Industry 4.0 Diagnosis from an iMillennial Educational Perspective

Abstract

1. Introduction: Industry 4.0 and the iMillennials Generation

2. Materials and Methods

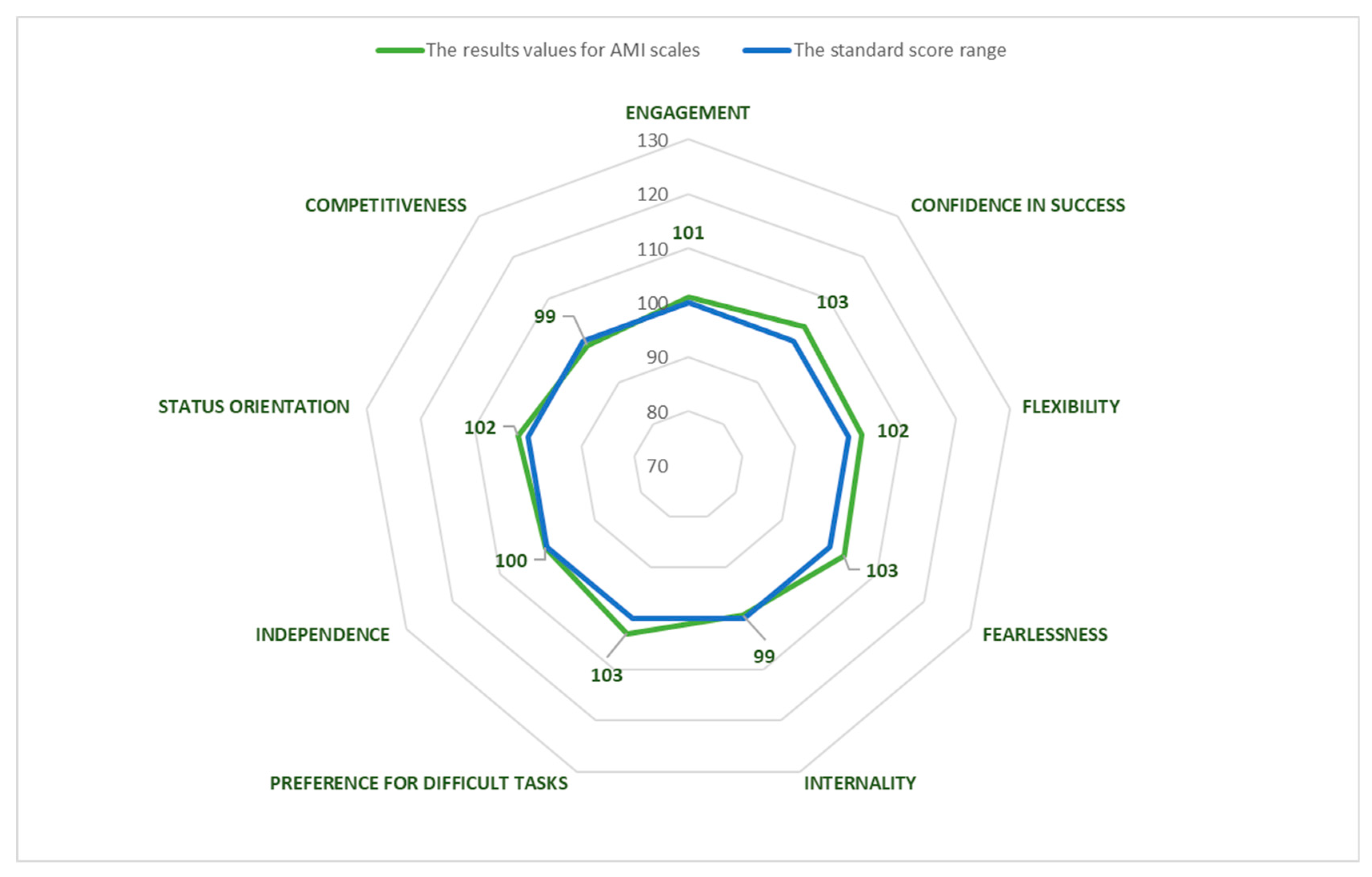

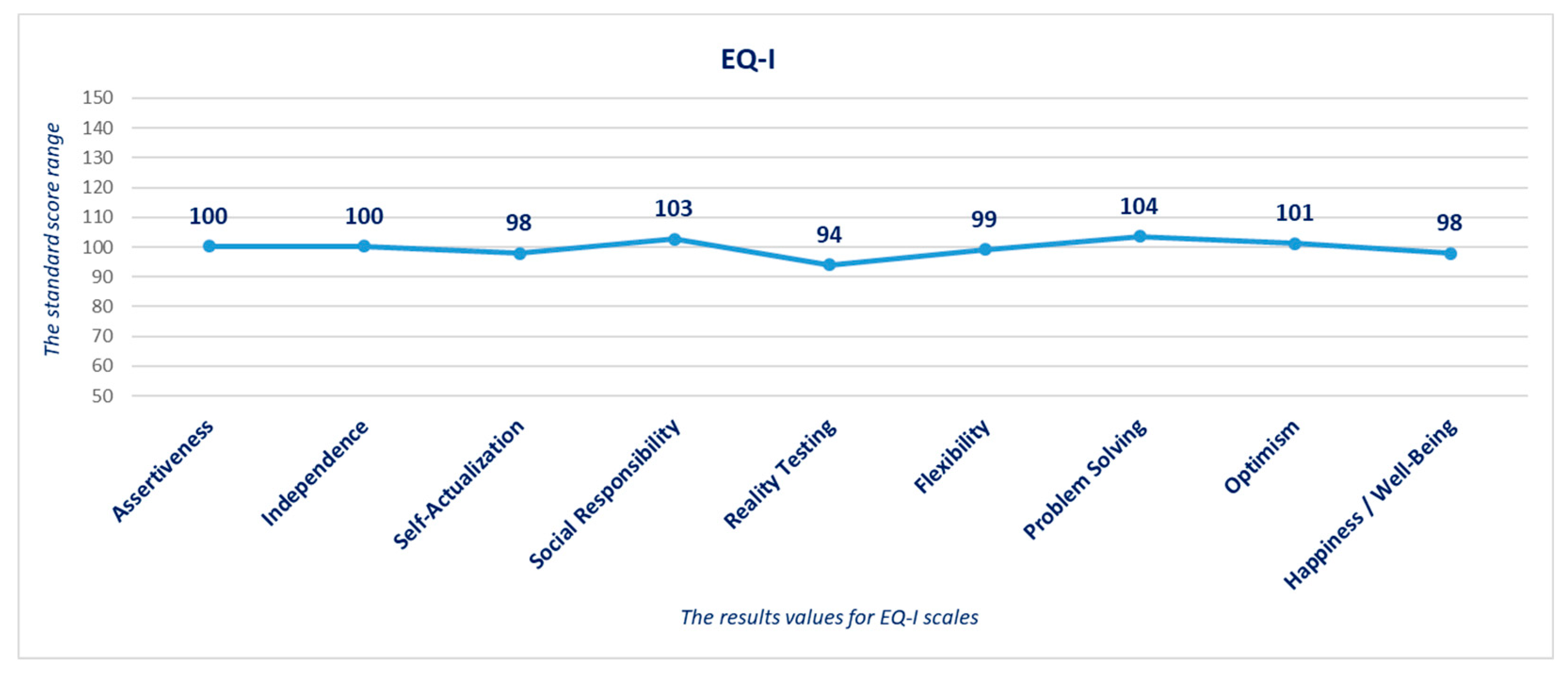

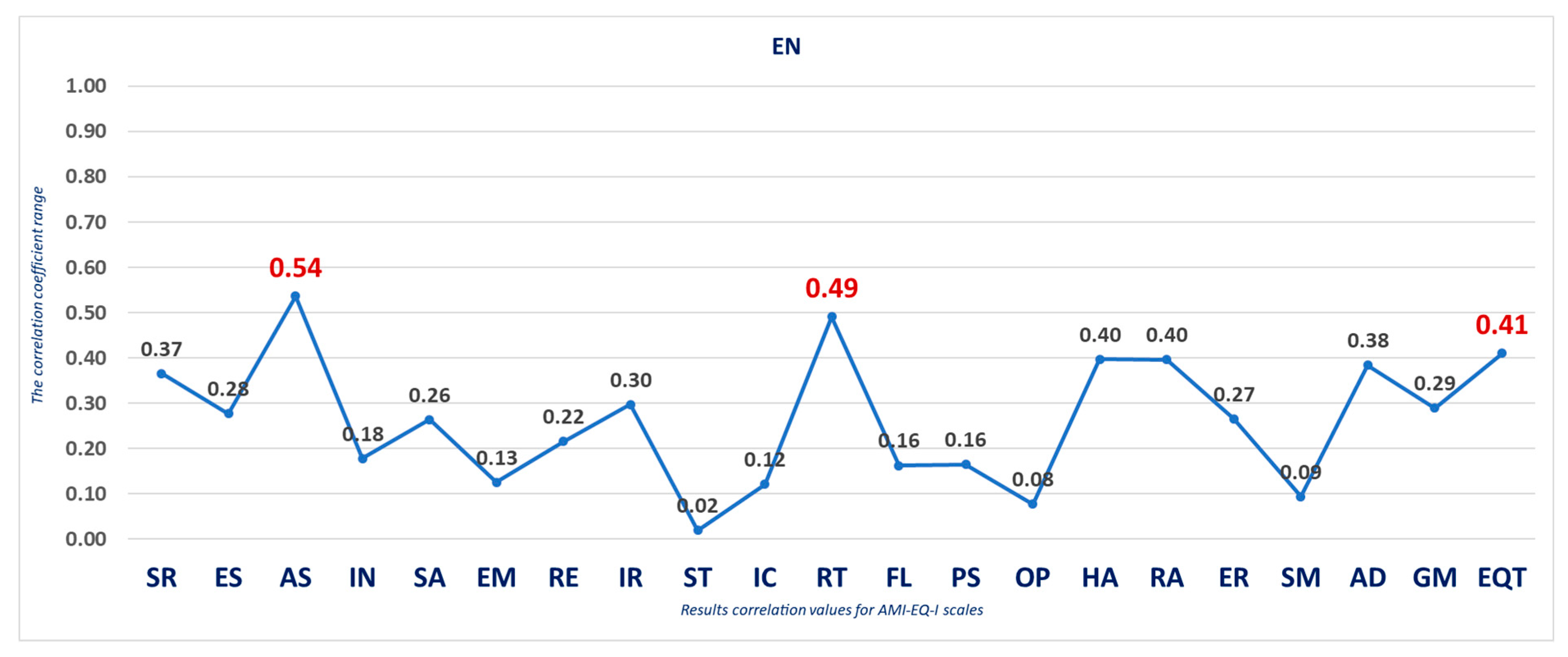

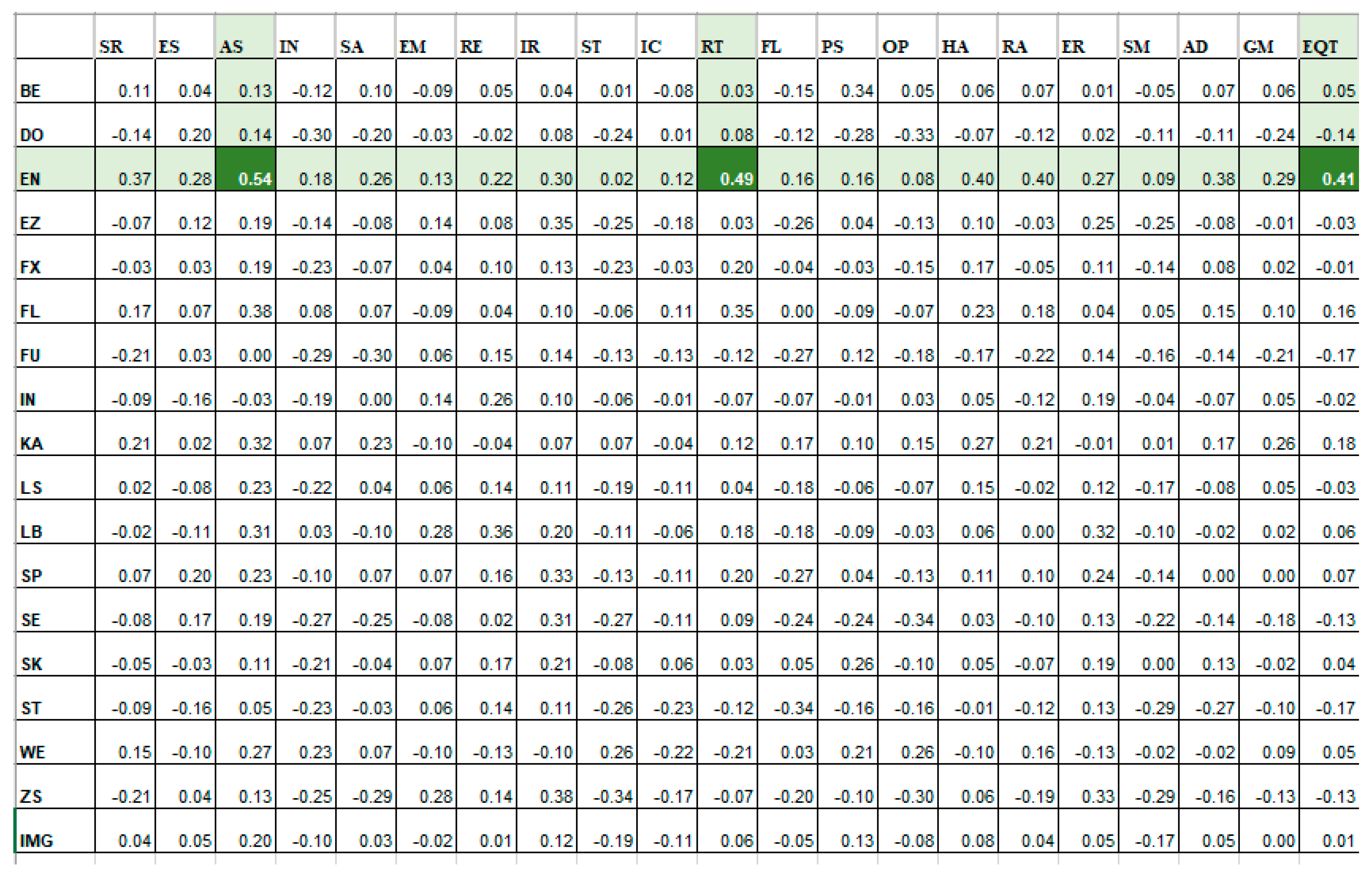

3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018. [Google Scholar] [CrossRef]

