Bearing Fault Diagnosis Based on Discriminant Analysis Using Multi-View Learning

Abstract

1. Introduction

2. Previous Works and Preliminaries

2.1. Canonical Correlation Analysis

2.2. Uncorrelated Linear Discriminant Analysis

3. Fault Diagnosis Method Based on Discriminant Analysis Using Multi-View Learning

3.1. Multi-View Feature Dataset Construction

- Step 1: Catch the fixed-point FFT amplitudes from the raw time-series vibration and acoustic signals as samples and , where denotes the vibration dataset and denotes the acoustic dataset. and represent the number of samples and p and q mean the dimensionality of the samples. In our work, p is equal to q.

- Step 2: Draw with label from as the vibration training dataset randomly, where denotes the number of vibration training datasets. The remaining samples from are the vibration test dataset .

- Step 3: Select with label from as the acoustic training dataset randomly, where denotes the number of acoustic training datasets. The remaining samples from are the acoustic test dataset . Then, , and constitutes the multi-view feature dataset, referring to the vibration and acoustic views.

3.2. Multi-View Feature Extraction and Diagnosis

- Step 1: Label the multi-view training dataset with and the unlabeled multi-view test dataset with in the process of the multi-view feature dataset generation.

- Step 3: Obtain tr()/tr(), and initialize and using empty matrices.

- Step 4: Construct the matrices and as in Equation (21).

- Step 5: Achieve the rth multi-view projection pair (, ) by solving Equation (20).

- Step 6: Update and , and then jump to Step 4 until the iteration termination condition that r is equal to d is satisfied.

- Step 7: Construct and , and then the MVF are extracted using Equation (23). Finally, the multi-view test dataset labels determined by the KNN classifier are achieved.

