A Combined Dynamic Programming and Simulation Approach to the Sizing of the Low-Level Order-Picking Area

Abstract

1. Introduction

2. Literature Review

2.1. Design Decision Problems

2.2. Applied Solution Methods

3. Problem Formulation

- Layouts of OPA and reserve area are already defined;

- All requests for order-picking in the picking period are realized in the OPA;

- Assortment of products in the OPA is already known, based on the expected demand in a planning period;

- At least one pallet of every product is present in the OPA;

- Before the picking period, there is sufficient time to provide the necessary quantity of products to the OPA;

- In the event of a lack of certain product in the OPA, emergency replenishments are performed during the picking period;

- The quantity of products in one emergency replenishments cycle is equal to one pallet of products;

- Demand of each product i (i = 1, …, N) during the picking period (expressed in case units) is described by Normal distribution Ni ~ (μi, σi), where μi is expected demand for the product i, and σi is standard deviation of the demand of the same product during the picking period. It should be noted that the normal distribution is the result of summing all individual product’s demands during the order-picking period, i.e., all demands of orders. As it is well known, regardless of distributions of added variables, an aggregated variable tends to follow the normal distribution even for a small number of added variables;

- Number of case units per pallet is npi (i = 1, …, N).

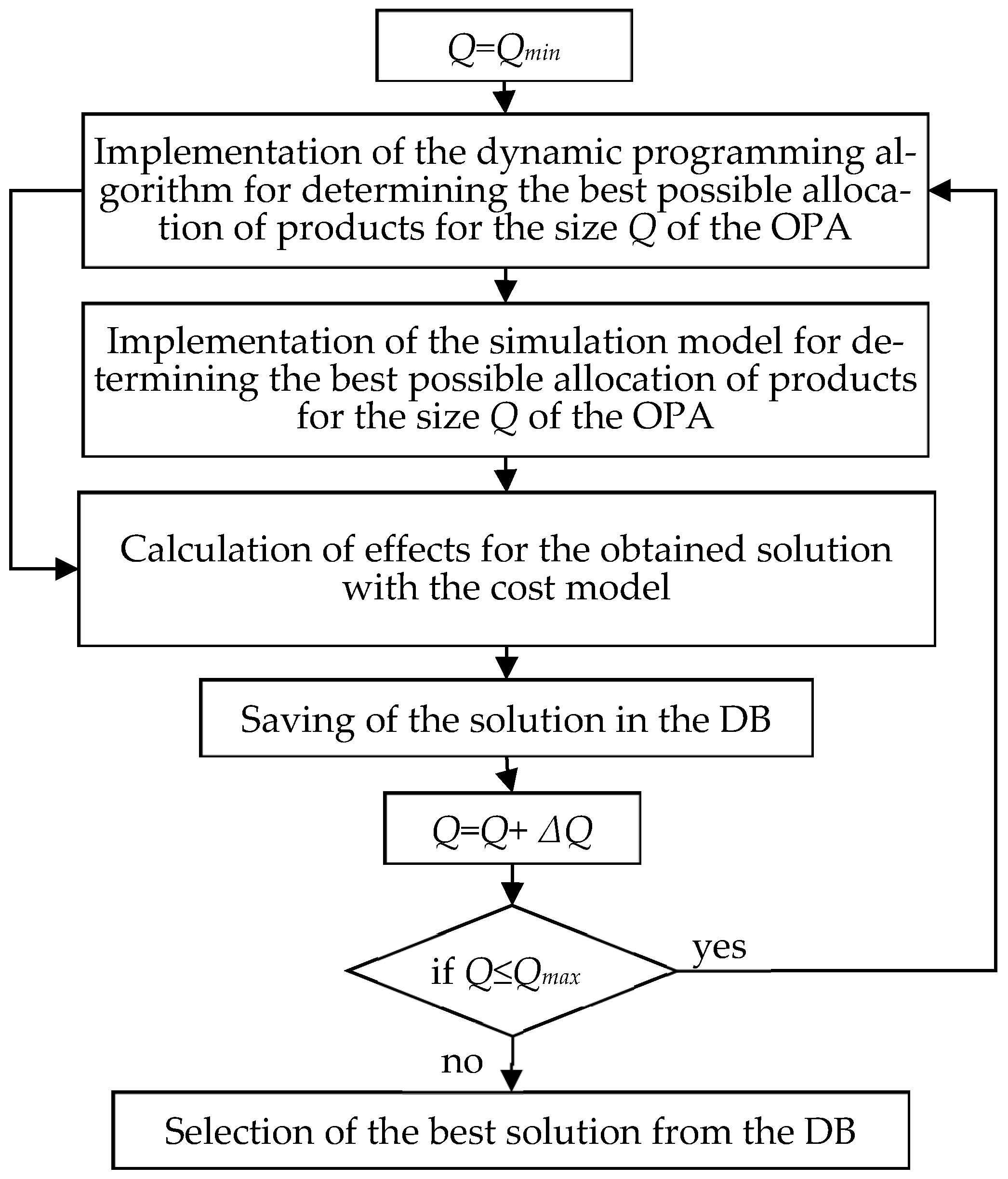

4. Solution Procedure

4.1. Optimization Model of Allocation

- N—the number of products in the OPA;

- T—order-picking period (shift, day, week, etc.);

- Di—a random variable that represents the demand for the product i (i = 1, …, N) expressed in the number of pallet units in T;

- mi—the maximum expected demand (in pallet units) for the product i during T;

- Ri—a variable that represents a number of replenishments of the product i during T;

- Zi—the number of pallet units of the product i assigned to the OPA at the beginning of T;

- Q—total OPA capacity (expressed in the number of pallet locations);

- qi—the number of pallets in the OPA assigned to the product i, i = 1, …, N; qi = 1, …, mi;

- P(qi)—the probability of satisfying the demand for the product i from the OPA during T from the qi pallets of that product;

- . The satisfaction rate is derived from the value of the standard Laplace function . Analogously, P(0) = 0, and for every P(qi) = 1;

- P—the probability of satisfying the demand from the OPA during T.;

- Cop (Q)—specific order-picking costs;

- nd—total number of orders in the observed period;

- lOPA—length of the order-picking path; corresponds to the number of pallet locations (OPA capacity) in OPA expressed in kilometers;

- vop—the average speed of an order-picker in OPA (km/h);

- top—hourly salary of one order-picker during T (EUR/h);

- Cr (Q)—replenishments costs of the OPA in the observed period of time;

- tr—the price of one replenishment (€/replenishment);

- Cse (Q)—specific costs of space and equipment in the OPA;

- tse—unit price per pallet location (space + equipment) (EUR/pallet location) for the observed period;

- S—number of remaining unallocated pallet places;

- qi*—optimal number of products allocated to the OPA;

- E_repl—the number of emergency replenishments of considered product in a simulation model;

- N_repl—the number of regular replenishments of considered product in a simulation model;

- Tmax—the length of a simulation run (in days);

- Sim_replications—the number of simulations run replications for a given solution.

