eLearning and eMaking: 3D Printing Blurring the Digital and the Physical

Abstract

:1. Introduction

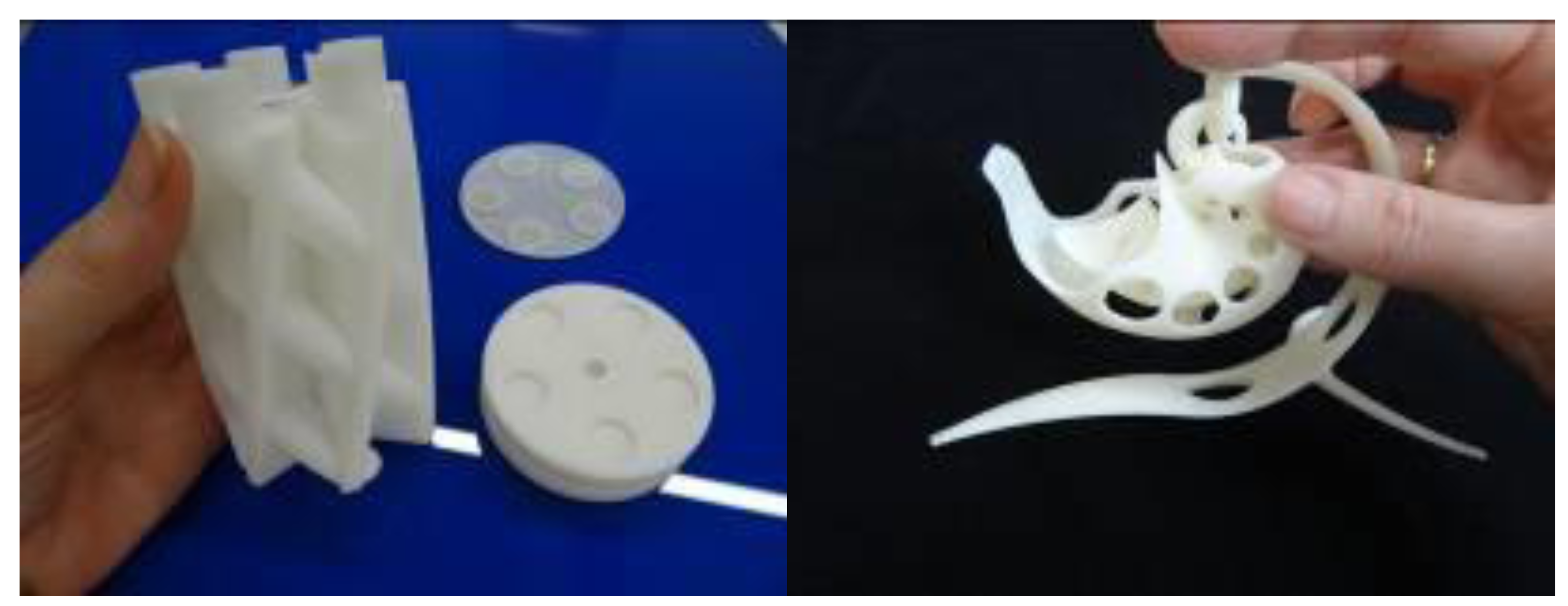

- The first deals with the straightforward, observable improvement in student work that has occurred with the introduction of 3D printing technology into the teaching studio.

- The second addresses the changing relationship that is observable between the students and the lecturers when the broader implications of 3D printing as part of eLearning are taken into account.

- The third gives examples of how the technology and eLearning are linking the student to a much bigger sense of the world, their responsibilities, ethics, etc. and are changing practice.