4. Experimental Evaluations

4.1. Experimental Setup and Dataset Preparation

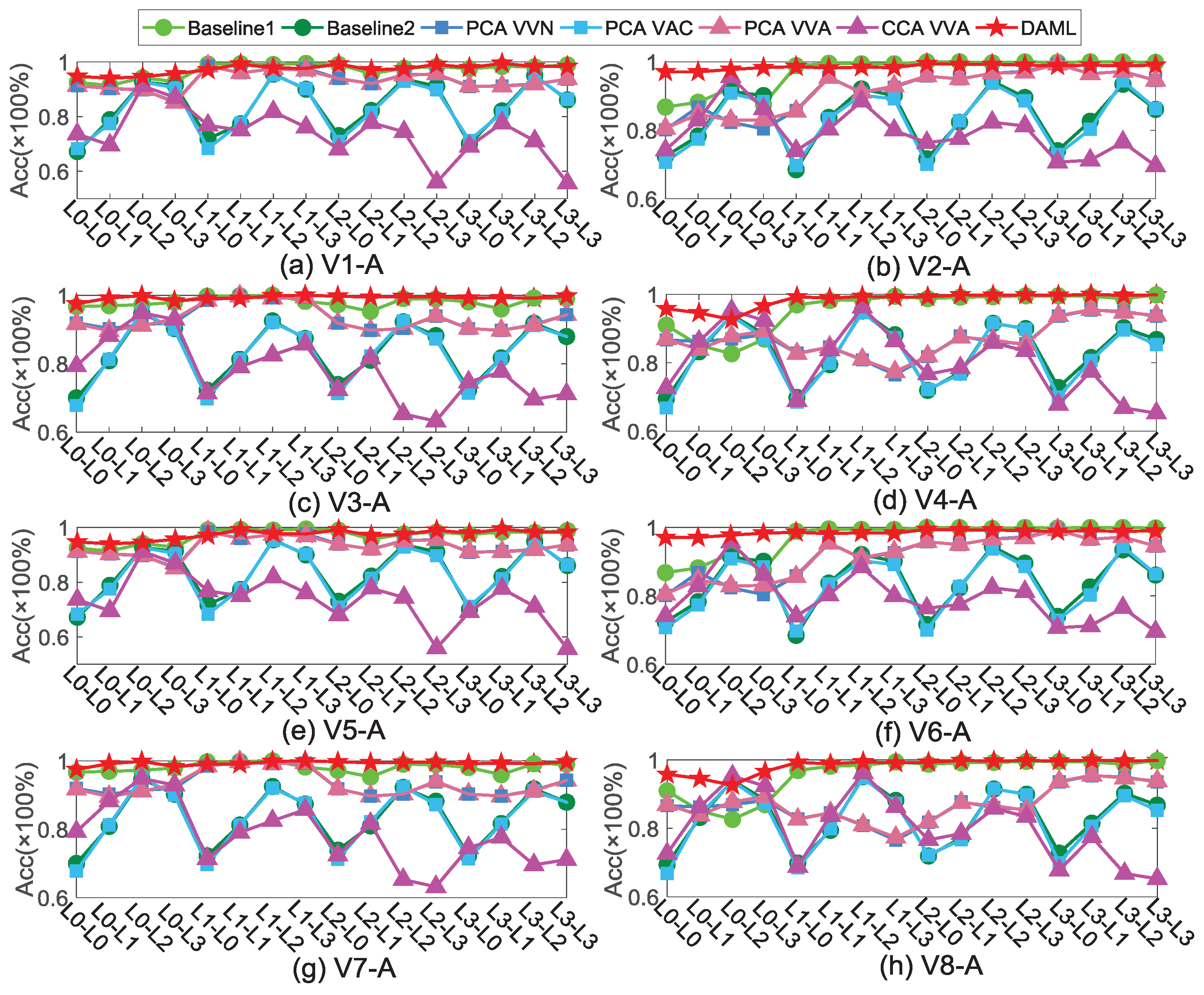

4.2. Diagnosis Results of the Proposed Method

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yi, W.; Guanghua, X.; Ailing, L.; Lin, L.; Kuosheng, J. An online tacholess order tracking technique based on generalized demodulation for rolling bearing fault detection. J. Sound Vib. 2016, 367, 233–249. [Google Scholar]

- Wang, L.; Wood, R.J.K.; Harvey, T.J.; Morris, S.; Powrie, H.E.G.; Care, I. Wear performance of oil lubricated silicon nitride sliding against various bearing steels. Wear 2003, 255, 657–668. [Google Scholar] [CrossRef]

- Tong, Z.; Li, W.; Zhang, B.; Jiang, F.; Zhou, G. Bearing Fault Diagnosis Under Variable Working Conditions Based on Domain Adaptation Using Feature Transfer Learning. IEEE Access 2018, 6, 76187–76197. [Google Scholar] [CrossRef]

- Jiao, J.; Zhao, M.; Lin, J. Unsupervised Adversarial Adaptation Network for Intelligent Fault Diagnosis. IEEE Trans. Ind. Electron. 2020, 67, 9904–9913. [Google Scholar] [CrossRef]

- Liu, X.; Azzam, B.; Harzendorf, F.; Kolb, J.; Schelenz, R.; Hameyer, K.; Jacobs, G. Early stage white etching crack identification using artificial neural networks. Forsch. Im Ingenieurwesen 2021, 85, 153–163. [Google Scholar] [CrossRef]

- Zhang, H.; He, Q. Tacholess bearing fault detection based on adaptive impulse extraction in the time domain under fluctuant speed. Meas. Sci. Technol. 2021, 31, 074004. [Google Scholar] [CrossRef]

- He, Q.; Ding, X. Sparse representation based on local time–frequency template matching for bearing transient fault feature extraction. J. Sound Vib. 2016, 370, 424–443. [Google Scholar] [CrossRef]

- Chen, L.; Zhenya, W.; Bo, Z. Intelligent fault diagnosis of rolling bearing using hierarchical convolutional network based health state classification. Adv. Eng. Inform. 2017, 32, 139–151. [Google Scholar]

- Sun, R.B.; Yang, Z.B.; Zhai, Z.; Chen, X.F. Sparse representation based on parametric impulsive dictionary design for bearing fault diagnosis. Mech. Syst. Signal Process. 2019, 122, 737–753. [Google Scholar] [CrossRef]

- Jardine, A.K.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Tian, J.; Morillo, C.; Azarian, M.; Pecht, M. Motor Bearing Fault Detection Using Spectral Kurtosis-Based Feature Extraction Coupled with K-Nearest Neighbor Distance Analysis. IEEE Trans. Ind. Electron. 2016, 63, 1793–1803. [Google Scholar] [CrossRef]

- Gao, S.; Xu, L.; Zhang, Y.; Pei, Z. Rolling bearing fault diagnosis based on intelligent optimized self-adaptive deep belief network. Meas. Sci. Technol. 2020, 31, 055009. [Google Scholar] [CrossRef]

- Xu, X.; Lei, Y.; Li, Z. An Incorrect Data Detection Method for Big Data Cleaning of Machinery Condition Monitoring. IEEE Trans. Ind. Electron. 2020, 67, 2326–2336. [Google Scholar] [CrossRef]

- Samanta, B.; Nataraj, C. Use of particle swarm optimization for machinery fault detection. Eng. Appl. Artif. Intell. 2009, 22, 308–316. [Google Scholar] [CrossRef]

- Li, Y.; Xu, M.; Wei, Y.; Huang, W. A new rolling bearing fault diagnosis method based on multiscale permutation entropy and improved support vector machine based binary tree. Measurement 2016, 77, 80–94. [Google Scholar] [CrossRef]