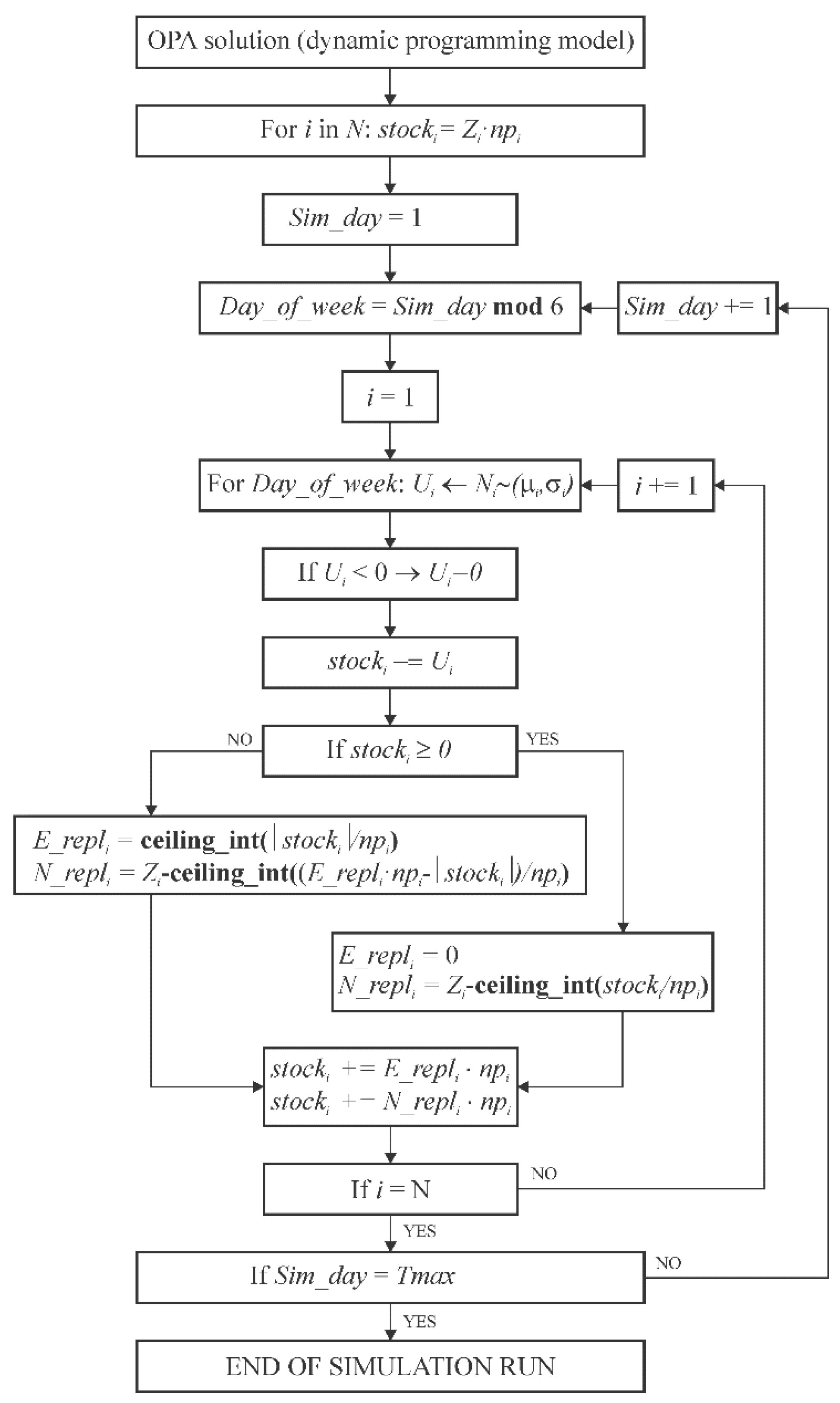

4.2. Simulation Model

| Algorithm 1: Pseudo-code of the simulation model. |

| for OPA_sol in DP_solutions: # OPA_sol represents a variant of representative demand data |