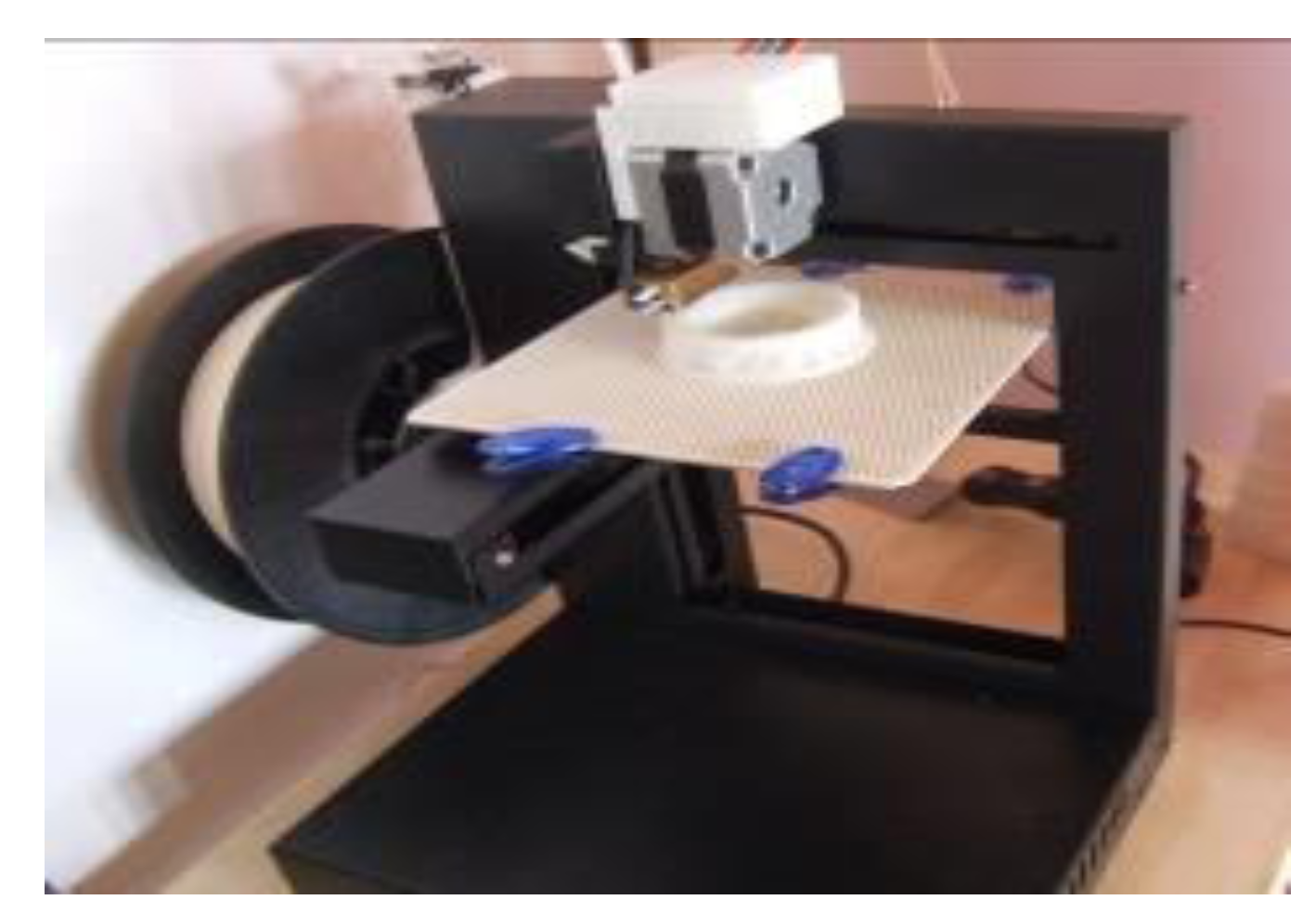

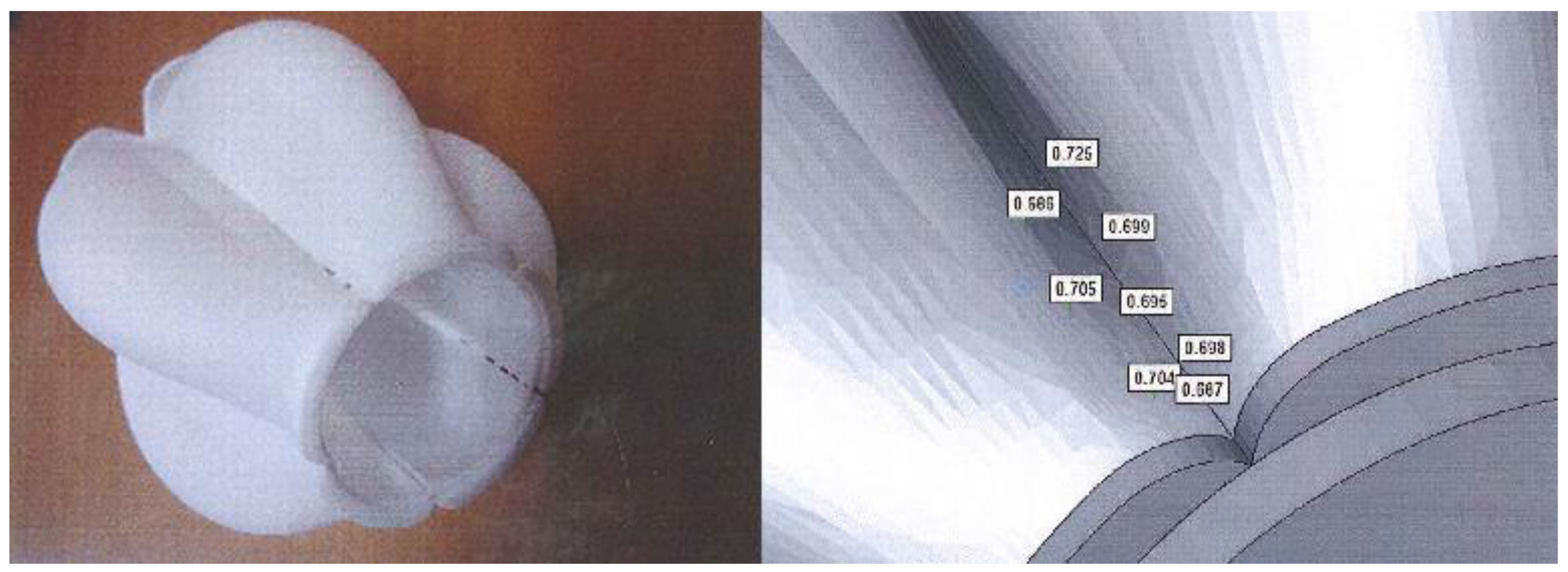

2. The Introduction of 3D Printing Technology into the Teaching Studio