- Michalos, G.; Makris, S.; Tsarouchi, P.; Guasch, T.; Kontovrakis, D.; Chryssolouris, G. Design considerations for safe human-robot collaborative workplaces. Procedia CIRP 2015, 37, 248–253. [Google Scholar] [CrossRef]

- Wang, L.; Gao, R.; Váncza, J.; Krüger, J.; Wang, X.V.; Makris, S.; Chryssolouris, G. Symbiotic human-robot collaborative assembly. CIRP Ann. 2019. [Google Scholar] [CrossRef]

- Tsarouchi, P.; Michalos, G.; Makris, S.; Athanasatos, T.; Dimoulas, K.; Chryssolouris, G. On a human–robot workplace design and task allocation system. Int. J. Comput. Integr. Manuf. 2017, 30, 1272–1279. [Google Scholar] [CrossRef]

- Michalos, G.; Makris, S.; Spiliotopoulos, J.; Misios, I.; Tsarouchi, P.; Chryssolouris, G. Robopartner: Seamless human-robot cooperation for intelligent, flexible and safe operations in the assembly factories of the future. Procedia CIRP 2014, 23, 71–76. [Google Scholar] [CrossRef]

- Someshwar, R.; Meyer, J.; Edan, Y. Models and methods for HR synchronization. IFAC Proc. Vol. 2012, 45, 829–834. [Google Scholar] [CrossRef]

- Roy, S.; Edan, Y. Investigating joint-action in short-cycle repetitive handover tasks: The role of giver versus receiver and its implications for human–robot collaborative system design. Int. J. Soc. Robot 2018. [Google Scholar] [CrossRef]

- Tsarouchi, P.; Matthaiakis, A.S.; Makris, S.; Chryssolouris, G. On a human-robot collaboration in an assembly cell. Int. J. Comput. Integr. Manuf. 2017, 30, 580–589. [Google Scholar] [CrossRef]