| for sim_iter in Sim_replications: |

| for Sim_day in range (1, Tmax): #where Sim_day =1 is Monday |

| define Day_of_week for Sim_day #what is the day in a week |

| for i in range (1, N): #for all products |

| for Day_of_week: Ui ← Ni~(μi, δi) # generate demand Ui for product i |

| stocki = stocki – Ui |

| if stocki <= 0: # if stocki has negative value |

| E_repli ← ceiling_int(abs(stocki)) # emergency replenishment (full pallets) |

| stocki = stocki + E_repli |

| if stocki < Zi: # if stocki is lower than planned value Zi in OPA |

| N_repli ← ceiling_int(Zi - stocki) # regular replenishment (full pallets) |

| stocki = stocki + N_repli |

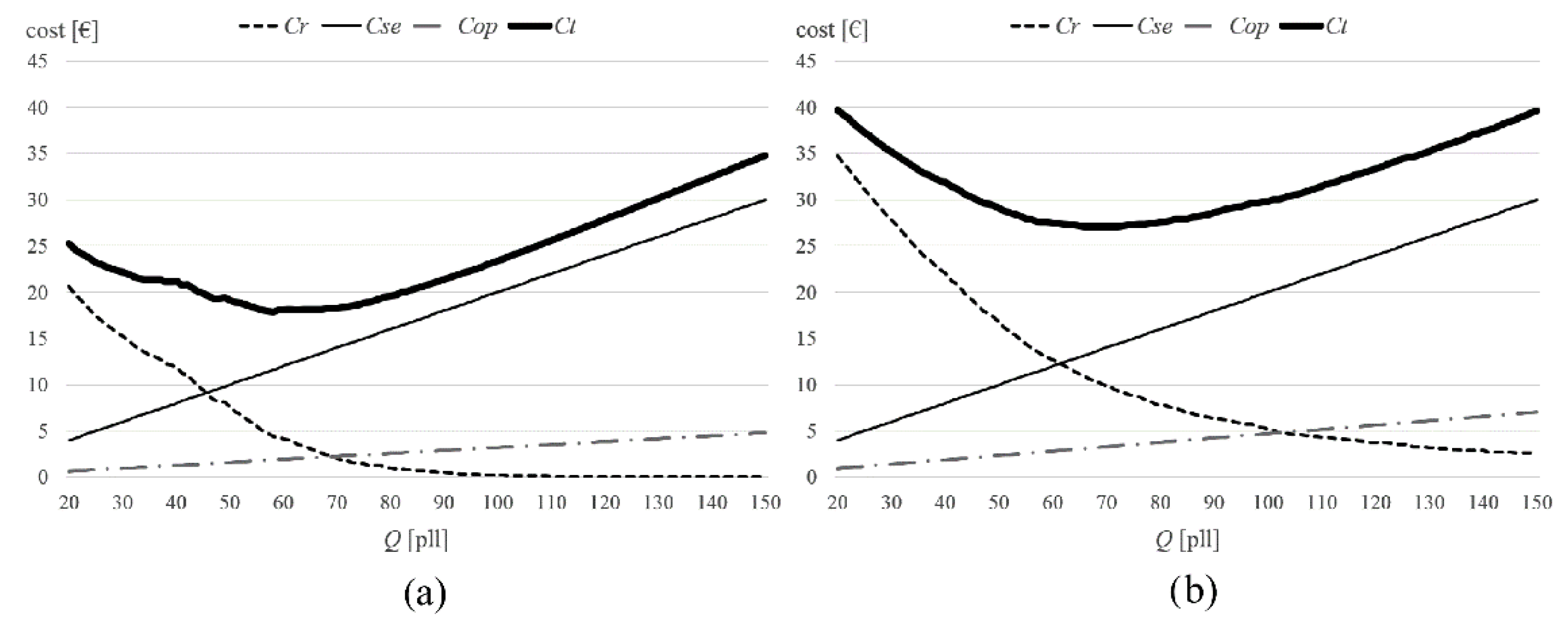

4.3. Cost Model

5. Case Study Computational Results

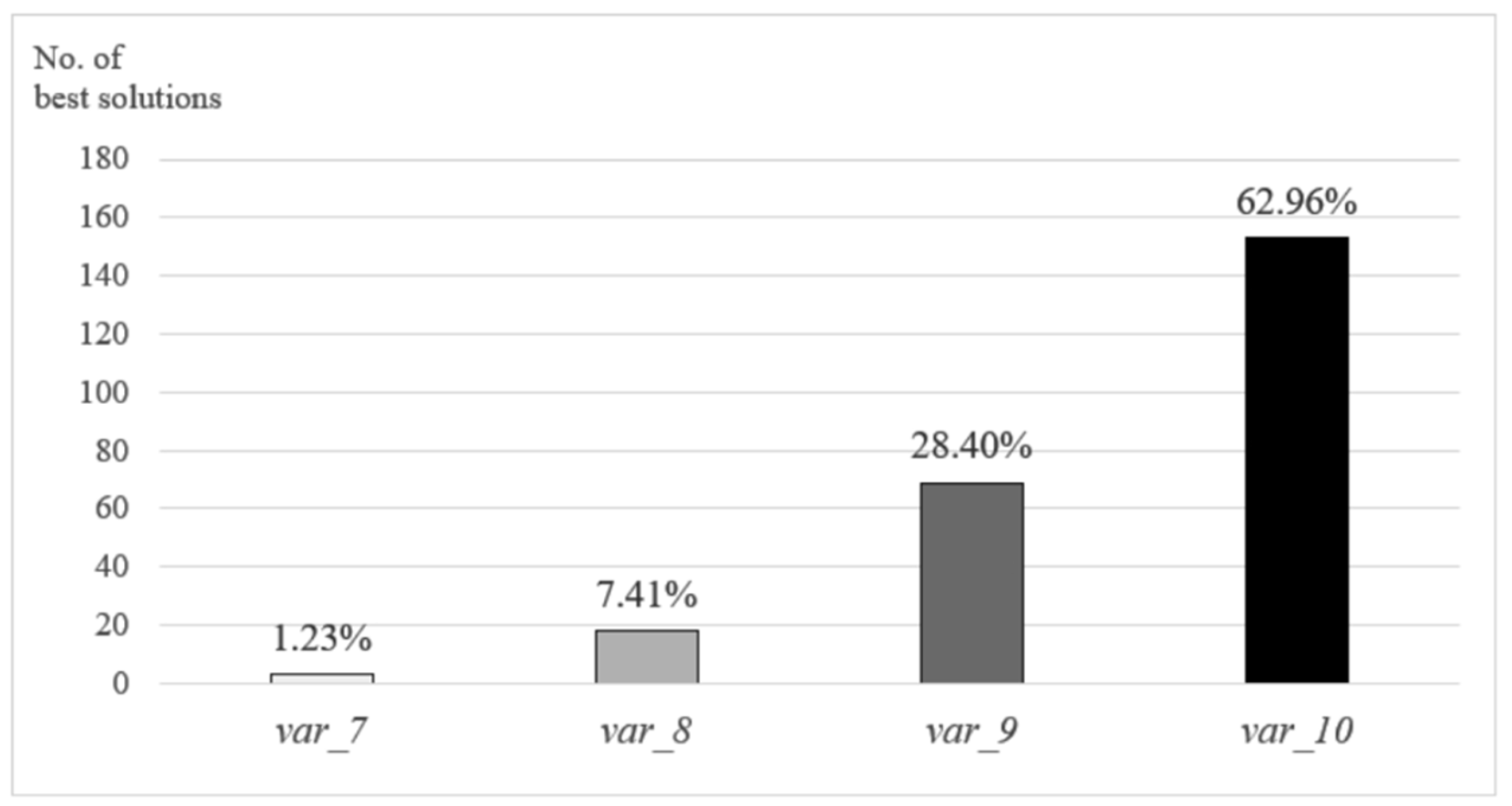

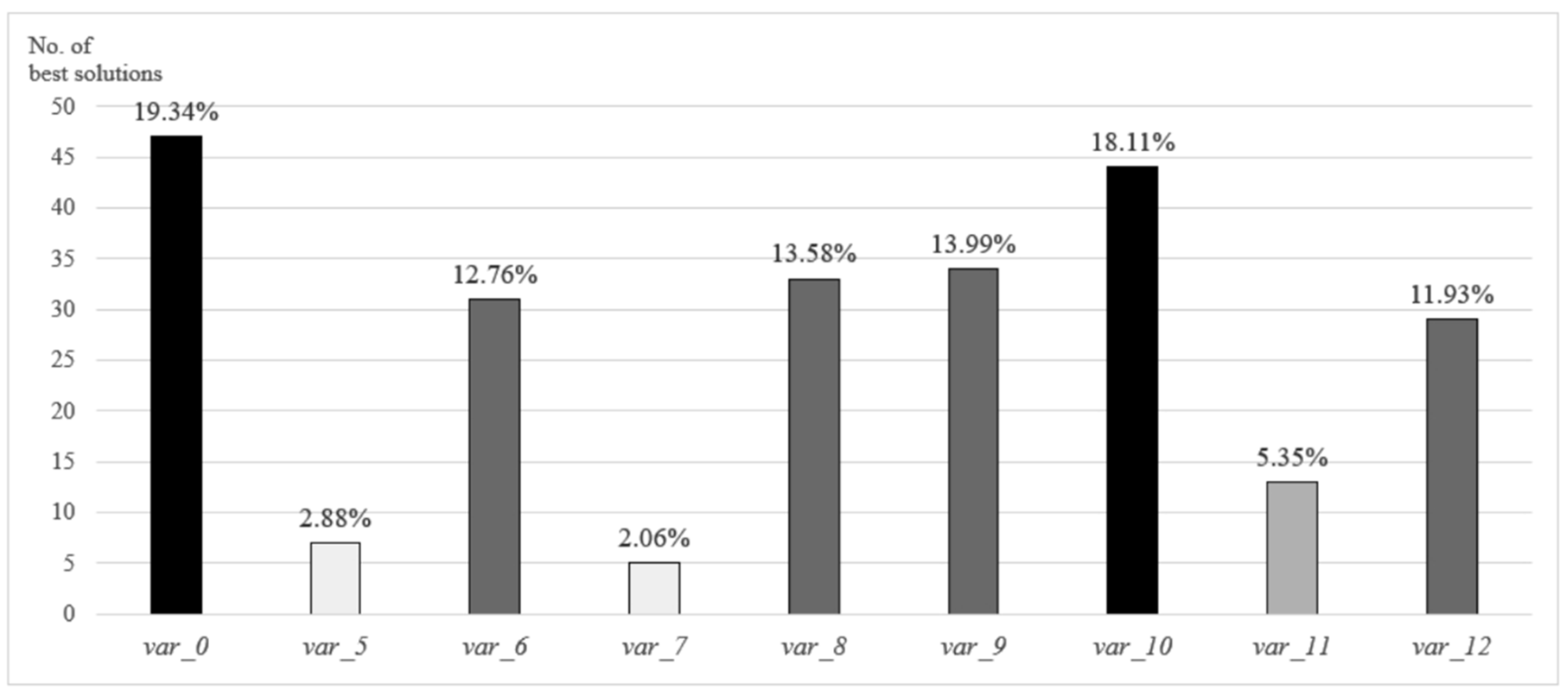

- var_0—daily demand mean and standard deviation calculated from the entire sample of 12 weeks;

- var_1, var_3, var_5, var_7, var_9, var_11—demand’s mean and standard deviation are equal to a day with 1st, 2nd, 3rd, 4th, 5th and 6th highest mean value, respectively (including average daily demand in the set of days);

- var_2, var_4, var_6, var_8, var_10, var_12—demand’s mean and standard deviation are equal to a day with 1st, 2nd, 3rd, 4th, 5th and 6th highest value of μi+3σi, respectively (including average daily demand in the set of days).

- The average driving speed of order-picker Vop (1.5 km/h);

- The cost of the order-picker (2 EUR/h);

- The width of the pallet location (1 m);

- Storage price (prices were based on the research and analysis of the prices of services provided by local providers with correction (reduction) for a profit rate of 15–20%) per week (0.2 EUR/pal per day);

- Price per emergency replenishment (1 EUR/pal).

5.1. Sensitivity Analysis of the Proposed Approach

- For set I, all parameters could take 90%, 100% or 110% of their original values from the case study;

- For set II, all parameters could take 50%, 100% or 200% of their original values from the case study.

5.1.1. Computational Results for Set I—Low Variations

5.1.2. Computational Results for Set II—High Variations

| Input Data Intensity | var_0 | var_1 | var_2 | var_3 | var_4 | var_5 | var_6 | var_7 | var_8 | var_9 | var_10 | var_11 | var_12 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 90% | 26 | 77 | 29 | 70 | 29 | 72 | 28 | 77 | 27 | 77 | 26 | 76 | 27 | 77 | 26 | 73 | 26 | 72 | 26 | 67 | 26 | 66 | 27 | 63 | 26 | 63 | 71.7 | |

| μi | 100% | 28 | 80 | 30 | 74 | 30 | 74 | 29 | 80 | 29 | 79 | 28 | 77 | 28 | 79 | 27 | 76 | 27 | 74 | 27 | 70 | 27 | 69 | 28 | 66 | 28 | 65 | 74.1 |

| 110% | 29 | 82 | 31 | 76 | 31 | 74 | 30 | 81 | 30 | 83 | 29 | 80 | 29 | 83 | 28 | 79 | 28 | 76 | 28 | 74 | 28 | 71 | 29 | 71 | 29 | 72 | 76.9 | |

| 90% | 26 | 76 | 28 | 72 | 29 | 70 | 27 | 80 | 27 | 81 | 26 | 75 | 26 | 76 | 26 | 72 | 26 | 71 | 26 | 67 | 26 | 66 | 27 | 63 | 27 | 63 | 71.8 | |

| σi | 100% | 28 | 80 | 30 | 74 | 30 | 74 | 29 | 80 | 29 | 78 | 28 | 78 | 28 | 79 | 27 | 76 | 27 | 74 | 27 | 70 | 27 | 69 | 28 | 67 | 28 | 67 | 74.4 |

| 110% | 29 | 83 | 31 | 74 | 32 | 75 | 30 | 78 | 30 | 79 | 29 | 80 | 29 | 84 | 29 | 80 | 29 | 77 | 28 | 73 | 28 | 71 | 29 | 70 | 29 | 70 | 76.5 | |

| 90% | 27 | 76 | 29 | 70 | 29 | 69 | 28 | 73 | 28 | 73 | 27 | 75 | 27 | 76 | 26 | 72 | 26 | 72 | 26 | 67 | 26 | 65 | 27 | 63 | 27 | 63 | 70.5 | |

| tr | 100% | 28 | 80 | 30 | 73 | 30 | 73 | 29 | 79 | 29 | 80 | 28 | 78 | 28 | 80 | 27 | 76 | 27 | 74 | 27 | 70 | 27 | 69 | 28 | 66 | 28 | 66 | 74.1 |

| 110% | 28 | 83 | 31 | 77 | 31 | 77 | 30 | 86 | 29 | 85 | 28 | 81 | 28 | 83 | 28 | 79 | 28 | 77 | 28 | 74 | 28 | 72 | 29 | 70 | 29 | 71 | 78.1 | |

| 90% | 27 | 80 | 30 | 74 | 30 | 75 | 28 | 81 | 28 | 81 | 27 | 79 | 27 | 80 | 27 | 76 | 27 | 75 | 27 | 71 | 27 | 69 | 28 | 67 | 27 | 67 | 75.1 | |

| tse | 100% | 28 | 80 | 30 | 73 | 30 | 73 | 29 | 79 | 29 | 79 | 28 | 78 | 28 | 80 | 27 | 76 | 27 | 74 | 27 | 70 | 27 | 68 | 28 | 66 | 28 | 67 | 74.2 |

| 110% | 28 | 79 | 30 | 73 | 30 | 72 | 29 | 78 | 29 | 78 | 28 | 77 | 28 | 79 | 28 | 75 | 28 | 74 | 27 | 69 | 27 | 68 | 28 | 66 | 28 | 66 | 73.4 | |

| 90% | 26 | 82 | 28 | 76 | 29 | 76 | 27 | 85 | 27 | 84 | 26 | 81 | 26 | 82 | 26 | 79 | 26 | 77 | 26 | 73 | 26 | 71 | 27 | 70 | 26 | 70 | 77.5 | |

| top | 100% | 28 | 80 | 30 | 73 | 30 | 73 | 29 | 80 | 29 | 79 | 28 | 78 | 28 | 80 | 27 | 76 | 27 | 74 | 27 | 70 | 27 | 69 | 28 | 65 | 28 | 66 | 74.1 |

| 110% | 29 | 77 | 31 | 71 | 31 | 70 | 30 | 74 | 30 | 74 | 29 | 75 | 29 | 77 | 29 | 73 | 29 | 72 | 28 | 68 | 28 | 66 | 29 | 63 | 29 | 63 | 71.1 | |