3. Changing the Student’s Perspective through 3D Printing as Part of an eLearning Strategy

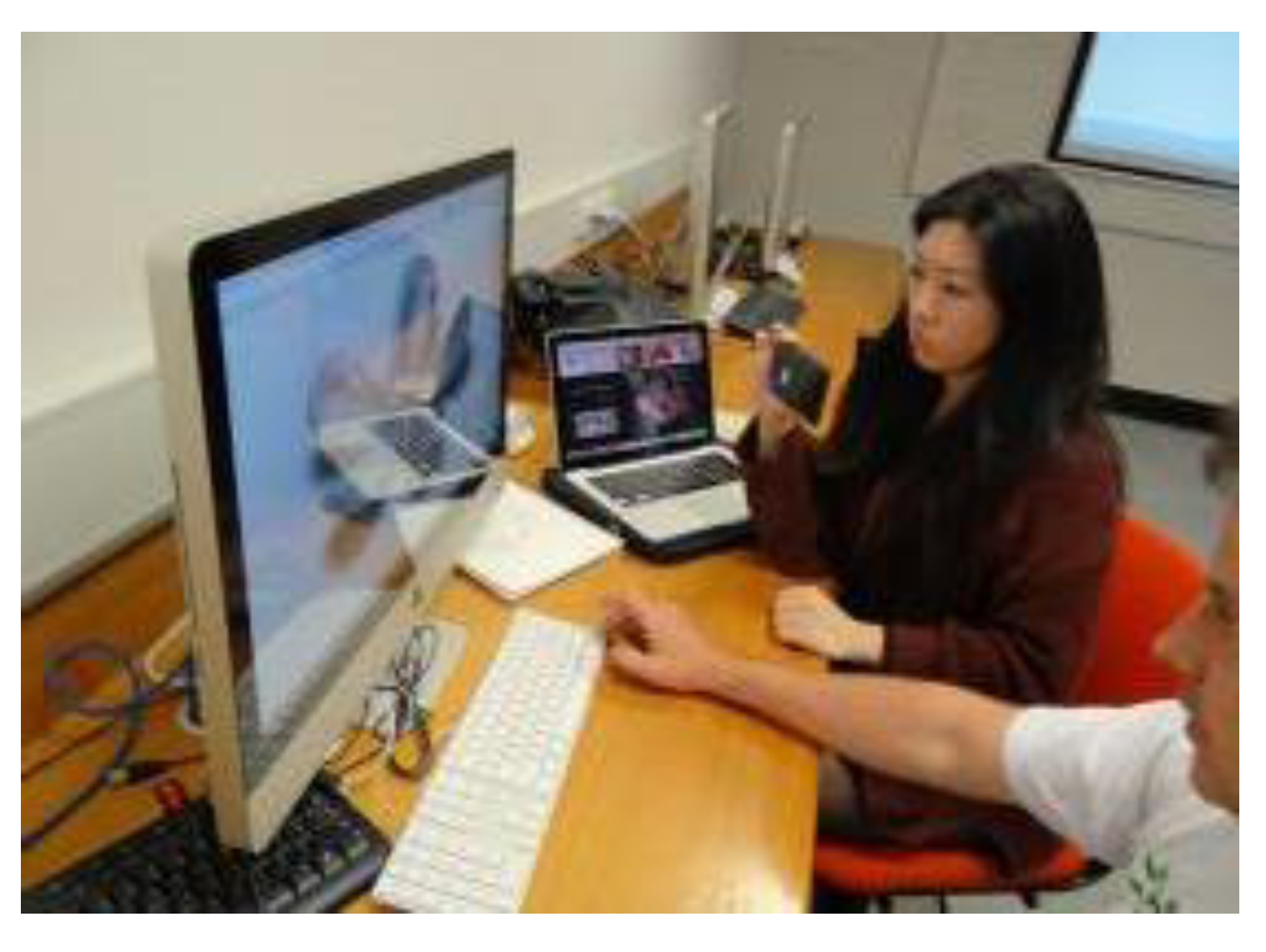

3.1. Changing Product Design Student/Lecturer Relationships

3.2. eLearning in a Global Digital World

4. eLearning, eMaking Changing the Students’ Understanding of the World and the Role of the Designer