- Chen, R.; Tang, L.; Hu, X.; Wu, H. Fault Diagnosis Method of Low-Speed Rolling Bearing Based on Acoustic Emission Signal and Subspace Embedded Feature Distribution Alignment. IEEE Trans. Ind. Inform. 2021, 17, 5402–5410. [Google Scholar] [CrossRef]

- Yao, J.; Liu, C.; Song, K.; Feng, C.; Jiang, D. Fault diagnosis of planetary gearbox based on acoustic signals. Appl. Acoust. 2021, 181, 108151. [Google Scholar] [CrossRef]

- Al-Ghamd, A.M.; Mba, D. A comparative experimental study on the use of acoustic emission and vibration analysis for bearing defect identification and estimation of defect size. Expert Syst. Appl. 2006, 20, 1537–1571. [Google Scholar] [CrossRef]

- Tandon, N.; Yadava, G.S.; Ramakrishna, A.K. A comparison of some condition monitoring techniques for the detection of defect in induction motor ball bearings. Mech. Syst. Signal Process. 2007, 21, 244–256. [Google Scholar] [CrossRef]

- Eftekharnejad, B.; Carrasco, M.; Charnley, B.; Mba, D. The application of spectral kurtosis on Acoustic Emission and vibrations from a defective bearing. Mech. Syst. Signal Process. 2011, 25, 266–284. [Google Scholar] [CrossRef]

- Dingcheng, Z.; Edward, S.; Mani, E.; Clive, R.; Dejie, Y. Intelligent acoustic-based fault diagnosis of roller bearings using a deep graph convolutional network. Measurement 2020, 156, 107585. [Google Scholar]

- Fei, C.W.; Choy, Y.S.; Bai, G.C.; Tang, W.Z. Multi-feature entropy distance approach with vibration and acoustic emission signals for process feature recognition of rolling element bearing faults. Struct. Health Monit. 2017, 17, 156–168. [Google Scholar] [CrossRef]

- Peng, B.; Bi, Y.; Xue, B.; Zhang, M.; Wan, S. Multi-View Feature Construction Using Genetic Programming for Rolling Bearing Fault Diagnosis [Application Notes]. IEEE Comput. Intell. Mag. 2021, 16, 79–94. [Google Scholar] [CrossRef]

- Madhusudana, C.K.; Kumar, H.; Narendranath, S. Fault Diagnosis of Face Milling Tool using Decision Tree and Sound Signal. Mater. Today Proc. 2018, 5, 12035–12044. [Google Scholar] [CrossRef]

- Shi, H.; Li, Y.; Bai, X.; Zhang, K.; Sun, X. A two-stage sound-vibration signal fusion method for weak fault detection in rolling bearing systems. Mech. Syst. Signal Process. 2022, 172, 109012. [Google Scholar] [CrossRef]

- Mohanty, S.; Gupta, K.K.; Raju, K.S. Hurst based vibro-acoustic feature extraction of bearing using EMD and VMD. Measurement 2018, 117, 200–220. [Google Scholar] [CrossRef]

- Iqbal, M.; Madan, A.K. CNC Machine-Bearing Fault Detection Based on Convolutional Neural Network Using Vibration and Acoustic Signal. J. Vib. Eng. Technol. 2022, 10, 1613–1621. [Google Scholar] [CrossRef]

- Wang, X.; Mao, D.; Li, X. Bearing fault diagnosis based on vibro-acoustic data fusion and 1D-CNN network. Measurement 2021, 173, 108518. [Google Scholar] [CrossRef]

- Li, C.; Sanchez, R.V.; Zurita, G.; Cerrada, M.; Cabrera, D.; Vásquez, R.E. Gearbox fault diagnosis based on deep random forest fusion of acoustic and vibratory signals. Mech. Syst. Signal Process. 2016, 76–77, 283–293. [Google Scholar] [CrossRef]

- Yan, X.; Hu, S.; Mao, Y.; Ye, Y.; Yu, H. Deep multi-view learning methods: A review. Neurocomputing 2021, 448, 106–129. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, X.; Xu, X.; Sun, S. Multi-view learning overview: Recent progress and new challenges. Inf. Fusion 2017, 38, 43–54. [Google Scholar] [CrossRef]

- Ding, Z.; Shao, M.; Fu, Y. Robust Multi-view Representation: A Unified Perspective from Multi-view Learning to Domain Adaption. In Proceedings of the Twenty-Seventh International Joint Conference on Artificial Intelligence, IJCAI-18, Stockholm, Sweden, 13–19 July 2018; pp. 5434–5440. [Google Scholar]

- Kan, M.; Shan, S.; Zhang, H.; Lao, S.; Chen, X. Multi-View Discriminant Analysis. IEEE Trans. Pattern Anal. Mach. Intell. 2016, 38, 188–194. [Google Scholar] [CrossRef]