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Derpich, I.; Sepúlveda, J.M.; Barraza, R.; Castro, F. Warehouse Optimization: Energy Efficient Layout and Design. Mathematics 2022, 10, 1705. [Google Scholar] [CrossRef]

- Gu, J.; Goetschalckx, M.; McGinnis, L.F. Research on Warehouse Operation: A Comprehensive Review. Eur. J. Oper. Res. 2007, 177, 1–21. [Google Scholar] [CrossRef]

- Gu, J.; Goetschalckx, M.; McGinnis, L.F. Research on Warehouse Design and Performance Evaluation: A Comprehensive Review. Eur. J. Oper. Res. 2010, 203, 539–549. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F.; Zhao, J.; Yang, J.; Tan, C.; Zhou, L. Performance Analysis of Picking Path Strategies in Chevron Layout Warehouse. Mathematics 2022, 10, 395. [Google Scholar] [CrossRef]

- de Koster, R.; Le-Duc, T.; Roodbergen, K.J. Design and Control of Warehouse Order Picking: A Literature Review. Eur. J. Oper. Res. 2007, 182, 481–501. [Google Scholar] [CrossRef]

- Djurdjević, D. Development of Models for the Design of Order-Picking Area; Faculty of Transport and Traffic Engineering, University of Belgrade: Belgrade, Serbia, 2013. [Google Scholar]

- Djurdjević, D.; Miljuš, M. The Procedure Proposal for Order-Pick Area Design. J. Teh. Vjesn.–Tech. Gaz. 2013, 20, 85–89. [Google Scholar]

- Baker, P.; Canessa, M. Warehouse Design: A Structured Approach. Eur. J. Oper. Res. 2009, 193, 425–436. [Google Scholar] [CrossRef]

- Rouwenhorst, B.; Reuter, B.; Stockrahm, V.; van Houtum, G.J.; Mantel, R.J.; Zijm, W.H.M. Warehouse Design and Control: Framework and Literature Review. Eur. J. Oper. Res. 2000, 122, 515–533. [Google Scholar] [CrossRef]

- Gu, J.; Goetschalckx, M.; McGinnis, L.F. Solving the Forward-Reserve Allocation Problem in Warehouse Order Picking Systems. J. Oper. Res. Soc. 2010, 61, 1013–1021. [Google Scholar] [CrossRef]

- van den Berg, J.P.; Sharp, G.P.; Gademann, A.J.R.M.; Pochet, Y. Forward-Reserve Allocation in a Warehouse with Unit-Load Replenishments. Eur. J. Oper. Res. 1998, 111, 98–113. [Google Scholar] [CrossRef]

- van Gils, T.; Ramaekers, K.; Caris, A.; de Koster, R.B.M. Designing Efficient Order Picking Systems by Combining Planning Problems: State-of-the-Art Classification and Review. Eur. J. Oper. Res. 2018, 267, 1–15. [Google Scholar] [CrossRef]

- Hackman, S.T.; Rosenblatt, M.J.; Olin, J.M. Allocating Items to an Automated Storage and Retrieval System. IIE Trans. 1990, 22, 7–14. [Google Scholar] [CrossRef]

- Frazelle, E.H.; Hackman, S.T.; Passy, U.; Platzman, L.K. The Forward-Reserve Problem. In Optimization in Industry 2: Mathematical Programming and Modeling Techniques in Practice; Ciriani, T., Leachman, R., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1994; pp. 43–61. ISBN 978-0-47194-192-7. [Google Scholar]

- Bartholdi, J.J.; Hackman, S.T. Allocating Space in a Forward Pick Area of a Distribution Center for Small Parts. IIE Trans. 2008, 40, 1046–1053. [Google Scholar] [CrossRef]

- Bahrami, B.; Aghezzaf, E.-H.; Limère, V. Enhancing the Order Picking Process through a New Storage Assignment Strategy in Forward-Reserve Area. Int. J. Prod. Res. 2019, 57, 6593–6614. [Google Scholar] [CrossRef]

- Guo, X.; Chen, R.; Du, S.; Yu, Y. Storage Assignment for Newly Arrived Items in Forward Picking Areas with Limited Open Locations. Transp. Res. Part E Logist. Transp. Rev. 2021, 151, 102359. [Google Scholar] [CrossRef]

- Mirzaei, M.; Zaerpour, N.; de Koster, R. The Impact of Integrated Cluster-Based Storage Allocation on Parts-to-Picker Warehouse Performance. Transp. Res. Part E Logist. Transp. Rev. 2021, 146, 102207. [Google Scholar] [CrossRef]

- Carafí, F.; Zevallos, A.; Gonzalez Ramirez, R.; Velez-Gallego, M. On the Effect of Product Demand Correlation on the Storage Space Allocation Problem in a Fast-Pick Area of a Warehouse. In Proceedings of the International Conference on Computational Logistics, Enschede, The Netherlands, 26–29 September 2021; Lecture Notes in Computer Science. Springer International Publishing: Berlin/Heidelberg, Germany, 2021; pp. 282–295, ISBN 978-3-03087-671-5. [Google Scholar]

- Wu, W.; de Koster, R.B.M.; Yu, Y. Forward-Reserve Storage Strategies with Order Picking: When Do They Pay Off? IISE Trans. 2020, 52, 961–976. [Google Scholar] [CrossRef]

- Shah, B. What Should Be Lean Buffer Threshold for the Forward-Reserve Warehouse? Int. J. Product. Perform. Manag. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Walter, R.; Boysen, N.; Scholl, A. The Discrete Forward–Reserve Problem–Allocating Space, Selecting Products, and Area Sizing in Forward Order Picking. Eur. J. Oper. Res. 2013, 229, 585–594. [Google Scholar] [CrossRef]

- Thomas, L.M.; Meller, R.D. Developing Design Guidelines for a Case-Picking Warehouse. Int. J. Prod. Econ. 2015, 170, 741–762. [Google Scholar] [CrossRef]

- Jiang, M.; Leung, K.H.; Lyu, Z.; Huang, G.Q. Picking-Replenishment Synchronization for Robotic Forward-Reserve Warehouses. Transp. Res. Part E: Logist. Transp. Rev. 2020, 144, 102138. [Google Scholar] [CrossRef]

- Altarazi, S.A.; Ammouri, M.M. Concurrent Manual-Order-Picking Warehouse Design: A Simulation-Based Design of Experiments Approach. Int. J. Prod. Res. 2018, 56, 7103–7121. [Google Scholar] [CrossRef]

- Caron, F.; Marchet, G.; Perego, A. Optimal Layout in Low-Level Picker-to-Part Systems. Int. J. Prod. Res. 2000, 38, 101–117. [Google Scholar] [CrossRef]

- Petersen, C.G. Considerations in Order Picking Zone Configuration. Int. J. Oper. Prod. Manag. 2002, 22, 793–805. [Google Scholar] [CrossRef]

- Petersen, C.G.; Aase, G. A Comparison of Picking, Storage, and Routing Policies in Manual Order Picking. Int. J. Prod. Econ. 2004, 92, 11–19. [Google Scholar] [CrossRef]

- Roodbergen, K.J.; Vis, I.F.A. A Model for Warehouse Layout. IIE Trans. 2006, 38, 799–811. [Google Scholar] [CrossRef]

- Roodbergen, K.J.; Sharp, G.P.; Vis, I.F.A. Designing the Layout Structure of Manual Order Picking Areas in Warehouses. IIE Trans. 2008, 40, 1032–1045. [Google Scholar] [CrossRef]

- Roodbergen, K.J.; Vis, I.F.A.; Taylor, G.D. Simultaneous Determination of Warehouse Layout and Control Policies. Int. J. Prod. Res. 2015, 53, 3306–3326. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Zhang, M.; Grosse, E.H.; Glock, C.H. Hybrid Order Picking: A Simulation Model of a Joint Manual and Autonomous Order Picking System. Comput. Ind. Eng. 2022, 167, 107981. [Google Scholar] [CrossRef]

- Lolli, F.; Lodi, F.; Giberti, C.; Coruzzolo, A.M.; Marinello, S. Order Picking Systems: A Queue Model for Dimensioning the Storage Capacity, the Crew of Pickers, and the AGV Fleet. Math. Probl. Eng. 2022, 2022, e6318659. [Google Scholar] [CrossRef]

- Hackman, S.T.; Platzman, L.K. Near-Optimal Solution of Generalized Resource Allocation Problems with Large Capacities. Oper. Res. 1990, 38, 902–910. [Google Scholar] [CrossRef]