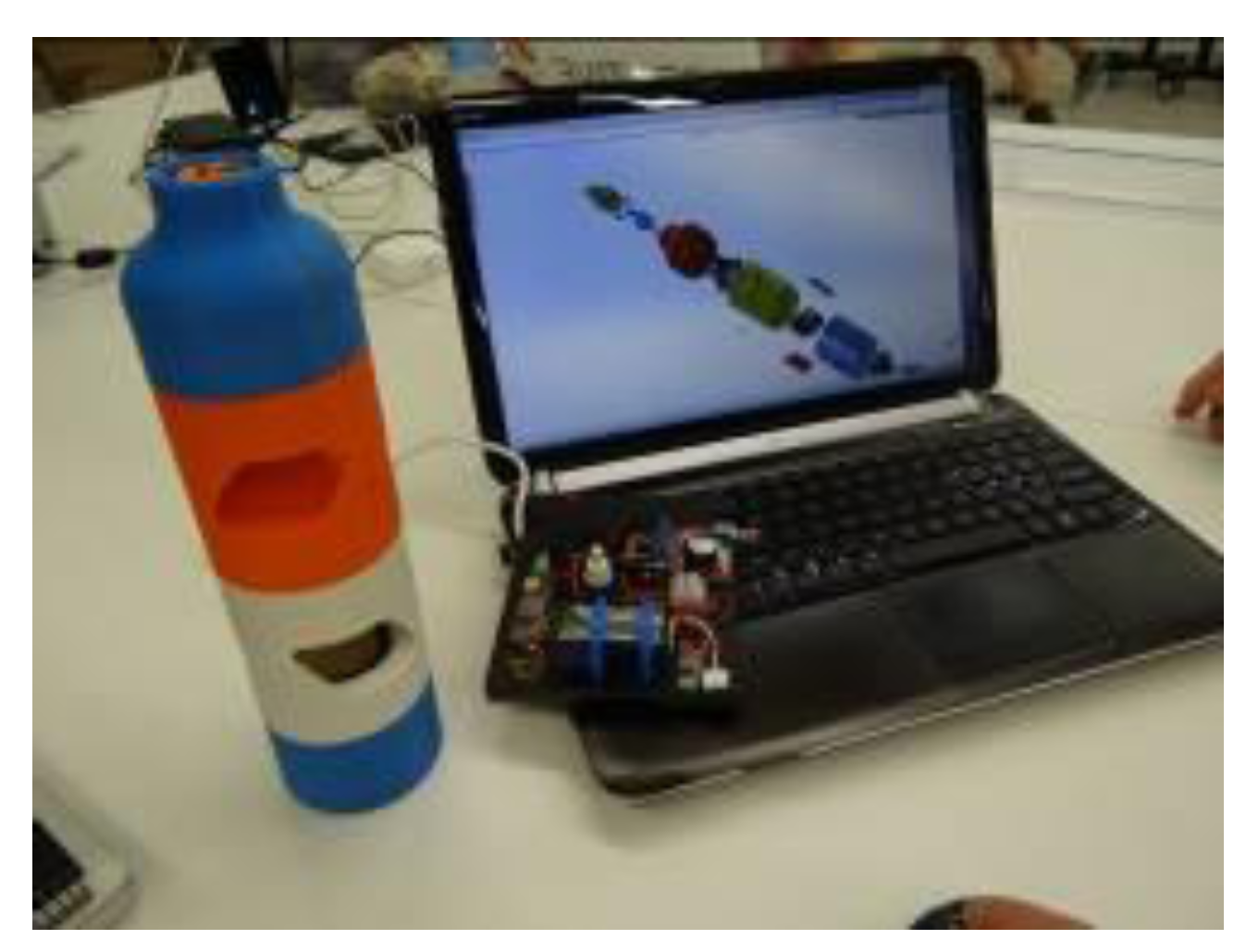

4.1. Learning about Sustainability through eLearning and 3D Printing

4.2. Connecting with Society

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Loy, J. Supporting creative learning for rapid prototyping and additive manufacturing through lessons from creative learning for CNC routering and laser cutting technologies. In Proceedings of the New Zealand Rapid Prototyping Conference, Auckland, New Zealand, 7-8 February 2011; Diegel, O., Ed.; Auckland University of Technology: Auckland, New Zealand, 2011. [Google Scholar]

- Weimer, M. Learner-Centered Teaching: Five Key Changes to Practice; Jossey Bass: San Francisco, CA, USA, 2002. [Google Scholar]

- The Making of Design; Terstiege, G. (Ed.) Birkhauser: Basel, Switzerland, 2009.

- Loy, J.; Canning, S. Changing the emphasis of learning through making in technology education. In Proceedings of the Technology Education Research Conference on Best Practice in Technology, Design and Engineering Education, Gold Coast, Australia, 5–8 December 2012; Griffith University: Brisbane, Australia, 2012; Volume 2, pp. 19–25. [Google Scholar]

- Intel. An Internet Minute. Available online: http://www.intel.com/content/www/us/en/communications/internet-minute-infographic.html (accessed on 24 June 2013).

- Loy, J.; Canning, S. Reconnecting through digital making. Ind. Design Educ. Netw. 2013, 2, 12–21. [Google Scholar]

- Wallis, L.H. Building the Studio Environment. In Design Studio Pedagogy: Horizons for the Future; Salama, A.M., Wilkinson, N., Eds.; Urban International Press: Gateshead, UK, 2007; pp. 201–218. [Google Scholar]

- Milton, A.; Rodgers, P. Product Design; Laurence King: London, UK, 2011. [Google Scholar]

- Make Space project. Available online: http://dschool.stanford.edu/makespace/ (accessed on 3 October 2013).