- Makris, S.; Tsarouchi, P.; Matthaiakis, A.S.; Athanasatos, A.; Chatzigeorgiou, X.; Stefos, M.; Giavridis, K.; Aivaliotis, S. Dual arm robot in cooperation with humans for flexible assembly. CIRP Ann. 2017, 66, 13–16. [Google Scholar] [CrossRef]

- Someshwar, R.; Edan, Y. Givers & receivers perceive handover tasks differently: Implications for human-robot collaborative system design. arXiv 2017, arXiv:1708.06207. [Google Scholar]

- Someshwar, R.; Meyer, J.; Edan, Y. A timing control model for HR synchronization. In Proceedings of the IFAC International Federation of Automatic Control, Dubrovnik, Croatia, 5–7 September 2012; pp. 698–703. [Google Scholar]

- Someshwar, R.; Kerner, Y. Optimization of waiting time in HR coordination. In Proceedings of the IEEE International Conference on Systems, Man, and Cybernetics, Manchester, UK, 13–16 October 2013; pp. 1918–1923. [Google Scholar]

- Delloite, 2018 Deloitte Millennial Survey. Millennials Disappointed in Business, Unprepared for Industry 4.0. Available online: https://www2.deloitte.com/content/dam/Deloitte/au/Documents/about-deloitte/hrc-millennial-survey-report-2018.pdf (accessed on 12 November 2019).

- Bar-On, R. Emotional Quotient Inventory, Technical Manual (A Measure of Emotional Intelligence); ASIN: B001I2UK3; Multi Health Systems, Inc.: North Tonawanda, NY, USA, 1997. [Google Scholar]

- Schuler, H.; Thornton, G.C., III; Frintrup, A.; Mueller-Hanson, R. AMI: Achievement Motivation Inventory. In Technical and User’s Manual; Hogrefe & Huber Publishers: Ashland, OH, USA, 2004. [Google Scholar]

- McKinsey & Company, McKinsey Operations Practice. Manufacturing the future: The Next Era of Global Growth and Innovation. McKinsey Global Institute, McKinsey Operations Practice. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/the-future-of-manufacturing (accessed on 12 November 2019).

- Schwab, K. The Fourth Industrial Revolution; Crown Business: New York, NY, USA, 2017; ISBN 978-1-5247-5886-8. [Google Scholar]

- Schwab, K. How Can We Embrace the Opportunities of the Fourth Industrial Revolution? Available online: http://www.weforum.org/agenda/2016/01/how-can-we-embrace-the-opportunities-of-the-fourth-industrial-revolution (accessed on 13 February 2019).

- Boston Consulting Group, Man and Machine in Industry 4.0. Available online: https://www.bcg.com/expertise/industries/engineered-products-infrastructure/man-machine-industry-4.0.aspx (accessed on 13 February 2019).

- Schwab, K.; Samans, R. The Future of jobs-Employment, Skills and Workforce Strategy for the Fourth Industrial Revolution. Available online: https://www.weforum.org/reports/the-future-of-jobs (accessed on 13 February 2019).

- Zuehlke, D. Smart Factory: Towards a Factory-of-things. Annu. Rev. Control 2010, 34, 129–138. [Google Scholar] [CrossRef]

- Cotet, C.E.; Popa, C.L.; Enciu, G.; Popescu, A.; Dobrescu, T. Using CAD and flow simulation for educational platform design and optimization. Int. J. Simul. Model. 2016, 15, 5–16. [Google Scholar] [CrossRef]

- Popa, C.L.; Carutasu, G.; Cotet, C.E.; Carutasu, N.L.; Dobrescu, T. Smart City Platform Development for an Automated Waste Collection System. Sustainability 2017, 9, 2064. [Google Scholar] [CrossRef]

- Dragoi, G.; Cotet, C.E.; Rosu, L.; Rosu, S.M. Role of the virtual networks in the Virtual Enterprise. J. Mech. Eng. 2006, 7–8, 526–531. [Google Scholar]

- Bienzeisler, B.; Schletz, A.; Gahle, A.K. Industrie 4.0 Ready Services. In Technologies trends Stuttgart; Fraunhofer IAO: Stuttgart, Germany, 2014. [Google Scholar]