- Dudziński, K.; Walukiewicz, S. Exact Methods for the Knapsack Problem and Its Generalizations. Eur. J. Oper. Res. 1987, 28, 3–21. [Google Scholar] [CrossRef]

| Paper | Problem to Be Solved | Implemented Method | ||

|---|---|---|---|---|

| Size of the OPA | Products to Be Stored in the OPA (Assignment) | Quantity of Products to Be Stored in the OPA (Allocation) | ||

| Hackman et al. [13] | * | * | Greedy heuristic | |

| Frazelle et al. [14] | * | * | * | Greedy heuristic |

| Van den Berg et al. [11] | * | * | Greedy heuristic | |

| Bartholdi and Hackman [15] | * | Analytical, optimal | ||

| Gu, et al. [10] | * | * | Branch and bound, optimal | |

| Bahrami et al. [16] | * | heuristic | ||

| Guo et al. [17] | * | Analytical, heuristics | ||

| Mirzaei et al. [18] | * | * | Heuristic | |

| Carafi et al. [19] | * | Analytical, heuristic | ||

| Wu et al. [20] | * | * | Analytical | |

| Shah [21] | * | Analytical | ||

| Product | i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | Avg μ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| The Number of Case Units Per Pall. | nci | 50 | 84 | 50 | 60 | 24 | 50 | 105 | 70 | 105 | 96 | 105 | 40 | 18 | 18 | 60 | 32 | 96 | 24 | 50 | 96 | |

| Monday | μi | 36.03 | 249.19 | 59.15 | 117.24 | 13.05 | 41.83 | 131.03 | 157.75 | 166.56 | 111.55 | 71.95 | 56.63 | 14.00 | 10.67 | 37.00 | 28.00 | 161.84 | 24.45 | 37.56 | 92.74 | 80.91 |

| σi | 31.56 | 265.86 | 57.66 | 290.46 | 17.52 | 29.91 | 387.04 | 354.30 | 94.01 | 157.46 | 60.36 | 83.04 | 13.03 | 9.05 | 35.77 | 20.00 | 444.84 | 28.40 | 36.65 | 94.05 | ||

| Tuesday | μi | 59.28 | 262.27 | 58.26 | 68.88 | 23.00 | 60.95 | 89.06 | 107.38 | 166.67 | 153.28 | 93.77 | 23.29 | 18.68 | 23.71 | 30.62 | 14.50 | 85.33 | 21.93 | 40.71 | 109.03 | 75.53 |

| σi | 57.04 | 443.57 | 52.29 | 47.63 | 23.33 | 53.61 | 347.36 | 350.12 | 47.14 | 153.58 | 73.12 | 23.69 | 19.61 | 19.65 | 29.34 | 4.50 | 60.31 | 26.63 | 38.07 | 80.97 | ||

| Wednesday | μi | 75.28 | 330.56 | 54.00 | 66.93 | 24.40 | 55.86 | 129.59 | 149.98 | 120.00 | 155.33 | 77.60 | 21.00 | 17.87 | 15.73 | 97.63 | 16.00 | 232.36 | 23.00 | 41.59 | 184.14 | 94.44 |

| σi | 59.46 | 519.88 | 32.42 | 43.87 | 32.37 | 47.39 | 319.71 | 394.06 | 40.00 | 179.02 | 57.01 | 14.71 | 16.03 | 11.57 | 89.40 | 4.00 | 527.50 | 32.95 | 18.58 | 305.38 | ||

| Thursday | μi | 74.94 | 333.85 | 72.60 | 65.87 | 29.25 | 40.67 | 227.96 | 144.77 | 399.00 | 119.47 | 79.13 | 20.53 | 18.31 | 14.20 | 43.75 | 29.75 | 336.45 | 33.00 | 30.64 | 190.77 | 115.25 |

| σi | 53.21 | 480.76 | 56.87 | 35.98 | 32.31 | 55.38 | 582.64 | 249.98 | 80.00 | 84.86 | 60.16 | 11.09 | 16.56 | 11.51 | 40.12 | 8.44 | 930.11 | 50.24 | 19.33 | 260.99 | ||

| Friday | μi | 50.78 | 377.07 | 39.53 | 108.68 | 16.08 | 38.30 | 197.31 | 142.55 | 245.64 | 112.52 | 84.05 | 43.67 | 15.63 | 19.43 | 104.80 | 61.00 | 705.93 | 60.86 | 54.37 | 156.36 | 131.73 |

| σi | 47.38 | 514.24 | 25.05 | 158.30 | 16.37 | 28.54 | 578.33 | 348.32 | 106.99 | 86.33 | 98.43 | 60.83 | 15.45 | 20.83 | 55.26 | 10.00 | 1573.86 | 115.51 | 47.84 | 165.38 | ||

| Saturday | μi | 40.81 | 255.81 | 49.19 | 65.52 | 20.96 | 22.13 | 188.35 | 119.59 | 10.00 | 93.65 | 103.97 | 228.33 | 15.20 | 21.47 | 25.86 | 62.00 | 524.24 | 19.25 | 46.77 | 124.83 | 101.90 |

| σi | 32.14 | 294.81 | 25.80 | 55.02 | 20.06 | 23.13 | 482.21 | 300.94 | 10.00 | 63.94 | 63.68 | 188.48 | 12.41 | 16.77 | 29.45 | 52.00 | 1357.56 | 22.53 | 28.12 | 91.70 | ||

| Daily demand (var_0) | μi | 56.44 | 299.70 | 53.88 | 81.84 | 21.73 | 44.50 | 156.62 | 137.39 | 193.75 | 125.98 | 86.86 | 39.65 | 16.69 | 17.87 | 52.18 | 33.75 | 329.88 | 28.29 | 41.82 | 138.81 | 97.88 |

| σi | 50.73 | 433.08 | 42.24 | 142.29 | 25.58 | 43.33 | 457.97 | 341.46 | 102.59 | 134.08 | 70.58 | 73.87 | 15.92 | 16.31 | 57.84 | 28.95 | 967.71 | 52.01 | 34.03 | 188.53 |

| Products | i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | Avg μ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| var_1 | μi | 75.28 | 377.07 | 72.60 | 117.24 | 29.25 | 60.95 | 227.96 | 157.75 | 399.00 | 155.33 | 103.97 | 228.33 | 18.68 | 23.71 | 104.80 | 62.00 | 705.93 | 60.86 | 54.37 | 190.77 | 161.29 |

| σi | 59.46 | 514.24 | 56.87 | 290.46 | 32.31 | 53.61 | 582.64 | 354.30 | 40.00 | 179.02 | 63.68 | 188.48 | 19.61 | 19.65 | 55.26 | 52.00 | 1573.86 | 115.51 | 47.84 | 260.99 | ||

| var_2 | μi | 75.28 | 377.07 | 72.60 | 117.24 | 29.25 | 60.95 | 227.96 | 149.98 | 245.64 | 155.33 | 84.05 | 228.33 | 18.68 | 23.71 | 97.63 | 62.00 | 705.93 | 60.86 | 54.37 | 184.14 | 151.55 |

| σi | 59.46 | 514.24 | 56.87 | 290.46 | 32.31 | 53.61 | 582.64 | 394.06 | 106.99 | 179.02 | 98.43 | 188.48 | 19.61 | 19.65 | 89.40 | 52.00 | 1573.86 | 115.51 | 47.84 | 305.38 | ||

| var_3 | μi | 74.94 | 333.85 | 59.15 | 108.68 | 24.40 | 55.86 | 197.31 | 149.98 | 245.64 | 153.28 | 93.77 | 56.63 | 18.31 | 21.47 | 97.63 | 61.00 | 524.24 | 33.00 | 46.77 | 184.14 | 127.00 |

| σi | 53.21 | 480.76 | 57.66 | 158.30 | 32.37 | 47.39 | 578.33 | 394.06 | 106.99 | 153.58 | 73.12 | 83.04 | 16.56 | 16.77 | 89.40 | 10.00 | 1357.56 | 50.24 | 28.12 | 305.38 | ||

| var_4 | μi | 74.94 | 330.56 | 59.15 | 108.68 | 24.40 | 40.67 | 197.31 | 157.75 | 193.75 | 153.28 | 93.77 | 56.63 | 18.31 | 19.43 | 104.80 | 33.75 | 524.24 | 28.29 | 40.71 | 190.77 | 122.56 |

| σi | 53.21 | 519.88 | 57.66 | 158.30 | 32.37 | 55.38 | 578.33 | 354.30 | 102.59 | 153.58 | 73.12 | 83.04 | 16.56 | 20.83 | 55.26 | 28.95 | 1357.56 | 52.01 | 38.07 | 260.99 | ||

| var_5 | μi | 59.28 | 330.56 | 58.26 | 81.84 | 23.00 | 44.50 | 188.35 | 144.77 | 193.75 | 125.98 | 86.86 | 43.67 | 17.87 | 19.43 | 52.18 | 33.75 | 336.45 | 28.29 | 41.82 | 156.36 | 103.35 |

| σi | 57.04 | 519.88 | 52.29 | 142.29 | 23.33 | 43.33 | 482.21 | 249.98 | 102.59 | 134.08 | 70.58 | 60.83 | 16.03 | 20.83 | 57.84 | 28.95 | 930.11 | 52.01 | 34.03 | 165.38 | ||

| var_6 | μi | 59.28 | 333.85 | 58.26 | 81.84 | 21.73 | 55.86 | 188.35 | 142.55 | 193.75 | 111.55 | 86.86 | 39.65 | 17.87 | 21.47 | 52.18 | 61.00 | 329.88 | 33.00 | 37.56 | 138.81 | 103.27 |

| σi | 57.04 | 480.76 | 52.29 | 142.29 | 25.58 | 47.39 | 482.21 | 348.32 | 102.59 | 157.46 | 70.58 | 73.87 | 16.03 | 16.77 | 57.84 | 10.00 | 967.71 | 50.24 | 36.65 | 188.53 | ||

| var_7 | μi | 56.44 | 299.70 | 54.00 | 68.88 | 21.73 | 41.83 | 156.62 | 142.55 | 166.67 | 119.47 | 84.05 | 39.65 | 16.69 | 17.87 | 43.75 | 29.75 | 329.88 | 24.45 | 41.59 | 138.81 | 94.72 |

