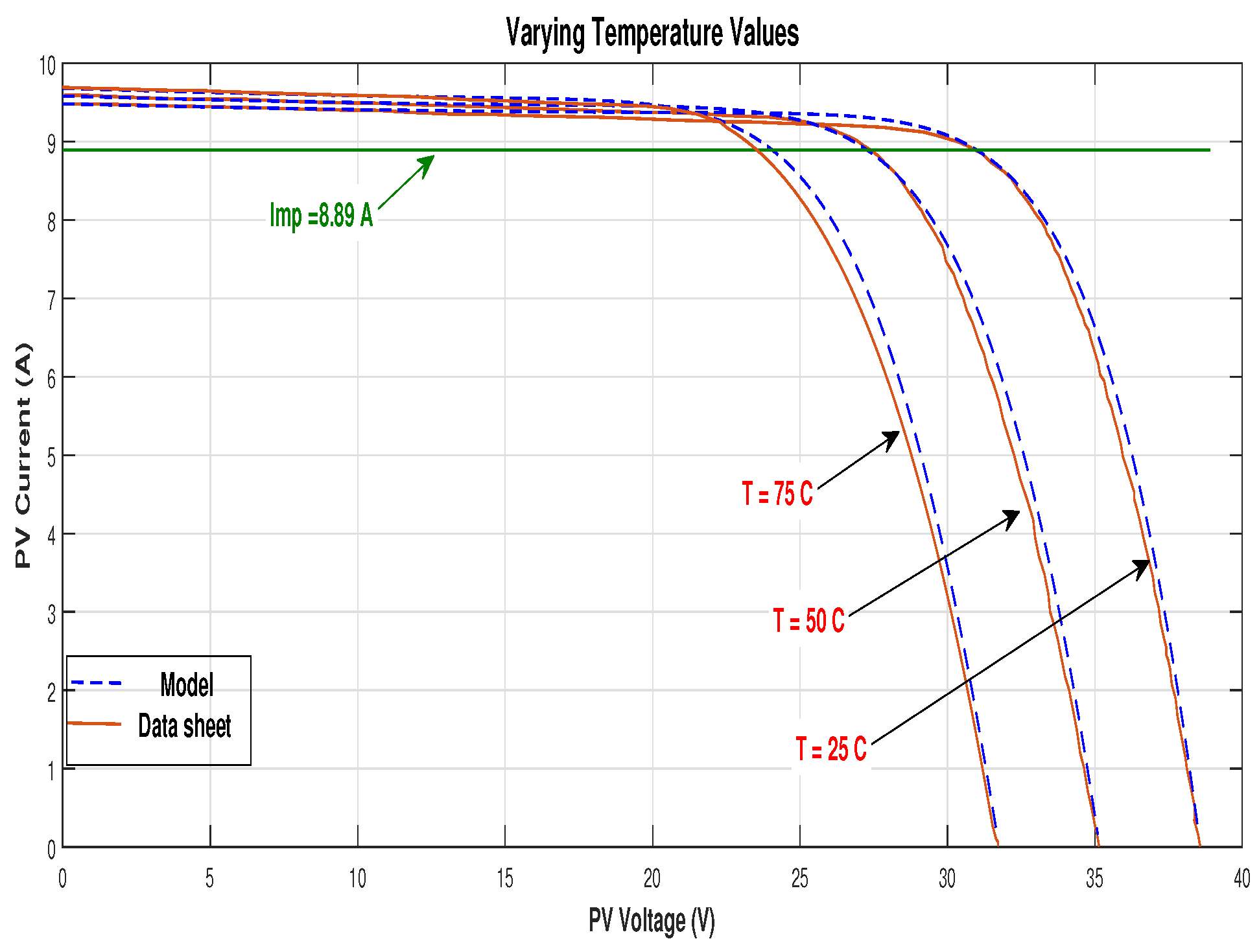

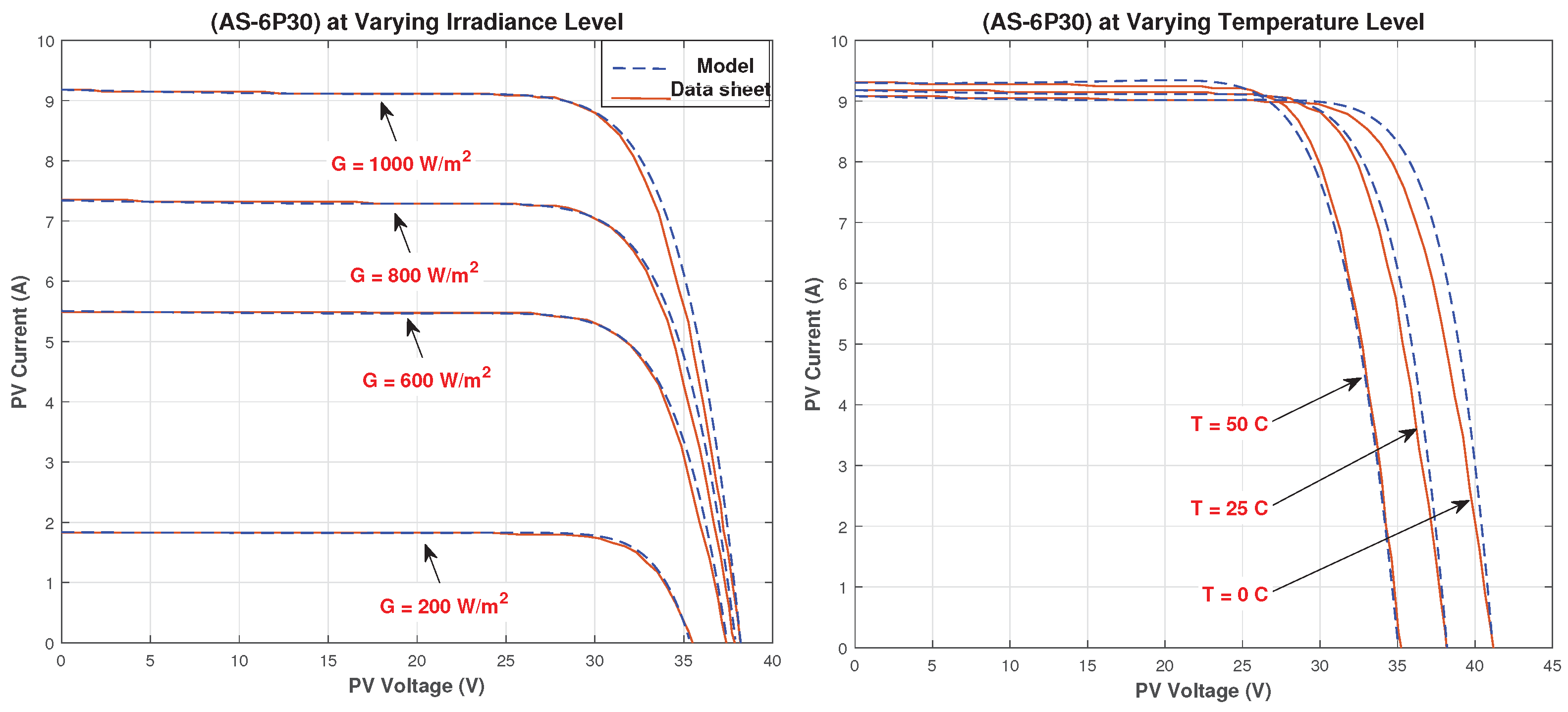

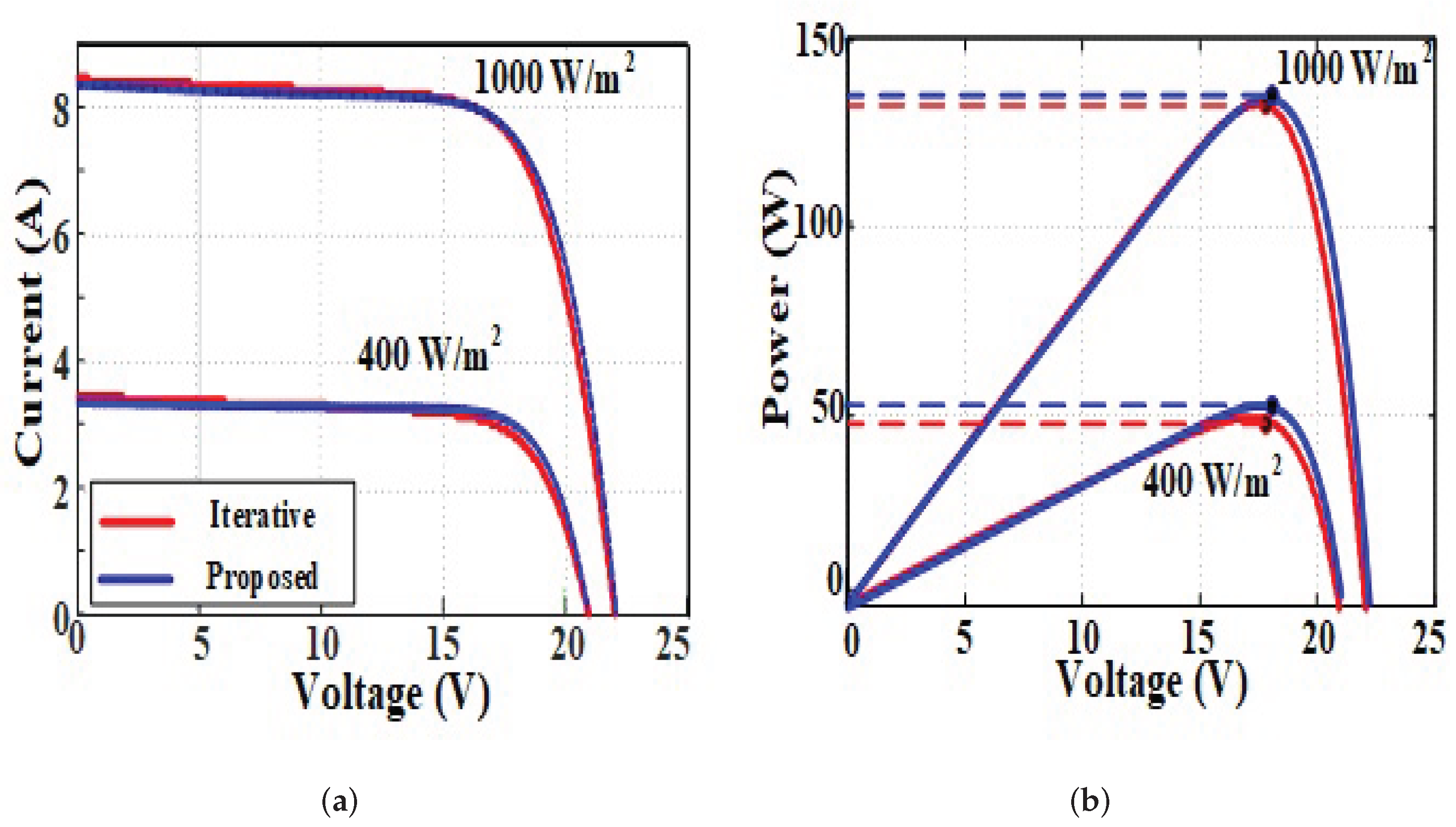

The simulation comparison results of the two models are shown in

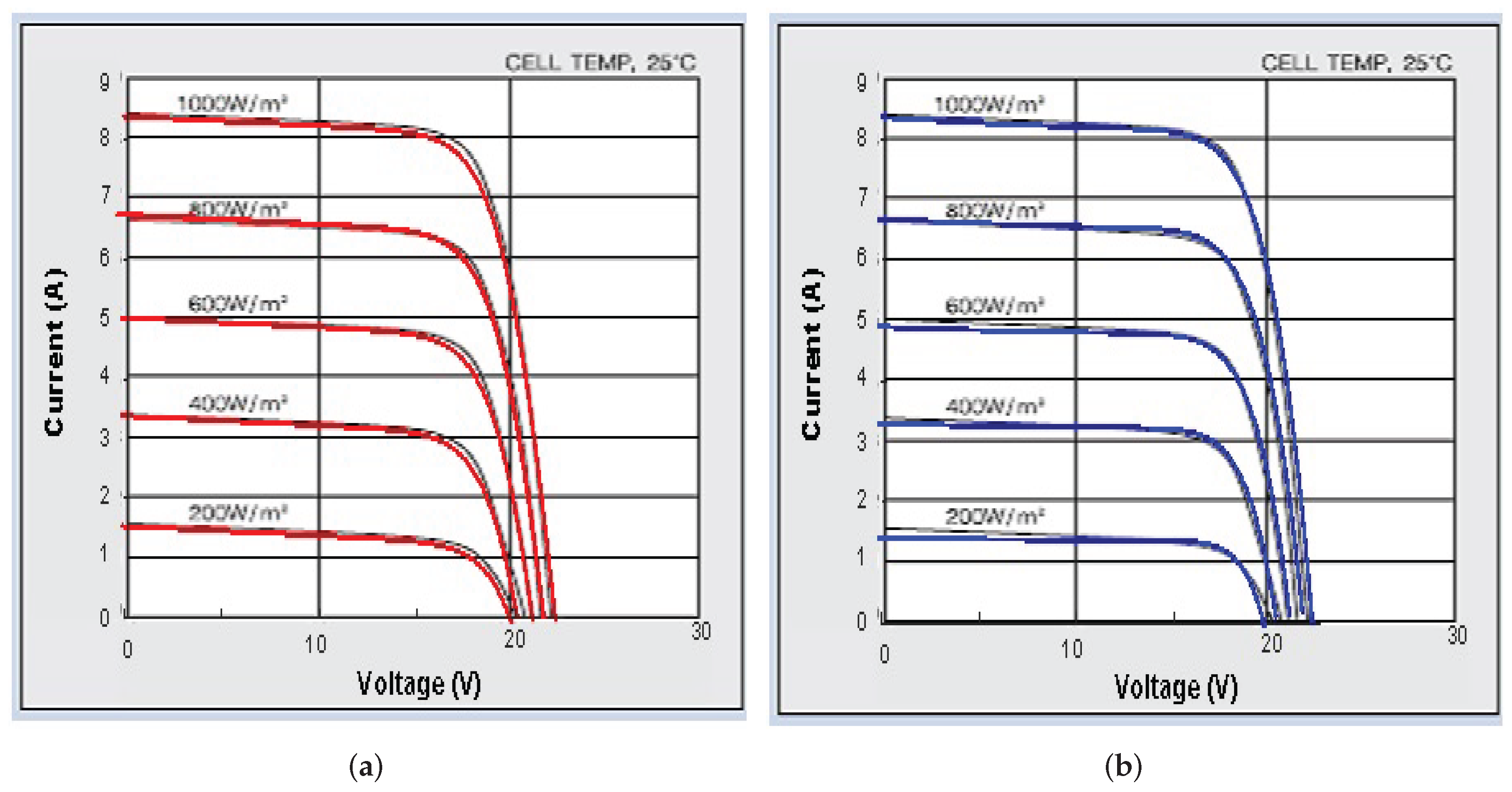

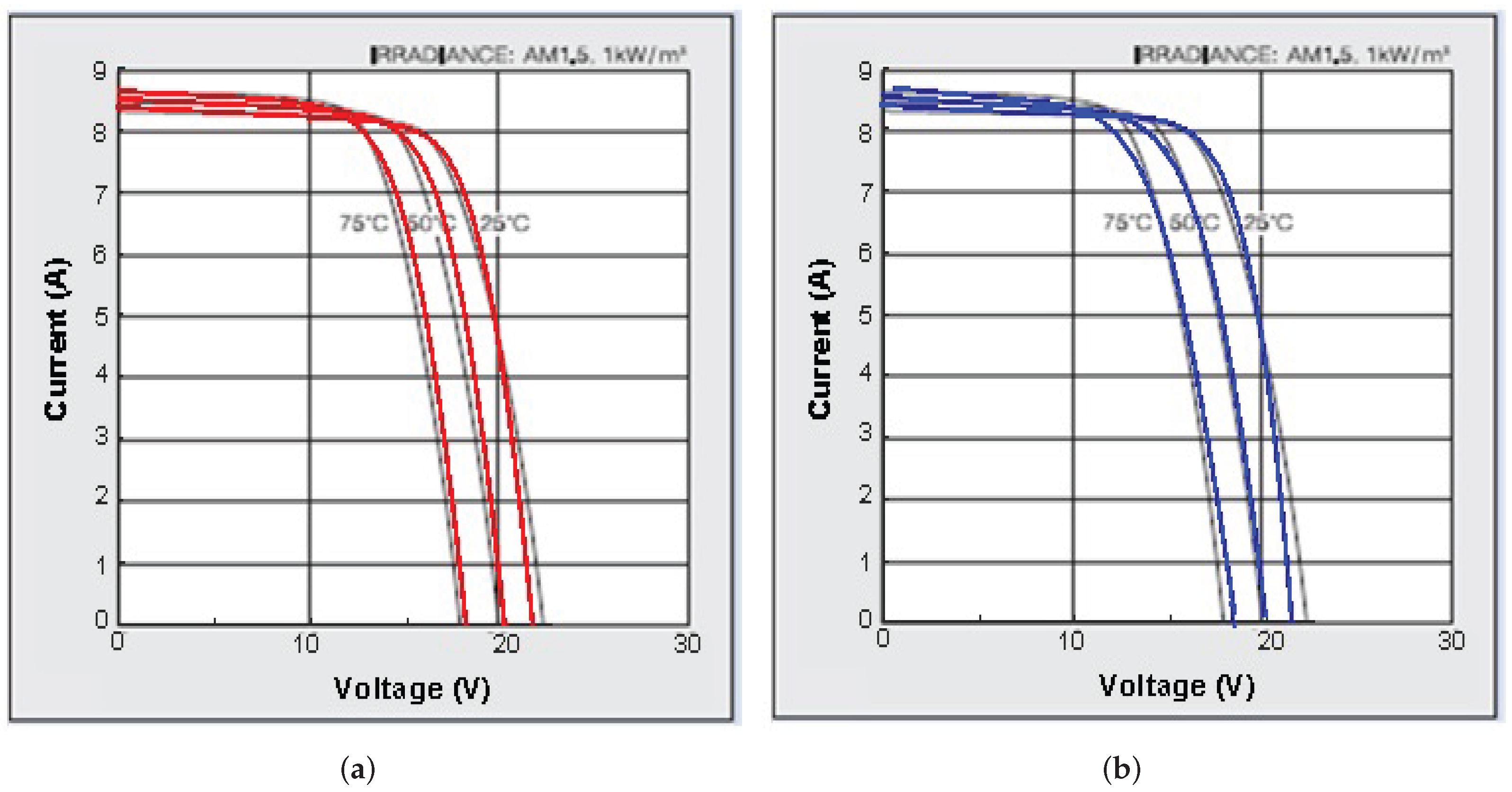

Figure 24 that represents the performance for different irradiance levels and

Figure 25 which represents the performance for different temperature values. Each figure include both I–V and P–V curves to illustrate the variance in the performance of the two models. From the simulation results of the conventional model and the proposed mathematical model it was found that the performance of the proposed one deliver better accuracy as its maximum power value is 135.056 W where the conventional model maximum power is 134.15 W for the same datasheet ratings at STC condition. This verifies the proposed model’s effectiveness, yet with simpler implementation and less computational time and efforts when compared to the iterative model. The proposed model depends solely on a generic empirical equation that requires only four basic electrical terms found in any PV datasheet without the need for any parameter estimation.