- Northcott, J.; Christie, I.; Walling, A. Employment Effects of New Technology in Manufacturing; Policy Studies Institute: London, UK, 1990; ISBN 0853744955. [Google Scholar]

- Popescu, D.; Anania, D.; Cotet, C.E.; Amza, C. Fully automated liquid penetrant inspection line simulation model for increasing productivity. Int. J. Simul. Model. 2013, 12, 82–93. [Google Scholar] [CrossRef]

- Spath, D.; Bauer, W.; Hämmerle, M. Requirements for an Evaluation Model for the Proactive Management of Human Resource Capacity in Volatile Markets. In Proceedings of the 22nd International Conference on Production Research ICPR–22, Iguasso Falls, Brazil, 28 July–1 August 2013. [Google Scholar]

- McKinsey Digital, Industry 4.0: How to Navigate the Digitization of the Manufacturing Sector; McKinsey: Berlin, Germany, 2015.

- Hirsch-Kreinsen, H. Digitization of industrial work: Development paths and prospects. J. Labour. Market. Res. 2016, 49, 1–14. [Google Scholar] [CrossRef]

- Mazali, T. From Industry 4.0 to Society 4.0, There and Back. AI Soc. 2018, 33, 405–411. [Google Scholar] [CrossRef]

- Bauernhansl, T.; Ten Hompel, M.; Vogel-Heuser, B. (Eds.) Industrie 4.0 in Produktion, Automatisierung und Logistik: Anwendung, Technologien und Migration; Springer Vieweg: Wiesbaden, Germany, 2014; ISBN 978-3-658-04681-1. [Google Scholar]

- Guran, M.; Coteţ, C.E.; Popa, C.L. 2009-Knowledge-based economy main requirements regarding the definitions and the measurements for innovation as a system. In Proceedings of the International Conference on Manufacturing Systems ICMAS 2009, Bucharest, Romania, 5–6 November 2009; Volume 4, pp. 371–374. [Google Scholar]

- Mannheim, K. The Problem of Generation, in K.; Mannheim, Essays on the Sociology of Knowledge; Routledge & Kegan Paul: London, UK, 1952; pp. 276–320. [Google Scholar]

- Strauss, W.; Howe, N. The Fourth Turning-an American Prophecy, Kindle Edition; Crown Publishing Group: New York, NY, USA, 1997; ISBN 978-076-790-046-1. [Google Scholar]

- Bencsik, A.; Machova, R. Knowledge Sharing Problems from the Viewpoint of Intergeneration Management. In Proceedings of the ICMLG2016-4th International Conference on Management, Leadership and Governance, ICMLG 2016, Saint Petersburg, Russia, 14–15 April 2016; p. 42. [Google Scholar]

- Bencsik, A.; Horváth-Csikós, G.; Juhász, T. Y and Z Generations at Workplaces. J. Compet. 2016, 8, 90–106. [Google Scholar] [CrossRef]

- Siminoff, A. Gen Z vs. Millenials: What’s the Difference? Available online: https://medium.com/askimpulse/gen-z-vs-millenials-whats-the-differece-5bf83d6e7f5 (accessed on 12 February 2019).

- Keszthelyi, C. Generation Z Brings ‘Flexibility’ and Change to Employers. Available online: https://bbj.hu/special-report/generation-z-brings-flexibility-and-change-to-employers_148062 (accessed on 12 February 2019).

- Belinne, J. The Care and Feeding of Your Young Employee: A Manager’s Guide to Millennials and Gen Z, Paperback; Kindle Edition; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2017. [Google Scholar]

- Hecklau, F.; Galeitzke, M.; Flachs, S.; Kohl, H. Holistic Approach for Human Resource Management in Industry 4.0. In Proceedings of the Procedia CIRP Conference on Learning Factories, Gjøvik, Norway, 29–30 June 2016; pp. 1–6. [Google Scholar]

| Characteristics/Meta-Factors | Particularity | Description |

|---|---|---|

| Behaviors | Goal orientation | This generation is motivated by social rewards, mentoring and constant feedback. They also want to make sense and be accountable. Like their predecessors, they also require flexible hours. |

| Positive attitude | Dynamism, a bright career, inspiring work atmosphere and flexibility in work schedule. | |

| Technical experience | Generation Z is the most technologically gifted generation, connected at the global level. | |