| σi | 50.73 | 433.08 | 32.42 | 47.63 | 25.58 | 29.91 | 457.97 | 348.32 | 47.14 | 84.86 | 98.43 | 73.87 | 15.92 | 16.31 | 40.12 | 8.44 | 967.71 | 28.40 | 18.58 | 188.53 | ||

| var_8 | μi | 56.44 | 299.70 | 53.88 | 65.52 | 23.00 | 44.50 | 156.62 | 137.39 | 166.56 | 125.98 | 103.97 | 43.67 | 16.69 | 17.87 | 43.75 | 28.00 | 336.45 | 23.00 | 41.82 | 156.36 | 97.06 |

| σi | 50.73 | 433.08 | 42.24 | 55.02 | 23.33 | 43.33 | 457.97 | 341.46 | 94.01 | 134.08 | 63.68 | 60.83 | 15.92 | 16.31 | 40.12 | 20.00 | 930.11 | 32.95 | 34.03 | 165.38 | ||

| var_9 | μi | 50.78 | 262.27 | 53.88 | 66.93 | 20.96 | 40.67 | 131.03 | 137.39 | 166.56 | 112.52 | 79.13 | 23.29 | 15.63 | 15.73 | 37.00 | 28.00 | 232.36 | 23.00 | 40.71 | 124.83 | 83.13 |

| σi | 47.38 | 443.57 | 42.24 | 43.87 | 20.06 | 55.38 | 387.04 | 341.46 | 94.01 | 86.33 | 60.16 | 23.69 | 15.45 | 11.57 | 35.77 | 20.00 | 527.50 | 32.95 | 38.07 | 91.70 | ||

| var_10 | μi | 50.78 | 262.27 | 54.00 | 68.88 | 20.96 | 41.83 | 131.03 | 107.38 | 166.67 | 119.47 | 79.13 | 23.29 | 15.63 | 15.73 | 37.00 | 29.75 | 232.36 | 24.45 | 46.77 | 124.83 | 82.61 |

| σi | 47.38 | 443.57 | 32.42 | 47.63 | 20.06 | 29.91 | 387.04 | 350.12 | 47.14 | 84.86 | 60.16 | 23.69 | 15.45 | 11.57 | 35.77 | 8.44 | 527.50 | 28.40 | 28.12 | 91.70 | ||

| var_11 | μi | 40.81 | 255.81 | 49.19 | 65.87 | 16.08 | 38.30 | 129.59 | 119.59 | 120.00 | 111.55 | 77.60 | 21.00 | 15.20 | 14.20 | 30.62 | 16.00 | 161.84 | 21.93 | 37.56 | 109.03 | 72.59 |

| σi | 32.14 | 294.81 | 25.80 | 35.98 | 16.37 | 28.54 | 319.71 | 300.94 | 40.00 | 157.46 | 57.01 | 14.71 | 12.41 | 11.51 | 29.34 | 4.00 | 444.84 | 26.63 | 36.65 | 80.97 | ||

| var_12 | μi | 40.81 | 255.81 | 49.19 | 66.93 | 13.05 | 38.30 | 89.06 | 119.59 | 120.00 | 112.52 | 71.95 | 21.00 | 14.00 | 14.20 | 30.62 | 14.50 | 161.84 | 21.93 | 41.59 | 92.74 | 69.48 |

| σi | 32.14 | 294.81 | 25.80 | 43.87 | 17.52 | 28.54 | 347.36 | 300.94 | 40.00 | 86.33 | 60.36 | 14.71 | 13.03 | 11.51 | 29.34 | 4.50 | 444.84 | 26.63 | 18.58 | 94.05 |

| DYNAMIC PROGRAMMING MODEL | SIMULATION MODEL (Average Results from 500 runs) | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | var0 | var1 | var2 | var3 | var4 | var5 | var6 | var7 | var8 | var9 | var10 | var11 | var12 | var0 | var1 | var2 | var3 | var4 | var5 | var6 | var7 | var8 | var9 | var10 | var11 | var12 |

| 49 | 25.65 | 45.55 | 45.36 | 34.47 | 33.82 | 26.88 | 28.03 | 23.88 | 24.60 | 19.59 | 19.43 | 15.43 | 15.09 | 29.66 | 33.19 | 32.71 | 31.29 | 31.47 | 30.33 | 30.58 | 29.54 | 29.95 | 29.25 | 29.40 | 29.46 | 29.43 |

| 50 | 25.39 | 45.19 | 45.37 | 34.52 | 33.38 | 26.72 | 28.10 | 23.98 | 24.38 | 19.31 | 19.15 | 15.27 | 15.03 | 29.39 | 32.78 | 32.86 | 31.29 | 30.99 | 30.11 | 30.60 | 29.36 | 29.70 | 28.93 | 29.07 | 29.27 | 29.25 |

| 54 | 25.58 | 44.33 | 44.37 | 34.01 | 32.33 | 26.22 | 26.87 | 23.95 | 24.09 | 19.23 | 18.41 | 15.19 | 15.17 | 29.46 | 32.02 | 31.99 | 31.01 | 30.02 | 29.45 | 29.34 | 29.14 | 29.08 | 28.55 | 28.18 | 28.48 | 28.50 |

| 58 | 25.37 | 43.50 | 43.67 | 33.11 | 32.61 | 26.10 | 27.00 | 23.61 | 23.73 | 18.76 | 17.89 | 15.37 | 15.11 | 28.95 | 31.65 | 31.60 | 30.04 | 30.12 | 29.18 | 29.49 | 28.64 | 28.59 | 27.79 | 27.55 | 28.34 | 28.08 |

| 60 | 25.28 | 43.19 | 43.03 | 33.20 | 32.05 | 25.98 | 26.86 | 23.63 | 23.75 | 18.53 | 18.04 | 15.52 | 15.22 | 28.86 | 31.33 | 30.88 | 30.25 | 29.52 | 29.09 | 29.24 | 28.60 | 28.47 | 27.52 | 27.49 | 28.11 | 27.95 |

| 61 | 25.40 | 42.87 | 43.06 | 33.31 | 32.16 | 25.72 | 26.70 | 23.73 | 23.89 | 18.67 | 18.18 | 15.57 | 15.29 | 28.87 | 30.99 | 30.95 | 30.24 | 29.57 | 28.85 | 29.10 | 28.66 | 28.50 | 27.51 | 27.48 | 28.01 | 27.96 |

| 65 | 25.39 | 42.08 | 42.07 | 32.58 | 31.77 | 25.72 | 26.57 | 22.92 | 23.52 | 18.66 | 18.17 | 16.04 | 15.79 | 28.58 | 30.33 | 30.71 | 29.52 | 29.29 | 28.56 | 28.71 | 27.83 | 28.02 | 27.25 | 27.17 | 28.04 | 27.92 |

| 67 | 25.63 | 41.67 | 41.90 | 32.38 | 31.73 | 25.78 | 26.39 | 23.04 | 22.91 | 18.60 | 18.15 | 16.33 | 16.06 | 28.63 | 30.51 | 30.64 | 29.43 | 29.14 | 28.54 | 28.53 | 27.73 | 27.56 | 27.13 | 27.08 | 28.08 | 28.04 |

| 68 | 25.58 | 41.42 | 41.65 | 32.21 | 31.77 | 25.42 | 26.50 | 22.76 | 23.04 | 18.61 | 18.23 | 16.44 | 16.25 | 28.60 | 30.30 | 30.35 | 29.28 | 29.28 | 28.12 | 28.61 | 27.55 | 27.61 | 27.10 | 27.08 | 28.17 | 27.95 |

| 70 | 25.62 | 40.98 | 41.23 | 32.08 | 31.47 | 25.41 | 26.48 | 22.77 | 22.77 | 18.71 | 18.30 | 16.78 | 16.56 | 28.57 | 29.85 | 30.16 | 29.28 | 28.99 | 28.12 | 28.55 | 27.53 | 27.41 | 27.16 | 27.08 | 28.39 | 28.02 |

| 72 | 24.95 | 40.70 | 40.92 | 31.85 | 31.24 | 25.12 | 25.81 | 22.33 | 22.78 | 18.91 | 18.43 | 17.12 | 16.91 | 27.92 | 30.09 | 30.19 | 29.08 | 28.83 | 27.81 | 27.92 | 27.25 | 27.41 | 27.19 | 27.11 | 28.29 | 28.15 |

| 75 | 24.74 | 40.44 | 40.62 | 31.63 | 31.31 | 24.98 | 25.71 | 22.33 | 22.45 | 19.31 | 18.85 | 17.64 | 17.52 | 27.82 | 30.20 | 30.26 | 28.93 | 28.95 | 27.68 | 27.86 | 27.31 | 27.25 | 27.26 | 27.31 | 28.49 | 28.14 |

| 76 | 24.73 | 40.23 | 40.42 | 31.59 | 31.25 | 25.08 | 25.44 | 22.37 | 22.60 | 19.39 | 18.94 | 17.84 | 17.70 | 27.79 | 30.03 | 30.07 | 28.95 | 28.93 | 27.81 | 27.67 | 27.36 | 27.35 | 27.35 | 27.39 | 28.55 | 28.24 |