- Yang, M.; Deng, C.; Nie, F. Adaptive-weighting discriminative regression for multi-view classification. Pattern Recognit. 2019, 88, 236–245. [Google Scholar] [CrossRef]

- Zhang, C.; Cui, Y.; Han, Z.; Zhou, J.T.; Fu, H.; Hu, Q. Deep Partial Multi-View Learning. IEEE Trans. Pattern Anal. Mach. Intell. 2022, 44, 2402–2415. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, Z.; Tao, Z.; Gao, Q.; Fu, Y. Generative Partial Multi-View Clustering With Adaptive Fusion and Cycle Consistency. IEEE Trans. Image Process. 2021, 30, 1771–1783. [Google Scholar] [CrossRef]

- Hardoon, D.R.; Szedmak, S.; Shawe-Taylor, J. Canonical Correlation Analysis: An Overview with Application to Learning Methods. Neural Comput. 2004, 16, 2639–2664. [Google Scholar] [CrossRef]

- Sun, S.; Xie, X.; Yang, M. Multiview Uncorrelated Discriminant Analysis. IEEE Trans. Cybern. 2016, 46, 3272–3284. [Google Scholar] [CrossRef]

- Jin, X.; Zhao, M.; Chow, T.W.; Pecht, M. Motor Bearing Fault Diagnosis Using Trace Ratio Linear Discriminant Analysis. IEEE Trans. Ind. Electron. 2014, 61, 2441–2451. [Google Scholar] [CrossRef]

- Jin, Z.; Yang, J.Y.; Hu, Z.S.; Lou, Z. Face recognition based on the uncorrelated discriminant transformation. Pattern Recognit. 2001, 34, 1405–1416. [Google Scholar] [CrossRef]

- Sun, Q.; Zeng, S.; Liu, Y.; Heng, P.; Xia, D. A new method of feature fusion and its application in image recognition. Pattern Recognit. 2005, 38, 2437–2448. [Google Scholar] [CrossRef]

- Hughes, G. On the mean accuracy of statistical pattern recognizers. IEEE Trans. Inf. Theory 1968, 14, 55–63. [Google Scholar] [CrossRef]

- van der Maaten, L.; Hinton, G. Visualizing Data using t-SNE. J. Mach. Learn. Res. 2017, 9, 2579–2605. [Google Scholar]

| Type | Inner Race | Outer Race | Number | Bearing | Balls |

|---|---|---|---|---|---|

| Diameter (mm) | Diameter (mm) | of Balls | Width (mm) | Diameter (mm) | |

| 6204 | 20 | 47 | 8 | 14 | 7.9 |

| Vibration Signal | Acoustic Signal | Working | Health | Random Selections |

|---|---|---|---|---|

| View | View | Conditions | Conditions | (%) |

| V1 | A | L0, L1 | NO, IF | 10, 30, 70 |

| L2, L3 | OF, BF | |||

| V2 | A | L0, L1 | NO, IF | 10, 30, 70 |

| L2, L3 | OF, BF | |||

| V3 | A | L0, L1 | NO, IF | 10, 30, 70 |

| L2, L3 | OF, BF | |||

| V4 | A | L0, L1 | NO, IF | 10, 30, 70 |

| L2, L3 | OF, BF | |||

| V5 | A | L0, L1 | NO, IF | 10, 30, 70 |

| L2, L3 | OF, BF | |||

| V6 | A | L0, L1 | NO, IF | 10, 30, 70 |

| L2, L3 | OF, BF | |||

| V7 | A | L0, L1 | NO, IF | 10, 30, 70 |

| L2, L3 | OF, BF | |||

| V8 | A | L0, L1 | NO, IF | 10, 30, 70 |

| L2, L3 | OF, BF |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, Z.; Li, W.; Zhang, B.; Gao, H.; Zhu, X.; Zio, E. Bearing Fault Diagnosis Based on Discriminant Analysis Using Multi-View Learning. Mathematics 2022, 10, 3889. https://doi.org/10.3390/math10203889

Tong Z, Li W, Zhang B, Gao H, Zhu X, Zio E. Bearing Fault Diagnosis Based on Discriminant Analysis Using Multi-View Learning. Mathematics. 2022; 10(20):3889. https://doi.org/10.3390/math10203889

Chicago/Turabian StyleTong, Zhe, Wei Li, Bo Zhang, Haifeng Gao, Xinglong Zhu, and Enrico Zio. 2022. "Bearing Fault Diagnosis Based on Discriminant Analysis Using Multi-View Learning" Mathematics 10, no. 20: 3889. https://doi.org/10.3390/math10203889

APA StyleTong, Z., Li, W., Zhang, B., Gao, H., Zhu, X., & Zio, E. (2022). Bearing Fault Diagnosis Based on Discriminant Analysis Using Multi-View Learning. Mathematics, 10(20), 3889. https://doi.org/10.3390/math10203889