| Multi-tasking | They can work efficiently with multiple tasks at the same time, with various sources of distraction in the background—multitasking. This kind of productivity flow could change how the activity is running. | |

| Global generation | Generation Z is the first truly global generation, primarily through technology, globalization and diverse cultural patterns, online entertainment, social trends, etc. | |

| Educational goal | The reformed reality from an educational point of view—moving from formal delivery to interactive environments. Therefore, education is no longer dependent on one stage of life but a lifelong reality. | |

| Attributes | Low concentration | The iMillennials generation consumes many data. The result is a more rapid transmission of information, increasing the consumption of information, but with decreased concentration. |

| Thinking outside the box | Ways of thinking differently, coming out of conventional patterns or matrices or from a new perspective. This expression often refers to new or creative, innovative thinking. It involves a process of thought focused on the implementation of an unusual approach to the structure of logical thinking. | |

| Taking career responsibility | iMillennials members seem to be more aware and concerned about their career. They are much more focused, determined and informed about career choice compared to Generation Y. | |

| Digital generation | They are digital integrators—the age at which we use technology for the first time determines how embedded it becomes in our lifestyle. | |

| Individualism | This is related to their competitiveness. They want to manage their projects so that their abilities shine. They do not want to depend on other people to do their job. | |

| Quick visual Interpretation | Transformation of visual interpretation pattern: image vs. word. Rapid processing of information. | |

| Values | “Carpe diem” | They like to be involved in lawsuits, to contribute to finding solutions and being more engaged in various experiences. |

| Meaningful work | The work carried out should be positive, deliberate and meaningful. Cultivating significance by focusing on the greater good of the work and by clearly showing the reason why the thing counts is a crucial practice researched to stimulate importance. | |

| Interpersonal relationships | The members of Generation Z revolt against personal interactions; human resources leaders should reassess how best to put the “human” aspect into business. For example, employment processes should focus on interviews in person more than online applications. | |

| Personal achievements | While all adult generations say that family is most important to their sense of self, the identity of Generation Z is best defined by their results. |

| Main Factors | AMI | EQ-I |

|---|---|---|

| Goal orientation | Status orientation | |

| Positive attitude | Flexibility Confidence in success | Flexibility |

| Technical experience | Competitiveness | |

| Educational purpose | Status orientation | |

| Thinking outside of the box | Preference for difficult tasks Fearlessness | Problem solving |

| Responsibility for careers | Engagement Internality | Social responsibility |

| Individualism | Independence | Assertiveness Independence |

| Carpe diem | Goal Setting | Reality testing |

| Meaningful work | Optimism Happiness | |

| Personal achievement | Pride in productivity | Self-actualization |

| Engagement | Identifies their availability to support an effort, its level and the individual workload. Actively engaged in their activity. Very active people, who give priority to work against other fields of business. |

| Confidence in success | Confidence in one’s success describes the expectation of positive results from the activities one carries out. They act accordingly and expect to succeed, building on their skills and knowledge, even when faced with difficulties, obstacles or competition. |

| Flexibility | The way they relate to new situations and tasks. They have high availability for new professional conditions and prefer change or uncertainty. They are attracted to new locations that allow them to experience novelty, even if it means accepting a certain degree of discomfort or even the risk of failure. |

| Fearlessness | The people described by this scale are not afraid of failure. When faced with important tasks and situations, they do not feel a high level of pressure, and therefore their results are not negatively influenced. |

| Internality | Internality denotes how the results of one’s actions are explained. They attribute the effects and consequences of their behavior to the actions taken. Depending on their response and effort, they interpret professional success or failure. |

| Preference for difficult tasks | They are described as ambitious, looking for challenges, ready for risk, self-questioning, wanting to prove their abilities, arduous, solving problems, stimulated by obstacles, testing their limits, and overcoming obstacles. Issues that arise are incentives rather than obstacles. |

| Independence | It is characterized as being responsible for oneself, autonomously, freely, and without obligations. They are involved in decision making; they are self-confident in the decision-making process. They want to decide on their way of working and make decisions independently. They do not like being controlled. |

| Status orientation | It describes the effort made to play an essential role in the social field and a leading place in the social hierarchy. Seeking recognition of their performance by others. They want to occupy influential positions and are interested in their professional promotion. Career growth prospects are, for them, essential motivators of professional performance. |