| 77 | 24.75 | 40.13 | 40.34 | 31.68 | 31.41 | 25.01 | 25.54 | 22.24 | 22.64 | 19.46 | 19.14 | 18.04 | 17.87 | 27.80 | 29.91 | 30.22 | 29.11 | 29.10 | 27.82 | 27.80 | 27.33 | 27.39 | 27.34 | 27.39 | 28.54 | 28.26 |

| 78 | 24.51 | 40.06 | 40.23 | 31.85 | 31.52 | 24.77 | 25.31 | 22.33 | 22.81 | 19.60 | 19.33 | 18.24 | 18.07 | 27.66 | 30.03 | 30.15 | 29.26 | 29.27 | 27.63 | 27.65 | 27.40 | 27.45 | 27.41 | 27.42 | 28.50 | 28.33 |

| 79 | 24.31 | 39.95 | 40.18 | 31.99 | 31.66 | 24.57 | 25.44 | 22.40 | 22.69 | 19.70 | 19.45 | 18.43 | 18.26 | 27.55 | 29.98 | 30.35 | 29.36 | 29.36 | 27.53 | 27.79 | 27.48 | 27.40 | 27.49 | 27.42 | 28.58 | 28.49 |

| 81 | 24.49 | 39.76 | 39.93 | 31.76 | 31.30 | 24.40 | 25.39 | 22.40 | 22.96 | 20.01 | 19.72 | 18.78 | 18.66 | 27.68 | 30.10 | 30.13 | 29.11 | 28.98 | 27.49 | 27.79 | 27.56 | 27.48 | 27.61 | 27.68 | 28.76 | 28.64 |

| 85 | 24.38 | 39.77 | 40.12 | 31.44 | 30.64 | 24.86 | 25.32 | 22.65 | 23.10 | 20.66 | 20.45 | 19.60 | 19.48 | 27.72 | 30.35 | 30.50 | 28.97 | 28.65 | 27.84 | 27.85 | 27.79 | 27.62 | 27.75 | 27.95 | 28.98 | 28.56 |

| 86 | 24.47 | 39.95 | 40.07 | 31.12 | 30.77 | 24.74 | 25.19 | 22.77 | 23.19 | 20.83 | 20.61 | 19.82 | 19.68 | 27.81 | 30.50 | 30.54 | 28.79 | 28.81 | 27.82 | 27.82 | 27.90 | 27.72 | 27.88 | 28.11 | 28.69 | 28.76 |

| 93 | 24.88 | 40.46 | 40.64 | 30.88 | 30.98 | 25.32 | 25.68 | 23.61 | 23.98 | 22.07 | 21.94 | 21.29 | 21.18 | 28.18 | 31.66 | 31.60 | 28.94 | 29.10 | 28.45 | 28.34 | 28.53 | 28.24 | 28.76 | 29.10 | 29.75 | 29.57 |

| 111 | 27.48 | 39.43 | 39.42 | 31.49 | 31.12 | 27.77 | 28.13 | 26.75 | 26.99 | 25.88 | 25.82 | 25.32 | 25.21 | 30.64 | 32.05 | 32.03 | 30.86 | 30.80 | 30.73 | 30.69 | 31.29 | 30.71 | 31.31 | 31.69 | 32.68 | 32.54 |

| 116 | 28.39 | 39.37 | 39.73 | 32.17 | 31.79 | 28.63 | 29.02 | 27.77 | 27.95 | 26.99 | 26.95 | 26.45 | 26.34 | 31.51 | 32.42 | 32.62 | 31.60 | 31.57 | 31.53 | 31.56 | 32.04 | 31.60 | 32.16 | 32.65 | 33.60 | 33.42 |

| 117 | 28.54 | 39.59 | 39.51 | 32.37 | 31.78 | 28.85 | 29.21 | 28.00 | 28.17 | 27.22 | 27.18 | 26.68 | 26.57 | 31.66 | 32.61 | 32.62 | 31.73 | 31.69 | 31.72 | 31.76 | 32.25 | 31.73 | 32.28 | 32.77 | 33.75 | 33.56 |

| Q | Number of Pallet Locations Per Product in OPA | DYNAMIC PROGRAMMING MODEL | SIMULATION MODEL (Average Results) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CPU Time (Sec) | Max f * | Cr | Cse | Cop | Ct | ||||||

| 20 | [1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1] | 0.02 | 0.00 | 20.68 | 4.00 | 0.64 | 25.32 | 34.79 | 4.00 | 0.94 | 39.725 |

| 30 | [2, 1, 2, 2, 2, 1, 1, 1, 2, 2, 1, 1, 1, 2, 1, 2, 1, 1, 2, 2] | 0.06 | 0.00 | 15.20 | 6.00 | 0.96 | 22.16 | 27.78 | 6.00 | 1.41 | 35.191 |

| 40 | [2, 1, 2, 2, 2, 2, 2, 1, 3, 3, 2, 2, 2, 2, 2, 2, 1, 2, 2, 3] | 0.12 | 0.01 | 11.89 | 8.00 | 1.28 | 21.17 | 22.05 | 8.00 | 1.88 | 31.926 |

| 50 | [3, 4, 2, 3, 2, 2, 3, 2, 3, 3, 2, 2, 2, 2, 2, 2, 3, 3, 2, 3] | 0.20 | 0.07 | 7.55 | 10.00 | 1.60 | 19.15 | 16.73 | 10.00 | 2.35 | 29.073 |

| 51 | [3, 4, 2, 3, 2, 2, 3, 3, 3, 3, 2, 2, 2, 2, 2, 2, 3, 3, 2, 3] | 0.21 | 0.07 | 7.09 | 10.20 | 1.63 | 18.92 | 16.20 | 10.20 | 2.39 | 28.794 |

| 52 | [3, 4, 2, 3, 2, 2, 4, 3, 3, 3, 2, 2, 2, 2, 2, 2, 3, 3, 2, 3] | 0.22 | 0.08 | 6.77 | 10.40 | 1.66 | 18.84 | 15.78 | 10.40 | 2.44 | 28.621 |

| 53 | [3, 4, 2, 3, 2, 2, 4, 3, 3, 3, 2, 2, 2, 2, 2, 2, 4, 3, 2, 3] | 0.23 | 0.10 | 6.32 | 10.60 | 1.70 | 18.61 | 15.35 | 10.60 | 2.49 | 28.431 |

| 54 | [3, 5, 2, 3, 2, 2, 4, 3, 3, 3, 2, 2, 2, 2, 2, 2, 4, 3, 2, 3] | 0.24 | 0.11 | 5.88 | 10.80 | 1.73 | 18.41 | 14.85 | 10.80 | 2.53 | 28.181 |

| 55 | [3, 5, 2, 3, 2, 2, 4, 4, 3, 3, 2, 2, 2, 2, 2, 2, 4, 3, 2, 3] | 0.25 | 0.12 | 5.50 | 11.00 | 1.76 | 18.26 | 14.40 | 11.00 | 2.58 | 27.983 |

| 56 | [3, 5, 2, 3, 2, 2, 4, 4, 3, 3, 2, 2, 2, 2, 2, 2, 5, 3, 2, 3] | 0.28 | 0.13 | 5.11 | 11.20 | 1.79 | 18.10 | 14.00 | 11.20 | 2.63 | 27.827 |

| 57 | [3, 6, 2, 3, 2, 2, 4, 4, 3, 3, 2, 2, 2, 2, 2, 2, 5, 3, 2, 3] | 0.28 | 0.15 | 4.75 | 11.40 | 1.82 | 17.97 | 13.58 | 11.40 | 2.67 | 27.654 |

| 58 | [3, 6, 2, 3, 2, 2, 4, 5, 3, 3, 2, 2, 2, 2, 2, 2, 5, 3, 2, 3] | 0.29 | 0.16 | 4.44 | 11.60 | 1.86 | 17.89 | 13.23 | 11.60 | 2.72 | 27.548 |

| 59 | [3, 6, 2, 3, 2, 2, 4, 5, 3, 3, 2, 2, 3, 2, 2, 2, 5, 3, 2, 3] | 0.30 | 0.18 | 4.34 | 11.80 | 1.89 | 18.03 | 12.98 | 11.80 | 2.77 | 27.549 |

| 60 | [3, 6, 2, 3, 2, 2, 5, 5, 3, 3, 2, 2, 3, 2, 2, 2, 5, 3, 2, 3] | 0.32 | 0.20 | 4.12 | 12.00 | 1.92 | 18.04 | 12.68 | 12.00 | 2.81 | 27.491 |

| 61 | [3, 6, 2, 3, 3, 2, 5, 5, 3, 3, 2, 2, 3, 2, 2, 2, 5, 3, 2, 3] | 0.33 | 0.21 | 4.03 | 12.20 | 1.95 | 18.18 | 12.42 | 12.20 | 2.86 | 27.477 |

| 62 | [3, 6, 2, 3, 3, 2, 5, 5, 3, 3, 2, 2, 3, 2, 2, 2, 6, 3, 2, 3] | 0.34 | 0.23 | 3.71 | 12.40 | 1.98 | 18.09 | 12.05 | 12.40 | 2.91 | 27.362 |

| 63 | [3, 7, 2, 3, 3, 2, 5, 5, 3, 3, 2, 2, 3, 2, 2, 2, 6, 3, 2, 3] | 0.36 | 0.25 | 3.42 | 12.60 | 2.02 | 18.03 | 11.71 | 12.60 | 2.95 | 27.268 |