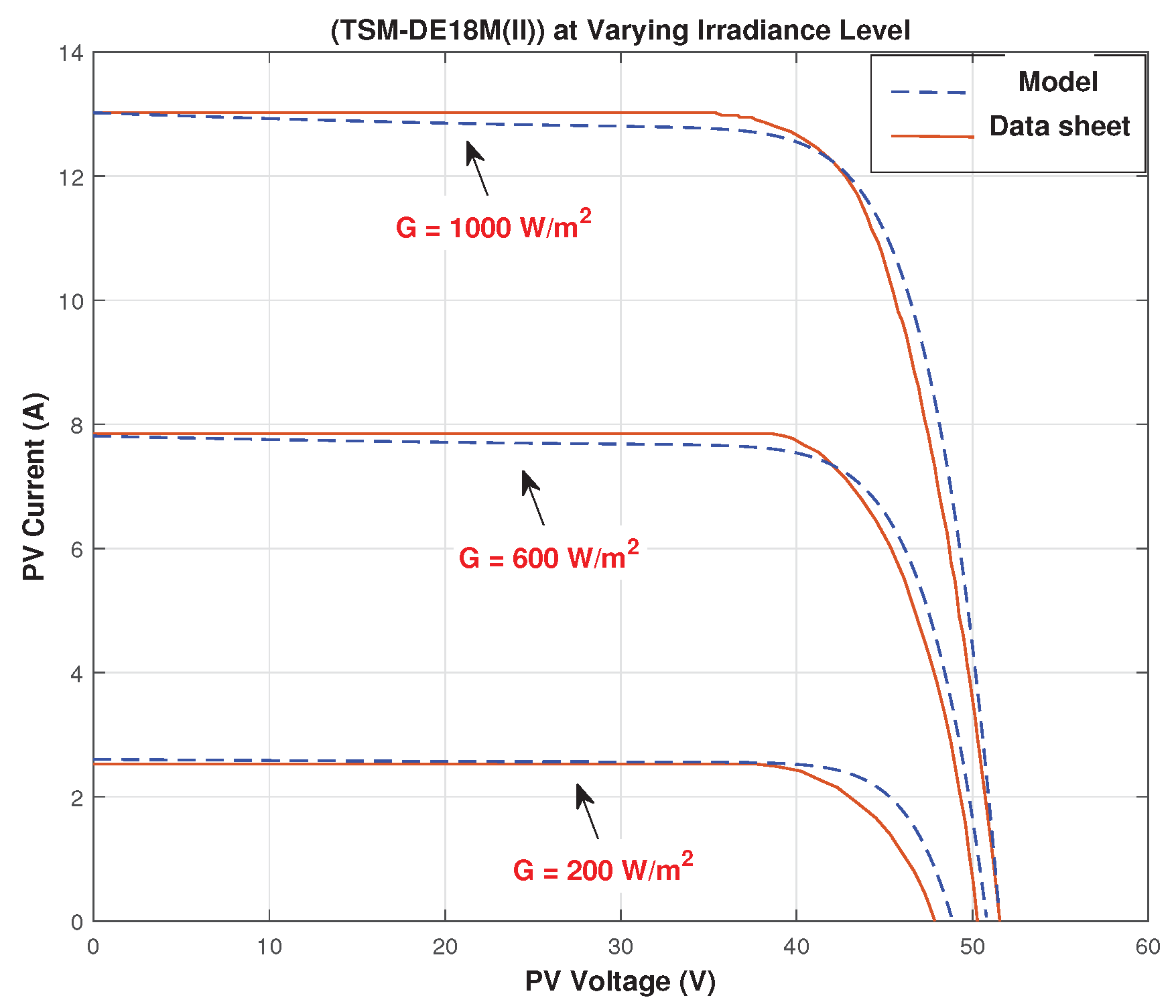

The proposed approach-based I–V curves versus the iterative approach-based ones, for

-

PV module, are compared to those of the P–V experimental datasheet curves. As shown in