| Competitiveness | It measures the tendency to experience competition as an incentive and as a motivation for professional performance. People with high values are looking for match and comparison with others. They are quickly challenged; they want to be better and faster than others. They need to win. The gain strengthens them in their effort. |

| Goal setting | Setting goals for both short-term tasks and long-term projects. They are future-oriented and have high expectations of what they want to achieve. They have long-term plans, and they know in which direction they want to develop, from a personal point of view. |

| AS: Assertiveness | Direct expression of one’s own beliefs, thoughts or ideas. They use their own opinions for constructive purposes. Assertiveness involves finding the right language to support one’s beliefs. |

| IN: Independence | Describes those who have high self-confidence. The importance of making the right decision in risk situations without being influenced by external factors. Identifies the persons who prefer being in a position to coordinate the activity in the team, taking initiative and responsibility. |

| SA: Self-actualization | The ability to realize their potential. Preference for learning new things that will bring them professional satisfaction. Identifies a long-term vision with motivational energy, and leads a meaningful life. |

| RE: Social responsibility | Ability to act responsibly. Socially responsible people accept, respect, and help others and respect social rules, also being able to use their skills to identify people with high moral and ethical standards. |

| RT: Reality testing | It characterizes people who can evaluate the relationship between what they experience (subjective) and what exists (objective). They are realistic people, looking for objective and pragmatic evidence to confirm, justify and support their feelings and actions. |

| FL: Flexibility | Rapid adaptation to unexpected situations, capable of responding to changes without rigidity. In search of new ideas and challenging, innovative situations in response to the problems they face. |

| PS: Problem-solving | A practical approach to solving the problems that arise, offering innovative solutions. The pleasure of facing risky situations. They have an individual ability to obtain intellectual and social resources. Heuristic and creative. |

| OP: Optimism | Positive attitude, which leads to high confidence in their strengths and themselves. They adapt quickly to troublesome or stressful situations. Optimistic people are generally desirable members of a team because they are more motivated and persevering. |

| HA: Happiness | The feeling of adequacy at work, in professional life, but also in leisure time and personal experience. They present a high degree of job satisfaction. They have a greater desire to explore, to seek new information and to have creative thinking. |

| AMI | EQ-I |

|---|---|

| Commitment | Assertiveness |

| An individual with a high score on the EN scale is described as an employee who is eager to work, diligent, busy, diligent, ambitious, enthusiastic for performance, dynamic, diligence, lively, action-oriented, entrepreneurial, agile, and restless, with ambitious skills. | Finding the right language to make others understand their point of view. Openly and constructively expresses their views. Expresses a categorical attitude to defend their beliefs, thoughts, and opinions, and express disapproval when they feel it. |

| Reality Testing | |

| It is a characteristic of people able to assess the correspondence between what they experience (subjective) and what exists in reality (objective). | |

| Realistic persons, with their feet on the ground, trying to keep a refreshing perspective on the reality of things. Another feature of them is that they are always in search of objective and pragmatic evidence to confirm their ideas. | |

| They focus on examining ways they can cope with situations as they arise. Attention to the relevant information for the immediate solving of problems, taking better decisions and with fewer errors. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cotet, G.B.; Carutasu, N.L.; Chiscop, F. Industry 4.0 Diagnosis from an iMillennial Educational Perspective. Educ. Sci. 2020, 10, 21. https://doi.org/10.3390/educsci10010021

Cotet GB, Carutasu NL, Chiscop F. Industry 4.0 Diagnosis from an iMillennial Educational Perspective. Education Sciences. 2020; 10(1):21. https://doi.org/10.3390/educsci10010021

Chicago/Turabian StyleCotet, Gabriela Beatrice, Nicoleta Luminita Carutasu, and Florina Chiscop. 2020. "Industry 4.0 Diagnosis from an iMillennial Educational Perspective" Education Sciences 10, no. 1: 21. https://doi.org/10.3390/educsci10010021

APA StyleCotet, G. B., Carutasu, N. L., & Chiscop, F. (2020). Industry 4.0 Diagnosis from an iMillennial Educational Perspective. Education Sciences, 10(1), 21. https://doi.org/10.3390/educsci10010021