| 64 | [3, 7, 3, 3, 3, 2, 5, 5, 3, 3, 2, 2, 3, 2, 2, 2, 6, 3, 2, 3] | 0.37 | 0.27 | 3.34 | 12.80 | 2.05 | 18.18 | 11.42 | 12.80 | 3.00 | 27.225 |

| 65 | [3, 7, 3, 3, 3, 2, 5, 6, 3, 3, 2, 2, 3, 2, 2, 2, 6, 3, 2, 3] | 0.46 | 0.30 | 3.09 | 13.00 | 2.08 | 18.17 | 11.12 | 13.00 | 3.05 | 27.171 |

| 66 | [3, 7, 3, 3, 3, 2, 5, 6, 3, 3, 2, 2, 3, 2, 2, 2, 7, 3, 2, 3] | 0.39 | 0.32 | 2.84 | 13.20 | 2.11 | 18.15 | 10.82 | 13.20 | 3.10 | 27.121 |

| 67 | [3, 8, 3, 3, 3, 2, 5, 6, 3, 3, 2, 2, 3, 2, 2, 2, 7, 3, 2, 3] | 0.40 | 0.34 | 2.60 | 13.40 | 2.14 | 18.15 | 10.54 | 13.40 | 3.14 | 27.078 |

| 68 | [3, 8, 3, 3, 3, 2, 6, 6, 3, 3, 2, 2, 3, 2, 2, 2, 7, 3, 2, 3] | 0.41 | 0.36 | 2.45 | 13.60 | 2.17 | 18.23 | 10.29 | 13.60 | 3.19 | 27.082 |

| 69 | [3, 8, 3, 3, 3, 2, 6, 7, 3, 3, 2, 2, 3, 2, 2, 2, 7, 3, 2, 3] | 0.43 | 0.38 | 2.26 | 13.80 | 2.21 | 18.27 | 10.08 | 13.80 | 3.24 | 27.116 |

| 70 | [3, 8, 3, 3, 3, 2, 6, 7, 3, 3, 2, 2, 3, 2, 2, 2, 8, 3, 2, 3] | 0.53 | 0.41 | 2.06 | 14.00 | 2.24 | 18.30 | 9.80 | 14.00 | 3.28 | 27.084 |

| 71 | [3, 9, 3, 3, 3, 2, 6, 7, 3, 3, 2, 2, 3, 2, 2, 2, 8, 3, 2, 3] | 0.47 | 0.43 | 1.88 | 14.20 | 2.27 | 18.36 | 9.59 | 14.20 | 3.33 | 27.124 |

| 72 | [3, 9, 3, 3, 3, 2, 6, 7, 3, 3, 2, 2, 3, 2, 2, 2, 9, 3, 2, 3] | 0.47 | 0.45 | 1.73 | 14.40 | 2.30 | 18.43 | 9.33 | 14.40 | 3.38 | 27.110 |

| 73 | [3, 9, 3, 3, 3, 2, 6, 8, 3, 3, 2, 2, 3, 2, 2, 2, 9, 3, 2, 3] | 0.49 | 0.47 | 1.59 | 14.60 | 2.33 | 18.53 | 9.15 | 14.60 | 3.42 | 27.170 |

| 74 | [3, 9, 3, 3, 3, 2, 7, 8, 3, 3, 2, 2, 3, 2, 2, 2, 9, 3, 2, 3] | 0.50 | 0.49 | 1.49 | 14.80 | 2.37 | 18.66 | 8.99 | 14.80 | 3.47 | 27.259 |

| 75 | [3, 9, 3, 3, 3, 2, 7, 8, 3, 3, 2, 2, 3, 2, 2, 2, 9, 4, 2, 3] | 0.53 | 0.51 | 1.45 | 15.00 | 2.40 | 18.85 | 8.80 | 15.00 | 3.52 | 27.314 |

| 80 | [3, 10, 3, 3, 3, 2, 7, 9, 3, 3, 2, 2, 3, 3, 2, 2, 10, 4, 2, 4] | 0.63 | 0.62 | 1.02 | 16.00 | 2.56 | 19.58 | 7.80 | 16.00 | 3.75 | 27.555 |

| 90 | [4, 12, 3, 3, 3, 3, 8, 10, 3, 4, 2, 2, 3, 3, 2, 2, 12, 4, 3, 4] | 0.86 | 0.79 | 0.49 | 18.00 | 2.88 | 21.37 | 6.35 | 18.00 | 4.22 | 28.566 |

| 100 | [4, 14, 3, 4, 3, 3, 9, 12, 3, 4, 3, 2, 3, 3, 3, 2, 14, 4, 3, 4] | 1.03 | 0.90 | 0.20 | 20.00 | 3.20 | 23.40 | 5.17 | 20.00 | 4.69 | 29.860 |

| 150 | [5, 23, 4, 5, 5, 4, 16, 21, 4, 5, 3, 3, 5, 4, 3, 2, 23, 6, 4, 5] | 2.57 | 1.00 | 0.00 | 30.00 | 4.80 | 34.80 | 2.59 | 30.00 | 7.03 | 39.620 |

| Input Data Intensity | var_0 | var_5 | var_6 | var_7 | var_8 | var_9 | var_10 | var_11 | var_12 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50% | 26 | 63 | 26 | 64 | 26 | 62 | 26 | 62 | 26 | 62 | 26 | 61 | 26 | 60 | 26 | 59 | 26 | 60 | 61.5 | |

| μi | 100% | 32 | 74 | 32 | 74 | 32 | 73 | 32 | 72 | 32 | 72 | 32 | 70 | 32 | 69 | 33 | 68 | 33 | 68 | 71.2 |

| 200% | 47 | 97 | 47 | 96 | 47 | 96 | 46 | 95 | 47 | 93 | 46 | 91 | 47 | 90 | 48 | 89 | 47 | 89 | 93.0 | |

| 50% | 25 | 64 | 25 | 64 | 25 | 64 | 25 | 63 | 26 | 62 | 26 | 62 | 26 | 61 | 27 | 62 | 27 | 62 | 62.9 | |

| σi | 100% | 32 | 76 | 32 | 75 | 32 | 75 | 32 | 74 | 32 | 73 | 32 | 71 | 32 | 70 | 33 | 69 | 33 | 70 | 72.5 |

| 200% | 48 | 94 | 48 | 95 | 48 | 92 | 47 | 93 | 47 | 92 | 47 | 89 | 46 | 88 | 47 | 85 | 47 | 85 | 90.4 | |

| 50% | 25 | 43 | 25 | 43 | 25 | 42 | 25 | 44 | 25 | 44 | 25 | 44 | 25 | 44 | 25 | 42 | 25 | 43 | 43.3 | |

| tr | 100% | 35 | 78 | 35 | 78 | 35 | 78 | 35 | 77 | 35 | 77 | 35 | 75 | 35 | 74 | 35 | 72 | 35 | 72 | 75.7 |

| 200% | 45 | 113 | 45 | 113 | 45 | 112 | 45 | 108 | 45 | 106 | 45 | 104 | 45 | 102 | 47 | 102 | 46 | 102 | 106.8 | |

| 50% | 32 | 85 | 32 | 86 | 32 | 85 | 32 | 84 | 32 | 82 | 32 | 81 | 32 | 80 | 33 | 79 | 32 | 79 | 82.3 | |

| tse | 100% | 34 | 79 | 34 | 79 | 34 | 78 | 34 | 78 | 34 | 77 | 34 | 76 | 34 | 74 | 35 | 73 | 35 | 73 | 76.4 |

| 200% | 39 | 69 | 39 | 69 | 39 | 69 | 39 | 68 | 39 | 67 | 38 | 66 | 38 | 65 | 39 | 64 | 39 | 64 | 67.0 | |

| 50% | 25 | 102 | 25 | 101 | 25 | 102 | 25 | 99 | 25 | 98 | 25 | 96 | 25 | 94 | 26 | 94 | 26 | 94 | 97.8 | |

| top | 100% | 34 | 79 | 34 | 79 | 34 | 77 | 33 | 78 | 34 | 77 | 33 | 75 | 33 | 74 | 34 | 72 | 34 | 73 | 76.0 |

| 200% | 46 | 53 | 46 | 53 | 47 | 53 | 46 | 53 | 46 | 52 | 46 | 52 | 46 | 51 | 46 | 50 | 46 | 50 | 51.9 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Djurdjević, D.; Bjelić, N.; Popović, D.; Andrejić, M. A Combined Dynamic Programming and Simulation Approach to the Sizing of the Low-Level Order-Picking Area. Mathematics 2022, 10, 3733. https://doi.org/10.3390/math10203733

Djurdjević D, Bjelić N, Popović D, Andrejić M. A Combined Dynamic Programming and Simulation Approach to the Sizing of the Low-Level Order-Picking Area. Mathematics. 2022; 10(20):3733. https://doi.org/10.3390/math10203733

Chicago/Turabian StyleDjurdjević, Dragan, Nenad Bjelić, Dražen Popović, and Milan Andrejić. 2022. "A Combined Dynamic Programming and Simulation Approach to the Sizing of the Low-Level Order-Picking Area" Mathematics 10, no. 20: 3733. https://doi.org/10.3390/math10203733

APA StyleDjurdjević, D., Bjelić, N., Popović, D., & Andrejić, M. (2022). A Combined Dynamic Programming and Simulation Approach to the Sizing of the Low-Level Order-Picking Area. Mathematics, 10(20), 3733. https://doi.org/10.3390/math10203733