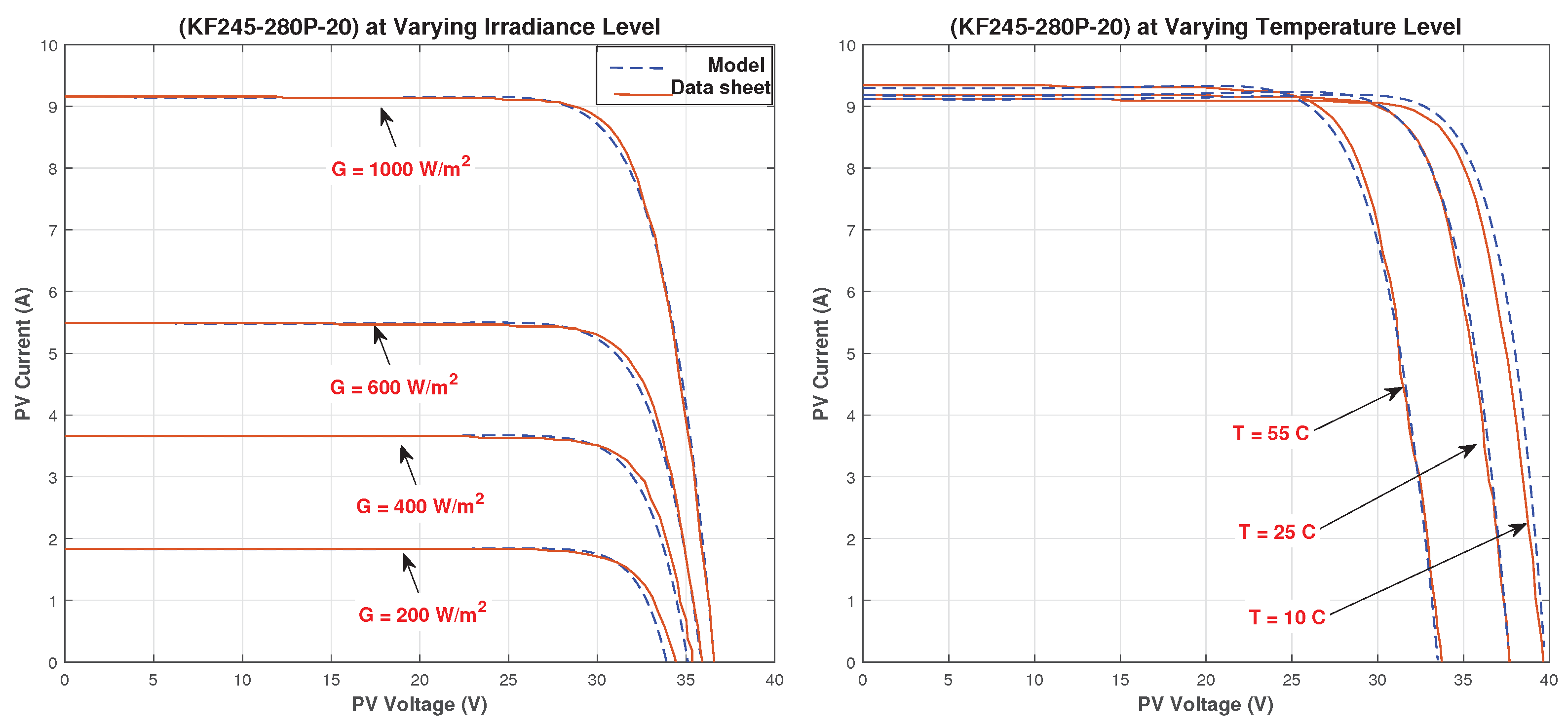

Figure 26 and

Figure 27, these comparisons are achieved at all the irradiance and temperature levels presented by the experimental datasheet curves which include low irradiance cases. Results show that both approaches gave close I–V curves to those experimental ones