- Ramsden, P. Learning to Teach in Higher Education, 2nd ed.; Routledge Falmer: Oxon, UK, 2003; p. 237. [Google Scholar]

- Race, P.; Pickford, R. Making Teaching Work: Teaching Smarter in Post-Compulsory Education; Sage Publications: New York, NY, USA, 2007. [Google Scholar]

- Garrow, L.; Hotle, S.; Mumbower, S. Flipped classroom. OR-MS Today 2013, 40, 10. [Google Scholar]

- Frombgen, E.; Babola, D.; Beye, A.; Boyce, S.; Flint, T.; Mancini, L.; van Eaton, K. Giving up control in the classrooms: Having students create and carry out simulations in IR courses. Polit. Sci. Polit. 2013, 46, 395–399. [Google Scholar] [CrossRef]

- Loy, J.; Ancher, S. Bridging the gap between aims and objectives for business clients and academic course planners in ‘linked’ learning projects. In Proceeding of the 13th International Conference on Engineering and Product Design Education on Design Education for Creativity and Business Innovation, London, UK, 8–9 September 2011; Institute of Engineering Designers: Wiltshire, UK, 2011; pp. 64–70. [Google Scholar]

- Bohemia, E.; Lauche, K.; Harman, K. Discussion paper: Issues related to conducting a global studio. In Proceeding of the 10th International Conference on Engineering and Product Design Education on New Perspectives in Design Education, Barcelona, Spain, 6–7 September 2008; Institute of Engineering Designers: Wiltshire, UK, 2008; pp. 596–601. [Google Scholar]

- Welch, D.; Loy, J. A Brave New Creativity. Art, Design and Communication in Higher Education 2013, 12(1), 89–100. [Google Scholar]

- Coles, J. The Fundamentals of Interior Architecture; AVA Publishing: Worthing, UK, 2007; p. 64. [Google Scholar]

- Hawken, P.; Lovins, A.; Lovins, L.H. Natural Capitalism: The Next Industrial Revolution; Earthscan: London, UK, 2010. [Google Scholar]

- Aldersley-Williams, H. The New Tin Ear: Manufacturing, Materials and the Rise of the User-Maker, RSA Design Projects. 2011. Available online: http://www.thersa.org/events/audio-and-past-events/2011/less-stuff,-more-performance,-better-fit (accessed on 6 May 2013).

- UCODO. Available online: http://www.ucodo.com/Store (accessed on 14 September 2013).

- Anderson, C. Makers: The Next Industrial Revolution; Crown Business: New York, NY, USA, 2012. [Google Scholar]

- Gershenfeld, N. Fab: The Coming Revolution on Your Desktop–From Personal Computers to Personal Fabrication; Basic books: New York, NY, USA, 2007. [Google Scholar]

- Amazing 3D Printing at Griffith. Available online: http://www.youtube.com/watch?v=YK_Ib6Io_aM (accessed on 20 September 2013).

- Segerman, H. 3D Printing for mathematical visualisation. Math. Intell. 2012, 34, 56–62. [Google Scholar] [CrossRef]

- Dee Fink, L. Creating Significant Learning Experiences: An Integrated Approach to Designing College Courses; Jossey-Bass: San Francisco, CA, USA, 2003. [Google Scholar]

Images

- All photographs taken by author unless otherwise stated.

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Loy, J. eLearning and eMaking: 3D Printing Blurring the Digital and the Physical. Educ. Sci. 2014, 4, 108-121. https://doi.org/10.3390/educsci4010108

Loy J. eLearning and eMaking: 3D Printing Blurring the Digital and the Physical. Education Sciences. 2014; 4(1):108-121. https://doi.org/10.3390/educsci4010108

Chicago/Turabian StyleLoy, Jennifer. 2014. "eLearning and eMaking: 3D Printing Blurring the Digital and the Physical" Education Sciences 4, no. 1: 108-121. https://doi.org/10.3390/educsci4010108

APA StyleLoy, J. (2014). eLearning and eMaking: 3D Printing Blurring the Digital and the Physical. Education Sciences, 4(1), 108-121. https://doi.org/10.3390/educsci4010108