presented in datasheet. However, this is achieved with the proposed simpler, faster, less parameter-dependent, and iteration-free empirical method.

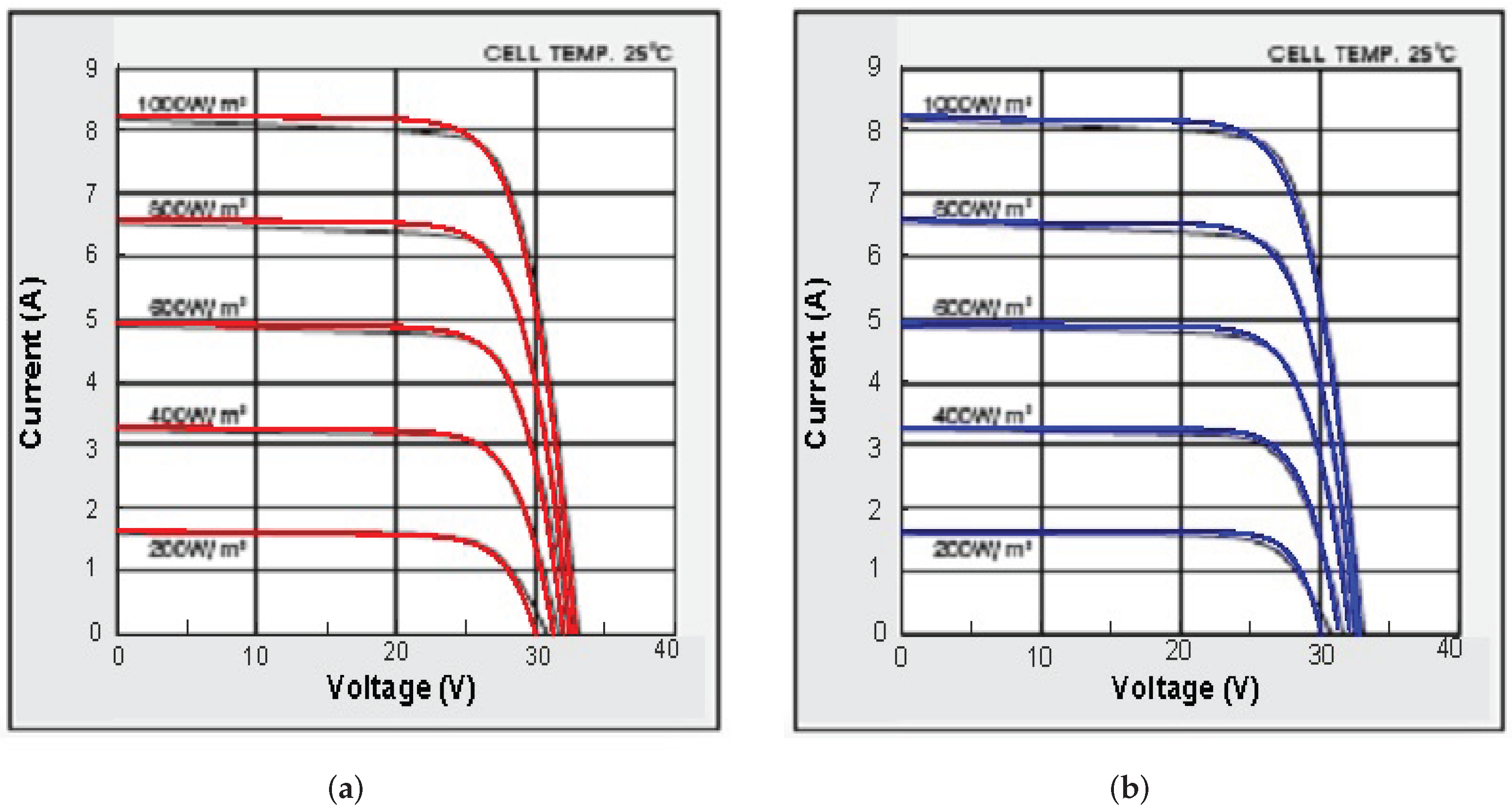

For further validation, the latter is retested with a different PV panel with different rating from another manufacturer, the

PV-module, with specifications presented in

Table 6. The experimental I–V curves applied are shown in

Figure 28 and

Figure 29. Results confirm that both techniques experience relatively close I–V curves which fit onto the experimental curves of this module with the datasheet given below:

8. Privileges and Limitations Discussion

The proposed empirical method is based mainly on the mathematical representation of experimental I–V curves extracted from a PV module datasheet. The model formulates the STC case in mathematical function depending on only four electrical components of the PV-panel (

,

). By investigating the STC case I–V curve, it was found that the point of maximum power is a critical point that divides the curve into two parts. The one on the left, starting from the short circuit point and ending at the maximum power point, is a straight line with a negative slope. The equation of this line is formulated based on these two points of the start and end, so it is represented in terms of the electrical terms mentioned earlier. The other curve to the right of the maximum power point is behaving similarly to the inverted decaying exponential function. The two points used to formulate the power of this exponential function are the point of maximum power and the open circuit point. The PV-model proposed in the paper is based on combining these two functions together, that is, the basic equation which is used to generate the STC case curve, as shown in

Figure 30. To represent the effect of changing in irradiance or temperature, the authors used other curves and investigated the impact of these changes on the curve relative to the STC case values.

It is worth nothing that this curve extraction is a one-time process, followed by the derivation of empirical equations that mathematically represent this curve for different irradiance and temperature conditions. These equations are valid for any other PV-model and can be applied for all PV ratings from different manufacturers i.e., any PV-module I–V characteristics and curves can be obtained by direct substitution of the new relative (, and ) in the derived empirical equations. Unlike the proposed approach, the physical models depend more on electrical terms, and not all of them are available on datasheets. Thus, they require parameter extraction techniques which depend on iterative and estimation approaches, which in turn adds to system complexity and computational time.

The

Table 7 summarizes the main differences between single-diode equivalent circuit-based iterative physical approach presented in

Section 7 and the proposed empirical approach regarding approach realization, error cause, implementation complexity, and computational time.

The proposed model relies on data extracted from PV panel manufacturer datasheets available on the market. Commonly, those curves listed in various vendors are experimentally obtained to achieve proper standardized certification as IEC, IEEE, NEC, or UL. In addition, data extraction is only performed once, as stated and performed by the authors. Any further investigation of other PV panels from any other vendors do not require curve extraction, as explained. Only four parameters are needed to substitute in the authors’ pre-elaborated proposed formula. Hence, fear form any further unavailability of experimental datasheets is not crucial.

The proposed technique in this paper is developed by using the captured images from the datasheet only once, and then, for generating any graphs at various rating power, the developed proposed model is used directly. There is no need to capture the images from the datasheet every time for reproduction, as this model features the graphs in terms of the electric parameters of the PV-panel (

,

and

). The developing process of the model used some curves from the main datasheet, then the rest of the curves were used for testing the model. After that, many datasheets at different rating power were used to validate the model. The authors generated the curves using the proposed model and compared them to the datasheet curves so these curves were not used to develop a newer model. The proposed model is formulated for generating I–V curves for three cases: (i) various irradiance level at fixed STC temperature (Equation (

1)), (ii) various temperature levels at fixed irradiance level (Equation (

2)), and (iii) certain value or irradiance and temperature differ from the STC case (Equation (

3)).

As the developed model is based on digitizing the characteristic curves captured from the datasheet there are some sources of error that affect the data accuracy. The first source of error is the resolution of the captured image from the datasheet. To overcome this source of error, aiming to enhance the accuracy of the extracted data from the datasheet, the authors used image editing software to increase the DPI of the figures.

The second source of error is the manual selection of the graph points in order to extract its numerical value. To mitigate this source of error, the authors used many graph digitizing software packages and compared their output to select the software that delivers the most accurate data extraction. The manual process itself is, unfortunately, unavoidable.